alternator JEEP CJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 179 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

H

12967

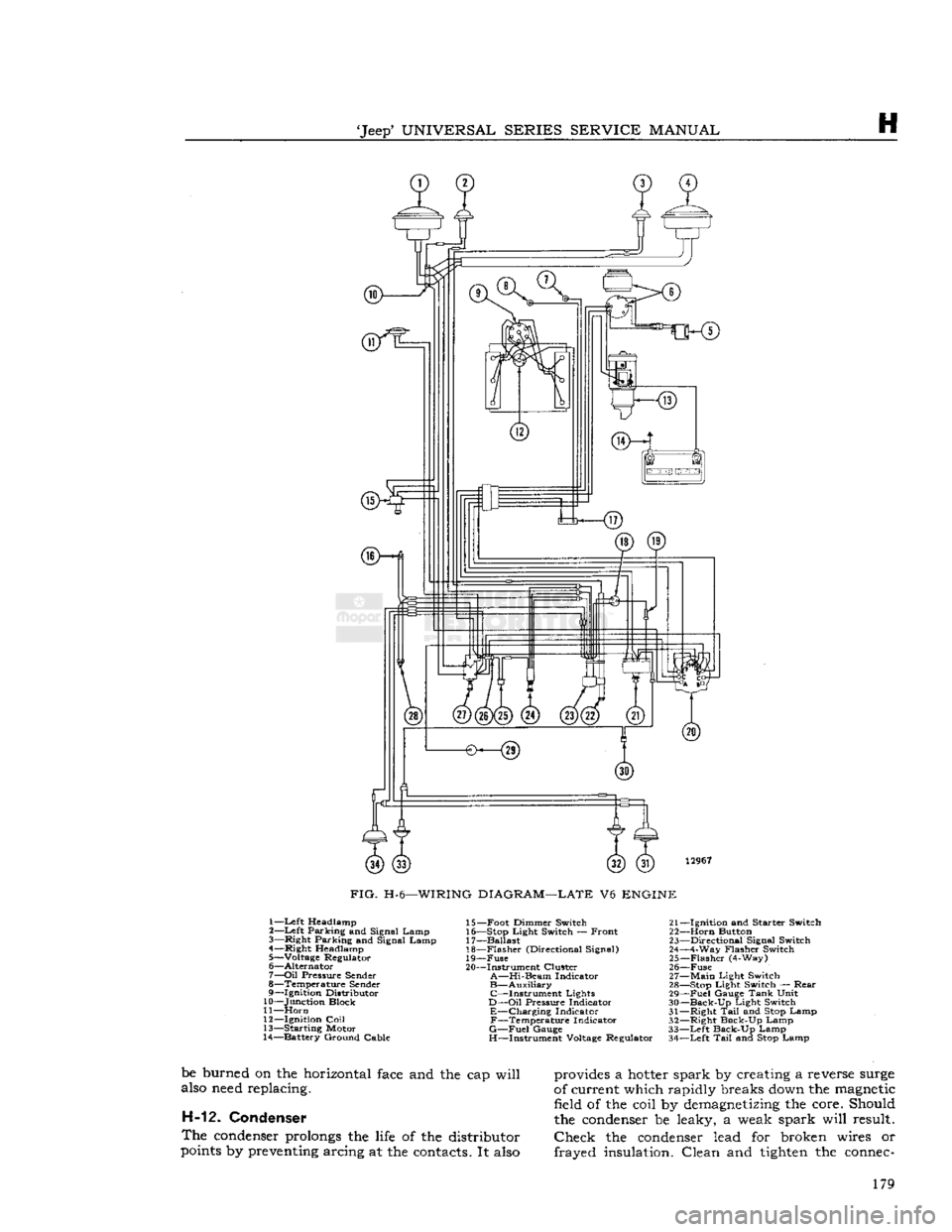

FIG.

H-6—WIRING

DIAGRAM—LATE

V6

ENGINE

1—Left Headlamp

2—

Left

Parking and Signal Lamp

3—

Right

Parking and Signal Lamp

4—

Right

Headlamp

5— Voltage Regulator

6—

Alternator

7—

Oil

Pressure

Sender

8— Temperature

Sender

9—

Ignition

Distributor

10— Junction Block

11—

Horn

12—

Ignition

Coil

13— Starting Motor

14— Battery Ground Cable 15— Foot Dimmer Switch 21-

16— Stop

Light

Switch — Front 22-

17— Ballast 23-

18—

Flasher

(Directional Signal) 24-

19—

Fuse

25-

20— Instrument Cluster 26-

A—Hi-Beam

Indicator 27-

B—Auxiliary

28- C—Instrument Lights 29-

D—Oil

Pressure

Indicator 30-

E—Charging Indicator 31-F—Temperature Indicator 32-

G—Fuel

Gauge

33-

H—Instrument Voltage Regulator 34-

-Ignition

and

Starter

Switch

-Horn

Button

-Directional

Signal Switch

-4-Way

Flasher

Switch

-Flasher

(4-Way)

-Fuse

-Main

Light

Switch

-Stop

Light

Switch —

Rear

-Fuel

Gauge

Tank

Unit

-Back-Up

Light

Switch

-Right

Tail

and Stop Lamp

-Right

Back-Up Lamp

-Left

Back-Up Lamp

-Left

Tail

and Stop Lamp

be burned on the horizontal

face

and the cap will

also

need

replacing. H-12. Condenser

The

condenser

prolongs

the

life

of the distributor

points

by

preventing

arcing at the

contacts.

It

also

provides

a

hotter

spark by creating a reverse

surge

of current which rapidly breaks

down

the

magnetic

field of the coil by

demagnetizing

the core. Should

the

condenser

be leaky, a weak spark will result.

Check

the

condenser

lead for broken wires or

frayed insulation. Clean and

tighten

the

connec-

179

Page 180 of 376

H

ELECTRICAL

SYSTEM

ffKHs)

3—<§)

