tire type JEEP CJ 1953 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 302 of 376

N

REAR

AXLE a.

Place the transmission in neutral.

b.

Raise one wheel off the floor and place a block

in

front and at the

rear

of the

opposite

wheel.

c.

Apply a torque wrench to the axle shaft nut of

the elevated wheel.

d.

Turn

wheel with torque wrench. Disregard

breakaway

torque and observe torque required to

continuously

turn

wheel smoothly. Torque should

read

40 lb-ft [5,53 kg-m.] or more.

N-23. Powr-Lok

Differential Disassembly

/

and Reassembly

Refer

to

Figs.

N-38 and N-39.

The

procedure for overhauling disc type

Powr-Lok

differentials is as follows:

a.

Remove axle shafts following procedure de

scribed

in Par. N-2.

b.

Remove housing cover and gasket.

c.

Remove the

Powr-Lok

differential from the axle.

Do not remove the ring gear or bearing

cone

and

rollers

unless replacement is to be made.

Mark

the hearing cups so they may later be reassembled

with

the same bearing cones.

Mark

the differential

case halves for correct alignment at reassembly.

Each

pinion mate cross shaft should also be marked

so that each pin cam surface

will

match with the

same

V-ramp

in the case when reassembled.

d.

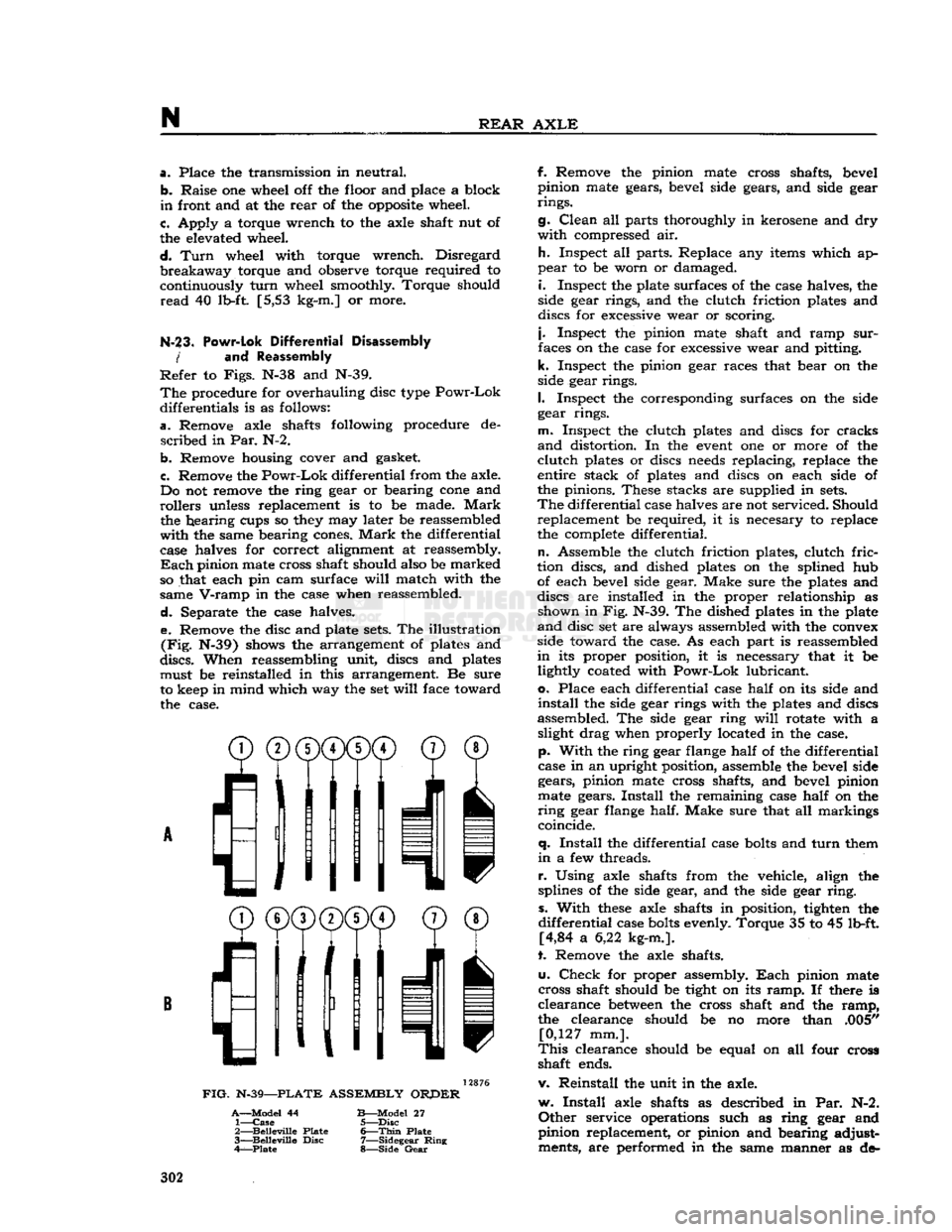

Separate the case halves. e. Remove the disc and plate

sets.

The illustration

(Fig.

N-39) shows the arrangement of plates and

discs.

When reassembling unit, discs and plates must be reinstalled in this arrangement. Be sure

to keep in mind which way the set

will

face toward the case.

^®(j)(j)CD©

® /'Ml

I

11

11 v

FIG.

N-39—PLATE

ASSEMBLY

ORPER

A—Model

44

B—Model

27 1—

Case

5—Disc

2—

Belleville

Plate

6—Thin

Plate

3—

Belleville

Disc

7—Sidegear

Ring

4—Plate

8—Side

Gear

f. Remove the pinion mate cross shafts, bevel

pinion mate gears, bevel side gears, and side gear

rings.

g.

