tow JEEP CJ 1953 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 30 of 376

c

TUNE-UP

meter during this

test

Connect the red lead

tc*

dis

tributor

primary

lead at the coil as shown in Fig.

C-21.

Connect black lead to the ground.

Turn

ignition switch on; with

engine

stopped, observe

dwell

meter. If the meter reads zero,

crank

the

engine

a fraction of a revolution to

close

the

breaker

points.

Distributor

resistance is normal, if dwell meter

pointer is within range of

black

bar. Distributor resistance is high, if

dwell

meter pointer is not

within

the black bar.

Remove test lead from

distri

butor terminal of coil and

connect

to

each

of the

following points to determine

where

the excessive resistance is:

Distributor

primary

terminal

Distributor

primary

terminal in the distributor

Breaker

point bracket

Ground

side of points

Distributor

housing

Where

a noticeable change occurs in the meter

reading

in

these

steps, make the necessary correc

tion and repeat the

test.

C-l 7. Distributor

Point

Dwell

Using

a dwell tester, connect red

lead

to the

distri

butor terminal at coil. Connect black lead to

ground.

Set selector switch to the number of

cylin

ders in the

engine

being tested. Operate

engine

speed at specified rpm. and

note

readings. Cam

dwell

angle must be 30° for the Dauntless V-6

Delco equipped engine, 29° ±: 3° Prestolite equipped

engine

and 42° for the

Hurricane

F4 engine. If the dwell reading is not to specifications,

trouble could be improper point spacing, point

rubbing,

defective block or breaker arm, or mis

aligned and worn distributor cam.

Adjust

dwell

as shown in Fig. C-14 for the Delco equipped

Dauntless V-6 engine. For cam dwell adjustment

of the Prestolite equipped V6 and

Hurricane

F4 engine, refer to Par. C-10,

step

a.

Dwell

variation is determined by noting any

dwell

change as the

engine

is operated at different

speeds.

Excessive

variation indicates a change in point opening that can result from shaft or bushing wear,

or

from the distributor plate shifting because of

wear

or

looseness.

Measure

dwell variation at idle speed, using same

test

hookup for checking dwell. Increase speed to 1750 rpm.;

note

dwell reading.

Then

slowly reduce

speed to idle while observing dwell meter. Dwell

variation

should not exceed 3°. If dwell variation

exceeds

3°

between

idle speed and 1750 rpm.,

probable wear in the distributor shaft, bushings, or

breaker

plate is indicated. Distributor should then be checked more thoroughly.

C-l8. Check Ignition Wires

and

Connections

Examine

and clean the insulation on all ignition

wires

and check all connections. Wires should be

firm,

flexible, and free from roughness and minute

cracks.

Bend wires to check for brittle,

cracked,

or

loose

insulation. Since defective insulation

will

per

mit

crossfiring or missing of the engine, defective

wires

should be replaced.

C-l9. Test Ignition

Cables

To

remove cables from

spark

plugs, use

Spark

Plug

Cable

Remover

Tool

W-274.

Twist

the

boot

slightly to break the seal and, grasping the rubber

protector

boot,

lift straight up with a steady even

pull.

Do not grasp the cable and

jerk

the cable off; this

will

damage the cables. Do not use a probe

on

these

wires; puncturing them may cause a

separation in the conductor. To remove ignition cables from the distributor cap or coil tower,

loosen

the nipple first, then grasp the upper part of the nipple and the cable and gently

pull

straight up.

Test

the cable with an ohmmeter. Resistance value

per

foot

is

3000-7000

ohms. The ignition cables

can

be checked for

circuit

continuity by removing

the cable from the

spark

plug and holding the cable

end Vi" [6,35 mm.] from the engine. A strong

spark

indicates

good

conductor continuity.

When

connecting the cable to the

spark

plug, be

certain

a

good

connection is made and that the

protector

boot

fits tight on the

spark

plug. A

partially

seated cable creates an additional gap in

the

circuit

and the resulting

spark

jump

will

cause

terminal

corrosion and cable damage.

C-20. Coil

When

an ignition coil is suspected of being defec tive, it should be checked on the car. A coil may

break

down after it has reached operating tempera

ture.

It is important that the coil be at operating

temperature when

tests

are made.

Note:

The ignition coil and ballast resistor for the

V-6

engine

must be of the same manufacturer.

Ballast

resistors and ignition coils of one manufac

turer

are interchangeable with both units of the

other.

C-21.

Service Air

Cleaner

Refer

to Par.

B-2 2

for the correct service of the

air

cleaner.

C-22.

Check Fuel Lines and

Screens

Check

all fuel line connections to guard against

leakage.

Check

fuel pump filter F4

engine

and

fuel

line filter V-6 engine. Replace fuel filter if

necessary.

C-23. Check Fuel Pump a.

Fuel

pump pressure is important, for low pres

sure

will

seriously affect

engine

operation and high

pressure

will

cause excessive fuel consumption and

possibly flood the carburetor. Should there be any doubt of normal operation, check the pressure with

a

gauge

as shown in Fig.

C-2 2.

The minimum and

maximum

allowable pressures are 2% to 3% lbs. [0,176 a

0,264

kg-cm2], for the

Hurricane

F4 en

gine.

Fuel

pump pressure at carburetor (inlet) on

the Dauntless V6-225

engine

should be 3% lbs.

[0,264

kg-cm2] minimum at specified

R.P.M.

idle

with

the vapor

return

hose

squeezed off.

With

the

vapor

return

hose

open pump pressure should be

2

V2

lbs. [0,176 kg-cm2] minimum.

b.

Test for volume, as a pump may build up suffi

cient pressure but

fail

to produce sufficient volume.

Turn

down the carburetor fuel line fitting on the

pump and with the tank line connected, pump out

30

Page 42 of 376

D

HURRICANE

F4

ENGINE

D-7.

Remove Water Pump

Remove the

bolts

and lockwashers that attach the

water pump to the cylinder block. Remove the water pump.

D-8.

Remove

Exhaust

Manifold

Remove the five nuts from the manifold studs.

Pull

the manifold off the mounting studs. Remove the center and two end gaskets from the cylinder

block. See Section Fl for exhaust emission con trolled engines.

D-9.

Remove Oil

Filler

Tube

Loop

a piece of wire several times around the tube

below the top and make a

loop

through which a

pry

bar may be used to pry over the top of the

engine

water

outlet

fitting.

Pull

on the tube, tapping it just above where it enters the crankcase.

D-10.

Remove Water Outlet Fitting

Remove the nuts and lockwashers that attach the

water

outlet

fitting to the cylinder head.

Lift

the

outlet

fitting from the cylinder head.

D-11.

Remove Thermostat

With

the water

outlet

fitting removed, the thermo

stat can be lifted from the water

outlet

elbow on the cylinder head.

D-12.

Remove

Crankshaft

Pulley

Remove the crankshaft nut.

Install

a puller and

pull

the pulley from the crankshaft.

D-13.

Remove Distributor

a.

Remove

spark

plug cables from the distributor

cap,

noting the order in which they are assembled to ensure correct reassembly. No. 1

spark

plug

terminal

is in the 5 o'clock position. Starting with this tower the cables are installed in a counterclockwise direction in

1-3-4-2

firing order.

b.

Remove the

primary

lead from the terminal

post

at the side of the distributor.

c. Remove the screw holding the distributor to the crankcase and lift the assembly from the engine.

D-14. Remove Oil Pump

The

oil pump is located externally on the left side

of the engine. If only the oil pump is being removed

with

the

engine

in the vehicle, set No. 1 piston at

TDC

for reference for reinstalling the oil pump

without greatly disturbing the ignition timing.

First

remove the distributor cover and

note

the

position of the distributor rotor.

If

the distributor is already removed, sight through

the distributor

hole

before removing the oil pump.

The

slot should be near vertical. Remove the capscrews and lockwashers attaching the oil pump

to the cylinder block.

Carefully

slide the oil pump

and

its drive shaft out of the cylinder block.

D-1S.

Remove

Crankcase

Ventilation Valve

To

remove the crankcase ventilation valve from

the elbow fitting screwed into the inlet manifold of the cylinder head, first remove the

hose

and

clamp from the valve (Fig. D-32), then using a

wrench

carefully unscrew the valve from the

elbow.

D-l6.

Remove Rooker Arm Assemblies

The

rocker arm cover was previously removed as

a

step

of the

engine

removal (Par. D-5).

Remove the nuts from the rocker arm shaft support

studs, and lift the rocker arm assembly off the studs.

Lift

the intake valve push rods out of the

cylinder

block.

D-17.

Remove

Cylinder

Head

a.

Removal.

Disconnect the oil line from the flared tube con

nector and remove the rocker arm attaching stud nuts, and rocker arm shaft assembly if not pre

viously removed. Two end head

bolts

cannot be removed until the rocker arm shaft is removed.

