service JEEP CJ 1953 Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

Page 71 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

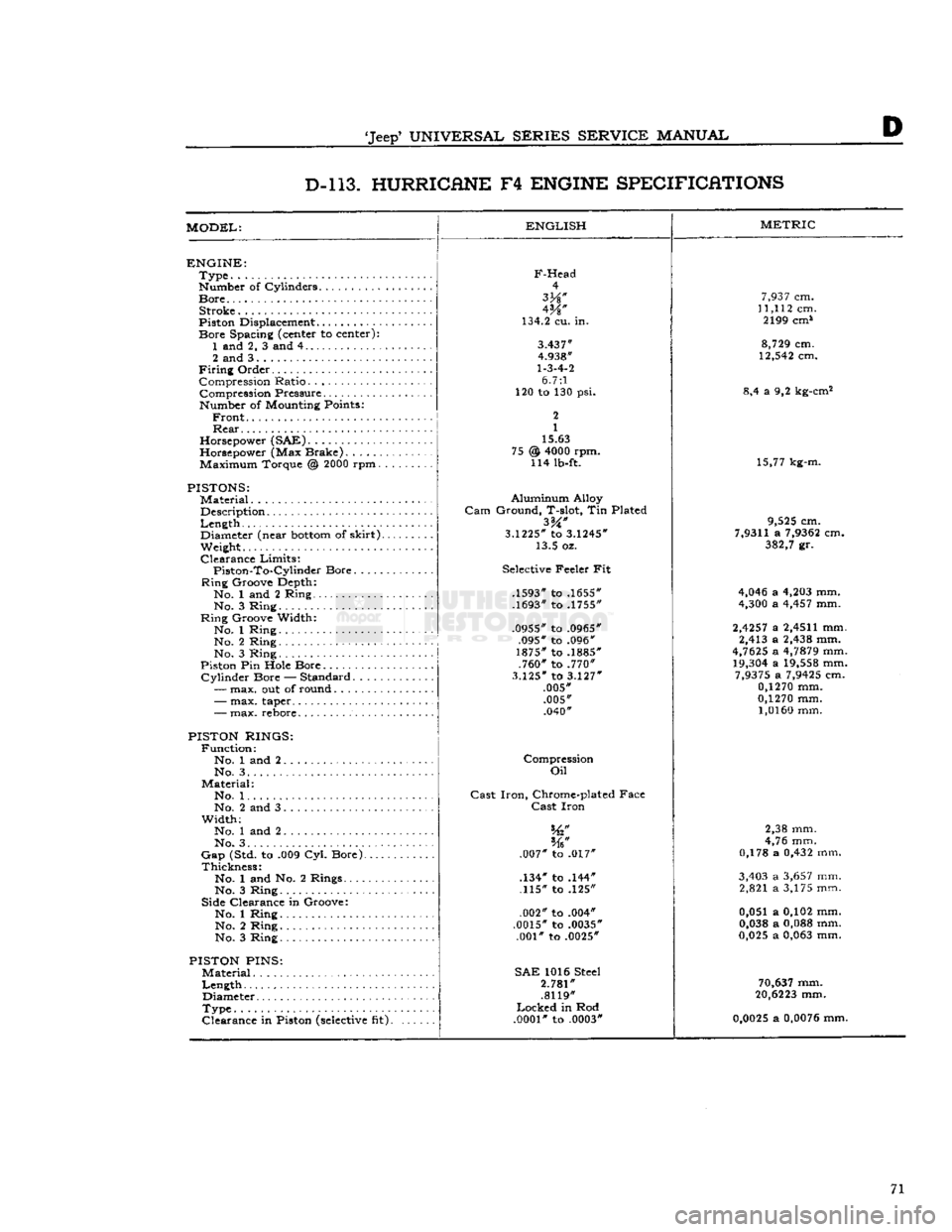

D D-l 13. HURRICANE

F4

ENGINE SPECIFICATIONS

MODEL:

ENGLISH

ENGINE:

Type

Number of Cylinders

Bore

Stroke

Piston Displacement...........

