ignition JEEP CJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 176 of 376

H

ELECTRICAL

SYSTEM

11474

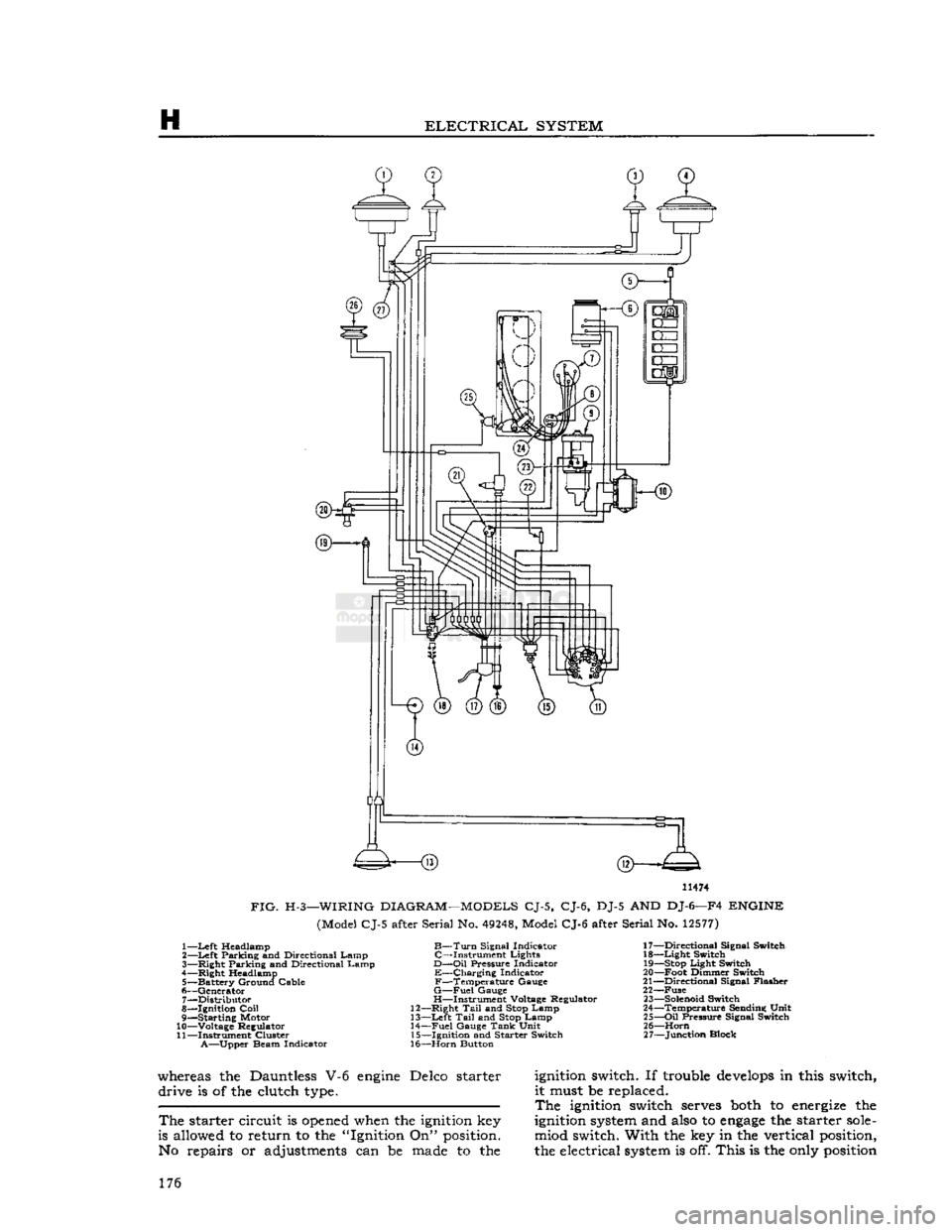

FIG.

H-3—WIRING

DIAGRAM—MODELS

CJ-5, CJ-6, DJ-5 AND DJ-6—F4

ENGINE

(Model CJ-5 after Serial No.

49248,

Model CJ-6 after Serial No.

12577)

1—

Left

Headlamp

B—Turn

Signal Indicator 17—Directional Signal Switch

2—

Left

Parking and Directional Lamp C—Instrument Lights 18—Light Switch

3— Right Parking and Directional Lamp

D—Oil

Pressure Indicator

19—Stop

Light Switch

4— Right Headlamp E—Charging Indicator 20—Foot Dimmer Switch

5— Battery Ground Cable F—Temperature Gauge 21—Directional Signal Flasher

6— Generator

G—Fuel

Gauge 22—Fuse 7— Distributor H—Instrument Voltage Regulator

23—Solenoid

Switch

8— Ignition

Coil

12—Right

Tail

and

Stop

Lamp 24—Temperature Sending Unit

9— Starting Motor 13—Left

Tail

and

Stop

Lamp 25—Oil Pressure Signal Switch

10— Voltage Regulator 14—Fuel Gauge

Tank

Unit 26—Horn

11— Instrument Cluster 15—Ignition and Starter Switch 27—Junction Block

A—Upper

Beam Indicator 16—Horn Button

whereas the Dauntless V-6

engine

Delco starter

ignition

switch. If trouble

develops

in this switch, drive is of the clutch

type.

it must be replaced.

The

ignition

switch

serves

both

to

energize

the

The

starter circuit is

opened

when the

ignition

key

ignition

system

and

also

to

engage

the starter

sole-

is allowed to return to the "Ignition On"

position.

