torque JEEP CJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 6 of 376

GENERAL

DATA

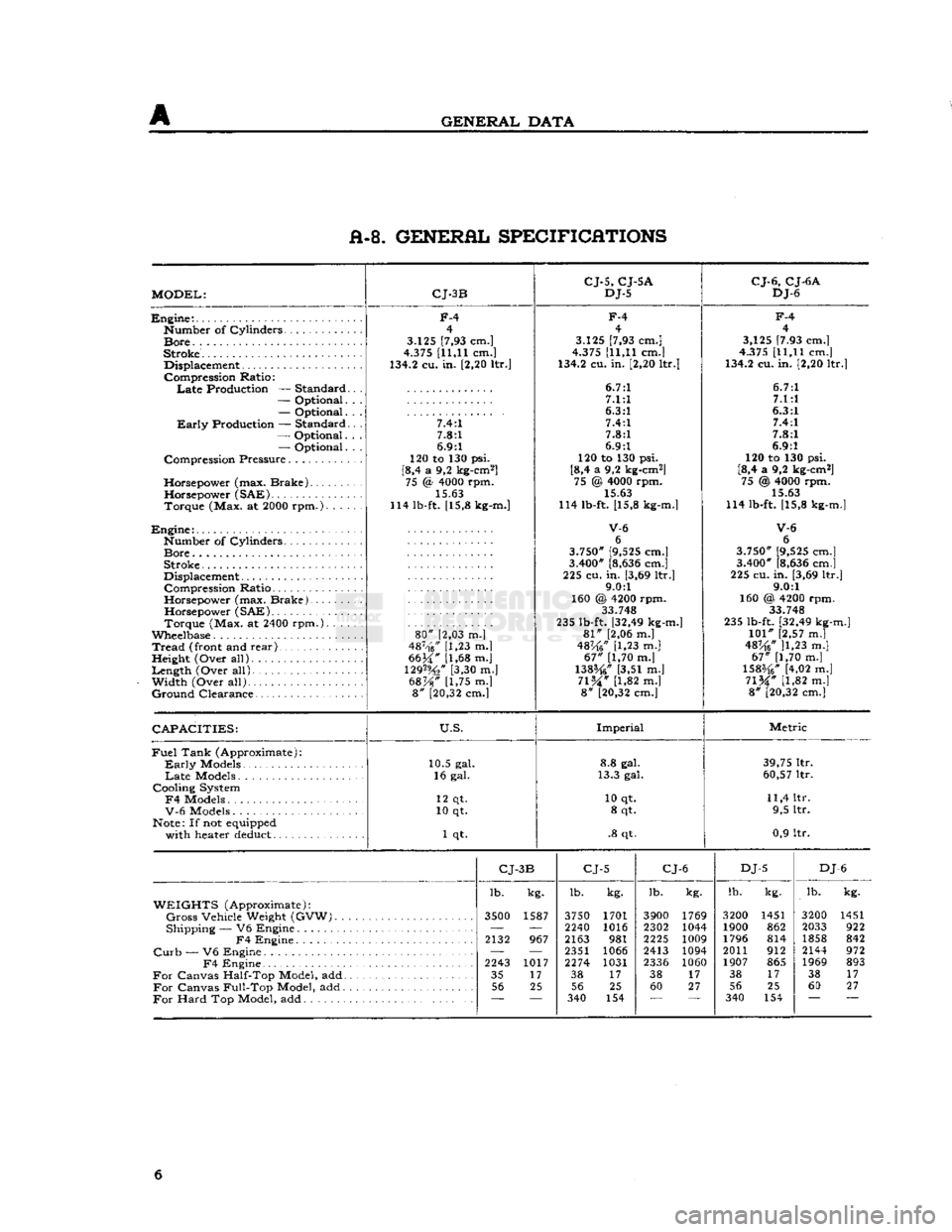

A-8. GENERAL SPECIFICATIONS

MODEL:

CJ-3B

CJ-5,

CJ-5A

DJ-5

CJ-6,

CJ-6A

DJ-6

Engine:.

Number

of

Cylinders

Bore.

.

Stroke.

Displacement

Compression

Ratio:

Late

Production —

Standard

—

Optional.

—

Optional.

Early

Production —

Standard

—

Optional.

—

Optional.

Compression

Pressure

Horsepower

(max.

Brake)

Horsepower

(SAE)

Torque

(Max. at 2000

rpm.).

. . .

Engine:

Number

of

Cylinders

Bore

Stroke

Displacement

Compression

Ratio

Horsepower

(max.

Brake).

Horsepower

(SAE)

Torque

(Max. at 2400

rpm.).

. . .

Wheelbase

Tread

(front and

rear)

,

Height

(Over

all)

Length

(Over

all).

Width

(Over

all)

Ground

Clearance

F-4

4

3.125 [7,93 cm.]

4.375 [11,11 cm.]

134.2 cu. in. [2,20 ltr.]

7.4:1 7.8:1

6.9:1

120 to 130 psi.

[8,4 a 9,2 kg-cm2] 75 <§ 4000 rpm.

15.63

114 lb-ft. [15,8 kg-m.]

80"

[2,03 m.]

487-'f6/' [1,23 m.|

6634" [1,68 m.j

129%"

[3,30 m.]

68%"

[1,75 m.] 8" [20,32 cm.]

F-4

4

3.125 [7,93 cm.]

4.375 [11,11 cm.]

134.2 cu. in. [2,20 ltr.]

6.7:1 7.1:1

6.3:1 7.4:1

7.8:1

6.9:1

120 to 130 psi.

[8,4 a 9,2 kg-cm2] 75 @ 4000 rpm. 15.63

114 lb-ft. [15,8 kg-m.]

V-6

6

3.750" [9,525 cm.]

3.400" [8,636 cm.]

225 cu.

in.

[3,69 ltr.] 9.0:1

160 @ 4200 rpm. 33.748

235 lb-ft. [32,49 kg-m.]

81"

[2,06 m.]

48K6"

[1,23 m.]

67"

[1,70 m.]

138%"

[3,51 m.]

71%"

[1,82 m.] 8" [20,32 cm.]

F-4

4

3,125 [7.93 cm.]

4.375 [11,11 cm.]

134.2 cu. in. [2,20 ltr.]

6.7:1 7.1:1

6.3:1 7.4:1

7.8:1

6.9:1

120 to 130 psi.

[8,4 a 9,2 kg-cm2] 75 @ 4000 rpm.

15.63

114 lb-ft. [15,8 kg-m.]

V-6

6

3.750" [9,525 cm.]

3.400" [8,636 cm.]

225 cu. in. [3,69 ltr.] 9.0:1

160 @, 4200 rpm. 33 748

235 lb-ft. [32,49 kg-m.]

101"

[2,57 m.]

48^6* ]1,23 m.]

67"

[1,70 m.]

1583/4" [4,02 m.]

71%"

[1,82 m.] 8" [20,32 cm.]

CAPACITIES:

U.S.

Imperial

Metric

Fuel

Tank

(Approximate):

Early

Models

Late

Models

Cooling

System

F4

Models

V-6

Models

Note: If not equipped

with

heater deduct 10.5 gal.

16 gal.

12 qt.

10 qt.

1 qt. 8.8 gal.

13.3 gal.

10 qt. 8 qt.

.8 qt. 39,75 ltr.

60,57 ltr.

11,4 ltr. 9,5 ltr.

0,9 ltr.

CJ-

3B

CJ-5

CJ-6

DJ-5

DJ

-6

lb. kg. lb.

kg. lb.

kg. lb.

kg. lb.

kg.

WEIGHTS

(Approximate):

Gross

Vehicle

Weight

(GVW).

3500

1587 3750 1701 3900 1769 3200 1451 3200 1451

Shipping

— V6

Engine

—

'—

2240 1016 2302 1044 1900 862 2033 922

F4

Engine

2132

967 2163

981 2225

1009 1796 814 1858 842

Curb

— V6

Engine

— —

2351 1066 2413 1094 2011 912 2144 972

F4

Engine

2243

1017 2274 1031

2336 1060 1907 865 1969 893

For

Canvas

Half-Top

Model, add 35

17 38

17 38

17 38

17 38 17

For

Canvas

Full-Top

Model, add 56

25 56 25 60 27 56 25 60 27

For

Hard

Top Model, add

~~

340

154 340 154 6

Page 12 of 376

B

LUBRICATION B-3.

