transmission oil JEEP CJ 1953 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 232 of 376

CLUTCH

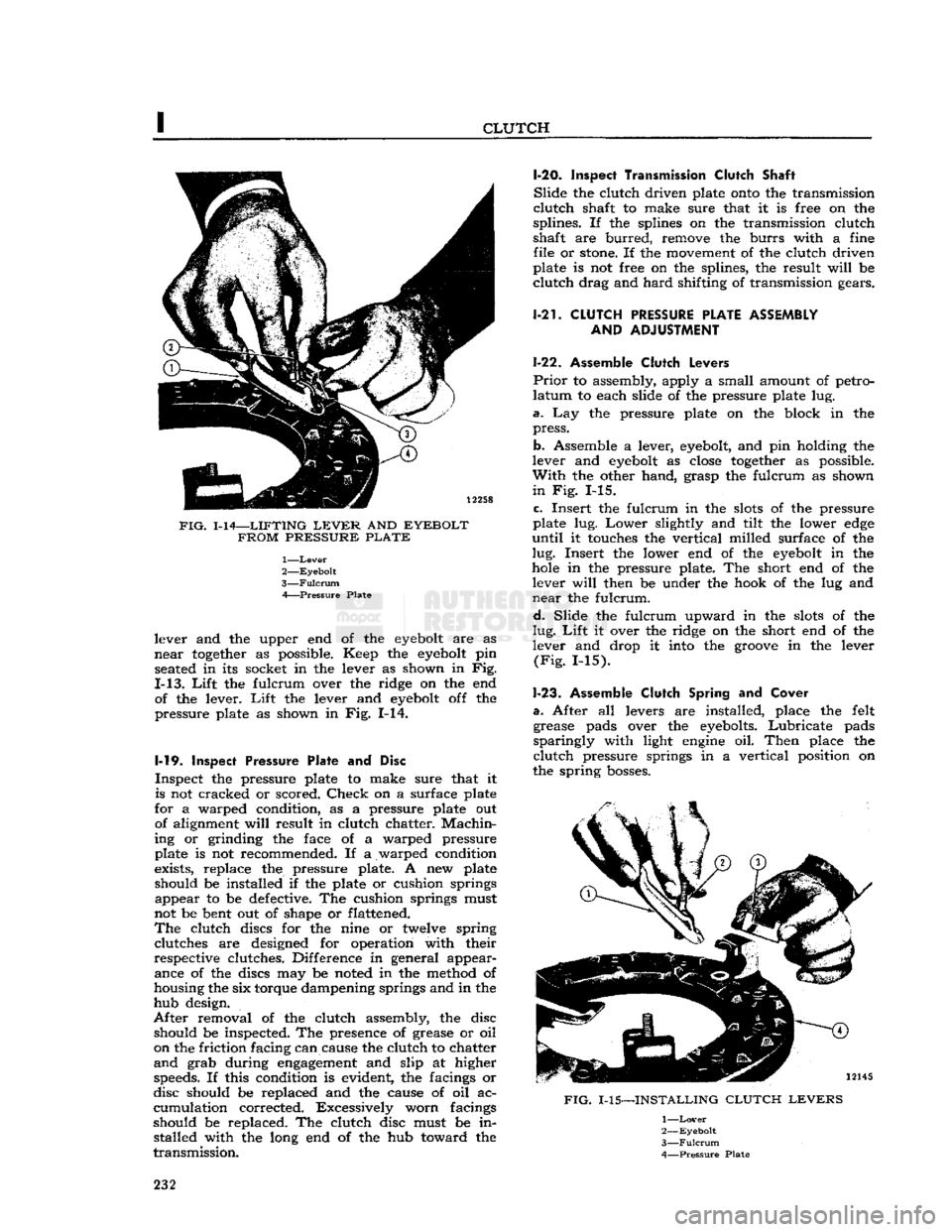

FIG.

1-14—LIFTING

LEVER

AND

EYEBOLT FROM PRESSURE PLATE

1—

Lever

2—

Eyebolt

3—

Fulcrum

A Pressure Plate

lever and the upper end of the

eyebolt

are as

near

together

as possible. Keep the

eyebolt

pin seated in its socket in the lever as shown in Fig.

1-13.

Lift

the fulcrum over the ridge on the end of the lever.

Lift

the lever and

eyebolt

off the

pressure plate as shown in Fig. 1-14.

1-19.

Inspect

Pressure Plate and Disc

Inspect the pressure plate to make sure that it is not cracked or scored.

Check

on a surface plate

for a warped condition, as a pressure plate out of alignment

will

result in clutch chatter.

Machin

ing or grinding the face of a warped pressure

plate is not recommended. If a warped condition

exists, replace the pressure plate. A new plate

should be installed if the plate or cushion springs appear to be defective. The cushion springs must

not be bent out of shape or flattened.

The

clutch discs for the nine or twelve spring clutches are designed for operation with their

respective clutches. Difference in general appear ance of the discs may be noted in the method of

housing the six torque dampening springs and in the

hub design.

After

removal of the clutch assembly, the disc should be inspected. The presence of grease or oil

on the friction facing can cause the clutch to chatter

and

grab during

engagement

and slip at higher speeds. If this condition is evident, the facings or

disc should be replaced and the cause of oil ac

cumulation corrected. Excessively worn facings

should be replaced. The clutch disc must be in stalled with the long end of the hub toward the

transmission.

1-20.

Inspect Transmission Clutch

Shaft

Slide

the clutch driven plate

onto

the transmission

clutch

shaft to make sure that it is free on the

splines. If the splines on the transmission clutch

shaft are

burred,

remove the

burrs

with a fine file or

stone.

If the movement of the clutch driven

plate is not free on the splines, the result

will

be

clutch

drag and

hard

shifting of transmission gears.

1-21.

CLUTCH

PRESSURE

PLATE ASSEMBLY AND

ADJUSTMENT

1-22. Assemble

Clutch

Levers

Prior

to assembly, apply a small amount of petro

latum

to each slide of the pressure plate lug.

a.

Lay the pressure plate on the block in the

press.

b. Assemble a lever,

eyebolt,

and pin holding the

lever and

eyebolt

as

close

together

as possible.

With

the other hand, grasp the fulcrum as shown

in

Fig. 1-15.

c.

Insert the fulcrum in the

slots

of the pressure

plate lug.

Lower

slightly and tilt the lower

edge

until

it touches the vertical milled surface of the

lug.

Insert the lower end of the

eyebolt

in the

hole

in the pressure plate. The short end of the lever

will

then be under the hook of the lug and

near

the fulcrum.

d.

Slide the fulcrum upward in the

slots

of the

lug.

Lift

it over the ridge on the short end of the

lever and drop it into the

groove

in the lever

(Fig.

1-15).

1-23.

Assemble

Clutch

Spring and

Cover

a.

After all levers are installed, place the felt grease pads over the eyebolts.

Lubricate

pads

sparingly

with light

engine

oil.

Then

place the

clutch

pressure springs in a vertical position on

the spring

bosses.

FIG.

1-15—INSTALLING

CLUTCH LEVERS

1—

Lover

2—

Eyebolt

3—

Fulcrum

4—

Pressure

Plate

232

Page 235 of 376

![JEEP CJ 1953 Owners Manual

Jeep

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

sta JEEP CJ 1953 Owners Manual

Jeep

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

sta](/img/16/57040/w960_57040-234.png)

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

I thickness: .285"

[0,724

cm.], .305"

[0,775

cm.].

Each

spacer should be hardened and ground to size, and then have the dimensional thickness

stamped thereon.

c.

From

flat bar stock at least Vfe" [3 mm.] thick,

make a

gauge

as shown in Fig. 1-22. Harden, grind

to size, and stamp sizes on the

gauge.

1-27.

Clutch Installation

a.

Very

sparingly, apply wheel bearing lubricant

to inner surface of pilot bushing in crankshaft.

Caution:

If

excessive

lubricant is applied to pilot bushing, it

will

run out on face of flywheel when

hot and

ruin

the driven plate facings.

b. Make sure that splines in the driven plate hub

are

clean; apply a light coat of lubricant to splines

of hub and transmission drive gear shaft. Slide plate over gear shaft several times; remove plate

from shaft and wipe off

excess

lubricant.