miod switch. With the key in the vertical

position,

No repairs or adjustments can be

made

to the the electrical

system

is off. This is the

only

position

176

Page 177 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

H

12968

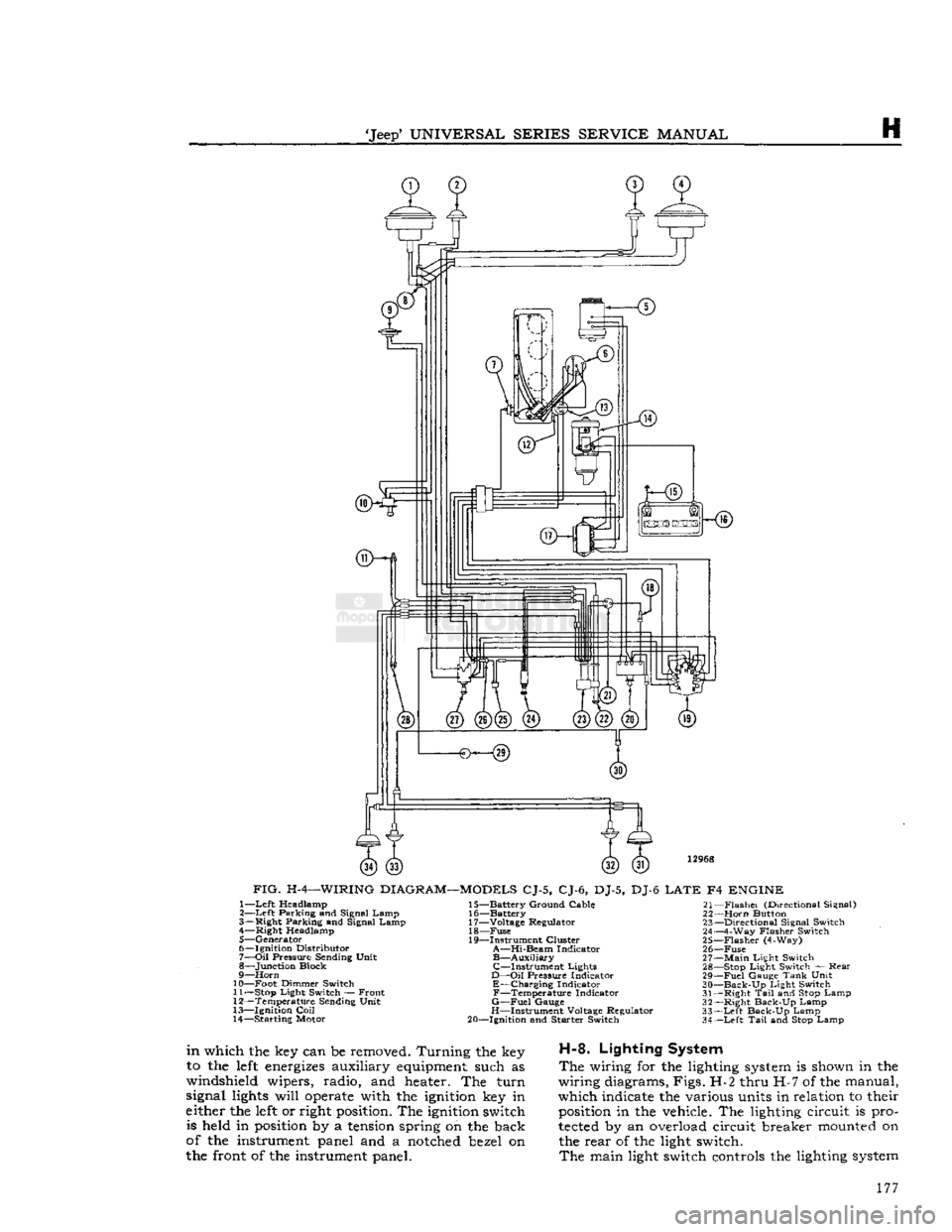

FIG.

H-4—WIRING

DIAGRAM—MODELS

CJ-5, CJ-6, DJ-5, DJ-6

LATE

F4

ENGINE

1—

Left

Headlamp

2—

Left

Parking and Signal Lamp

3— Right Parking and Signal Lamp 4— Right Headlamp

5— Generator

6— Ignition Distributor

7—

Oil

Pressure Sending Unit

8— Junction Block

9—

Horn

10— Foot Dimmer Switch 11—

Stop

Light Switch — Front

12— Temperature Sending Unit

13— Ignition

Coil

14— Starting Motor 15— Battery Ground Cable

16— Battery

17— Voltage Regulator 18—

Fuse

19— Instrument Cluster

A—Hi-Beam

Indicator

B—Auxiliary

C—Instrument

Lights

D—Oil

Pressure Indicator

E—Charging

Indicator

F—Temperature

Indicator

G—Fuel

Gauge

H—Instrument Voltage Regulator

20— Ignition and Starter Switch 21—

Flashei

(Directional Signal)

22—

Horn

Button 23— Directional Signal Switch

24— 4-Way Flasher Switch

25—

Flasher

(4-Way)

26—

Fuse

27—

Main

Light Switch 28—

Stop

Light Switch — Rear

29—

Fuel

Gauge

Tank

Unit

30—

Back-Up

Light Switch

31— Right

Tail

and

Stop

Lamp

32— Right Back-Up Lamp

33—

Left

Back-Up Lamp

34—

Left

Tail

and

Stop

Lamp

in

which the key can be removed. Turning the key

to the

left

energizes

auxiliary

equipment

such as

windshield wipers, radio, and heater. The turn

signal

lights

will

operate

with the

ignition

key in

either the

left

or right

position.

The

ignition

switch is held in

position

by a

tension

spring on the back

of the instrument panel and a

notched

bezel on

the front of the instrument panel.

H-8.

Lighting System

The

wiring for the lighting

system

is shown in the

wiring diagrams, Figs. H-2 thru H-7 of the manual,

which indicate the various units in relation to their

position

in the vehicle. The lighting circuit is pro

tected

by an overload circuit breaker

mounted

on the rear of the light switch.

The

main light switch controls the lighting

system

177

Page 178 of 376

H

ELECTRICAL

SYSTEM

14365

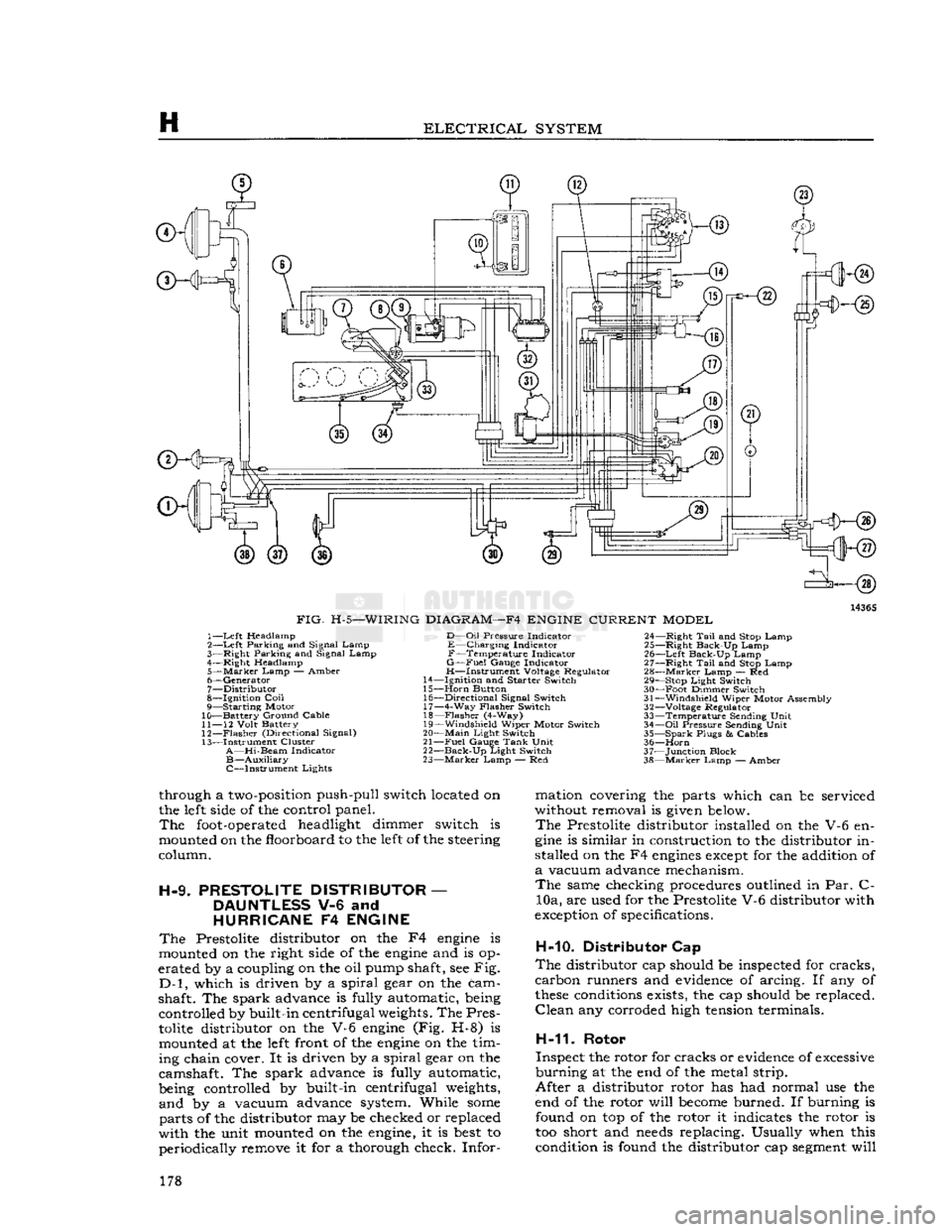

FIG.