Clean

all parts thoroughly in kerosene and dry

with

compressed air.

h.

Inspect all parts. Replace any items which ap

pear

to be worn or damaged.

i.

Inspect the plate surfaces of the case halves, the

side gear rings, and the clutch friction plates and

discs for excessive wear or scoring.

j.

Inspect the pinion mate shaft and ramp

sur

faces on the case for excessive wear and pitting,

k.

Inspect the pinion gear races that bear on the

side gear rings.

I.

Inspect the corresponding surfaces on the side

gear rings.

m.

Inspect the clutch plates and discs for cracks

and

distortion. In the

event

one or more of the

clutch

plates or discs

needs

replacing, replace the

entire stack of plates and discs on each side of

the pinions. These stacks are supplied in

sets.

The

differential case halves are not serviced. Should replacement be required, it is necesary to replace

the complete differential.

n.

Assemble the clutch friction plates, clutch

fric

tion discs, and dished plates on the splined hub of each bevel side gear. Make sure the plates and

discs are installed in the proper relationship as shown in Fig. N-39. The dished plates in the plate

and

disc set are always assembled with the convex

side toward the case. As each part is reassembled

in

its proper position, it is necessary that it be lightly coated with

Powr-Lok

lubricant,

o.

Place each differential case

half

on its side and

install

the side gear rings with the plates and discs

assembled. The side gear ring

will

rotate with a slight drag when properly located in the case,

p.

With

the ring gear flange

half

of the differential

case in an upright position, assemble the bevel side gears, pinion mate cross shafts, and bevel pinion

mate gears.

Install

the remaining case

half

on the

ring

gear flange half. Make sure that all markings

coincide.

q.

Install

the differential case

bolts

and

turn

them

in

a few threads.

r.

Using axle shafts from the vehicle, align the

splines of the side gear, and the side gear

ring,

s.

With

these

axle shafts in position, tighten the

differential

case

bolts

evenly. Torque 35 to 45 lb-ft. [4,84 a 6,22 kg-m.].

t. Remove the axle shafts.

u.

Check

for proper assembly.

Each

pinion mate

cross shaft should be tight on its

ramp.

If there is

clearance

between

the cross shaft and the

ramp,

the clearance should be no more than .005" [0,127 mm.].

This

clearance should be equal on all four cross

shaft ends.

v. Reinstall the unit in the axle.

w.

Install

axle shafts as described in Par. N-2.

Other

service operations such as ring gear and

pinion replacement, or pinion and bearing adjust ments, are performed in the same manner as de- 302