Bore

Spacing (center to center): 1 and 2, 3 and 4

2 and 3

Firing

Order Compression Ratio Compression Pressure... .

Number of Mounting Points:

Front

Rear

Horsepower (SAE)

Horsepower (Max Brake) Maximum Torque @

2000

rpm.

PISTONS:

Material

Description

Length

,.

Diameter (near

bottom

of

skirt).

Weight.

Clearance

Limits:

Piston-To-Cylindcr

Bore

Ring

Groove Depth:

No. 1 and 2 Ring No. 3 Ring

Ring

Groove Width:

No. 1 Ring No. 2 Ring

No. 3 Ring

Piston Pin Hole Bore

Cylinder

Bore — Standard.....

—

max. out of round

F-Head

4

W

134.2 cu. in.

3.437"

4.938"

1-3-4-2

6.7:1

120 to 130 psi.

2

1

15.63

@

4000

rpm. 114 lb-ft. 75

-

max. taper..

-

max. rebore.

PISTON RINGS:

Function:

No. 1 and 2 No. 3. .

Material:

No. 1. .

No. 2 and 3

Width;

No. 1 and 2

No. 3. . . .

Gap

(Std. to .009 Cyl. Bore).

Thickness:

No. 1 and No. 2 Rings....

No. 3 Ring

Side Clearance in Groove:

No. 1 Ring No. 2 Ring

No. 3 Ring

PISTON

PINS:

Material

Length

Diameter

Type

Clearance

in Piston

(selective

fit).

Aluminum

Alloy

Gam

Ground, T-slot, Tin Plated

3.1225*

to

3.1245*

13.5 oz.

Selective Feeler Fit

.1593" to .1655"

.1693" to .1755"

.0955" to .0965" .095" to .096"

1875" to .1885" .760" to .770"

3.125"

to

3.127"

.005" .005" .040"

Compression

Oil

Cast

Iron,

Chrome-plated Face

Cast

Iron

.007" to .017"

.134" to .144" .115" to .125"

.002" to .004"

.0015" to .0035" .001" to .0025"

SAE

1016 Steel

2.781"

.8119"

Locked

in Rod

.0001"

to .0003"

METRIC

7,937

cm.

11,112

cm. 2199 cm*

8,729

cm.

12,542

cm.

8,4 a 9,2 kg-cm2

15,77 kg-m.

9,525

cm.

7,9311

a

7,9362

cm.

382,7

gr.

4,046

a

4,203

mm.

4,300

a

4,457

mm.

2,4257

a

2,4511

mm. 2,413 a

2,438

mm.

4,7625

a

4,7879

mm.

19,304

a

19,558

mm.

7,9375

a

7,9425

cm.

0,1270

mm.

0,1270

mm.

1,0160

mm.

2,38 mm.

4,76 mm.

0,178 a

0,432

mm.

3,403

a

3,657

mm. 2,821 a 3,175 mm.

0,051 a 0,102 mm.

0,038

a

0,088

mm.

0,025

a

0,063

mm.

70,637

mm.

20,6223

mm.