Caution:

Driven plate facings must be kept clean

and

dry.

c.

Fill

groove

in throwout bearing collar with wheel bearing lubricant. See Fig. 1-23. Make sure

that front bearing retainer of transmission is clean;

apply a light coat of wheel bearing lubricant. Slide

throwout bearing over bearing retainer several times. Remove bearing from retainer and wipe off

excess

lubricant.

12736

FIG.

1-23—LUBRICATION

POINTS

—

CLUTCH

THROWOUT

BEARING

COLLAR

1—Coat

This

Groove 2—Pack

This

Recess

d.

Clean

and apply wheel bearing lubricant to ball

stud in flywheel housing and to the

seat

in clutch

fork.

e.

If disassembled, install pressure plate in the cover assembly, lining up the

groove

on its

edge

with the

groove

on the

edge

of the cover.

Install

pressure plate retracting springs, and the three

drive

strap-to-pressure plate

bolts

and lock washers.

Torque

bolts

11 lb-ft. [1,51 kg-m.].

Note:

The diaphragm

type

clutch assembly is fac

tory calibrated and requires no adjustment

before

installation. Refer to Par. 1-14 to adjust Borg and

Beck

coil spring

type

clutch assembly.

f.

Install

the pressure plate and driven plate on

flywheel. Support both assemblies with a spare

main

drive gear.

Note:

Be certain that

mark

on clutch cover is

aligned with the

mark

made on the flywheel during

clutch removal.

g.

Install

clutch attaching

bolts

and tighten alter nately so that clutch is drawn squarely

into

position

on flywheel.

Each

bolt

must be

tightened

one turn at a time to avoid bending the clutch cover flange.

Torque

bolts

30 to 40 lb-ft. [4,1 a 5,5 kg-m.].

h.

Lubricate

the ball stud and clutch fork with

wheel bearing lubricant and install clutch fork.

Note:

Be certain that fork retaining spring is

tight

on pivot ball stud.

i.

Install

flywheel housing on

engine

cylinder

block.

Caution:

Be certain that dowel pins are installed

in

cylinder block.

j.

Lubricate

the recess on the inside of the throw-

out bearing collar. Be careful not to use too much

lubricant.

See Fig. 1-23.

Caution:

Make certain that the lips of the spring

retainer (attached to the clutch fork) are in

groove

of the bearing. See Fig. 1-24.

k.

Install

throwout bearing assembly and connect

clutch linkage.

I.

Install

transmission as described in Section J. m. Adjust clutch for %"

[19,05

mm.] free travel,

see

Par.

1-3. 235

Page 237 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

I

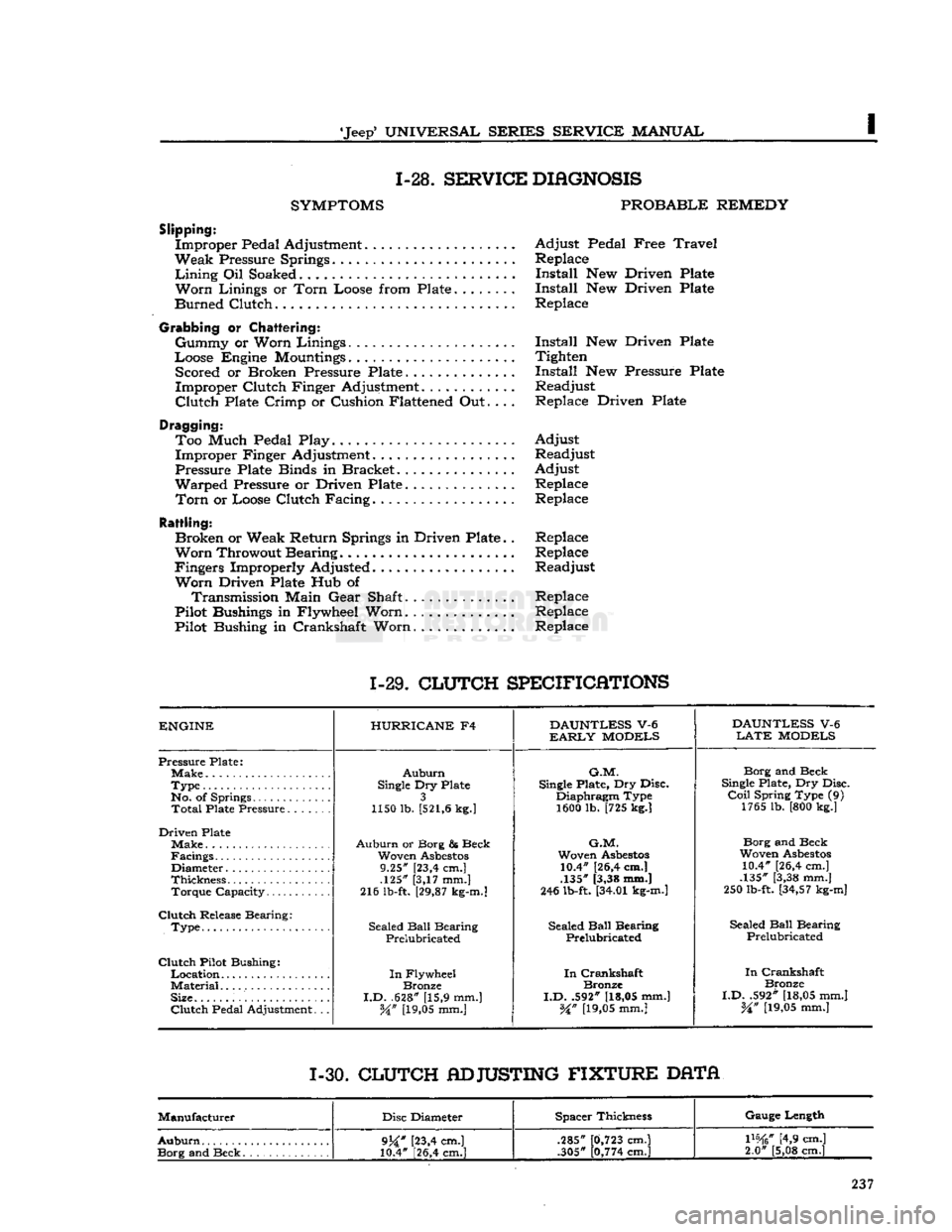

1-28.

SERVICE

DIAGNOSIS

SYMPTOMS

PROBABLE

REMEDY

Slipping:

Improper Pedal Adjustment Adjust Pedal Free

Travel

Weak Pressure Springs Replace

Lining

Oil Soaked Install New Driven Plate

Worn

Linings or

Torn

Loose from Plate Install New Driven Plate

Burned Clutch Replace

Grabbing

or

Chattering:

Gummy or Worn Linings Install New Driven Plate

Loose Engine

Mountings

Tighten Scored or Broken Pressure Plate Install New Pressure Plate

Improper Clutch Finger Adjustment............ Readjust

Clutch

Plate Crimp or Cushion Flattened Out.... Replace Driven Plate

Dragging: Too Much Pedal Play. Adjust Improper Finger Adjustment. Readjust

Pressure Plate Binds in Bracket Adjust

Warped Pressure or Driven Plate Replace

Torn

or Loose Clutch Facing. Replace

Rattling:

Broken or Weak Return Springs in Driven Plate.. Replace

Worn

Throwout Bearing Replace

Fingers Improperly Adjusted Readjust

Worn

Driven Plate Hub of Transmission Main Gear Shaft.............. Replace

Pilot Bushings in Flywheel Worn.

.............

Replace

Pilot Bushing in Crankshaft Worn Replace

1-29.

CLUTCH

SPECIFICATIONS

ENGINE

HURRICANE

F4

DAUNTLESS

V-6

DAUNTLESS

V-6

EARLY

MODELS

LATE

MODELS

Pressure Plate;

Auburn

G.M.

Borg and Beck

Type

Single

Dry Plate

Single

Plate, Dry Disc.

Single

Plate, Dry Disc.