Remove the cylinder head bolts.

There

is one

cylinder

head bolt located below the carburetor

mounting, inside the intake manifold, that must

not be overlooked.

Carefully

lift the cylinder head off the block.

Remove the valve push rods and the valve lifters.

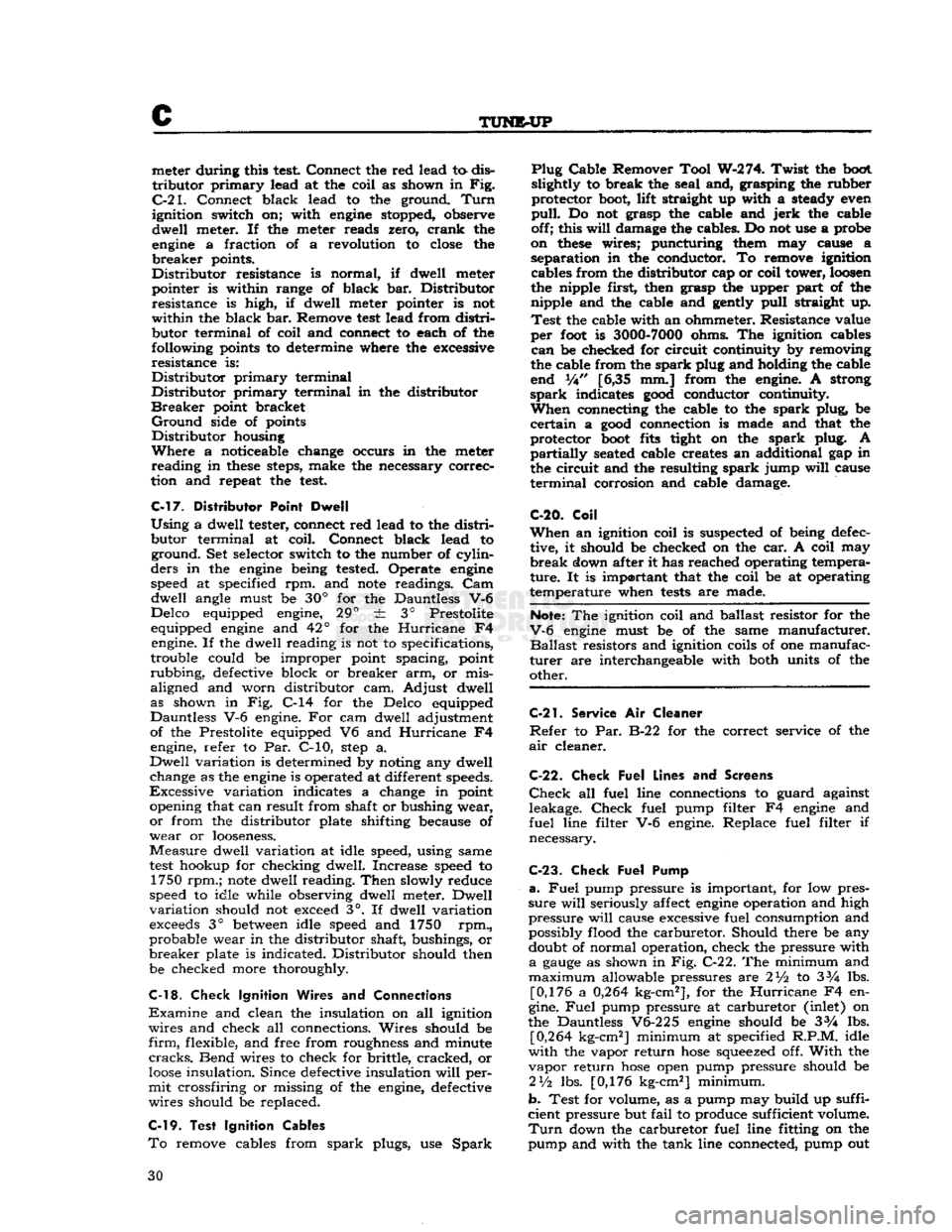

FIG.

D-3—REMOVING

RIDGE

WITH

REAMER

Remove and discard the cylinder head gasket,

b. Disassembly.

Disassemble the parts of the cylinder head as

follows:

With

a spring compressor tool remove the

two-piece

locks recessed in the valve spring re

tainers.

Pull

the

O-ring,

valve spring, and valve out

of the cylinder head. Identify the valves for return to the same

guides

from which they are removed.

42

Page 49 of 376

'Jeep'

UNIVERSAL SERIES

SERVICE

MANUAL

D

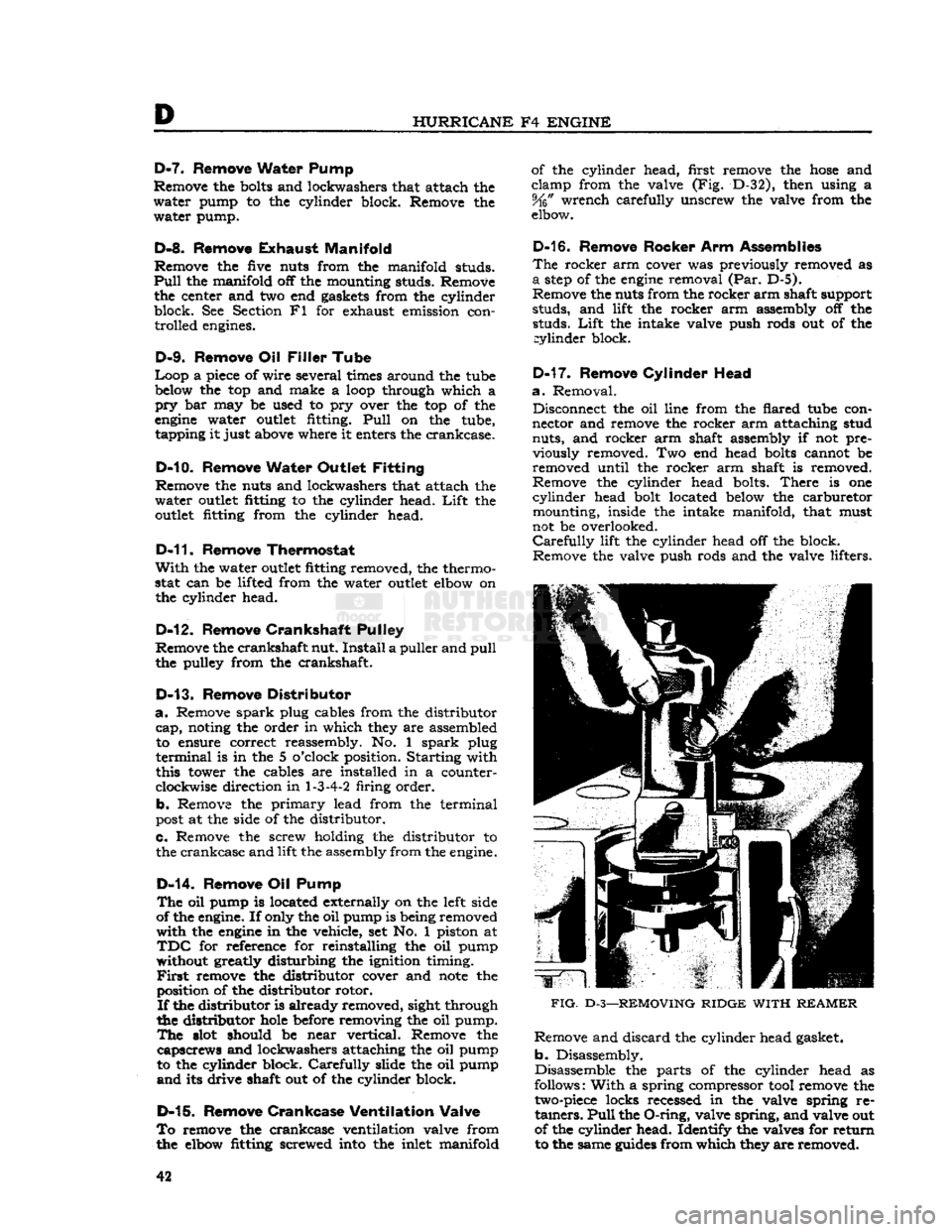

FIG.

D-ll—CHECKING PISTON

AND

CONNECTING

ROD

ALIGNMENT 1—

Feeler

Gauge

2—

Fixture

the

opposite

side from the oil spray

hole

in the

bearing

end of the connecting rod. See Fig. D-10.

Install

the piston pin lock screw and torque 35 to

41 lb-ft. [4,8 a 5,7 kg-m.].

d.

Place piston and rod assembly in a connecting

rod

aligning fixture and check alignment of the

assembly as shown in

Fig. D-ll.