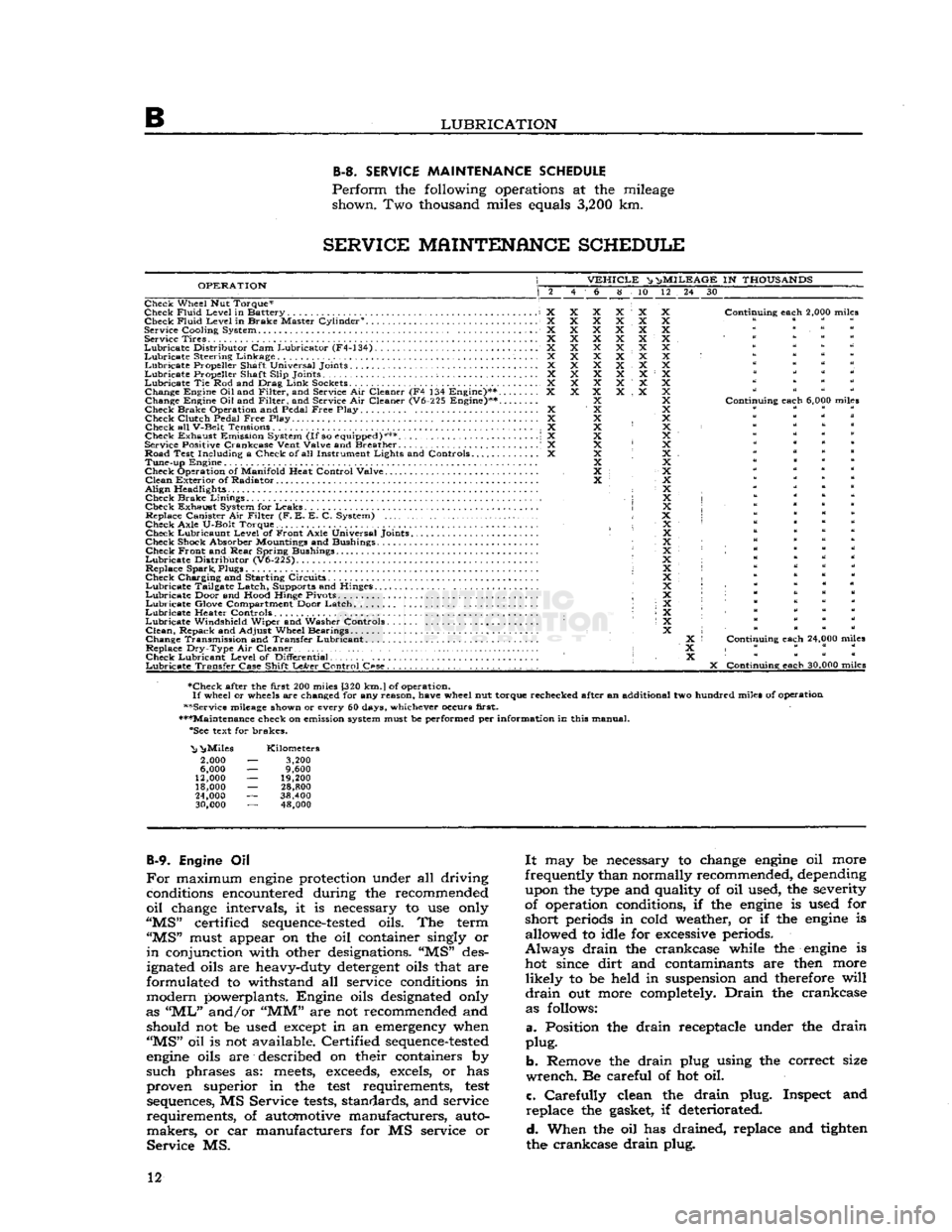

SERVICE

MAINTENANCE

SCHEDULE

Perform

the following operations at the mileage shown. Two thousand miles equals

3,200

km.

SERVICE

MAINTENANCE

SCHEDULE

OPERATION

VEHICLE

^ n>

MILEAGE

IN

THOUSANDS

6 8 10 12 24 30

Check Wheel Nut Torque*

Check

Fluid

Level

in Battery X Check

Fluid

Level

in Brake Master Cylinder0. X

Service

Cooling

System X Service Tires X

Lubricate

Distributor

Cam Lubricator (F4-134) X

Lubricate

Steering Linkage X

Lubricate

Propeller Shaft Universal Joints X

Lubricate

Propeller Shaft

Slip

Joints ; X

Lubricate

Tie Rod and Drag

Link

Sockets................................... X Change Engine

Oil

and

Filter,

and Service Air Cleaner (F4 134 Engine)** X

Change Engine Oil and

Filter,

and Service Air Cleaner (V6-225 Engine)**....

Check Brake Operation and Pedal

Free

Play X Check

Clutch

Pedal

Free

Play. .... X

Check all

V-Belt

Tensions X

Check Exhaust Emission System

(If

so equipped)*** \ X

Service Positive

Crankcase

Vent

Valve

and Breather . .' X

Road Test

Including

a Check of all Instrument

Lights

and Controls X Tune-up Engine

Check Operation of

Manifold

Heat

Control

Valve

Clean

Exterior of Radiator

Align

Headlights • Check Brake

Linings

,

Check Exhaust System for Leaks Replace Canister Air

Filter

(F. E. E. C. System)

Check

Axle

U-Bolt

Torque. Check Lubricaunt

Level

of Front

Axle

Universal Joints

Check Shock Absorber Mountings and Bushings Check Front and

Rear

Spring Bushings

Lubricate

Distributor

(V6-225).

Replace Spark, Plugs

Check Charging and Starting Circuits

Lubricate

Tailgate Latch, Supports and Hinges.

Lubricate

Door and

Hood

Hinge Pivots ;

Lubricate

Glove Compartment Door Latch

Lubricate

Heater Controls •

Lubricate

Windshield

Wiper and Washer Controls

Clean,

Repack and

Adjust

Wheel Bearings

Change Transmission and Transfer Lubricant. .

Replace

Dry-Type

Air Cleaner • Check Lubricant

Level

of

Differential

Lubricate

Transfer

Case

Shift

LeArer

Control

C«se.

. , . . . . . . . .

Continuing

each

2,000 miles

Continuing

each

6,000 miles

Continuing

each

24,000 miles

X

Continuing

each

30,000 miles

•Check after the

first

200 miles [320

km.

J

of operation.

If

wheel or wheels are changed for any

reason,

have

wheel nut torque rechecked after an additional two hundred miles of operation

••Service mileage shown or every 60 days, whichever occurs

first.

•••Maintenance check on emission system must be performed per

information

in this manual. "See text for brakes.

"Nj

^Miles

2,000

6,000

12,000

18,000

24,000

30,000

Kilometers

3,200

9,600

19,200

28,800

38,400 48,000

B-9.

Engine Oil

For

maximum

engine

protection under all driving conditions encountered during the recommended

oil

change intervals, it is necessary to use only

"MS"

certified

sequence-tested

oils. The term

"MS"

must appear on the oil container singly or

in

conjunction with other designations. "MS" des

ignated oils are heavy-duty detergent oils that are

formulated to withstand all service conditions in

modern powerplants. Engine oils designated only

as

"ML"

and/or

"MM"

are not recommended and should not be used except in an emergency when

"MS"

oil is not available. Certified

sequence-tested

engine

oils are described on their containers by

such

phrases as:

meets,

exceeds,

excels, or has

proven superior in the

test

requirements,

test

sequences, MS Service

tests,

standards, and service

requirements,

of automotive manufacturers, auto

makers,

or car manufacturers for MS service or

Service

MS.

It

may be necessary to change

engine

oil more

frequently than normally recommended, depending upon the type and quality of oil used, the severity

of operation conditions, if the

engine

is used for

short

periods in cold weather, or if the

engine

is allowed to idle for excessive periods.

Always

drain

the crankcase while the

engine

is hot since

dirt

and contaminants are then more

likely

to be held in suspension and therefore

will

drain

out more completely.

Drain

the crankcase as follows:

a.

Position the

drain

receptacle under the

drain

plug.

b.

Remove the

drain

plug using the correct size

wrench.

Be careful of hot oil.

c.

Carefully

clean the

drain

plug. Inspect and

replace

the gasket, if deteriorated.

d.

When the oil has drained, replace and tighten

the crankcase

drain

plug. 12

Page 16 of 376

B

LUBRICATION

Note:

Hard

shifting of the transmission gear in

cold weather is a positive indication that the

lubri

cant

is of the wrong viscosity or of poor quality

which

allows it to congeal.

B-38.

Optional

4-Speed

Transmission

and

Transfer Case

The

four-speed transmission and transfer case re

quire

separate lubrication for each unit as

they

have no cross-over oil passage. At each transmission

service check, the

fill

plugs of

both

four-speed

transmission

and transfer case should be pulled

and

the lubricant refilled to level if necessary.

