alternator belt JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 169 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

G

cation period. It is

good

preventive maintenance to

replace a badly frayed, worn or cracked fan belt

before it breaks in operation.

To

replace the fan belt,

loosen

the attaching

bolts

at each generator or alternator brace-to-engine mounting and pivot the alternator or generator to

ward

the

engine

to gain slack needed to install the new belt Remove the old belt. Position the new

belt over the fan pulley, over the crankshaft pulley,

then over the generator or alternator pulley.

Pull

the generator or alternator away from the

engine

until

belt tension is

firm.

Then tighten the generator

or

alternator mounting

bolts

and check the tension

as indicated above. Reset the generator or alternator as necessary for correct belt tension.

Finally,

torque

the generator or alternator mounting

bolts

25 to 35 lb-ft. [3,4 a 4,8 kg-m.].

Note:

On the Dauntless V-6

engine

when adjusting

the fan belt tension, the alternator mounting

bolts

should be torqued 30 to 40 lb-ft. [4,14 to 5,53

kg-m.].

If a fan belt tension

gauge

(W-283) is

avail

able, proper tension should be 80 pounds [36,2 kg.].

G-l

9. Engine Overheating

An

engine

will

not be damaged by high coolant

temperatures unless the coolant boils. The pres

surized

cooling system on the 'Jeep' vehicles raises the boiling point of the coolant solution. Should

overheating be encountered, and the fault is be

lieved to be in the cooling system check for the

following:

a.

Proper coolant level. See

Filling

Cooling Sys

tem Par. G-2.

b. Poor air flow.

Check

for dirty radiator core. (See Radiator Par. G-5).

Check

for faulty belt

pulley operation, worn or

loose

fan belt, or dam aged fan.

Clean,

repair, replace or adjust as neces

sary.

c. Foaming coolant.

Check

for air leaks at water

pump,

hose

connection and filler cap. Tighten, re

pair

or replace as necessary.

d.

Surging or "after boil".

Check

pressure cap and

replace if valves or gasket are faulty.

e.

External

leaks.

Check

the following for leaks:

Hoses and clamps, water pump, radiator, head gas

ket, core plugs and drain cocks, as well as the cylin der head or block for

cracks.

f.

Internal

leaks.

Check

for faulty head gasket,

cracked

cylinder head or block.

g. Poor coolant flow.

Check

hose

condition, water pump, fan belt, and repair or replace as necessary. Inspect block for rust or scale, and clean and flush

the system, if necessary.

h.

Check

the temperature

gauge.

169

Page 195 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

H

no soldering or unsoldering of leads; two complete

rectifying

diode assemblies

which

eliminate the need

for removing and replacing individual diodes; a

corpplete isolation diode assembly; and a rotor

assembly complete with shaft,

pole

pieces, field

coil,

and slip rings.

The

transistorized

voltage

regulator is an electronic

switching device. It

senses

the

voltage

appearing

at the auxiliary terminal of the alternator and

supplies the necessary field current for maintaining

the system

voltage

at the output terminal. The

output current is determined by the battery electri

cal

load; such as headlights, heater, etc.

The

transistorized

voltage

regulator is a sealed

unit,

has no adjustments, and must be replaced

as a complete unit.

H-64. ALTERNATOR

PRECAUTIONS

The

following precautions must be observed to

prevent damage to the alternator and regulator.

a.

Never reverse battery connections. Always

check

the battery polarity with a voltmeter before

any

connections are made to be sure that all con

nections correspond to the battery ground polarity of the vehicle.

b.

Booster batteries for starting must be properly

connected. Make sure that the negative cable of

the booster battery is connected to the negative

terminal

of the battery in the vehicle. The positive

cable of the booster battery should be connected

to the positive terminal of the battery in the

vehicle.

c.

Disconnect the battery cables before using a fast charger.

d.

Never use a fast charger as a booster for

starting

the vehicle.

e.

Never disconnect the

voltage

regulator while

the

engine

is running.

f.

Do not ground the alternator output terminal.

g.

Do not operate the alternator on an open

circuit

with

the field energized.

h.

Do not attempt to polarize an alternator.

These

precautions are stated here as an aid to

service

personnel. They are also restated at appro

priate

places in the

text

of this section of the

manual.

H-65. ALTERNATOR

CHARGING

SYSTEM SERVICE

Important:

All alternator

tests

for the 35, 40 and

55 amp alternator are the same, however, there is a

difference

between

the location of the various ter

minals

and field current specifications. The field

current

of the 35 amp alternator should be 1.7 to 2.3 amps, 40 and 55 amp alternators should be 1.8

to 2.4 amps, with

full

battery

voltage

applied to

the filed coil. Disassembly and assembly procedures

are

the same for all three alternators.

Terminal

locations and wire harness color

codes

for the 35,

40 and 55 amp alternator are shown in Fig. H-38.

H-66.

Service Diagnosis

In

diagnosing a suspected malfunction of the

alternator

charging system, consideration must

be given to the complete electrical power plant of the vehicle; including the alternator, regulator,

ignition switch, charge indicator lamp, battery,

and

all associated wiring. If it is suspected that the

alternator

is not fully charging the battery and

fulfilling

the electrical requirements of the electrical

system, several checks should be made before

checking

the alternator itself:

Note:

Whenever service is required in connection

with

an alternator problem, the first

step

should be to verify that the wiring harness hook-up is correct

as indicated in Fig. H-38.

a.

Test the condition of the battery and

state

of

charge

(Par. H-2).

If the battery is not fully charged

and

in

good

condition, use a replacement battery

for making alternator system

tests.

Caution:

Make certain that the negative battery

post

is connected to ground when making the

battery installation. Serious damage to the alter

nator

can result if battery polarity is reversed.

b.

Check

fan belt for proper tension (Par.

C-27).

Caution:

To increase belt tension, apply pressure

to alternator front housing only as permanent damage can result if pressure is applied to

rear

housing.

H-67.

