recommended oil JEEP CHEROKEE 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: CHEROKEE, Model: JEEP CHEROKEE 2023Pages: 276, PDF Size: 12.55 MB

Page 80 of 276

78STARTING AND OPERATING

(Continued)

IF ENGINE FAILS TO START

If the engine fails to start after you have followed the

“Normal Starting” procedure and the vehicle has not

experienced an Extended Park condition as previously

defined, it may be flooded. Push the accelerator pedal all

the way to the floor and hold it there while the engine is

cranking. This should clear any excess fuel in case the

engine is flooded. The starter motor will engage

automatically, run for 10 seconds, and then disengage.

Once this occurs, release the accelerator pedal and the

brake pedal, wait 10 to 15 seconds, then repeat the

“Normal Starting” procedure.AFTER STARTING

The idle speed is controlled automatically, and it will

decrease as the engine warms up.

ENGINE BREAK-IN RECOMMENDATIONS

A long break-in period is not required for the engine and

drivetrain (transmission and axle) in your vehicle.

Drive moderately during the first 300 miles (500 km).

After the initial 60 miles (100 km), speeds up to 50 or

55 mph (80 or 90 km/h) are desirable.

While cruising, brief full-throttle acceleration within the

limits of local traffic laws contributes to a good break-in.

Wide-open throttle acceleration in low gear can be

detrimental and should be avoided.

The engine oil installed in the engine at the factory is a

high-quality energy conserving type lubricant. Oil changes

should be consistent with anticipated climate conditions

under which vehicle operations will occur. For the

recommended viscosity and quality grades see

Úpage 256.

NOTE:A new engine may consume some oil during its first few

thousand miles (kilometers) of operation. This should be

considered a normal part of the break-in and not inter -

preted as a problem.

PARKING BRAKE

ELECTRIC PARK BRAKE (EPB)

Your vehicle is equipped with an EPB that offers simple

operation, and some additional features that make the

parking brake more convenient and useful.

The parking brake is primarily intended to prevent the

vehicle from rolling while parked. Before leaving the

vehicle, make sure that the parking brake is applied. Also,

be certain to leave the transmission in PARK (P).

You can engage the parking brake in two ways:

Manually, by applying the EPB switch.

Automatically, by enabling the Auto Park Brake feature

in the customer programmable features

Úpage 132.

The EPB switch is located in the center console, behind

the gear selector.

CAUTION!

To prevent damage to the starter, do not crank

continuously for more than 10 seconds at a time. Wait

10 to 15 seconds before trying again.

WARNING!

Never pour fuel or other flammable liquid into the

throttle body air inlet opening in an attempt to start

the vehicle. This could result in flash fire causing

serious personal injury.

Do not attempt to push or tow your vehicle to get it

started. Vehicles equipped with an automatic trans -

mission cannot be started this way. Unburned fuel

could enter the catalytic converter and once the

engine has started, ignite and damage the converter

and vehicle.

If the vehicle has a discharged battery, booster

cables may be used to obtain a start from a booster

battery or the battery in another vehicle. This type of

start can be dangerous if done improperly

Úpage 200.

WARNING!CAUTION!

Never use Non-Detergent Oil or Straight Mineral Oil in

the engine or damage may result.

23_KL_OM_EN_USC_t.book Page 78

Page 190 of 276

188SAFETY

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nut/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake lights and

exterior lights while you work the controls. Check turn signal

and high beam indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check the area under the vehicle after overnight parking

for fuel, coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel or brake fluid leaks are

suspected, the cause should be located and corrected

immediately.

EXHAUST GAS

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system. Whenever a change is noticed in the sound of the exhaust

system, when exhaust fumes can be detected inside the

vehicle, or when the underside or rear of the vehicle is

damaged, have an authorized dealer inspect the complete

exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition,

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

CARBON MONOXIDE WARNINGS

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check the floor mat fasteners are secure to the

vehicle carpet. Fully depress each pedal to check for

interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

It is recommended to only use mild soap and water

to clean your floor mats. After cleaning, always check

your floor mat has been properly installed and is

secured to your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO), which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing (CO), follow

these safety tips:

Do not run the engine in a closed garage or in

confined areas any longer than needed to move your

vehicle in or out of the area.

If you are required to drive with the trunk/liftgate/

rear doors open, make sure that all windows are

closed and the climate control BLOWER switch is set

at high speed. DO NOT use the recirculation mode.