H-5—WIRING

DIAGRAM—F4

ENGINE

CURRENT

MODEL

1—

Left

Headlamp

2—

Left

Parking and Signal Lamp

3—

Right

Parking and Signal Lamp

4—

Right

Headlamp

5—

Marker

Lamp

— Amber

6—

Generator

7—

Distributor

8—

Ignition

Coil

9— Starting Motor

10— Battery Ground Cable

11—

12

Volt

Battery

12—

Flasher

(Directional Signal)

13— Instrument Cluster

A—Hi-Beam

Indicator

B—Auxiliary

C—Instrument Lights

D—Oil

Pressure

Indicator

E—Charging Indicator

F—Temperature Indicator

G—Fuel

Gauge

Indicator

H—Instrument Voltage Regulator

14—

Ignition

and

Starter

Switch

15—

Horn

Button 16—

Directional

Signal Switch 17— 4-Way

Flasher

Switch

18—

Flasher

(4-Way)

19—

Windshield

Wiper Motor Switch

20—

Main

Light

Switch

21—

Fuel

Gauge

Tank

Unit

22—

Back-Up

Light

Switch

23—

Marker

Lamp — Red 24—

Right

Tail

and Stop Lamp

25—

Right

Back-Up Lamp

26—

Left

Back-Up Lamp

27—

Right

Tail

and Stop Lamp

28—

Marker

Lamp — Red 29— Stop

Light

Switch

30— Foot Dimmer Switch

31—

Windshield

Wiper Motor Assembly

32—

Voltage Regulator

33— Temperature Sending

Unit

34—

Oil

Pressure

Sending

Unit

35— Spark

Plugs

&

Cables

36—

Horn

37— Junction Block

38—

Marker

Lamp — Amber

through a

two-position

push-pull switch located on

the

left

side

of the control panel.

The

foot-operated

headlight dimmer switch is

mounted on the floorboard to the

left

of the steering

column.

H-9.

PRESTOLITE

DISTRIBUTOR

—

DAUNTLESS

V-6 and

HURRICANE

F4

ENGINE

The

Prestolite distributor on the F4

engine

is

mounted on the right

side

of the

engine

and is op

erated by a coupling on the oil pump shaft, see Fig.

D-l,

which is driven by a spiral gear on the cam

shaft. The spark advance is fully automatic, being controlled by built-in centrifugal

weights.

The Pres

tolite

distributor on the V-6

engine

(Fig. H-8) is mounted at the

left

front of the

engine

on the tim

ing chain cover. It is driven by a spiral gear on the

camshaft. The spark advance is fully automatic,

being controlled by built-in centrifugal

weights,

and by a vacuum advance system. While

some

parts of the distributor may be checked or replaced

with the unit mounted on the

engine,

it is

best

to periodically remove it for a thorough check. Infor mation covering the parts which can be serviced

without removal is

given

below.

The

Prestolite distributor installed on the V-6 en

gine

is similar in construction to the distributor in

stalled on the F4

engines

except

for the addition of

a

vacuum advance mechanism.

The

same checking procedures outlined in Par. C- 10a, are used for the Prestolite V-6 distributor with

exception

of specifications.

H-10. Distributor Cap

The

distributor cap should be inspected for cracks,

carbon runners and

evidence

of arcing. If any of

these

conditions

exists, the cap should be replaced.

Clean

any corroded high

tension

terminals.

H-11.

Rotor

Inspect the rotor for cracks or

evidence

of

excessive

burning at the end of the metal strip.

After a distributor rotor has had normal use the

end of the rotor will

become

burned. If burning is found on top of the rotor it indicates the rotor is

too short and

needs

replacing. Usually when this condition is found the distributor cap

segment

will 178

Page 179 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

H

12967

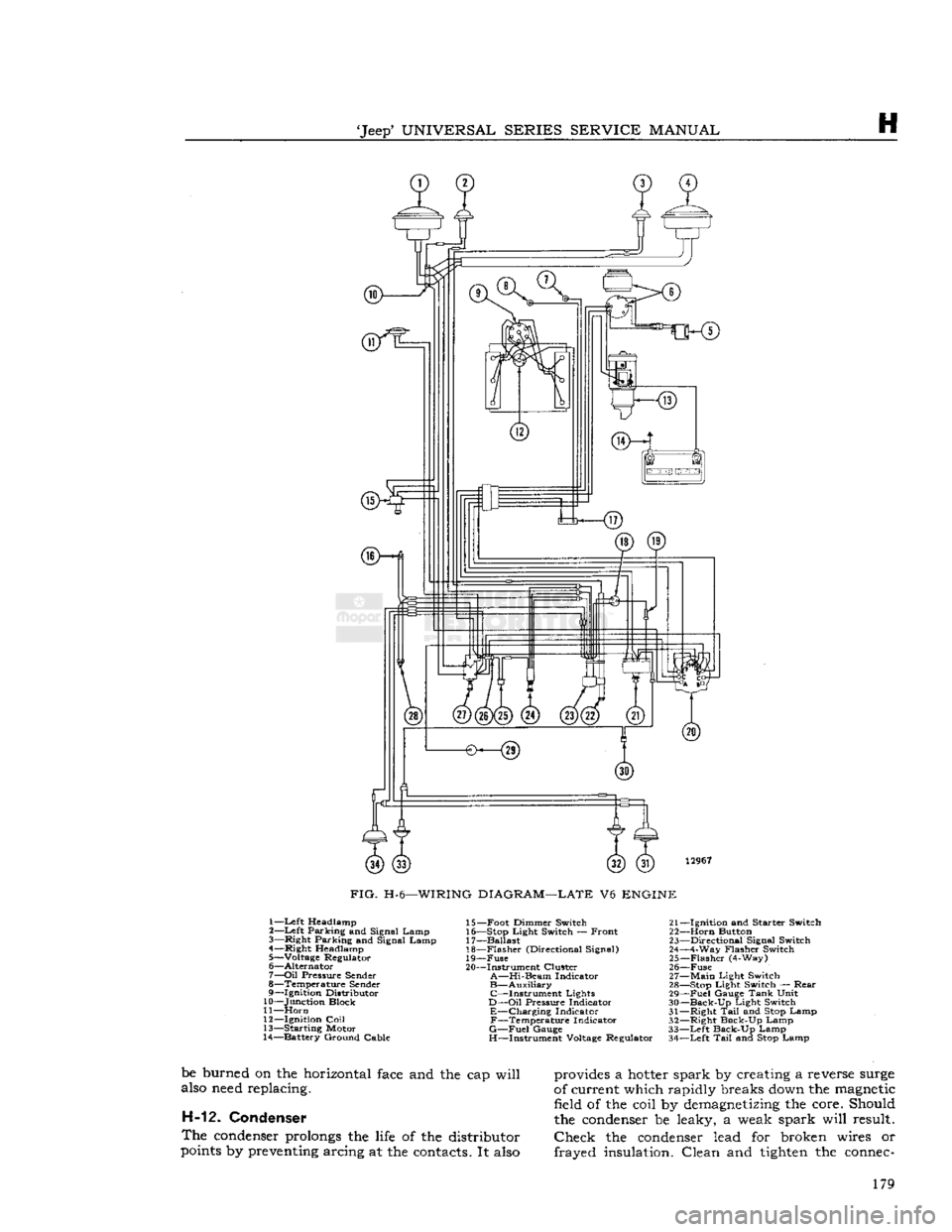

FIG.