Page 324 of 376

p

BRAKES

13264

FIG- P-2—DOUBLE

SAFETY BRAKE

MASTER

CYLINDER

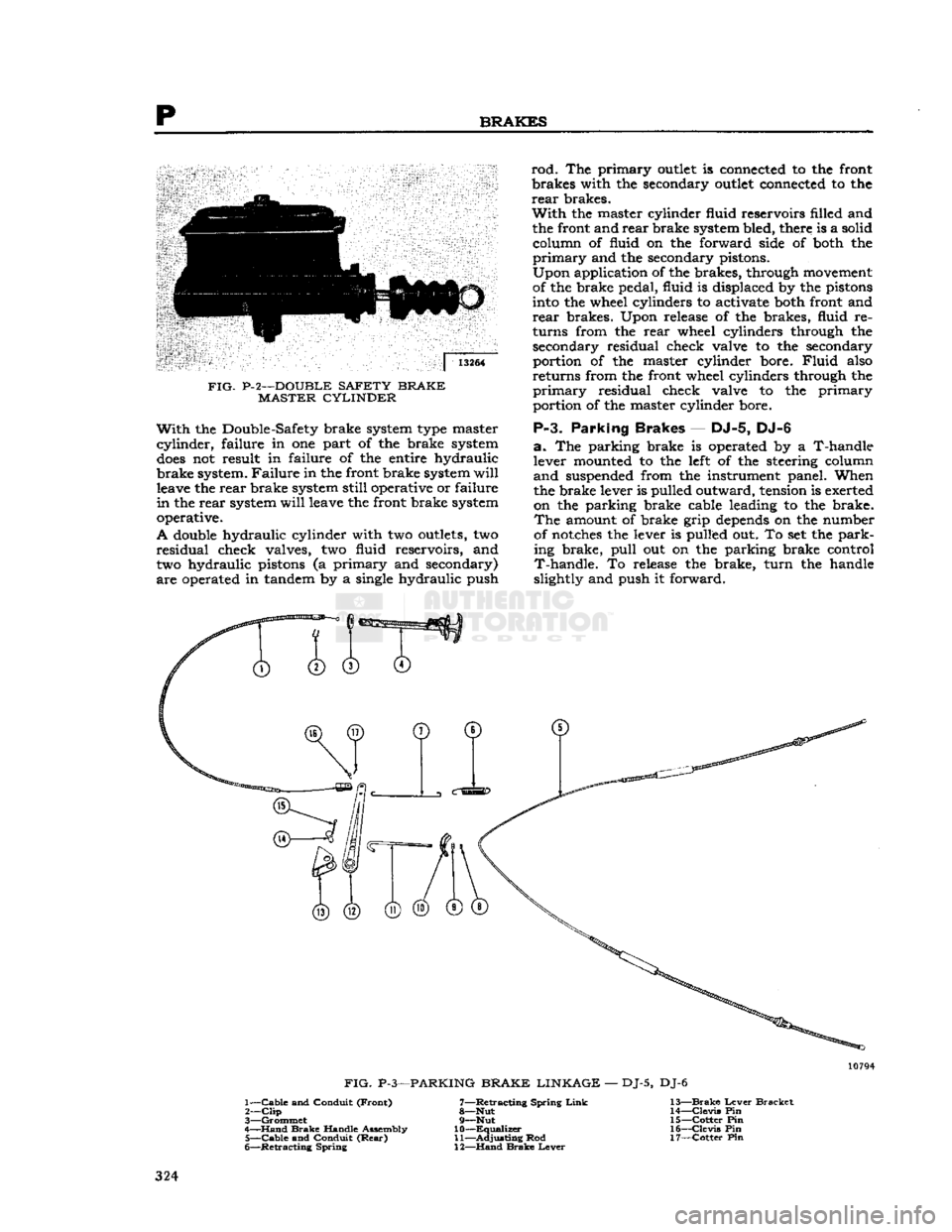

With

the Double-Safety brake system type master

cylinder,

failure

in one part of the brake system

does

not result in

failure

of the entire hydraulic

brake system. Failure in the

front

brake system

will

leave the rear brake system

still

operative or

failure

in

the rear system

will

leave the

front

brake system

operative.

A

double hydraulic

cylinder

with

two outlets, two

residual

check valves, two

fluid

reservoirs, and

two

hydraulic pistons (a

primary

and secondary)

are operated in tandem by a single hydraulic push

rod.

The

primary

outlet is connected to the

front

brakes

with

the secondary outlet connected to the rear brakes.

With

the master

cylinder

fluid

reservoirs

filled

and the

front

and rear brake system

bled,

there is a

solid

column

of

fluid

on the

forward

side of both the

primary

and the secondary pistons.

Upon

application

of the brakes, through movement

of

the brake pedal,

fluid

is displaced by the pistons

into

the wheel cylinders to activate both

front

and

rear brakes.

Upon

release

of the brakes,

fluid

re

turns

from

the rear wheel cylinders through the secondary residual check valve to the secondary

portion

of the master

cylinder

bore.

Fluid

also

returns

from

the

front

wheel cylinders through the

primary

residual check valve to the

primary

portion

of the master

cylinder

bore.

P-3.

Parking

Brakes

— DJ-5, DJ-6

a.

The parking brake is operated by a T-handle

lever

mounted to the

left

of the steering

column

and

suspended

from

the instrument panel. When

the brake lever is

pulled

outward, tension is exerted

on

the parking brake cable leading to the brake.

The

amount of brake

grip

depends

on the number

of

notches the lever is

pulled

out. To set the park

ing

brake,

pull

out on the parking brake

control

T-handle.

To

release

the brake,

turn

the handle

slightly

and push it

forward.

0

FIG.

P-3—PARKING

BRAKE LINKAGE

—

DJ-5,

DJ-6

1—

Cable

and

Conduit

(Front)

7—Retracting

Spring

Link

13—Brake

Lever

Bracket

2—

Clip

8—Nut

14—Clevis

Pin

3—

Grommet

9—Nut

15—Cotter

Pin

4—

Hand

Brake

Handle

Assembly

10—Equalizer

16—Clevis

Pin

5—

Cable

and

Conduit

(Rear)

11—Adjusting

Rod

17—Cotter

Pin

6—

Retracting

Spring

12—Hand

Brake

Lever

324

Page 326 of 376

p

BRAKES

be either a defective master cylinder or the use of

low grade brake fluid which has expanded because

of heat. Use standard duty brake fluid conforming to

SAE-J1703

specification.

P-7.

Bleeding

Brakes

The

hydraulic

brake system must be bled whenever

a

fluid line has been disconnected or air

gets

into the system. A leak in the system may sometimes

be indicated by the presence of a spongy brake

pedal.

Air trapped in the system is compressible

and

does

not permit the pressure, applied to the

brake

pedal, to be transmitted solidly through to

the brakes. The system must be absolutely free

from

air at all times. When bleeding brakes, bleed

at that wheel with the

longest

line from the master

FIG.

P-5—BLEEDING

BRAKES

1—Bleeder

Screw

cylinder

first, the next

longest

second, etc. During

the bleeding operation the master cylinder must

be kept at least %

full

of hydraulic brake fluid.

To

bleed the brakes, first carefully clean all

dirt

from

around the master cylinder filler plug. If

bleeder tank is used follow the manufacturers in

structions.

Remove the filler plug and

fill

the master

cylinder

to the lower

edge

of filler neck.

Clean

off

all

bleeder connections at all four wheel cylinders.

Attach

bleeder

hose

and fixture to right

rear

wheel

cylinder

bleeder screw and place end of tube in a

glass jar, and submerged in brake fluid. Open the bleeder valve one-half to three-quarters of a

turn.

See

Fig.

P-5.

Depress the

foot

pedal, allowing it to return very

slowly. Continue this pumping action to force the

fluid

through the line and out of the bleeder

hose

which

carries with it any air in the system. When bubbles cease to appear at the end of the bleeder

hose, close the bleeder valve and remove the hose.

After

the bleeding operation at each wheel cylinder

has been completed,

fill

the master cylinder reser

voir

and replace the filler plug.

Do not re-use the liquid which has been removed

from

the lines through the bleeding process because

of air bubbles and

dirt.

P-8.

Brake Hoses

a.

Hydraulic

lines (tubing and hose) are the means

of transmitting fluid under pressure between the master cylinder and the wheel cylinders.

Note:

On

some

vehicles a proportioning valve is

located in the

rear

brake line along the inside left

frame

side

rail.

The valve is not serviceable and

must be replaced as an assembly.

Should

replacement be necessary make certain the valve is properly positioned with the centerline of

the hex plug (in the bottom of the valve) in the

vertical

position. Refer to Fig. P-l.

The

hoses

are the flexible links between the wheels

or

axles and the frame or body. The

hoses

must

withstand

the fluid pressures without expansion

and

must be free to flex during spring deflection

and

wheel turns without causing damage to the

hose.

b.