B-39.

Transfer

Case

Linkage

The

transfer case shift linkage should be lubricated

periodically.

All

bearing surfaces that are assembled

with

studs and cotter pins should be disassembled, cleaned, and coated with a

good

waterproof grease.

The

bearing surfaces that cannot be disassembled

should be lubricated with a lubricant that

will

penetrate the bearing

area.

These bearings include

the two on the cross shaft assembly and the

threaded stud.

The

type

of penetrating lubricant recommended is

DuPont

"PM 7", No. 2911, or its equivalent.

B-40.

Brake Master Cylinder

Clean

the top of the

fill

cap and also the housing

area

around it. Remove the cap and observe the

fluid

level. It should be

half

an inch

below

the top

of the fill-hole. If not, add brake fluid to

half

inch

[1,3 cm.]

below

the top of the fill-hole. Use

only heavy-duty brake fluid conforming to speci

fication

SAE-J-1703.

Be sure to handle the brake

fluid

in clean dispensers and containers that

will

not introduce even the

slightest

amount of other

liquids

or foreign particles. Replace and tighten

the

fill

cap.

B-41.

Adjust Brakes

Refer

to Section P.

B-42.

Brake Linings

Refer

to Section P.

B-43.

Adjust Clutch

Refer

to Section I.

B-44.

Clutch Cross Shaft (Lever Type)

Lubricate

the clutch cross shaft in accordance with

specifications given in the

Lubrication

chart: see

Item

1. Chassis Bearings.

B-45.

Tie Rod and Drag

Link

Sockets

The

tie rod and drag

link

sockets

are equipped

with

lubrication

fittings

and should be lubricated

per

specifications given in the

Lubrication

chart: see Item 1. Chassis Bearings.

B-46.

Front

and

Rear Spring

Bushings

The

condition of the spring bushings is indicated

by the alignment of the spring pivot and spring

shackle

bolts.

Check

the alignment of

these

bolts,

and

check that nuts are

tightened

securely.

B-47.

Spring

Shackles

Rubber

bushings are provided on the spring

shackles.

These rubber bushings have no lubrication

fitting and it is very important that

they

never be lubricated.

B-48.

Shock Absorbers

Visually

check for broken mounts or bolts, worn

or

missing bushings on the shock absorbers. Refer

to Section S.

B-49.

Front and

Rear

Axle

U-Bolts

Torque

the front and

rear

axle U-bolts. Refer to Section S.

B-50. Front

and

Rear

Axle

Differentials

—

Lubricant Levels

The

lubricant

level of all front and

rear

differentials should be at the level of the fill-hole.

B-51.

Front and

Rear

Axle

Differentials

—

Changing

Lubricant

B-52.

Conventional Differentials

To

remove the lubricant from the front or

rear

differential,

it is necessary to remove the housing cover. Let the lubricant

drain

out, and then flush

the differential with a flushing oil or light

engine

oil

to clean out the housing

(except

Powr-Lok

or

Trac-Lok

Differentials). Do not use water, steam,

kerosene, or

gasoline

for flushing.

Reinstall

the housing cover, replacing the gasket whenever necessary, torquing the cover

bolts

to 15 to 25 lb-ft. [2,1 a 3,4 kg-m.].

Remove the filler plug, and

refill

the differential

housing as specified in the

Lubrication

Specifica

tions.

B-53.

Powr-Lok

or

Trac-Lok Differential

Some vehicles may be equipped with the

Powr-Lok

or

Trac-Lok

Differential as optional equipment.

Special

lubricant and ordinary multipurpose gear

lubricants

must

not be used. Use only

'Jeep*

Differ

ential

Oil,

Part

No. 94557.

Powr-Lok

or

Trac-Lok

differentials may be cleaned

only by disassembling the unit and wiping with

clean

rags. Do not flush the unit. Refer to Sec

tion N.

B-54.

Front Axle Universal Joint

—

Lube

Check

the level of the front axle universal joint

lubricant

at each front wheel by removing the

fill-hole plug. The lubricant should be level with

the fill-hole. If required, add lubricant as specified

in

Lubrication

Specifications.

B-55.

Front

Axle

Universal

Joint

— Service

On

all 4-wheel drive vehicles the front axle

uni

versal

joint should be serviced by removing the shaft and thoroughly cleaning the universal joints

and

housing. For the correct procedures, refer to

Section M. 16

Page 19 of 376

Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

c

TUNE-UP

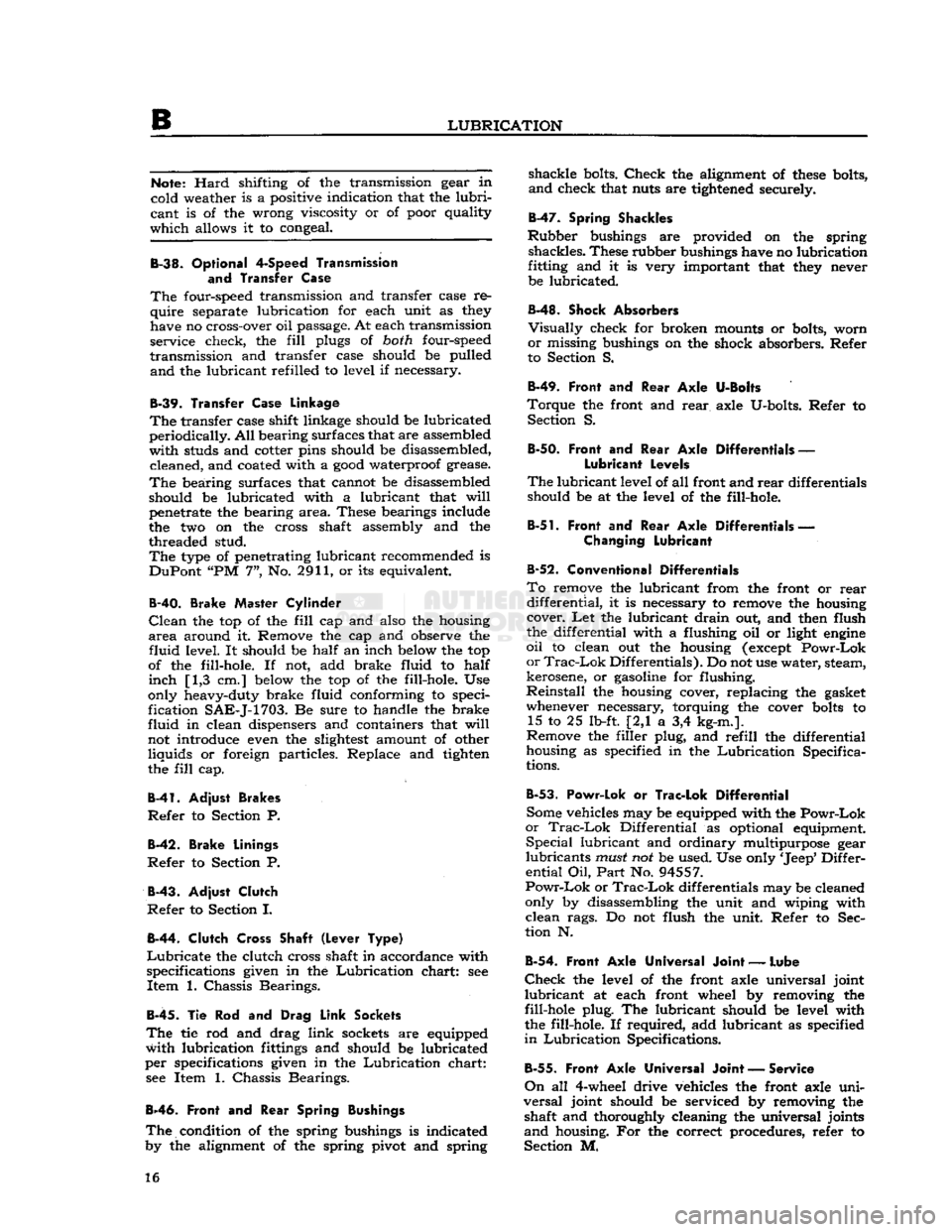

Contents

SUBJECT

PAR.

GENERAL

C-l

TUNE-UP

.C-2

Air

Cleaner

C-21

Battery

. C-3

Carburetor

Adjustments

C-2 5

Coil

C-20

Crankcase

Ventilation C-6

Cylinder

Compression C-9

Cylinder

Head(s) .C-5

Dash

Pot Adjustments .C-26

Distributor

Service C-10

thru

C-13

Distributor

Resistance Test C-l6

Fan

Belt

C-2 7

Fuel

Lines

and Screens

C-2

2

C-l.