H-6—WIRING

DIAGRAM—LATE

V6

ENGINE

1—Left Headlamp

2—

Left

Parking and Signal Lamp

3—

Right

Parking and Signal Lamp

4—

Right

Headlamp

5— Voltage Regulator

6—

Alternator

7—

Oil

Pressure

Sender

8— Temperature

Sender

9—

Ignition

Distributor

10— Junction Block

11—

Horn

12—

Ignition

Coil

13— Starting Motor

14— Battery Ground Cable 15— Foot Dimmer Switch 21-

16— Stop

Light

Switch — Front 22-

17— Ballast 23-

18—

Flasher

(Directional Signal) 24-

19—

Fuse

25-

20— Instrument Cluster 26-

A—Hi-Beam

Indicator 27-

B—Auxiliary

28- C—Instrument Lights 29-

D—Oil

Pressure

Indicator 30-

E—Charging Indicator 31-F—Temperature Indicator 32-

G—Fuel

Gauge

33-

H—Instrument Voltage Regulator 34-

-Ignition

and

Starter

Switch

-Horn

Button

-Directional

Signal Switch

-4-Way

Flasher

Switch

-Flasher

(4-Way)

-Fuse

-Main

Light

Switch

-Stop

Light

Switch —

Rear

-Fuel

Gauge

Tank

Unit

-Back-Up

Light

Switch

-Right

Tail

and Stop Lamp

-Right

Back-Up Lamp

-Left

Back-Up Lamp

-Left

Tail

and Stop Lamp

be burned on the horizontal

face

and the cap will

also

need

replacing. H-12. Condenser

The

condenser

prolongs

the

life

of the distributor

points

by

preventing

arcing at the

contacts.

It

also

provides

a

hotter

spark by creating a reverse

surge

of current which rapidly breaks

down

the

magnetic

field of the coil by

demagnetizing

the core. Should

the

condenser

be leaky, a weak spark will result.

Check

the

condenser

lead for broken wires or

frayed insulation. Clean and

tighten

the

connec-

179

Page 180 of 376

H

ELECTRICAL

SYSTEM

ffKHs)

3—<§)

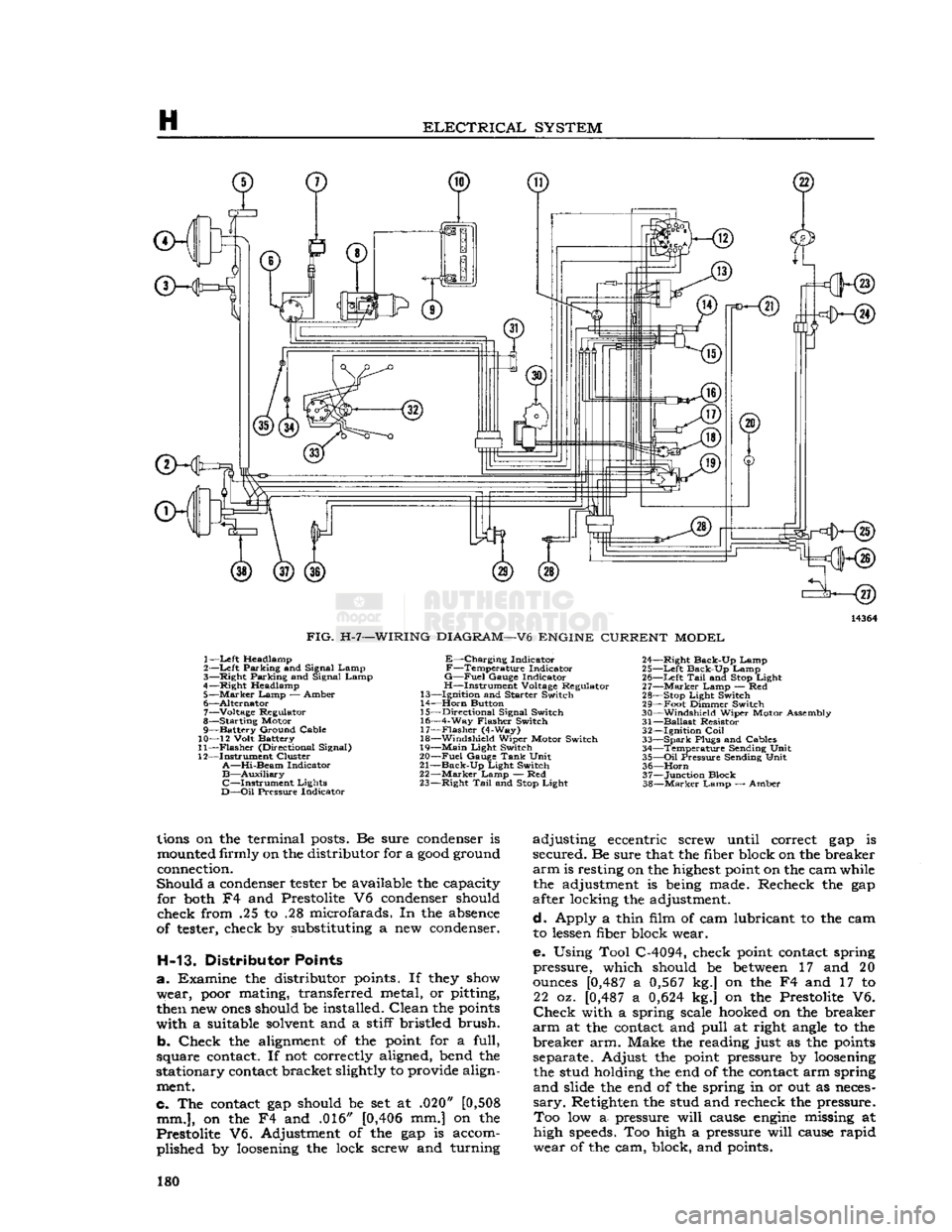

FIG.

H-7—WIRING

DIAGRAM—V6

ENGINE

CURRENT

MODEL

1—

Left

Headlamp

2—Left Parking and Signal Lamp

3— Right Parking and Signal Lamp

4—Right Headlamp 5—

Marker

Lamp — Amber

6— Alternator 7— Voltage Regulator

8— Starting Motor

9— Battery Ground Cable

10— 12 Volt Battery

11—

Flasher

(Directional Signal)

12— Instrument Cluster

A—Hi-Beam

Indicator

B—Auxiliary

C—Instrument

Lights

D—Oil

Pressure Indicator

E—Charging

Indicator

F—Temperature

Indicator

G—Fuel

Gauge Indicator

H—Instrument Voltage Regulator

13— Ignition and Starter Switch

14—

Horn

Button

15— Directional Signal Switch

16— 4-Way Flasher Switch 17—

Flasher

(4-Way)

18— Windshield Wiper Motor Switch

19—

Main

Light Switch

20—

Fuel

Gauge

Tank

Unit

21—

Back-Up

Light Switch

22—

Marker

Lamp — Red

23— Right

Tail

and

Stop

Light 24— Right Back-Up Lamp

25—

Left

Back-Up Lamp 26—

Left

Tail

and

Stop

Light

27—

Marker

Lamp — Red

28—

Stop

Light Switch

29— Foot Dimmer Switch

30— Windshield Wiper Motor Assembly

31—

Ballast

Resistor 32— Ignition

Coil

33—

Spark

Plugs and Cables 34— Temperature Sending Unit

35—

Oil

Pressure Sending Unit 36—

Horn

37— Junction Block

38—

Marker

Lamp — Amber

lions

on the terminal

posts.

Be sure

condenser

is

mounted

firmly on the distributor for a

good

ground

connection.

Should a

condenser

tester

be available the capacity for

both

F4 and Prestolite V6

condenser

should

check from .25 to .28 microfarads. In the

absence

of

tester,

check by substituting a new

condenser.

H-13. Distributor Points

a. Examine the distributor

points.

If

they

show

wear,

poor

mating, transferred metal, or pitting,

then

new

ones

should be installed. Clean the

points

with a suitable

solvent

and a stiff bristled brush.

b. Check the

alignment

of the

point

for a full,

square

contact.