Hydraulic

lines are subject to damage and

deterioration. Hoses should be inspected for cuts,

chafing,

cracks,

twists and

loose

frame supports.

Hydraulic

tubing should be inspected for signs of

leakage (due to faulty flares or

loose

connections);

restrictions

(due to dents or corrosion); and wear (due to friction against other metal parts). Always

use correct type and size of wrench on fittings.

Avoid

damage to female fittings by supporting fit

ting with tube nut during removal of assembly.

c.

On fittings where gaskets are used, always use

a

new gasket. Copper gaskets take a set and may

not form a

good

seal if reused.

d.

When replacing hydraulic brake hose, attach

hose

to wheel cylinder and securely tighten hose,

then attach

opposite

end to frame fitting or tubing.

Avoid

twists in

hose

when assembling to frame fitting

or

tubing. Hold

hose

end securely with

wrench

while attaching tubing to hose. If

hose

end

clip

is used, make certain clip is assembled properly.

Check

for interference during spring deflection or

rebound and during front wheel turns.

e.

Check

for any possible contact between front

brake

hose

and inner sidewall of tire when the front

wheels are in maximum

turn

position.

Check

for sufficient but not excessive length of

hose

between

the clamp and the wheels by turning the wheels

from

one extreme

turn

position to the otherl

f.

Check

that there is no possibility of any contact between the

tail

pipe and

rear

brake

hose

under

all

operating conditions.

P-9.

Brake Pedal Adjustment

There

should always be at least W [12,7 mm.]

free pedal travel before the push rod

engages

the master cylinder piston.

This

adjustment is accomplished by shortening or 326

Page 337 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

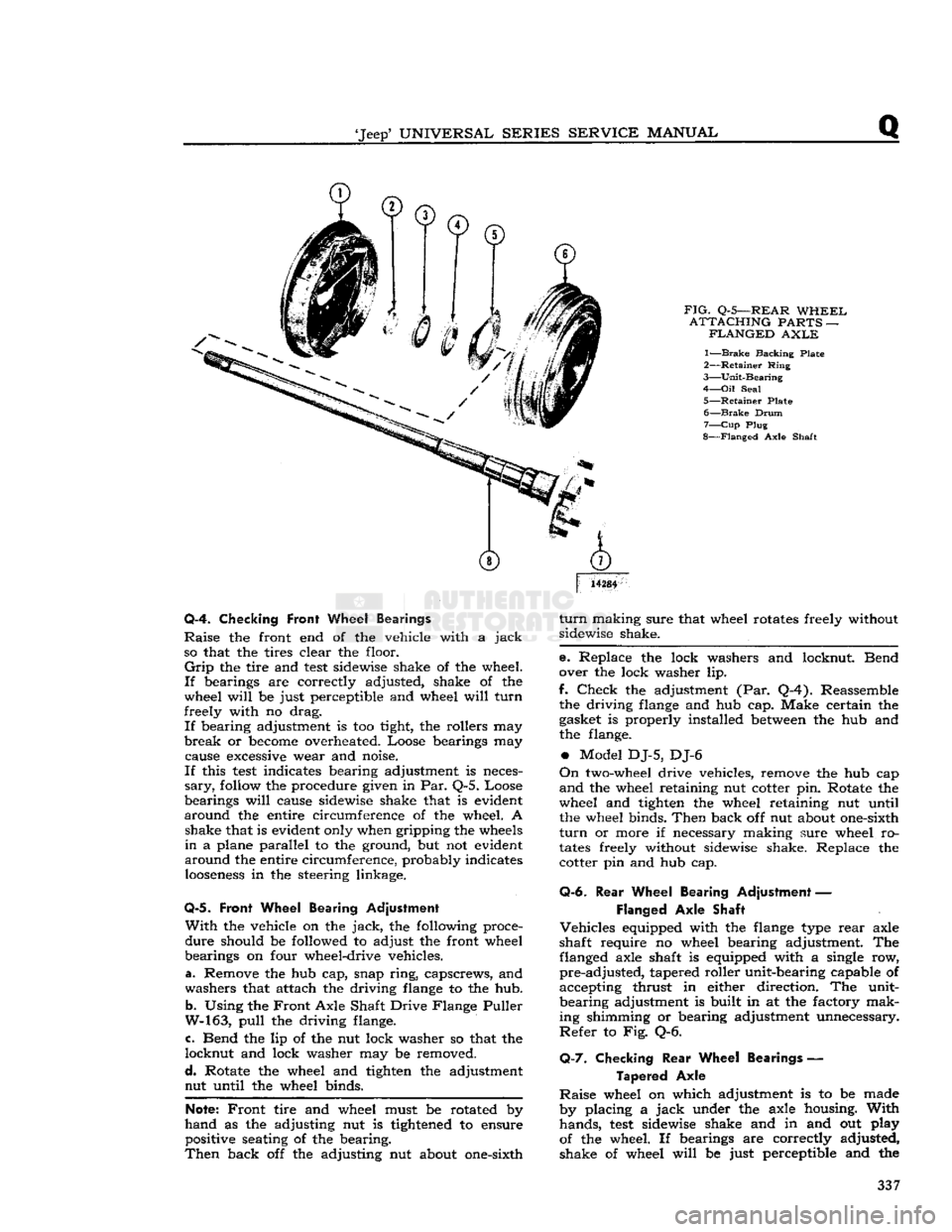

FIG.

Q-5—REAR

WHEEL

ATTACHING

PARTS —

FLANGED

AXLE

1—

Brake

Backing Plate

2—

Retainer

Ring

3—

Unit-Bearing

4—

Oil

Seal

5—

Retainer

Plate 6—

Brake

Drum

7—

Cup

Plug

8—

Flanged

Axle Shaft

14284

Q-4. Checking

Front

Wheel Bearings

Raise

the front end of the vehicle with a

jack

so that the tires clear the floor.