GENERAL

An

engine tune-up should be performed for all

Jeep Vehicles each 6000 miles [9.600 km.] or at the end of each 250 hours off-the-road operation,

to ensure best possible performance at all times.

The

tune-up should follow the sequence given in

this section.

Because of federal laws limiting exhaust emissions,

it

is even more important that the engine tune-up is

done

accurately, using the specifications listed

on the tune-up sticker found in each engine com

partment.

Note;

To ensure proper operation and effectiveness

of the exhaust emission control system, and to

comply with

Federal

and State requirements, a

recheck

of ignition timing, idle speed and idle mix

ture

and necessary adjustments must be performed

after the first

2,000

miles [3.200 km.] of vehicle

operation.

A

minor engine tune-up should be performed every

6,000

miles [9.600 km.] or at the end of 250 hours

of off-the-road use.

Major

engine tune-up should

be performed every 12,000 miles [19.300 km.].

The

parts of units which affect power and perform

ance may be divided into three groups:

(1) Units affecting compression

(2) Units affecting ignition

(3) Units affecting carburetion

The

tune-up procedure should cover

these

groups

in

the order given. While the items affecting com

pression and ignition may be handled according

to personal preference, correction of items in the

carburetion

group should not be attempted until

all

items affecting compression and ignition have

been satisfactorily corrected.

Note:

To make sure hydro-carbon and carbon

monoxide emissions

will

be within limits, it is very

impotrant

that the adjustments be followed exactly

as listed on the sticker found in each engine compartment.

SUBJECT

PAR.

Fuel

Pump . . C-23

Heat

Control

Valve C-7

Ignition

Cables C-19

Ignition

Timing

. C-14

Ignition

Wires C-l8

Manifold

C-5

Manifold

Vacuum C-24

Point

Dwell C-17

Primary

Circuit

Tests

.................

C-15

Spark

Plugs C-4

Tappets

C-8

ROAD TEST C-2

8

SERVICE

DIAGNOSIS

. : C-29

TUNE-UP SPECIFICATIONS..

C-30

Minor

engine tune-up consists of the following.

Inspect

and correct as required:

Battery

cables and connections.

Alternator

and regulator wiring.

Primary

— Secondary wiring, distributor cap.

Cylinder

head torque.

Contact

point dwell.

Vacuum

and centrifugal advance.

Ignition

timing.

Spark

plugs for correct air gap.

Adjust

idle speed and idle air mixture.

Adjust

all drive belt tensions.

Clean

carburetor air cleaner.

Lubricate

exhaust manifold damper.

Major

engine tune-up includes the following.

Inspect

and correct as required:

Battery

condition and charging

circuit.

Clean,

lubricate

and tighten battery cable connec

tions.

Ingition

system.

Spark

plugs; replace if necessary or clean and gap.

Compression

check.

Primary—Secondary

wiring, distributor cap.

Replace

contact points and condenser.

Lubricate

distributor cam with cam grease.

Adjust

contact points.

Check

vacuum and centrifugal advance. Set ignition timing.

Torque

cylinder head.

Adjust

idle speed and idle air mixture.

Replace

fuel filter element (every 12,000 miles [19.300

km.]).

Adjust

all drive belt tensions.

IMPORTANT: SPECIFICATIONS

FOR EN-

GINE

RPM.

DISTRIBUTOR POINT DWELL,

AND IGNITION TIMING GIVEN

IN

TUNE- UP SECTION

C

REFER

TO

VEHICLES

WITH

AND WITHOUT EXHAUST EMISSION CON

TROL

SYSTEMS.

FOR

VEHICLES

EQUIPPED WITH EXHAUST

EMISSION CONTROL SYSTEMS ALSO

REFER

TO

SECTION

Fl (F4-134

ENGINE)

AND

F2 (V6-225

ENGINE).

19

Page 21 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

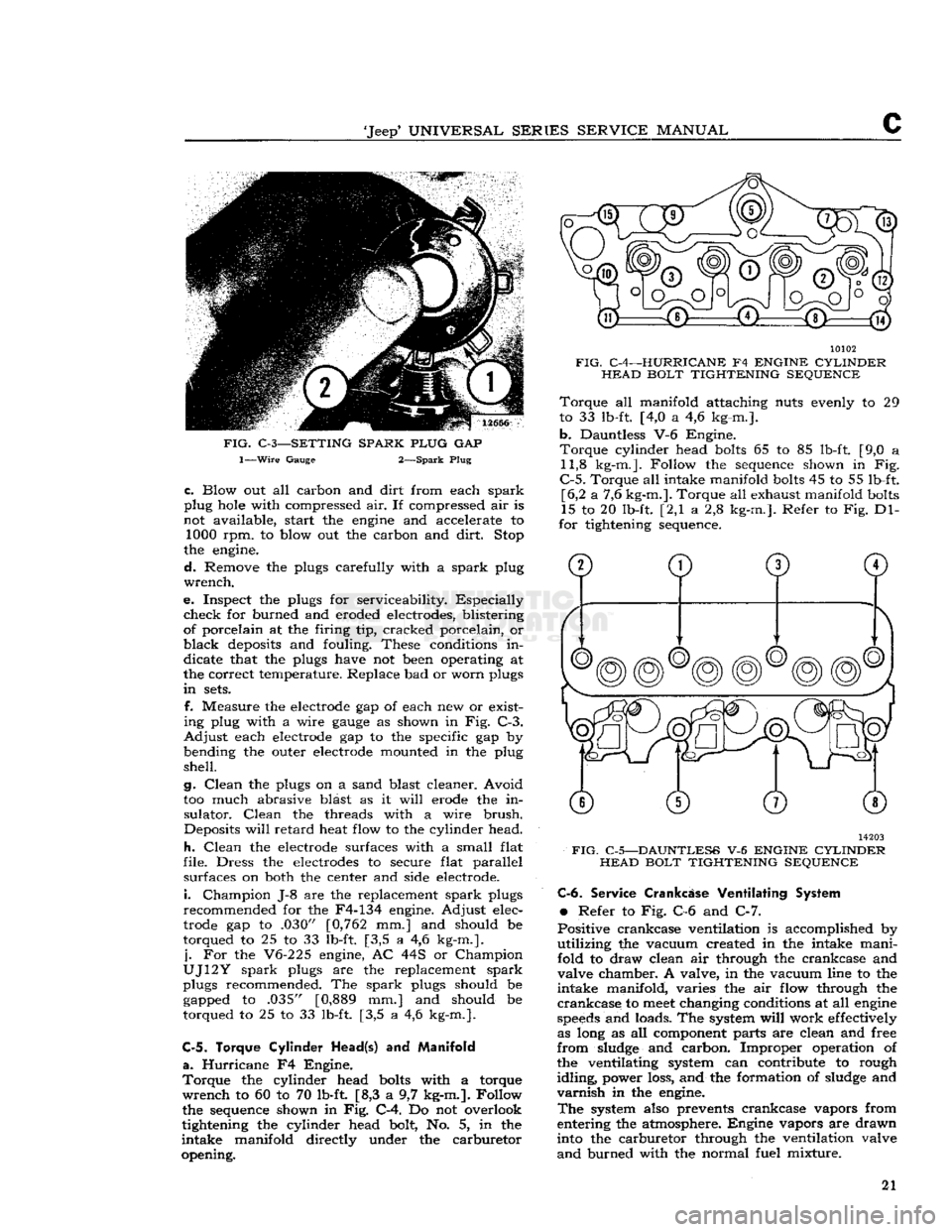

FIG.

C-3—SETTING SPARK PLUG

GAP

1—Wire

Gauge 2—Spark Plug

c.

Blow out all carbon and

dirt

from each

spark

plug hole with compressed air. If compressed air is

not available, start the engine and accelerate to 1000 rpm. to blow out the carbon and

dirt.

Stop

the engine.

d.

Remove the plugs carefully with a

spark

plug

wrench.

e. Inspect the plugs for serviceability. Especially

check

for burned and eroded electrodes, blistering

of porcelain at the firing tip, cracked porcelain, or

black

deposits and fouling. These conditions in

dicate that the plugs have not been operating at

the correct temperature. Replace bad or worn plugs

in

sets.

f. Measure the electrode gap of each new or exist

ing plug with a wire

gauge

as shown in Fig. C-3.

Adjust

each electrode gap to the specific gap by

bending the outer electrode mounted in the plug

shell.

g.

