coolant temperature JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 169 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

G

cation period. It is

good

preventive maintenance to

replace a badly frayed, worn or cracked fan belt

before it breaks in operation.

To

replace the fan belt,

loosen

the attaching

bolts

at each generator or alternator brace-to-engine mounting and pivot the alternator or generator to

ward

the

engine

to gain slack needed to install the new belt Remove the old belt. Position the new

belt over the fan pulley, over the crankshaft pulley,

then over the generator or alternator pulley.

Pull

the generator or alternator away from the

engine

until

belt tension is

firm.

Then tighten the generator

or

alternator mounting

bolts

and check the tension

as indicated above. Reset the generator or alternator as necessary for correct belt tension.

Finally,

torque

the generator or alternator mounting

bolts

25 to 35 lb-ft. [3,4 a 4,8 kg-m.].

Note:

On the Dauntless V-6

engine

when adjusting

the fan belt tension, the alternator mounting

bolts

should be torqued 30 to 40 lb-ft. [4,14 to 5,53

kg-m.].

If a fan belt tension

gauge

(W-283) is

avail

able, proper tension should be 80 pounds [36,2 kg.].

G-l

9. Engine Overheating

An

engine

will

not be damaged by high coolant

temperatures unless the coolant boils. The pres

surized

cooling system on the 'Jeep' vehicles raises the boiling point of the coolant solution. Should

overheating be encountered, and the fault is be

lieved to be in the cooling system check for the

following:

a.

Proper coolant level. See

Filling

Cooling Sys

tem Par. G-2.

b. Poor air flow.

Check

for dirty radiator core. (See Radiator Par. G-5).

Check

for faulty belt

pulley operation, worn or

loose

fan belt, or dam aged fan.

Clean,

repair, replace or adjust as neces

sary.

c. Foaming coolant.

Check

for air leaks at water

pump,

hose

connection and filler cap. Tighten, re

pair

or replace as necessary.

d.

Surging or "after boil".

Check

pressure cap and

replace if valves or gasket are faulty.

e.

External

leaks.

Check

the following for leaks:

Hoses and clamps, water pump, radiator, head gas

ket, core plugs and drain cocks, as well as the cylin der head or block for

cracks.

f.

Internal

leaks.

Check

for faulty head gasket,

cracked

cylinder head or block.

g. Poor coolant flow.

Check

hose

condition, water pump, fan belt, and repair or replace as necessary. Inspect block for rust or scale, and clean and flush

the system, if necessary.

h.

Check

the temperature

gauge.

169

Page 212 of 376

H

ELECTRICAL

SYSTEM

H-124. Testing Indicators and Gauges

Two

gauges

(fuel and temperature) and two in dicators (oil pressure and battery charge) that are

located in the instrument cluster are electrically operated.

The

fuel

gauge

is connected by a single wire to a

float-and-slide-rheostat sending unit in the fuel

tank.

The

temperature

gauge

is connected by a single

wire

to a resistance-type sending unit mounted on the engine.

The

battery charge indicator operates when there

is a difference in potential

between

the generator

and

the battery

.The

battery charge indicator lights

when the generator is not charging the battery. The

indicator

light

goes

out when the generator

begins

to charge the battery.

The

oil pressure indicator is connected by a single

wire

to a diaphragm switch located on the engine.

When

engine

oil pressure is low or zero and the

ignition switch is on, the oil pressure indicator

will

light. When

engine

speed is increased slightly above idle speed, raising the oil pressure to approximately 6 psi. [0,2 kg-cm2], the diaphragm switch

will

open the circuit and the indicator light

will

go out.

A

voltage

regulator maintains a constant

voltage

to the

gauges

in normal operation. On early vehicles,

this

voltage

regulator was mounted on the

rear

of

the instrument cluster. On current vehicles, the

voltage

regulator is integral with the fuel

gauge.

Should

trouble

develop

in the

gauges,

first check the regulator (fuel

gauge

on current production vehicle). If the

voltage

to the regulator is below 10 volts system low

gauge

readings

will

result.

Voltage in

excess

of 16 volts

will

not affect

gauge

readings but may result in premature wear of the

regulator contacts. If the

voltage

to the regulator is

within

the above limits, check the electrical con nections to the regulator (or fuel gauge), especially

the ground connection. If the readings of all the

gauges

is too high, or they all read too low, replace

the regulator (or fuel gauge).

If

the temperature

gauge

or heat indicator in the

instrument cluster have failed, the cause may

originate from the jumper bar shorting out against the instrument case.

Check

the jumper bar

between

the temperature

gauge

and heat indicator at the

rear

of the instrument case. On later production vehicles, the jumper bar is covered with an in

sulating

sleeve

to protect it from shorting out

against the instrument case. If the jumper bar

does

not have this

sleeve,

either install one or

wrap

the bar with plastic electrical tape to

half

an

inch [12,7 mm.] from each end. When installing the jumper bar, be sure the curved

segment

is

closest to the fuel

gauge.

Should

only one of the two

gauges

register incor

rectly,

check the lead wire from the

gauge

to the

sending unit for shorts or open connections. Next disconnect the

gauge

from the sending unit, and

connect the

gauge

to a new fuel tank sending unit

which

has been grounded to the vehicle.

If

the

gauge

registers incorrectly when operating the new unit,

replace the

gauge;

if correctly, replace the sending

unit.

Should

a new fuel tank unit not be available for testing, use a 12-volt

test

light in its place. When

the

gauge

is operating correctly, the pointer

will

move

approximately three-quarters across the

dial.

On

some

vehicles, the temperature

gauge

may

register on or

close

to the H (hot)

mark

when

coolant temperature is

190°F.

to

200°F.