If not correctly aligned, bend the

stationary

contact

bracket slightly to provide align

ment.

c. The

contact

gap should be set at .020"

[0,508

mm.],

on the F4 and .016"

[0,406

mm.] on the

Prestolite V6. Adjustment of the gap is accom plished by

loosening

the lock screw and turning adjusting eccentric screw until correct gap is

secured. Be sure that the fiber block on the breaker

arm

is resting on the

highest

point

on the cam while the adjustment is

being

made. Recheck the gap

after locking the adjustment.

d. Apply a thin film of cam lubricant to the cam to

lessen

fiber block wear.

e. Using Tool C-4094, check

point

contact

spring

pressure, which should be

between

17 and 20

ounces

[0,487

a

0,567

kg.] on the F4 and 17 to 22 oz.

[0,487

a

0,624

kg.] on the Prestolite V6.

Check

with a spring scale

hooked

on the breaker

arm

at the

contact

and pull at right

angle

to the

breaker arm. Make the reading just as the

points

separate. Adjust the

point

pressure by

loosening

the stud holding the end of the

contact

arm spring

and slide the end of the spring in or out as

neces

sary.

Retighten the stud and recheck the pressure. Too low a- pressure will

cause

engine

missing at

high

speeds.

Too high a pressure will

cause

rapid

wear of the cam, block, and

points.

180

Page 182 of 376

H

ELECTRICAL

SYSTEM

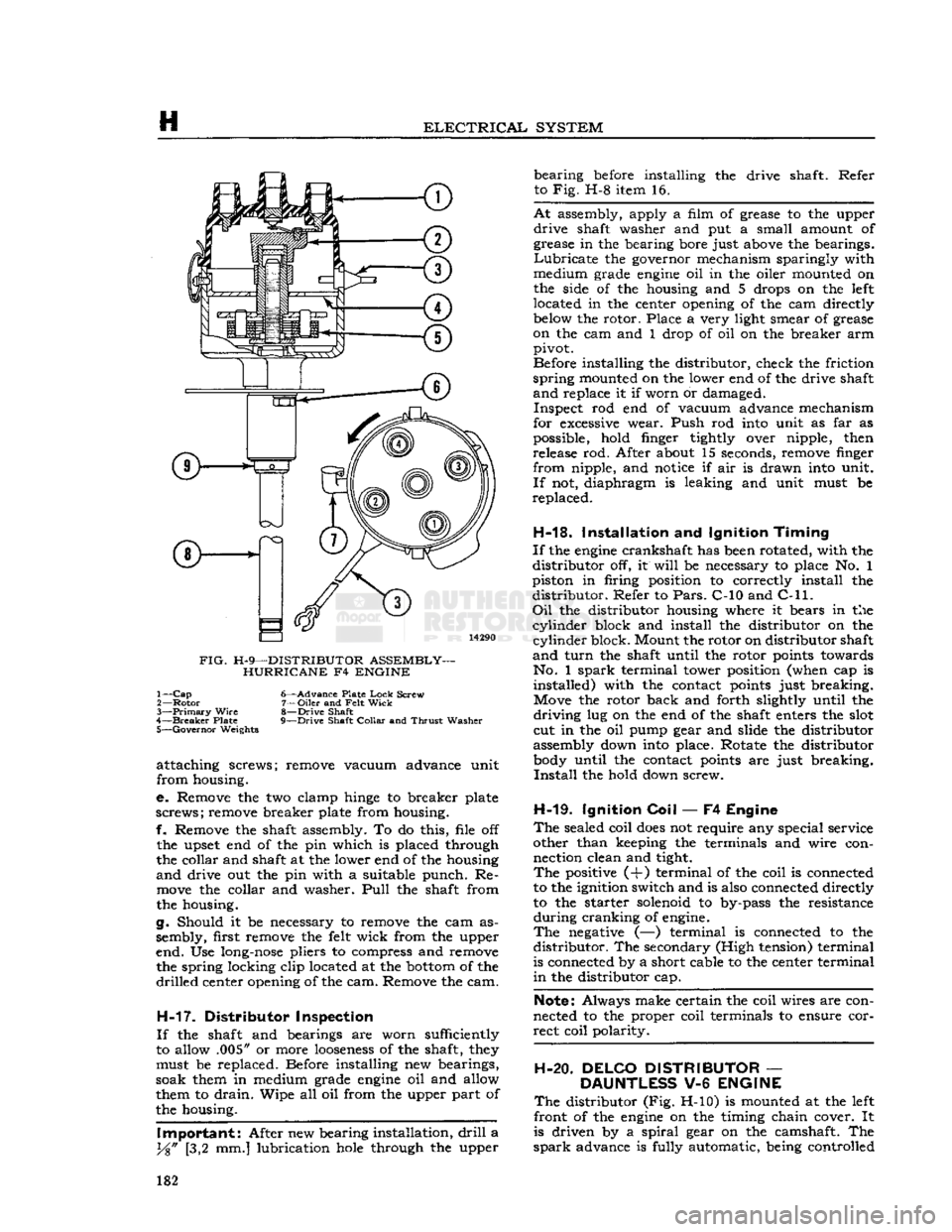

FIG.

H-9—DISTRIBUTOR ASSEMBLY- HURRICANE F4 ENGINE 1—

Cap

6—Advance Plate

Lock

Screw

2—

Rotor

7—Oiler and

Felt

Wick

3—

Primary

Wire

8—Drive Shaft

4—

Breaker

Plate 9—Drive Shaft

Collar

and

Thrust

Washer 5—

Governor

Weights

attaching screws; remove vacuum advance unit

from housing.

e. Remove the two clamp

hinge

to breaker plate

screws; remove breaker plate from housing.

f. Remove the shaft assembly. To do this, file off

the upset end of the pin which is placed through

the collar and shaft at the lower end of the housing

and

drive out the pin with a suitable punch. Re

move

the collar and washer.

Pull

the shaft from

the housing.

g. Should it be necessary to remove the cam as

sembly, first remove the

felt

wick from the upper

end. Use

long-nose

pliers to compress and remove the spring locking clip located at the

bottom

of the

drilled

center opening of the cam. Remove the cam.

H-17.

Distributor Inspection

If

the shaft and bearings are worn sufficiently

to allow .005" or more

looseness

of the shaft,

they

must be replaced. Before installing new bearings,

soak them in medium grade

engine

oil and allow

them to

drain.

Wipe all oil from the upper part of

the housing.

Important:

After new bearing installation,

drill

a

y%"

[3,2 mm.] lubrication

hole

through the upper bearing

before

installing the drive shaft. Refer

to Fig. H-8 item 16.

At

assembly, apply a film of grease to the upper

drive

shaft washer and put a small amount of

grease in the bearing bore just

above

the bearings.

Lubricate

the governor mechanism sparingly with

medium grade

engine

oil in the oiler mounted on

the side of the housing and 5 drops on the

left

located in the center opening of the cam directly

below

the rotor. Place a very light smear of grease

on the cam and 1 drop of oil on the breaker arm pivot.

Before installing the distributor, check the friction

spring

mounted on the lower end of the drive shaft

and

replace it if worn or damaged. Inspect rod end of vacuum advance mechanism

for

excessive

wear. Push rod

into

unit as far as

possible, hold finger tightly over nipple, then release rod. After about 15 seconds, remove finger

from nipple, and

notice

if air is drawn

into

unit.

If

not, diaphragm is leaking and unit must be

replaced.

H-18.

Installation and Ignition

Timing

If

the

engine

crankshaft has

been

rotated, with the

distributor off, it

will

be necessary to place No. 1

piston in firing position to correctly install the distributor. Refer to

Pars.

C-10 and

C-ll. Oil

the distributor housing where it bears in the

cylinder

block and install the distributor on the

cylinder

block. Mount the rotor on distributor shaft

and

turn

the shaft until the rotor

points

towards No. 1

spark

terminal tower position (when cap is installed) with the contact

points

just breaking. Move the rotor back and forth slightly until the

driving

lug on the end of the shaft enters the

slot

cut in the oil pump gear and slide the distributor

assembly down

into

place. Rotate the distributor

body

until the contact

points

are just breaking.

