low beam JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 282 of 376

FRONT

AXLE

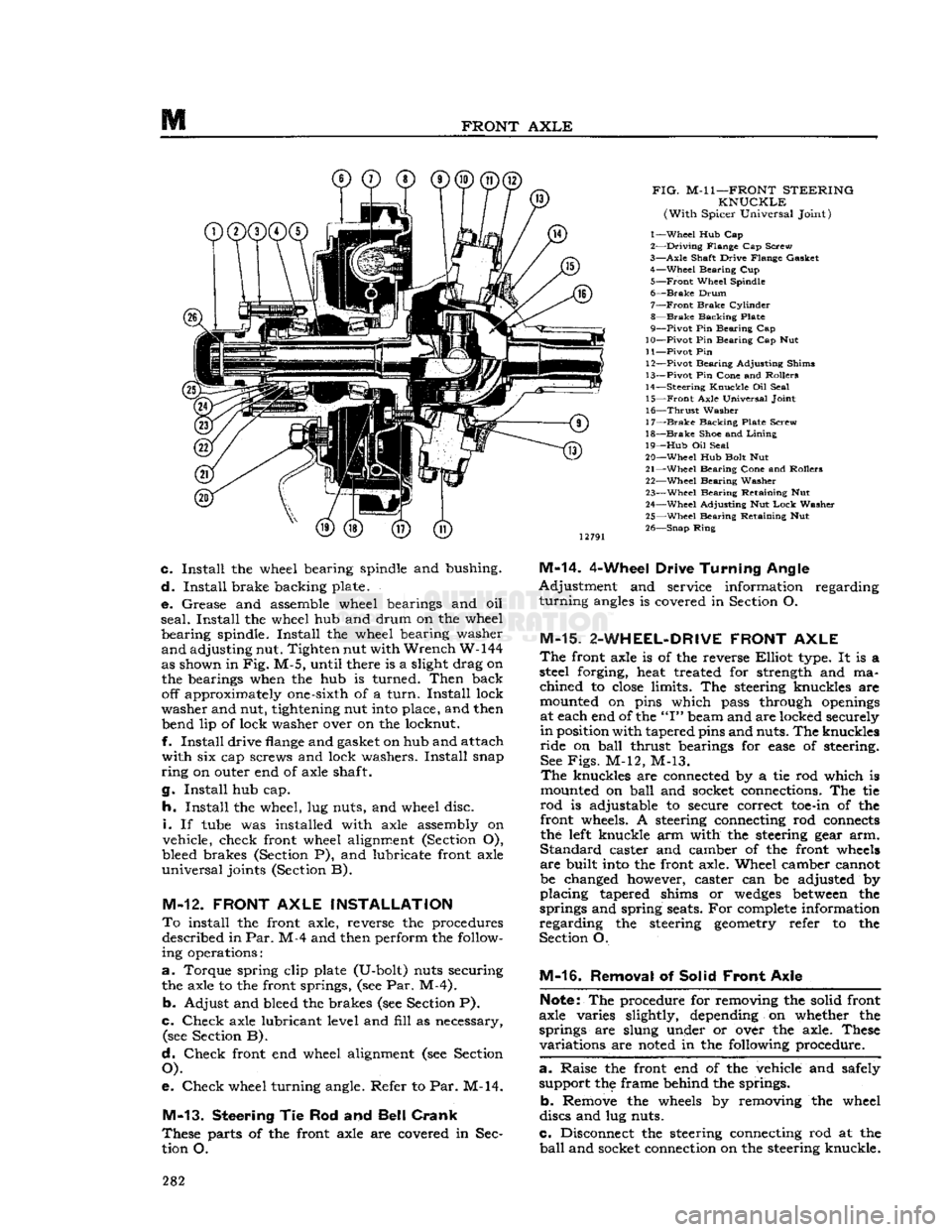

FIG.

M-l

1—FRONT

STEERING

KNUCKLE

(With

Spicer Universal Joint)

1—

Wheel

Hub Cap

2—

Driving

Flange Cap Screw

3—

Axle

Shaft Drive Flange Gasket 4—

Wheel

Bearing Cup

5—

Front

Wheel Spindle

6—

Brake

Drum

7—

Front

Brake

Cylinder

8—

Brake

Backing Plate

9—

Pivot

Pin Bearing Cap

10—

Pivot

Pin Bearing Cap Nut

11—

Pivot

Pin 12—

Pivot

Bearing Adjusting Shims

13—

Pivot

Pin Cone and Rollers

14—

Steering

Knuckle

Oil Seal 15—

Front

Axle Universal Joint

16—

Thrust

Washer

17—

Brake

Backing Plate Screw

18—

Brake

Shoe and

Lining

19—

Hub

Oil Seal

20—

Wheel

Hub Bolt Nut

21—

Wheel

Bearing Cone and Rollers 22—

Wheel

Bearing Washer

23—

Wheel

Bearing Retaining Nut

24—

Wheel

Adjusting Nut

Lock

Washer

25—

Wheel

Bearing Retaining Nut

26—

Snap

Ring

c.

