steering JEEP CJ 1953 Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 336 of 376

Q

WHEELS

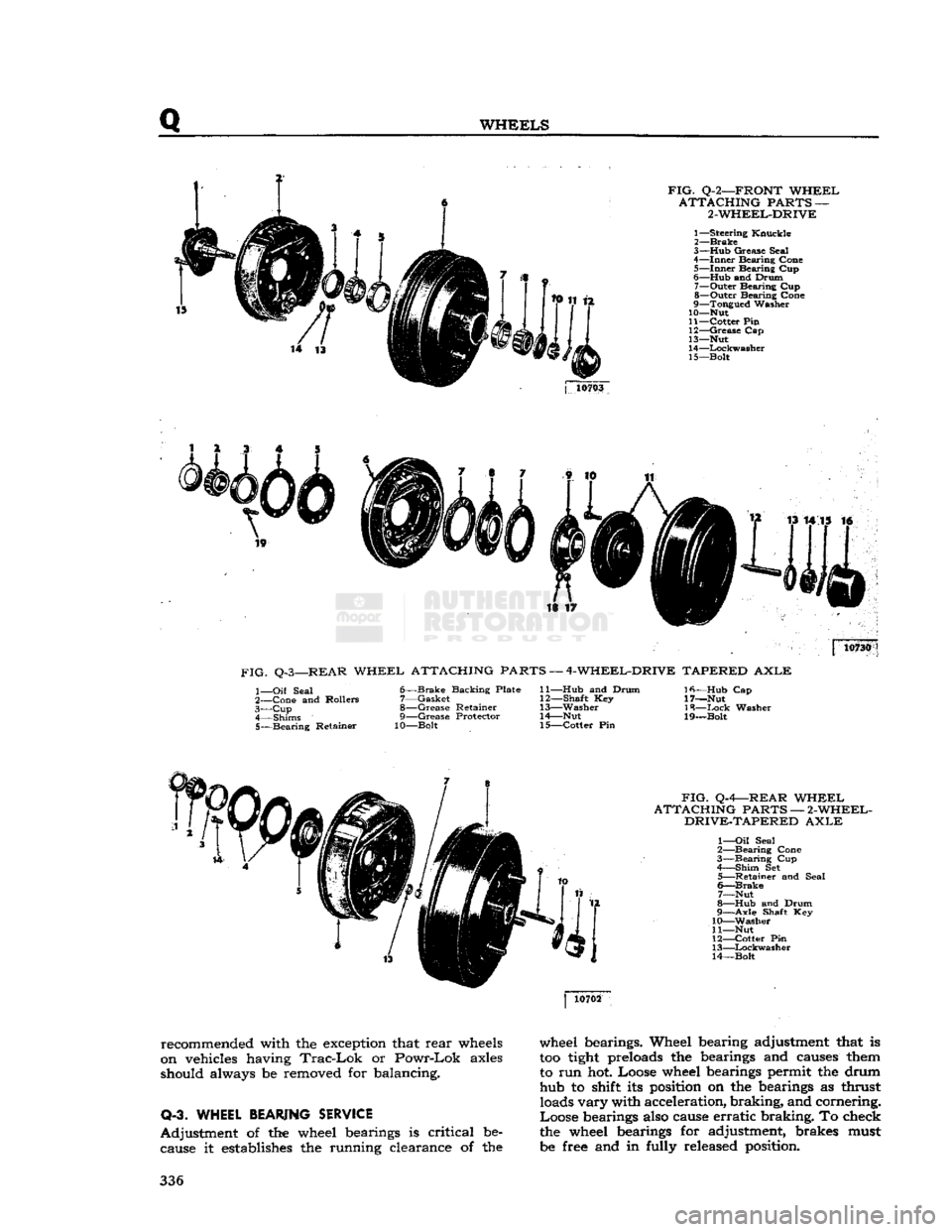

FIG.

Q-2—FRONT

WHEEL

ATTACHING

PARTS —

2-WHEEL-DRIVE

1—

Steering

Knuckle

2—

Brake

3— Hub

Grease

Seal

4—

Inner

Bearing

Cone

5—

Inner

Bearing

Cup

6—

Hub

and

Drum

7—

Outer

Bearing

Cup

8—

Outer

Bearing

Cone

9—

Tongued

Washer

10— Nut

11—

Cotter

Pin

12—

Grease

Cap

13— Nut

14—

Lockwasher

15—

Bolt

j

10703

is ir 10730

FIG.

Q-3—REAR

WHEEL

ATTACHING PARTS —

4-WHEEL-DRIVE

TAPERED

AXLE

1—

Oil

Seal

2—

Cone

and

Rollers

3— Cup

4—

Shims

5—

Bearing

Retainer

6—

Brake

Backing

Plate

7—

Gasket

8—

Grease

Retainer

9—

Grease

Protector

10—Bolt

11— Hub

and

Drum

12—

Shaft

Key

13—

Washer

14—

Nut

15—

Cotter

Pin

Ifi—Hub

Cap

17—Nut

18—

Ixick

Washer

19—Bolt

FIG.

Q-4—REAR

WHEEL

ATTACHING

PARTS —

2-WHEEL-

DRIVE-TAPERED

AXLE

1—

Oil

Seal

2—

Bearing

Cone

3—

Bearing

Cup

4—

Shim

Set

5—

Retainer

and

Seal

6—

Brake

7—

Nut

8—

Hub

and

Drum

9—

Axle

Shaft Key

10—

Washer

11— Nut

12—

Cotter

Pin

13—

Lockwasher

14—

Bolt

recommended with the exception that

rear

wheels

on vehicles having

Trac-Lok

or

Powr-Lok

axles

should always be removed for balancing.

Q-3. WHEEL

BEARING

SERVICE

Adjustment

of the wheel bearings is

critical

be cause it establishes the running clearance of the wheel bearings. Wheel bearing adjustment that is

too

tight

preloads the bearings and causes them

to run hot. Loose wheel bearings permit the drum hub to shift its position on the bearings as thrust loads

vary

with acceleration,

braking,

and cornering.

Loose

bearings also cause

erratic

braking.