Clean

the plugs on a sand blast cleaner. Avoid

too much abrasive blast as it

will

erode the in

sulator.

Clean

the threads with a wire

brush.

Deposits

will

retard

heat flow to the cylinder head.

h.

Clean

the electrode surfaces with a small flat

file. Dress the electrodes to secure flat parallel surfaces on both the center and side electrode.

i.

Champion J-8 are the replacement

spark

plugs

recommended for the F4-134 engine. Adjust elec

trode gap to .030" [0,762 mm.] and should be

torqued to 25 to 33 lb-ft. [3,5 a 4,6 kg-m.].

j.

For the V6-225 engine, AC 44S or Champion

UJ12Y

spark

plugs are the replacement

spark

plugs recommended. The

spark

plugs should be gapped to .035" [0,889 mm.] and should be

torqued to 25 to 33 lb-ft. [3,5 a 4,6 kg-m.].

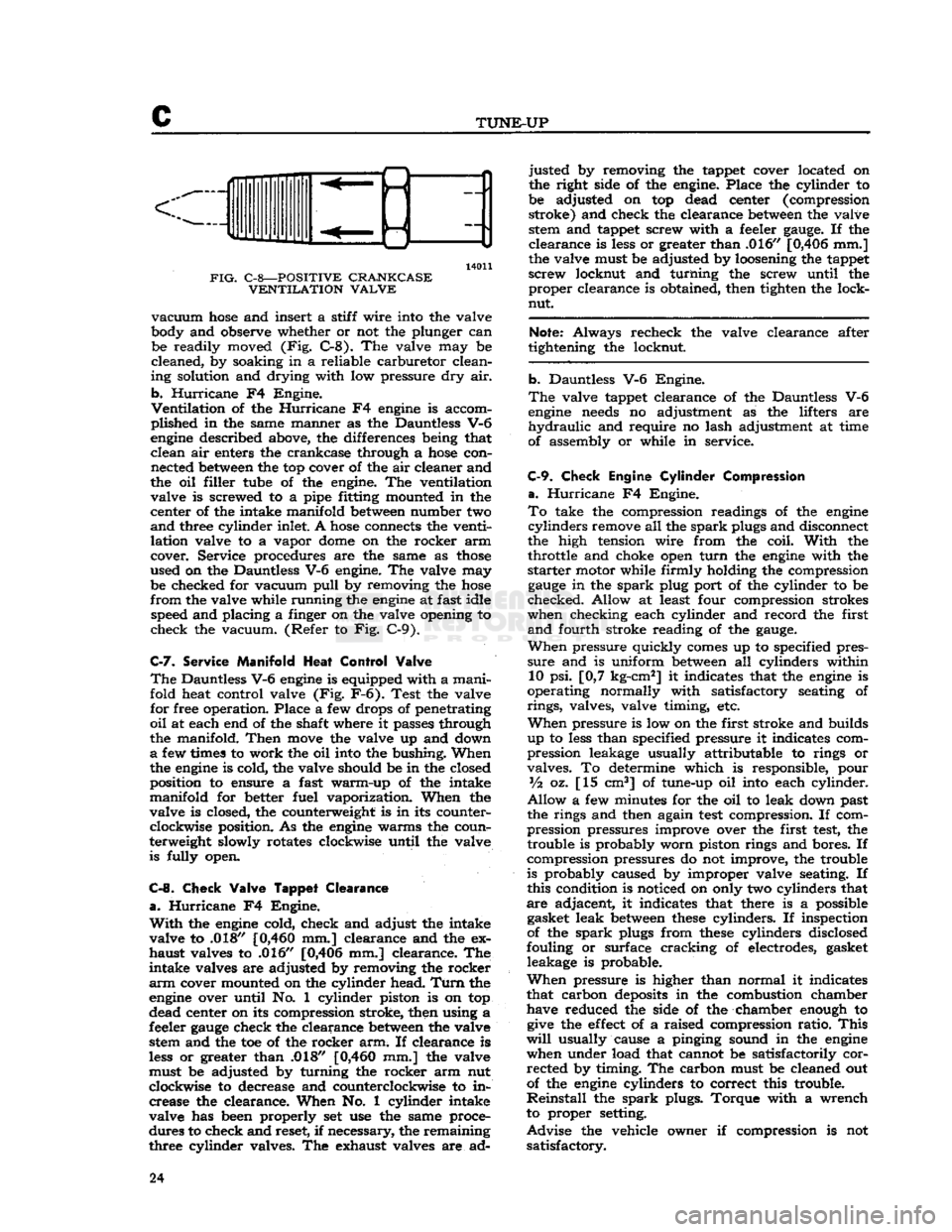

C-5. Torque Cylinder

Head(s)

and

Manifold

a.

Hurricane

F4 Engine.

Torque

the cylinder head bolts with a torque

wrench

to 60 to 70 lb-ft [8,3 a 9,7 kg-m.]. Follow

the sequence shown in Fig. C-4. Do not overlook

tightening the cylinder head bolt, No. 5, in the

intake

manifold directly under the carburetor

opening. 10102

FIG.

C-4—HURRICANE

F4

ENGINE CYLINDER HEAD BOLT TIGHTENING SEQUENCE

Torque

all manifold attaching nuts evenly to 29

to 33 lb-ft. [4,0 a 4,6 kg-m.].

b.

Dauntless V-6 Engine.

Torque

cylinder head bolts 65 to 85 lb-ft. [9,0 a 11,8 kg-m.]. Follow the sequence shown in Fig.

C-5.

Torque all intake manifold bolts 45 to 55 lb-ft. [6,2 a 7,6 kg-m.]. Torque all exhaust manifold bolts

15 to 20 lb-ft. [2,1 a 2,8 kg-m.]. Refer to Fig. Dl-

for tightening sequence. 14203

FIG.

C-5—DAUNTLESS

V-6

ENGINE CYLINDER HEAD BOLT TIGHTENING SEQUENCE C-6.

Service

Crankcase

Ventilating System

•

Refer to Fig. C-6 and C-7.

Positive crankcase ventilation is accomplished by

utilizing

the vacuum created in the intake mani

fold to draw clean air through the crankcase and

valve chamber. A valve, in the vacuum line to the

intake

manifold, varies the air flow through the

crankcase

to

meet

changing conditions at all engine

speeds

and loads. The system

will

work effectively as long as all component parts are clean and free

from

sludge and carbon. Improper operation of the ventilating system can contribute to rough

idling,

power loss, and the formation of sludge and

varnish

in the engine.

The

system also prevents crankcase vapors from

entering the atmosphere. Engine vapors are drawn

into the carburetor through the ventilation valve

and

burned with the normal fuel mixture. 21

Page 24 of 376

c

TUNE-UP

14011

FIG.

C-8—POSITIVE CRANKCASE VENTILATION VALVE

vacuum

hose

and insert a stiff wire into the valve

body and observe whether or not the plunger can be readily moved (Fig. C-8). The valve may be

cleaned, by soaking in a reliable carburetor clean

ing solution and drying with low pressure dry air.

b.

Hurricane

F4 Engine.

Ventilation

of the

Hurricane

F4

engine

is accom

plished in the same manner as the Dauntless V-6

engine

described above, the differences being that clean air enters the crankcase through a

hose

con nected

between

the top cover of the air cleaner and

the oil filler tube of the engine. The ventilation valve is screwed to a pipe fitting mounted in the

center of the intake manifold

between

number two

and

three cylinder inlet. A

hose

connects the venti

lation valve to a vapor

dome

on the rocker arm

cover. Service procedures are the same as

those

used on the Dauntless V-6 engine. The valve may be checked for vacuum

pull

by removing the

hose

from

the valve while running the

engine

at fast idle speed and placing a finger on the valve opening to

check the vacuum. (Refer to Fig. C-9).

C-7.

Service

Manifold

Heat

Control

Valve

The

Dauntless V-6

engine

is equipped with a manifold heat control valve (Fig. F-6). Test the valve

for free operation. Place a few drops of penetrating

oil

at each end of the shaft where it passes through

the manifold.

Then

move

the valve up and down

a

few times to work the oil into the bushing. When

the

engine

is cold, the valve should be in the closed

position to ensure a fast warm-up of the intake

manifold for better fuel vaporization. When the

valve is closed, the counterweight is in its counter clockwise position. As the

engine

warms the coun

terweight slowly rotates clockwise until the valve is fully open.

C-8.

Check

Valve

Tappet

Clearance

a.

Hurricane

F4 Engine.

