wheel JEEP CHEROKEE 2023 Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: CHEROKEE, Model: JEEP CHEROKEE 2023Pages: 276, PDF Size: 12.55 MB

Page 195 of 276

IN CASE OF EMERGENCY193

(Continued)

5. Remove the chocks.

6. Remove the scissor jack and wheel bolt wrench from

the spare wheel as an assembly. Turn the jack screw

to the left to loosen the wheel bolt wrench, and

remove the wrench from the jack assembly.

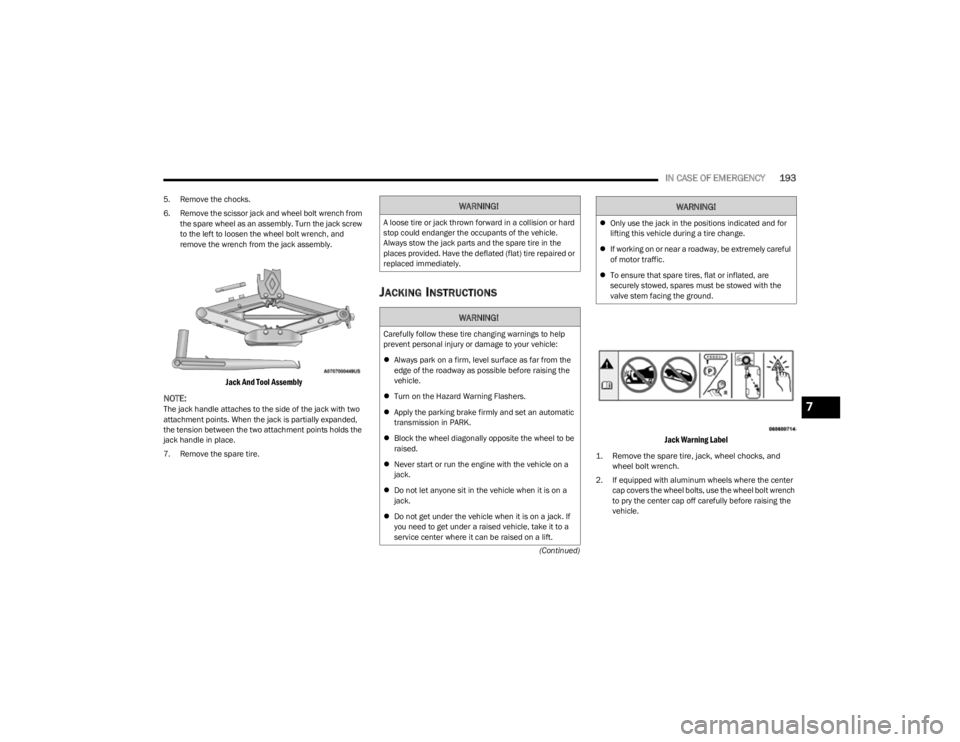

Jack And Tool Assembly

NOTE:

The jack handle attaches to the side of the jack with two

attachment points. When the jack is partially expanded,

the tension between the two attachment points holds the

jack handle in place.

7. Remove the spare tire.

JACKING INSTRUCTIONS

Jack Warning Label

1. Remove the spare tire, jack, wheel chocks, and wheel bolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts, use the wheel bolt wrench

to pry the center cap off carefully before raising the

vehicle.

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or

replaced immediately.

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set an automatic

transmission in PARK.

Block the wheel diagonally opposite the wheel to be

raised.

Never start or run the engine with the vehicle on a

jack.

Do not let anyone sit in the vehicle when it is on a

jack.

Do not get under the vehicle when it is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

If working on or near a roadway, be extremely careful

of motor traffic.

To ensure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

WARNING!

7

23_KL_OM_EN_USC_t.book Page 193

Page 196 of 276

194IN CASE OF EMERGENCY

3. Before raising the vehicle, use the wheel bolt wrench

to loosen, but not remove, the wheel bolts on the

wheel with the flat tire. Turn the wheel bolts counter -

clockwise one turn while the wheel is still on the

ground.