0,0025

a

0,0076

mm. 71

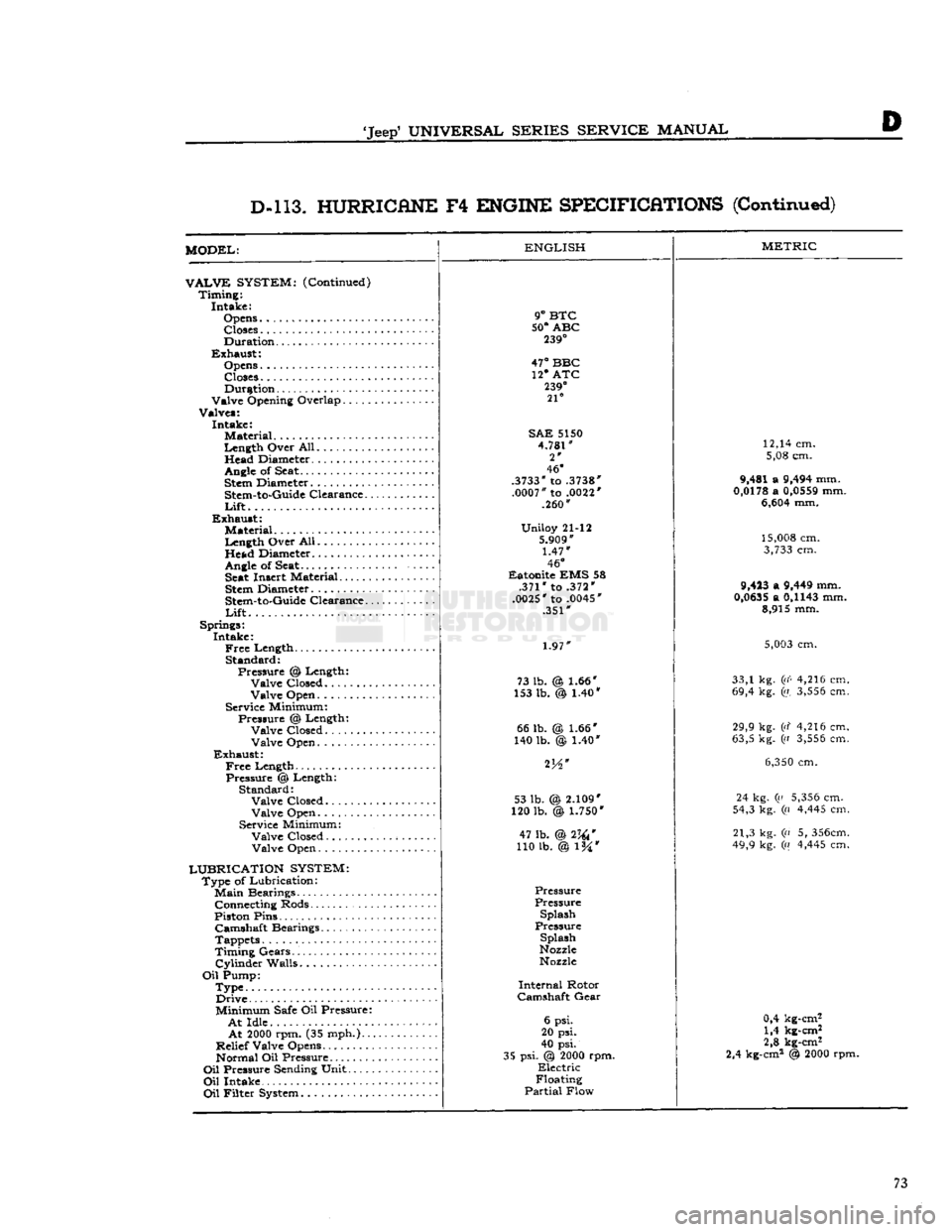

Page 73 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

D

D-l 13. HURRICANE

F4

ENGINE SPECIFICATIONS

(Continued)

MODEL:

VALVE

SYSTEM:

(Continued) Timing: Intake:

Opens Closes

Duration

Exhaust: Opens

Closes Duration

Valve Opening Overlap

Valves: Intake: Material

Length Over All. Head Diameter.

.........

Angle

of Seat.

Stem

Diameter

Stem-to-Guide

Clearance..

Lift

Exhaust: Material

Length Over All Head Diameter

Angle

of

Seat Seat

Insert Material

Stem

Diameter

Stem-to-Guide

Clearance..

Lift

Springs: Intake:

Free

Length Standard: Pressure % Length: Valve Closed........

Valve Open

Service Minimum: Pressure @ Length: Valve Closed Valve Open

Exhaust:

Free

Length Pressure @ Length: Standard: Valve Closed

Valve Open

Service Minimum: Valve Closed. Valve Open

LUBRICATION SYSTEM:

Type of Lubrication:

Main

Bearings Connecting Rods

Piston Pins Camshaft Bearings

Tappets

Timing Gears.'.