No. of Springs 3 Diaphragm Type

Coil

Spring Type (9)

Total

Plate Pressure 1150 lb.

[521,6

kg.]

1600 lb. [725 kg.] 1765 lb. [800 kg.]

Driven Plate Make

Auburn

or Borg & Beck

G.M.

Borg and Beck

Facings Woven

Asbestos

Woven

Asbestos

Woven

Asbestos

Diameter 9.25" [23,4 cm.] 10.4" [26,4 cm.]

10.4" [26,4 cm.]

Thickness .125" [3,17 mm.] .135" [3,38 mm.]

.135" [3,38 mm.]

Torque Capacity 216 lb-ft.

[29,87

kg-m.]

246 lb-ft.

[34.01

kg-m.]

250 lb-ft.

[34,57

kg-m]

Clutch

Release Bearing: Sealed

Ball

Bearing

.

Type Sealed

Ball

Bearing Sealed

Ball

Bearing Sealed

Ball

Bearing

.

Type

Prelubricated Prelubricated

Prelubricated

Clutch

Pilot Bushing:

In

Crankshaft

In

Flywheel

In

Crankshaft

In

Crankshaft

Material

Bronze Bronze

Bronze

Size.

I.D.

.628" [15,9 mm.]

I.D.

.592"

[18,05

mm.]

I.D.

.592"

[18,05

mm.]

Clutch

Pedal Adjustment. .. W

[19,05

mm.]

%n

[19,05

mm.]

%n

[19,05

mm.]

1-30.

CLUTCH

ADJUSTING

FIXTURE

DATA

Manufacturer Disc Diameter Spacer Thickness Gauge Length

Auburn

9j£"

[23,4 cm.]

10.4" [26,4 cm.] .285"

.305"

0,723

cm.]

0,774

cm.]

mtf

[4,9 cm.]

2.0" [5,08 cm.]

9j£"

[23,4 cm.]

10.4" [26,4 cm.] .285"

.305"

0,723

cm.]

0,774

cm.]

mtf

[4,9 cm.]

2.0" [5,08 cm.]

Page 241 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

J

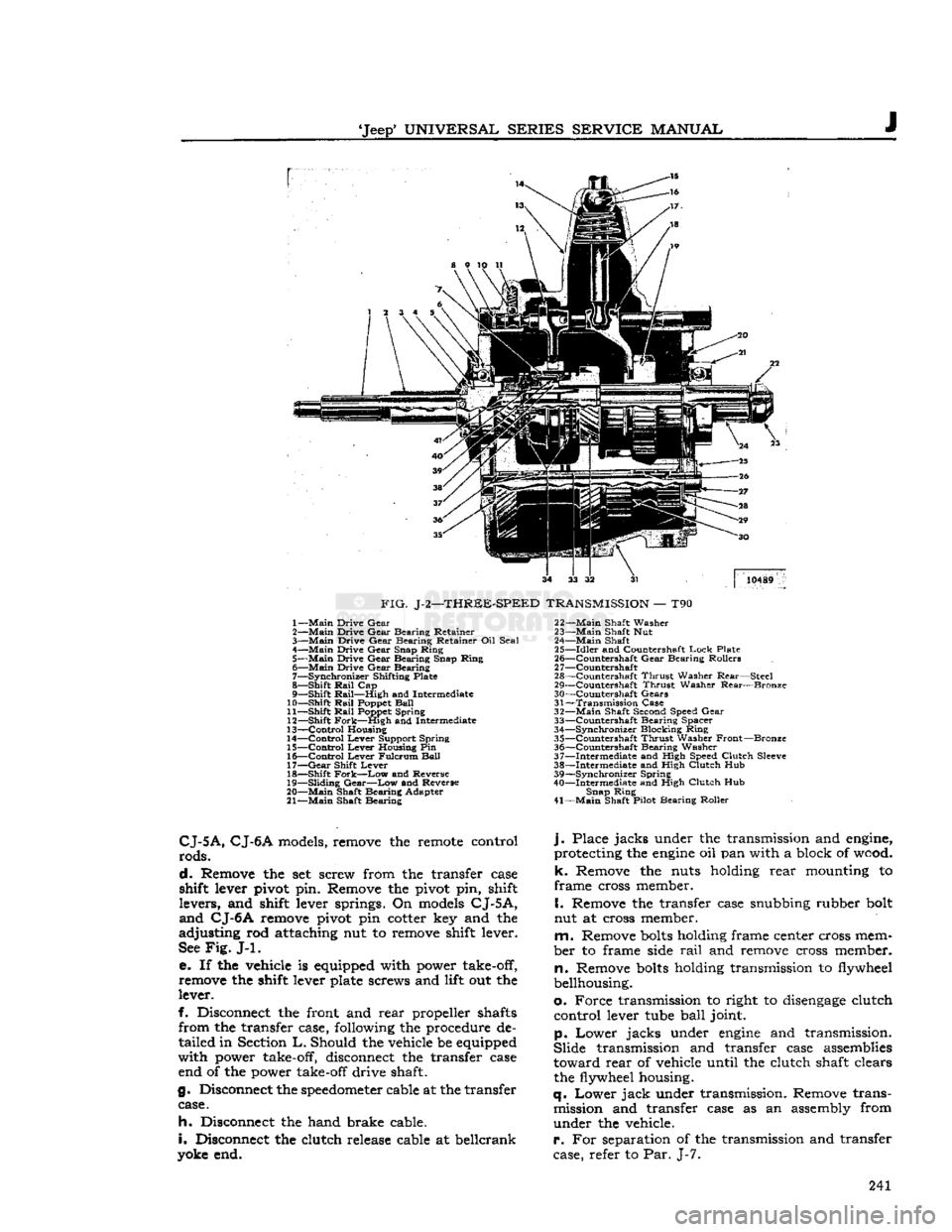

10489

FIG.

J-2—THREE-SPEED

TRANSMISSION

— T90 1—

Main

Drive

Gear

2—

Main

Drive

Gear

Bearing

Retainer

3—

Main

Drive

Gear

Bearing

Retainer Oil

Seal

4—

Main

Drive

Gear

Snap

Ring

5—

Main

Drive

Gear

Bearing

Snap

Ring

6—

Main

Drive

Gear

Bearing

7—

Synchronizer

Shifting Plate

8—

Shift

Rail

Cap

9—

Shift

Rail—High

and Intermediate

10—

Shift

Rail

Poppet

Ball

11—

Shift

Rail

Poppet

Spring

12—

Shift

Fork—High

and Intermediate

13—

Control

Housing

14—

Control

Lever

Support

Spring

15—

Control

Lever

Housing Pin

16—

Control

Lever

Fulcrum

Ball

17—

Gear

Shift

Lever

18—

Shift

Fork—Low

and Reverse

19—

Sliding

Gear—Low

and Reverse

20—

Main

Shaft

Bearing

Adapter

21—

Main

Shaft

Bearing

22—

Main

Shaft

Washer

23—

Main

Shaft Nut

24—

Main

Shaft

25—

Idler

and Countershaft

Lock

Plate

26—

^Countershaft

Gear

Bearing

Rollers

2

7—Countershaft

28—

Countershaft

Thrust

Washer

Rear—Steel

29—

Countershaft

Thrust

Washer

Rear—Bronze

30—

Countershaft

Gears

31—

Transmission

Case

32—

Main

Shaft Second Speed

Gear

33—

Countershaft

Bearing

Spacer

34—

Synchronizer

Blocking

Ring

35—

Countershaft

Thrust

Washer

Front—Bronze

36—

Countershaft

Bearing

Washer

37—

Intermediate

and High Speed

Clutch

Sleeve

38—

Intermediate

and High

Clutch

Hub

39—

Synchronizer

Spring

40—

Intermediate

and High

Clutch

Hub

Snap

Ring

41—

Main

Shaft Pilot

Bearing

Roller

CJ-5A,

CJ-6A

models, remove the remote control

rods.

d.

Remove the set screw from the transfer case

shift lever pivot pin. Remove the pivot pin, shift

levers,

and shift lever springs. On models

CJ-5A,

and

CJ-6A

remove pivot pin cotter key and the

adjusting

rod attaching nut to remove shift lever.