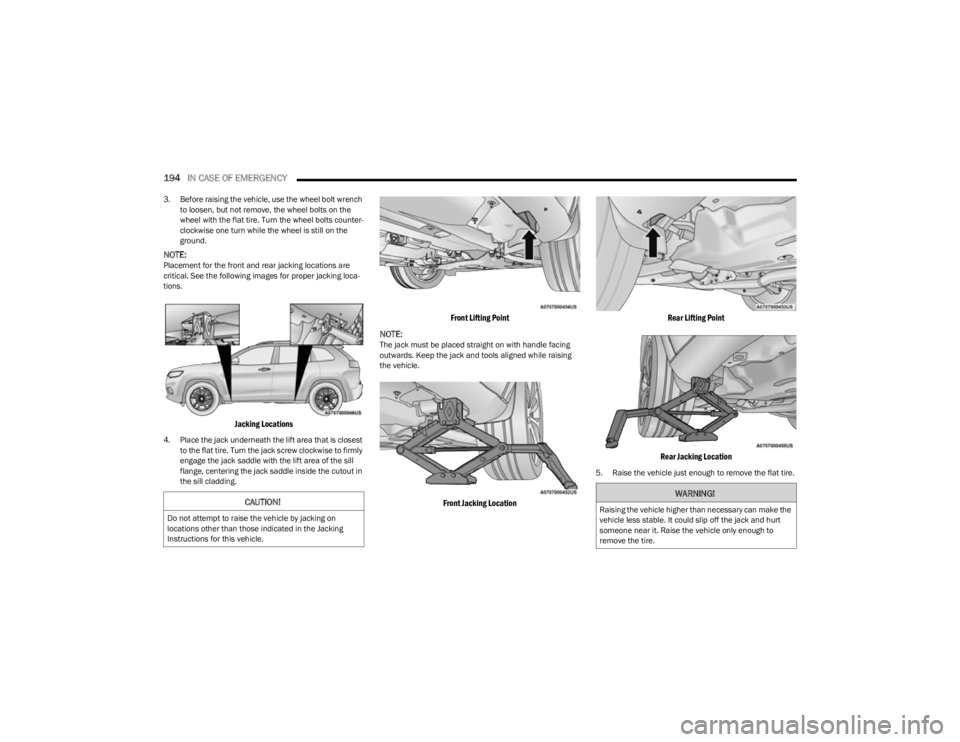

NOTE:Placement for the front and rear jacking locations are

critical. See the following images for proper jacking loca -

tions.

Jacking Locations

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw clockwise to firmly

engage the jack saddle with the lift area of the sill

flange, centering the jack saddle inside the cutout in

the sill cladding.

Front Lifting Point

NOTE:

The jack must be placed straight on with handle facing

outwards. Keep the jack and tools aligned while raising

the vehicle.

Front Jacking Location Rear Lifting Point

Rear Jacking Location

5. Raise the vehicle just enough to remove the flat tire.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

WARNING!

Raising the vehicle higher than necessary can make the

vehicle less stable. It could slip off the jack and hurt

someone near it. Raise the vehicle only enough to

remove the tire.

23_KL_OM_EN_USC_t.book Page 194

Page 197 of 276

IN CASE OF EMERGENCY195

6. Remove the wheel bolts and tire.

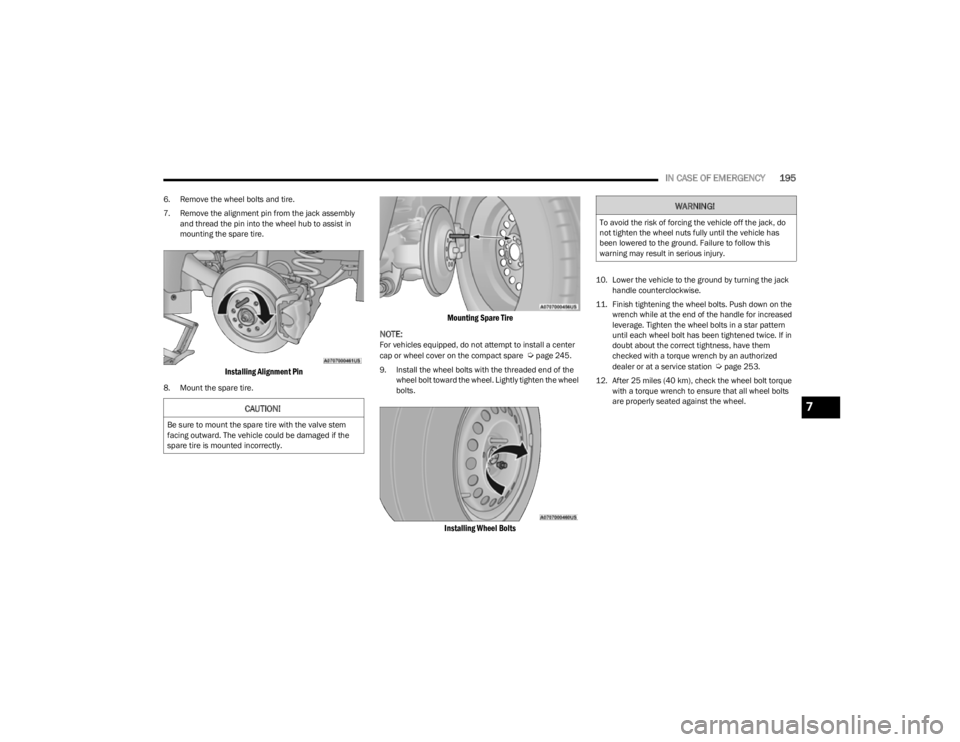

7. Remove the alignment pin from the jack assembly

and thread the pin into the wheel hub to assist in

mounting the spare tire.