Install

the hold down screw.

H-19.

Ignition

Coil

— F4 Engine

The

sealed coil

does

not require any special service

other than keeping the terminals and wire con nection clean and tight.

The

positive (+) terminal of the coil is connected

to the ignition switch and is also connected directly

to the starter solenoid to by-pass the resistance

during

cranking of

engine.

The

negative

(—) terminal is connected to the

distributor. The secondary (High tension) terminal

is connected by a short cable to the center terminal

in

the distributor cap.

Note:

Always make certain the coil wires are con

nected to the proper coil terminals to ensure cor

rect coil polarity.

H-20. DELCO DISTRIBUTOR

—

DAUNTLESS

V-6

ENGINE

The

distributor (Fig. H-10) is mounted at the

left

front of the

engine

on the timing chain cover. It

is driven by a

spiral

gear on the camshaft. The

spark

advance is fully automatic, being controlled 182

Page 183 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

H

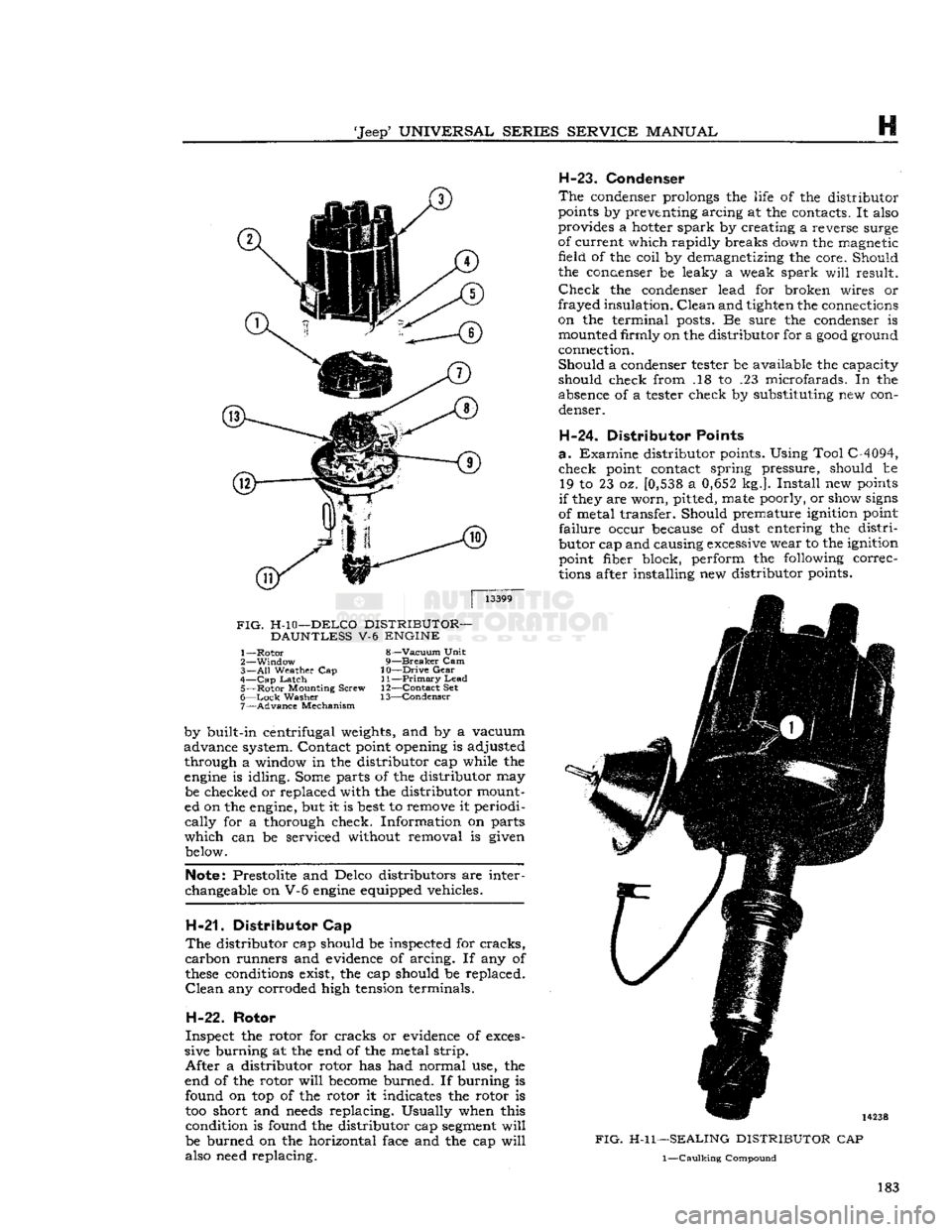

|

13399

FIG.

H-10—DELCO

DISTRIBUTOR—

DAUNTLESS

V-6

ENGINE

1—

Rotor

8—Vacuum

Unit

2—

Window

9—Breaker Cam

3—

All

Weather Cap

10—Drive

Gear

4—

Cap

Latch

11—Primary Lead 5—

Rotor

Mounting

Screw 12—Contact Set

6—

Lock

Washer 13—Condenser

7—

Advance

Mechanism

by

built-in

centrifugal weights, and by a vacuum

advance

system. Contact point opening is adjusted

through

a window in the distributor cap

while

the engine is

idling.

Some

parts

of the distributor may be checked or replaced

with

the distributor mount

ed on the engine, but it is

best

to remove it periodi

cally

for a thorough check. Information on

parts

which

can be serviced without removal is given

below.

Note:

Prestolite and Delco distributors are inter

changeable

on V-6 engine equipped vehicles.

H-21.

Distributor Cap

The distributor cap should be inspected for cracks,

carbon runners and evidence of arcing. If any of

these

conditions exist, the cap should be replaced. Clean any corroded high tension terminals.

H-22.

Rotor

Inspect the rotor for cracks or evidence of

exces

sive burning at the end of the metal strip.

After

a distributor rotor has had normal use, the

end of the rotor

will

become

burned. If burning is

found

on top of the rotor it indicates the rotor is too short and

needs

replacing. Usually when this

condition

is found the distributor cap

segment

will

be burned on the horizontal face and the cap

will

also

need

replacing.

H-23.

Condenser

The

condenser

prolongs the

life

of the distributor

points by preventing arcing at the contacts. It

also

provides a hotter spark by creating a

reverse

surge

of

current

which

rapidly

breaks

down the magnetic

field

of the

coil

by demagnetizing the core. Should

the

ccnaenser

be leaky a weak spark

will

result. Check the

condenser

lead for broken wires or

frayed

insulation.

Clean and tighten the connections

on

the terminal

posts.

Be

sure

the

condenser

is mounted

firmly

on the distributor for a good ground

connection.

Should

a

condenser

tester

be available the capacity

should check

from

.18 to .23 microfarads. In the

absence

of a

tester

check by substituting new con

denser.

H-24. Distributor Points

a-

Examine distributor points. Using

Tool

C-4094, check point contact spring

pressure,

should be 19 to 23 oz. [0,538 a 0,652 kg.]. Install new points

if

they are

worn,

pitted,

mate

poorly, or show

signs

of

metal transfer. Should premature

ignition

point

failure

occur

because

of dust entering the

distri

butor cap and causing

excessive

wear to the

ignition

point

fiber block, perform the

following

correc

tions after installing new distributor points.

FIG. H-l

1—SEALING

DISTRIBUTOR

CAP

1—Caulking

Compound

183

Page 184 of 376

H

ELECTRICAL

SYSTEM

14237

FIG.

H-l2—DRILLING DISTRIBUTOR

CAP 1—%'

Vent

Hole

Location

Seal

the distributor cap access window and the

area

beneath the distributor cap with caulking

compound as shown in

Fig. H-ll.