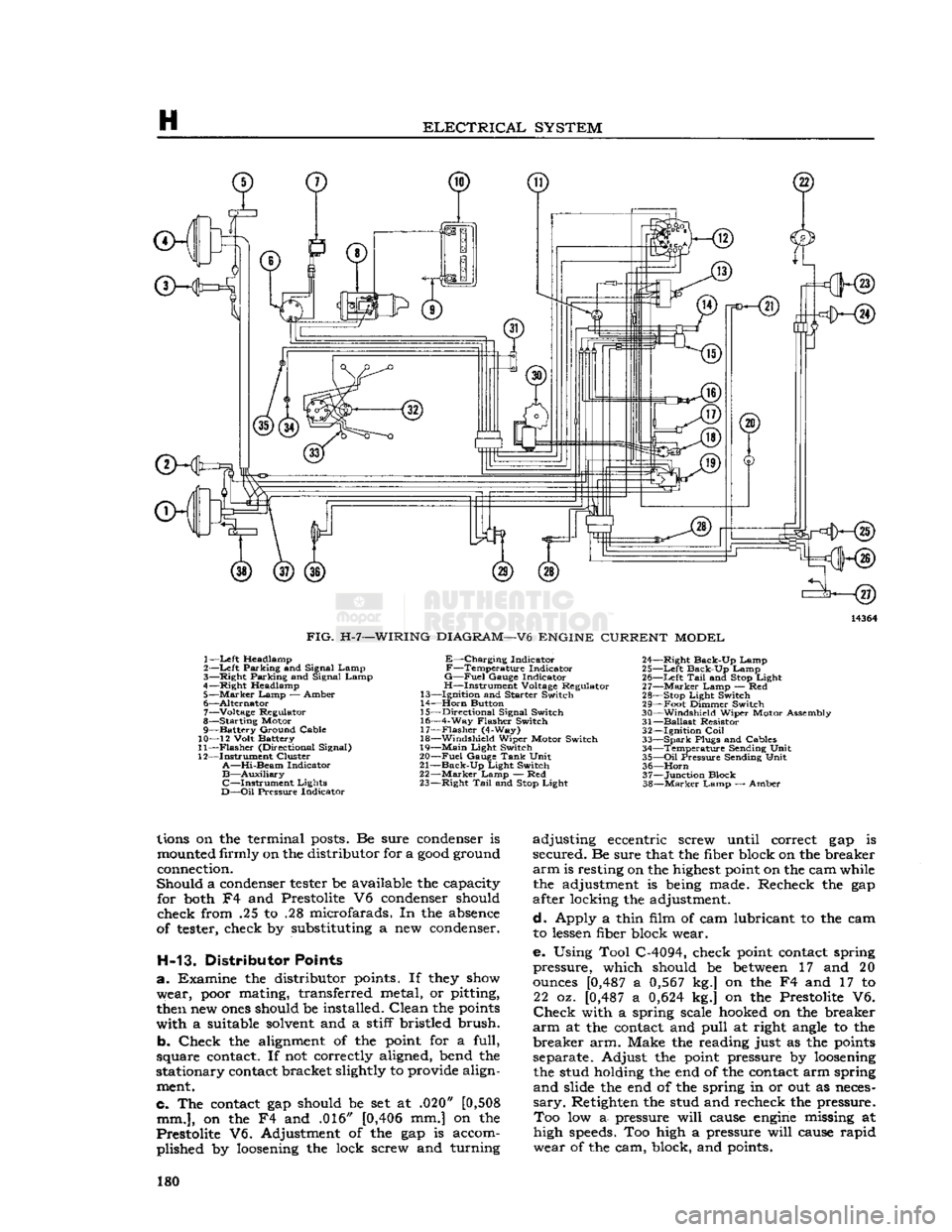

FIG.

H-7—WIRING

DIAGRAM—V6

ENGINE

CURRENT

MODEL

1—

Left

Headlamp

2—Left Parking and Signal Lamp

3— Right Parking and Signal Lamp

4—Right Headlamp 5—

Marker

Lamp — Amber

6— Alternator 7— Voltage Regulator

8— Starting Motor

9— Battery Ground Cable

10— 12 Volt Battery

11—

Flasher

(Directional Signal)

12— Instrument Cluster

A—Hi-Beam

Indicator

B—Auxiliary

C—Instrument

Lights

D—Oil

Pressure Indicator

E—Charging

Indicator

F—Temperature

Indicator

G—Fuel

Gauge Indicator

H—Instrument Voltage Regulator

13— Ignition and Starter Switch

14—

Horn

Button

15— Directional Signal Switch

16— 4-Way Flasher Switch 17—

Flasher

(4-Way)

18— Windshield Wiper Motor Switch

19—

Main

Light Switch

20—

Fuel

Gauge

Tank

Unit

21—

Back-Up

Light Switch

22—

Marker

Lamp — Red

23— Right

Tail

and

Stop

Light 24— Right Back-Up Lamp

25—

Left

Back-Up Lamp 26—

Left

Tail

and

Stop

Light

27—

Marker

Lamp — Red

28—

Stop

Light Switch

29— Foot Dimmer Switch

30— Windshield Wiper Motor Assembly

31—

Ballast

Resistor 32— Ignition

Coil

33—

Spark

Plugs and Cables 34— Temperature Sending Unit

35—

Oil

Pressure Sending Unit 36—

Horn

37— Junction Block

38—

Marker

Lamp — Amber

lions

on the terminal

posts.

Be sure

condenser

is

mounted

firmly on the distributor for a

good

ground

connection.

Should a

condenser

tester

be available the capacity for

both

F4 and Prestolite V6

condenser

should

check from .25 to .28 microfarads. In the

absence

of

tester,

check by substituting a new

condenser.

H-13. Distributor Points

a. Examine the distributor

points.

If

they

show

wear,

poor

mating, transferred metal, or pitting,

then

new

ones

should be installed. Clean the

points

with a suitable

solvent

and a stiff bristled brush.

b. Check the

alignment

of the

point

for a full,

square

contact.

If not correctly aligned, bend the

stationary

contact

bracket slightly to provide align

ment.

c. The

contact

gap should be set at .020"

[0,508

mm.],

on the F4 and .016"

[0,406

mm.] on the

Prestolite V6. Adjustment of the gap is accom plished by

loosening

the lock screw and turning adjusting eccentric screw until correct gap is

secured. Be sure that the fiber block on the breaker

arm

is resting on the

highest

point

on the cam while the adjustment is

being

made. Recheck the gap

after locking the adjustment.

d. Apply a thin film of cam lubricant to the cam to

lessen

fiber block wear.

e. Using Tool C-4094, check

point

contact

spring

pressure, which should be

between

17 and 20

ounces

[0,487

a

0,567

kg.] on the F4 and 17 to 22 oz.

[0,487

a

0,624

kg.] on the Prestolite V6.

Check

with a spring scale

hooked

on the breaker

arm

at the

contact

and pull at right

angle

to the

breaker arm. Make the reading just as the

points

separate. Adjust the

point

pressure by

loosening

the stud holding the end of the

contact

arm spring

and slide the end of the spring in or out as

neces

sary.

Retighten the stud and recheck the pressure. Too low a- pressure will

cause

engine

missing at

high

speeds.

Too high a pressure will

cause

rapid

wear of the cam, block, and

points.

180

Page 194 of 376

H

ELECTRICAL

SYSTEM H-61.

Test Nine

Operate

at a medium speed with the jumper re moved. Remove the regulator cover and hold the

voltage

regulator contacts closed.

a.

Voltage builds up—voltage regulator contacts

burned

or dirty or incorrect regulator setting.

Clean

the contacts and adjust the regulator as in

Par.

H-47d.

b.

Voltage

does

not build up—clean contacts and

repeat

test.

If the

voltage

still

does

not build up, see

test

10.

H-62.

Test Ten

Remove the regulator cover and hold the current

regulator contacts closed.

a.

Voltage builds up—current regulator contacts

burned

or dirty or incorrect regulator setting.

Clean

the contacts and adjust the regulator as in

Par.

H-47d.

b.

Voltage

does

not build up—clean the contacts

and

repeat the

test.

If the

voltage

still

does

not

build

up remove the regulator for an overhaul.

H-63. ALTERNATOR CHARGING SYSTEM

Most vehicles have, as standard equipment, a 35-

amp.,

12-volt, negative ground alternator and a

transistorized

voltage

regulator.

The

alternator charging circuit consists of the

battery, alternator,

voltage

regulator, ignition

switch,

and charge indicator light.

An

alternator differs from a conventional DC

shunt generator in that the armature is stationary,

and

is called the stator, while the field rotates,

and

is called the rotor.

With

the alternator con

struction,

the higher current values involved in

the stator may be conducted to the external circuit through fixed leads and connections, rather than

through a rotating commutator and brushes, as in the DC generator.

The

alternator employs a three-phase stator

winding. The rotor consists of a field coil encased

between

six poled interleaved sections, producing

a

twelve

pole

magnetic field with alternator north

and

south poles. By rotating the rotor inside the stator, an alternating current is induced in the stator windings.

This

alternating current is

changed to direct current by

diodes

and conducted

to the output terminal of the alternator.

Six

silicon

diode

rectifiers act as electrical one-way valves.

Three

of the

diodes

have negative polarity

and

are grounded. The other three

diodes

have

positive polarity and connected to the output

terminal.

In all alternators discussed in this

manual,

the

diodes

are pressed into heat sinks.

There

are two heat sinks, one positive and the

other negative.

Since

the

diodes

have a high resistance to the

flow of

current

in one direction and a low resistance

in

the

opposite

direction, they are connected in a

manner

which allows current to flow from the

alternator to the battery in the low resistance

direction.

The high resistance in the

opposite

direction prevents the flow of current from the

battery to the alternator. Because of this feature,

no

circuit

breaker

is

required

between

the alternator

and

the battery.

Residual

magnetism in the rotor field

poles

is

negligible. Therefore the starting field current must be supplied by the battery. It is connected

to the field winding through the ignition switch

and

charge indicator lamp.

As

in the DC shunt generator, the alternator

voltage

is regulated by varying the field current.

In

these

alternator systems, this is accomplished

electronically in the transistorized

voltage

reg

ulator.