Installing Alignment Pin

8. Mount the spare tire.

Mounting Spare Tire

NOTE:

For vehicles equipped, do not attempt to install a center

cap or wheel cover on the compact spare Úpage 245.

9. Install the wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the wheel

bolts.

Installing Wheel Bolts

10. Lower the vehicle to the ground by turning the jack handle counterclockwise.

11. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice. If in

doubt about the correct tightness, have them

checked with a torque wrench by an authorized

dealer or at a service station

Úpage 253.

12. After 25 miles (40 km), check the wheel bolt torque with a torque wrench to ensure that all wheel bolts

are properly seated against the wheel.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered to the ground. Failure to follow this

warning may result in serious injury.

7

23_KL_OM_EN_USC_t.book Page 195

Page 199 of 276

IN CASE OF EMERGENCY197

(Continued)

Using The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the following

symbols to indicate the air or sealant mode.

Selecting Air Mode

Push in the Mode Select Knob and turn to this

position for air pump operation only. Use the

Black Air Pump Hose when selecting this mode.

Selecting Sealant Mode

Push in the Mode Select Knob and turn to this

position to inject the Tire Service Kit Sealant

and to inflate the tire. Use the Sealant Hose

(clear hose) when selecting this mode.

Using The Power Button

Push and release the Power Button once to

turn on the Tire Service Kit. Push and release

the Power Button again to turn Off the Tire

Service Kit.

Using The Deflation Button

Push the Deflation Button to reduce the air

pressure in the tire if it becomes overinflated.

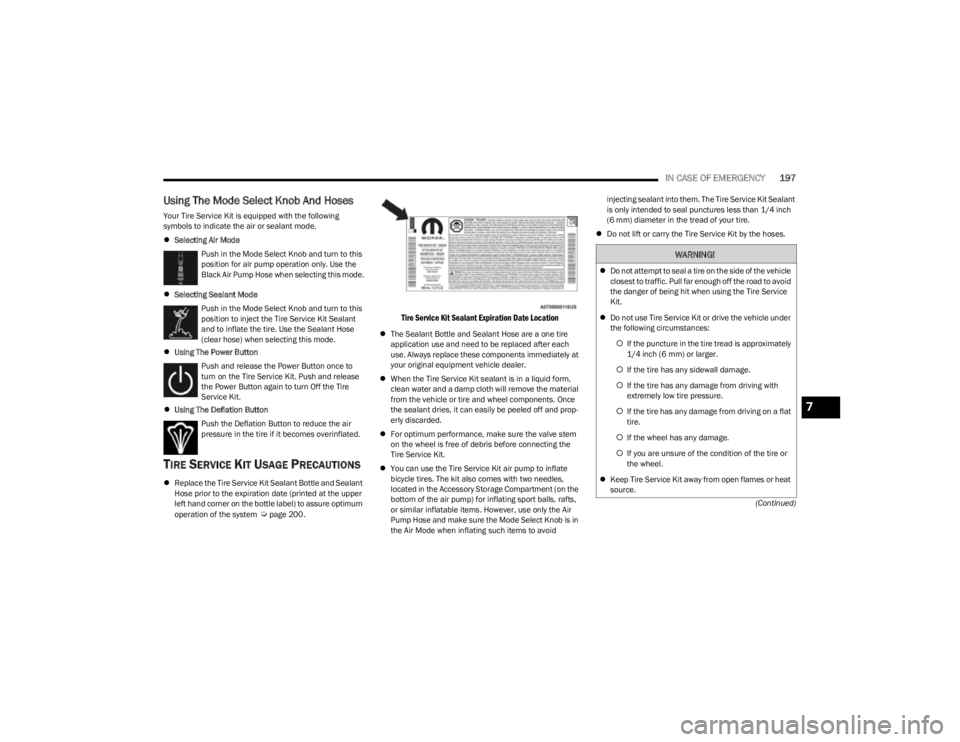

TIRE SERVICE KIT USAGE PRECAUTIONS

Replace the Tire Service Kit Sealant Bottle and Sealant

Hose prior to the expiration date (printed at the upper

left hand corner on the bottle label) to assure optimum

operation of the system

Úpage 200.

Tire Service Kit Sealant Expiration Date Location

The Sealant Bottle and Sealant Hose are a one tire

application use and need to be replaced after each

use. Always replace these components immediately at

your original equipment vehicle dealer.