At approximately

180°

from the distributor cap access window,

drill

a

[2,38 mm.] vent

hole

[31,75

mm.]

from the

bottom

of the distributor cap as shown

in

Fig. H-l2. b. To adjust breaker point cam dwell, refer to

Par.

C-10.

H-25.

Centrifugal Advance

Refer

to Fig. H-13.

Inspect for

excessive

wear

between

centrifugal

weights

and advance cam, or pivot pins.

Turn

weight

base plate in a clockwise direction until

weights

are fully extended, then release and allow springs to return to retard position. Repeat several times. Springs should return

weights

to

stop

without sticking and there should be no

excess

free

movement

in the retard position.

H-26.

Distributor Removal

a.

Disconnect the distributor primary wire from

coil

and disconnect

hose

from vacuum advance

mechanism of distributor. Insert a screwdriver in upper

slotted

end of two distributor cap retainers.

Press

downward, and turn 90

degrees

counterclock

wise to release. Remove cap from distributor hous ing.

b. Make an index

mark

on distributor housing

(Fig.

H-14) in line with center of rotor. Carefully

note

the direction the vacuum unit

points

in

rela

tion to

engine

so that the distributor can be in

stalled in the same position after it is serviced.

Caution:

If

engine

is turned over while distributor is removed,

complete

ignition timing procedure

must be followed upon distributor installation.

c. Remove attaching cap screw and distributor

clamp from timing chain cover.

Lift

distributor up

ward

and remove it from timing chain cover.

H-27.

Distributor Disassembly (Delco)

Refer

to Fig. H-l5.

a.

Remove rotor, breaker point assembly, and capacitor from distributor.

FIG.

H-13—CENTRIFUGAL ADVANCE

MECHANISM (DELCO)

A—No

Advance

1—

Advance

Weights

2—

Advance

Cam

B—Full

Advance

3—Full

Advance

FIG.

H-14—DELCO DISTRIBUTOR

ROTOR

POSITION

1

—Rotor

Tip

Lined

Up

With

Notch

184

Page 187 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

H

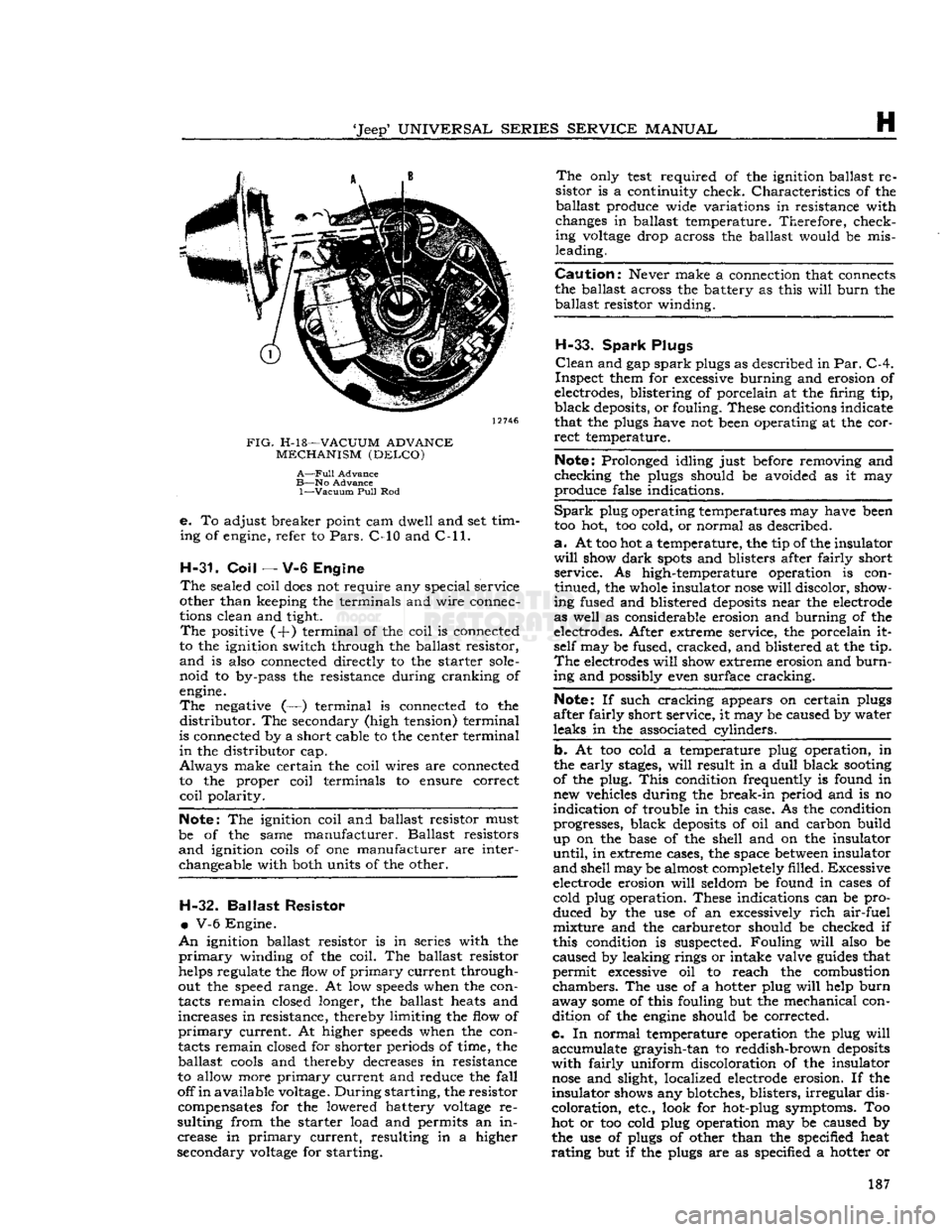

12746

FIG.

H-l8—VACUUM

ADVANCE

MECHANISM

(DELCO)

A—Full

Advance

B—No

Advance

1—Vacuum

Pull

Rod

e.

To adjust breaker point cam dwell and set tim

ing of engine, refer to

Pars.

C-10 and

C-ll.

H-31. Coil

— V-6 Engine

The

sealed coil

does

not require any special service

other than keeping the terminals and wire connec

tions clean and tight.

The

positive (+) terminal of the coil is connected

to the ignition switch through the ballast resistor,

and

is also connected directly to the starter

sole

noid to by-pass the resistance during cranking of

engine.

The

negative (—) terminal is connected to the

distributor.

The secondary (high tension) terminal

is connected by a short cable to the center terminal

in

the distributor cap.

Always

make certain the coil wires are connected to the proper coil terminals to ensure correct

coil

polarity.

Note:

The ignition coil and ballast resistor must

be of the same manufacturer. Ballast resistors

and

ignition coils of one manufacturer are interchangeable with both units of the other. H-32.

Ballast

Resistor

•

V-6 Engine.

An

ignition ballast resistor is in series with the

primary

winding of the coil. The ballast resistor

helps regulate the flow of

primary

current through

out the speed range. At low

speeds

when the con

tacts remain closed longer, the ballast heats and

increases in resistance, thereby limiting the flow of

primary

current. At higher

speeds

when the con

tacts remain closed for shorter periods of time, the ballast

cools

and thereby decreases in resistance

to allow more

primary

current and reduce the

fall

off

in

available voltage.

During

starting, the resistor compensates for the lowered battery

voltage

re

sulting from the starter load and permits an in crease in

primary

current, resulting in a higher

secondary

voltage

for starting.

The

only

test

required of the ignition ballast re

sistor is a continuity check. Characteristics of the ballast produce wide variations in resistance with

changes in ballast temperature. Therefore, check ing

voltage

drop across the ballast would be mis

leading.

Caution:

Never make a connection that connects

the ballast across the battery as this

will

burn

the ballast resistor winding.