If it is necessary to sit in a parked vehicle with the

engine running, adjust your heating or cooling

controls to force outside air into the vehicle. Set the

blower at high speed.

WARNING!

Carbon monoxide (CO) in exhaust gases is deadly.

Follow the precautions below to prevent carbon

monoxide poisoning:

Do not inhale exhaust gases. They contain carbon

monoxide, a colorless and odorless gas, which can

kill. Never run the engine in a closed area, such as a

garage, and never sit in a parked vehicle with the

engine running for an extended period. If the vehicle

is stopped in an open area with the engine running

for more than a short period, adjust the ventilation

system to force fresh, outside air into the vehicle.

Guard against carbon monoxide with proper mainte -

nance. Have the exhaust system inspected every

time the vehicle is raised. Have any abnormal condi -

tions repaired promptly. Until repaired, drive with all

side windows fully open.

23_KL_OM_EN_USC_t.book Page 188

Page 201 of 276

IN CASE OF EMERGENCY199

If the sealant (white fluid) does flow through the Sealant

Hose:

1. Continue to operate the pump until sealant is no

longer flowing through the hose (typically takes

30 - 70 seconds). As the sealant flows through the

Sealant Hose, the Pressure Gauge can read as high

as 70 psi (4.8 Bar). The Pressure Gauge will

decrease quickly from approximately 70 psi

(4.8 Bar) to the actual tire pressure when the

Sealant Bottle is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle is empty.

Continue to operate the pump and inflate the tire to

the pressure indicated on the tire pressure label on

the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure

Gauge.

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

NOTE:Never operate the compressor for longer than 20 minutes.

Risk of Overheating.

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recommended

inflation pressure before continuing. If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 Bar) pressure within 15 minutes:

1. Push the Power Button to turn off the Tire Service

Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle and place the sticker on the

instrument panel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the fitting at the end

of the hose, and place the Tire Service Kit in the

vehicle storage location.

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the tire,

drive the vehicle 5 miles (8 km) or 10 minutes to ensure

distribution of the Tire Service Kit Sealant within the tire.

Do not exceed 50 mph (80 km/h).

(E) After Driving:

Pull over to a safe location Úpage 198.

1. Push in the Mode Select Knob and turn to the Air Mode position.

2. Uncoil the power plug and insert the plug into the vehicle's 12 Volt power outlet.

3. Uncoil the Air Pump Hose (black in color) and screw the fitting at the end of hose onto the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge.

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button to turn on Tire Service Kit and inflate the tire to the pressure indicated on the

tire and loading information label on the driver-side

door opening.

CAUTION!

The metal end fitting from Power Plug may get hot

after use, so it should be handled carefully.

Failure to reinstall the cap on the fitting at the end of

the Sealant Hose can result in sealant contacting

your skin, clothing, and the vehicle’s interior. It can

also result in sealant contacting internal Tire Service

Kit components which may cause permanent

damage to the kit.

WARNING!

Tire Service Kit is not a permanent flat tire repair. Have

the tire inspected and repaired or replaced after using

Tire Service Kit. Do not exceed 50 mph (80 km/h) until

the tire is repaired or replaced. Failure to follow this

warning can result in injuries that are serious or fatal to

you, your passengers, and others around you.

7

23_KL_OM_EN_USC_t.book Page 199

Page 202 of 276

200IN CASE OF EMERGENCY

NOTE:If the tire becomes overinflated, push the Deflation Button

to reduce the tire pressure to the recommended inflation

pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem,

reinstall the cap on the valve stem and unplug from

12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been repaired.

6. Replace the Sealant Bottle and Sealant Hose assembly at an authorized dealer as soon as possible

Úpage 200.

NOTE:When having the tire serviced, advise the authorized

dealer or service center that the tire has been sealed

using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (clear in color).

2. Locate the red colored round Sealant Bottle release button at the lower right hand corner of the kit.

3. Push and hold the Sealant Bottle release button, then pull out the bottle holding the button.

4. Clean any remaining sealant from the Tire Service Kit housing. 5. Position the new Sealant Bottle in the housing so that

the Sealant Hose aligns with the hose slot in the front

of the housing. Push and hold the Sealant Bottle

release button, then push the bottle into the housing

by holding the button. An audible click will be heard

indicating the bottle is locked into place. Release the

button.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose and return the hose to its storage

area (located on top of the housing).