Alternator In Vehicle Tests

The

following

tests

are made with the alternator

in

the vehicle with output and regulator connec

tions maintained to the alternator except as noted

in

Fig. H-27 and H-28. The field plug and

voltage

regulator are disconnected for

these

tests.

The

tests

are given in proper order and detail in the

following paragraphs.

a.

Isolation Diode Test: To determine if the isola

tion diode is open or shorted, refer to Par. H-69.

b.

Alternator Output Test: To isolate the trouble

to the alternator or regulator, refer to Par. H-70.

c.

Alternator

Field

Circuit

Test: To determine the condition of the field

circuit

(brushes and rotor),

refer

to Par. H-73.

d.

Brush

Insulation

and Continuity

Test:

To deter

mine the condition of the

brush,

refer to

Par.

H-75.

e.

Rotor In-Vehicle Test: To determine whether

the rotor coil is open or shorted, refer to

Par.

H-73.

f. Any further

tests

must be conducted with the

alternator

removed and disassembled. When this

is done, the condition of the rotor, the rectifying

and

isolation diodes, and the stator can be further

tested.

A

commercial alternator tester Sun

Electric

Model

VAT-20

or equivalent can be used to make all

necessary

tests

on the alternator system. If a com

mercial

tester is used, follow the recommended

testing procedure outlined by the tester manu

facturer.

If

a commercial tester is not available, follow the

testing procedure as outlined in this manual.

H-68.

Test Equipment

a.

Volt Ampere Tester such as Sun

Electric

Model

VAT-20

or equivalent with meter ranges as shown

in

the following list can be used. 195

Page 198 of 376

H

ELECTRICAL

SYSTEM

terminal

and bracket. Test lamp should not light.

If

it

does,

the

brush

is shorted and must be replaced,

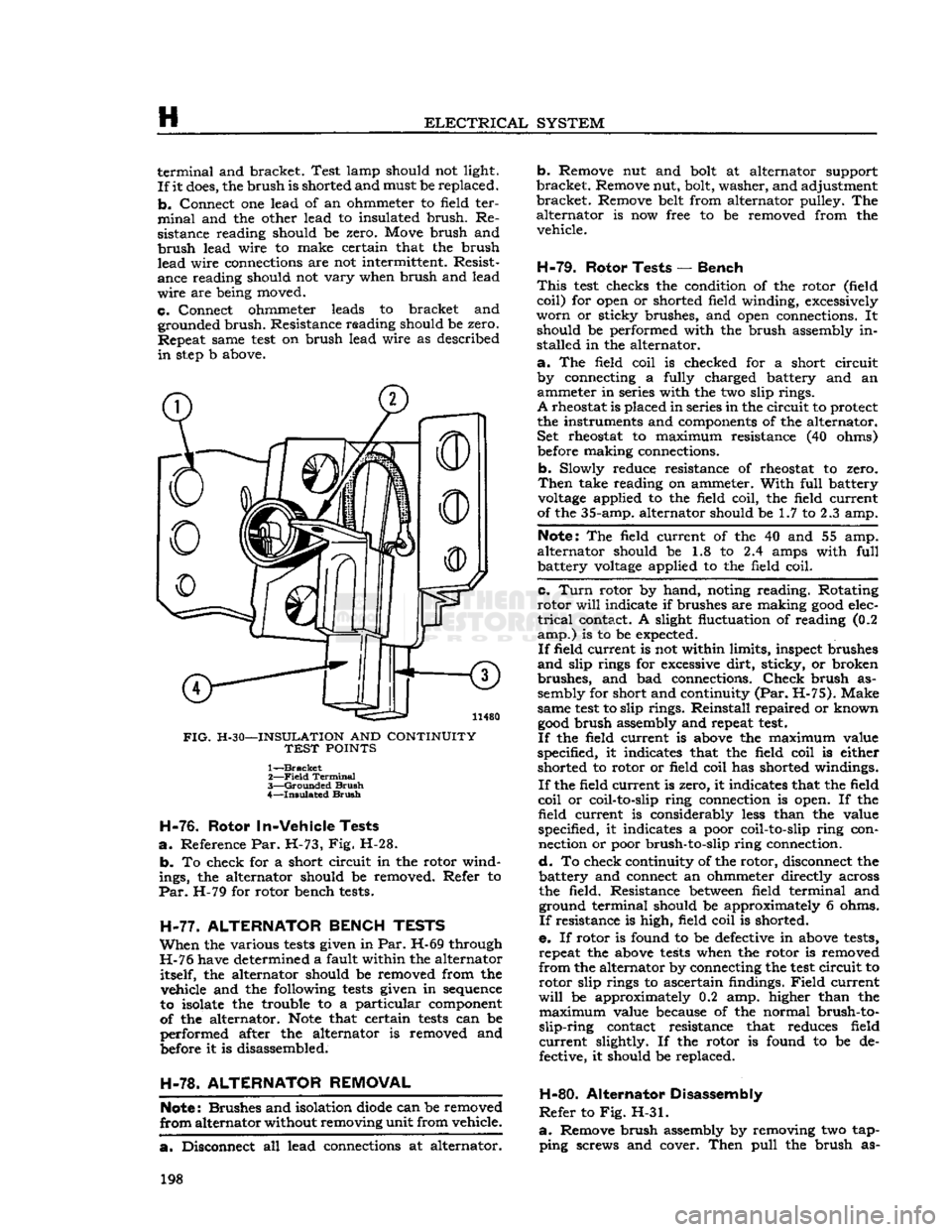

b.

Connect one lead of an ohmmeter to field ter

minal

and the other lead to insulated brush. Re

sistance reading should be zero. Move brush and

brush

lead wire to make certain that the brush lead wire connections are not intermittent. Resist

ance reading should not vary when brush and lead

wire

are being moved.

C.

Connect ohmmeter leads to bracket and grounded brush. Resistance reading should be zero.

Repeat same

test

on brush lead wire as described

in

step

b above.

FIG.