To check

the wheel bearings for adjustment, brakes must

be free and in fully released position. 336

Page 337 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

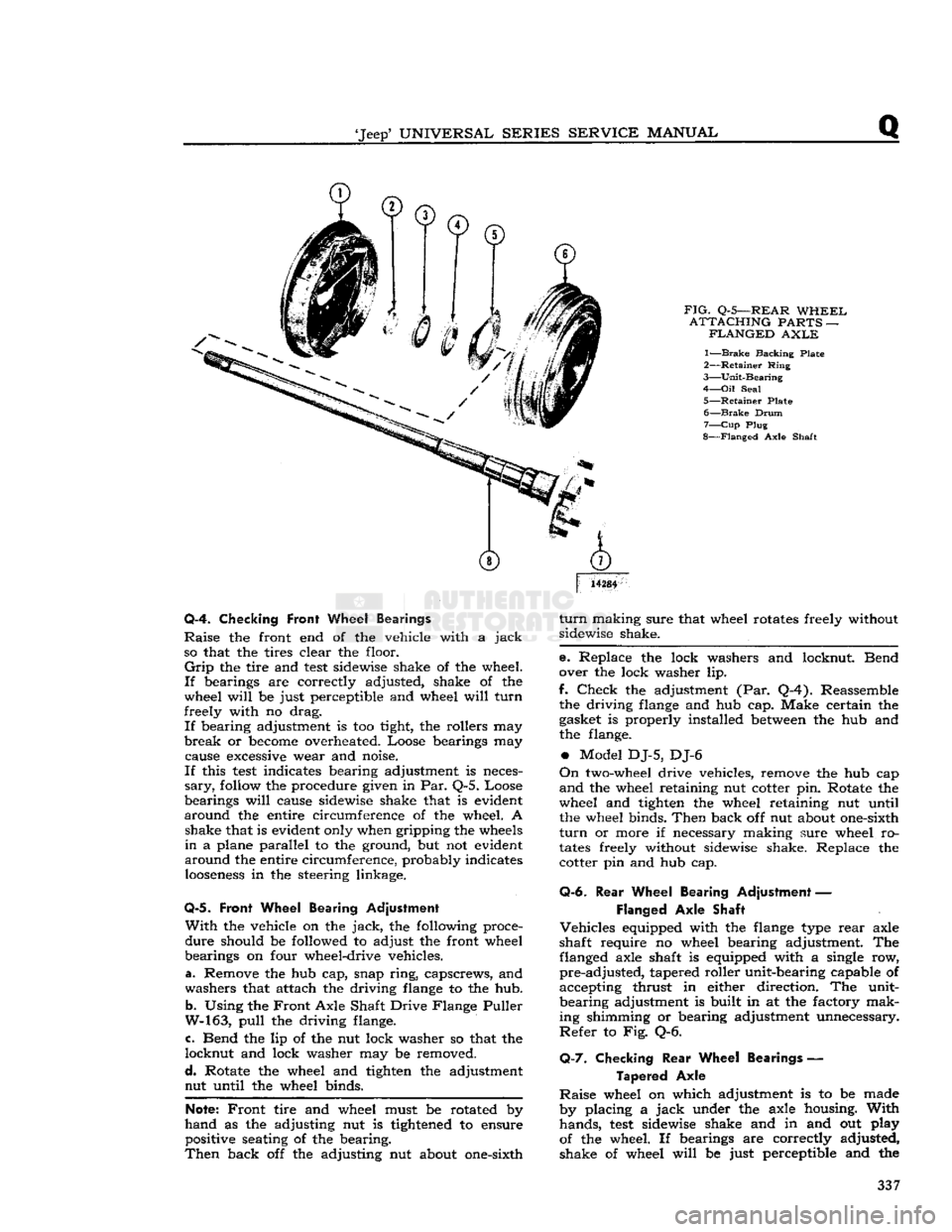

FIG.

Q-5—REAR

WHEEL

ATTACHING

PARTS —

FLANGED

AXLE

1—

Brake

Backing Plate

2—

Retainer

Ring

3—

Unit-Bearing

4—

Oil

Seal

5—

Retainer

Plate 6—

Brake

Drum

7—

Cup

Plug

8—

Flanged

Axle Shaft

14284

Q-4. Checking

Front

Wheel Bearings

Raise

the front end of the vehicle with a

jack

so that the tires clear the floor.

Grip

the tire and

test

sidewise shake of the wheel.

If

bearings are correctly adjusted, shake of the

wheel

will

be just perceptible and wheel

will

turn

freely with no drag.

If

bearing adjustment is too tight, the rollers may

break

or

become

overheated. Loose bearings may cause

excessive

wear and noise.

If

this

test

indicates bearing adjustment is neces

sary,

follow

the procedure given in Par. Q-5. Loose

bearings

will

cause sidewise shake that is evident

around

the entire circumference of the wheel. A shake that is evident only when gripping the

wheels

in

a plane parallel to the ground, but not evident

around

the entire circumference, probably indicates

looseness

in the steering linkage.

Q-5.

Front Wheel Bearing Adjustment

With

the vehicle on the

jack,

the following proce

dure

should be followed to adjust the front wheel

bearings on four wheel-drive vehicles.

a. Remove the hub cap, snap

ring,

capscrews, and

washers that attach the driving

flange

to the hub.

b.

Using the

Front

Axle Shaft Drive Flange Puller

W-163,

pull

the driving flange.

c. Bend the lip of the nut lock washer so that the

locknut

and lock washer may be removed.

d.

Rotate the wheel and tighten the adjustment nut until the wheel binds.

Note:

Front

tire and wheel must be rotated by

hand

as the adjusting nut is

tightened

to ensure positive seating of the bearing.

Then

back off the adjusting nut about one-sixth

turn

making sure that wheel rotates freely without

sidewise shake.

e. Replace the lock washers and locknut. Bend

over the lock washer lip.

f.

Check

the adjustment (Par. Q-4). Reassemble the driving

flange

and hub cap. Make certain the

gasket is properly installed

between

the hub and

the flange.

•

Model DJ-5, DJ-6

On

two-wheel drive vehicles, remove the hub cap

and

the wheel retaining nut cotter pin. Rotate the

wheel and tighten the wheel retaining nut until the wheel binds.

Then

back off nut about one-sixth

turn

or more if necessary making sure wheel ro

tates

freely without sidewise shake. Replace the cotter pin and hub cap.

Q-6.

Rear

Wheel Bearing Adjustment —

Flanged

Axle Shaft

Vehicles

equipped with the

flange

type

rear

axle

shaft require no wheel bearing adjustment. The flanged axle shaft is equipped with a single row,

pre-adjusted,

tapered roller unit-bearing capable of

accepting thrust in either direction. The unit-

bearing

adjustment is built in at the factory mak

ing shimming or bearing adjustment unnecessary.

Refer

to Fig. Q-6.

Q-7.

Checking

Rear

Wheel Bearings —

Tapered

Axle

Raise

wheel on which adjustment is to be made

by placing a

jack

under the axle housing.

With

hands,

test

sidewise shake and in and out play

of the wheel. If bearings are correctly adjusted,

shake of wheel

will

be just perceptible and the 337

Page 341 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

R

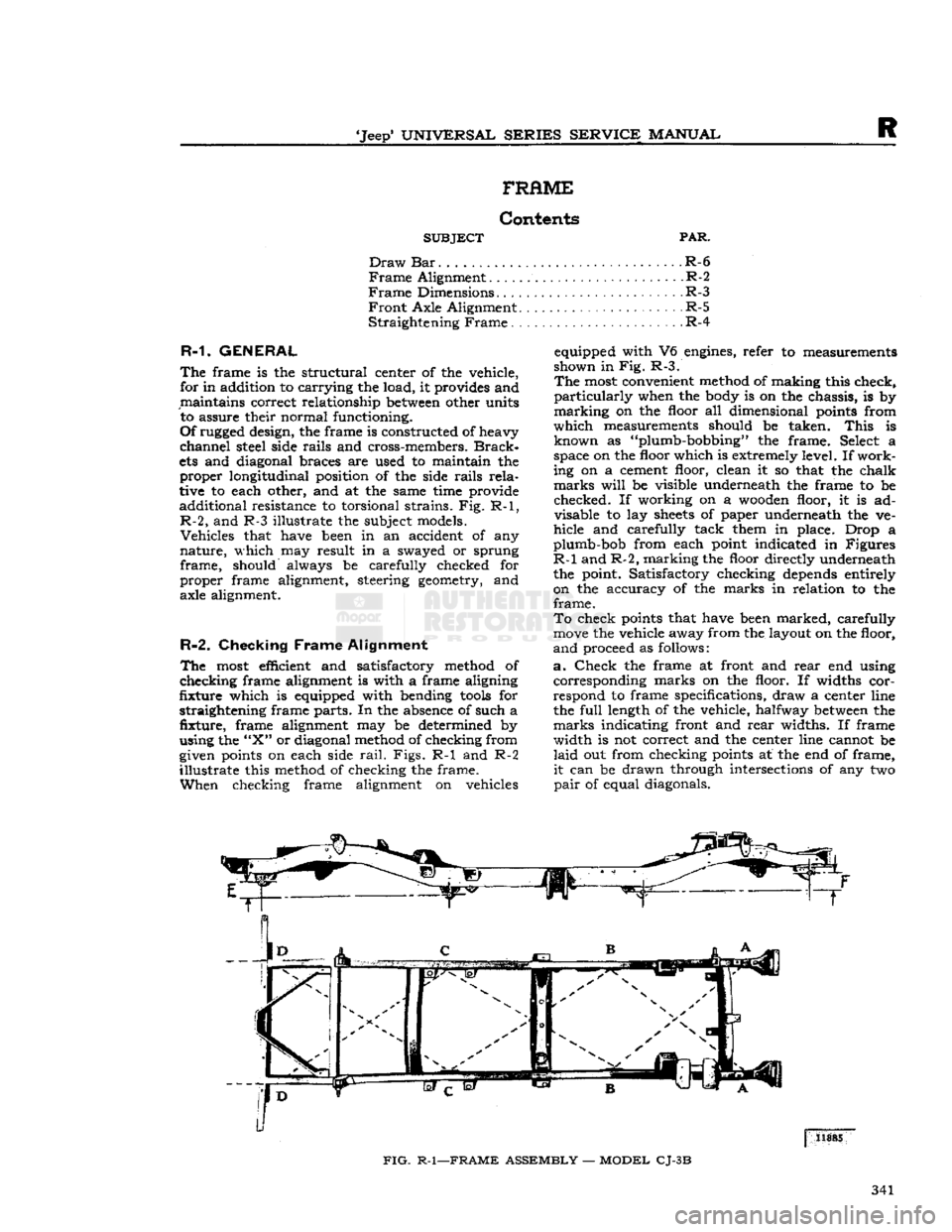

FRAME

Contents

SUBJECT

PAR.

Draw

Bar

R-6

Frame

Alignment

.R-2

Frame

Dimensions

.R-3

Front

Axle Alignment.