7. Return the Tire Service Kit to its storage location in the vehicle.

JUMP STARTING

If your vehicle has a discharged battery, it can be jump

started using a set of jumper cables and a battery in

another vehicle or by using a portable battery booster

pack. Jump starting can be dangerous if done improperly,

so please follow the procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow the

manufacturer’s operating instructions and precautions.

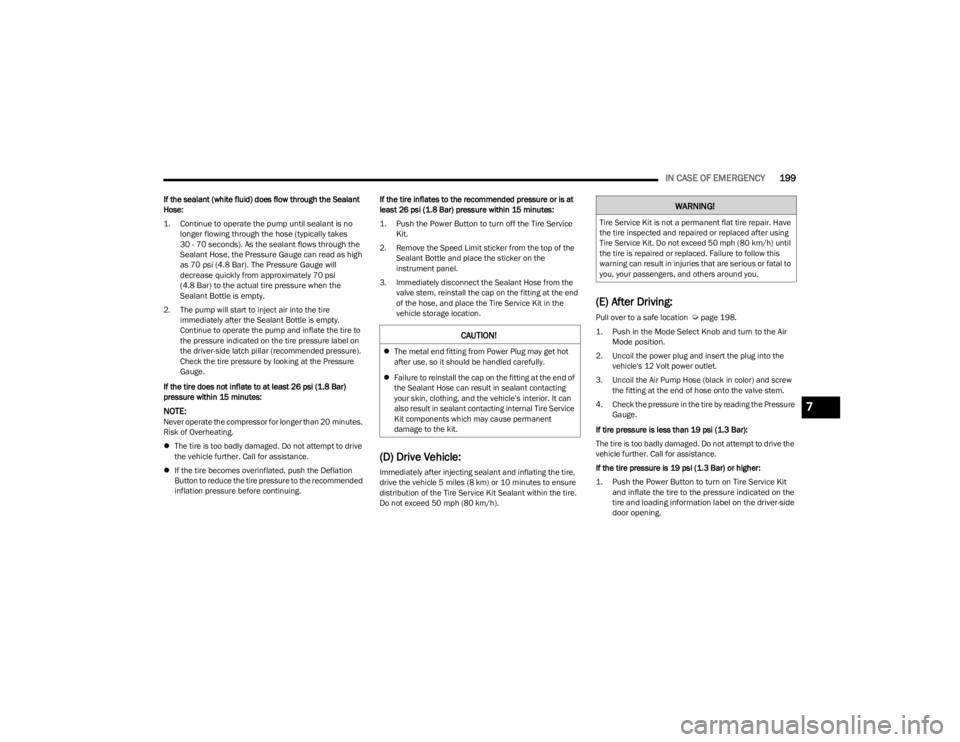

PREPARATIONS FOR JUMP START

The battery in your vehicle is located in the front of the

engine compartment, behind the left headlight assembly.

Positive (+) Battery Post

See the following steps to prepare for jump starting:

1. Apply the parking brake, shift the automatic transmission into PARK (P) and turn the ignition OFF.

2. Turn off the heater, radio, and all electrical accessories.

3. If using another vehicle to jump start the battery, park the vehicle within the jumper cable’s reach, apply the

parking brake and make sure the ignition is OFF.WARNING!

Do not attempt jump starting if the battery is frozen. It

could rupture or explode and cause personal injury.

CAUTION!