See

Fig.

J-l.

e. If the vehicle is equipped with power take-off,

remove the shift lever plate screws and lift out the

lever.

f. Disconnect the front and

rear

propeller shafts

from

the transfer case, following the procedure de

tailed

in Section

L.

Should the vehicle be equipped

with

power take-off, disconnect the transfer case end of the power take-off drive shaft.

g. Disconnect the

speedometer

cable at the transfer case.

h.

Disconnect the hand brake cable.

i.

Disconnect the clutch release cable at beilcrank

yoke end.

j.

Place

jacks

under the transmission and engine,

protecting the

engine

oil pan with a block of wood,

k.

Remove the nuts holding

rear

mounting to

frame

cross member.

I.

Remove the transfer case snubbing rubber bolt

nut at cross member.

m.

Remove

bolts

holding frame center cross mem

ber

to frame side

rail

and remove cross member,

n.

Remove

bolts

holding transmission to flywheel

bellhousing.

o.

Force

transmission to right to

disengage

clutch

control

lever tube

ball

joint.

p.

Lower

jacks

under

engine

and transmission.

Slide

transmission and transfer case assemblies

toward

rear

of vehicle until the clutch shaft clears the flywheel housing.

q.

Lower

jack

under transmission. Remove trans mission and transfer case as an assembly from

under

the vehicle.

r.

For separation of the transmission and transfer

case, refer to Par. J-7. 241

Page 242 of 376

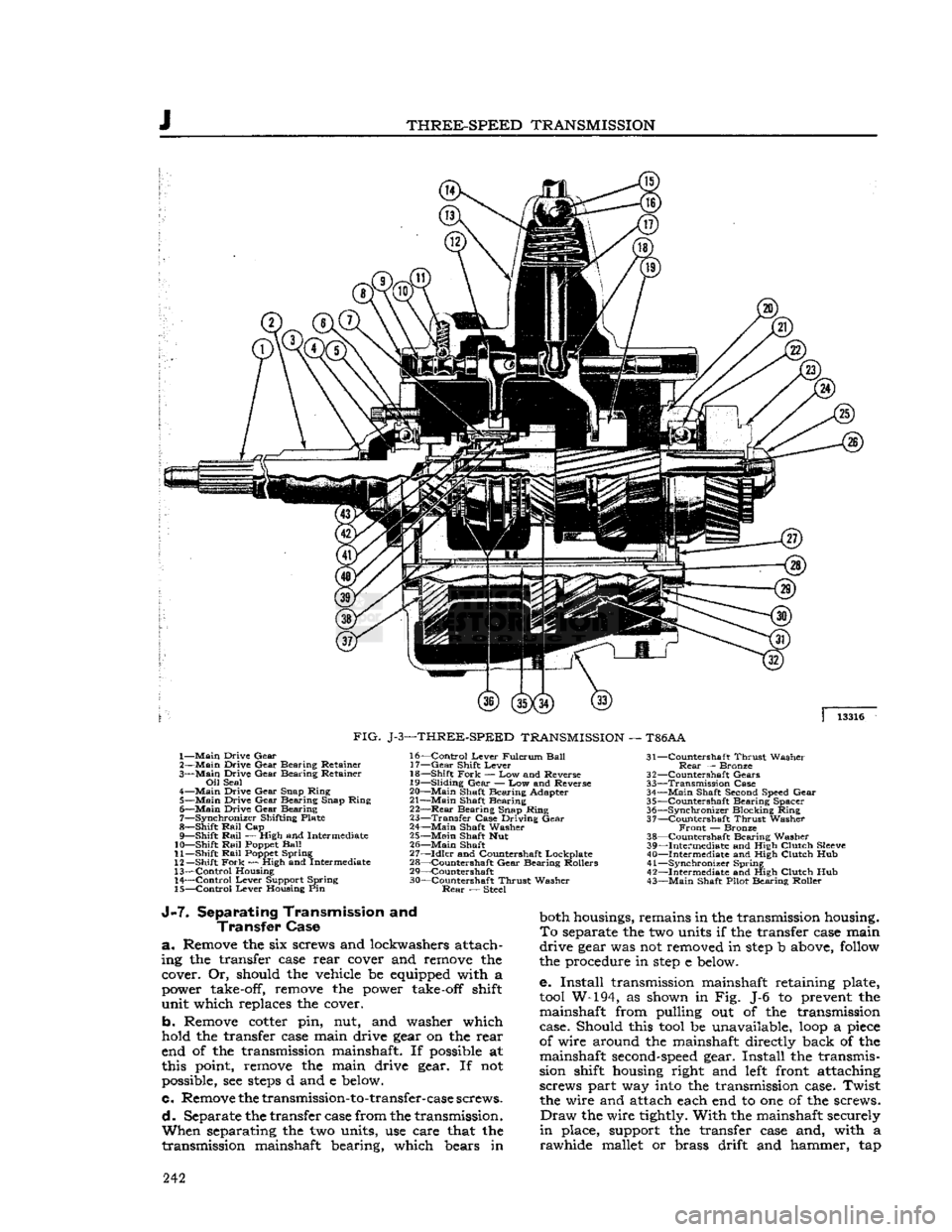

THREE-SPEED

TRANSMISSION

FIG.

J-3—THREE-SPEED

TRANSMISSION

—

T86AA

1—

Main

Drive

Gear

2—

Main

Drive

Gear

Bearing Retainer

3—

Main

Drive

Gear

Bearing Retainer

Oil

Seal

4—

Main

Drive

Gear

Snap Ring

5—

Main

Drive

Gear

Bearing Snap Ring

6—

Main

Drive

Gear

Bearing 7— Synchronizer Shifting Plate

8— Shift

Rail

Cap

9— Shift

Rail

— High and Intermediate

10— Shift

Rail

Poppet

Ball

11— Shift

Rail

Poppet

Spring

12— Shift

Fork

— High and Intermediate

13—

Control

Housing 14—

Control

Lever Support Spring

15—

Control

Lever Housing Pin 16—

Control

Lever

Fulcrum

Ball

17—

Gear

Shift Lever

18— Shift

Fork

— Low and Reverse

19— Sliding

Gear

— Low and Reverse

20—

Main

Shaft Bearing Adapter 21—

Main

Shaft Bearing

22—

Rear

Bearing Snap Ring

23—

Transfer

Case Driving

Gear

24—

Main

Shaft Washer

25—Main Shaft Nut

26—

Main

Shaft

27—

Idler

and Countershaft Lockplate

28— Countershaft

Gear

Bearing Rollers

29— Countershaft

30— Countershaft Thrust Washer

Rear

— Steel 31— Countershaft Thrust Washer

Rear

— Bronze

32— Countershaft Gears

33—

Transmission

Case

34—

Main

Shaft Second Speed

Gear

35— Countershaft Bearing Spacer

36— Synchronizer Blocking Ring 37— Countershaft Thrust Washer

Front

— Bronze

38— Countershaft Bearing Washer

39— Intermediate and High Clutch

Sleeve

40— Intermediate and High Clutch Hub

41

—Synchronizer Spring

42— Intermediate and High Clutch Hub

43—

Main

Shaft Pilot Bearing Roller J-7.

Separating Transmission

and

Transfer Case

a.

Remove the six screws and lockwashers attach

ing the transfer case rear cover and remove the cover. Or, should the vehicle be equipped with a

power

take-off,

remove the power take-off shift

unit which replaces the cover.

b. Remove

cotter

pin, nut, and washer which

hold the transfer case main drive gear on the rear

end of the transmission mainshaft. If

possible

at

this point, remove the main drive gear. If not possible, see

steps

d and e

below.

c. Remove the transmission-to-transfer-case screws.

d.

Separate the transfer case from the transmission.

When separating the two units, use care that the

transmission mainshaft bearing, which bears in

both

housings, remains in the transmission housing.

To

separate the two units if the transfer case main

drive gear was not removed in

step

b

above,

follow

the procedure in

step

e

below.

e.