H-30—INSULATION

AND

CONTINUITY

TEST

POINTS

1^-Brackct

2—

Field

Terminal

3—

Grounded

Brush

4—

Insulated

Brush

H-76.

Rotor

In-Vehicle

Tests

a.

Reference Par. H-73, Fig. H-28.

b.

To check for a short circuit in the rotor wind

ings, the alternator should be removed. Refer to

Par.

H-79 for rotor bench

tests.

H-77.

ALTERNATOR

BENCH

TESTS

When

the various

tests

given in

Par.

H-69 through

H-76 have determined a fault within the alternator itself, the alternator should be removed from the vehicle and the following

tests

given in

sequence

to isolate the trouble to a particular

component

of the alternator.

Note

that certain

tests

can be

performed after the alternator is removed and

before

it is disassembled.

H-78.

ALTERNATOR

REMOVAL

Note:

Brushes and isolation

diode

can be removed

from

alternator without removing unit from vehicle.

a.

Disconnect all lead connections at alternator.

b.

Remove nut and

bolt

at alternator support

bracket.

Remove nut, bolt, washer, and adjustment

bracket.

Remove belt from alternator pulley. The alternator is now free to be removed from the

vehicle.

H-79.

Rotor Tests

—

Bench

This

test

checks the condition of the rotor (field coil) for

open

or shorted field winding, excessively

worn

or sticky brushes, and

open

connections. It should be performed with the brush assembly in

stalled in the alternator.

a.

The field coil is checked for a short circuit

by connecting a fully charged battery and an ammeter in series with the two slip rings.

A

rheostat is placed in series in the

circuit

to protect

the instruments and

components

of the alternator. Set rheostat to maximum resistance (40 ohms)

before

making connections.

b.

Slowly reduce resistance of rheostat to zero.

Then

take reading on ammeter. With full battery

voltage

applied to the field coil, the field current

of the 35-amp. alternator should be 1.7 to 2.3 amp.

Note:

The field current of the 40 and 55 amp.

alternator should be 1.8 to 2.4 amps with full battery

voltage

applied to the field coil.

c.

Turn

rotor by hand, noting reading. Rotating

rotor

will

indicate if brushes are making

good

elec

trical

contact. A slight fluctuation of reading (0.2

amp.)

is to be expected.

If

field current is not within limits, inspect brushes

and

slip rings for

excessive

dirt, sticky, or broken

brushes, and bad connections.

Check

brush as sembly for short and continuity (Par. H-75). Make

same

test

to slip rings. Reinstall repaired or known

good

brush assembly and repeat

test.

If

the field current is

above

the maximum value

specified, it indicates that the field coil is either

shorted to rotor or field coil has shorted windings.

If

the field current is zero, it indicates that the field

coil

or coil-to-slip ring connection is open. If the field

current

is considerably

less

than the value

specified, it indicates a poor coil-to-slip ring con nection or poor brush-to-slip ring connection.

d.

To check continuity of the rotor, disconnect the

battery and connect an ohmmeter directly across

the field. Resistance

between

field terminal and ground terminal should be approximately 6 ohms.

If

resistance is high, field coil is shorted.

e.

If rotor is found to be

defective

in

above

tests,

repeat the

above

tests

when the rotor is removed

from

the alternator by connecting the

test

circuit

to rotor slip rings to ascertain findings.

Field

current

will

be approximately 0.2 amp. higher than the

maximum

value because of the normal brush-to-

slip-ring

contact resistance that reduces field

current

slightly. If the rotor is found to be de

fective, it should be replaced.

H-80.

Alternator Disassembly

Refer

to Fig. H-31.

a.

Remove brush assembly by removing two tap ping screws and cover. Then pull the brush as- 198