Grip

the tire and

test

sidewise shake of the wheel.

If

bearings are correctly adjusted, shake of the

wheel

will

be just perceptible and wheel

will

turn

freely with no drag.

If

bearing adjustment is too tight, the rollers may

break

or

become

overheated. Loose bearings may cause

excessive

wear and noise.

If

this

test

indicates bearing adjustment is neces

sary,

follow

the procedure given in Par. Q-5. Loose

bearings

will

cause sidewise shake that is evident

around

the entire circumference of the wheel. A shake that is evident only when gripping the

wheels

in

a plane parallel to the ground, but not evident

around

the entire circumference, probably indicates

looseness

in the steering linkage.

Q-5.

Front Wheel Bearing Adjustment

With

the vehicle on the

jack,

the following proce

dure

should be followed to adjust the front wheel

bearings on four wheel-drive vehicles.

a. Remove the hub cap, snap

ring,

capscrews, and

washers that attach the driving

flange

to the hub.

b.

Using the

Front

Axle Shaft Drive Flange Puller

W-163,

pull

the driving flange.

c. Bend the lip of the nut lock washer so that the

locknut

and lock washer may be removed.

d.

Rotate the wheel and tighten the adjustment nut until the wheel binds.

Note:

Front

tire and wheel must be rotated by

hand

as the adjusting nut is

tightened

to ensure positive seating of the bearing.

Then

back off the adjusting nut about one-sixth

turn

making sure that wheel rotates freely without

sidewise shake.

e. Replace the lock washers and locknut. Bend

over the lock washer lip.

f.

Check

the adjustment (Par. Q-4). Reassemble the driving

flange

and hub cap. Make certain the

gasket is properly installed

between

the hub and

the flange.

•

Model DJ-5, DJ-6

On

two-wheel drive vehicles, remove the hub cap

and

the wheel retaining nut cotter pin. Rotate the

wheel and tighten the wheel retaining nut until the wheel binds.

Then

back off nut about one-sixth

turn

or more if necessary making sure wheel ro

tates

freely without sidewise shake. Replace the cotter pin and hub cap.

Q-6.

Rear

Wheel Bearing Adjustment —

Flanged

Axle Shaft

Vehicles

equipped with the

flange

type

rear

axle

shaft require no wheel bearing adjustment. The flanged axle shaft is equipped with a single row,

pre-adjusted,

tapered roller unit-bearing capable of

accepting thrust in either direction. The unit-

bearing

adjustment is built in at the factory mak

ing shimming or bearing adjustment unnecessary.

Refer

to Fig. Q-6.

Q-7.

Checking

Rear

Wheel Bearings —

Tapered

Axle

Raise

wheel on which adjustment is to be made

by placing a

jack

under the axle housing.