Do not use a portable battery booster pack or any other

booster source with a system voltage greater than

12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

23_KL_OM_EN_USC_t.book Page 200

Page 209 of 276

IN CASE OF EMERGENCY207

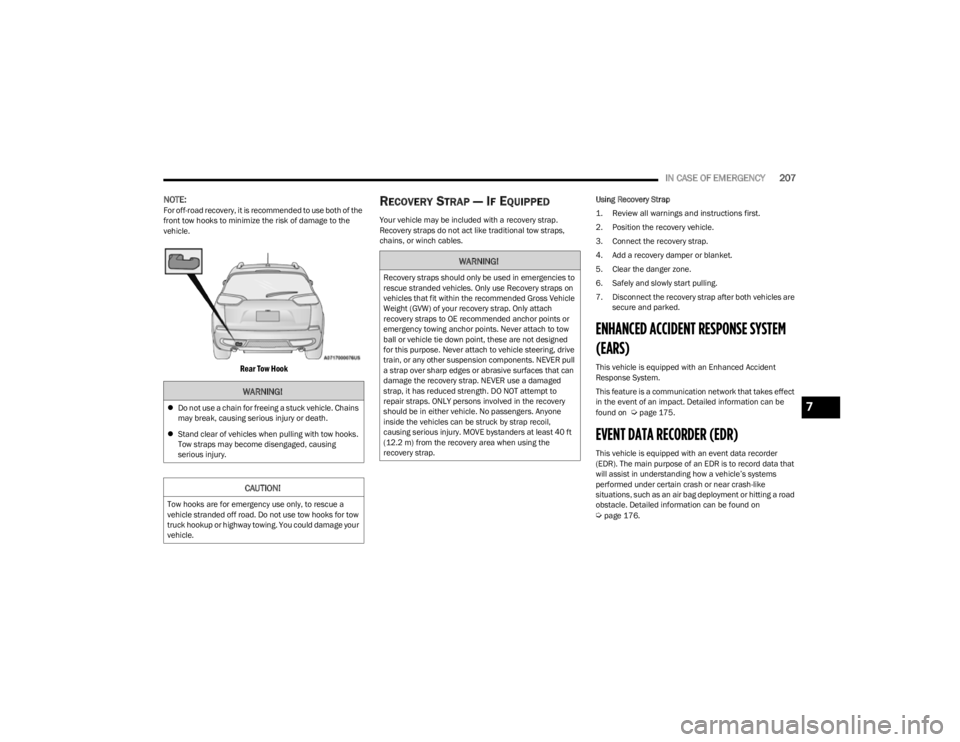

NOTE:For off-road recovery, it is recommended to use both of the

front tow hooks to minimize the risk of damage to the

vehicle.

Rear Tow Hook

RECOVERY STRAP — IF EQUIPPED

Your vehicle may be included with a recovery strap.

Recovery straps do not act like traditional tow straps,

chains, or winch cables. Using Recovery Strap

1. Review all warnings and instructions first.

2. Position the recovery vehicle.

3. Connect the recovery strap.

4. Add a recovery damper or blanket.

5. Clear the danger zone.

6. Safely and slowly start pulling.

7. Disconnect the recovery strap after both vehicles are

secure and parked.

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS)

This vehicle is equipped with an Enhanced Accident

Response System.

This feature is a communication network that takes effect

in the event of an impact. Detailed information can be

found on

Úpage 175.

EVENT DATA RECORDER (EDR)

This vehicle is equipped with an event data recorder

(EDR). The main purpose of an EDR is to record data that

will assist in understanding how a vehicle’s systems

performed under certain crash or near crash-like

situations, such as an air bag deployment or hitting a road

obstacle. Detailed information can be found on

Úpage 176.

WARNING!

Do not use a chain for freeing a stuck vehicle. Chains

may break, causing serious injury or death.

Stand clear of vehicles when pulling with tow hooks.

Tow straps may become disengaged, causing

serious injury.

CAUTION!

Tow hooks are for emergency use only, to rescue a

vehicle stranded off road. Do not use tow hooks for tow

truck hookup or highway towing. You could damage your

vehicle.

WARNING!

Recovery straps should only be used in emergencies to

rescue stranded vehicles. Only use Recovery straps on

vehicles that fit within the recommended Gross Vehicle

Weight (GVW) of your recovery strap. Only attach

recovery straps to OE recommended anchor points or

emergency towing anchor points. Never attach to tow

ball or vehicle tie down point, these are not designed

for this purpose. Never attach to vehicle steering, drive

train, or any other suspension components. NEVER pull

a strap over sharp edges or abrasive surfaces that can

damage the recovery strap. NEVER use a damaged

strap, it has reduced strength. DO NOT attempt to

repair straps. ONLY persons involved in the recovery

should be in either vehicle. No passengers. Anyone

inside the vehicles can be struck by strap recoil,

causing serious injury. MOVE bystanders at least 40 ft

(12.2 m) from the recovery area when using the

recovery strap.

7

23_KL_OM_EN_USC_t.book Page 207

Page 217 of 276

SERVICING AND MAINTENANCE215

PRESSURE WASHING

Cleaning the engine compartment with a high pressure

washer is not recommended.

VEHICLE MAINTENANCE

An authorized dealer has the qualified service personnel,

special tools, and equipment to perform all service

operations in an expert manner. Service Manuals are

available which include detailed service information for your vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:Intentional tampering with emissions control systems may

void your warranty and could result in civil penalties being

assessed against you.