No current regulator is required since all

alternators have self-limiting current character

istics.

The

entire DC output of the alternator has to pass

through the isolation diode. The isolation

diode

is

not essential for rectification. Its purpose is threefold.

It

provides automatic solid

state

switch for

illumi

nating the alternator charge

-

discharge indicator

light when the alternator is not charging properly.

It

automatically connects the

voltage

regulator to

the alternator and battery when the alternator is

operating.

It

eliminates electrical leakage across the alternator

diodes

so that leakage is negligible when the vehicle

is not in use.

The

isolation

diode

is mounted in a separate alumi

num

heat sink. The 35-amp. alternator has a single

silicon diode. The alternator is designed to supply the electrical demands of the battery and the

accessory circuits through a wide range of

engine

speeds. The alternator is lighter and more compact

than

a conventional DC shunt generator of com

parable

electrical size.

The

principal

components of the alternator are

the stator, the rotor, the slip ring end head, the

drive

end head, the

diode

rectifiers, and the isolation diode.

a.

The stator consists of a laminated iron core on

which

the three-phase windings are wound in

slots

around

the inside circumference. A

pair

of leads

are

connected to each of the three points of the

winding. One of each

pair

of leads connects to a

negative

diode

rectifier and one to a positive

diode

rectifier.

b.

The rotor consists of a single field coil encased

between

two six-fingered, interleaved iron sections assembled to the shaft. The two ends of the field

coil

are connected to two slip rings which are in

sulated from each other and from the shaft.

c. The slip ring end head supports the rectifier heat sinks; a prelubricated sealed

ball

bearing, in

which

the rotor shaft rotates; and the brush holders

and

brushes.

d.

The drive end head supports a prelubricated

sealed

ball

bearing in which the drive end of the rotor shaft rotates.

e. The

diode

rectifiers are pressed in the rectifier brackets or heat sinks and are connected to the

stator leads.

f. The isolation

diode

is pressed in the aluminum heat sink mounted to the

rear

of the alternator. The

complete assembly is covered with a red insulating coating.

For

repairing the alternator, many of its major components are furnished as complete assemblies

including:

complete brush assembly which requires 194

Page 195 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

H

no soldering or unsoldering of leads; two complete

rectifying

diode assemblies

which

eliminate the need

for removing and replacing individual diodes; a

corpplete isolation diode assembly; and a rotor

assembly complete with shaft,

pole

pieces, field

coil,

and slip rings.

The

transistorized

voltage

regulator is an electronic

switching device. It

senses

the

voltage

appearing

at the auxiliary terminal of the alternator and

supplies the necessary field current for maintaining

the system

voltage

at the output terminal. The

output current is determined by the battery electri

cal

load; such as headlights, heater, etc.

The

transistorized

voltage

regulator is a sealed

unit,

has no adjustments, and must be replaced

as a complete unit.

H-64. ALTERNATOR

PRECAUTIONS

The

following precautions must be observed to

prevent damage to the alternator and regulator.

a.

Never reverse battery connections. Always

check

the battery polarity with a voltmeter before

any

connections are made to be sure that all con

nections correspond to the battery ground polarity of the vehicle.

b.

Booster batteries for starting must be properly

connected. Make sure that the negative cable of

the booster battery is connected to the negative

terminal

of the battery in the vehicle. The positive

cable of the booster battery should be connected

to the positive terminal of the battery in the

vehicle.

c.

Disconnect the battery cables before using a fast charger.

d.

Never use a fast charger as a booster for

starting

the vehicle.

e.

Never disconnect the

voltage

regulator while

the

engine

is running.

f.

Do not ground the alternator output terminal.

g.

Do not operate the alternator on an open

circuit

with

the field energized.

h.

Do not attempt to polarize an alternator.

These

precautions are stated here as an aid to

service

personnel. They are also restated at appro

priate

places in the

text

of this section of the

manual.

H-65. ALTERNATOR

CHARGING

SYSTEM SERVICE

Important:

All alternator

tests

for the 35, 40 and

55 amp alternator are the same, however, there is a

difference

between

the location of the various ter

minals

and field current specifications. The field

current

of the 35 amp alternator should be 1.7 to 2.3 amps, 40 and 55 amp alternators should be 1.8

to 2.4 amps, with

full

battery

voltage

applied to

the filed coil. Disassembly and assembly procedures

are

the same for all three alternators.

Terminal

locations and wire harness color

codes

for the 35,

40 and 55 amp alternator are shown in Fig. H-38.

H-66.

Service Diagnosis

In

diagnosing a suspected malfunction of the

alternator

charging system, consideration must

be given to the complete electrical power plant of the vehicle; including the alternator, regulator,

ignition switch, charge indicator lamp, battery,

and

all associated wiring. If it is suspected that the

alternator

is not fully charging the battery and

fulfilling

the electrical requirements of the electrical

system, several checks should be made before

checking

the alternator itself:

Note:

Whenever service is required in connection

with

an alternator problem, the first

step

should be to verify that the wiring harness hook-up is correct

as indicated in Fig. H-38.

a.

Test the condition of the battery and

state

of

charge

(Par. H-2).

If the battery is not fully charged

and

in

good

condition, use a replacement battery

for making alternator system

tests.

Caution:

Make certain that the negative battery

post

is connected to ground when making the

battery installation. Serious damage to the alter

nator

can result if battery polarity is reversed.

b.

Check

fan belt for proper tension (Par.

C-27).

Caution:

To increase belt tension, apply pressure

to alternator front housing only as permanent damage can result if pressure is applied to

rear

housing.

H-67.

Alternator In Vehicle Tests

The

following

tests

are made with the alternator

in

the vehicle with output and regulator connec

tions maintained to the alternator except as noted

in

Fig. H-27 and H-28. The field plug and

voltage

regulator are disconnected for

these

tests.

The

tests

are given in proper order and detail in the

following paragraphs.

a.

Isolation Diode Test: To determine if the isola

tion diode is open or shorted, refer to Par. H-69.

b.

Alternator Output Test: To isolate the trouble

to the alternator or regulator, refer to Par. H-70.

c.

Alternator

Field

Circuit

Test: To determine the condition of the field

circuit

(brushes and rotor),

refer

to Par. H-73.

d.

Brush

Insulation

and Continuity

Test:

To deter

mine the condition of the

brush,

refer to

Par.

H-75.

e.

Rotor In-Vehicle Test: To determine whether

the rotor coil is open or shorted, refer to

Par.

H-73.

f. Any further

tests

must be conducted with the

alternator

removed and disassembled. When this

is done, the condition of the rotor, the rectifying

and

isolation diodes, and the stator can be further

tested.

A

commercial alternator tester Sun

Electric

Model

VAT-20

or equivalent can be used to make all

necessary

tests

on the alternator system. If a com

mercial

tester is used, follow the recommended

testing procedure outlined by the tester manu

facturer.

If

a commercial tester is not available, follow the

testing procedure as outlined in this manual.

H-68.

Test Equipment

a.

Volt Ampere Tester such as Sun

Electric

Model

VAT-20

or equivalent with meter ranges as shown

in

the following list can be used. 195

Page 196 of 376

H

ELECTRICAL

SYSTEM DC

ammeter — 0 to 60 ampere

DC

ammeter — 0 to 5 ampere

DC

voltmeter — 0 to 16 volt

Rheostat — 40 ohm capable of

handling

3 amps.

Carbon

Pile — 45 amperes

b.

Diode Rectifier Tester C-3829.

c.

12-volt DC

test

lamp.

d.

Ohmmeter of any commercial type is not absolutely necessary but can be helpful.