Cylinder

Walls

Oil

Pump: Type Drive

Minimum

Safe

Oil Pressure:

At

Idle

At

2000

rpm. (35 mph.)..

Relief Valve Opens Normal Oil Pressure

Oil

Pressure

Sending

Unit

Oil

Intake

Oil

Filter

System

ENGLISH

9°

BTC

50°

ABC

239°

47°

BBC 12* ATC

239°

21°

SAE

5150

4.781"

2*

46°

.3733"

to

.3738"

.0007"

to

.0022'

.260"

Uniloy 21-12

5.909"

1.47"

46°

Eatonite EMS 58 .371" to .372"

.0025"

to

.0045'

.351"

1.97"

73 lb. @ 1.66"

153 lb. @ 1.40* 66 lb.

140 lb. 1.66*

)

1.40" 53 lb. (

120 lb.

2.109"

\

1.750*

47 lb. @2W

110 lb. @ l%*

Pressure

Pressure Splash

Pressure

Splash

Nozzle

Nozzle

Internal

Rotor

Camshaft

Gear

6 psi.

20 psi.

40 psi.

35 psi. @

2000

rpm.

Electric

Floating

Partial

Flow

METRIC

12,14 cm. 5,08 cm.

9,481 a

9,494

mm.

0,0178

a

0,0559

mm.

6,604

mm.

15,008

cm.

3,733

cm.

9,423

a

9,449

mm.

0,0635

a

0,1143

mm. 8,915 mm.

5,003

cm.

33,1 kg.

(i(<

4,216 cm.

69,4 kg. (a.

3,556

cm.

29,9 kg. (d 4,216 cm.

63,5 kg. ((i

3,556

cm.

6,350

cm.

24 kg. (a

5,356

cm.

54,3 kg. (a

4,445

cm.

21,3 kg. (n 5,

356cm.

49,9 kg. («

4,445

cm.