ENGINE OIL

Engine Oil Selection

Use only the manufacturer's recommended fluid Úpage 256.

American Petroleum Institute (API)

Approved Engine Oil

These symbols mean that the oil has been certified by the

API. The manufacturer only recommends API trademark

oils.

The API Starburst trademark certifies 0W-20,

0W-30 and 5W-30 engine oils.

The API Donut trademark certifies 0W-40 and

5W-40 engine oil.

Synthetic Engine Oils

Your engine was designed for synthetic engine oils, only

use synthetic API approved engine oils.

Synthetic engine oils which do not have both the correct

API trademark and the correct SAE viscosity grade

numbers should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against the

addition of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered product and

its performance may be impaired by supplemental

additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service

station or governmental agency for advice on how and

where used oil and oil filters can be safely discarded in

your area.

CAUTION!

It is essential when replacing the cables on the

battery that the positive cable is attached to the posi -

tive post and the negative cable is attached to the

negative post. Battery posts are marked positive (+)

and negative (-) and are identified on the battery

case. Cable clamps should be tight on the terminal

posts and free of corrosion.

If a “fast charger” is used while the battery is in the

vehicle, disconnect both vehicle battery cables

before connecting the charger to the battery. Do not

use a “fast charger” to provide starting voltage.

CAUTION!

Precautions have been taken to safeguard all parts and

connections however, the pressures generated by these

machines is such that complete protection against

water ingress cannot be guaranteed.

WARNING!

You can be badly injured working on or around a motor

vehicle. Only do service work for which you have the

knowledge and the proper equipment. If you have any

doubt about your ability to perform a service job, take

your vehicle to a competent mechanic.

CAUTION!

Do not use chemical flushes in your engine oil as the

chemicals can damage your engine. Such damage is

not covered by the New Vehicle Limited Warranty.

8

23_KL_OM_EN_USC_t.book Page 215

Page 220 of 276

218SERVICING AND MAINTENANCE

Refrigerant Recovery And Recycling

R-134a — If Equipped

R-134a Air Conditioning Refrigerant is a Hydrofluo -

rocarbon (HFC) that is an ozone-friendly substance. It is

recommended that air conditioning service be performed

by an authorized dealer or other service facilities using

recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system PAG

compressor oil and refrigerants.

Refrigerant Recovery And Recycling

R-1234yf — If Equipped

R-1234yf Air Conditioning Refrigerant is a Hydrofluo-

roolefin (HFO) that is endorsed by the Environmental

Protection Agency and is an ozone-friendly substance with

a low global-warming potential. It is recommended that air

conditioning service be performed by an authorized dealer

using recovery and recycling equipment.

NOTE:Use only manufacturer approved A/C system PAG

compressor oil, and refrigerants.