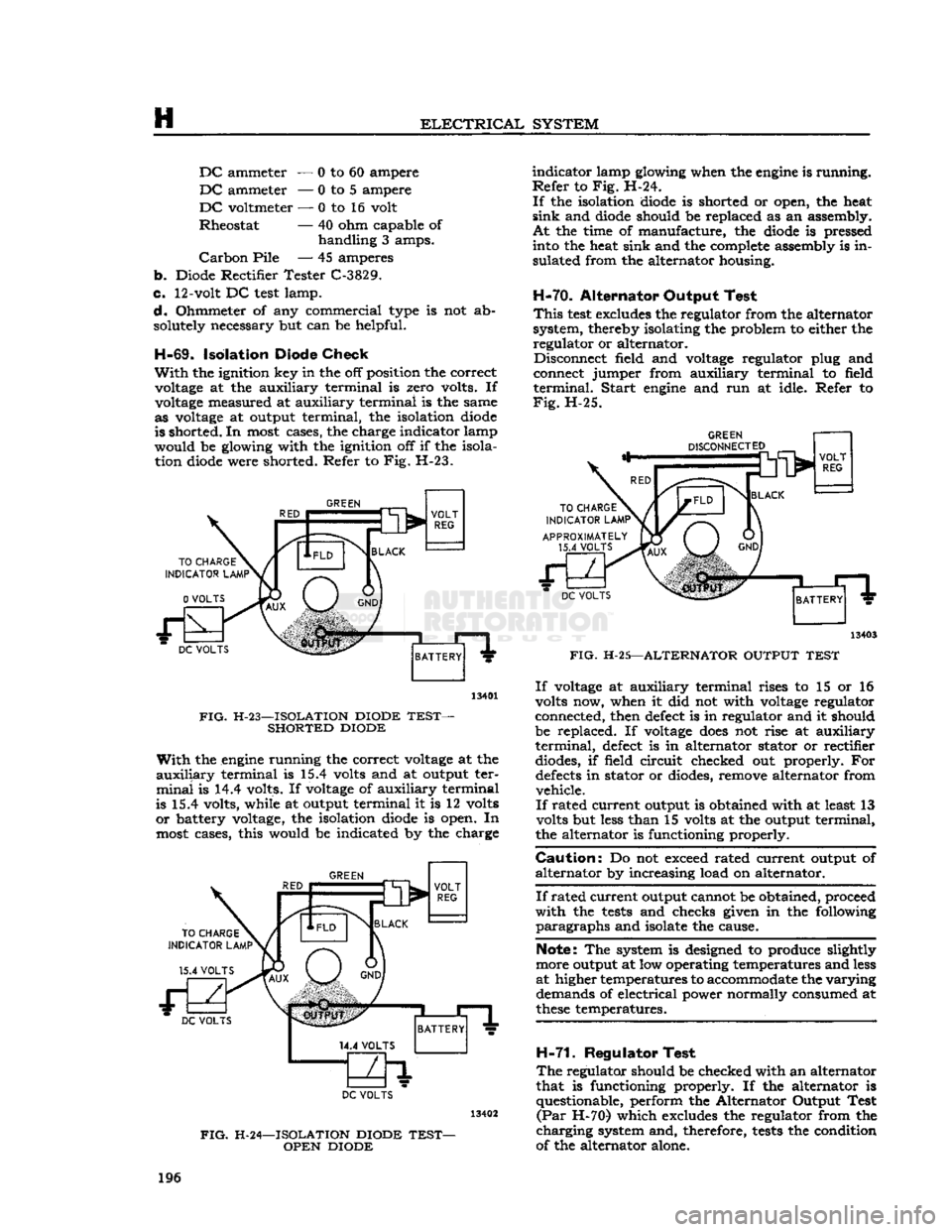

H-69.

Isolation Diode

Check

With

the ignition key in the off position the correct voltage at the auxiliary terminal is zero volts. If

voltage measured at auxiliary terminal is the same as voltage at output terminal, the isolation diode

is shorted. In most cases, the charge indicator lamp

would be glowing with the ignition off if the isola tion diode were shorted. Refer to Fig. H-23.

GREEN

DC

VOLTS

13401

FIG.

H-23—ISOLATION DIODE

TEST-

SHORTED DIODE

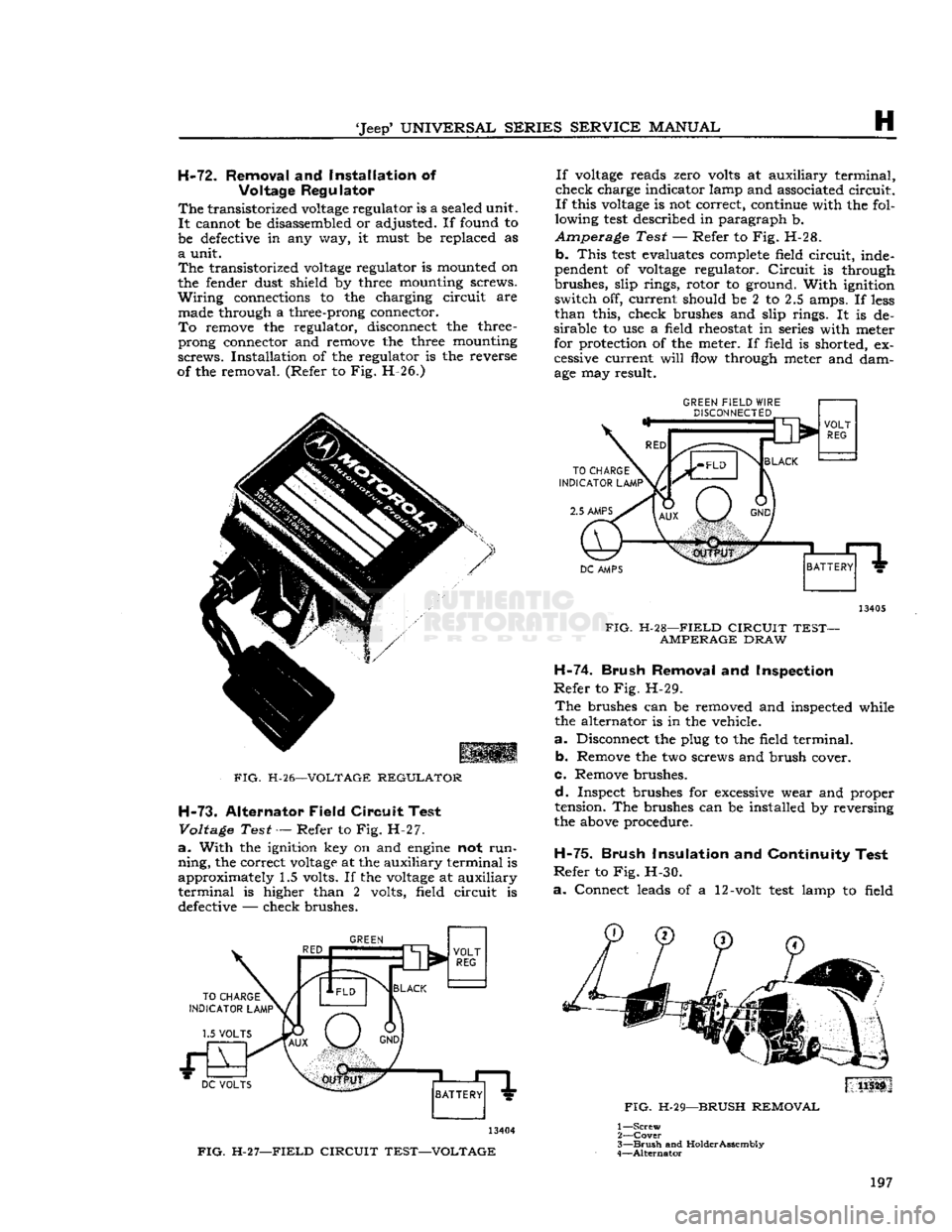

With

the engine running the correct voltage at the

auxiliary

terminal is 15.4 volts and at output ter

minal

is 14.4 volts. If voltage of auxiliary terminal

is 15.4 volts, while at output terminal it is 12 volts

or

battery voltage, the isolation diode is open. In

most cases, this would be indicated by the charge

GREEN

TO

CHARGE

INDICATOR

LAMP1

15.4

VOLTS BLACK

VOLT

REG DC

VOLTS

BATTERY

DC

VOLTS

FIG.

H-24—ISOLATION DIODE

TEST-

OPEN DIODE

indicator

lamp glowing when the engine is running.

Refer

to Fig. H-24.