Follow instructions

furnished

with the fixture.

e. Using a feeler

gauge

and new piston rings, check the width of the two compression ring

grooves

and

the oil ring groove. Replace the piston if the widths of the

grooves

are not with the limits given in

the specifications.

Insert

feeler

gauge

between

ring and piston to back

of groove. Replace piston if ring

grooves

are not

within

allowable tolerances. If a feeler

gauge

larger

FIG.

D-l 2—CHECKING PISTON RING

SIDE

CLEARANCE

1—

Feeler

Gauge

2—

Piston

Ring

FIG.

D-13—PISTON

RING

GAP

than

.006" [0,152 mm.] can be inserted

J^6"

[1,6

mm.]

between

piston and upper compression

ring,

groove

is worn excessively bell-mouthed and

piston should be replaced.

f.

Check

piston ring end gap by placing compres sion ring in cylinder bore below ring travel using head of an inverted piston as a plunger to push

ring

in squarely. End gap must be as shown in

Par.

D-37 for all rings. If less, file ends to obtain

minimum

gap.

With

cylinders bored to an exact

ring

oversize of

+.020", +.030",

or

+.040"

[0,508-

0,762-1,016

mm.] the proper end clearance as given in Par. D-37

will

result. If end

gaps

are

not within the limits given in Par.

D-3

7, rings are

of the wrong size or were incorrectly filed for fitting.

g.

Install

a new ring set using either production replacement rings or service type oil control rings.

Production

type replacement piston rings are the

same as the original factory-installed rings while

service oil control ring

sets

have different com

ponents, notably the oil ring expander. Follow

instructions of

manufacturer

for proper installation.

Use

a piston ring expander to install rings on pistons. Do not expand rings more than necessary

to install, also be careful not to

burr

the piston

with

ends of rings.

Install

bottom

(oil) ring first, center ring second, and top ring last.

The

width of the compression rings is [2,38

mm.] and that of the oil control ring is f^" [4,78

mm.].

While the compression rings are of the same

size, they are different in construction and must

not be interchanged.

Install

these

rings as shown

in

Fig. D-14. The upper compression ring has an

inside beveled

edge

which must be installed toward

the piston top. The face of the lower compression

ring

is tapered approximately .001" [0,025 mm.].

The

letters T or TOP on the upper

edge

indicate

how the ring is to be installed. 49

Page 51 of 376

![JEEP CJ 1953 Service Manual

-Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

E>

[5,928 a

5,926

cm.] for all main bearings. Allowable

taper or out-of-round of the journals is .001"

[0,0254

mm.].

D-42.

Checking Connecting Ro JEEP CJ 1953 Service Manual

-Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

E>

[5,928 a

5,926

cm.] for all main bearings. Allowable

taper or out-of-round of the journals is .001"

[0,0254

mm.].

D-42.

Checking Connecting Ro](/img/16/57040/w960_57040-50.png)

-Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

E>

[5,928 a

5,926

cm.] for all main bearings. Allowable

taper or out-of-round of the journals is .001"

[0,0254

mm.].

D-42.

Checking Connecting Rod

Crankpins

Check

the crankpin diameters with a micrometer

to ensure that they are not out-of-round or tapered more than .001"

[0,0254

mm.] The standard

crank-

pin

diameter is

1.9383*

to

1.9375"

[4,9233

a

4,9213

cm.].

D-43.

Crankshaft

Main

Bearings

The

crankshaft rotates on three main bearings

with

a running clearance of .0003" to .0029"

[0,0076

a

0,0736

mm.].

These

bearings are positioned and prevented from

rotating in their supports in the cylinder block by

dowel pins. Dowel pins are used in both the center

and

the

rear

bearing caps. No dowel pins are used

in

the front bearing cap because the bearing has

a

flange. The front main bearing takes the end

thrust

of the crankshaft. The main bearings are of premium type which provides long bearing life.

They

are replaceable and when correctly installed, provide proper clearance without filing, boring,

scraping,

or shimming. Crankshaft bearings can

be removed from this

engine

only with the

engine

out of the vehicle. Crankshaft bearings must be replaced as a complete set of three bearings, each

bearing consisting of two halves.

Main

bearings

are

available in the standard size and the following

undersizes:

.001" [0,025mm.] .012" [0,305 mm.] .002" [0,051mm.] .020" [0,508 mm.] .010" [0,254mm.] .030" [0,762 mm.]

The

.001" and .002" undersize main bearings are

for use with standard size crankshafts having

slightly worn

journals.

The .010", .020", and .030" undersize bearings are for use with undersize

crankshafts

in

those

sizes. The .012" undersize

bearings are for use with .010" undersize

crank

shafts having slightly worn journals. Bearing sizes

are

rubber stamped on the reverse side of each

bearing half.

D-44. Crankshaft

Main

Bearing Inspection

The

crankshaft

journals

must be carefully inspected

as detailed previously in Par. D-41. Worn journals

will

require undersize bearings. Scored, flaked, or

worn

bearings must be replaced. Measure the main

bearing bores in the cylinder block using a

telescope

gauge

and micrometer. Measure the bores at right

angles to the split line and at 45° to the split line.

The

bores should not be over .001"

[0,0254

mm.]

out-of-round or .001" in taper from end to end.

Also,

the bores should not be more then .001"

oversize, considering the average diameter of the

bore.

D-45.

Fitting Crankshaft

Main

Bearings

Using

Plastigage

After

wiping and carefully inspecting the bearing bore, install the proper bearing. See that the oil

hole

in the bearing upper half registers properly

with

the oil

hole

in the block, and that the bearing

lock fits properly in the notch in the block.

Install

the crankshaft if replacing bearings with the

engine

out of the vehicle. The desired running fit (dif

ference

between

the diameter of the crankshaft

journal

and the inside diameter of the fitted bear ing) for a main bearing is .0003" to .0029"

[0,0076

a

0,0736

mm.]. With a dimension in

excess

of this

standard

running fit, a satisfactory bearing replacement cannot be made and it

will

be necessary to

regrind

the crankshaft.

Install

the bearing lower

half

and the bearing cap and draw the nuts down

equally and only slightly tight. Rotate the

crank

shaft by hand to be sure it turns freely without

drag.

Pull

the nuts tighter, first one then the other,

a

little at a time, intermittently rotating the

crank

shaft by hand until the recommended torque of

35 to 45 lb-ft. [4,8 a 6,2 kg-m.] is reached. If the

bearings are of the correct size, and lubricated with

light oil before installation, the crankshaft should

turn

freely in the bearings. If the crankshaft cannot

be turned, a larger bearing is

required.

If there is no binding or tightness, it is still necessary to check

clearance to guard against too

loose

a fit. Never file

either the bearing cap or the bearing to compensate

for too much clearance. Do not use shims under a

bearing cap or behind a bearing shell. Do not run a

new bearing half with a worn bearing half. The use

of "Plastigage" of the proper size to measure .001" [0,025 mm.] clearance is recommended for check

ing crankshaft main bearing clearance. The method

of checking clearance is as follows:

a.

Remove the bearing cap and carefully wipe

all

oil from the bearing and the

journal.

b.

Lay a piece of "Plastigage" y%" [3 mm.]

shorter than the width of the bearing across the

journal

(lengthwise of the crankshaft).

c.

Install

the bearing and cap and tighten first

one nut, then the other, a little at a time to the specified torque. As the bearing

tightens

down

around

the

journal,

the "Plastigage" flattens to a

width that indicates the bearing clearance.

d.

Remove the cap and measure the width of

the flattened "Plastigage," using the scale printed

on the

edge

of the envelope. The proper size "Plasti

gage"

will

accurately measure clearance down to .001".

e. If the flattened "Plastigage" tapers toward the middle, or toward the end, or both ends, there

is a difference in clearance, indicating a taper, a

low

spot,

or other irregularity of the bearing or

journal.

D-46.

Fitting Crankshaft

Main

Bearings

Using

Shim Stock

Thin

feeler or shim stock may be used instead of "Plastigage" to check bearing clearances. The

method is simple, but care must be taken to protect

the bearing metal surface from

injury

by too much pressure against the feeler stock,

a.