With

the

engine

cold, check and adjust the intake

valve to .018"

[0,460

mm.] clearance and the ex

haust valves to .016" [0,406 mm.] clearance. The

intake valves are adjusted by removing the rocker

arm

cover mounted on the cylinder head.

Turn

the

engine

over until No. 1 cylinder piston is on top

dead center on its compression stroke, then using a

feeler

gauge

check the clearance

between

the valve stem and the toe of the rocker arm. If clearance is

less

or greater than .018"

[0,460

mm.] the valve

must be adjusted by turning the rocker arm nut

clockwise to decrease and counterclockwise to in crease the clearance. When No. 1 cylinder intake

valve has been properly set use the same proce

dures to check and reset, if necessary, the remaining

three cylinder valves. The exhaust valves are ad justed by removing the tappet cover located on

the right side of the engine. Place the cylinder to

be adjusted on top dead center (compression stroke) and check the clearance

between

the valve stem and tappet screw with a feeler

gauge.

If the

clearance is

less

or greater than .016" [0,406 mm.]

the valve must be adjusted by loosening the tappet

screw locknut and turning the screw until the proper clearance is obtained, then tighten the lock-

nut.

Note:

Always recheck the valve clearance after

tightening the locknut.

b. Dauntless V-6 Engine.

The

valve tappet clearance of the Dauntless V-6

engine

needs

no adjustment as the lifters are

hydraulic

and require no lash adjustment at time

of assembly or while in service.

C-9.

Check

Engine

Cylinder

Compression

a.

Hurricane

F4 Engine.

To

take the compression readings of the

engine

cylinders

remove all the

spark

plugs and disconnect

the high tension wire from the coil.

With

the throttle and choke open

turn

the

engine

with the

starter

motor while firmly holding the compression

gauge

in the

spark

plug port of the cylinder to be

checked. Allow at least four compression strokes

when checking each cylinder and record the first

and

fourth stroke reading of the

gauge.

When

pressure quickly

comes

up to specified pres

sure

and is uniform

between

all cylinders within 10 psi. [0,7 kg-cm2] it indicates that the

engine

is

operating normally with satisfactory seating of

rings,

valves, valve timing, etc.

When

pressure is low on the first stroke and builds

up to

less

than specified pressure it indicates com

pression leakage usually attributable to rings or

valves. To determine which is responsible, pour

Vz

oz. [15 cm3] of tune-up oil into each cylinder.

Allow

a few minutes for the oil to leak down past

the rings and then again

test

compression. If com

pression pressures improve over the first

test,

the trouble is probably worn piston rings and bores. If

compression pressures do not improve, the trouble

is probably caused by improper valve seating. If

this condition is noticed on only two cylinders that

are adjacent, it indicates that there is a possible gasket leak

between

these

cylinders. If inspection

of the

spark

plugs from

these

cylinders disclosed

fouling or surface cracking of electrodes, gasket leakage is probable.

When

pressure is higher than normal it indicates

that carbon

deposits

in the combustion chamber have reduced the side of the chamber enough to

give

the

effect

of a raised compression ratio.

This

will

usually cause a pinging sound in the

engine

when under load that cannot be satisfactorily corrected by timing. The carbon must be cleaned out

of the

engine

cylinders to correct this trouble.

Reinstall

the

spark

plugs. Torque with a wrench

to proper setting.

Advise

the vehicle owner if compression is not satisfactory. 24

Page 35 of 376

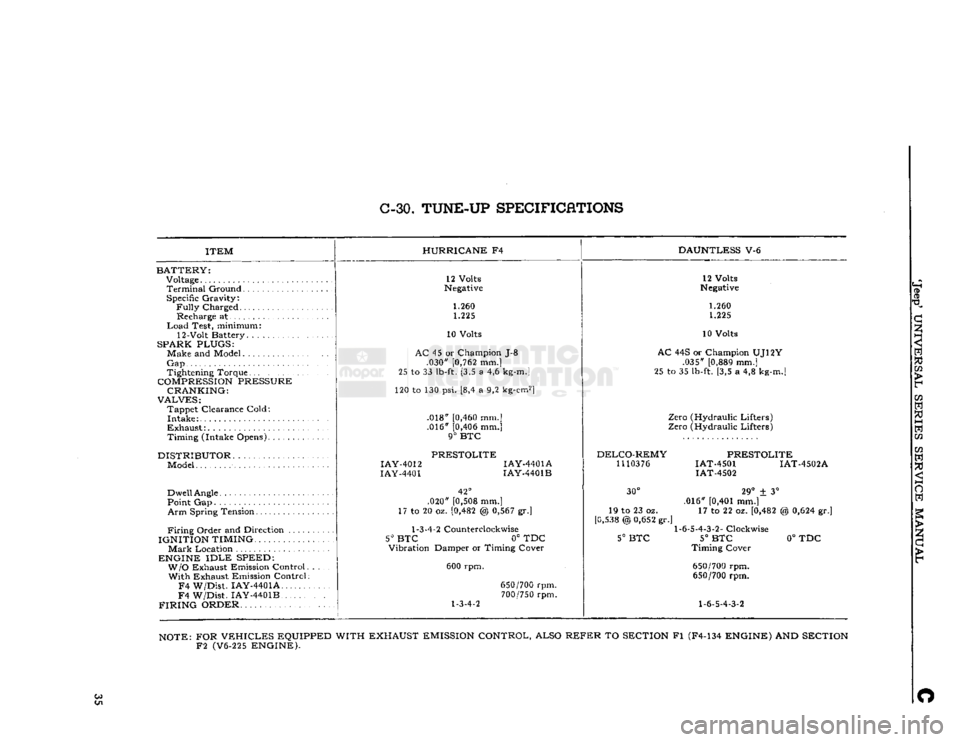

C-30.

TUNE-UP

SPECIFICATIONS

ITEM

BATTERY:

Voltage

Terminal

Ground Specific Gravity:

Fully

Charged Recharge at

Load

Test, minimum:

12-Volt Battery. .

SPARK PLUGS:

Make and Model

Gap

Tightening Torque

COMPRESSION

PRESSURE CRANKING:

VALVES:

Tappet Clearance Cold:

Intake

Exhaust:

Timing (Intake Opens)

DISTRIBUTOR

Model

Dwell

Angle

Point Gap

Arm

Spring Tension

Firing

Order and Direction ....

IGNITION TIMING.

Mark

Location

ENGINE

IDLE

SPEED: W/O

Exhaust Emission Control With Exhaust Emission Control

F4

W/Dist. IAY-4401A

F4

W/Dist. IAY-4401B

FIRING

ORDER HURRICANE

F4

DAUNTLESS

V-6

12 Volts

Negative

1.260 1.225

10 Volts

AC

45 or Champion J-8 .030"

[0,762

mm.]

25 to 33

lb-ft.

[3,5 a 4,6

kg-m.]

120 to 130 psi. [8,4 a 9,2

kg-cm2]

.018"

[0,460

mm.] .016"

[0,406

mm.]

9°

BTC

PRESTOLITE

IAY-4012

IAY-4401A

IAY-4401

IAY-4401B

42°

.020"

[0,508

mm.]

17 to 20 oz.

[0,482

@

0,567

gr.]

1-3-4-2

Counterclockwise

5° BTC

0° TDC

Vibration Damper or Timing Cover

600 rpm.

1-3-4-2

650/700

rpm.

700/750

rpm. 12 Volts

Negative

1.260 1.225

10 Volts

AC

44S or Champion UJ12Y .035"

[0,889

mm.]

25 to 35

lb-ft.

[3,5 a 4,8

kg-m.]

Zero (Hydraulic Lifters)

Zero (Hydraulic Lifters)

DELCO-REMY

1110376

PRESTOLITE

IAT-4501 IAT-4502A

IAT-4502

30°

19 to 23 oz.

[0,538

@

0,652

gr.'

5°

BTC

29°

± 3°

.016"

[0,401

mm.] 17 to 22 oz.

[0,482

1-6-5-4-3-2-

Clockwise

5°

BTC

Timing Cover

650/700

rpm.

650/700

rpm.

1-6-5-4-3-2

%

0,624

gr.]

0°

TDC

NOTE:

FOR

VEHICLES

EQUIPPED WITH EXHAUST

EMISSION

CONTROL, ALSO

REFER

TO

SECTION

Fl (F4-134

ENGINE)

AND

SECTION

F2

(V6-225

ENGINE).