R-5

Straightening

Frame

R-4

R-1.

GENERAL

equipped with V6 engines, refer

to

measurements

The

frame

is the

structural center

of

the vehicle,

B£?wn

in

FiB-

R"f

, _ , r' .

for in addition

to

carrying

the load,

it

provides and The inost convenient method

of

making this check,

maintains

correct relationship

between

other units

Particularly

when

the

body

is on the

chassis,

is by

to assure their normal functioning. marking

on the

floor

all

dimensional points from

Of

rugged design, the frame

is

constructed of heavy

fhlch

measurements should

be

taken.

This

is

channel

steel side

rails

and cross-members.

Brack-

known

a\

Plumb-bobbing

the

frame Select

a

ets and diagonal braces

are

used

to

maintain

the

?Pace

on the

floof

^hlch

»

extr«nely

level If

work-

proper

longitudinal position

of the

side

rails

rela-

ing Pn

a.,fPen^

c*ean

* s°

that

the fha*k

tive

to

each other, and

at the

same time provide

*****

Jl!*

be

vJs.lble

underneath

the

frame

to be

additional

resistance

to

torsional strains. Fig. R-1, checked

If

workmg

on a

wooden

floor

it is ad-

R-2,

and R-3 illustrate

the

subject models. disable

la^

f f * V

Underneath

*he ve"

Vehicles

that have been

in an

accident

of any

hide

and

carefully tack them

m

place. Drop

a

nature,

which

may

result

in a

swayed

or

sprung gumb-bob from each point indicated

in

Figures

frame,

should always

be

carefully checked

for ^

an?

L'maJkl?g the uflo?r

Meetly underneath

proper

frame alignment, steering geometry,

and the

point. Satisfactory checking depends entirely

axle alignment.

on the

accuracy

of the

marks

in

relation

to the

frame.

To

check points that have been marked, carefully

move

the vehicle away from the layout on the floor,

R-2.

Checking

Frame

Alignment

anci

proceed

as

follows:

The

most efficient

and

satisfactory method

of a.

Check

the

frame

at

front

and

rear

end

using

checking

frame alignment

is

with

a

frame aligning corresponding marks

on the

floor.

If

widths

cor-

fixture

which

is

equipped with bending

tools

for

respond

to

frame specifications, draw

a

center line

straightening frame parts. In the absence

of

such

a the

full

length

of

the vehicle, halfway

between

the

fixture,

frame

alignment

may be

determined

by

marks indicating front and

rear

widths.

If

frame

using the

"X"

or diagonal method of checking from width

is not

correct and

the

center line cannot

be

given points

on

each side

rail.

Figs.

R-1 and R-2

laid

out

from checking points

at the

end

of

frame,

illustrate

this method

of

checking

the

frame.

it

can

be

drawn through intersections

of

any

two

When

checking frame alignment

on

vehicles

pair

of

equal diagonals.

FIG.

R-1—FRAME

ASSEMBLY

—

MODEL

CJ-3B

341

Page 345 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

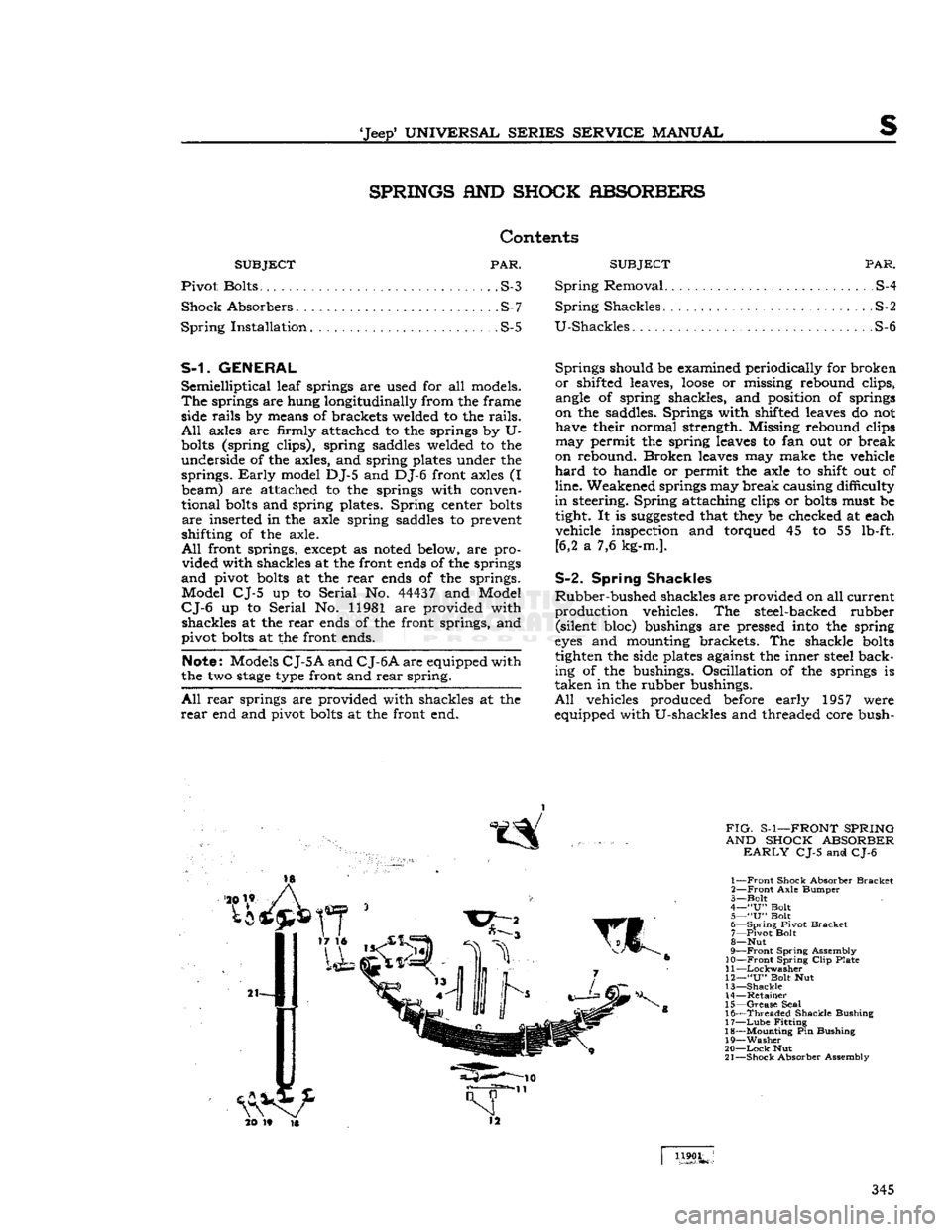

s

SPRINGS

AND

SHOCK

ABSORBERS

Contents

SUBJECT

PAR. SUBJECT PAR.

Pivot Bolts S-3 Spring Removal S-4

Shock

Absorbers S-7 Spring Shackles S-2

Spring

Installation S-5 U-Shackles S-6

S-1.

GENERAL

Semielliptical

leaf springs are used for all models.

The

springs are hung longitudinally from the frame

side rails by means of brackets welded to the

rails.

All

axles are firmly attached to the springs by U-

bolts

(spring clips), spring saddles welded to the

underside of the axles, and spring plates under the

springs.

Early

model DJ-5 and DJ-6 front axles (I beam) are attached to the springs with conven

tional

bolts

and spring plates. Spring center

bolts

are

inserted in the axle spring saddles to prevent

shifting of the axle.

All

front springs, except as noted below, are provided with shackles at the front ends of the springs

and

pivot

bolts

at the

rear

ends of the springs. Model CJ-5 up to

Serial

No. 44437 and Model

CJ-6

up to

Serial

No. 11981 are provided with shackles at the

rear

ends of the front springs, and

pivot

bolts

at the front ends.

Note:

Models

CJ-5A

and

CJ-6A

are equipped with

the two

stage

type front and

rear

spring.

All

rear

springs are provided with shackles at the

rear

end and pivot

bolts

at the front end.

Springs

should be examined periodically for broken

or

shifted leaves,

loose

or missing rebound clips,

angle of spring shackles, and position of springs

on the saddles. Springs with shifted leaves do not have their normal strength. Missing rebound clips may permit the spring leaves to fan out or break

on rebound. Broken leaves may make the vehicle

hard

to handle or permit the axle to shift out of

line.

Weakened springs may break causing difficulty

in

steering. Spring attaching clips or

bolts

must be tight. It is

suggested

that they be checked at each

vehicle inspection and torqued 45 to 55 lb-ft. [6,2 a 7,6 kg-m.].