Install

the wheel bearing spindle and bushing.

d.

Install

brake backing plate.

e.

Grease and assemble wheel bearings and oil

seal.

Install

the wheel hub and drum on the wheel

bearing

spindle.

Install

the wheel bearing washer

and

adjusting nut. Tighten nut with

Wrench

W-144

as shown in

Fig.

M-5, until there is a slight drag on the bearings when the hub is turned.

Then

back off approximately one-sixth of a

turn.

Install

lock

washer

and nut, tightening nut

into

place, and then bend lip of lock washer over on the locknut.

f.

Install

drive

flange

and gasket on hub and attach

with

six cap screws and lock washers.

Install

snap

ring

on outer end of axle shaft.

g.

Install

hub cap.

h.

Install

the wheel, lug nuts, and wheel disc.

i.

If

tube

was installed with axle assembly on

vehicle, check front wheel alignment (Section O),

bleed brakes (Section P), and lubricate front axle

universal

joints (Section B).

M-12.

FRONT

AXLE

INSTALLATION

To

install the front axle, reverse the procedures described in

Par.

M-4 and then perform the follow

ing operations:

a.

Torque spring clip plate (U-bolt) nuts securing the axle to the front springs, (see Par. M-4).

b.

Adjust and bleed the brakes (see Section P).

c.

Check

axle lubricant level and

fill

as necessary, (see Section B).

d.

Check

front end wheel alignment (see Section

O).

e.

Check

wheel turning angle. Refer to Par. M-14.

M-13.

Steering

Tie Rod and

Bell Crank

These

parts of the front axle are covered in Sec

tion O.

M-14.

4-Wheel Drive

Turning

Angle

Adjustment

and service information regarding

turning

angles

is covered in Section O.

M-15.

2-WHEEL-DRIVE

FRONT

AXLE

The

front axle is of the reverse

Elliot

type. It is a

steel forging, heat treated for strength and ma

chined

to

close

limits. The steering knuckles are

mounted on pins which pass through

openings

at each end of the

"I"

beam and are locked securely

in

position with tapered pins and nuts. The knuckles

ride

on

ball

thrust bearings for

ease

of steering. See

Figs.

M-12, M-13.

The

knuckles are connected by a tie rod which is

mounted on

ball

and socket connections. The tie

rod

is adjustable to secure correct

toe-in

of the front wheels. A steering connecting rod

connects

the

left

knuckle arm with the steering gear arm.

Standard

caster and camber of the front

wheels

are

built

into

the front axle. Wheel camber cannot

be changed however, caster can be adjusted by

placing

tapered shims or

wedges

between

the

springs and spring seats. For

complete

information

regarding

the steering

geometry

refer to the

Section O.

M-16.

Removal of Solid

Front

Axle

Note:

The procedure for removing the solid front

axle varies slightly, depending on whether the

springs are slung under or over the axle. These

variations

are

noted

in the following procedure.

a. -

Raise the front end of the vehicle and safely support the frame behind the springs.

b.

Remove the

wheels

by removing the wheel

discs and lug nuts.

c.

Disconnect the steering connecting rod at the

ball

and socket connection on the steering knuckle. 282

Page 345 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

s

SPRINGS

AND

SHOCK

ABSORBERS

Contents

SUBJECT

PAR. SUBJECT PAR.

Pivot Bolts S-3 Spring Removal S-4

Shock

Absorbers S-7 Spring Shackles S-2

Spring

Installation S-5 U-Shackles S-6

S-1.

GENERAL

Semielliptical

leaf springs are used for all models.

The

springs are hung longitudinally from the frame

side rails by means of brackets welded to the

rails.

All

axles are firmly attached to the springs by U-

bolts

(spring clips), spring saddles welded to the

underside of the axles, and spring plates under the

springs.

Early

model DJ-5 and DJ-6 front axles (I beam) are attached to the springs with conven

tional

bolts

and spring plates. Spring center

bolts

are

inserted in the axle spring saddles to prevent

shifting of the axle.

All

front springs, except as noted below, are provided with shackles at the front ends of the springs

and

pivot

bolts

at the

rear

ends of the springs. Model CJ-5 up to

Serial

No. 44437 and Model

CJ-6

up to

Serial

No. 11981 are provided with shackles at the

rear

ends of the front springs, and

pivot

bolts

at the front ends.

Note:

Models

CJ-5A

and

CJ-6A

are equipped with

the two

stage

type front and

rear

spring.

All

rear

springs are provided with shackles at the

rear

end and pivot

bolts

at the front end.

Springs

should be examined periodically for broken

or

shifted leaves,

loose

or missing rebound clips,

angle of spring shackles, and position of springs

on the saddles. Springs with shifted leaves do not have their normal strength. Missing rebound clips may permit the spring leaves to fan out or break

on rebound. Broken leaves may make the vehicle

hard

to handle or permit the axle to shift out of

line.

Weakened springs may break causing difficulty

in

steering. Spring attaching clips or

bolts

must be tight. It is

suggested

that they be checked at each

vehicle inspection and torqued 45 to 55 lb-ft. [6,2 a 7,6 kg-m.].