0,4 kg-cm2 1,4 kg-cm2

2,8 kg-cm2

2,4 kg-cm2 @

2000

rpm. 73

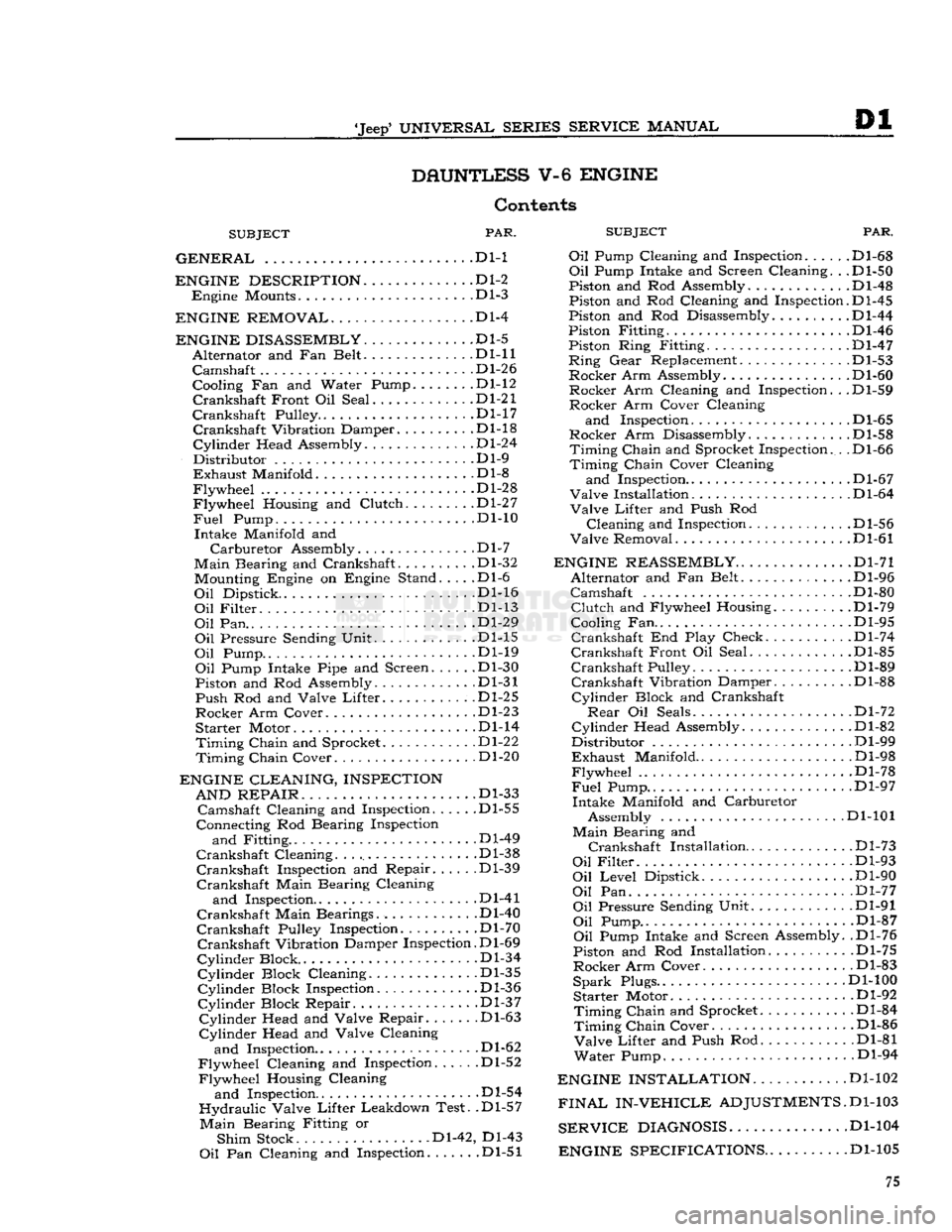

Page 75 of 376

'Jeep'

UNIVERSAL SERIES

SERVICE

MANUAL

Dl

DAUNTLESS

V-6

ENGINE

Contents

SUBJECT

PAR.

SUBJEC

GENERAL

.... . . Dl-1 Oil Pump Cl(

ENGINE DESCRIPTION

D1-2

Engine

Mounts Dl-3

ENGINE REMOVAL

Dl-4

ENGINE DISASSEMBLY

Dl-5

Alternator

and Fan Belt Dl-11

Camshaft

.... Dl-26

Cooling Fan and Water Pump.

......

.Dl-12

Crankshaft

Front Oil Seal .Dl-21

Crankshaft

Pulley D1-17

Crankshaft

Vibration Damper Dl-18

Cylinder

Head Assembly Dl-24

Distributor

Dl-9

Exhaust

Manifold .Dl-8

Flywheel

Dl-28

Flywheel

Housing and

Clutch

Dl-27

Fuel

Pump. ... . .Dl-10

Intake

Manifold and

Carburetor

Assembly.

.............

.Dl-7

Main

Bearing and Crankshaft. Dl-32 Mounting Engine on Engine Stand. . . . .Dl-6

Oil

Dipstick. Dl-16

Oil

Filter

Dl-13

Oil

Pan.. ...

.......

.Dl-29

Oil

Pressure Sending Unit Dl-15

Oil

Pump Dl-19

Oil

Pump Intake Pipe and Screen Dl-30

Piston and Rod Assembly. Dl-31

Push

Rod and Valve

Lifter.