When the Tire Service Kit sealant is in a liquid form,

clean water and a damp cloth will remove the material

from the vehicle or tire and wheel components. Once

the sealant dries, it can easily be peeled off and prop -

erly discarded.

For optimum performance, make sure the valve stem

on the wheel is free of debris before connecting the

Tire Service Kit.

You can use the Tire Service Kit air pump to inflate

bicycle tires. The kit also comes with two needles,

located in the Accessory Storage Compartment (on the

bottom of the air pump) for inflating sport balls, rafts,

or similar inflatable items. However, use only the Air

Pump Hose and make sure the Mode Select Knob is in

the Air Mode when inflating such items to avoid injecting sealant into them. The Tire Service Kit Sealant

is only intended to seal punctures less than 1/4 inch

(6 mm) diameter in the tread of your tire.

Do not lift or carry the Tire Service Kit by the hoses.

WARNING!

Do not attempt to seal a tire on the side of the vehicle

closest to traffic. Pull far enough off the road to avoid

the danger of being hit when using the Tire Service

Kit.

Do not use Tire Service Kit or drive the vehicle under

the following circumstances:

If the puncture in the tire tread is approximately

1/4 inch (6 mm) or larger.

If the tire has any sidewall damage.

If the tire has any damage from driving with

extremely low tire pressure.

If the tire has any damage from driving on a flat

tire.

If the wheel has any damage.

If you are unsure of the condition of the tire or

the wheel.

Keep Tire Service Kit away from open flames or heat

source.

7

23_KL_OM_EN_USC_t.book Page 197

Page 200 of 276

198IN CASE OF EMERGENCY

SEALING A TIRE WITH TIRE SERVICE KIT

(A) Whenever You Stop To Use Tire Service

Kit:

1. Pull over to a safe location and turn on the vehicle’s

Hazard Warning Flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the

ground. This will allow the Tire Service Kit Hoses and to reach the valve stem and keep the Tire Service Kit

flat on the ground. This will provide the best

positioning of the kit when injecting the sealant into

the deflated tire and running the air pump. Move the

vehicle as necessary to place the valve stem in this

position before proceeding.

3. Place the transmission in PARK (P) (auto transmission) or in Gear (manual transmission) and

place the ignition in the OFF position.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose onto the

valve stem.

5. Uncoil the Power Plug and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or nails) from

the tire.

(C) Injecting Tire Service Kit Sealant Into

The Deflated Tire:

Always start the engine before turning ON the Tire

Service Kit.

NOTE:Manual transmission vehicles must have the parking

brake engaged and the gear selector in NEUTRAL.

After pushing the Power Button, the sealant (white

fluid) will flow from the Sealant Bottle through the

Sealant Hose and into the tire.

NOTE:Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within

0 – 10 seconds through the Sealant Hose:

1. Push the Power Button to turn Off the Tire Service

Kit. Disconnect the Sealant Hose from the valve

stem. Make sure the valve stem is free of debris.

Reconnect the Sealant Hose to the valve stem.

Check that the Mode Select Knob is in the Sealant

Mode position and not Air Mode. Push the Power

Button to turn On the Tire Service Kit.

2. Connect the Power Plug to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the engine is running before turning ON

the Tire Service Kit.

3. The Sealant Bottle may be empty due to previous use. Call for assistance.

NOTE:If the Mode Select Knob is on Air Mode and the pump is

operating, air will dispense from the Air Pump Hose only,

not the Sealant Hose.

A loose Tire Service Kit thrown forward in a collision

or hard stop could endanger the occupants of the

vehicle. Always stow the Tire Service Kit in the place

provided. Failure to follow these warnings can result

in injuries that are serious or fatal to you, your

passengers, and others around you.

Take care not to allow the contents of Tire Service Kit

to come in contact with hair, eyes, or clothing. Tire

Service Kit sealant is harmful if inhaled, swallowed,

or absorbed through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately with plenty of

water if there is any contact with eyes or skin. Change

clothing as soon as possible, if there is any contact

with clothing.

Tire Service Kit Sealant solution contains latex. In

case of an allergic reaction or rash, consult a physi -

cian immediately. Keep Tire Service Kit out of reach

of children. If swallowed, rinse mouth immediately

with plenty of water and drink plenty of water. Do not

induce vomiting! Consult a physician immediately.

WARNING!

23_KL_OM_EN_USC_t.book Page 198

Page 206 of 276

204IN CASE OF EMERGENCY

6. Move the gear selector to the NEUTRAL (N) position.

7. The vehicle may then be started in NEUTRAL (N).

8. Reinstall the gear selector boot.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or snow, it can

often be moved using a rocking motion. Turn the steering

wheel right and left to clear the area around the front

wheels. Push and hold the lock button on the gear

selector. Then shift back and forth between DRIVE (D) and

REVERSE (R), while gently pressing the accelerator.