Cut a piece of .001" [0,025 mm.] thick, by Yl [12,7 mm.] wide, feeler stock }4" [3 mm.]

shorter than the width of the bearing. Coat this 51

Page 52 of 376

D

HURRICANE

F4

ENGINE

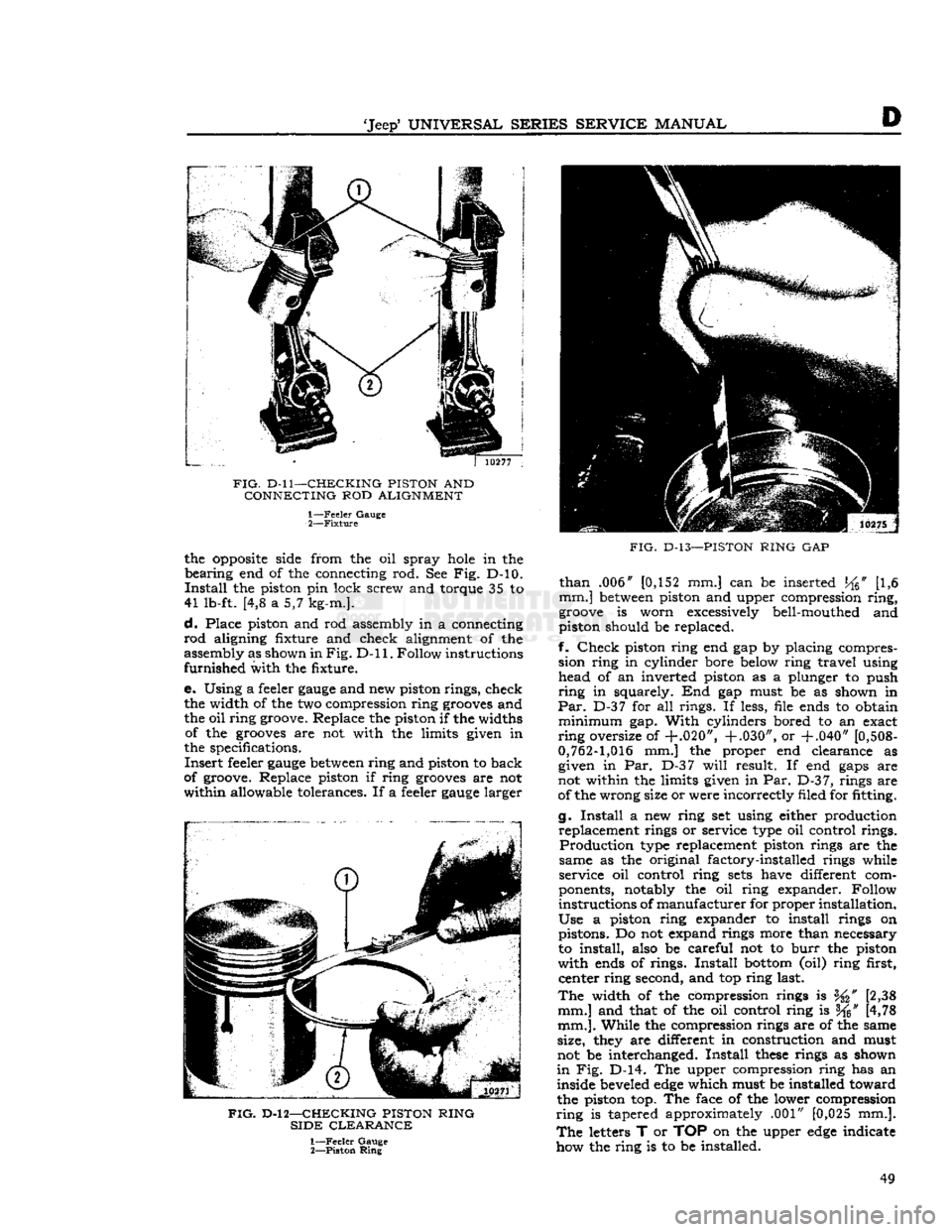

10442

FIG.

D-l6—SHIM

STOCK

IN

POSITION

ON

MAIN

BEARING

1—0.001"

Feeler Stock H' Wide feeler stock with light

engine

oil and lay it on the

bearing

in the cap, as shown in

Fig.

D-16.

With

the

shim

in this position, install the bearing and cap

on the crankshaft.

b.

Tighten the bearing cap nuts, first one and

then the other, a little at a time to 35 to 45 lb-ft. torque [4,8 a 6,2 kg-m.].

c.

Turn

the crankshaft by hand not more than

one inch in either direction.

Caution:

Turning

the crankshaft more may imbed the shim stock in the bearing, giving a false indica

tion of fit and damaging the bearing.

If

the bearing clearance is correct, the piece of .001"

feeler stock should produce a light to heavy drag.

If

there is little or no drag the bearing fit is too

loose.

If the crankshaft

will

not

turn

there is not

enough clearance. In either case another bearing must be selected to provide the proper fit.

d.

After the bearing has been correctly fitted, remove the shim stock, wipe the bearing and

journal

carefully and apply clean

engine

oil to the

surfaces.

Replace the cap and tighten the nuts first one, then the other, a little at a time, to the

prescribed

torque. The crankshaft should now

turn

freely without drag.

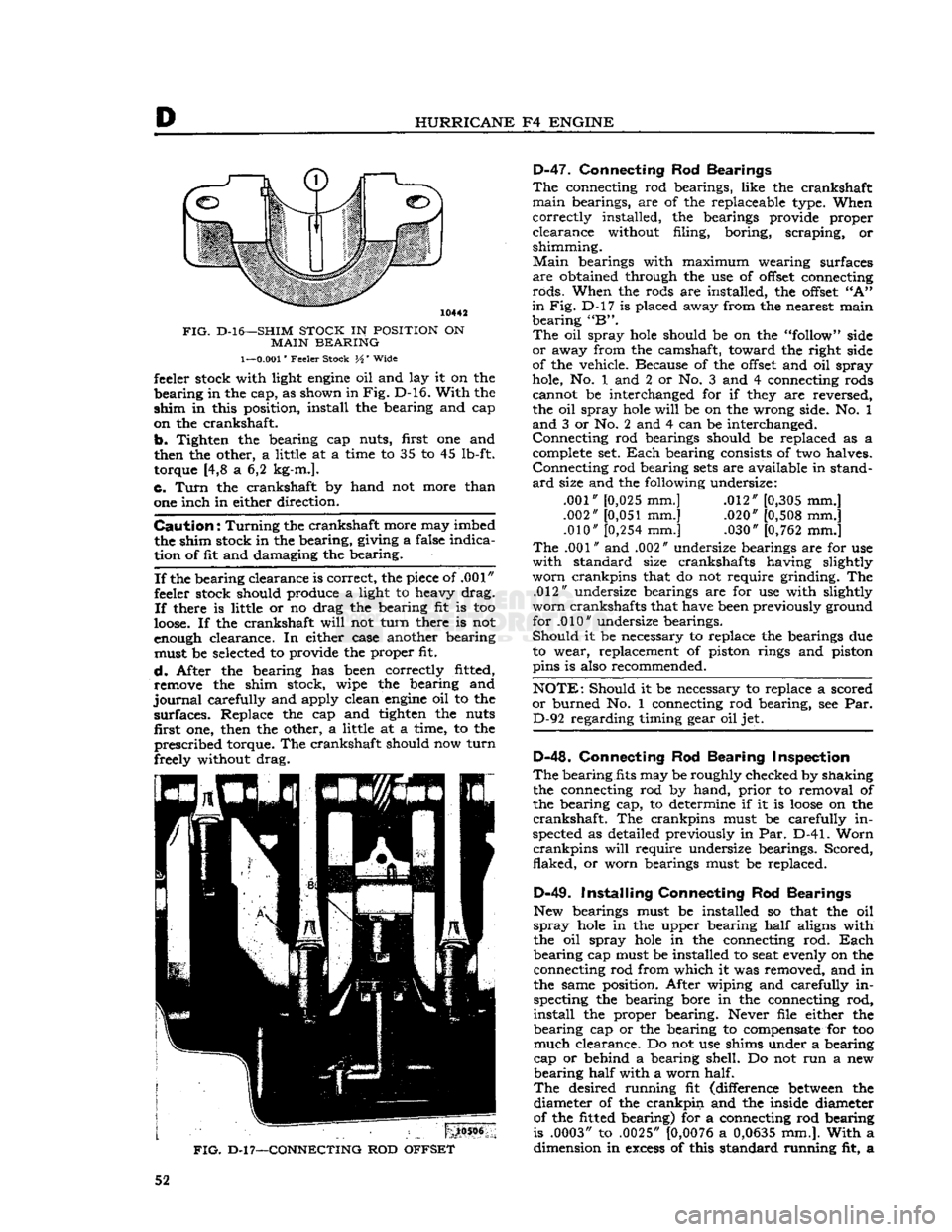

FIG.

D-l

7—CONNECTING

ROD

OFFSET

D-47.

Connecting Rod Bearings

The

connecting rod bearings, like the crankshaft

main

bearings, are of the replaceable type. When

correctly

installed, the bearings provide proper

clearance

without filing, boring, scraping, or

shimming.

Main

bearings with maximum wearing surfaces

are

obtained through the use of

offset

connecting

rods.

When the rods are installed, the

offset

"A"

in

Fig. D-l7 is placed away from the nearest main

bearing

"B".