S-2.

Spring Shackles

Rubber-bushed

shackles are provided on all current

production vehicles. The steel-backed rubber (silent bloc) bushings are pressed into the spring

eyes

and mounting brackets. The shackle

bolts

tighten the side plates against the inner steel back

ing of the bushings. Oscillation of the springs is

taken in the rubber bushings.

All

vehicles produced before early 1957 were

equipped with U-shackles and threaded core bush-

*3(

21-

to It is

FIG-

S-1—FRONT SPRING

AND SHOCK ABSORBER

EARLY

CJ-5 and CJ-6

1—

Front

Shock Absorber

Bracket

2—

Front

Axle

Bumper

3—

Bolt

4—

"U"

Bolt

5—

"U"

Bolt

6—

Spring

Pivot

Bracket

7—

Pivot

Bolt

8—

Nut

9—

Front

Spring

Assembly

10—Front

Spring

Clip

Plate

11

—Lockwasher

12—

"U"

Bolt Nut

13—

Shackle

14—

Retainer

15—

Grease

Seal

16—

Threaded

Shackle

Bushing

17—

Lube

Fitting

18—

Mounting

Pin Bushing

19—

Washer

20—

Lock

Nut

21—

Shock

Absorber Assembly

1190L

345

Page 361 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

U

DESCRIPTION

—

Continued

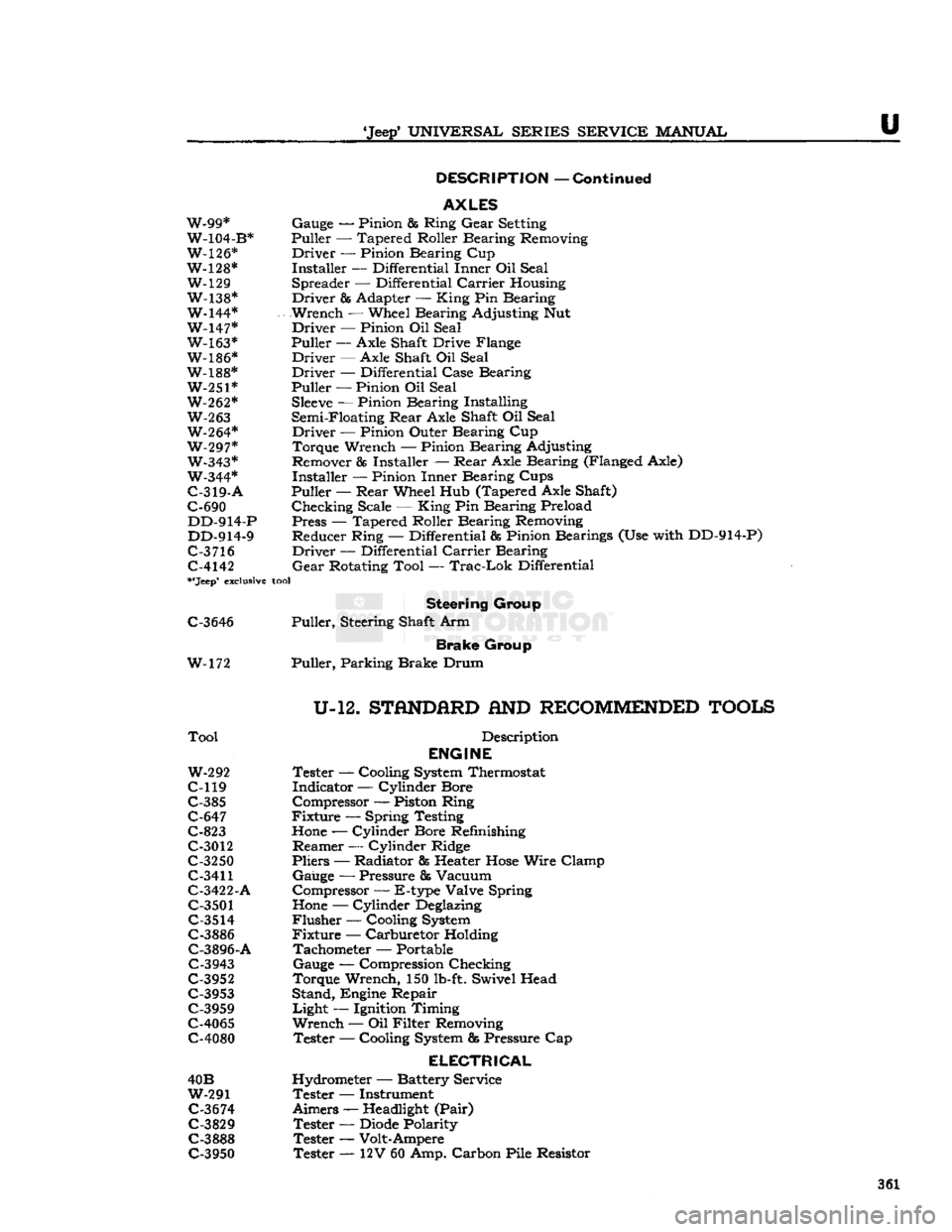

AXLES

W-99* Gauge — Pinion & Ring

Gear

Setting

W-104-B* Puller — Tapered Roller Bearing Removing

W-126* Driver — Pinion Bearing Cup

W-128* Installer — Differential Inner Oil Seal W-129 Spreader — Differential

Carrier

Housing

W-138* Driver & Adapter —

King

Pin Bearing

W-144* Wrench — Wheel Bearing Adjusting Nut W-147* Driver — Pinion Oil Seal W-163* Puller

—-

Axle Shaft Drive Flange

W-186* Driver — Axle Shaft Oil Seal

W-188* Driver — Differential Case Bearing W-251* Puller — Pinion Oil Seal

W-262*

Sleeve

— Pinion Bearing Installing

W-263

Semi-Floating

Rear

Axle Shaft Oil Seal W-264* Driver — Pinion Outer Bearing Cup

W-297* Torque Wrench — Pinion Bearing Adjusting W-343* Remover

85

Installer —

Rear

Axle Bearing (Flanged Axle)

W-344* Installer — Pinion Inner Bearing Cups

C-319-A

Puller —

Rear

Wheel Hub (Tapered Axle Shaft)

C-690 Checking Scale —

King

Pin Bearing Preload DD-914-P Press — Tapered Roller Bearing Removing

DD-914-9 Reducer Ring — Differential & Pinion Bearings (Use with DD-914-P)

C-3

716 Driver — Differential

Carrier

Bearing C-4142

Gear

Rotating Tool —

Trac-Lok

Differential

**Jeep*

exclusive

tool

Steering

Group

C-3646 Puller, Steering Shaft Arm

Brake

Group

W-172 Puller, Parking Brake Drum

U-12.

STflNDfiRD

AND

RECOMMENDED

TOOLS

Tool

Description

ENGINE

W-292

Tester — Cooling

System

Thermostat

C-119 Indicator — Cylinder Bore C-385 Compressor — Piston Ring

C-647 Fixture — Spring Testing

C-823

Hone

— Cylinder Bore Refinishing

C-3012 Reamer — Cylinder Ridge

C-3250 Pliers — Radiator fis Heater

Hose

Wire Clamp

C-3411

Gauge — Pressure & Vacuum

C-3422-A Compressor — E-type Valve Spring

C-3501

Hone

— Cylinder

Deglazing

C-3514

Flusher — Cooling

System

C-3886 Fixture — Carburetor Holding C-3896-A Tachometer — Portable

C-3943 Gauge — Compression Checking

C-3952 Torque Wrench, 150

lb-ft.