If

the isolation diode is shorted or open, the heat

sink

and diode should be replaced as an assembly.

At

the time of manufacture, the diode is pressed into the heat sink and the complete assembly is in

sulated from the alternator housing.

H-70.

Alternator Output Test

This

test

excludes the regulator from the alternator

system, thereby isolating the problem to either the regulator or alternator. Disconnect field and voltage regulator plug and

connect jumper from auxiliary terminal to field

terminal.

Start

engine and run at idle. Refer to

Fig.

H-25.

DC

VOLTS

13403

FIG.

H-25—ALTERNATOR OUTPUT

TEST

If

voltage at auxiliary terminal rises to 15 or 16

volts now, when it did not with voltage regulator

connected, then defect is in regulator and it should

be replaced. If voltage

does

not rise at auxiliary

terminal,

defect is in alternator stator or rectifier diodes, if field circuit checked out properly. For

defects

in stator or diodes, remove alternator from vehicle.

If

rated current output is obtained with at least 13

volts but less than 15 volts at the output terminal,

the alternator is functioning properly.

Caution:

Do not exceed rated current output of

alternator

by increasing load on alternator.

If

rated

current

output cannot be obtained, proceed

with

the

tests

and checks given in the following

paragraphs

and isolate the cause.

Note: The system is designed to produce slightly

more output at low operating temperatures and less

at higher temperatures to accommodate the

varying

demands of electrical power normally consumed at

these

temperatures.

H-71.

Regulator Test

The

regulator should be checked with an alternator

that is functioning properly. If the alternator is questionable, perform the Alternator Output Test

(Par

H-70) which excludes the regulator from the

charging

system and, therefore,

tests

the condition

of the alternator alone. 196

Page 197 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

H

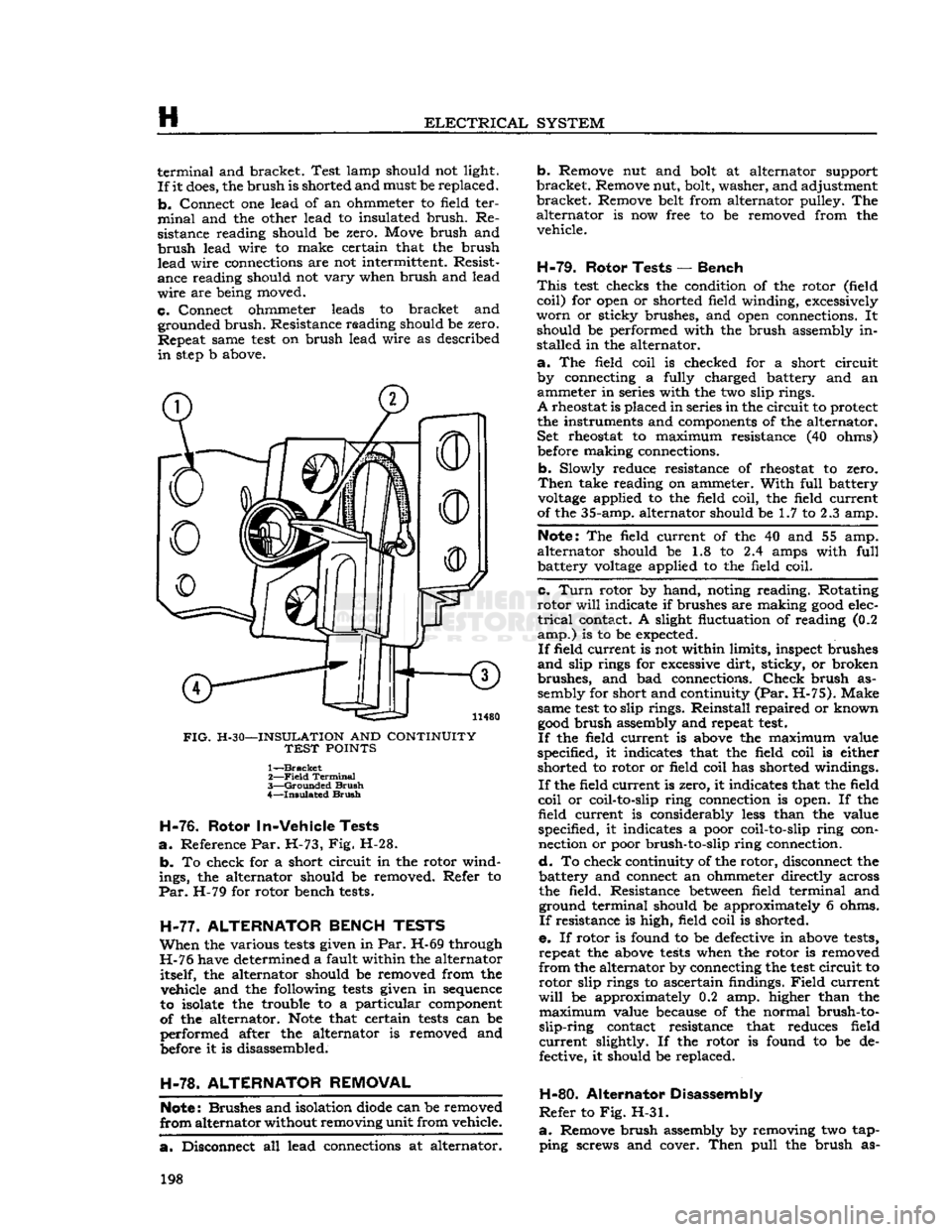

H-72.

Removal

and

Installation

of

Voltage Regulator

The

transistorized

voltage

regulator is a sealed unit.

It

cannot be disassembled or adjusted. If found to

be defective in any way, it must be replaced as

a

unit.

The

transistorized

voltage

regulator is mounted on

the fender dust shield by three mounting screws.

Wiring

connections to the charging circuit are made through a three-prong connector.

To

remove the regulator, disconnect the three

-

prong connector and remove the three mounting

screws.

Installation of the regulator is the reverse

of the removal. (Refer to Fig. H-26.)

FIG.

H-26—VOLTAGE

REGULATOR

H-73.

Alternator Field Circuit Test

Voltage

Test — Refer to Fig. H-27.

a.

With the ignition key on and

engine

not

run

ning,

the correct

voltage

at the auxiliary terminal is

approximately 1.5 volts. If the

voltage

at auxiliary

terminal

is higher than 2 volts, field circuit is defective — check brushes.

GREEN

13404

FIG.

H-27—FIELD

CIRCUIT TEST—VOLTAGE If

voltage

reads zero volts at auxiliary terminal,

check charge indicator lamp and associated circuit.

If

this

voltage

is not correct, continue with the fol

lowing

test

described in paragraph b.

Amperage Test — Refer to Fig. H-28. b.

This

test

evaluates complete field circuit, inde

pendent of

voltage

regulator.

Circuit

is through

brushes, slip rings, rotor to ground. With ignition switch off, current should be 2 to 2.5 amps. If

less

than

this, check brushes and slip rings. It is de

sirable

to use a field rheostat in series with meter

for protection of the meter. If field is shorted, ex

cessive current

will

flow through meter and dam

age may result.

GREEN

FIELD

WIRE

DISCONNECTED

13405

FIG.

H-28—FIELD

CIRCUIT TEST- AMPERAGE

DRAW

H-74.

Brush Removal

and

Inspection

Refer

to Fig. H-29.

The

brushes can be removed and inspected while

the alternator is in the vehicle.

a.

Disconnect the plug to the field terminal. b. Remove the two screws and brush cover.

c. Remove brushes.

d.

Inspect brushes for excessive wear and proper

tension. The brushes can be installed by reversing

the above procedure.

H-75.

Brush Insulation

and

Continuity Test

Refer

to Fig. H-30.

a.

Connect leads of a 12-volt

test

lamp to field

FIG.

H-29—BRUSH

REMOVAL

1—

Screw

2—

Cover

3—

Brush

and

Holder

Assembly

4—

Alternator

197

Page 198 of 376

H

ELECTRICAL

SYSTEM

terminal

and bracket. Test lamp should not light.

If

it

does,

the

brush

is shorted and must be replaced,

b.