NOTE:Shifts between DRIVE (D) and REVERSE (R) can only be

achieved at wheel speeds of 5 mph (8 km/h) or less.

Whenever the transmission remains in NEUTRAL (N) for

more than two seconds, you must press the brake pedal

to engage DRIVE (D) or REVERSE (R). Use the least amount of accelerator pedal pressure that

will maintain the rocking motion without spinning the

wheels or racing the engine.NOTE:Push the ESC OFF button (if necessary), to place the Elec

-

tronic Stability Control (ESC) system in “Partial Off” mode,

before rocking the vehicle

Úpage 145. Once the vehicle

has been freed, push the ESC OFF button again to restore

“ESC On” mode.

WARNING!

Fast spinning tires can be dangerous. Forces generated

by excessive wheel speeds may cause damage, or even

failure, of the axle and tires. A tire could explode and

injure someone. Do not spin your vehicle's wheels

faster than 30 mph (48 km/h) or for longer than 30

seconds continuously without stopping when you are

stuck and do not let anyone near a spinning wheel, no

matter what the speed.

CAUTION!

Racing the engine or spinning the wheels may lead to

transmission overheating and failure. Allow the

engine to idle with the transmission in NEUTRAL for

at least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce the

risk of clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

When “rocking” a stuck vehicle by shifting between

DRIVE and REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain damage may

result.

Revving the engine or spinning the wheels too fast

may lead to transmission overheating and failure. It

can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmis -

sion shifting occurring).

23_KL_OM_EN_USC_t.book Page 204

Page 207 of 276

IN CASE OF EMERGENCY205

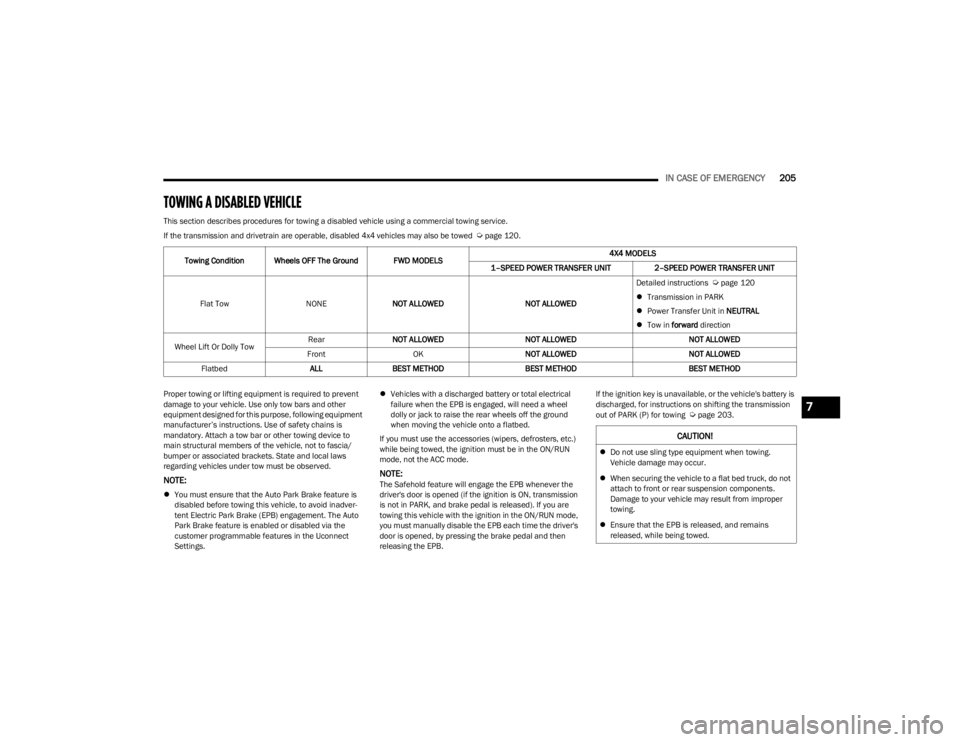

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service.

If the transmission and drivetrain are operable, disabled 4x4 vehicles may also be towed

Úpage 120.

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use only tow bars and other

equipment designed for this purpose, following equipment

manufacturer’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towing device to

main structural members of the vehicle, not to fascia/

bumper or associated brackets. State and local laws

regarding vehicles under tow must be observed.

NOTE:

You must ensure that the Auto Park Brake feature is

disabled before towing this vehicle, to avoid inadver -

tent Electric Park Brake (EPB) engagement. The Auto

Park Brake feature is enabled or disabled via the

customer programmable features in the Uconnect

Settings.

Vehicles with a discharged battery or total electrical

failure when the EPB is engaged, will need a wheel

dolly or jack to raise the rear wheels off the ground

when moving the vehicle onto a flatbed.