Swivel Head C-3953 Stand, Engine Repair

C-3959 Light — Ignition Timing

C-4065 Wrench — Oil Filter Removing

C-4080 Tester — Cooling

System

fig

Pressure Cap

ELECTRICAL

40B Hydrometer — Battery Service

W-291 Tester — Instrument

C-3674

Aimers —

Headlight

(Pair)

C-3829 Tester —

Diode

Polarity

C-3888 Tester — Volt-Ampere C-3950 Tester — 12V 60 Amp. Carbon Pile Resistor 361

Page 362 of 376

u

MISCELLANEOUS

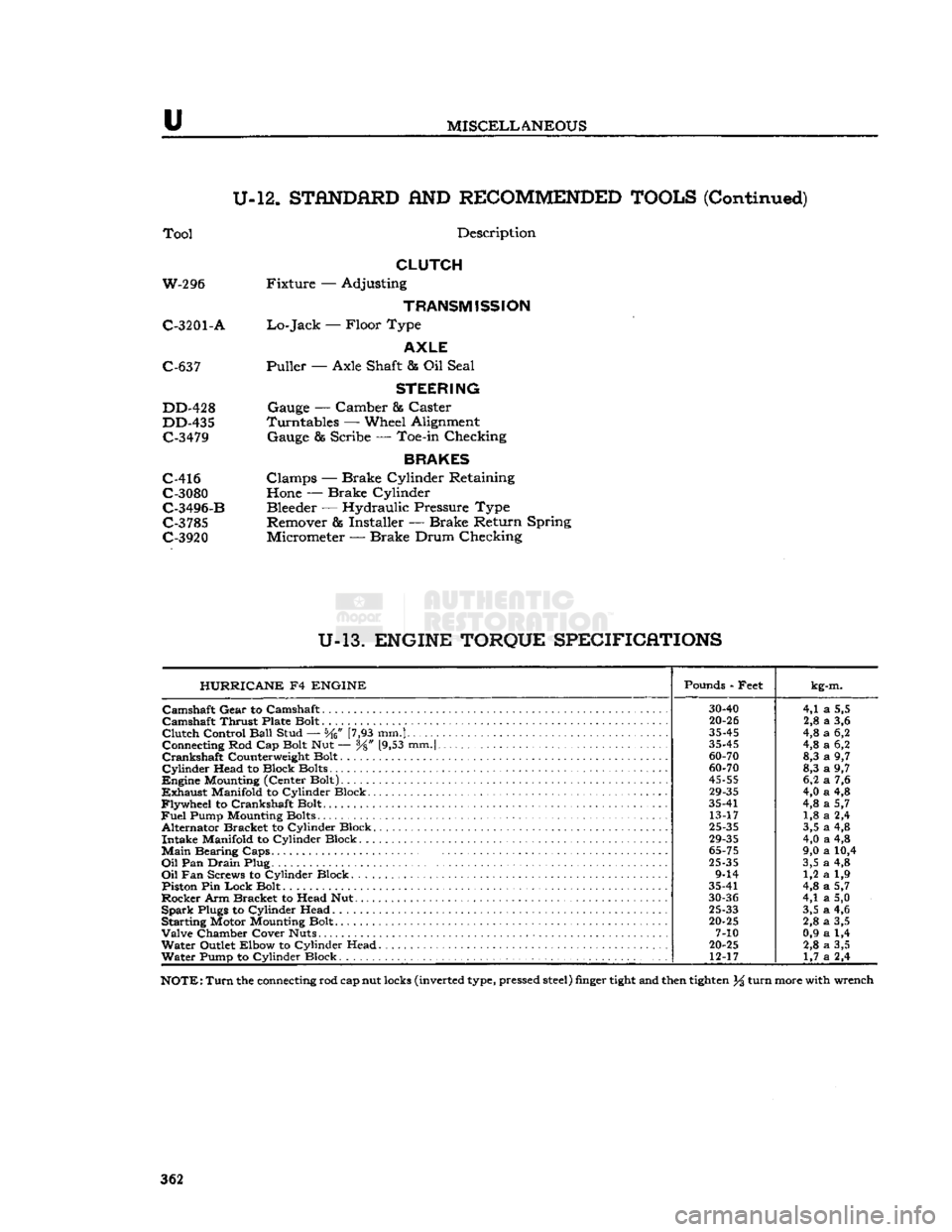

U-12.

STANDARD

AND

RECOMMENDED TOOLS

(Continued)

Tool

Description

CLUTCH

W-296 Fixture — Adjusting

TRANSMISSION

C-3201

- A

Lo-Jack

— Floor Type

AXLE

C-637 Puller — Axle Shaft & Oil Seal

STEERING

DD-428 Gauge — Camber & Caster

DD-435 Turntables — Wheel Alignment C-3479 Gauge & Scribe — Toe-in Checking

BRAKES

C-416 Clamps — Brake Cylinder Retaining C-3080 Hone — Brake Cylinder

C-3496-B Bleeder — Hydraulic Pressure Type C-3785 Remover & Installer — Brake Return Spring

C-3920 Micrometer — Brake Drum Checking

U-13.

ENGINE TORQUE SPECIFICATIONS HURRICANE

F4

ENGINE

Pounds - Feet

kg-m.

30-40

4,1

a

5,5

Camshaft

Thrust Plate Bolt

20-26

2,8

a

3,6

Clutch

Control

Ball

Stud — [7,93 mm.]

35-45

4,8

a

6,2

Connecting Rod Cap Bolt Nut — y8" [9,53 mm.|

35-45

4,8

a

6,2

60-70

8,3

a

9,7

Cylinder

Head to Block Bolts

60-70

8,3

a

9,7

45-55

6,2

a

7,6

29-35

4,0

a

4,8

Flywheel

to Crankshaft Bolt. 35-41

4,8

a

5,7

Fuel

Pump Mounting Bolts 13-17 1,8

a

2,4

Alternator Bracket to Cylinder Block.

25-35

3,5

a

4,8

29-35

4,0

a

4,8

Main

Bearing

Caps.

.

65-75

9,0

a

10,4

Oil

Pan

Drain

Plug

25-35

3,5

a

4,8

9-14 1,2

a

1,9

Piston Pin

Lock

Bolt 35-41

4,8

a

5,7

30-36

4,1

a

5,0

Spark

Plugs to Cylinder Head

25-33

3,5

a

4,6

Starting Motor Mounting Bolt.

20-25

2,8

a

3,5

7-10 0,9

a

1,4

Water

Outlet Elbow to Cylinder Head

20-25

2,8

a

3,5

Water

Pump to Cylinder Block 12-17

1,7

a

2,4

NOTE:

Turn

the connecting rod cap nut locks (inverted type, pressed

steel)

finger

tight

and then

tighten

% turn more with wrench

362

Page 364 of 376

u

MISCELLANEOUS

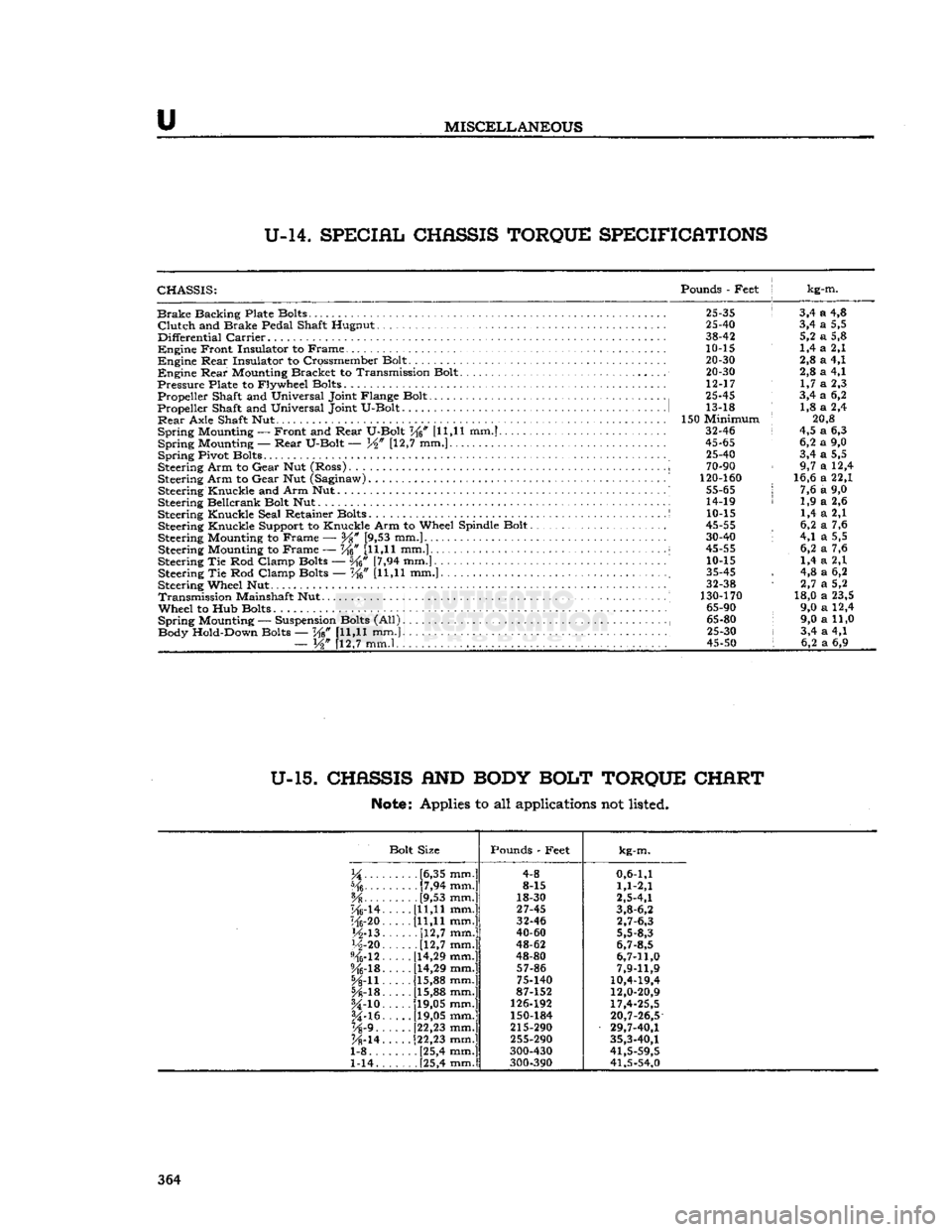

U-14.