Install transmission mainshaft retaining plate,

tool

W-194, as shown in Fig. J-6 to prevent the mainshaft from pulling out of the transmission

case. Should this

tool

be unavailable,

loop

a

piece

of wire around the mainshaft directly back of the mainshaft

second-speed

gear. Install the transmis

sion shift housing right and

left

front attaching

screws part way

into

the transmission case. Twist

the wire and attach each end to one of the screws.

Draw

the wire tightly. With the mainshaft securely

in

place, support the transfer case and, with a rawhide mallet or brass drift and hammer, tap 242

Page 244 of 376

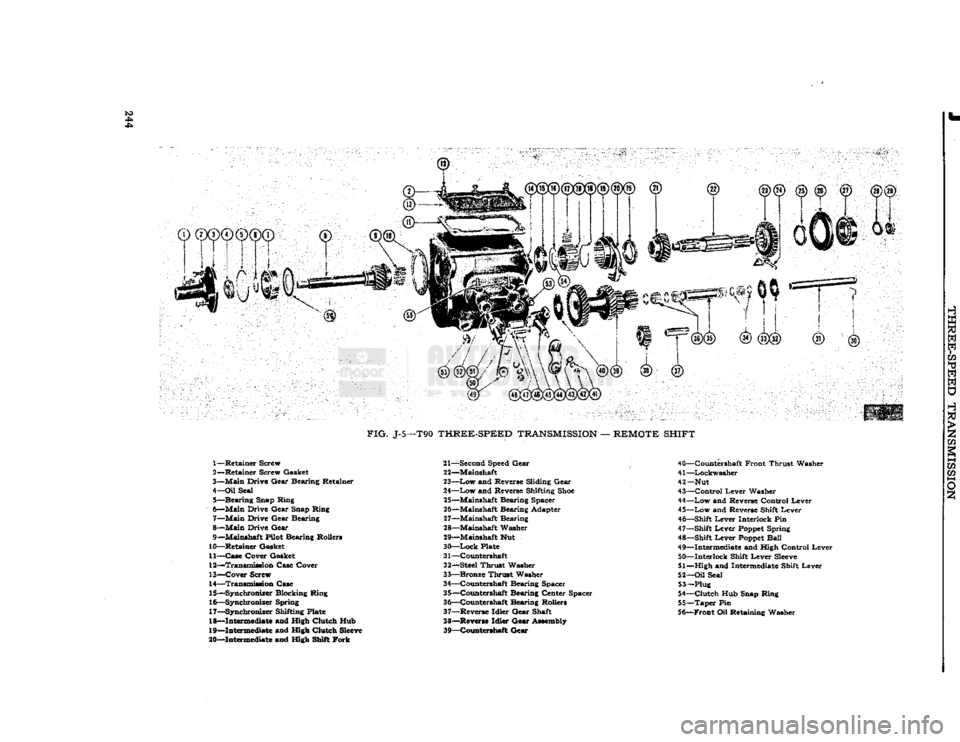

1— Retainer Screw

2— Retainer Screw Gasket

3—

Main

Drive Gear Bearing Retainer

4—

Oil

Seal 5— Bearing Snap Ring

6—

Main

Drive Gear Snap Ring 7—

Main

Drive Gear Bearing

8—

Main

Drive Gear

9— Mainshaft Pilot Bearing Rollers

10— Retainer Gasket

11—

Case

Cover Gasket 12—Transmission Case Cover

13—

Cover

Screw

14— Transmission Case 15— Synchronizer Blocking Ring

16— Synchronizer Spring

17— Synchronizer Shifting Plate

18— Intermediate and High Clutch Hub

19—

Intermediate

and High Clutch

Sleeve

20— Intermediate and High Shift

Fork

21—

Second

Speed

Gear

22— Mainshaft

23—

Low

and Reverse Sliding Gear 24—

Low

and Reverse Shifting

Shoe

25— Mainshaft Bearing Spacer

26— Mainshaft Bearing Adapter

27— Mainshaft Bearing

28— Mainshaft Washer

29— Mainshaft Nut

30—

Lock

Plate

31— Countershaft

32—

Steel

Thrust Washer

33— Bronze Thrust Washer

34— Countershaft Bearing Spacer

35— Countershaft Bearing Center Spacer

36— Countershaft Bearing Rollers

37— Reverse Idler Gear Shaft

38— Reverse Idler Gear Assembly

39— Countershaft Gear 40— Countershaft Front Thrust Washer

41—

Lockwasher

42— Nut

43—

Control

Lever Washer

44—

Low

and Reverse Control Lever

45—

Low

and Reverse Shift Lever

46— Shift Lever Interlock Pin

47— Shift Lever

Poppet

Spring

48— Shift Lever

Poppet

Ball

49— Intermediate and High Control Lever 50— Interlock Shift Lever

Sleeve

51— High and Intermediate Shift Lever

52—

Oil

Seal 53— Plug

54—

Clutch

Hub Snap Ring 55—

Taper

Pin

56—

Front

Oil Retaining Washer

Page 245 of 376

'Jeep*

UNIVERSAL

SERIES'

SERVICE

MANUAL

lightly

on the end of the

mainshaft

to

loosen

the

gear

and

separate

the two

units.

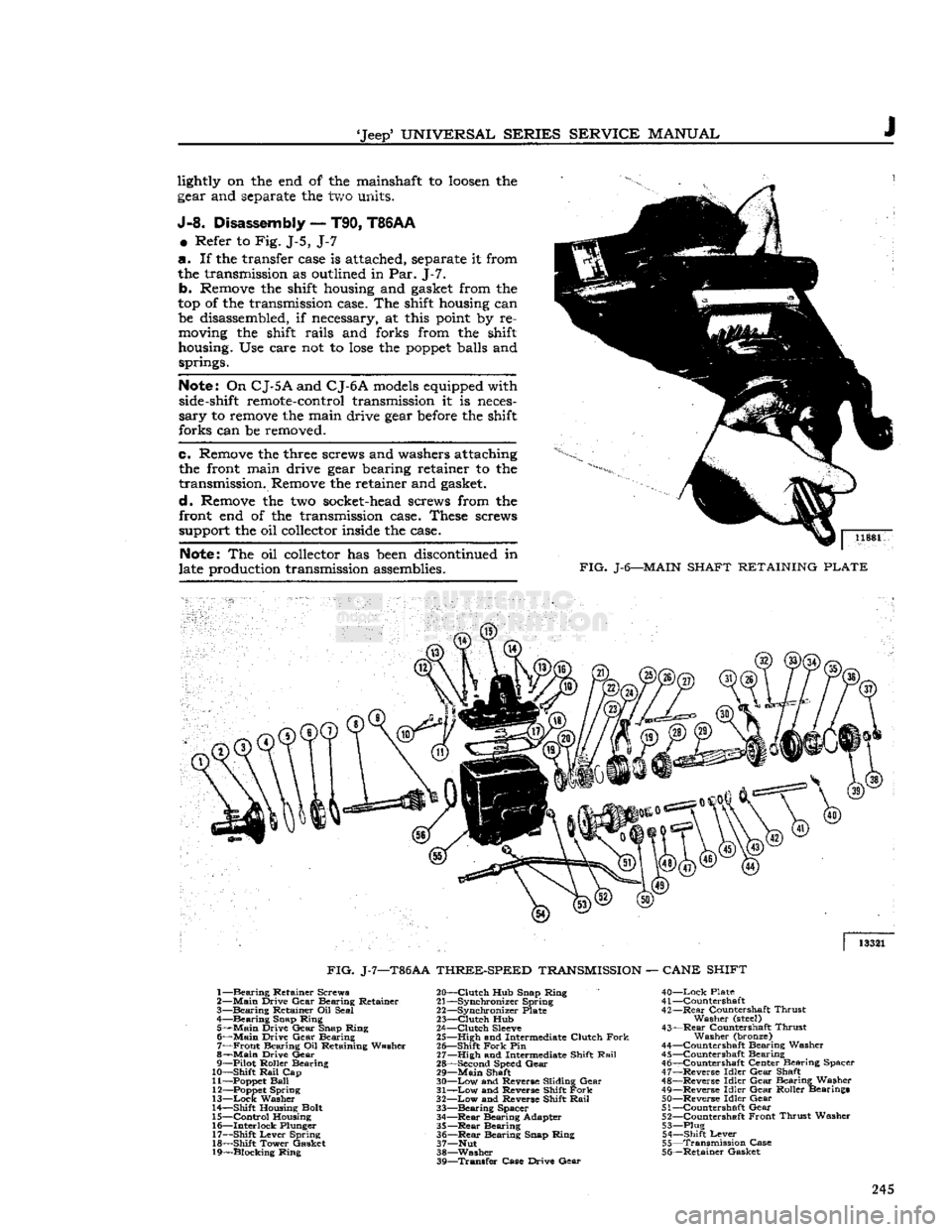

J-8.