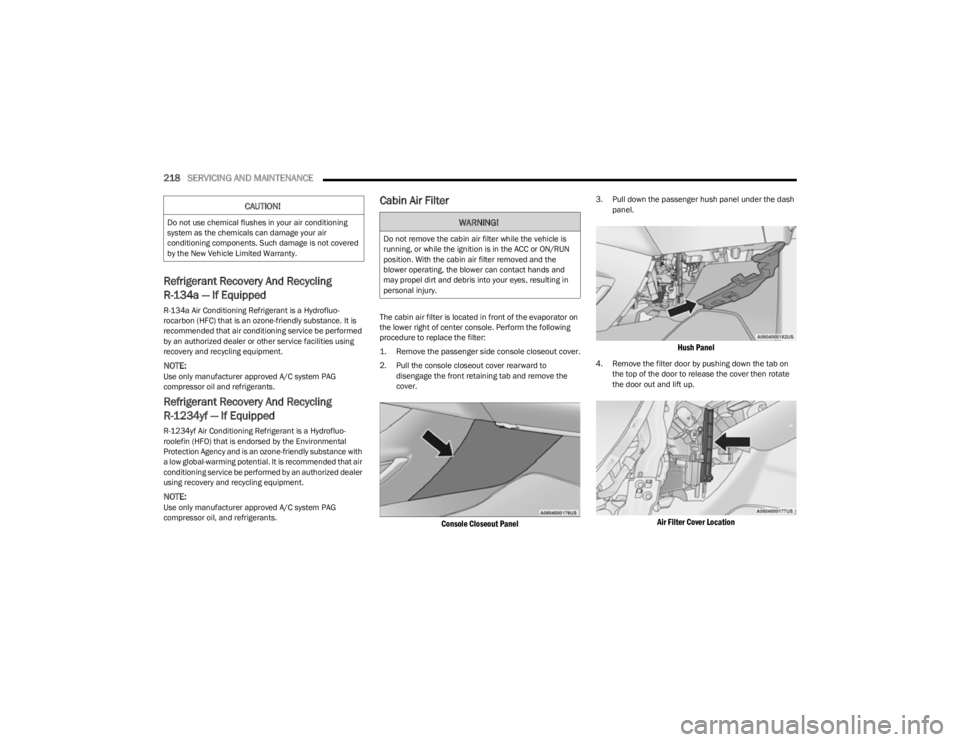

Cabin Air Filter

The cabin air filter is located in front of the evaporator on

the lower right of center console. Perform the following

procedure to replace the filter:

1. Remove the passenger side console closeout cover.

2. Pull the console closeout cover rearward to disengage the front retaining tab and remove the

cover.

Console Closeout Panel

3. Pull down the passenger hush panel under the dash panel.

Hush Panel

4. Remove the filter door by pushing down the tab on the top of the door to release the cover then rotate

the door out and lift up.

Air Filter Cover Location

CAUTION!

Do not use chemical flushes in your air conditioning

system as the chemicals can damage your air

conditioning components. Such damage is not covered

by the New Vehicle Limited Warranty.WARNING!

Do not remove the cabin air filter while the vehicle is

running, or while the ignition is in the ACC or ON/RUN

position. With the cabin air filter removed and the

blower operating, the blower can contact hands and

may propel dirt and debris into your eyes, resulting in

personal injury.

23_KL_OM_EN_USC_t.book Page 218

Page 226 of 276

224SERVICING AND MAINTENANCE

NOTE:

It is the owner's responsibility to maintain the proper

level of protection against freezing according to the

temperatures occurring in the area where the vehicle is

operated.

Use care when filling under hood fluids such as Engine

Oil, Windshield Washer Solvent, Antifreeze etc. to mini -

mize spillage onto top of engine. Any excess fluid that

is spilled onto the top of the engine should be removed

using compressed air or absorbent cloth.

Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could

lead to severe internal engine damage. If any coolant is

needed to be added to the system, please contact a

local authorized dealer.

Mixing engine coolant types is not recommended and

can result in cooling system damage. If HOAT and OAT

coolant are mixed in an emergency, have an authorized

dealer drain, flush, and refill with OAT coolant

(conforming to MS.90032) as soon as possible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of engine

coolant (antifreeze), and to ensure that engine coolant will

return to the radiator from the coolant expansion bottle/

recovery tank (if equipped).

The cap should be inspected and cleaned if there is any

accumulation of foreign material on the sealing surfaces.

Disposal Of Used Coolant

Used ethylene glycol-based coolant (antifreeze) is a

regulated substance requiring proper disposal. Check with

your local authorities to determine the disposal rules for

your community. To prevent ingestion by animals or

children, do not store ethylene glycol-based coolant in

open containers or allow it to remain in puddles on the

ground, clean up any ground spills immediately. If

ingested, seek emergency assistance immediately.

Coolant Level

The coolant bottle provides a quick visual method for

determining that the coolant level is adequate. With the

engine off and cold, the level of the engine coolant

(antifreeze) in the bottle should be between the ranges

indicated on the bottle.

The radiator normally remains completely full, so there is

no need to remove the radiator/coolant pressure cap

unless checking for engine coolant freeze point or replacing coolant. Advise your service attendant of this. As

long as the engine operating temperature is satisfactory,

the coolant only needs to be checked once a month.

When additional engine coolant is needed to maintain the

proper level, only OAT coolant that meets the

requirements of the manufacturer Material Standard

MS.90032 should be added to the coolant bottle. Do not

overfill.

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilometers

of operation, you may observe vapor coming from the front

of the engine compartment. This is normally a result of

moisture from rain, snow, or high humidity accumulating

on the radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to enter

the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

Do not overfill the coolant expansion bottle.

Check the coolant freeze point in the radiator and in

the coolant expansion bottle. If engine coolant needs

to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

If frequent engine coolant additions are required, the

cooling system should be pressure tested for leaks.