If you must use the accessories (wipers, defrosters, etc.)

while being towed, the ignition must be in the ON/RUN

mode, not the ACC mode.

NOTE:The Safehold feature will engage the EPB whenever the

driver's door is opened (if the ignition is ON, transmission

is not in PARK, and brake pedal is released). If you are

towing this vehicle with the ignition in the ON/RUN mode,

you must manually disable the EPB each time the driver's

door is opened, by pressing the brake pedal and then

releasing the EPB. If the ignition key is unavailable, or the vehicle's battery is

discharged, for instructions on shifting the transmission

out of PARK (P) for towing

Úpage 203.

Towing Condition Wheels OFF The Ground FWD MODELS

4X4 MODELS

1–SPEED POWER TRANSFER UNIT 2–SPEED POWER TRANSFER UNIT

Flat Tow NONENOT ALLOWED NOT ALLOWEDDetailed instructions

Úpage 120

Transmission in PARK

Power Transfer Unit in NEUTRAL

Tow in forward direction

Wheel Lift Or Dolly Tow Rear

NOT ALLOWED NOT ALLOWED NOT ALLOWED

Front OK NOT ALLOWED NOT ALLOWED

Flatbed ALLBEST METHOD BEST METHOD BEST METHOD

CAUTION!

Do not use sling type equipment when towing.

Vehicle damage may occur.

When securing the vehicle to a flat bed truck, do not

attach to front or rear suspension components.

Damage to your vehicle may result from improper

towing.

Ensure that the EPB is released, and remains

released, while being towed.

7

23_KL_OM_EN_USC_t.book Page 205

Page 208 of 276

206IN CASE OF EMERGENCY

(Continued)

FRONT-WHEEL DRIVE (FWD) MODELS

The FCA US LLC recommends towing your vehicle with all

four wheels OFF of the ground using a flatbed.

If flatbed equipment is not available, this vehicle must be

towed with the front wheels OFF of the ground (using a

towing dolly, or wheel lift equipment with the front wheels

raised).

Ensure that the Electric Park Brake (EPB) is released, and

remains released, while being towed. The EPB does not

need to be released, if all four wheels are OFF the ground.

4X4 MODELS WITH 1–SPEED POWER

T

RANSFER UNIT

The FCA US LLC requires towing with all four wheels OFF

the ground.

Acceptable methods are to tow the vehicle on a flatbed, or

with one end of vehicle raised and the opposite end on a

towing dolly.

4X4 MODELS WITH 2–SPEED POWER

T

RANSFER UNIT

The FCA US LLC recommends towing with all four wheels

OFF the ground.

Acceptable methods are to tow the vehicle on a flatbed or

with one end of the vehicle raised and the opposite end on

a towing dolly.

If flatbed equipment is not available and the Power

Transfer Unit is operable, vehicles with a 2–speed Power

Transfer Unit may be towed (in the forward direction, with

ALL wheels on the ground), under the following conditions:

The Power Transfer Unit must be in NEUTRAL (N).

The transmission must be in PARK (P) .

Ensure that the EPB is released, and remains released,

while being towed

Úpage 120.