SPECIAL

CHASSIS

TORQUE

SPECIFICATIONS

CHASSIS:

Pounds

-

Feet

j kg-m.

Brake

Backing Plate Bolts.

25-35 ! 3,4 a 4,8

Clutch

and

Brake Pedal Shaft Hugnut

25-40 3,4 a 5,5

Differential

Carrier

38-42 5,2 a 5,8

Engine

Front Insulator

to

Frame.

10-15 1,4 a 2,1

Engine

Rear

Insulator

to

Crossmember Bolt.

. . ... 20-30 2,8 a 4,1

Engine

Rear

Mounting Bracket

to

Transmission Bolt.

20-30 2,8 a 4,1

Pressure

Plate

to

Flywheel Bolts

12-17 1,7 a 2,3

Propeller Shaft

and

Universal Joint Flange Bolt

25-45 3,4 a 6,2

Propeller Shaft

and

Universal Joint U-Bolt

1 13-18 : 1,8 a 2,4

Rear

Axle Shaft

Nut 150

Minimum

; 20,8

Spring

Mounting

—

Front

and

Rear

U-Bolt

V^n [11,11 mm.] 32-46 i 4,5 a 6,3

Spring

Mounting —-

Rear

U-Bolt

— [12,7 mm.] 45-65 6,2 a 9,0

Spring

Pivot Bolts

." 25-40 3,4 a 5,5

Steering Arm

to

Gear

Nut

(Ross)

..

i

70-90 9,7 a 12,4

Steering Arm

to

Gear

Nut

(Saginaw)

' 120-160 16,6 a 22,1

Steering Knuckle

and

Arm Nut..........

55-65 j 7,6 a 9,0

Steering Bellcrank Bolt

Nut 14-19 < 1,9 a 2,6

Steering Knuckle Seal Retainer Bolts

S 10-15 1,4 a 2,1

Steering Knuckle Support

to

Knuckle Arm

to

Wheel Spindle Bolt

45-55 , 6,2 a 7,6

Steering Mounting

to

Frame

—

Y%

[9,53 mm.] 30-40 '• 4,1 a 5,5

Steering Mounting

to

Frame

— W [11,11

mm.]...

i 45-55 6,2 a 7,6

Steering

Tie Rod

Clamp Bolts

— [7,94 mm.] 10-15 1,4 a 2,1

Steering

Tie Rod

Clamp Bolts

— Ke" [U,H mm.] ; 35-45 , 4,8 a 6,2

Steering Wheel

Nut 32-38 1 2,7 a 5,2

Transmission

Mainshaft

Nut 130-170 18,0 a 23,5

Wheel

to Hub

Bolts

65-90 9,0 a 12,4

Spring

Mounting

—

Suspension Bolts

(All) , 65-80 9,0 a 11,0

Body Hold-Down Bolts

— W [11,11 mm.} 25-30 i 3,4 a 4,1

—

W [12,7 mm.l , . . 45-50 I 6,2 a 6,9

U-15.

CHASSIS

AND

BODY

BOLT

TORQUE

CHART

Note:

Applies to all applications not listed.

Bolt Size Pounds

-

Feet

kg-m.

.....

[6,35 mm.] 4-8

0,6-1,1

[7,94 mm.] 8-15

1,1-2,1

[9,53 mm.] 18-30

2,5-4,1

"Mrl4.

[11,11 mm.]

27-45

3,8-6,2

116-20. [11,11 mm.] 32-46

2,7-6,3

M-13.

[12,7

mm.]

40-60

5,5-8,3

H-20

[12,7

mm.]

48-62

6,7-8,5

%-12.

[14,29 mm.]

48-80

6,7-11,0

%-lB.

[14,29 mm.]

57-86

7,9-11,9

5A-n. [15,88 mm.]

75-140

10,4-19,4

[15,88 mm.] 87-152

12,0-20,9

U-io.

[19,05 mm.]

126-192

17,4-25,5

§4-16.

[19,05 mm.]

150-184

20,7-26,5

Vs'9..

[22,23 mm.]

215-290

29,7-40,1

K-14.

[22,23 mm.]

255-290

35,3-40,1

1-8 [25,4 mm.] 300-430

41,5-59,5

1-14. . [25,4 mm.]