Disassembly

—

T90,

T86AA

®

Refer to Fig. J-5, J-7

a. If the transfer

case

is

attached,

separate

it from

the

transmission

as

outlined

in Par. J-7. b.

Remove

the

shift

housing

and

gasket

from the

top of the

transmission

case.

The

shift

housing

can

be

disassembled,

if

necessary,

at

this

point

by re

moving

the

shift

rails and forks from the

shift

housing.

Use care not to

lose

the

poppet

balls

and

springs.

Note;

On

CJ-5

A

and

C

J-6A

models

equipped

with

side-shift

remote-control

transmission

it is

neces

sary to

remove

the main drive

gear

before

the

shift

forks can be

removed.

e.

Remove

the

three

screws

and

washers

attaching

the

front

main drive

gear

bearing

retainer to the

transmission.

Remove

the retainer and

gasket,

d.

Remove

the two

socket-head

screws

from the

front

end of the

transmission

case.

These

screws

support

the oil

collector

inside

the

case.

Note:

The oil

collector

has

been

discontinued

in

late

production

transmission

assemblies.

11881

FIG.

J-6—MAIN

SHAFT

RETAINING

PLATE

13321

FIG.

J-7—T86AA

THREE-SPEED

TRANSMISSION

—

CANE

SHIFT

1—

Bearing

Retainer Screws

2—

Main

Drive Gear Bearing Retainer

3—

Bearing

Retainer Oil Seal

,

4—Bearing Snap Ring

5—

Main

Drive Gear Snap Ring 6—

Main

Drive Gear Bearing 7—

Front

Bearing Oil Retaining Washer

8—

Main

Drive Gear

9— Pilot Roller Bearing

10— Shift

Rail

Cap

11—

Poppet

Ball

12—

Poppet

Spring

13—

Lock

Washer

14— Shift Housing Bolt

15—

Control

Housing 16— Interlock Plunger

17— Shift Lever Spring

18— Shift Tower Gasket

19— Blocking Ring 20—

Clutch

Hub Snap Ring

21— Synchronizer Spring

22— Synchronizer Plate

23—

Clutch

Hub

24—

Clutch

Sleeve

25— High and Intermediate Clutch

Fork

26— Shift

Fork

Pin

27— High and Intermediate Shift

Rail

28— Second Speed Gear 29—

Main

Shaft

30—

Low

and Reverse Sliding Gear

31—

Low

and Reverse Shift

Fork

32—

Low

and Reverse Shift

Rail

33—

Bearing

Spacer

34—

—Rear

Bearing Adapter

35—Rear

Bearing 36—

Rear

Bearing Snap Ring

37— Nut

38—Washer 39—

Transfer

Case Drive Gear

40—Lock

Plate

41 —Countershaft

42—

Rear

Countershaft Thrust Washer

(steel)

43—

Rear

Countershaft Thrust Washer (bronze)

44— Countershaft Bearing Washer

45— Countershaft Bearing 46— Countershaft Center Bearing Spacer

47— Reverse Idler Gear Shaft

48— Reverse Idler Gear Bearing Washer

49— Reverse Idler Gear Roller Bearings 50— Reverse Idler Gear

51— Countershaft Gear 52— Countershaft Front Thrust Washer

53— Plug 54— Shift Lever

55—

Transmission

Case

56— Retainer Gasket 245

Page 246 of 376

J

THREE-SPEED

TRANSMISSION

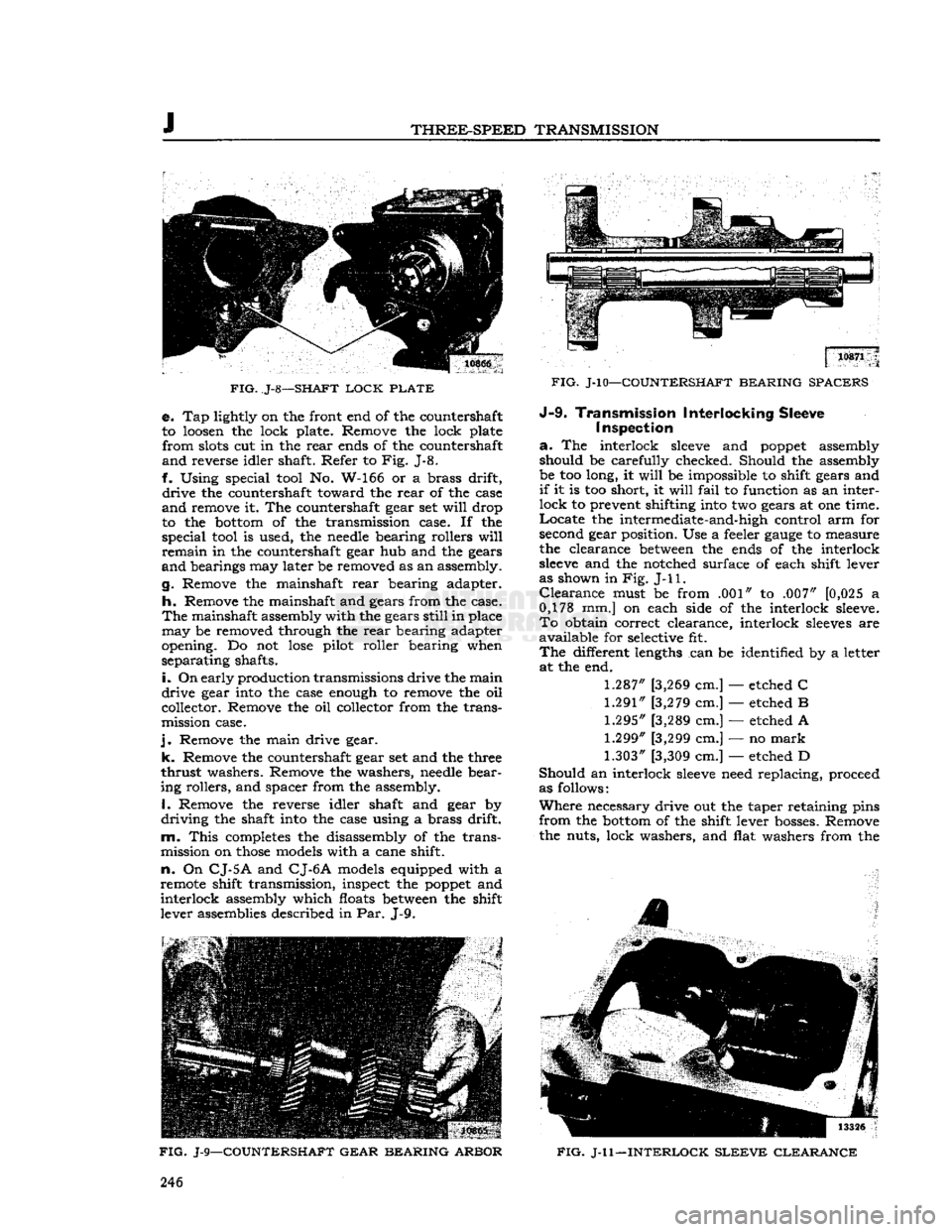

FIG.