S-2.

Spring Shackles

Rubber-bushed

shackles are provided on all current

production vehicles. The steel-backed rubber (silent bloc) bushings are pressed into the spring

eyes

and mounting brackets. The shackle

bolts

tighten the side plates against the inner steel back

ing of the bushings. Oscillation of the springs is

taken in the rubber bushings.

All

vehicles produced before early 1957 were

equipped with U-shackles and threaded core bush-

*3(

21-

to It is

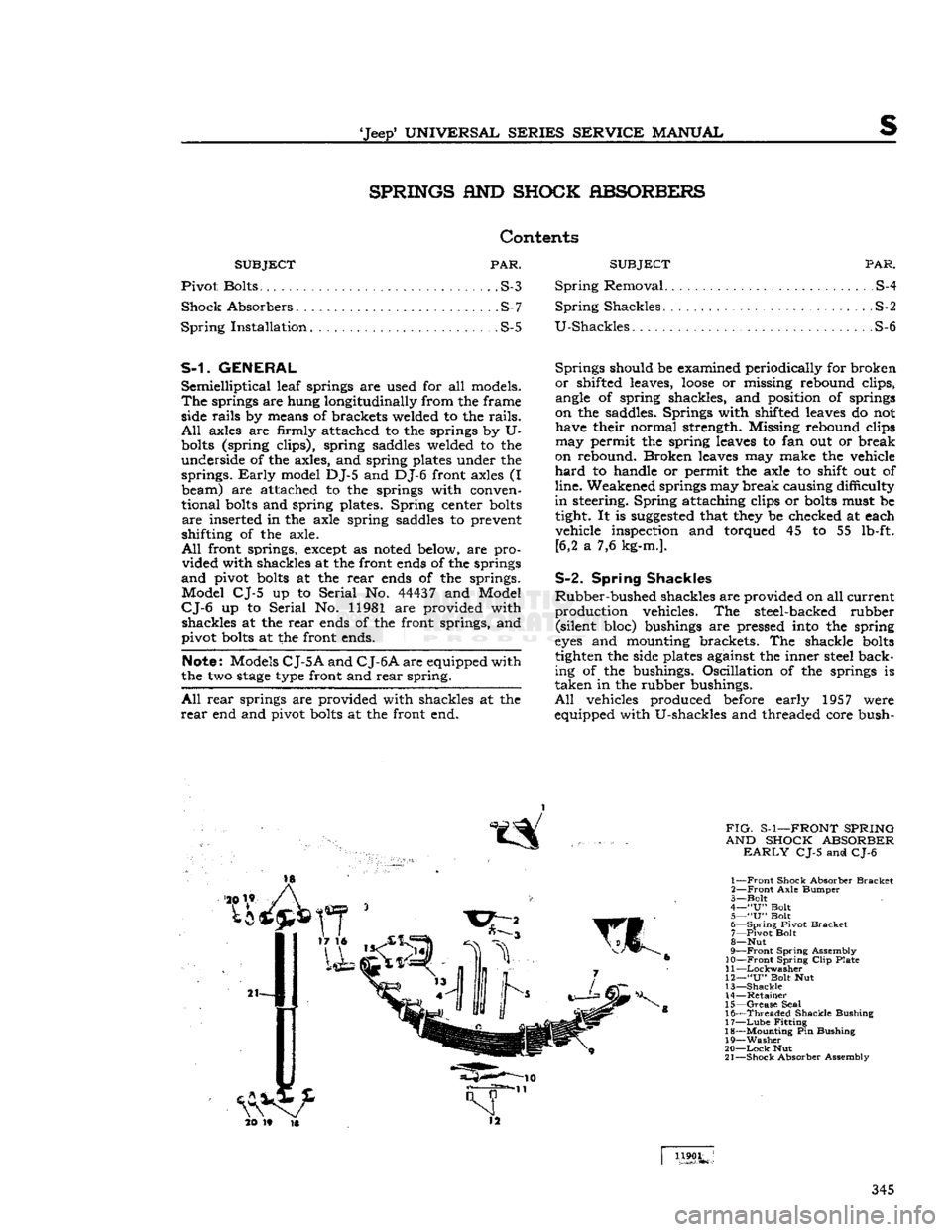

FIG-

S-1—FRONT SPRING

AND SHOCK ABSORBER

EARLY

CJ-5 and CJ-6

1—

Front

Shock Absorber

Bracket

2—

Front

Axle

Bumper

3—

Bolt

4—

"U"

Bolt

5—

"U"

Bolt

6—

Spring

Pivot

Bracket

7—

Pivot

Bolt

8—

Nut

9—

Front

Spring

Assembly

10—Front

Spring

Clip

Plate

11

—Lockwasher

12—

"U"

Bolt Nut

13—

Shackle

14—

Retainer

15—

Grease

Seal

16—

Threaded

Shackle

Bushing

17—

Lube

Fitting

18—

Mounting

Pin Bushing

19—

Washer

20—

Lock

Nut

21—

Shock

Absorber Assembly

1190L

345