H-33.

Spark

Plugs

Clean

and gap

spark

plugs as described in

Par.

C-4.

Inspect them for excessive burning and erosion of

electrodes, blistering of porcelain at the firing tip,

black

deposits, or fouling. These conditions indicate

that the plugs have not been operating at the cor

rect

temperature.

Note:

Prolonged idling just before removing and

checking the plugs should be avoided as it may

produce false indications.

Spark

plug operating temperatures may have been

too hot, too cold, or normal as described.

a.

At too hot a temperature, the tip of the insulator

will

show

dark

spots

and blisters after fairly short service. As high-temperature operation is con

tinued, the whole insulator

nose

will

discolor, show

ing fused and blistered

deposits

near the electrode

as well as considerable erosion and burning of the

electrodes. After extreme service, the porcelain it self may be fused, cracked, and blistered at the tip.

The

electrodes

will

show extreme erosion and

burn

ing and possibly even surface cracking.

Note:

If such cracking appears on certain plugs

after fairly short service, it may be caused by water

leaks in the associated cylinders.

b. At too cold a temperature plug operation, in

the early

stages,

will

result in a

dull

black

sooting

of the plug.

This

condition frequently is found in new vehicles during the break-in period and is no

indication of trouble in this case. As the condition progresses, black

deposits

of oil and carbon build

up on the base of the shell and on the insulator

until,

in extreme cases, the space

between

insulator

and

shell may be almost completely filled. Excessive

electrode erosion

will

seldom be found in cases of cold plug operation. These indications can be pro

duced by the use of an excessively

rich

air-fuel mixture and the carburetor should be checked if

this condition is suspected. Fouling

will

also be

caused by leaking rings or intake valve

guides

that

permit excessive oil to reach the combustion

chambers.

The use of a hotter plug

will

help

burn

away

some

of this fouling but the mechanical con dition of the

engine

should be corrected.

c. In normal temperature operation the plug

will

accumulate grayish-tan to reddish-brown

deposits

with

fairly uniform discoloration of the insulator

nose

and slight, localized electrode erosion. If the

insulator shows any blotches, blisters,

irregular

dis

coloration, etc., look for hot-plug symptoms. Too

hot or too cold plug operation may be caused by

the use of plugs of other than the specified heat

rating

but if the plugs are as specified a hotter or 187

Page 192 of 376

H

ELECTRICAL

SYSTEM

Regulator

ground screw to battery ground post

—.03-volt maximum.

Generator

frame to battery ground post—.03-volt

maximum.

H-47.

Test Procedure

a.

Circuit

Breaker—Connect

an ammeter in series between the regulator B-terminal and the lead

wire

removed from that terminal. Connect a

voltmeter between the regulator

A-terminal

and the regulator mounting base. Disconnect the field lead

from

the regulator

F-terminal

and insert a variable resistance (3 amp., 50 ohm capacity) between the

lead

and the regulator terminal. Run the generator

at about 1000 generator rpm. Insert all the re

sistance in the field

circuit,

then slowly reduce the

resistance noting the voltage reading just before the change caused by the closing of the circuit

breaker.

Increase the charging rate to the figure

specified for the regulator being tested then reduce

the charging rate by inserting resistance in the

field

circuit.

Note

the voltmeter and ammeter

reading

just before the circuit breaker

opens

and

the ammeter reading drops to zero. The closing voltage and the opening voltage or current should

be within the limits specified. An accurate method

for noting the exact instant of the opening or closing

of the circuit breaker is to connect a headphone (2000 ohms or higher) to the battery and armature

terminals

of the regulator. When the contacts

open or close a

click

will

be

heard

in the headphones.

To

adjust the closing voltage change the armature

spring

tension by bending the hanger at the lower end of the spring. Increase the spring tension to

raise

the closing voltage or decrease the tension

to lower the closing voltage. To adjust the opening voltage raise or lower the stationary contact

keeping the contacts perfectly aligned. Increasing

the contact gap lowers the opening

'

voltage.

Change

the contact gap by expanding or contract

ing the stationary contact bracket, keeping the

contacts aligned. Do not adjust the gap between

the contacts to less than the specified minimum.

b.

Voltage Regulator—Connect the ammeter as in

step

a. Connect the voltmeter between the regulator

B-terminal

and the regulator base. Remove the

variable

resistance from the field

circuit.

Run the

generator at

half

output for 15 minutes to bring

the regulator to normal operating temperature.

Keep

the cover on the regulator during the

warm-

up period and also when taking readings.

Stop the engine then bring it up to approximately 2500 generator rpm. Adjust the amperage to

half

maximum

output by turning on lights or accessor

ies and then

note

the voltmeter reading.

This

read

ing should be within the limits specified for the voltage regulator operation. To adjust the oper

ating voltage change the

armature

spring tension by

bending the hanger at the lower end of the

arma

ture

spring. After each adjustment

stop

the engine then restart it.

Bring

it up to speed and adjust the

current

before taking a reading. In order to obtain

an

accurate indication of the operation of the volt

age regulator unit connect a headphone (2000 ohm

or

higher) between the

F-terminal

and ground to

pick

up the sound of the opening and closing of the

contacts. The clicks should be regular and clear without irregularities or missing. If the

tone

is not

clear

and regular remove the regulator cover and

inspect the contacts. The contacts should be flat

and

not burned excessively and should be aligned

to make

full

face contact. If the contacts need

cleaning refer to paragraph d for the method.

c.

Current

Regulator—Connect the regulator and the

test

equipment as in

step

b. Running the generator at approximately 3000 generator rpm.,

turn

on lights and accessories so that the generator must charge at maximum rate. The ammeter should give a reading within the limits specified.

To

adjust opening amperage, change the armature

spring

tension by bending the hanger at the lower

end of the armature spring. After each adjustment,

stop

the engine, then restart it.

Bring

the engine up to speed and take an ammeter reading. Keep

the cover on the regulator when taking

these

readings.

Connect

a headphone (2000 ohms or higher) be

tween the regulator

F-terminal

and ground to pick

up the sound of opening and closing of the contacts.

Clear,

regular clicks should be heard over the

headphones; they should not be

irregular

or missing.

If

the

tone

is not clear and regular remove the

regulator cover and inspect the contacts. The

contacts should be flat and not burned excessively

and

should be aligned to make

full

face contact. If

the contacts need cleaning refer to paragraph d.

below for the method.

d.

Contacts—Inspect the contacts on all three

units.

In normal use the contacts

will

become

grayed.

If the contacts are burned or dirty or if they are not smooth, file the contacts with a #6

American,

Swiss cut, equalling file. Move the file

parallel

and lengthwise to the armature.

File

just

enough so that the contacts present a smooth

sur

face toward each other. It is not necessary to remove every trace of pitting. After filing, dampen

a

piece of linen or lintless bond tape in refined

carbon

tetrachloride and draw the tape between

the contacts. Repeat with a dry piece of tape. Use

clean

tape for each set of contacts.

e. Recheck—Operate the unit at

half

maximum

output for five minutes with the cover on the regu

lator.

Repeat the testing procedure for all units as described in a, b, c above. Be sure cover is on regu

lator

when taking readings.

H-48.

Quick

Checks

H-49.

Low Charging Rate with a

Fully

Charged

Battery

A

fully charged battery and a low charging rate

indicates normal regulator operation.

A

further check of the regulator operation can be

made by using the starting motor for 5 to 10

seconds with the ignition switch in the "off" posi tion.

Then

start the engine and operate at a genera

tor speed of 2500 to 3000 rpm. The charging rate should rise to its maximum value then taper off to

a

minimum charge as the battery becomes charged.

H-50.

High Charging Rate with a

Fully

Charged

Battery

This

is usually an indication that the voltage regu

lator

is not operating correctly. The high voltage 192