300-390 41,5-54,0 364

Page 371 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

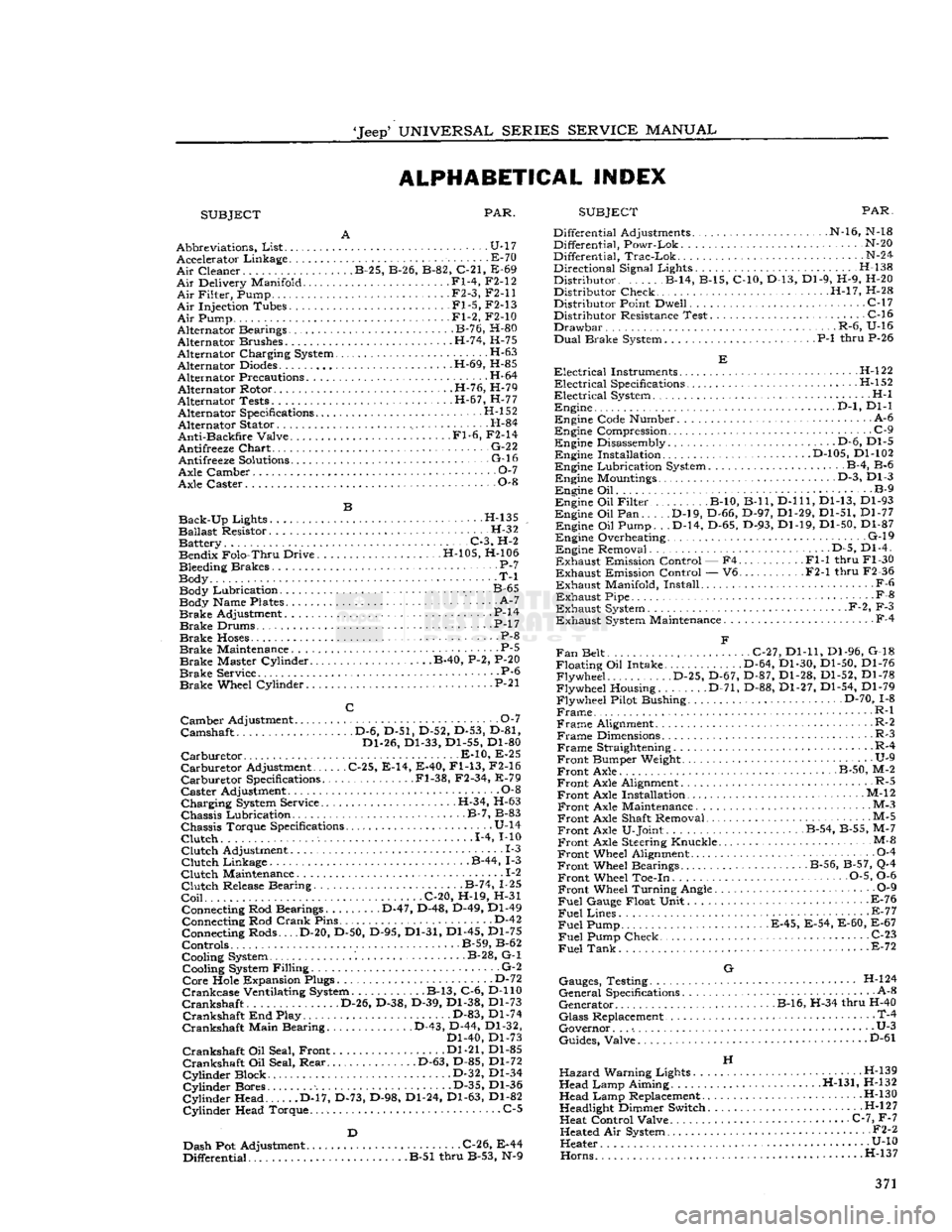

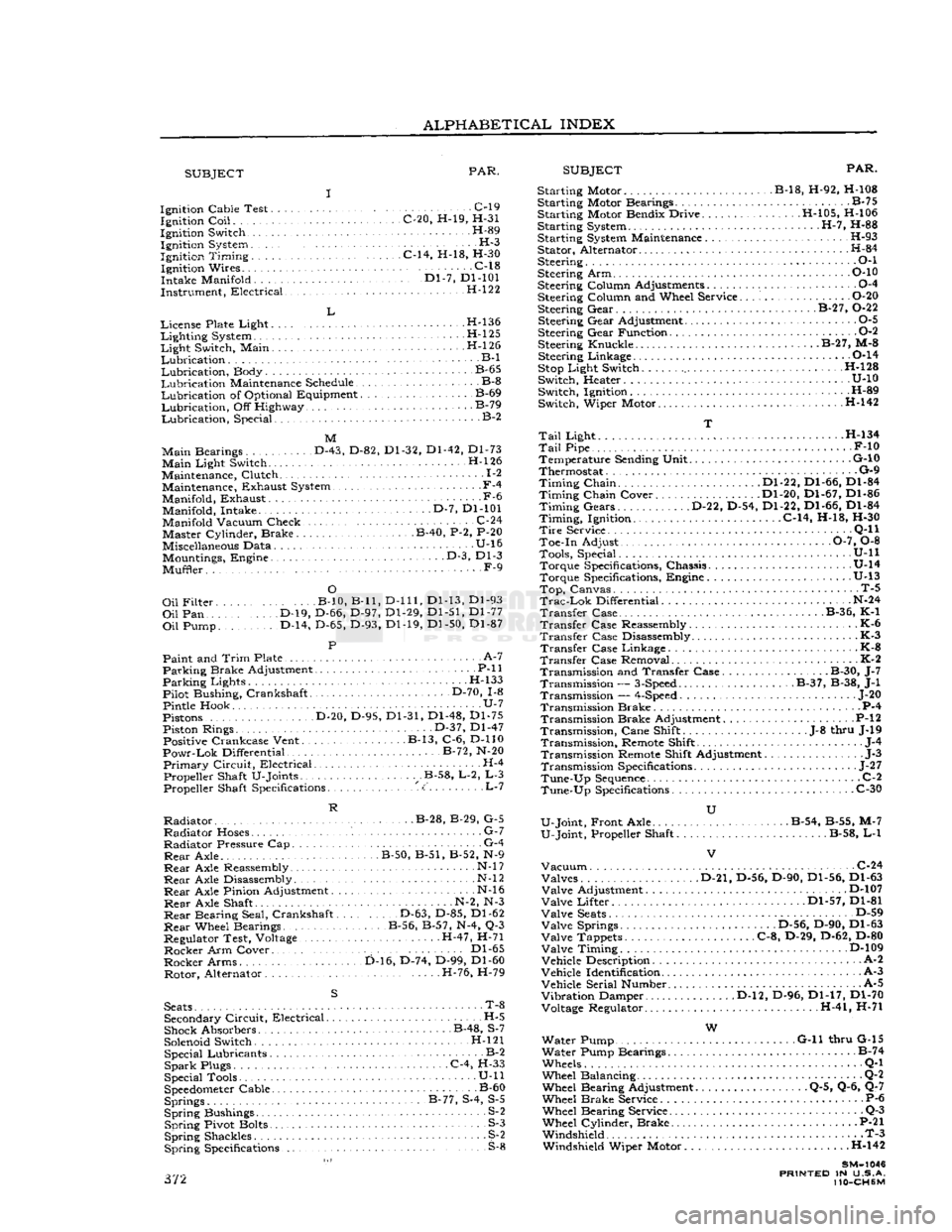

ALPHABETICAL INDEX

SUBJECT PAR.

SUBJECT

PAR.

Abbreviations,

List

U-17 Accelerator Linkage E-70

Air

Cleaner B-25, B-26, B-82, C-21, E-69

Air

Delivery Manifold Fl-4, F2-12

Air

Filter, Pump • F2-3, F2-11

Air

Injection Tubes Fl-5, F2-13

Air

Pump Fl-2, F2-10

Alternator Bearings B-76, H-80

Alternator Brushes H-74, H-75

Alternator Charging System •

•

H-63

Alternator

Diodes

H-69, H-85

Alternator Precautions H-64 Alternator Rotor H-76, H-79

Alternator Tests H-67, H-77 Alternator Specifications H-l 52

Alternator Stator H-84

Anti-Backfire

Valve Fl-6, F2-14

Antifreeze

Chart

• G-22 Antifreeze

Solutions

- G-16

Axle Camber O-l

Axle Caster 0-8

Back-Up

Lights H-135

Ballast

Resistor. H-32 Battery C-3, H-2 Bendix Folo-Thru Drive H-105, H-106

Bleeding Brakes P-7

Body T-l Body Lubrication. B-65 Body Name Plates ' A-7

Brake

Adjustment P-14

Brake

Drums. • .P-17

Brake

Hoses

P-8

Brake

Maintenance . P-5

Brake

Master Cylinder B-40, P-2, P-20

Brake

Service P-6

Brake

Wheel Cylinder • P-21

Camber

Adjustment 0-7

Camshaft D-6, D-51, D-52, D-53, D-81, Dl-26, Dl-33, Dl-55, Dl-80

Carburetor

E-10, E-25

Carburetor

Adjustment C-25, E-14, E-40,

Fl-13,

F2-16

Carburetor

Specifications .Fl-38, F2-34, E-79

Caster

Adjustment 0-8

Charging

System Service. .H-34, H-63

Chassis

Lubrication B-7, B-83

Chassis

Torque Specifications U-14

Clutch

1-4, MO

Clutch

Adjustment 1-3

Clutch

Linkage B-44, 1-3

Clutch

Maintenance .. 1-2

Clutch

Release Bearing B-74, 1-25

Coil

C-20, H-19, H-31 Connecting Rod Bearings D-47, D-48, D-49, Dl-49 Connecting Rod

Crank

Pins D-42

Connecting Rods... .D-20, D-50, D-95, Dl-31, Dl-45, Dl-75

Controls B-59, B-62

Cooling System B-28, G-l Cooling System Filling G-2

Core

Hole Expansion Plugs D-72

Crankcase

Ventilating System B-13, C-6, D-110

Crankshaft

D-26, D-38, D-39, Dl-38, Dl-73

Crankshaft

End Play. D-83, Dl-74

Crankshaft

Main Bearing D-43, D-44, Dl-32, Dl-40, Dl-73

Crankshaft

Oil Seal, Front Dl-21, Dl-85

Crankshaft

Oil Seal, Rear D-63, D-85, Dl-72

Cylinder

Block D-32, Dl-34

Cylinder

Bores D-35, Dl-36

Cylinder

Head D-17, D-73, D-98, Dl-24, Dl-63, Dl-82

Cylinder

Head Torque. C-5

Dash Pot Adjustment C-26, E-44

Differential B-51 thru B-53, N-9 Differential Adjustments N-16, N-18

Differential, Powr-Lok N-20

Differential,

Trac-Lok

N-24

Directional Signal Lights. . H-138

Distributor B-14, B-15, C-10, D-13, Dl-9, H-9, H-20 Distributor Check H-l7, H-28

Distributor Point Dwell C-17 Distributor Resistance Test C-16

Drawbar

.R-6, U-16

Dual

Brake System P-l thru P-26

Electrical

Instruments H-l22

Electrical

Specifications .H-l52

Electrical

System H-l Engine .

..D-l,

Dl-1

Engine Code Number A-6

Engine Compression .

.

C-9 Engine Disassembly . • .D-6, Dl-5 Engine Installation D-105, Dl-102

Engine Lubrication System B-4, B-6 Engine Mountings D-3, Dl-3

Engine Oil B-9

Engine Oil Filter B-10, B-ll,

D-lll,

Dl-13, Dl-93

Engine Oil Pan D-l9, D-66, D-97, Dl-29, Dl-51, Dl-77 Engine Oil Pump. . .D-14, D-65, D-93, Dl-19, Dl-50, Dl-87

Engine Overheating. G-l9 Engine Removal D-5, Dl-4.