Maintain engine coolant concentration at a minimum

of 50% OAT coolant (conforming to MS.90032) and

distilled water for proper corrosion protection of your

engine which contains aluminum components.

WARNING!

Do not open hot engine cooling system. Never add

engine coolant (antifreeze) when the engine is over -

heated. Do not loosen or remove the cap to cool an

overheated engine. Heat causes pressure to build up

in the cooling system. To prevent scalding or injury,

do not remove the pressure cap while the system is

hot or under pressure.

Do not use a pressure cap other than the one speci -

fied for your vehicle. Personal injury or engine

damage may result.

23_KL_OM_EN_USC_t.book Page 224

Page 227 of 276

SERVICING AND MAINTENANCE225

Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory engine cooling performance,

poor gas mileage, and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all brake

system components should be inspected periodically.

Refer to the Maintenance Plan for the proper

maintenance intervals

Úpage 209.

Fluid Level Check — Brake Master Cylinder

The fluid level of the brake master cylinder should be

checked whenever the vehicle is serviced, or immediately

if the Brake System Warning Light is on. If necessary, add

fluid to bring level within the designated marks on the side

of the reservoir of the brake master cylinder. Be sure to

clean the top of the master cylinder area before removing cap. With disc brakes, fluid level can be expected to fall as

the brake pads wear. Brake fluid level should be checked

when pads are replaced. If the brake fluid is abnormally

low, check the system for leaks. For further information

Úpage 256.

AUTOMATIC TRANSMISSION

Special Additives

It is strongly recommended against using any special

additives in the transmission. Automatic Transmission

Fluid (ATF) is an engineered product and its performance

may be impaired by supplemental additives. Therefore, do

not add any fluid additives to the transmission. Avoid

using transmission sealers as they may adversely affect

seals.

Fluid Level Check

The fluid level is preset at the factory and does not require

adjustment under normal operating conditions. Routine

fluid level checks are not required; therefore the

transmission has no dipstick. An authorized dealer can

check your transmission fluid level using special service

tools. If you notice fluid leakage or transmission

malfunction, visit an authorized dealer immediately to

have the transmission fluid level checked. Operating the

vehicle with an improper fluid level can cause severe

transmission damage.

WARNING!

Riding the brakes can lead to brake failure and possibly

a collision. Driving with your foot resting or riding on the

brake pedal can result in abnormally high brake

temperatures, excessive lining wear, and possible brake

damage. You would not have your full braking capacity

in an emergency.

WARNING!

Use only manufacturer's recommended brake fluid.

For further information Úpage 256. Using the wrong

type of brake fluid can severely damage your brake

system and/or impair its performance. The proper

type of brake fluid for your vehicle is also identified

on the original factory installed hydraulic master

cylinder reservoir.

To avoid contamination from foreign matter or mois -

ture, use only new brake fluid or fluid that has been

in a tightly closed container. Keep the master

cylinder reservoir cap secured at all times. Brake

fluid in a open container absorbs moisture from the

air resulting in a lower boiling point. This may cause

it to boil unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This could

result in a collision.

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts, causing the

brake fluid to catch fire. Brake fluid can also damage

painted and vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum-based fluid to contaminate

the brake fluid. Brake seal components could be

damaged, causing partial or complete brake failure.

This could result in a collision.

CAUTION!

Do not use chemical flushes in your transmission as the

chemicals can damage your transmission components.

Such damage is not covered by the New Vehicle Limited

Warranty.

8

23_KL_OM_EN_USC_t.book Page 225

Page 245 of 276

SERVICING AND MAINTENANCE243

(Continued)