Connect one lead of an ohmmeter to field ter

minal

and the other lead to insulated brush. Re

sistance reading should be zero. Move brush and

brush

lead wire to make certain that the brush lead wire connections are not intermittent. Resist

ance reading should not vary when brush and lead

wire

are being moved.

C.

Connect ohmmeter leads to bracket and grounded brush. Resistance reading should be zero.

Repeat same

test

on brush lead wire as described

in

step

b above.

FIG.

H-30—INSULATION

AND

CONTINUITY

TEST

POINTS

1^-Brackct

2—

Field

Terminal

3—

Grounded

Brush

4—

Insulated

Brush

H-76.

Rotor

In-Vehicle

Tests

a.

Reference Par. H-73, Fig. H-28.

b.

To check for a short circuit in the rotor wind

ings, the alternator should be removed. Refer to

Par.

H-79 for rotor bench

tests.

H-77.

ALTERNATOR

BENCH

TESTS

When

the various

tests

given in

Par.

H-69 through

H-76 have determined a fault within the alternator itself, the alternator should be removed from the vehicle and the following

tests

given in

sequence

to isolate the trouble to a particular

component

of the alternator.

Note

that certain

tests

can be

performed after the alternator is removed and

before

it is disassembled.

H-78.

ALTERNATOR

REMOVAL

Note:

Brushes and isolation

diode

can be removed

from

alternator without removing unit from vehicle.

a.

Disconnect all lead connections at alternator.

b.

Remove nut and

bolt

at alternator support

bracket.

Remove nut, bolt, washer, and adjustment

bracket.

Remove belt from alternator pulley. The alternator is now free to be removed from the

vehicle.

H-79.

Rotor Tests

—

Bench

This

test

checks the condition of the rotor (field coil) for

open

or shorted field winding, excessively

worn

or sticky brushes, and

open

connections. It should be performed with the brush assembly in

stalled in the alternator.

a.

The field coil is checked for a short circuit

by connecting a fully charged battery and an ammeter in series with the two slip rings.

A

rheostat is placed in series in the

circuit

to protect

the instruments and

components

of the alternator. Set rheostat to maximum resistance (40 ohms)

before

making connections.

b.

Slowly reduce resistance of rheostat to zero.

Then

take reading on ammeter. With full battery

voltage

applied to the field coil, the field current

of the 35-amp. alternator should be 1.7 to 2.3 amp.

Note:

The field current of the 40 and 55 amp.

alternator should be 1.8 to 2.4 amps with full battery

voltage

applied to the field coil.

c.

Turn

rotor by hand, noting reading. Rotating

rotor

will

indicate if brushes are making

good

elec

trical

contact. A slight fluctuation of reading (0.2

amp.)

is to be expected.

If

field current is not within limits, inspect brushes

and

slip rings for

excessive

dirt, sticky, or broken

brushes, and bad connections.

Check

brush as sembly for short and continuity (Par. H-75). Make

same

test

to slip rings. Reinstall repaired or known

good

brush assembly and repeat

test.

If

the field current is

above

the maximum value

specified, it indicates that the field coil is either

shorted to rotor or field coil has shorted windings.

If

the field current is zero, it indicates that the field

coil

or coil-to-slip ring connection is open. If the field

current

is considerably

less

than the value

specified, it indicates a poor coil-to-slip ring con nection or poor brush-to-slip ring connection.

d.

To check continuity of the rotor, disconnect the

battery and connect an ohmmeter directly across

the field. Resistance

between

field terminal and ground terminal should be approximately 6 ohms.

If

resistance is high, field coil is shorted.

e.

If rotor is found to be

defective

in

above

tests,

repeat the

above

tests

when the rotor is removed

from

the alternator by connecting the

test

circuit

to rotor slip rings to ascertain findings.

Field

current

will

be approximately 0.2 amp. higher than the

maximum

value because of the normal brush-to-

slip-ring

contact resistance that reduces field

current

slightly. If the rotor is found to be de

fective, it should be replaced.

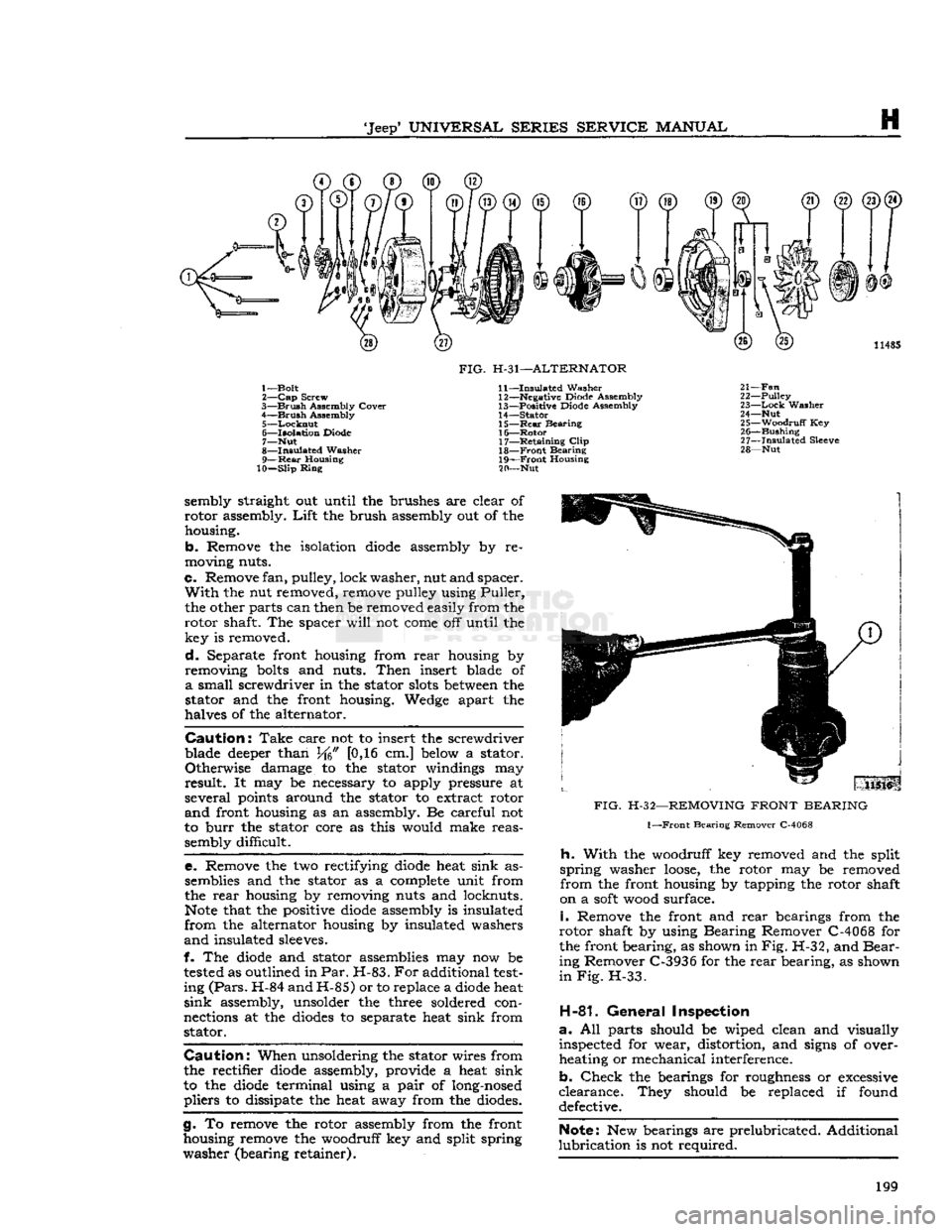

H-80.

Alternator Disassembly

Refer

to Fig. H-31.

a.

Remove brush assembly by removing two tap ping screws and cover. Then pull the brush as- 198

Page 199 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

H

©

© © ® (a

1—

Bolt

2— Cap

Screw

3—

Brush

Assembly

Cover

4—

Brush

Assembly

5—

Locknut

6—

Isolation

Diode 7— Nut

8—

Insulated

Washer

9—

Rear

Housing

10—Slip

Ring

FIG.