Page 202 of 376

H

ELECTRICAL

SYSTEM

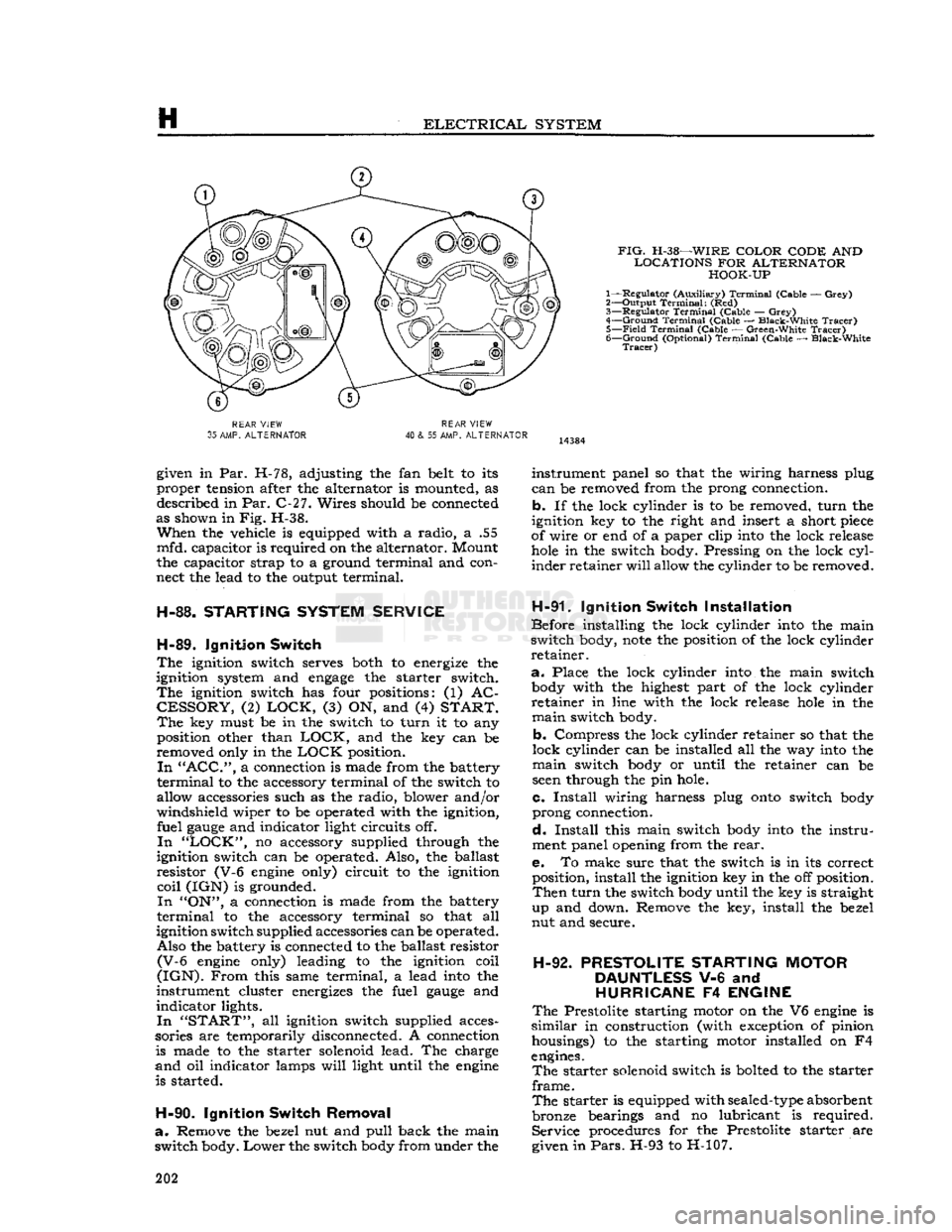

FIG.

H-38—WIRE

COLOR CODE

AND

LOCATIONS

FOR

ALTERNATOR HOOK-UP

1— Regulator (Auxiliary)

Terminal

(Cable —

Grey)

2— Output

Terminal:

(Red)

3—

Regulator

Terminal

(Cable —

Grey)

4—

Ground

Terminal

(Cable — Black-White

Tracer)

5—

Field

Terminal

(Cable — Green-White

Tracer)

6—

Ground

(Optional)

Terminal

(Cable — Black-White

Tracer)

REAR

VIEW

35

AMP.

ALTERNATOR

REAR

VIEW

40

& 55 AMP.

ALTERNATOR

given in Par. H-78, adjusting the fan belt to its

proper tension after the alternator is mounted, as described in Par. C-27. Wires should be connected

as shown in Fig. H-38.

When

the vehicle is equipped with a radio, a .55

mfd. capacitor is required on the alternator. Mount

the capacitor strap to a ground terminal and con

nect the lead to the output terminal.

H-88.

STARTING

SYSTEM

SERVICE

H-89.

Ignition

Switch

The

ignition switch serves both to energize the

ignition system and

engage

the starter switch.

The

ignition switch has four positions: (1) AC

CESSORY,

(2)

LOCK,

(3) ON, and (4)

START. The

key must be in the switch to turn it to any position other than

LOCK,

and the key can be

removed only in the

LOCK

position.

In "ACC",

a connection is made from the battery

terminal

to the accessory terminal of the switch to

allow accessories such as the radio, blower and/or

windshield wiper to be operated with the ignition, fuel

gauge

and indicator light circuits off.

In "LOCK",

no accessory supplied through the

ignition switch can be operated. Also, the ballast

resistor (V-6

engine

only) circuit to the ignition

coil

(IGN) is grounded.

In

"ON", a connection is made from the battery

terminal

to the accessory terminal so that all

ignition switch supplied accessories can be operated. Also the battery is connected to the ballast resistor

(V-6

engine

only) leading to the ignition coil

(IGN).

From

this same terminal, a lead

into

the

instrument cluster energizes the fuel

gauge

and

indicator lights.

In "START",

all ignition switch supplied acces

sories are temporarily disconnected. A connection is made to the starter solenoid lead. The charge

and

oil indicator lamps

will

light until the

engine

is started.

H-90.

Ignition

Switch

Removal

a.

Remove the bezel nut and pull back the main

switch body.

Lower

the switch

body

from under the instrument panel so that the wiring harness plug

can

be removed from the prong connection,

b. If the lock cylinder is to be removed, turn the

ignition key to the right and insert a short

piece

of wire or end of a paper clip

into

the lock release

hole

in the switch body. Pressing on the lock

cyl

inder retainer

will

allow the cylinder to be removed.

H-91.

Ignition

Switch

Installation

Before installing the lock cylinder

into

the main

switch body,

note

the position of the lock cylinder

retainer.

a.

Place the lock cylinder

into

the main switch

body

with the highest part of the lock cylinder

retainer in line with the lock release

hole

in the

main

switch body.

b. Compress the lock cylinder retainer so that the

lock cylinder can be installed all the way

into

the

main

switch

body

or until the retainer can be

seen

through the pin hole.

c.

Install

wiring harness plug

onto

switch

body

prong connection.

d.

Install

this main switch

body

into

the instru

ment panel opening from the

rear.

e. To make sure that the switch is in its correct position, install the ignition key in the off position.

Then

turn the switch

body

until the key is straight

up and down. Remove the key, install the bezel

nut and secure.

H-92.

PRESTOLITE

STARTING

MOTOR

DAUNTLESS

V-6 and

HURRICANE

F4

ENGINE

The

Prestolite starting motor on the V6

engine

is

similar

in construction (with exception of pinion housings) to the starting motor installed on F4

engines.

The

starter solenoid switch is bolted to the starter

frame.

The

starter is equipped with

sealed-type

absorbent

bronze bearings and no lubricant is required. Service procedures for the Prestolite starter are

given in

Pars.