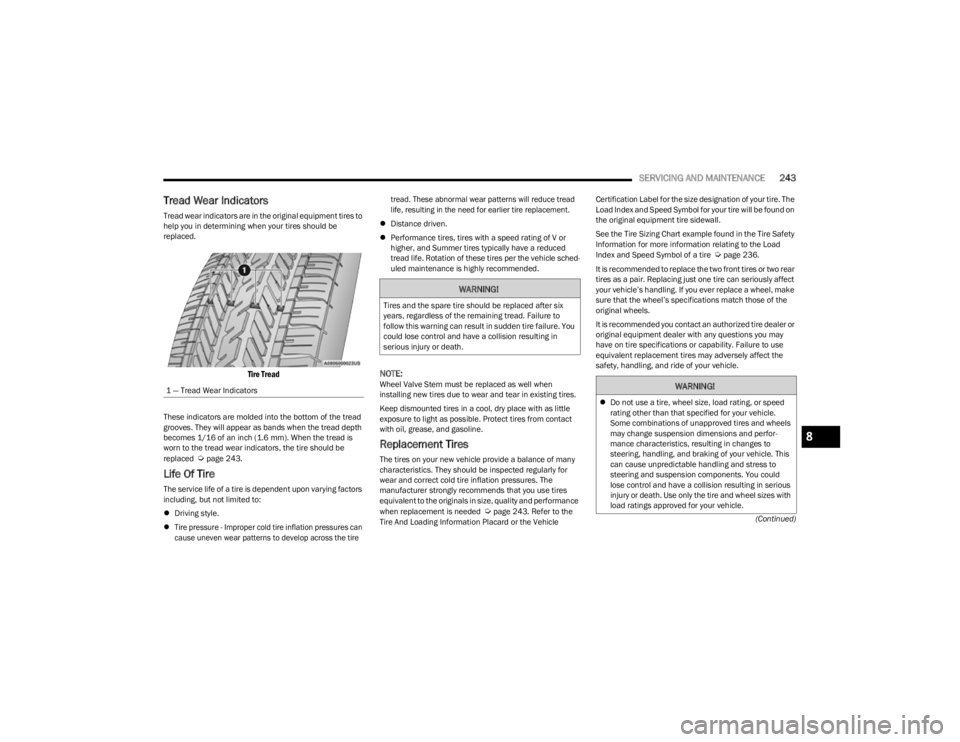

Tread Wear Indicators

Tread wear indicators are in the original equipment tires to

help you in determining when your tires should be

replaced.

Tire Tread

These indicators are molded into the bottom of the tread

grooves. They will appear as bands when the tread depth

becomes 1/16 of an inch (1.6 mm). When the tread is

worn to the tread wear indicators, the tire should be

replaced

Úpage 243.

Life Of Tire

The service life of a tire is dependent upon varying factors

including, but not limited to:

Driving style.

Tire pressure - Improper cold tire inflation pressures can

cause uneven wear patterns to develop across the tire tread. These abnormal wear patterns will reduce tread

life, resulting in the need for earlier tire replacement.

Distance driven.

Performance tires, tires with a speed rating of V or

higher, and Summer tires typically have a reduced

tread life. Rotation of these tires per the vehicle sched-

uled maintenance is highly recommended.

NOTE:Wheel Valve Stem must be replaced as well when

installing new tires due to wear and tear in existing tires.

Keep dismounted tires in a cool, dry place with as little

exposure to light as possible. Protect tires from contact

with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of many

characteristics. They should be inspected regularly for

wear and correct cold tire inflation pressures. The

manufacturer strongly recommends that you use tires

equivalent to the originals in size, quality and performance

when replacement is needed

Úpage 243. Refer to the

Tire And Loading Information Placard or the Vehicle Certification Label for the size designation of your tire. The

Load Index and Speed Symbol for your tire will be found on

the original equipment tire sidewall.

See the Tire Sizing Chart example found in the Tire Safety

Information for more information relating to the Load

Index and Speed Symbol of a tire

Úpage 236.

It is recommended to replace the two front tires or two rear

tires as a pair. Replacing just one tire can seriously affect

your vehicle’s handling. If you ever replace a wheel, make

sure that the wheel’s specifications match those of the

original wheels.

It is recommended you contact an authorized tire dealer or

original equipment dealer with any questions you may

have on tire specifications or capability. Failure to use

equivalent replacement tires may adversely affect the

safety, handling, and ride of your vehicle.

1 — Tread Wear Indicators

WARNING!

Tires and the spare tire should be replaced after six

years, regardless of the remaining tread. Failure to

follow this warning can result in sudden tire failure. You

could lose control and have a collision resulting in

serious injury or death.

WARNING!

Do not use a tire, wheel size, load rating, or speed

rating other than that specified for your vehicle.

Some combinations of unapproved tires and wheels

may change suspension dimensions and perfor -

mance characteristics, resulting in changes to

steering, handling, and braking of your vehicle. This

can cause unpredictable handling and stress to

steering and suspension components. You could

lose control and have a collision resulting in serious

injury or death. Use only the tire and wheel sizes with

load ratings approved for your vehicle.

8

23_KL_OM_EN_USC_t.book Page 243