The

oil spray

hole

should be on the "follow" side

or

away from the camshaft, toward the right side

of the vehicle. Because of the

offset

and oil spray

hole, No. 1 and 2 or No. 3 and 4 connecting rods cannot be interchanged for if they are reversed,

the oil spray

hole

will

be on the wrong side. No. 1

and

3 or No. 2 and 4 can be interchanged.

Connecting

rod bearings should be replaced as a complete set.

Each

bearing consists of two halves.

Connecting

rod bearing

sets

are available in stand

ard

size and the following undersize:

.001" [0,025 mm.] .012" [0,305 mm.]

.002"

[0,051

mm.] .020" [0,508 mm.] .010"

[0,254

mm.] .030" [0,762 mm.]

The

.001" and .002" undersize bearings are for use

with

standard size crankshafts having slightly

worn

crankpins that do not require grinding. The .012" undersize bearings are for use with slightly

worn

crankshafts that have been previously ground for .010" undersize bearings.

Should

it be necessary to replace the bearings due to wear, replacement of piston rings and piston

pins is also recommended.

NOTE:

Should it be necessary to replace a scored

or

burned No. 1 connecting rod bearing, see Par. D-92 regarding timing gear oil jet.

D-48.

Connecting Rod Bearing Inspection

The

bearing fits may be roughly checked by shaking the connecting rod by hand,

prior

to removal of

the bearing cap, to determine if it is

loose

on the

crankshaft.

The crankpins must be carefully in

spected as detailed previously in Par. D-41.

Worn

crankpins

will

require undersize bearings. Scored,

flaked,

or

worn bearings must be replaced.

D-49.

Installing Connecting Rod Bearings

New bearings must be installed so that the oil

spray

hole

in the upper bearing

half

aligns with

the oil spray

hole

in the connecting rod.

Each

bearing

cap must be installed to seat evenly on the connecting rod from which it was removed, and in

the same position. After wiping and carefully in specting the bearing bore in the connecting rod,

install

the proper bearing. Never file either the

bearing

cap or the bearing to compensate for too

much

clearance. Do not use shims under a bearing

cap or behind a bearing shell. Do not run a new

bearing

half

with a worn half.

The

desired running fit (difference

between

the diameter of the

crankpin

and the inside diameter

of the fitted bearing) for a connecting rod bearing

is .0003" to .0025"

[0,0076

a

0,0635

mm.].

With

a dimension in

excess

of this standard running fit, a 52

Page 63 of 376

![JEEP CJ 1953 Service Manual

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

D

is .004" to .007"

[0,102

a 0,178 mm.] as measured

by a dial indicator. Should a check

show

too little

end play, place a shim of suitable thickness

JEEP CJ 1953 Service Manual

Jeep

UNIVERSAL SERIES SERVICE

MANUAL

D

is .004" to .007"

[0,102

a 0,178 mm.] as measured

by a dial indicator. Should a check

show

too little

end play, place a shim of suitable thickness](/img/16/57040/w960_57040-62.png)

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

D

is .004" to .007"

[0,102

a 0,178 mm.] as measured

by a dial indicator. Should a check

show

too little

end play, place a shim of suitable thickness

between

the camshaft shoulder and the spacer. Too much

end play may be corrected by removing shims or

dressing off the spacer a slight amount. See Fig. D-33.

D-82. Install Crankshaft and Bearings

Fit

the three upper main bearings

into

their

respective

locations

in the cylinder block. Fit the

three lower main bearings

into

their respective

bearing caps.

NOTE:

It is

possible

to incorrectly install the front main bearing. The bearing is properly installed in

the cap with the narrower of the two radial oil

grooves

toward the front

edge

of the cap. If this

bearing is not properly installed, the oil

grooves

in

the two halves of the bearing will not match at the

parting line and premature failure of the bearing

will

result.

Lubricate

all bearing surfaces

generously

with

clean, light

engine

oil. Place the crankshaft in

position

in the cylinder block and install the main

bearing caps. Torque the

bolts

65 to 75 lb-ft.

[9,0 a 10,4 kg-m.] rotating the crankshaft after

each bearing cap is

tightened

D-83. Check Crankshaft End-Play

End

play of the crankshaft is set by the running

clearance

between

the crankshaft thrust washer

and the front

face

of the front main bearing. The

standard end play is .004" to .006"

[0,102

a 0,152

mm.] which is controlled by .002"

[0,051

mm.]

shims placed

between

the thrust washer and the

shoulder on the crankshaft. Check the end play

with a dial indicator as shown in

Fig.

D-34. If clear ance is incorrect, adjustment is made by adding or

removing shims.

Install

the thrust washer with the

beveled

inner

edge

toward the front bearing.

10668

FIG.

D-33—VALVES, CAMSHAFT,

AND

TIMING GEARS

1— Nut

2—

Left

Rocker Arm

3—

Rocker

Arm Shaft Spring

4—

Rocker

Shaft

Lock

Screw 5—

Rocker

Shaft

6— Nut 7—

Right

Rocker Arm

8—

Rocker

Arm Shaft Bracket

9—

Intake

Valve Tappet Adjusting Screw

10—

Intake

Valve Upper Retainer

Lock

11—

Oil

Seal

12—

Intake

Valve Spring Upper Retainer 13—

Intake

Valve Spring

14—

Intake

Valve Push Rod 15—

Intake

Valve

16—

Intake

Valve Tappet

17—

Camshaft

18—

Camshaft

Front Bearing

19—

Camshaft

Thrust Plate Spacer

20—

Camshaft

Thrust Plate

21— Bolt and Lockwasher

22— Bolt 13—Lockwasher

24—Camshaft

Gear

Washer 25—

Crankshaft

Gear

26—

Camshaft

Gear

27— Woodruff Key No. 9

28—

Exhaust

Valve Tappet

29— Tappet Adjusting Screw

30—

Spring

Retainer

Lock

31— Roto Cap Assembly

32—

Exhaust

Valve Spring

33—

Exhaust

Valve

34—

Rocker

Shaft Support Stud

35—

Washer

36—

Rocker

Arm Cover Stud 63

Page 66 of 376

D

HURRICANE

F4

ENGINE

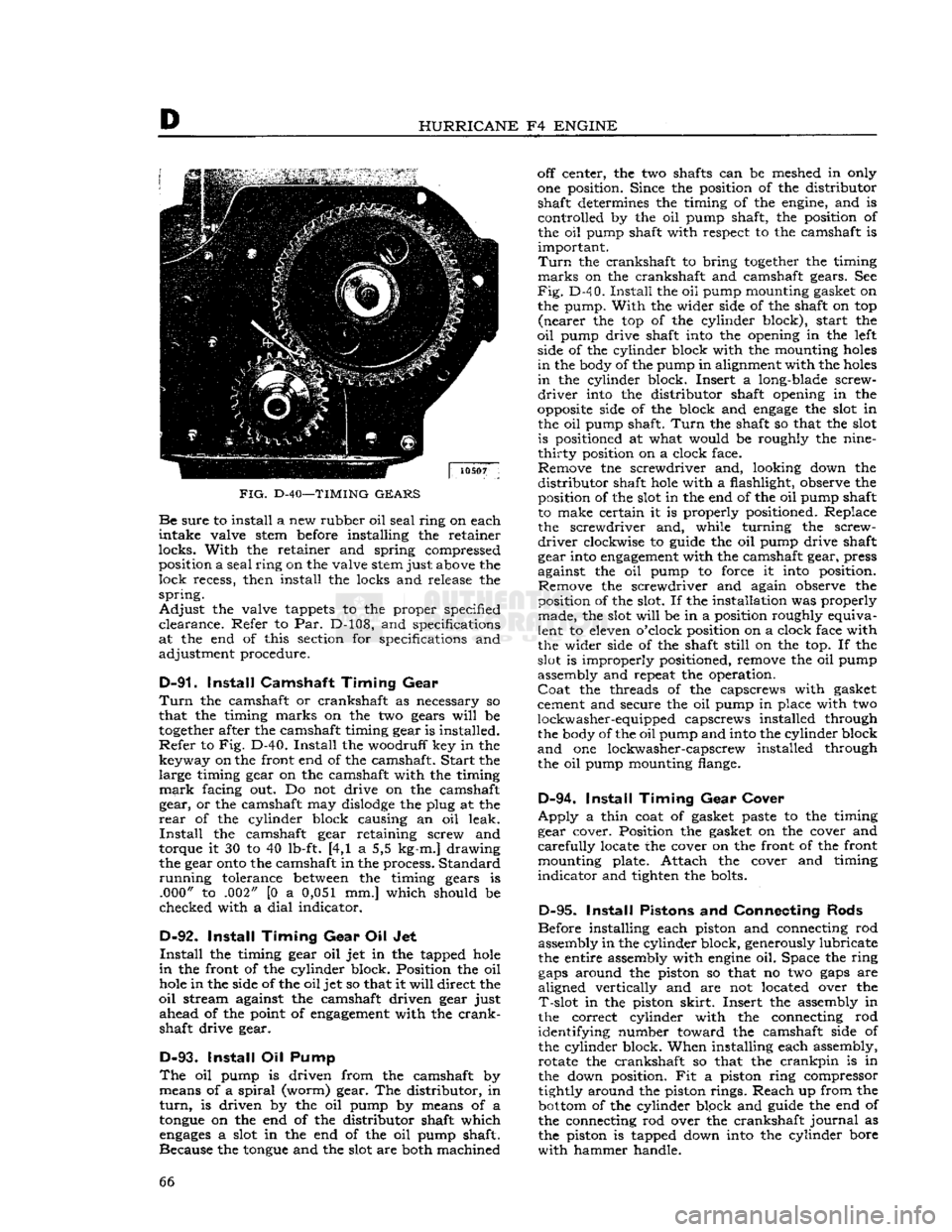

FIG.