H-93 to H-107. 202

Page 220 of 376

H

ELECTRICAL

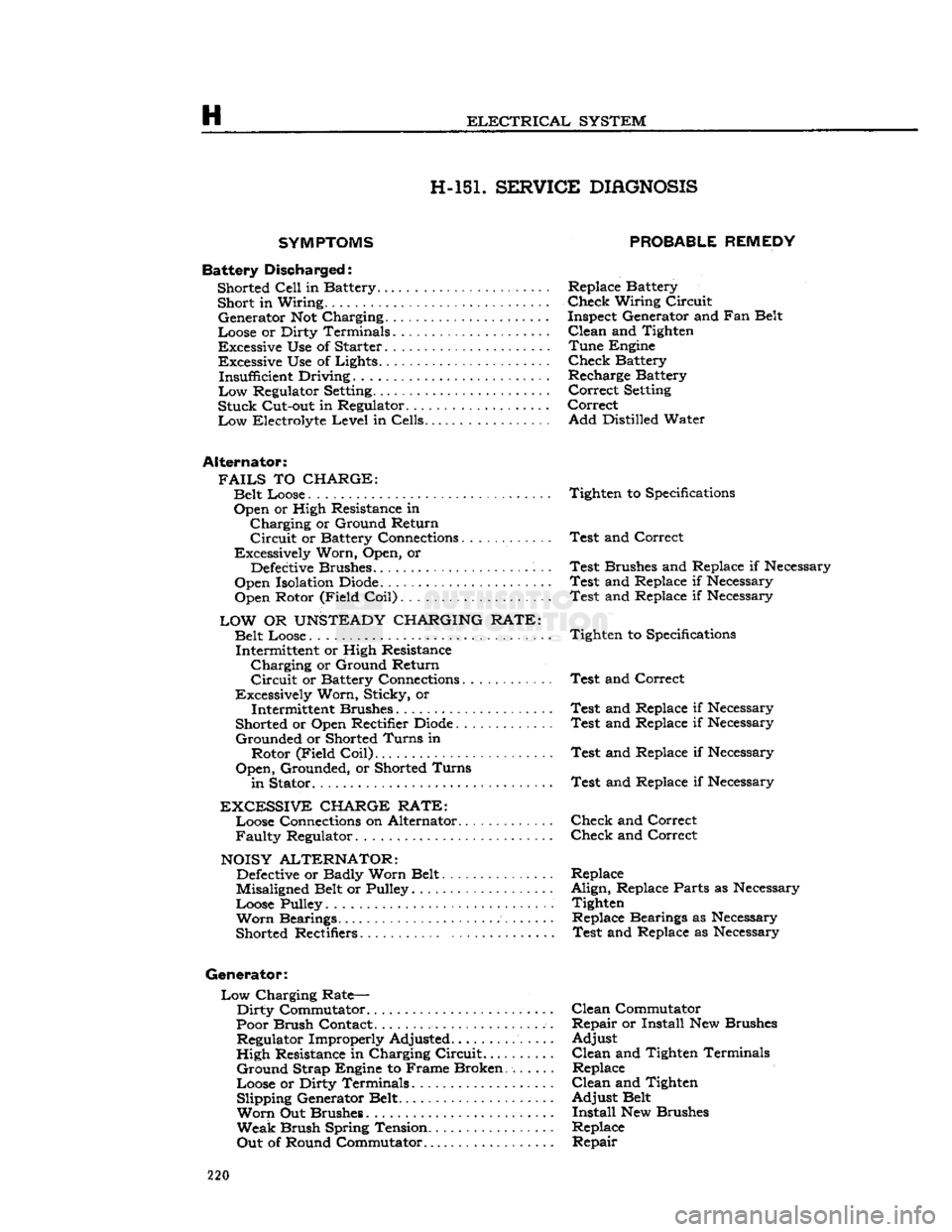

SYSTEM H-15L SERVICE

DIAGNOSIS

SYMPTOMS

Battery

Discha

rged: Shorted

Cell

in Battery......... Short in Wiring..

•

Generator Not Charging ,

Loose or Dirty Terminals

Excessive Use of Starter Excessive Use of Lights...... Insufficient Driving.........

Low

Regulator

Setting.......

Stuck

Cut-out in Regulator. ..

Low

Electrolyte

Level

in Cells

Alternator:

FAILS

TO

CHARGE:

Belt Loose Open or High Resistance in

Charging

or Ground Return

Circuit

or Battery Connections............

Excessively Worn, Open, or

Defective

Brushes.

Open Isolation

Diode.

Open Rotor (Field

Coil)

LOW

OR

UNSTEADY

CHARGING RATE:

Belt Loose.... Intermittent or High Resistance

Charging

or Ground Return

Circuit

or Battery Connections

Excessively Worn, Sticky, or Intermittent Brushes

Shorted or Open Rectifier

Diode

Grounded

or Shorted

Turns

in Rotor (Field

Coil)

Open,

Grounded, or Shorted

Turns

in

Stator

EXCESSIVE

CHARGE RATE:

Loose Connections on Alternator...........

Faulty

Regulator

NOISY

ALTERNATOR:

Defective

or Badly Worn Belt

Misaligned Belt or Pulley

Loose Pulley

Worn

Bearings.

Shorted Rectifiers

Generator:

Low

Charging Rate—

Dirty

Commutator

Poor Brush Contact.

................

Regulator Improperly Adjusted.......

High

Resistance in Charging

Circuit...

Ground

Strap Engine to Frame Broken

Loose or Dirty Terminals Slipping Generator Belt

Worn

Out Brushes

Weak

Brush Spring Tension..........