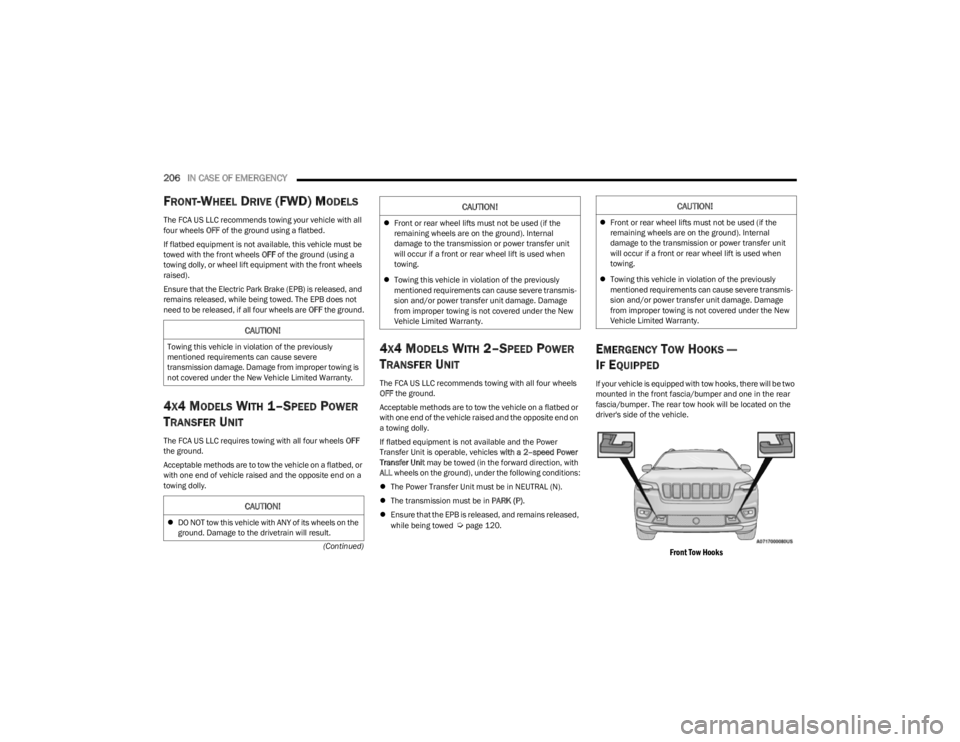

EMERGENCY TOW HOOKS —

I

F EQUIPPED

If your vehicle is equipped with tow hooks, there will be two

mounted in the front fascia/bumper and one in the rear

fascia/bumper. The rear tow hook will be located on the

driver's side of the vehicle.

Front Tow Hooks

CAUTION!

Towing this vehicle in violation of the previously

mentioned requirements can cause severe

transmission damage. Damage from improper towing is

not covered under the New Vehicle Limited Warranty.

CAUTION!

DO NOT tow this vehicle with ANY of its wheels on the

ground. Damage to the drivetrain will result.

Front or rear wheel lifts must not be used (if the

remaining wheels are on the ground). Internal

damage to the transmission or power transfer unit

will occur if a front or rear wheel lift is used when

towing.

Towing this vehicle in violation of the previously

mentioned requirements can cause severe transmis -

sion and/or power transfer unit damage. Damage

from improper towing is not covered under the New

Vehicle Limited Warranty.

CAUTION!CAUTION!

Front or rear wheel lifts must not be used (if the

remaining wheels are on the ground). Internal

damage to the transmission or power transfer unit

will occur if a front or rear wheel lift is used when

towing.

Towing this vehicle in violation of the previously

mentioned requirements can cause severe transmis -

sion and/or power transfer unit damage. Damage

from improper towing is not covered under the New

Vehicle Limited Warranty.