With

hands,

test

sidewise shake and in and out play

of the wheel. If bearings are correctly adjusted,

shake of wheel

will

be just perceptible and the 337

Page 339 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

Q

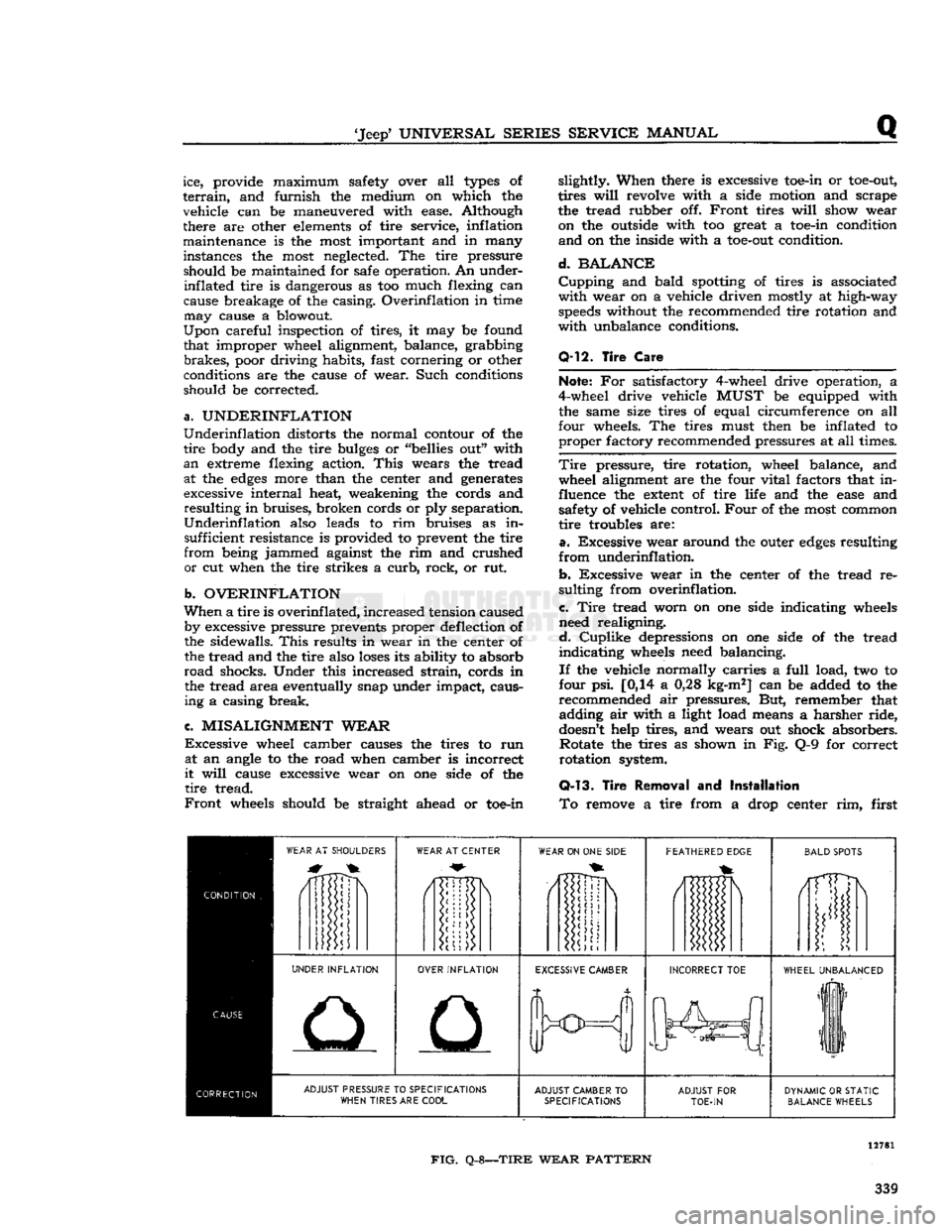

ice, provide maximum safety over all

types

of

terrain,

and furnish the medium on which the

vehicle can be maneuvered with ease. Although

there are other

elements

of tire service, inflation maintenance is the most important and in many

instances the most neglected. The tire pressure should be maintained for safe operation. An under- inflated tire is dangerous as too much flexing can

cause breakage of the casing. Overinflation in time

may

cause a blowout.

Upon

careful inspection of tires, it may be found

that improper wheel alignment, balance, grabbing

brakes,

poor driving habits, fast cornering or other

conditions are the cause of wear. Such conditions

should be corrected.

a.

UNDERINFLATION

Underinflation

distorts the normal contour of the

tire

body and the tire

bulges

or "bellies out" with

an

extreme flexing action.

This

wears the tread at the

edges

more than the center and generates

excessive internal heat, weakening the cords and

resulting

in bruises, broken cords or ply separation.

Underinflation

also leads to rim bruises as in sufficient resistance is provided to prevent the tire

from

being jammed against the rim and crushed

or

cut when the tire strikes a

curb,

rock, or rut.

b.

OVERINFLATION

When

a tire is

overinf

lated,

increased tension caused by excessive pressure prevents proper deflection of

the sidewalls.

This

results in wear in the center of the tread and the tire also

loses

its ability to absorb

road

shocks. Under this increased

strain,

cords in the tread area eventually snap under impact, causing a casing break.

c.

MISALIGNMENT

WEAR

Excessive

wheel camber causes the tires to run at an angle to the road when camber is incorrect

it

will

cause excessive wear on one side of the

tire

tread.

Front

wheels should be straight ahead or toe-in slightly. When there is excessive toe-in or

toe-out,

tires

will

revolve with a side motion and scrape

the tread rubber off.

Front

tires

will

show wear on the outside with too great a toe-in condition

and

on the inside with a

toe-out

condition.

d.

BALANCE

Cupping

and bald spotting of tires is associated

with

wear on a vehicle driven mostly at high-way

speeds

without the recommended tire rotation and

with

unbalance conditions.

Q-12.

Tire

Care

Note;

For satisfactory 4-wheel drive operation, a

4-wheel drive vehicle

MUST

be equipped with the same size tires of equal circumference on all

four wheels. The tires must then be inflated to

proper

factory recommended pressures at all times.

Tire

pressure, tire rotation, wheel balance, and wheel alignment are the four vital factors that in

fluence the

extent

of tire life and the

ease

and safety of vehicle control.

Four

of the most common

tire

troubles are:

a.

Excessive wear around the outer

edges

resulting

from

underinflation.

b.

Excessive wear in the center of the tread re

sulting from overinflation.

c.

Tire

tread worn on one side indicating wheels

need realigning.

d.

Cuplike

depressions on one side of the tread

indicating

wheels need balancing.

If

the vehicle normally carries a

full

load, two to

four psi. [0,14 a 0,28 kg-m2] can be added to the

recommended air pressures. But, remember that adding air with a light load means a harsher ride,

doesn't

help tires, and wears out shock absorbers. Rotate the tires as shown in Fig. Q-9 for correct

rotation system.

Q-13.

Tire

Removal

and

Installation

To

remove a tire from a drop center rim, first

WEAR

AT SHOULDERS

WEAR

AT CENTER

WEAR

ON ONE

SIDE

FEATHERED

EDGE

BALD

SPOTS

/1TTDN

i

UNDER

INFLATION

OVER

INFLATION

EXCESSIVE

CAMBER

INCORRECT

TOE

WHEEL

UNBALANCED

liF

11

ADJUST

PRESSURE TO

SPECIFICATIONS

WHEN

TIRES ARE

COOL

ADJUST

CAMBER

TO

SPECIFICATIONS

ADJUST

FOR

TOE-IN

DYNAMIC

OR

STATIC

BALANCE

WHEELS

FIG.