H-31—ALTERNATOR

11—

Insulated

Washer 12— Negative Diode Assembly

13—

Positive Diode Assembly

14—

Stator

15—

Rear

Bearing 16—

Rotor

17—

Retaining

Clip

18—

Front

Bearing

19—

Front

Housing

20— Nut 11485

21—

Fan

22—

Pulley

23—

Lock

Washer

24— Nut 25—

Woodruff

Key 26—

Bushing

27—

Insulated

Sleeve

28— Nut sembly straight out until the brushes are clear of

rotor

assembly.

Lift

the brush assembly out of the housing.

b.

Remove the isolation

diode

assembly by re

moving nuts.

c.

Remove fan, pulley, lock

washer,

nut and spacer.

With

the nut removed, remove pulley using

Puller,

the other parts can then be removed easily from the

rotor

shaft. The spacer

will

not

come

off until the key is removed.

d.

Separate front housing from

rear

housing by

removing

bolts

and nuts.

Then

insert blade of

a

small screwdriver in the stator

slots

between

the

stator and the front housing. Wedge apart the

halves of the alternator.

Caution:

Take

care not to insert the screwdriver

blade deeper than J/f6" [0,16 cm.] below a stator.

Otherwise

damage to the stator windings may

result.

It may be necessary to apply pressure at

several

points around the stator to extract rotor

and

front housing as an assembly. Be careful not

to

burr

the stator core as this would make reas sembly difficult.

e.

Remove the two rectifying

diode

heat sink assemblies and the stator as a complete unit from

the

rear

housing by removing nuts and locknuts.

Note

that the positive

diode

assembly is insulated

from

the alternator housing by insulated washers

and

insulated sleeves.

f. The

diode

and stator assemblies may now be

tested

as outlined in

Par.

H-83.

For

additional

test

ing

(Pars.

H-84 and H-85) or to replace a

diode

heat

sink

assembly, unsolder the three soldered con

nections at the

diodes

to separate heat sink from stator.

Caution:

When unsoldering the stator wires from

the rectifier

diode

assembly, provide a heat sink

to the

diode

terminal using a

pair

of long-nosed

pliers

to dissipate the heat away from the diodes.

g.

To remove the rotor assembly from the front

housing remove the woodruff key and split spring

washer

(bearing retainer).

FIG.

H-32—REMOVING

FRONT

BEARING

1—Front

Bearing Remover C-4068

h.

With

the woodruff key removed and the split

spring

washer

loose,

the rotor may be removed

from

the front housing by tapping the rotor shaft

on a

soft

wood surface.

i.

Remove the front and

rear

bearings from the

rotor

shaft by using Bearing Remover C-4068 for

the front bearing, as shown in

Fig.

H-32, and

Bear

ing Remover C-3936 for the

rear

bearing, as shown

in Fig.

H-33.

H-81.

General

Inspection

a.

All parts should be wiped clean and visually inspected for wear, distortion, and signs of over

heating or mechanical interference.

b.

Check

the bearings for roughness or excessive

clearance.

They should be replaced if found defective.

Note:

New bearings are prelubricated. Additional

lubrication

is not required. 199

Page 200 of 376

H

ELECTRICAL

SYSTEM

|

lists

>

FIG.

H-33—REMOVING

REAR

BEARING

1—

Rear

Bearing

2—

Rear

Bearing

Remover C-3936

The

alternator end housing may be

wiped

clean

with

a

cloth

dampened in solvent if excessively

dirty

but should not be

buffed

as this

will

destroy

special treatment given to

inhibit

corrosion.

H-82.

Out-Of-Circuit

Rotor Test

Refer

to

Pars.

H-76 and H-79 for

tests

to be per formed on the rotor. If

these

tests

were not performed while the alternator was assembled, they

can

be performed with the alternator removed by following the procedure given in

these

paragraphs.

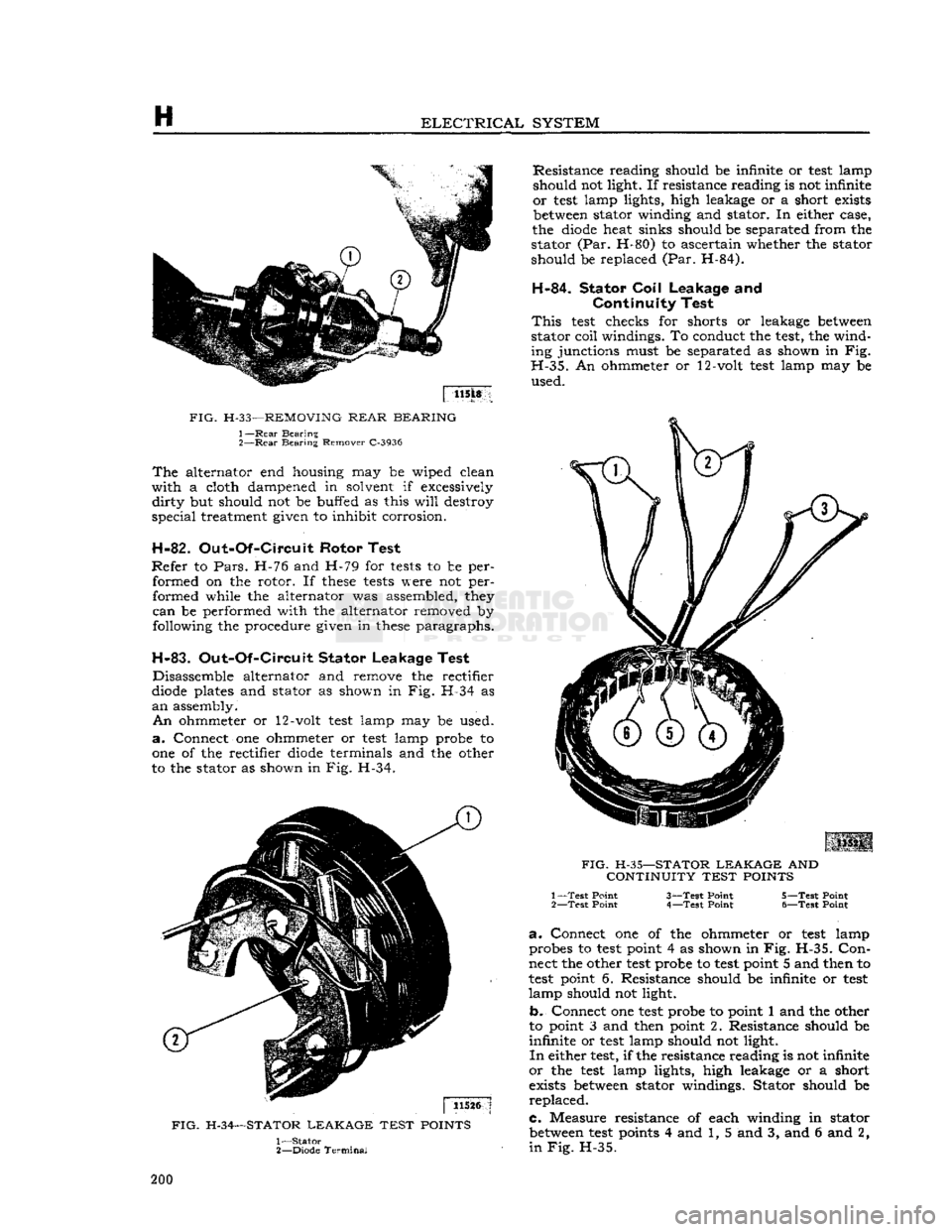

H-83.

Out-Of-Circuit

Stator Leakage Test Disassemble alternator and remove the rectifier

diode plates and stator as shown in Fig. H-34 as

an

assembly.

An

ohmmeter or 12-volt

test

lamp may be used,

a.

Connect one ohmmeter or

test

lamp probe to

one of the rectifier diode terminals and the other

to the stator as shown in Fig. H-34.

FIG.