Out

of Round Commutator

PROBABLE REMEDY

Replace Battery

Check

Wiring

Circuit

Inspect Generator and Fan Belt

Clean

and Tighten

Tune

Engine

Check

Battery

Recharge Battery

Correct

Setting

Correct

Add

Distilled Water

Tighten to

Specifications

Test

and Correct

Test

Brushes and Replace if Necessary

Test

and Replace if Necessary

Test

and Replace if Necessary

Tighten to

Specifications

Test

and Correct

Test

and Replace if Necessary

Test

and Replace if Necessary

Test

and Replace if Necessary

Test

and Replace if Necessary

Check

and Correct

Check

and Correct

Replace

Align,

Replace Parts as Necessary Tighten Replace Bearings as Necessary

Test

and Replace as Necessary

Clean

Commutator

Repair

or Install New Brushes

Adjust

Clean

and Tighten Terminals Replace

Clean

and Tighten

Adjust

Belt

Install

New Brushes

Replace

Repair

220

Page 360 of 376

u

MISCELLANEOUS

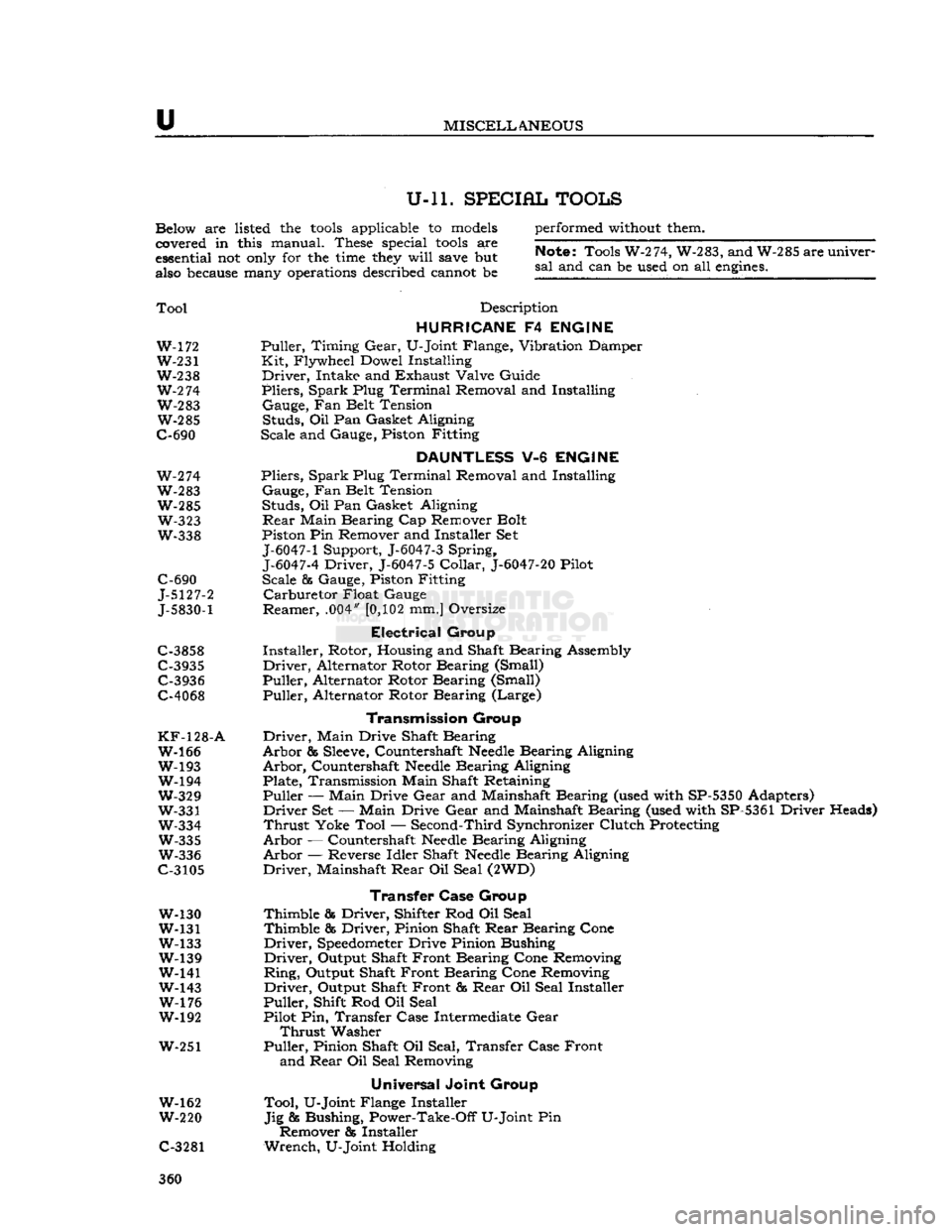

U-ll. SPECIAL TOOLS

Below are listed the

tools

applicable to

models

covered in this manual. These special

tools

are

essential not

only

for the

time

they

will

save

but

also

because

many

operations

described cannot be performed

without

them.

Note;

Tools W-274, W-283, and W-285 are univer

sal

and can be used on all

engines.

Tool

Description

HURRICANE

F4

ENGINE

W-172 Puller, Timing

Gear,

U-Joint Flange, Vibration Damper W-231 Kit, Flywheel Dowel Installing

W-238 Driver, Intake and Exhaust Valve Guide

W-2

74 Pliers, Spark Plug Terminal Removal and Installing W-283 Gauge, Fan Belt Tension W-285 Studs, Oil Pan Gasket Aligning

C-690 Scale and Gauge, Piston Fitting

DAUNTLESS

V-6

ENGINE

W-274 Pliers, Spark Plug Terminal Removal and Installing

W-283 Gauge, Fan Belt Tension W-285 Studs, Oil Pan Gasket Aligning W-323

Rear

Main Bearing Cap Remover Bolt

W-338 Piston Pin Remover and Installer Set

J-6047-1

Support, J-6047-3 Spring,

J-6047-4

Driver, J-6047-5

Collar,

J-6047-20

Pilot

C-690 Scale & Gauge, Piston Fitting

J-5127-2 Carburetor Float Gauge

J-5830-1

Reamer, .004"

[0,102

mm.] Oversize

Electrical

Group

C-3858 Installer, Rotor, Housing and Shaft Bearing Assembly

C-3935 Driver, Alternator Rotor Bearing (Small) C-3936 Puller, Alternator Rotor Bearing (Small)

C-4068 Puller, Alternator Rotor Bearing (Large)

Transmission

Group

KF-128-A

Driver, Main Drive Shaft Bearing W-166 Arbor &

Sleeve,

Countershaft

Needle

Bearing Aligning

W-193 Arbor, Countershaft

Needle

Bearing Aligning W-194 Plate, Transmission Main Shaft Retaining

W-329 Puller — Main Drive

Gear

and Mainshaft Bearing (used with SP-5350 Adapters)