Exhaust

Emission Control — F4 Fl-1 thru Fl-30

Exhaust

Emission Control — V6 F2-1 thru F2-36

Exhaust

Manifold, Install F-6

Exhaust

Pipe -

•

F-8

Exhaust

System F-2, F-3

Exhaust

System Maintenance F-4

Fan

Belt C-27, Dl-11, Dl-96, G-18

Floating Oil Intake. D-64, Dl-30, Dl-50, Dl-76 Flywheel D-25, D-67, D-87, Dl-28, Dl-52, Dl-78

Flywheel Housing. D-71, D-88, Dl-27, Dl-54, Dl-79

Flywheel Pilot Bushing D-70, 1-8

Frame

R-l

Frame

Alignment. R-2

Frame

Dimensions R-3

Frame

Straightening R-4

Front

Bumper Weight. • U-9

Front

Axle B-50, M-2

Front

Axle Alignment R-5

Front

Axle Installation • M-12

Front

Axle Maintenance M-3

Front

Axle Shaft Removal M-5

Front

Axle U-Joint B-54, B-55, M-7

Front

Axle Steering Knuckle M-&

Front

Wheel Alignment 0-4

Front

Wheel Bearings B-56, B-57, Q-4

Front

Wheel Toe-in 0-5, 0-6

Front

Wheel Turning Angle 0-9

Fuel

Gauge Float Unit F-76

Fuel

Lines - E-77

Fuel

Pump E-45, E-54, E-60, E-67

Fuel

Pump Check C-23

Fuel

Tank

E-72

G

Gauges, Testing H-l24

General

Specifications A-8

Generator B-16, H-34 thru H-40

Glass

Replacement • T-4

Governor. . .

•.

• U-3

Guides, Valve D"61

H

Hazard

Warning Lights H-139

Head Lamp Aiming H-131, H-132 Head Lamp Replacement H-130

Headlight Dimmer Switch H-l

2

7

Heat Control Valve C-7, F-7 Heated Air System • •

•

F2-2

Heater U-10

Horns.....

....H-137 371

Page 372 of 376

ALPHABETICAL

INDEX

SUBJECT

PAR.

SUBJECT

PAR.

Ignition Cable Test C-l9 Ignition

Coil

C-20, H-19, H-31

Ignition Switch H-89 Ignition System H-3

Ignition

Timing

C-14, H-18, H-30 Ignition Wires C-18

Intake Manifold '." Dl-7, Dl-101

Instrument, Electrical H-122

L

License Plate Light H-l36

Lighting

System H-l25

Light

Switch, Main . H-l 26

Lubrication

B-l

Lubrication,

Body B-65

Lubrication

Maintenance Schedule B-8

Lubrication

of Optional Equipment B-69

Lubrication,

Off Highway B-79

Lubrication,

Special. B-2

M

Main

Bearings D-43, D-82, Dl-32, Dl-42, Dl-73

Main

Light Switch. H-l26

Maintenance, Clutch 1-2 Maintenance, Exhaust System.,

-

F-4

Manifold, Exhaust -F-6 Manifold, Intake D-7, Dl-101

Manifold Vacuum Check. .C-24 Master Cylinder, Brake B-40, P-2, P-20

Miscellaneous Data U-16 Mountings, Engine • • •

-

D-3, Dl-3

Muffler. F-9

O

Oil

Filter B-10, B-ll,

D-lll,

Dl-13, Dl-93

Oil

Pan D-19, D-66, D-97, Dl-29, Dl-51, Dl-77

Oil

Pump. D-14, D-65, D-93, Dl-19, Dl-50, Dl-87

P

Paint and

Trim

Plate • • A-7

Parking

Brake Adjustment P-ll

Parking

Lights H-133

Pilot Bushing, Crankshaft D-70, 1-8

Pintle Hook U-7

Pistons D-20, D-95, Dl-31, Dl-48, Dl-75 Piston Rings. • • •

•

D-37, Dl-47 Positive Crankcase Vent. B-13, C-6, D-110

Powr-Lok

Differential B-72, N-20

Primary

Circuit,

Electrical H-4 Propeller Shaft U-Joints .B-58, L-2, L-3 Propeller Shaft Specifications <:' L-7

R

Radiator

B-28, B-29, G-5

Radiator

Hoses. G-7

Radiator

Pressure Cap G-4

Rear

Axle. B-50, B-51, B-52, N-9

Rear

Axle Reassembly • N-l

7

Rear

Axle Disassembly N-l

2

Rear

Axle Pinion Adjustment N-l6

Rear

Axle Shaft N-2, N-3

Rear

Bearing Seal, Crankshaft D-63, D-85, Dl-62

Rear

Wheel Bearings B-56, B-57, N-4, Q-3

Regulator Test, Voltage H-47, H-71

Rocker

Arm Cover.. . Dl-65

Rocker

Arms D-16, D-74, D-99, Dl-60 Rotor, Alternator H-76, H-79

S

Seats

• T-8 Secondary

Circuit,

Electrical H-5

Shock Absorbers B-48, S-7

Solenoid Switch. H-l21 Special Lubricants B-2

Spark

Plugs C-4, H-33

Special Tools • U-ll

Speedometer

Cable B-60 Springs B-77, S-4, S-5

Spring

Bushings S-2

Spring

Pivot Bolts S-3

Spring

Shackles S^2

Spring

Specifications S-8 372 Starting Motor B-18, H-92, H-108

Starting Motor Bearings B-75

Starting Motor Bendix Drive H-105, H-106

Starting System H-7, H-88

Starting System Maintenance H-93 Stator, Alternator H-84

Steering • • •

•

O-l

Steering Arm P-10

Steering Column Adjustments 0-4

Steering Column and Wheel Service O-20 Steering Gear. . B-27, 0-22

Steering Gear Adjustment 0-5

Steering Gear Function 0-2

Steering Knuckle. B-27, M-8 Steering Linkage 0-14

Stop

Light Switch H-128

Switch, Heater U-10 Switch, Ignition H-89

Switch, Wiper Motor H-142

T

Tail

Light . H-134

Tail

Pipe F-10 Temperature Sending Unit G-10

Thermostat G-9

Timing

Chain Dl-22, Dl-66, Dl-84

Timing

Chain Cover Dl-20, Dl-67, Dl-86

Timing

Gears D-22, D-54, Dl-22, Dl-66, Dl-84

Timing,

Ignition. C-14, H-18, H-30

Tire

Service . •

•

Q-l

1

Toe-in Adjust 0-7, 0-8 Tools, Special. . .

........

U-ll Torque Specifications, Chassis U-14

Torque Specifications, Engine .U-13

Top,

Canvas. T-5

Trac-Lok

Differential N-24

Transfer

Case B-36, K-1

Transfer

Case Reassembly K-6

Transfer

Case Disassembly K-3

Transfer

Case Linkage - K-8

Transfer

Case Removal K-2 Transmission and Transfer Case. B-30, J-7 Transmission —

3-Speed

B-37, B-38, J-l

Transmission —

4-Speed

... J-20

Transmission Brake P-4 Transmission Brake Adjustment P-l

2

Transmission,

Cane Shift .J-8 thru J-19

Transmission,

Remote Shift J-4

Transmission Remote Shift Adjustment J-3

Transmission Specifications

-

J-27

Tune-Up

Sequence

C-2

Tune-Up

Specifications C-30

U

U-Joint, Front Axle . . B-54, B-55, M-7

U-Joint, Propeller Shaft B-58, L-l

Vacuum

C-24 Valves D-21, D-56, D-90, Dl-56, Dl-63

Valve

Adjustment D-107

Valve

Lifter Dl-57, Dl-81

Valve

Seats

D-59

Valve

Springs .D-56, D-90, Dl-63

Valve

Tappets C-8, D-29, D-62, D-80

Valve

Timing D-109

Vehicle Description A-2

Vehicle Identification A-3

Vehicle Serial Number. A-5

Vibration

Damper D-l2, D-96, Dl-17, Dl-70 Voltage Regulator. H-41, H-71

W

Water Pump G-ll thru G-15

Water Pump Bearings B-74

Wheels Q-l

Wheel Balancing Q-2 Wheel Bearing Adjustment Q-5, Q-6, Q-7

Wheel Brake Service P-6 Wheel Bearing Service Q-3

Wheel Cylinder, Brake P-21 Windshield T-3 Windshield Wiper Motor . .H-142

SM-1046

PRINTED

IN U.S.A.

110-CH6M