D-40—TIMING

GEARS Be

sure

to install a new rubber oil

seal

ring on each

intake

valve stem before installing the retainer

locks.

With

the retainer and spring compressed position a

seal

ring

on the valve stem just above the

lock

recess, then install the locks and release the

spring.

Adjust

the valve tappets to the proper specified

clearance.

Refer to Par. D-108, and specifications

at the end of this section for specifications and

adjustment procedure.

D-91.

Install

Camshaft

Timing

Gear

Turn

the camshaft or crankshaft as necessary so

that the timing marks on the two gears

will

be

together

after the camshaft timing gear is installed.

Refer

to Fig. D-40.

Install

the woodruff key in the key way on the front end of the camshaft.

Start

the large timing gear on the camshaft with the timing

mark

facing out. Do not drive on the camshaft gear, or the camshaft may

dislodge

the plug at the

rear

of the cylinder block causing an oil leak.

Install

the camshaft gear retaining screw and

torque it 30 to 40 lb-ft. [4,1 a 5,5 kg-m.] drawing

the gear

onto

the camshaft in the process. Standard

running

tolerance

between

the timing gears is .000" to .002" [0 a 0,051 mm.] which should be

checked with a

dial

indicator.

D-92.

Install

Timing

Gear

Oil Jet

Install

the timing gear oil jet in the tapped

hole

in

the front of the cylinder block. Position the oil

hole

in the side of the oil jet so that it

will

direct the

oil

stream against the camshaft driven gear just

ahead

of the point of

engagement

with the

crank

shaft drive gear.

D-93.

Install

Oil Pump

The

oil pump is driven from the camshaft by means of a

spiral

(worm) gear. The distributor, in

turn,

is driven by the oil pump by means of a

tongue

on the end of the distributor shaft which

engages

a slot in the end of the oil pump shaft.

Because the

tongue

and the slot are both machined off center, the two shafts can be meshed in only

one position. Since the position of the distributor shaft determines the timing of the engine, and is

controlled by the oil pump shaft, the position of the oil pump shaft with respect to the camshaft is

important.

Turn

the crankshaft to bring

together

the timing

marks

on the crankshaft and camshaft gears. See

Fig.

D-4 0.

Install

the oil pump mounting gasket on

the pump.

With

the wider side of the shaft on top

(nearer

the top of the cylinder block), start the

oil

pump drive shaft into the opening in the left side of the cylinder block with the mounting

holes

in

the body of the pump in alignment with the

holes

in

the cylinder block. Insert a long-blade screw

driver

into the distributor shaft opening in the

opposite

side of the block and

engage

the slot in the oil pump shaft.

Turn

the shaft so that the slot is positioned at what would be roughly the nine-

thirty

position on a clock face. Remove tne screwdriver and, looking down the

distributor

shaft

hole

with a flashlight, observe the position of the slot in the end of the oil pump shaft

to make certain it is properly positioned. Replace the screwdriver and, while turning the screw

driver

clockwise to guide the oil pump drive shaft

gear into

engagement

with the camshaft gear, press

against the oil pump to force it into position. Remove the screwdriver and again observe the

position of the slot. If the installation was properly made, the slot

will

be in a position roughly equiva

lent to eleven o'clock position on a clock face with

the wider side of the shaft

still

on the top. If the

slot is improperly positioned, remove the oil pump

assembly and repeat the operation.

Coat

the threads of the capscrews with gasket

cement and secure the oil pump in place with two

lockwasher-equipped capscrews installed through the body of the oil pump and into the cylinder block

and

one lockwasher-capscrew installed through

the oil pump mounting flange.

D-94.

Install

Timing

Gear

Cover

Apply

a thin coat of gasket paste to the timing

gear cover. Position the gasket on the cover and

carefully

locate the cover on the front of the front mounting plate. Attach the cover and timing

indicator

and tighten the bolts.

D-95.

Install

Pistons and Connecting Rods

Before installing each piston and connecting rod assembly in the cylinder block, generously lubricate

the entire assembly with

engine

oil. Space the ring

gaps

around the piston so that no two

gaps

are

aligned vertically and are not located over the

T-slot

in the piston

skirt.

Insert the assembly in

the correct cylinder with the connecting rod

identifying number toward the camshaft side of

the cylinder block. When installing each assembly, rotate the crankshaft so that the

crankpin

is in

the down position. Fit a piston ring compressor

tightly around the piston rings. Reach up from the

bottom

of the cylinder block and guide the end of

the connecting rod over the crankshaft

journal

as

the piston is tapped down into the cylinder bore

with

hammer handle. 66

Page 67 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

D

Lubricate

the connecting rod bearing surfaces

generously with

engine

oil and install the bearing

cap with the numbered side matched to the num

bered side of the connecting rod. Torque the nuts

evenly 35 to 45 lb-ft. [4,8 a 6,2 kg-m.]. The con

necting rod cap nuts are locked with stamped nuts.

Used

stamped nuts should be discarded and re

placed with new

ones.

These locking stamped nuts

should be installed with the flat face toward the

connecting rod nut.

Turn

the locking nut finger

tight and then 34

turn

more with a wrench. Refer

to Par. D-36 for detailed information on fitting pistons and rings in the cylinder bores.

D-96.

Install

Crankshaft

Pulley

Align

the keyway in the pulley with the woodruff key installed in the crankshaft. Drive the pulley

onto

the crankshaft and secure it in place with

the crankshaft pulley nut. Insert a block of wood

between

one of the counterweights on the

crank

shaft and the side of the cylinder block to prevent the crankshaft from turning, then tighten the nut.

D-97.

Install

Oil Pan

Before installing the oil pan, make a final internal

inspection particularly making certain that the

inside of the cylinder block is clean. Apply a thin

coat of gasket paste on the oil pan. Place the new

oil

pan gasket in position. Set the oil pan in posi

tion on the cylinder block and install the oil pan.

Torque

the attaching

bolts

12 to 15 lb-ft. [1,7 a 2,1

kg-m.].

Install

the oil pan

drain

plug and gasket

and

tighten the plug securely.

D-98.

Install

Cylinder

Head

Make

certain that the entire top of the cylinder

block

assembly, the lower surface of the cylinder

head,

and the cylinder head gasket are clean. Blow

all

dirt

or carbon out of the blind tapped bolt

holes

in

the cylinder block before the cylinder head and gasket are installed. Using aerosol spray sealer

Part

No. 994757, spray a thincoat on both surfaces

of the head gasket, position the new cylinder head gasket with the crimped

edges

of the gasket metal down (See Fig. D-31).