W-331 Driver Set — Main Drive

Gear

and Mainshaft Bearing (used with SP-5361 Driver Heads)

W-334 Thrust Yoke Tool — Second-Third Synchronizer Clutch Protecting W-335 Arbor — Countershaft

Needle

Bearing Aligning

W-336 Arbor — Reverse Idler Shaft

Needle

Bearing Aligning

C-3105 Driver, Mainshaft

Rear

Oil Seal (2WD)

Transfer Case

Group

W-130 Thimble & Driver, Shifter Rod Oil Seal

W-131 Thimble & Driver, Pinion Shaft

Rear

Bearing Cone

W-133 Driver,

Speedometer

Drive Pinion Bushing W-139 Driver, Output Shaft Front Bearing Cone Removing

W-141 Ring, Output Shaft Front Bearing Cone Removing

W-143 Driver, Output Shaft Front &

Rear

Oil Seal Installer W-176 Puller, Shift Rod Oil Seal

W-192 Pilot Pin, Transfer Case Intermediate

Gear

Thrust

Washer

W-251 Puller, Pinion Shaft Oil Seal, Transfer Case Front and

Rear

Oil Seal Removing

Universal

Joint Group

W-162 Tool, U-Joint Flange Installer

W-220 Jig & Bushing, Power-Take-Off U-Joint Pin Remover & Installer

C-3281 Wrench, U-Joint Holding 360

Page 371 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

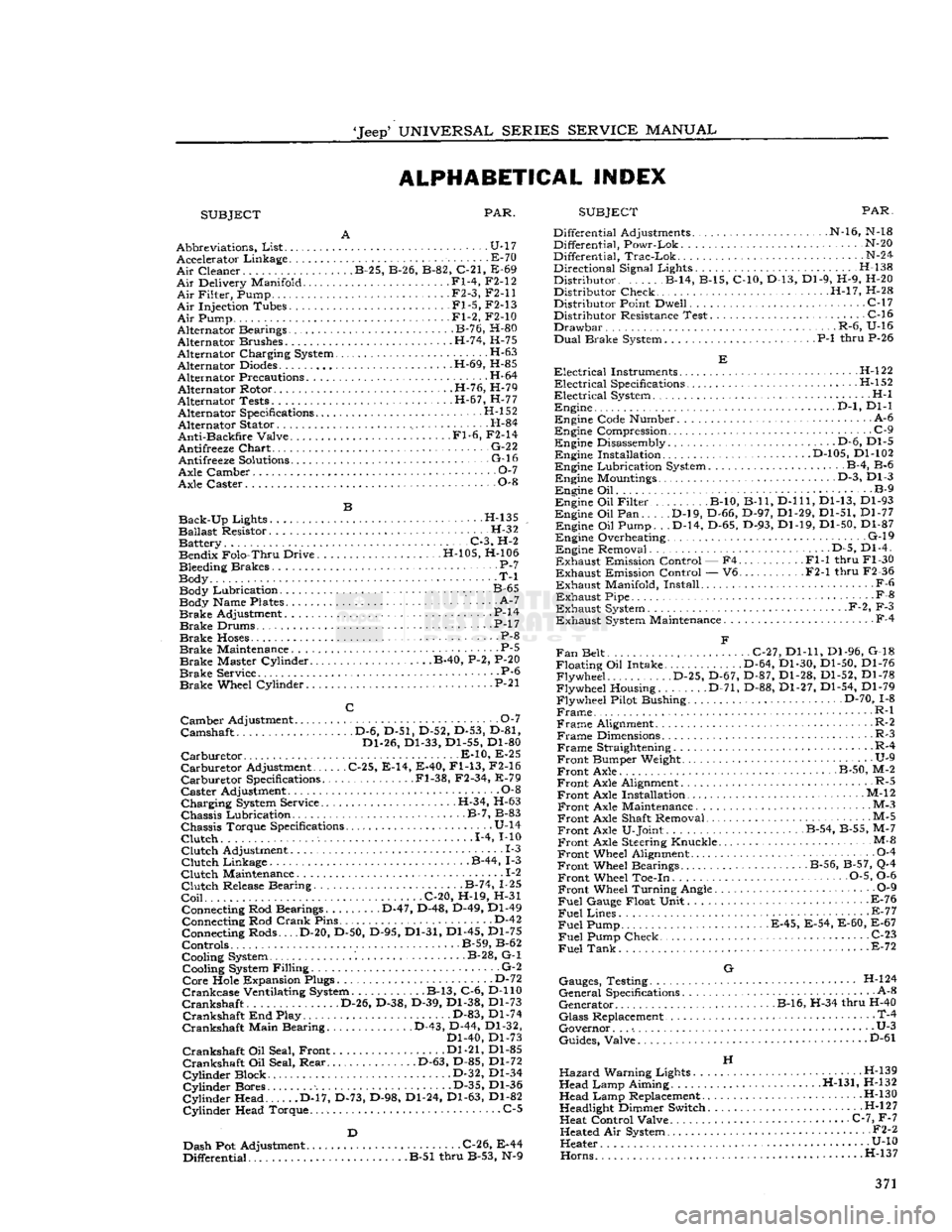

ALPHABETICAL INDEX

SUBJECT PAR.

SUBJECT

PAR.