.Dl-25

Rocker

Arm Cover Dl-23

Starter

Motor Dl-14

Timing

Chain

and Sprocket Dl-22

Timing

Chain

Cover Dl-20

ENGINE CLEANING, INSPECTION AND REPAIR

. . ... .Dl-33

Camshaft

Cleaning and Inspection Dl-55

Connecting Rod Bearing Inspection

and

Fitting .Dl-49

Crankshaft

Cleaning Dl-38

Crankshaft

Inspection and Repair Dl-39

Crankshaft

Main Bearing Cleaning

and

Inspection Dl-41

Crankshaft

Main Bearings. Dl-40

Crankshaft

Pulley Inspection. Dl-70

Crankshaft

Vibration Damper Inspection. D1-69

Cylinder

Block .Dl-34

Cylinder

Block Cleaning Dl-35

Cylinder

Block Inspection Dl-36

Cylinder

Block Repair. .Dl-37

Cylinder

Head and Valve Repair .Dl-63

Cylinder

Head and Valve Cleaning

and

Inspection.. . .Dl-62

Flywheel

Cleaning and Inspection Dl-52

Flywheel

Housing Cleaning

and

Inspection Dl-54

Hydraulic

Valve

Lifter

Leakdown Test. .Dl-57

Main

Bearing Fitting or

Shim

Stock Dl-42, Dl-43

Oil

Pan Cleaning and Inspection .Dl-51

PAR.

and

Inspection. .... .Dl-68

Oil

Pump Intake and Screen Cleaning. . .Dl-50

Piston and Rod Assembly.

...........

.Dl-48

Piston and Rod Cleaning and Inspection.D1-45

Piston and Rod Disassembly Dl-44

Piston Fitting Dl-46

Piston Ring Fitting. .Dl-47

Ring

Gear

Replacement. .Dl-53

Rocker

Arm Assembly. Dl-60

Rocker

Arm Cleaning and Inspection. . .Dl-59

Rocker

Arm Cover Cleaning

and

Inspection D1-65

Rocker

Arm Disassembly .Dl-58

Timing

Chain

and Sprocket Inspection. . .Dl-66

Timing

Chain

Cover Cleaning

and

Inspection.. . Dl-67

Valve

Installation D1-64

Valve

Lifter

and Push Rod

Cleaning

and Inspection. . Dl-56

Valve

Removal Dl-61

ENGINE REASSEMBLY

Dl-71

Alternator

and Fan Belt Dl-96

Camshaft

Dl-80

Clutch

and Flywheel Housing Dl-79

Cooling Fan.. . .Dl-95

Crankshaft

End Play Check. . Dl-74

Crankshaft

Front Oil Seal Dl-85

Crankshaft

Pulley Dl-89

Crankshaft

Vibration Damper Dl-88

Cylinder

Block and Crankshaft

Rear

Oil Seals Dl-72

Cylinder

Head Assembly .Dl-82

Distributor

Dl-99

Exhaust

Manifold Dl-98

Flywheel

.Dl-78

Fuel

Pump.. .. . Dl-97

Intake

Manifold and Carburetor Assembly Dl-101

Main

Bearing and

Crankshaft

Installation

.

Dl-73

Oil

Filter

Dl-93

Oil

Level

Dipstick Dl-90

Oil

Pan Dl-77

Oil

Pressure Sending Unit Dl-91

Oil

Pump.. .Dl-87

Oil

Pump Intake and Screen Assembly. .Dl-76

Piston and Rod Installation Dl-75

Rocker

Arm Cover. Dl-83

Spark

Plugs.. Dl-100

Starter

Motor Dl-92

Timing

Chain

and Sprocket.

..........

.Dl-84

Timing

Chain

Cover Dl-86

Valve

Lifter

and Push Rod Dl-81

Water

Pump. Dl-94

ENGINE INSTALLATION

Dl-102

FINAL

IN-VEHICLE

ADJUSTMENTS.