J-8—SHAFT

LOCK

PLATE

e. Tap lightly on the front end of the countershaft

to loosen the lock plate. Remove the lock plate

from

slots cut in the

rear

ends of the countershaft

and

reverse idler shaft. Refer to Fig. J-8.

f. Using special tool No. W-166 or a brass drift,

drive

the countershaft toward the

rear

of the case

and

remove it. The countershaft gear set

will

drop

to the bottom of the transmission case. If the

special

tool is used, the needle bearing rollers

will

remain

in the countershaft gear hub and the gears

and

bearings may later be removed as an assembly.

g. Remove the mainshaft

rear

bearing adapter.

h.

Remove the mainshaft and gears from the case.

The

mainshaft assembly with the gears

still

in place

may

be removed through the

rear

bearing adapter

opening. Do not

lose

pilot roller bearing when

separating

shafts.

i.

On

early production transmissions drive the main

drive

gear into the case enough to remove the oil

collector. Remove the oil collector from the trans

mission case.

j.

Remove the main drive gear,

k.

Remove the countershaft gear set and the three

thrust

washers. Remove the washers, needle bear

ing rollers, and spacer from the assembly. 1, Remove the reverse idler shaft and gear by

driving

the shaft into the case using a brass drift,

m.

This

completes the disassembly of the trans

mission on

those

models with a cane shift,

n.

On

CJ-5

A

and

CJ-6 A

models equipped with a

remote shift transmission, inspect the poppet and

interlock

assembly which floats between the shift

lever assemblies described in Par. J-9.

FIG.

J-9—COUNTERSHAFT GEAR BEARING ARBOR

FIG.

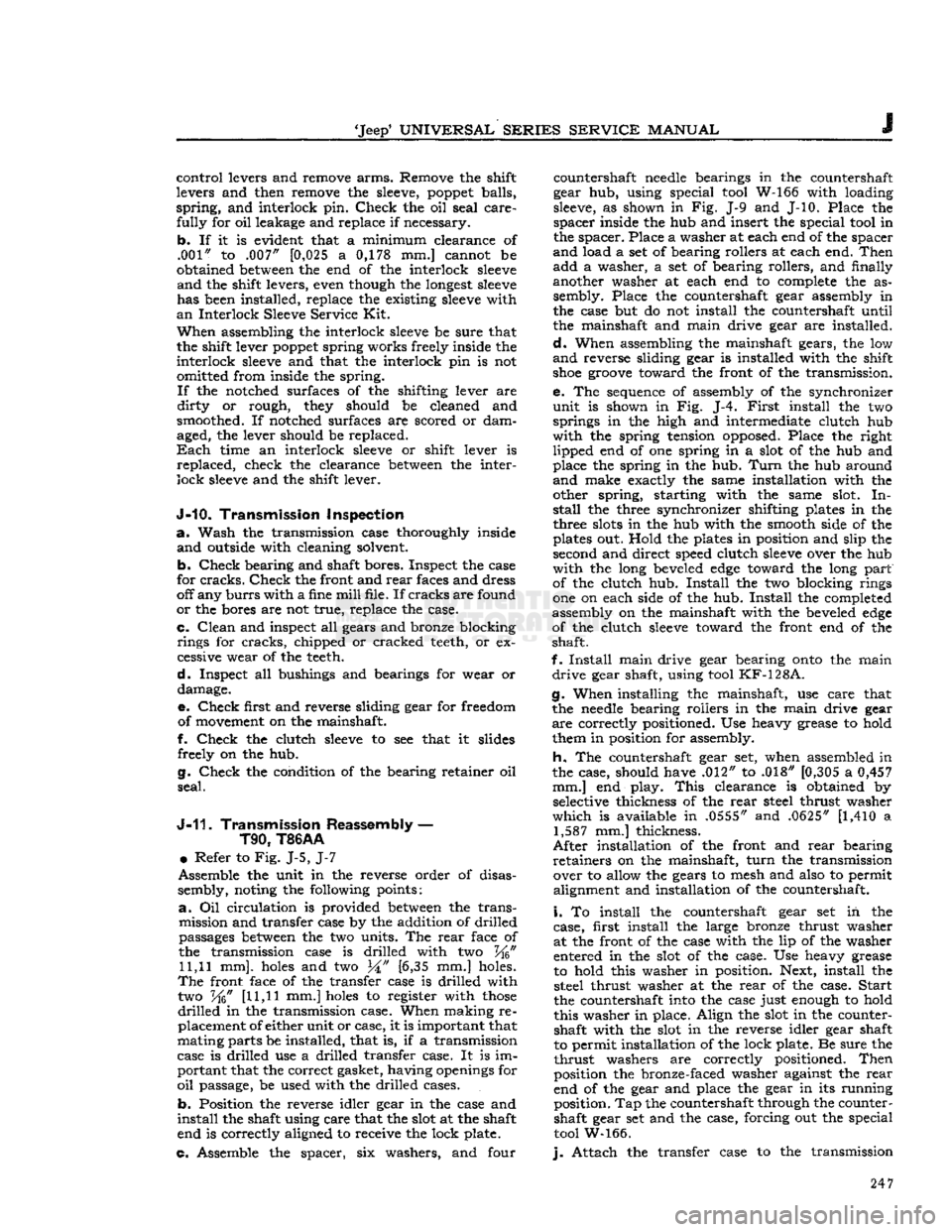

J-l0—COUNTERSHAFT BEARING SPACERS J-9-

Transmission Interlocking Sleeve

I

inspection

a.

The interlock

sleeve

and poppet assembly should be carefully checked. Should the assembly

be too long, it

will

be impossible to shift gears and

if

it is too short, it

will

fail

to function as an inter

lock

to prevent shifting into two gears at one time.

Locate

the intermediate-and-high control arm for

second gear position. Use a feeler

gauge

to measure

the clearance between the ends of the interlock

sleeve

and the notched surface of each shift lever

as shown in Fig.

J-l

1.

Clearance

must be from .001" to .007" [0,025 a

0,178 mm.] on each side of the interlock sleeve.

To

obtain correct clearance, interlock

sleeves

are

available

for selective fit.

The

different lengths can be identified by a letter at the end.

1.287"

[3,269 cm.] — etched C

1.291"

[3,279 cm.] — etched B

1.295"

[3,289 cm.] — etched A

1.299"

[3,299 cm.] — no

mark

1.303"

[3,309 cm.] — etched D

Should

an interlock

sleeve

need replacing, proceed

as follows:

Where

necessary drive out the taper retaining pins

from

the bottom of the shift lever bosses. Remove

the nuts, lock washers, and flat washers from the

4

FIG.

J-l 1—INTERLOCK

SLEEVE

CLEARANCE

246

Page 247 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

J

control

levers and remove arms. Remove the shift

levers and then remove the

sleeve,

poppet

balls,

spring,

and interlock pin.

Check

the oil seal care

fully

for oil leakage and replace if necessary,

b.

If it is evident that a minimum clearance of .001" to .007" [0,025 a 0,178 mm.] cannot be

obtained

between

the end of the interlock

sleeve

and

the shift levers, even though the

longest

sleeve

has been installed, replace the existing

sleeve

with

an

Interlock Sleeve Service Kit.

When

assembling the interlock

sleeve

be sure that

the shift lever

poppet

spring works freely inside the

interlock

sleeve

and that the interlock pin is not

omitted from inside the spring.

If

the notched surfaces of the shifting lever are

dirty

or rough, they should be cleaned and

smoothed. If notched surfaces are scored or dam

aged, the lever should be replaced.

Each

time an interlock

sleeve

or shift lever is

replaced,

check the clearance

between

the inter

lock

sleeve

and the shift lever.

J-10.

Transmission

Inspection

a.

Wash the transmission case thoroughly inside

and

outside with cleaning solvent.

b.

Check

bearing and shaft bores. Inspect the case

for

cracks.

Check

the front and

rear

faces and dress

off any

burrs

with a fine

mill

file. If

cracks

are found

or

the bores are not true, replace the case.

c.

Clean

and inspect all gears and bronze blocking

rings for

cracks,

chipped or cracked teeth, or excessive wear of the teeth.

d.

Inspect all bushings and bearings for wear or damage.

e.

Check

first and reverse sliding gear for freedom of movement on the mainshaft.

f.

Check

the clutch

sleeve

to see that it slides freely on the hub.

g.