Co O

Page 38 of 376

HURRICANE

F4

ENGINE

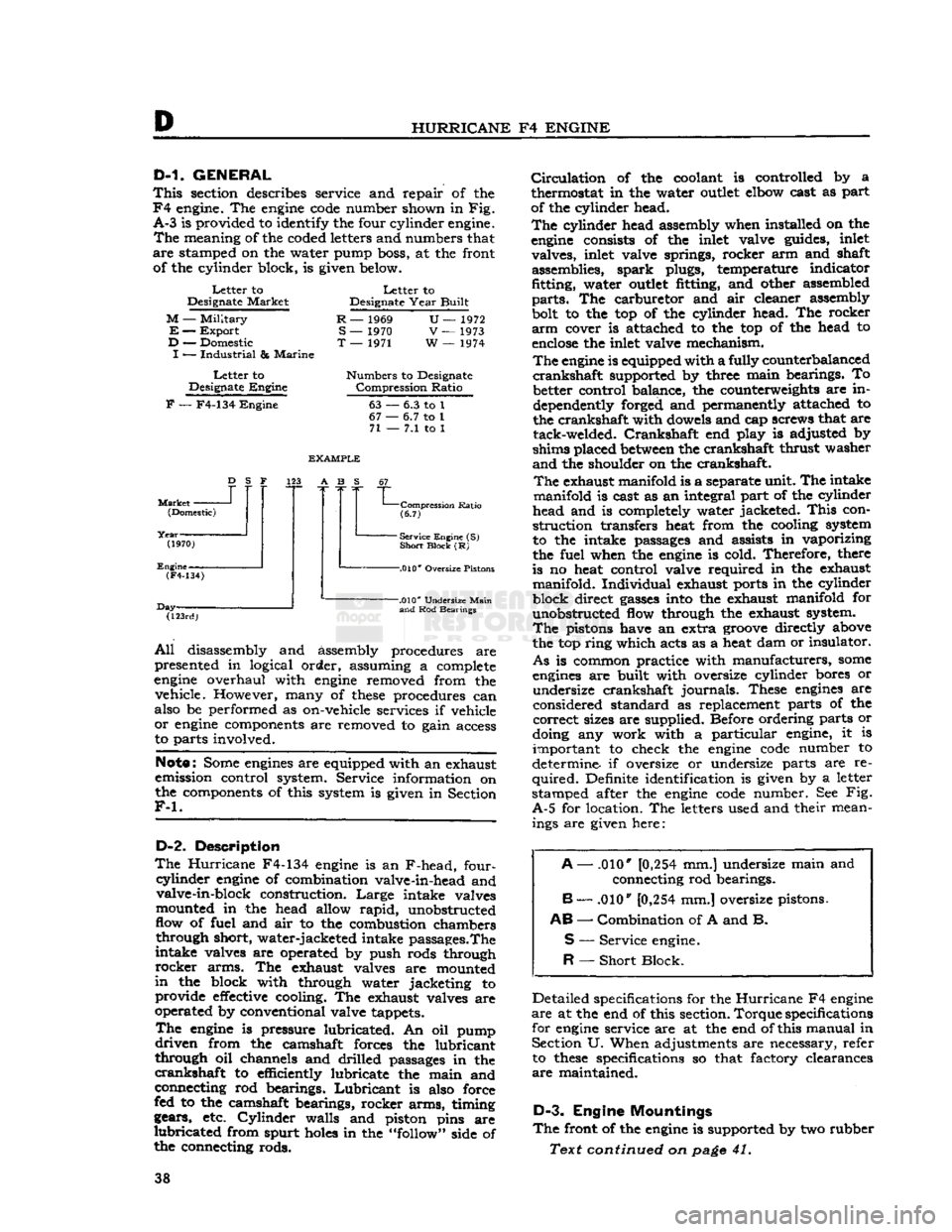

D-1.

GENERAL

This

section describes service and repair of the

F4

engine. The

engine

code

number shown in Fig.

A-3

is provided to identify the four cylinder engine.

The

meaning of the coded letters and numbers that

are

stamped on the water pump boss, at the front of the cylinder block, is given below.

Letter

to

Designate

Market

M

—

Military

E

—

Export

D

— Domestic

I

—

Industrial

&

Marine

Letter

to

Designate

Engine

Letter

to

Designate

Year

Built

R

— 1969

S

— 1970

T

— 1971

U—

1972

V

— 1973

W

— 1974

Numbers

to Designate

Compression

Ratio

F

— F4-134

Engine

63

67

•

71

-

6.3 to 1

•

6.7 to 1

-

7.1 to 1

Market

-

D

S F

(Domestic)

(1970)

Engine-

EXAMPLE

123 A B S

(F4-134)

Day- "L

Compression

Ratio

(6.7)

-

Service Engine (S)

Short

Block

(R)

-.010*

Oversize Pistons

(123rd)

-.010*

Undersize

Main

and

Rod Bearings

All

disassembly and assembly procedures are

presented in logical order, assuming a complete

engine

overhaul with

engine

removed from the vehicle. However, many of

these

procedures can

also be performed as on-vehicle services if vehicle

or

engine

components are removed to gain access

to parts involved.

Note:

Some

engines

are equipped with an exhaust

emission control system. Service information on

the components of this system is given in Section

F-l.

D-2.

Description

The

Hurricane

F4-134

engine

is an F-head, four-

cyiinder

engine

of combination valve-in-head and valve-in-block construction.

Large

intake valves

mounted in the head allow

rapid,

unobstructed

flow of fuel and air to the combustion chambers through short, water-jacketed intake passages.The

intake valves are operated by push rods through

rocker

arms. The exhaust valves are mounted

in

the block with through water jacketing to provide

effective

cooling. The exhaust valves are

operated by conventional valve tappets.

The

engine

is pressure lubricated. An oil pump

driven

from the camshaft forces the lubricant

through oil channels and drilled passages in the

crankshaft

to efficiently lubricate the main and

connecting rod bearings.

Lubricant

is also force

fed to the camshaft bearings, rocker arms, timing

gears, etc.

Cylinder

walls and piston pins are

lubricated

from spurt

holes

in the "follow" side of

the connecting rods.

Circulation

of the coolant is controlled by a

thermostat in the water

outlet

elbow cast as part

of the cylinder head.

The

cylinder head assembly when installed on the

engine

consists of the inlet valve guides, inlet valves, inlet valve springs, rocker arm and shaft assemblies, spark plugs, temperature indicator

fitting, water

outlet

fitting, and other assembled

parts.

The carburetor and air cleaner assembly

bolt to the top of the cylinder head. The rocker

arm

cover is attached to the top of the head to

enclose

the inlet valve mechanism.

The

engine

is equipped with a fully counterbalanced

crankshaft

supported by three main bearings. To better control balance, the counterweights are in

dependently forged and permanently attached to

the crankshaft with dowels and cap screws that are tack-welded.

Crankshaft

end play is adjusted by

shims placed

between

the crankshaft thrust washer

and

the shoulder on the crankshaft.

The

exhaust manifold is a separate unit. The intake

manifold is cast as an integral part of the cylinder

head and is completely water jacketed.

This

con

struction transfers heat from the cooling system

to the intake passages and assists in vaporizing

the fuel when the

engine

is cold. Therefore, there

is no heat control valve required in the exhaust manifold. Individual exhaust ports in the cylinder

block direct

gasses

into the exhaust manifold for unobstructed flow through the exhaust system.

The

pistons have an extra

groove

directly above

the top ring which acts as a heat dam or insulator.

As

is common practice with manufacturers,

some

engines

are built with oversize cylinder bores or undersize crankshaft journals. These

engines

are

considered standard as replacement parts of the

correct

sizes are supplied. Before ordering parts or

doing any work with a particular engine, it is important to check the

engine

code

number to

determine if oversize or undersize parts are re

quired.

Definite identification is given by a letter

stamped after the

engine

code

number. See Fig.

A-5

for location. The letters used and their mean ings are given here:

A

— .010*

[0,254

mm.] undersize main and

connecting rod bearings.

B

— .010"

[0,254

mm.] oversize pistons.

AB

—

Combination

of A and B.

S

—

Service

engine.

R

—

Short

Block.

Detailed specifications for the

Hurricane

F4

engine

are

at the end of this section.

Torque

specifications

for

engine

service are at the end of this manual in Section U. When adjustments are necessary, refer to

these

specifications so that factory clearances

are

maintained.

D-3.

Engine Mountings

The

front of the

engine

is supported by two rubber

Text continued on

page

41. 38

Page 49 of 376

'Jeep'

UNIVERSAL SERIES

SERVICE

MANUAL

D

FIG.

D-ll—CHECKING PISTON

AND

CONNECTING

ROD

ALIGNMENT 1—

Feeler

Gauge

2—

Fixture

the

opposite

side from the oil spray

hole

in the

bearing

end of the connecting rod. See Fig. D-10.