[88°C.

a

93°C.].

In such cases, a 25-ohm,

1-watt

resistor

may be installed on the temperature

gauge

which

will

place the pointer just beyond the center

mark

at a coolant temperature of

190°F.

to

200°F.

Install

the resistor

between

the two terminals on the back

of the

gauge.

Insulate the

exposed

leads of the resistor with electrical tape.

If

the oil pressure indicator

does

not indicate cor

rectly,

first check the light bulb. Next check all

connections and lead wires. If, after all possible

defects

are corrected, the indicator light

does

not go on and off properly, then the diaphragm type

switch in the cylinder block should be replaced.

H-12S.

LIGHTING SYSTEM The

wiring of the lighting systems is shown in

the wiring diagrams, which indicate the various units in relation to their positions in the vehicle.

The

wires in the various circuits are of different

colors or are marked by tracers to aid when check

ing individual circuits.

The

lighting circuits of all models are protected by

an

overload circuit breaker mounted on the back of the main light switch and no replaceable fuse is

required.

The

upper and lower headlight beams are con

trolled by a

foot

switch located on the toe board

to the left of the clutch pedal.

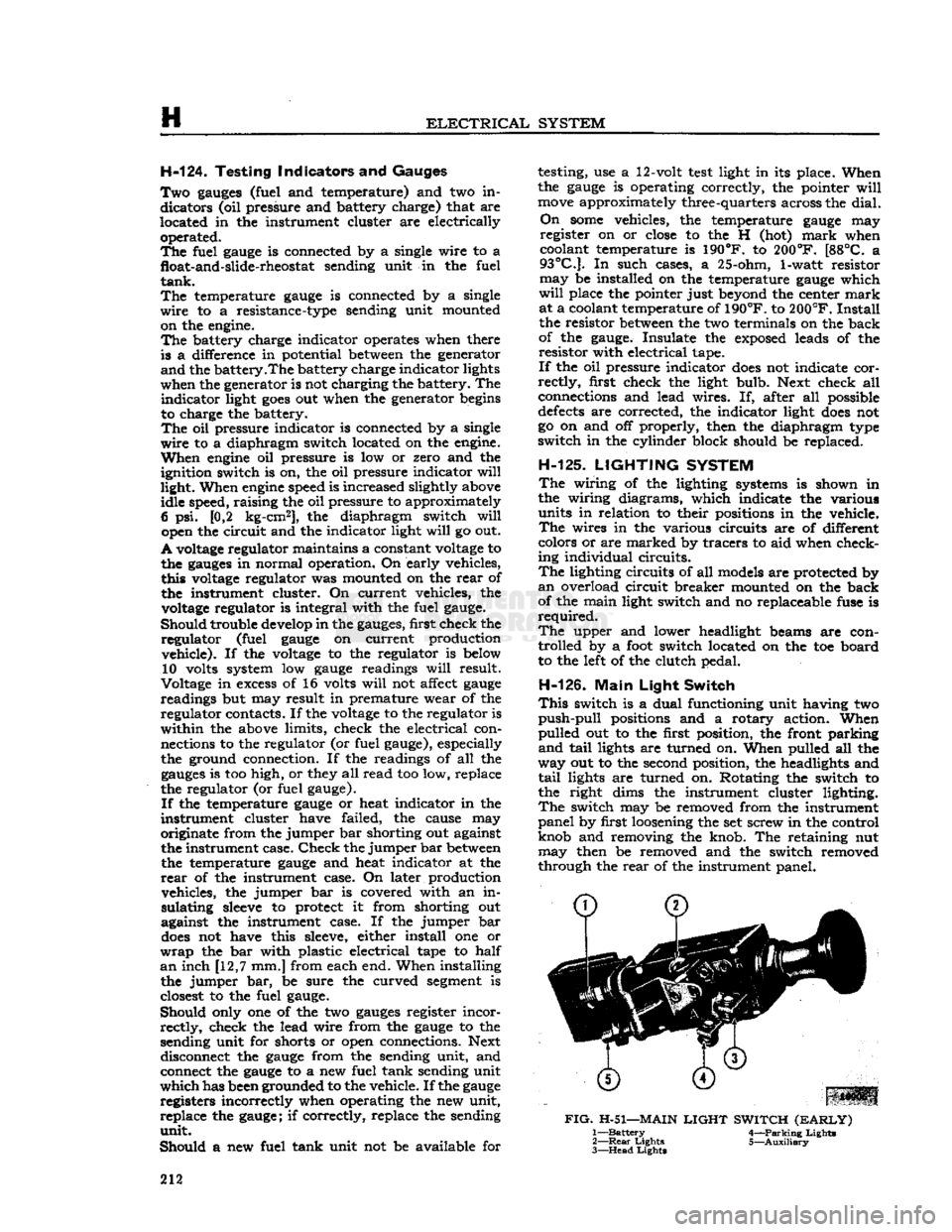

H-126.

Main

Light

Switch

This

switch is a dual functioning unit having two

push-pull

positions and a rotary action. When

pulled out to the first position, the front parking

and

tail

lights are turned on. When pulled all the

way out to the second position, the headlights and

tail

lights are turned on. Rotating the switch to

the right dims the instrument cluster lighting.

The

switch may be removed from the instrument

panel by first loosening the set screw in the control

knob and removing the knob. The retaining nut may then be removed and the switch removed

through the

rear

of the instrument panel.

FIG.

H-51—MAIN

LIGHT

SWITCH

(EARLY)

1—

Battery

4—Parking Lights

2—

Rear

Lights 5—Auxiliary

3—

Head

Lights

212