This

gasket position allows a

positive seal along the narrow surfaces of the

cylin

der

head

between

the combustion chambers and

eliminates the possibility of burning combustion

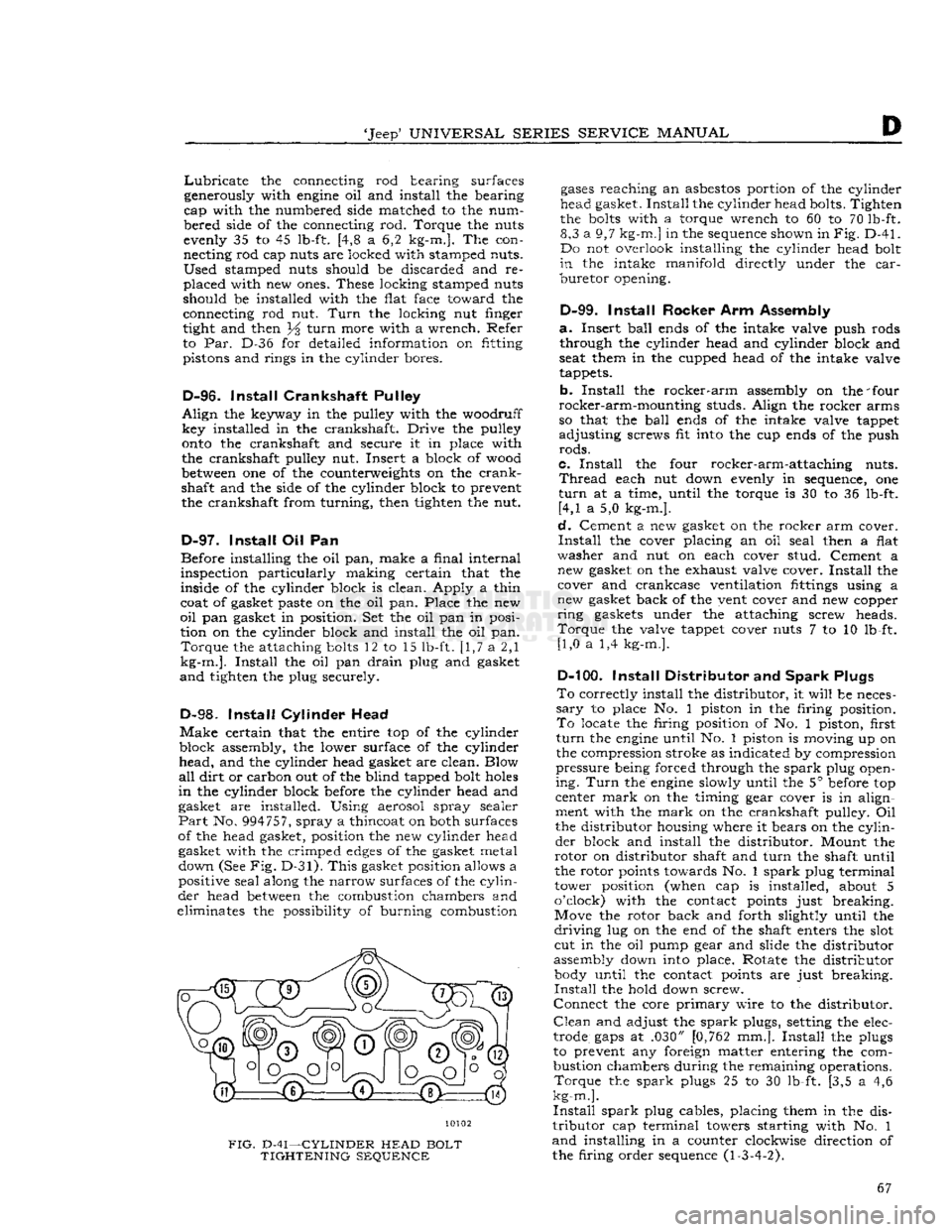

10102

FIG.

D-41—CYLINDER

HEAD

BOLT

TIGHTENING

SEQUENCE

gases

reaching

an

asbestos

portion of the cylinder

head gasket.

Install

the cylinder head bolts. Tighten

the

bolts

with a torque wrench to 60 to 70 lb-ft. 8,3 a 9,7

kg-m.]

in the sequence shown in

Fig.

D-41.

Do not overlook installing the cylinder head bolt

in

the intake

manifold

directly under the

car

buretor

opening.

D-99.

Install

Rocker Arm Assembly

a.

Insert

ball

ends of the intake valve push rods through the cylinder head and cylinder block and

seat them in the cupped head of the intake valve

tappets.

b.

Install

the

rocker-arm

assembly on the 'four

rocker-arm-mounting

studs. Align the rocker arms

so that the

ball

ends of the intake valve tappet

adjusting

screws fit into the cup ends of the push

rods.

c.

Install

the four rocker-arm-attaching nuts.

Thread

each nut down evenly in sequence, one

turn

at a time, until the torque is 30 to 36 lb-ft. [4,1 a 5,0 kg-m.].

d.

Cement a new gasket on the rocker arm cover.

Install

the cover placing an oil seal then a flat

washer

and nut on each cover stud. Cement a new gasket on the exhaust valve cover.

Install

the cover and crankcase ventilation fittings using a

new gasket back of the vent cover and new copper

ring

gaskets under the attaching screw heads.

Torque

the valve tappet cover nuts 7 to 10 lb-ft. [1,0 a 1,4 kg-m.].

D-100.

Install

Distributor and

Spark

Plugs

To

correctly install the distributor, it

will

be neces

sary

to place No. 1 piston in the firing position.

To

locate the firing position of No. 1 piston, first

turn

the

engine

until No. 1 piston is moving up on

the compression stroke as indicated by compression

pressure

being forced through the

spark

plug open

ing.

Turn

the

engine

slowly until the 5° before top

center

mark

on the timing gear cover is in align

ment with the

mark

on the crankshaft pulley. Oil

the distributor housing where it bears on the

cylin

der

block and install the distributor. Mount the

rotor

on distributor shaft and

turn

the shaft until

the rotor points towards No. 1

spark

plug terminal

tower position (when cap is installed, about 5

o'clock) with the contact points just breaking.

Move the rotor back and forth slightly until the

driving

lug on the end of the shaft enters the slot cut in the oil pump gear and slide the distributor

assembly down into place. Rotate the distributor body until the contact points are just breaking.

Install

the hold down screw.

Connect

the core

primary

wire to the distributor.

Clean

and adjust the

spark

plugs, setting the elec

trode

gaps

at .030" [0,762 mm.].

Install

the plugs

to prevent any foreign matter entering the com

bustion chambers during the remaining operations.

Torque

the

spark

plugs 25 to 30 lb-ft. [3,5 a 4,6

kg-m.].

Install

spark

plug cables, placing them in the dis

tributor

cap terminal towers starting with No. 1

and

installing in a counter clockwise direction of

the firing order sequence (1-3-4-2). 67

Page 89 of 376

Dl

'Jeep5

UNIVERSAL

SERIES

SERVICE

MANUAL

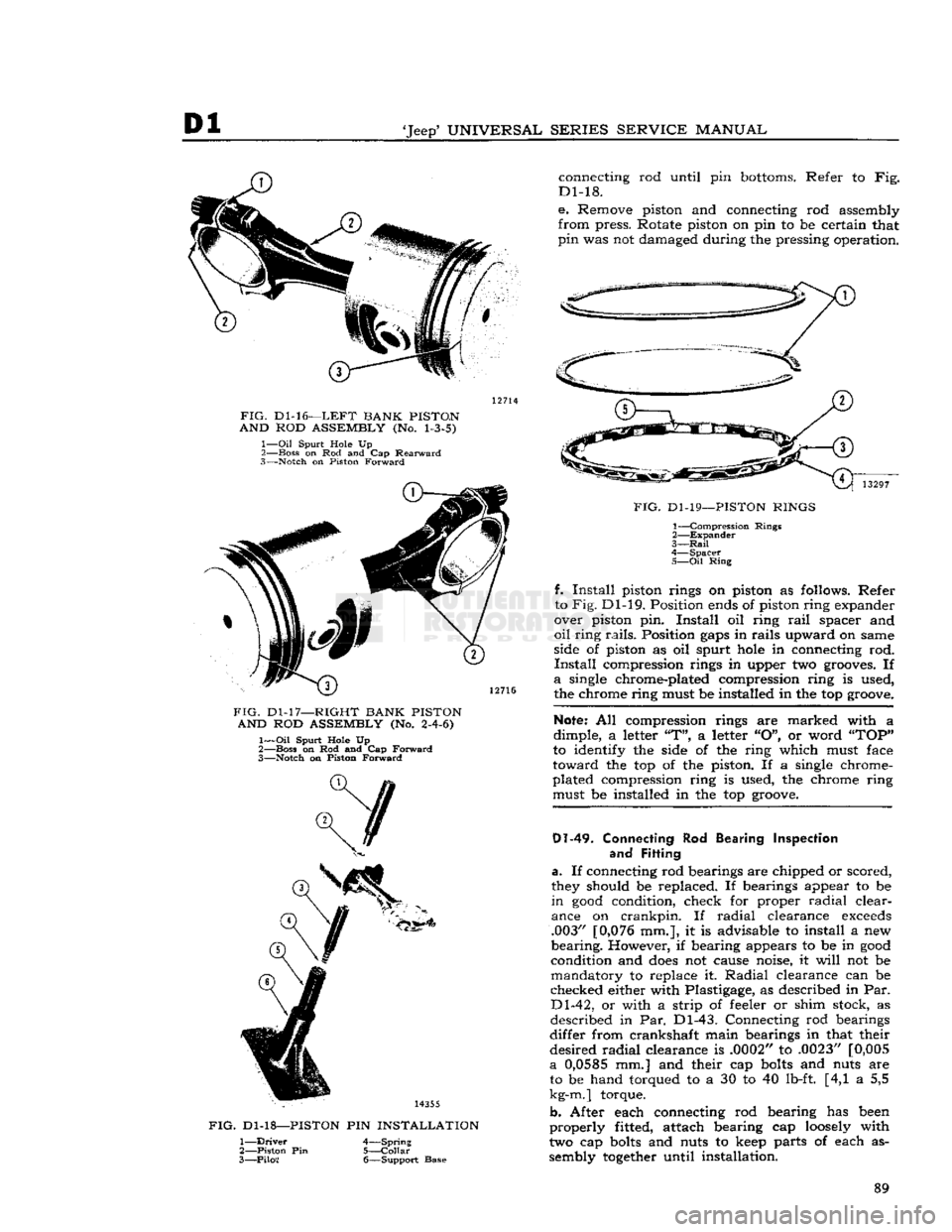

FIG.