Install

the piston pin lock screw and torque 35 to

41 lb-ft. [4,8 a 5,7 kg-m.].

d.

Place piston and rod assembly in a connecting

rod

aligning fixture and check alignment of the

assembly as shown in

Fig. D-ll.

Follow instructions

furnished

with the fixture.

e. Using a feeler

gauge

and new piston rings, check the width of the two compression ring

grooves

and

the oil ring groove. Replace the piston if the widths of the

grooves

are not with the limits given in

the specifications.

Insert

feeler

gauge

between

ring and piston to back

of groove. Replace piston if ring

grooves

are not

within

allowable tolerances. If a feeler

gauge

larger

FIG.

D-l 2—CHECKING PISTON RING

SIDE

CLEARANCE

1—

Feeler

Gauge

2—

Piston

Ring

FIG.

D-13—PISTON

RING

GAP

than

.006" [0,152 mm.] can be inserted

J^6"

[1,6

mm.]

between

piston and upper compression

ring,

groove

is worn excessively bell-mouthed and

piston should be replaced.

f.

Check

piston ring end gap by placing compres sion ring in cylinder bore below ring travel using head of an inverted piston as a plunger to push

ring

in squarely. End gap must be as shown in

Par.

D-37 for all rings. If less, file ends to obtain

minimum

gap.

With

cylinders bored to an exact

ring

oversize of

+.020", +.030",

or

+.040"

[0,508-

0,762-1,016

mm.] the proper end clearance as given in Par. D-37

will

result. If end

gaps

are

not within the limits given in Par.

D-3

7, rings are

of the wrong size or were incorrectly filed for fitting.

g.

Install

a new ring set using either production replacement rings or service type oil control rings.

Production

type replacement piston rings are the

same as the original factory-installed rings while

service oil control ring

sets

have different com

ponents, notably the oil ring expander. Follow

instructions of

manufacturer

for proper installation.

Use

a piston ring expander to install rings on pistons. Do not expand rings more than necessary

to install, also be careful not to

burr

the piston

with

ends of rings.

Install

bottom

(oil) ring first, center ring second, and top ring last.

The

width of the compression rings is [2,38

mm.] and that of the oil control ring is f^" [4,78

mm.].

While the compression rings are of the same

size, they are different in construction and must

not be interchanged.

Install

these

rings as shown

in

Fig. D-14. The upper compression ring has an

inside beveled

edge

which must be installed toward

the piston top. The face of the lower compression

ring

is tapered approximately .001" [0,025 mm.].

The

letters T or TOP on the upper

edge

indicate

how the ring is to be installed. 49

Page 51 of 376

![JEEP CJ 1953 Service Manual

-Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

E>

[5,928 a

5,926

cm.] for all main bearings. Allowable

taper or out-of-round of the journals is .001"

[0,0254

mm.].

D-42.

Checking Connecting Ro JEEP CJ 1953 Service Manual

-Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

E>

[5,928 a

5,926

cm.] for all main bearings. Allowable

taper or out-of-round of the journals is .001"

[0,0254

mm.].

D-42.

Checking Connecting Ro](/img/16/57040/w960_57040-50.png)

-Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

E>

[5,928 a

5,926

cm.] for all main bearings. Allowable

taper or out-of-round of the journals is .001"

[0,0254

mm.].

D-42.

Checking Connecting Rod

Crankpins

Check

the crankpin diameters with a micrometer

to ensure that they are not out-of-round or tapered more than .001"

[0,0254

mm.] The standard

crank-

pin

diameter is

1.9383*

to

1.9375"

[4,9233

a

4,9213

cm.].

D-43.

Crankshaft

Main

Bearings

The

crankshaft rotates on three main bearings

with

a running clearance of .0003" to .0029"

[0,0076

a

0,0736

mm.].

These

bearings are positioned and prevented from

rotating in their supports in the cylinder block by

dowel pins. Dowel pins are used in both the center

and

the

rear

bearing caps. No dowel pins are used

in

the front bearing cap because the bearing has

a

flange. The front main bearing takes the end

thrust

of the crankshaft. The main bearings are of premium type which provides long bearing life.

They

are replaceable and when correctly installed, provide proper clearance without filing, boring,

scraping,

or shimming. Crankshaft bearings can

be removed from this

engine

only with the

engine

out of the vehicle. Crankshaft bearings must be replaced as a complete set of three bearings, each

bearing consisting of two halves.

Main

bearings

are

available in the standard size and the following

undersizes:

.001" [0,025mm.] .012" [0,305 mm.] .002" [0,051mm.] .020" [0,508 mm.] .010" [0,254mm.] .030" [0,762 mm.]

The

.001" and .002" undersize main bearings are

for use with standard size crankshafts having

slightly worn

journals.

The .010", .020", and .030" undersize bearings are for use with undersize

crankshafts

in

those

sizes. The .012" undersize

bearings are for use with .010" undersize

crank

shafts having slightly worn journals. Bearing sizes

are

rubber stamped on the reverse side of each

bearing half.

D-44. Crankshaft

Main

Bearing Inspection

The

crankshaft

journals

must be carefully inspected

as detailed previously in Par. D-41. Worn journals

will

require undersize bearings. Scored, flaked, or

worn

bearings must be replaced. Measure the main

bearing bores in the cylinder block using a

telescope

gauge

and micrometer. Measure the bores at right

angles to the split line and at 45° to the split line.

The

bores should not be over .001"

[0,0254

mm.]

out-of-round or .001" in taper from end to end.

Also,

the bores should not be more then .001"

oversize, considering the average diameter of the

bore.

D-45.

Fitting Crankshaft

Main

Bearings

Using

Plastigage

After

wiping and carefully inspecting the bearing bore, install the proper bearing. See that the oil

hole

in the bearing upper half registers properly

with

the oil

hole

in the block, and that the bearing

lock fits properly in the notch in the block.

Install

the crankshaft if replacing bearings with the

engine

out of the vehicle. The desired running fit (dif

ference

between

the diameter of the crankshaft

journal

and the inside diameter of the fitted bear ing) for a main bearing is .0003" to .0029"

[0,0076

a

0,0736

mm.]. With a dimension in

excess

of this

standard

running fit, a satisfactory bearing replacement cannot be made and it

will

be necessary to

regrind

the crankshaft.

Install

the bearing lower

half

and the bearing cap and draw the nuts down

equally and only slightly tight. Rotate the

crank

shaft by hand to be sure it turns freely without

drag.

Pull

the nuts tighter, first one then the other,

a

little at a time, intermittently rotating the

crank

shaft by hand until the recommended torque of

35 to 45 lb-ft. [4,8 a 6,2 kg-m.] is reached. If the

bearings are of the correct size, and lubricated with

light oil before installation, the crankshaft should

turn

freely in the bearings. If the crankshaft cannot

be turned, a larger bearing is

required.

If there is no binding or tightness, it is still necessary to check

clearance to guard against too

loose

a fit. Never file

either the bearing cap or the bearing to compensate

for too much clearance. Do not use shims under a

bearing cap or behind a bearing shell. Do not run a

new bearing half with a worn bearing half. The use

of "Plastigage" of the proper size to measure .001" [0,025 mm.] clearance is recommended for check

ing crankshaft main bearing clearance. The method

of checking clearance is as follows:

a.

Remove the bearing cap and carefully wipe

all

oil from the bearing and the

journal.

b.

Lay a piece of "Plastigage" y%" [3 mm.]

shorter than the width of the bearing across the

journal

(lengthwise of the crankshaft).

c.

Install

the bearing and cap and tighten first

one nut, then the other, a little at a time to the specified torque. As the bearing

tightens

down

around

the

journal,

the "Plastigage" flattens to a

width that indicates the bearing clearance.

d.

Remove the cap and measure the width of

the flattened "Plastigage," using the scale printed

on the

edge

of the envelope. The proper size "Plasti

gage"

will

accurately measure clearance down to .001".

e. If the flattened "Plastigage" tapers toward the middle, or toward the end, or both ends, there

is a difference in clearance, indicating a taper, a

low

spot,

or other irregularity of the bearing or

journal.

D-46.

Fitting Crankshaft

Main

Bearings

Using

Shim Stock

Thin

feeler or shim stock may be used instead of "Plastigage" to check bearing clearances. The

method is simple, but care must be taken to protect

the bearing metal surface from

injury

by too much pressure against the feeler stock,

a.

Cut a piece of .001" [0,025 mm.] thick, by Yl [12,7 mm.] wide, feeler stock }4" [3 mm.]

shorter than the width of the bearing. Coat this 51