Abbreviations,

List

U-17 Accelerator Linkage E-70

Air

Cleaner B-25, B-26, B-82, C-21, E-69

Air

Delivery Manifold Fl-4, F2-12

Air

Filter, Pump • F2-3, F2-11

Air

Injection Tubes Fl-5, F2-13

Air

Pump Fl-2, F2-10

Alternator Bearings B-76, H-80

Alternator Brushes H-74, H-75

Alternator Charging System •

•

H-63

Alternator

Diodes

H-69, H-85

Alternator Precautions H-64 Alternator Rotor H-76, H-79

Alternator Tests H-67, H-77 Alternator Specifications H-l 52

Alternator Stator H-84

Anti-Backfire

Valve Fl-6, F2-14

Antifreeze

Chart

• G-22 Antifreeze

Solutions

- G-16

Axle Camber O-l

Axle Caster 0-8

Back-Up

Lights H-135

Ballast

Resistor. H-32 Battery C-3, H-2 Bendix Folo-Thru Drive H-105, H-106

Bleeding Brakes P-7

Body T-l Body Lubrication. B-65 Body Name Plates ' A-7

Brake

Adjustment P-14

Brake

Drums. • .P-17

Brake

Hoses

P-8

Brake

Maintenance . P-5

Brake

Master Cylinder B-40, P-2, P-20

Brake

Service P-6

Brake

Wheel Cylinder • P-21

Camber

Adjustment 0-7

Camshaft D-6, D-51, D-52, D-53, D-81, Dl-26, Dl-33, Dl-55, Dl-80

Carburetor

E-10, E-25

Carburetor

Adjustment C-25, E-14, E-40,

Fl-13,

F2-16

Carburetor

Specifications .Fl-38, F2-34, E-79

Caster

Adjustment 0-8

Charging

System Service. .H-34, H-63

Chassis

Lubrication B-7, B-83

Chassis

Torque Specifications U-14

Clutch

1-4, MO

Clutch

Adjustment 1-3

Clutch

Linkage B-44, 1-3

Clutch

Maintenance .. 1-2

Clutch

Release Bearing B-74, 1-25

Coil

C-20, H-19, H-31 Connecting Rod Bearings D-47, D-48, D-49, Dl-49 Connecting Rod

Crank

Pins D-42

Connecting Rods... .D-20, D-50, D-95, Dl-31, Dl-45, Dl-75

Controls B-59, B-62

Cooling System B-28, G-l Cooling System Filling G-2

Core

Hole Expansion Plugs D-72

Crankcase

Ventilating System B-13, C-6, D-110

Crankshaft

D-26, D-38, D-39, Dl-38, Dl-73

Crankshaft

End Play. D-83, Dl-74

Crankshaft

Main Bearing D-43, D-44, Dl-32, Dl-40, Dl-73

Crankshaft

Oil Seal, Front Dl-21, Dl-85

Crankshaft

Oil Seal, Rear D-63, D-85, Dl-72

Cylinder

Block D-32, Dl-34

Cylinder

Bores D-35, Dl-36

Cylinder

Head D-17, D-73, D-98, Dl-24, Dl-63, Dl-82

Cylinder

Head Torque. C-5

Dash Pot Adjustment C-26, E-44

Differential B-51 thru B-53, N-9 Differential Adjustments N-16, N-18

Differential, Powr-Lok N-20

Differential,

Trac-Lok

N-24

Directional Signal Lights. . H-138

Distributor B-14, B-15, C-10, D-13, Dl-9, H-9, H-20 Distributor Check H-l7, H-28

Distributor Point Dwell C-17 Distributor Resistance Test C-16

Drawbar

.R-6, U-16

Dual

Brake System P-l thru P-26

Electrical

Instruments H-l22

Electrical

Specifications .H-l52

Electrical

System H-l Engine .

..D-l,

Dl-1

Engine Code Number A-6

Engine Compression .

.

C-9 Engine Disassembly . • .D-6, Dl-5 Engine Installation D-105, Dl-102

Engine Lubrication System B-4, B-6 Engine Mountings D-3, Dl-3

Engine Oil B-9

Engine Oil Filter B-10, B-ll,

D-lll,

Dl-13, Dl-93

Engine Oil Pan D-l9, D-66, D-97, Dl-29, Dl-51, Dl-77 Engine Oil Pump. . .D-14, D-65, D-93, Dl-19, Dl-50, Dl-87

Engine Overheating. G-l9 Engine Removal D-5, Dl-4.

Exhaust

Emission Control — F4 Fl-1 thru Fl-30

Exhaust

Emission Control — V6 F2-1 thru F2-36

Exhaust

Manifold, Install F-6

Exhaust

Pipe -

•

F-8

Exhaust

System F-2, F-3

Exhaust

System Maintenance F-4

Fan

Belt C-27, Dl-11, Dl-96, G-18

Floating Oil Intake. D-64, Dl-30, Dl-50, Dl-76 Flywheel D-25, D-67, D-87, Dl-28, Dl-52, Dl-78

Flywheel Housing. D-71, D-88, Dl-27, Dl-54, Dl-79

Flywheel Pilot Bushing D-70, 1-8

Frame

R-l

Frame

Alignment. R-2

Frame

Dimensions R-3

Frame

Straightening R-4

Front

Bumper Weight. • U-9

Front

Axle B-50, M-2

Front

Axle Alignment R-5

Front

Axle Installation • M-12

Front

Axle Maintenance M-3

Front

Axle Shaft Removal M-5

Front

Axle U-Joint B-54, B-55, M-7

Front

Axle Steering Knuckle M-&

Front

Wheel Alignment 0-4

Front

Wheel Bearings B-56, B-57, Q-4

Front

Wheel Toe-in 0-5, 0-6

Front

Wheel Turning Angle 0-9

Fuel

Gauge Float Unit F-76

Fuel

Lines - E-77

Fuel

Pump E-45, E-54, E-60, E-67

Fuel

Pump Check C-23

Fuel

Tank

E-72

G

Gauges, Testing H-l24

General

Specifications A-8

Generator B-16, H-34 thru H-40

Glass

Replacement • T-4

Governor. . .

•.

• U-3

Guides, Valve D"61

H

Hazard

Warning Lights H-139

Head Lamp Aiming H-131, H-132 Head Lamp Replacement H-130

Headlight Dimmer Switch H-l

2

7

Heat Control Valve C-7, F-7 Heated Air System • •

•

F2-2

Heater U-10

Horns.....

....H-137 371