Q-8—TIRE

WEAR

PATTERN

339

Page 340 of 376

Q

WHEELS

11463

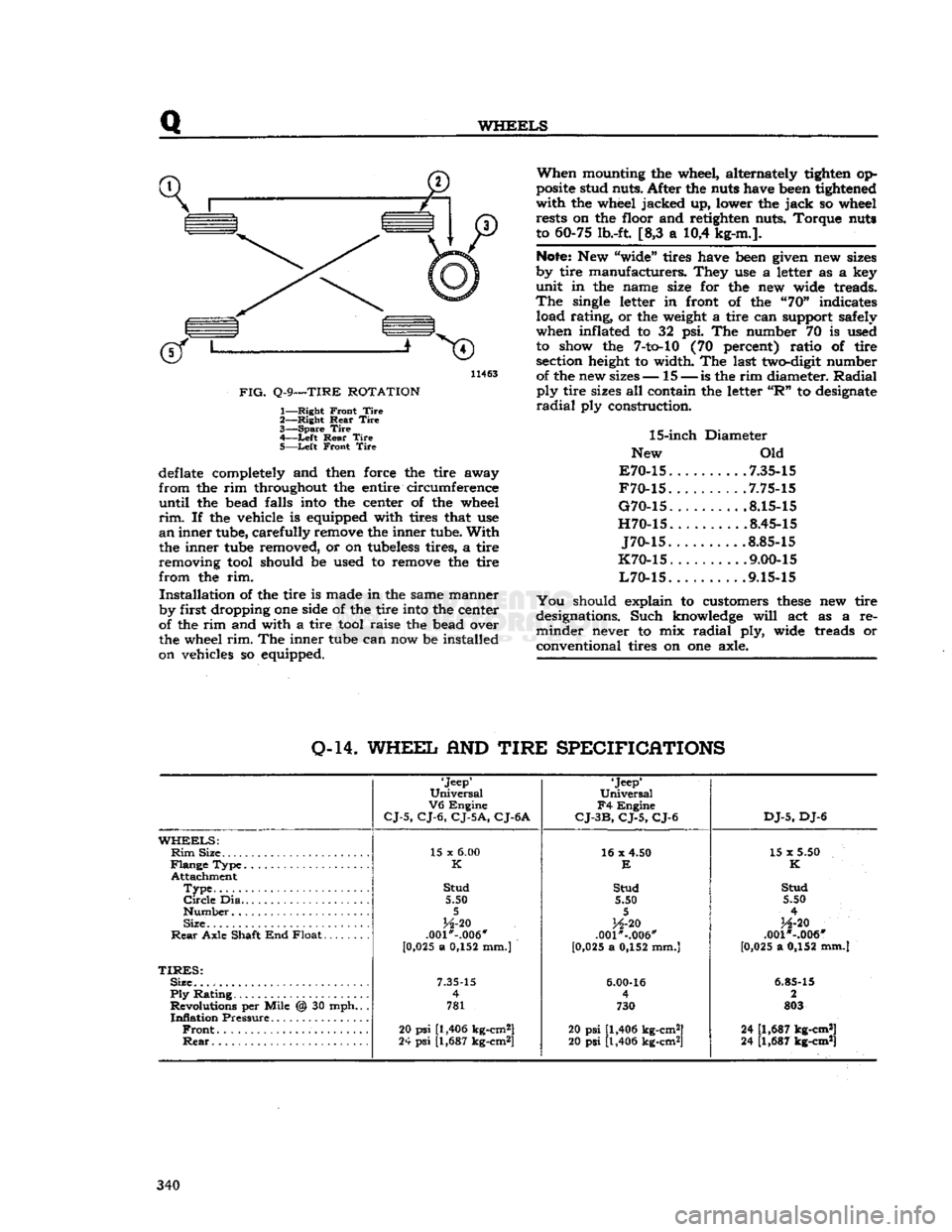

FIG.

Q-9—TIRE

ROTATION

1—

Right

Front

Tire

2—

Right

Rear

Tire

3—

Spare

Tire

4—

-Left

Rear

Tire

5—

Left

Front

Tire

deflate completely and then force the tire away

from

the rim throughout the entire circumference

until

the bead falls into the center of the wheel

rim.

If the vehicle is equipped with tires that use

an

inner tube, carefully remove the inner tube.

With

the inner tube removed, or on tubeless tires, a tire

removing tool should be used to remove the tire

from

the rim.

Installation

of the tire is made in the same manner

by first dropping one side of the tire into the center

of the rim and with a tire tool raise the bead over

the wheel

rim.

The inner tube can now be installed

on vehicles so equipped.

When

mounting the wheel, alternately tighten op

posite stud nuts. After the nuts have been tightened

with

the wheel jacked up, lower the

jack

so wheel rests on the floor and retighten nuts. Torque nuts

to 60-75 lb.-ft. [8,3 a 10,4 kg-m.].

Note:

New "wide" tires have been given new sizes

by tire manufacturers. They use a letter as a key

unit

in the name size for the new wide treads.

The

single letter in front of the "70" indicates load rating, or the weight a tire can support safely

when inflated to 32 psi. The number 70 is used to show the

7-to-10

(70 percent) ratio of tire section height to width. The last two-digit number of the new sizes— 15 —

is

the rim diameter.

Radial

ply

tire sizes all contain the letter

"R"

to designate

radial

ply construction.

15-inch

Diameter

New Old

E70-15

7.35-15

F70-15

.7.75-15

G70-15

8.15-15

H70-15

8.45-15

J70-15

.8.85-15

K70-15

. .... .9.00-15

L70-15

9.15-15

You

should explain to customers

these

new tire

designations. Such knowledge

will

act as a re

minder

never to mix

radial

ply, wide treads or

conventional tires on one axle.

0-14.

WHEEL

AND

TIRE

SPECIFICATIONS

'Jeep'

Universal

V6

Engine

CJ-5,

CJ-6,

CJ-5A,

CJ-6A

'Jeep*

Universal

F4

Engine

CJ-3B,

CJ-5,

CJ-6

DJ-5,

DJ-6

WHEELS:

Rim

Size 15 x

6.00

16 x 4.50

15 x 5.50

K

E

K

Attachment

Type

Stud

Stud Stud

Circle

Dia 5.50 5.50 5.50

5 5

4

Size

H-20

H-20

H-20

Rear

Axle Shaft End Float .001*-.006"

.001"-.006" .001 *-.006"

[0 ,025 a 0,152 mm.)

[0,025 a 0,152 mm.] [0,025 a 0,152 mm.]

TIRES:

Size.