23_KL_OM_EN_USC_t.book Page 206

Page 234 of 276

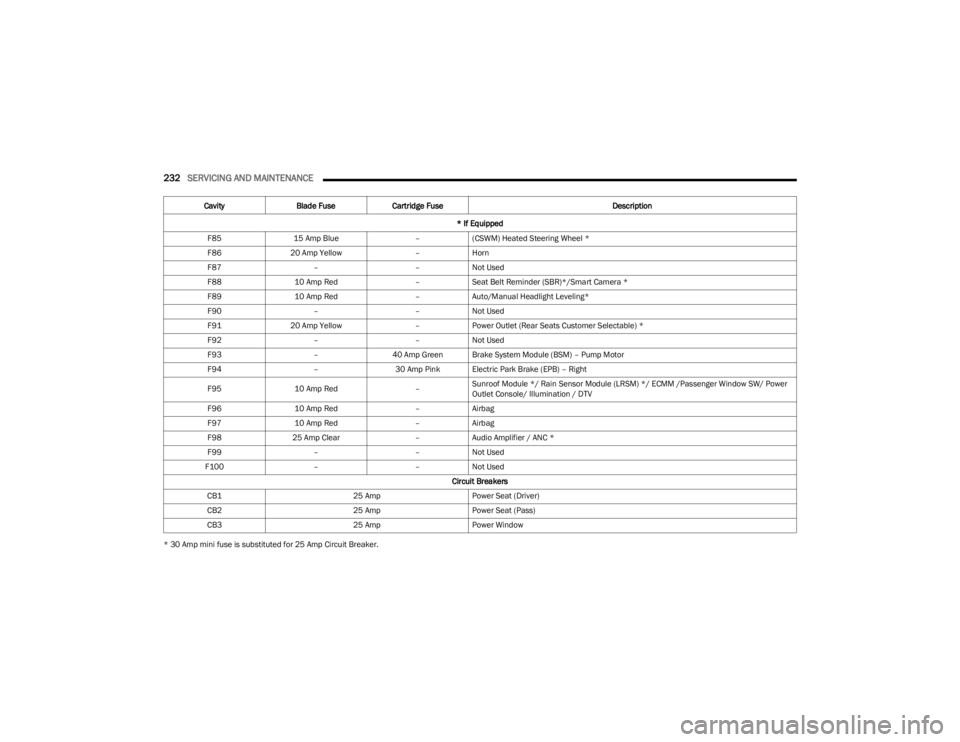

232SERVICING AND MAINTENANCE

* 30 Amp mini fuse is substituted for 25 Amp Circuit Breaker.F85

15 Amp Blue –(CSWM) Heated Steering Wheel *

F86 20 Amp Yellow –Horn

F87 ––Not Used

F88 10 Amp Red –Seat Belt Reminder (SBR)*/Smart Camera *

F89 10 Amp Red –Auto/Manual Headlight Leveling*

F90 ––Not Used

F91 20 Amp Yellow –Power Outlet (Rear Seats Customer Selectable) *

F92 ––Not Used

F93 –40 Amp Green Brake System Module (BSM) – Pump Motor

F94 –30 Amp Pink Electric Park Brake (EPB) – Right

F95 10 Amp Red –Sunroof Module */ Rain Sensor Module (LRSM) */ ECMM /Passenger Window SW/ Power

Outlet Console/ Illumination / DTV

F96 10 Amp Red –Airbag

F97 10 Amp Red –Airbag

F98 25 Amp Clear –Audio Amplifier / ANC *

F99 ––Not Used

F100 ––Not Used

Circuit Breakers

CB1 25 AmpPower Seat (Driver)

CB2 25 AmpPower Seat (Pass)

CB3 25 AmpPower Window

Cavity

Blade Fuse Cartridge Fuse Description

* If Equipped

23_KL_OM_EN_USC_t.book Page 232

Page 244 of 276

242SERVICING AND MAINTENANCE

Example: If garage temperature = 68°F (20°C) and the

outside temperature = 32°F (0°C) then the cold tire

inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12°F (7°C) for this

outside temperature condition.

Tire pressure may increase from 2 to 6 psi (13 to 40 kPa)

during operation. DO NOT reduce this normal pressure

build up or your tire pressure will be too low.

Tire Pressures For High Speed Operation

The manufacturer advocates driving at safe speeds and

within posted speed limits. Where speed limits or

conditions are such that the vehicle can be driven at high

speeds, maintaining correct tire inflation pressure is very

important. Increased tire pressure and reduced vehicle

loading may be required for high-speed vehicle operation.

Refer to an authorized tire dealer or original equipment

vehicle dealer for recommended safe operating speeds,

loading and cold tire inflation pressures.

Radial Ply Tires

Tire Repair

If your tire becomes damaged, it may be repaired if it

meets the following criteria:

The tire has not been driven on when flat.

The damage is only on the tread section of your tire

(sidewall damage is not repairable).

The puncture is no greater than ¼ of an inch (6 mm).

Consult an authorized tire dealer for tire repairs and

additional information.

Damaged Run Flat tires, or Run Flat tires that have

experienced a loss of pressure should be replaced

immediately with another Run Flat tire of identical size and

service description (Load Index and Speed Symbol).

Replace the tire pressure sensor as well as it is not

designed to be reused.

Run Flat Tires — If Equipped

Run Flat tires allow you the capability to drive 50 miles

(80 km) at 50 mph (80 km/h) after a rapid loss of inflation

pressure. This rapid loss of inflation is referred to as the

Run Flat mode. A Run Flat mode occurs when the tire

inflation pressure is of/or below 14 psi (96 kPa). Once a Run Flat tire reaches the Run Flat mode it has limited

driving capabilities and needs to be replaced immediately.

A Run Flat tire is not repairable. When a Run Flat tire is

changed after being driven under a Run Flat mode 14 psi

(96 kPa) condition, please replace the TPMS sensor as it

is not designed to be reused.

NOTE:TPMS sensor must be replaced after driving the vehicle on

a flat tire condition.

It is not recommended driving a vehicle loaded at full

capacity or to tow a trailer while a tire is in the Run Flat

mode.

See the Tire Pressure Monitoring System section for more

information

Úpage 155.

Tire Spinning

When stuck in mud, sand, snow, or ice conditions, do not

spin your vehicle's wheels above 30 mph (48 km/h) or for

longer than 30 seconds continuously without stopping.

WARNING!

High speed driving with your vehicle under maximum

load is dangerous. The added strain on your tires could

cause them to fail. You could have a serious collision.

Do not drive a vehicle loaded to the maximum capacity

at continuous speeds above 75 mph (120 km/h).

WARNING!

Combining radial ply tires with other types of tires on

your vehicle will cause your vehicle to handle poorly.

The instability could cause a collision. Always use radial

ply tires in sets of four. Never combine them with other

types of tires.

WARNING!

Fast spinning tires can be dangerous. Forces generated

by excessive wheel speeds may cause tire damage or

failure. A tire could explode and injure someone. Do not

spin your vehicle's wheels faster than 30 mph (48 km/h)

for more than 30 seconds continuously when you are

stuck, and do not let anyone near a spinning wheel, no

matter what the speed.

23_KL_OM_EN_USC_t.book Page 242