Check

the condition of the bearing retainer oil

seal.

J-11.

Transmission

Reassembly

—

T90,

T86AA

•

Refer to Fig. J-5, J-7

Assemble the unit in the reverse order of disas

sembly, noting the following points:

a.

Oil circulation is provided

between

the trans mission and transfer case by the addition of drilled

passages

between

the two units. The

rear

face of

the transmission case is drilled with two %" 11,11 mm],

holes

and two [6,35 mm.] holes.

The

front face of the transfer case is drilled with

two %"

[11,11

mm.]

holes

to register with

those

drilled

in the transmission case. When making re

placement of either unit or case, it is important that

mating parts be installed, that is, if a transmission

case is drilled use a drilled transfer case. It is im

portant that the correct gasket, having

openings

for

oil

passage, be used with the drilled cases.

b.

Position the reverse idler gear in the case and

install

the shaft using care that the slot at the shaft end is correctly aligned to receive the lock plate.

c. Assemble the spacer, six washers, and four countershaft

needle

bearings in the countershaft

gear hub, using special tool W-166 with loading

sleeve,

as shown in Fig. J-9 and J-10. Place the

spacer

inside the hub and insert the special tool in

the spacer. Place a washer at each end of the spacer

and

load a set of bearing rollers at each end.

Then

add

a washer, a set of bearing rollers, and finally

another washer at each end to complete the as sembly. Place the countershaft gear assembly in

the case but do not install the countershaft until

the mainshaft and main drive gear are installed.

d.

When assembling the mainshaft gears, the low

and

reverse sliding gear is installed with the shift

shoe

groove

toward the front of the transmission.

e. The sequence of assembly of the synchronizer

unit

is shown in Fig. J-4.

First

install the two springs in the high and intermediate clutch hub

with

the spring tension opposed. Place the right lipped end of one spring in a slot of the hub and

place the spring in the hub.

Turn

the hub around

and

make exactly the same installation with the other spring, starting with the same slot. In

stall

the three synchronizer shifting plates in the

three

slots

in the hub with the smooth side of the

plates out. Hold the plates in position and slip the second and direct speed clutch

sleeve

over the hub

with

the long beveled

edge

toward the long part

of the clutch hub.

Install

the two blocking rings

one on each side of the hub.

Install

the completed

assembly on the mainshaft with the beveled

edge

of the clutch

sleeve

toward the front end of the

shaft.

f.

Install

main drive gear bearing

onto

the main

drive

gear shaft, using tool

KF-128A.

g.

When installing the mainshaft, use care that the

needle

bearing rollers in the main drive gear

are

correctly positioned. Use heavy grease to hold

them in position for assembly.

h.

The countershaft gear set, when assembled in

the case, should have .012" to .018" [0,305 a

0,457

mm.] end play.

This

clearance is obtained by selective thickness of the

rear

steel thrust washer

which

is available in .0555" and .0625"

[1,410

a 1,587 mm.] thickness.

After

installation of the front and

rear

bearing

retainers

on the mainshaft,

turn

the transmission over to allow the gears to mesh and also to permit alignment and installation of the countershaft.

i.

To install the countershaft gear set in the

case, first install the large bronze thrust washer

at the front of the case with the lip of the washer

entered in the slot of the case. Use heavy grease to hold this washer in position. Next, install the steel thrust washer at the

rear

of the case.

Start

the countershaft into the case just enough to hold

this washer in place. Align the slot in the counter shaft with the slot in the reverse idler gear shaft

to permit installation of the lock plate. Be sure the

thrust

washers are correctly positioned.

Then

position the bronze-faced washer against the

rear

end of the gear and place the gear in its running

position.

Tap

the countershaft through the countershaft gear set and the case, forcing out the special

tool W-166.

j.

Attach the transfer case to the transmission 247

Page 248 of 376

J

THREE-SPEED

TRANSMISSION

before

the unit is installed in the vehicle. When

doing this, use care that the countershaft and

reverse

idler shaft lock plate shown in Fig. J-8

is correctly positioned in the recess in the transfer case housing.

Three

\

Y%"

long [2,86 cm.] screws and

two 1" long [2,54 cm.] screws are used to attach the

transfer

case housing to the transmission housing.

Install

the 1" long [2,54 cm.] screws in the lower

left

and lower right mounting holes.

FIG.

J-12—SYNCHRONIZER

SPRINGS

J-12.

Transmission — T96

•

Model DJ-5, DJ-6

a.

Remove the shift housing and gasket from the top of the transmission case if it has not

been

pre viously removed. The shift housing can be disas

sembled, if necessary, at this point by removing the

shift

rails

and forks from the shift housing. Use

care

and do not

lose

the

poppet

balls and springs.

b.

Drain

the lubricant from housing and wash

the assembly with a suitable solvent.

c.

Remove the screws from the front main bearing

retainer

and remove retainer.

d.

Remove nut which attaches the companion

flange

to the main shaft; also the flat washer and

lock

washer.

e.

Remove the companion

flange

with special puller

tool

W-172.

f. Remove the screws attaching the

rear

bearing

retainer

to case and remove retainer and gasket.

g. Remove oil seal

speedometer

drive gear and

main

shaft

rear

bearing from the bearing retainer.

h.

Remove the reverse idler and countershaft

lock

plate.

i.

Using

tool

W-193 or a

soft

drift, drive the

countershaft out through the

rear

of the case allow

ing the counterhsaft gears to drop to the

bottom

of the case.

j.

Remove the main drive gear with bearing

through the front of the case.

Note

that this gear cannot be removed when the countershaft gears are

in

position.

Take

care when removing this gear not

to misplace the thirteen

needle

type

rollers in the

gear end of the shaft which make up the main shaft

pilot bearing.

k.

Remove the main shaft snap

ring,

the main

shaft bearing snap ring and the mainshaft bearing

which

is grooved, from the main shaft.

I.

Remove the bronze blocking ring then remove

the clutch hub and synchronizer assembly through

the top.

m.

Remove the low and reverse sliding gears and

the constant mesh gear and main shaft in one unit,

through the top.

n.

Remove the countershaft gears through the

top.

Take

care not to misplace the twenty rollers at each end of the long spacer as well as the two

thrust

washers and the two roller spacer bearings,

o.

Using a

soft

drift, drive the reverse idler shaft

out toward the

rear

and remove the gear.

J-13.

Transmission Cleaning and Inspection

Refer

to Fig. J-7.

a.

Wash the transmission case inside and

outside

with

cleaning solvent.

b.

Check

bearing and shaft bores. Inspect the case

for

cracks.

Check

the front and

rear

faces

and dress off any

burrs

with a fine

mill

file. If cracks

are

found or the bores are not true, replace the case.

c.

Clean

and inspect all gears and bronze blocking

rings

for

cracks,

chipped or cracked

teeth,

or ex

cessive wear of the

teeth.

Note:

Whenever any transmission gear requires

replacement, the gear with which it

meshes

should also be replaced.

d.

Inspect all bushings and bearings for wear or damage.

e.

Check

low-and-reverse sliding gear for freedom

of

movement

on the main shaft.

f.

Check

the intermediate-and-high clutch

sleeve

to see that it slides freely on the intermediate-and-

high clutch hub.

J-14. Transmission Reassembly

—-

T96

a.

Position the reverse idler gear in the case and

install

the shaft using care that the

slot

at the shaft

end is correctly aligned to receive the lock plate.

b.

To assemble the countershaft gear, it is neces

sary

to use Tool W-193 or equivalent

Fig. J-9.

Place

the special

tool

through the gear set and insert the

long spacer positioning it at the center of the gear

set. Place a set of twenty rollers at each end of the

spacer

followed by a spacing washer at each end.

A

small amount of grease

will

hold the spacing

washer

in position. Place the assembled counter shaft gear set in the

bottom

of the case with the

large gear toward the front.

C*

Install

the

rear

main shaft bearing on the main shaft with the closed side of the bearing toward

the front or low end of the shaft. Replace the bear

ing snap ring and main shaft snap

ring,

d.

Pass the front end of the main shaft through the

rear

bearing opening and assemble the low and 248