H-34—STATOR

LEAKAGE

TEST

POINTS

1—

Stator

2—

Diode

Terminal

Resistance

reading should be infinite or

test

lamp

should not light. If resistance reading is not infinite

or

test

lamp lights, high leakage or a short exists between stator winding and stator. In either case,

the diode heat sinks should be separated from the

stator (Par. H-80) to ascertain whether the stator

should be replaced (Par. H-84).

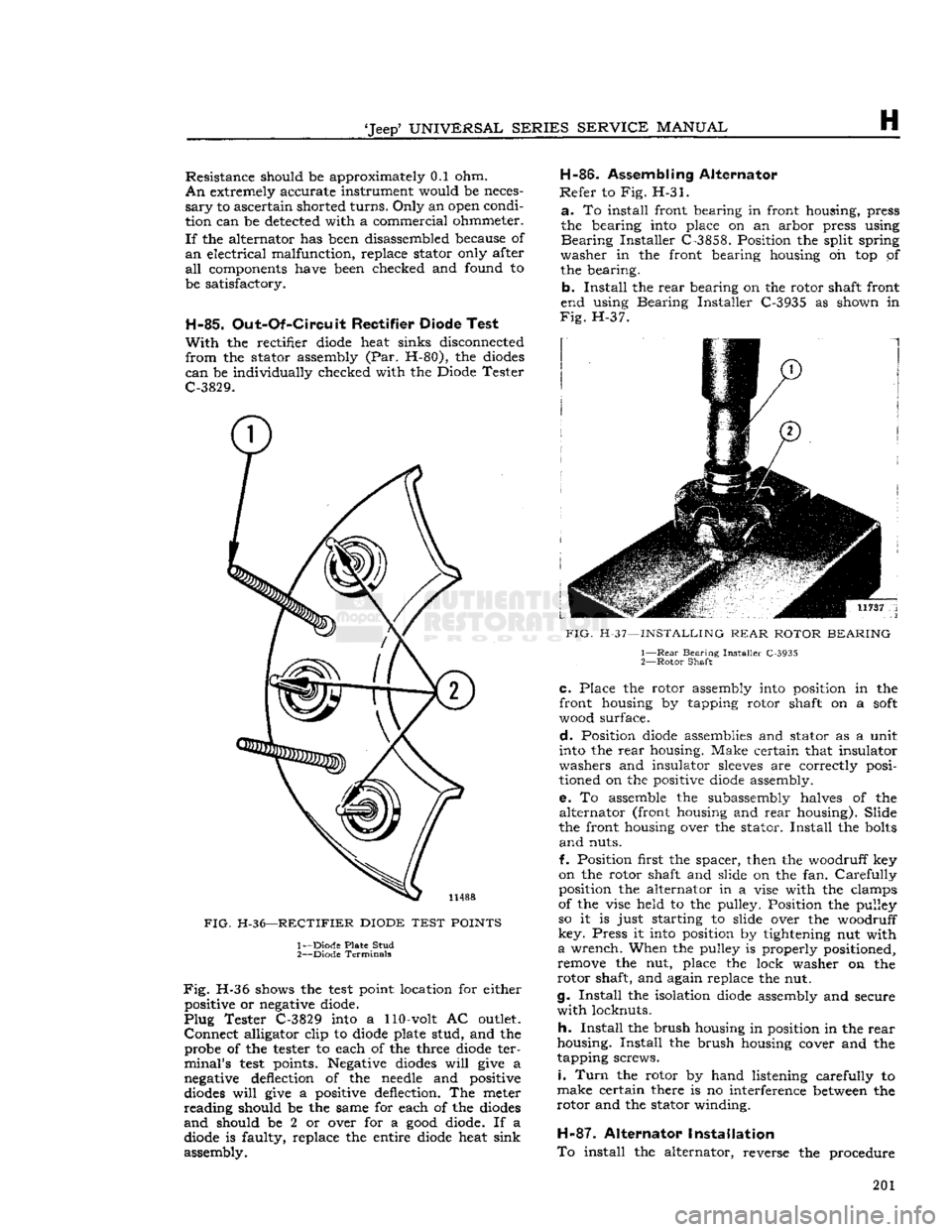

H-84.

Stator

Coil

Leakage and

Continuity

Test

This

test

checks for shorts or leakage between

stator coil windings. To conduct the

test,

the wind

ing junctions must be separated as shown in Fig.

H-35.

An ohmmeter or 12-volt

test

lamp may be used.

|

.11521 •

FIG.

H-35—STATOR

LEAKAGE

AND

CONTINUITY

TEST

POINTS 1—

Test

Point 3—Test Point 5—Test Point

2—

Test

Point 4—Test Point 6—Test Point

a.

Connect one of the ohmmeter or

test

lamp probes to

test

point 4 as shown in Fig. H-35.

Con

nect the other

test

probe to

test

point 5 and then to

test

point 6. Resistance should be infinite or

test

lamp

should not light.

b.

Connect one

test

probe to point 1 and the other

to point 3 and then point 2. Resistance should be infinite or

test

lamp should not light.

In

either

test,

if the resistance reading is not infinite

or

the

test

lamp lights, high leakage or a short

exists between stator windings. Stator should be

replaced.

c.

Measure resistance of each winding in stator between

test

points 4 and 1, 5 and 3, and 6 and 2,

in Fig.

H-35. 200

Page 201 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

H

Resistance

should be approximately 0.1 ohm.

An

extremely accurate instrument would be neces

sary

to ascertain shorted turns.

Only

an open condi

tion can be detected with a commercial ohmmeter.

If

the alternator has been disassembled because of

an

electrical malfunction, replace stator only after

all

components have been checked and found to

be satisfactory.

H-85.

Out-Of-Circuit

Rectifier Diode Test

With

the rectifier diode heat sinks disconnected

from

the stator assembly (Par. H-80), the diodes

can

be individually checked with the Diode Tester

C-3829.

FIG.

H-36—RECTIFIER

DIODE

TEST

POINTS

1— Diode Plate Stud

2—

Diode Terminals

Fig.

H-36 shows the

test

point location for either positive or negative diode.

Plug

Tester C-3829 into a 110-volt AC outlet.

Connect

alligator clip to diode plate stud, and the probe of the tester to each of the three diode ter

minal's

test

points. Negative diodes

will

give a

negative deflection of the needle and positive

diodes

will

give a positive deflection. The meter

reading

should be the same for each of the diodes

and

should be 2 or over for a

good

diode. If a diode is faulty, replace the entire diode heat sink

assembly. H-86.

Assembling Alternator

Refer

to Fig. H-31.

a.

To install front bearing in front housing, press

the bearing into place on an arbor press using

Bearing

Installer C-3858. Position the split spring

washer

in the front bearing housing oh top of the bearing.

b.

Install

the

rear

bearing on the rotor shaft front

end using Bearing Installer C-3935 as shown in

Fig.

H-37.

FIG.

H-37—INSTALLING

REAR

ROTOR

BEARING

1—

Rear

Bearing Installer C-3935

2—

Rotor

Shaft

C.

Place the rotor assembly

into

position in the

front housing by tapping rotor shaft on a

soft

wood surface.

d.

Position diode assemblies and stator as a unit

into the

rear

housing. Make certain that insulator

washers and insulator

sleeves

are correctly posi

tioned on the positive diode assembly.

e.

To assemble the subassembly halves of the

alternator

(front

housing and

rear

housing). Slide

the front housing over the stator.

Install

the bolts

and

nuts.

f. Position first the spacer, then the woodruff key

on the rotor shaft and slide on the fan.

Carefully

position the alternator in a vise with the clamps

of the vise held to the pulley. Position the pulley

so it is just starting to slide over the woodruff

key.

Press it into position by tightening nut with

a

wrench. When the pulley is properly positioned,

remove the nut, place the lock washer on the

rotor

shaft, and again replace the nut.

g.

Install

the isolation diode assembly and secure

with

locknuts.

h.

Install

the brush housing in position in the

rear

housing.

Install

the brush housing cover and the

tapping screws.

i.

Turn

the rotor by hand listening carefully to

make

certain there is no interference between the

rotor

and the stator winding.

H-87.

Alternator Installation

To

install the alternator, reverse the procedure 201