7.35-15

6.00-16

6.85-15

Ply

Rating 4

4 2

Revolutions per Mile @ 30 mph.. . 781 730 803

Inflation

Pressure

Front

20

psi

[1,406 kg-cm2]

20 psi [1,406 kg-cm2] 24 [1,687 kg-cm*]

Rear

24

psi

[1,687 kg-cm*]

20 psi [1,406 kg-cm2] 24 [1,687 kg-cm*] 340

Page 352 of 376

BODY

10728

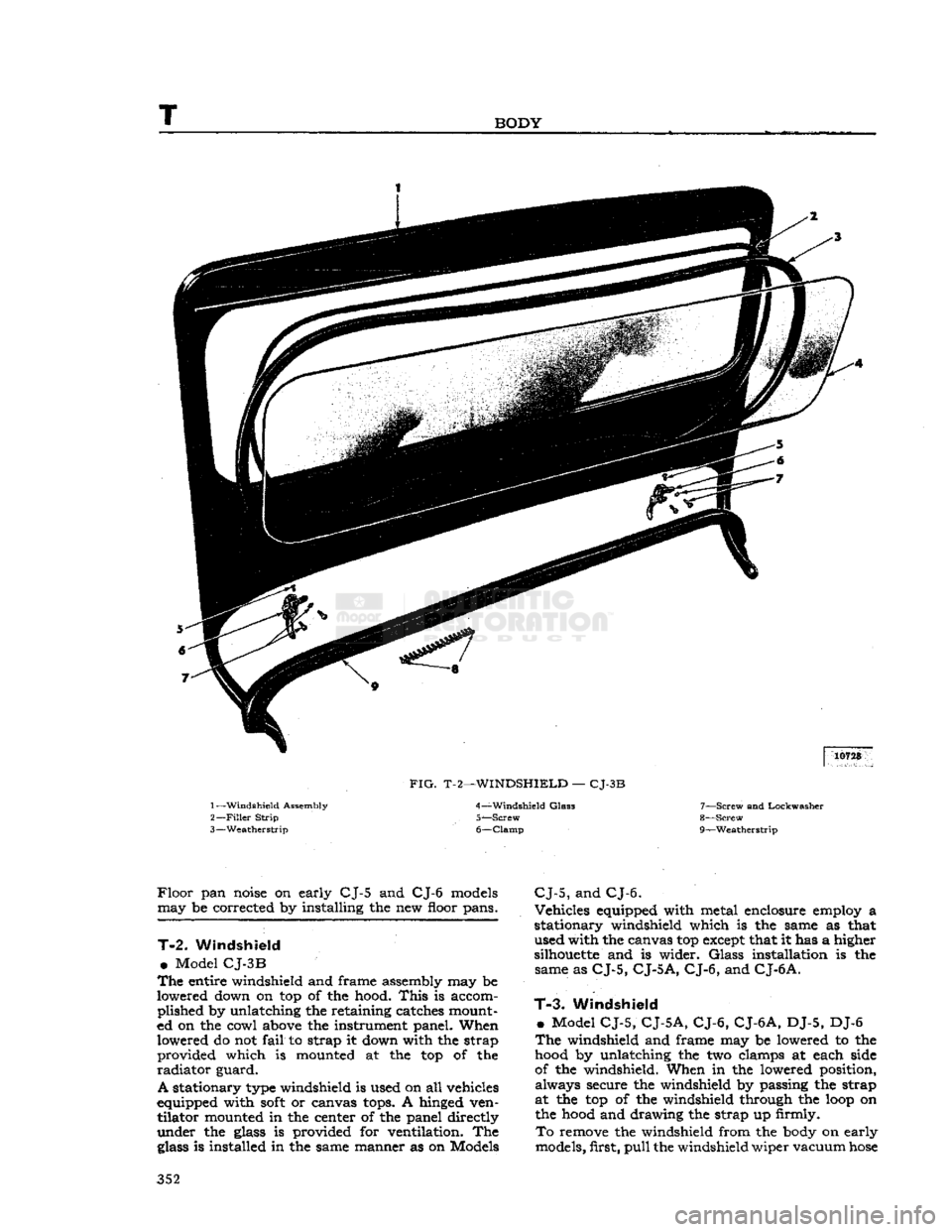

FIG.

T-2—WINDSHIELD

—

CJ-3B

1—

Windshield

Assembly

2—

Filler

Strip

3—

Weatherstrip 4—

Windshield

Glas3

5—

Screw

6—

Clamp

7—

Screw

and Lockwasher

8—

Screw

r

9— —Weatherstrip

Floor

pan

noise

on early CJ-5 and CJ-6

models

may be corrected by installing the new floor pans.

T-2.

Windshield

•

Model

CJ-3B

The

entire windshield and frame assembly may be

lowered down on top of the hood.

This

is accom plished by unlatching the retaining catches mount

ed on the cowl

above

the instrument panel. When lowered do not

fail

to strap it down with the strap provided which is mounted at the top of the

radiator

guard.

A

stationary

type

windshield is used on all vehicles

equipped with

soft

or canvas

tops.

A hinged ven tilator mounted in the center of the panel directly

under the

glass

is provided for ventilation. The

glass

is installed in the same manner as on Models

CJ-5,

and

CJ-6.

Vehicles equipped with metal enclosure employ a

stationary windshield which is the same as that used with the canvas top

except

that it has a higher

silhouette

and is wider.

Glass

installation is the same as

CJ-5,

CJ-5

A, CJ-6,

and

CJ-6

A.

T-3.

Windshield

»

Model

CJ-5, CJ-5A, CJ-6, CJ-6A,

DJ-5, DJ-6

The

windshield and frame may be lowered to the

hood

by unlatching the two clamps at each side

of the windshield. When in the lowered position, always secure the windshield by passing the strap

at the top of the windshield through the

loop

on the

hood

and drawing the strap up firmly.

To

remove the windshield from the

body

on early

models, first,

pull

the windshield wiper vacuum

hose

352