Dl-16—LEFT

BANK

PISTON

AND

ROD

ASSEMBLY

(No.

1-3-5)

1—

Oil

Spurt Hole Up

2— Boss on Rod and Cap

Rearward

3—

Notch on Piston

Forward

12716

FIG.

Dl-17—RIGHT

BANK

PISTON

AND

ROD

ASSEMBLY

(No. 2-4-6)

1—

Oil

Spurt Hole Up

2— Boss on Rod and Cap

Forward

3—

Notch on Piston

Forward

14355

FIG.

Dl-18—-PISTON

PIN

INSTALLATION

connecting rod until pin

bottoms.

Refer to Fig.

Dl-18.

e.

Remove piston and connecting rod assembly

from

press. Rotate piston on pin to be certain that

pin

was not damaged during the pressing operation. 13297

1—

Driver

2— Piston Pin

3—

Piloi

4—

Spring

5—

Collar

6—

Support

Base

FIG.

Dl-19—PISTON

RINGS

1—

Compression

Rings

2—

Expander

3—

Rail

4—

Spacer

5—

Oil

Ring

f.

Install

piston rings on piston as follows. Refer

to Fig. Dl-19. Position ends of piston ring expander

over piston pin.

Install

oil ring

rail

spacer and

oil

ring

rails.

Position

gaps

in rails upward on same

side of piston as oil spurt

hole

in connecting rod.

Install

compression rings in upper two grooves. If

a

single chrome-plated compression ring is used,

the chrome ring must be installed in the top groove.

Note:

All compression rings are marked with a

dimple, a letter

"T",

a letter

"O",

or word

"TOP"

to identify the side of the ring which must face

toward

the top of the piston. If a single chrome-

plated compression ring is used, the chrome ring must be installed in the top groove.

Dl-49.

Connecting

Rod

Bearing Inspection and Fitting

a.

If connecting rod bearings are chipped or scored,

they should be replaced. If bearings appear to be

in

good

condition, check for proper

radial

clear

ance on crankpin. If

radial

clearance

exceeds

.003" [0,076 mm.], it is advisable to install a new

bearing.

However, if bearing appears to be in

good

condition and

does

not cause noise, it

will

not be mandatory to replace it.

Radial

clearance can be

checked either with Plastigage, as described in Par.

Dl-42,

or with a strip of feeler or shim stock, as

described in Par. Dl-43. Connecting rod bearings

differ from crankshaft main bearings in that their

desired

radial

clearance is .0002" to .0023" [0,005

a

0,0585

mm.] and their cap

bolts

and nuts are to be hand torqued to a 30 to 40 lb-ft. [4,1 a 5,5

kg-m.] torque.

b. After each connecting rod bearing has been

properly

fitted, attach bearing cap

loosely

with

two cap

bolts

and nuts to keep parts of each as

sembly

together

until installation. 89

Page 90 of 376

DAUNTLESS

V-6

ENGINE

Note:

The rib on

edge

of cap and the conical

boss

on web of connecting rod must be toward

rear

of

engine

in all connecting rod assemblies of left

cyl

inder

bank and toward front of

engine

in all connecting rod assemblies of right cylinder bank.

Dl-50.

Oil

Pump Intake

and

Screen Cleaning

a.

Pry screen from housing and examine for clog

ging due to deposit of sludge or other foreign

material.

b.

Clean

the screen and housing thoroughly in sol

vent; dry with compressed air.

c.

Install

screen in housing.

Dl-51.

Oil Pan Cleaning and Inspection

Inspect

the oil pan for corrosion, dents, leaks, and

other damage. Inspect its mounting flange carefully

for damage or distortion to be certain that it

will

give

a

good

seal.

Dl-52.

Flywheel Cleaning

and

Inspection

Clean

the flywheel with suitable cleaning solvent;

dry

with compressed air. Inspect clutch face for

burned

or scuffed condition and for rivet grooves.

Inspection

for run out or improper mounting is de

scribed

in installation procedure.

Inspect

teeth

of the flywheel

ring

gear for

burrs,

nicks,

and minor distortion. If necessary and pos

sible, use a small emery wheel to remove

burrs

and

reshape teeth. If gear

teeth

are broken,

cracked,

seriously

burred

or deformed, the

ring

gear must be replaced.

Dl-53.

Ring Gear Replacement

a.

Drill

a

hole

between

two

ring

gear teeth; then

split

the gear with a cold chisel. Be careful not to

damage

ring

gear shoulder or seat surfaces of fly

wheel.

b.

Polish several

spots

on the new

ring

gear to be

installed.

With

a hot plate or slowly moving torch,

heat the new

ring

gear until polished

spots

become

blue, about

600°F.

[312°C.].

Caution:

Do not heat the

ring

gear to a temperature

greater than

800°F.

[424°C.].

Excessive heat

will

destroy heat treatment given to

ring

gear during

manufacture.

c.

Quickly

install

ring

gear on flywheel. Chamfered

edge

of

ring

gear must be toward

ring

gear shoulder

of flywheel. Be certain that

ring

gear is seated prop

erly.

Allow

ring

gear to cool slowly, so that it

will

be held tightly in place.

Dl-54.

Flywheel Housing Cleaning and Inspection

Both

flywheel and clutch are enclosed by a fly

wheel housing. Its front surface is bolted to the

engine

cylinder block, and its

rear

surface acts as

front

support to the transmission.

Clean

the fly wheel housing with a suitable cleaning solvent; dry

with

compressed air. Inspect front and

rear

surfaces

for distortion and improper alignment with each

other;

these

planes must be

parallel

to assure

proper

alignment

between

engine

and transmission.

Dl-55.

Camshaft Cleaning

and

Inspection

Clean

both camshaft and camshaft bearing surfaces

with

a suitable cleaning solvent; dry with com

pressed air.

Note:

The steel-backed babbitt-lined camshaft

bearings are pressed into the crankcase.

From

front

to

rear,

each bearing is .030" [0,76 mm.] smaller

in

diameter than the preceding bearing.

From

front

to

rear,

each camshaft

journal

is correspondingly

smaller

in diameter.

The

camshaft bearings must be line reamed to

proper

diameter after being pressed into crankcase.

Since

this operation requires special reaming equip

ment, the original bearings should be retained un

less

they are severly damaged. Slightly scored cam

shaft bearings are satisfactory if the surfaces of camshaft journals are polished, bearings are

polished to remove

burrs,

and

radial

clearance

between

camshaft and bearings is within .0015"

to .004" [0,038 a 0,102 mm.].

Dl-56.

Valve Lifter

and

Push

Rod

Cleaning and Inspection

a.

Examine the cam contact surface at lower end of each valve lifter body. If surface is excessively

worn,

galled, or otherwise damaged, discard the

valve lifter. Also examine the mating camshaft

lobe

for excessive wear or damage.

b.

Disassemble one or two valve lifters, as de

scribed

below, and inspect them for

dirt

or

varnish.

If

they are dirty or have a varnish deposit, clean

and

inspect all twelve valve lifters. Otherwise,

service

only

those

valve lifters which do not operate

properly.

c.

To disassemble each valve lifter, depress the

push

rod seat with a push rod, and remove the

plunger retainer from the valve lifter body with

a

retainer remover. Remove push rod seat and

plunger from valve lifter body. If plunger sticks

in

valve lifter body, place body in large end of

a

plunger remover tool, with plunger downward.

While

holding lifter with thumb, rap the open end

of remover against a block of wood with just enough force to jar the plunger from body. Refer to

Figs.

Dl-20, Dl-22 and Dl-23.

d.

Drain

oil from valve lifter and remove the check

valve retainer,

ball,

valve spring, and plunger

spring.

e. Keep all parts of each valve lifter separated

during

part cleaning and inspection. The valve

lifter

body and plunger are selectively fitted to each other and must not be interchanged with parts

of other valve lifters.

f. Rinse all valve lifter parts in kerosene to remove as much oil as possible.

This

will

reduce contamina

tion of the cleaning solvent. Immerse all parts in cleaning solvent for approximately one hour. The

time required

will

depend on varnish

deposits

and

effectiveness

of the solvent. After the varnish has

dissolved or has

softened

sufficiently to permit re

moval

by wiping, allow parts to

drain.

Varnish

can

then be cleaned from the valve lifter body

with

a

brush.

Rinse the parts in kerosene to dissolve 90