D1-103

SERVICE

DIAGNOSIS

Dl-104

ENGINE SPECIFICATIONS

. .Dl-105 75

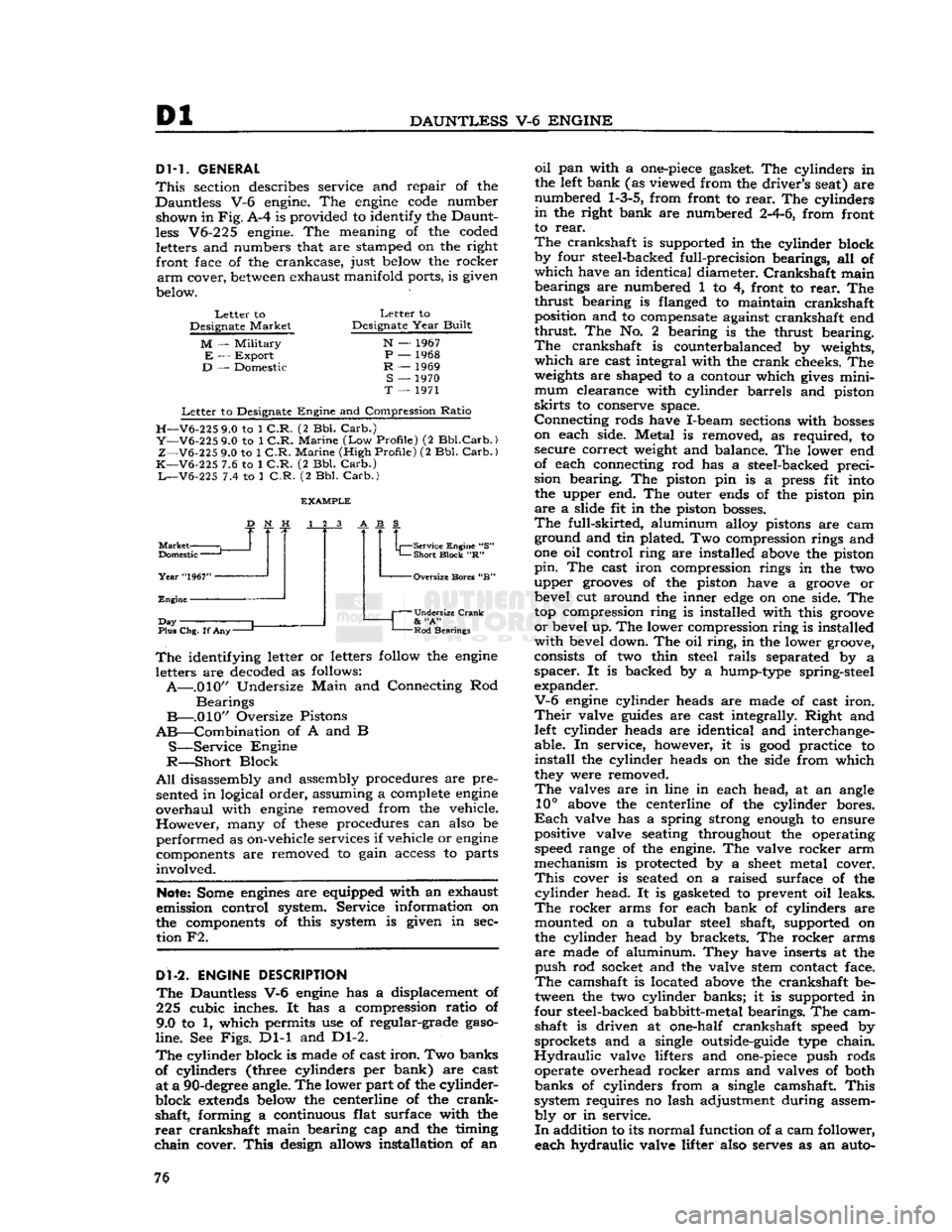

Page 76 of 376

Dl

DAUNTLESS

V-6

ENGINE

DM.

GENERAL

This

section describes service and repair of the

Dauntless V-6 engine. The

engine

code

number shown in

Fig.

A-4 is provided to identify the Daunt

less

V6-225 engine. The meaning of the coded letters and numbers that are stamped on the right front face of the crankcase, just below the rocker

arm

cover,

between

exhaust manifold ports, is given

below.

Letter

to

Designate

Market

M

—

Military

E

—

Export

D

— Domestic

Letter

to

Designate

Year

Built

N

— 1967

P

— 1968

R

— 1969

S

— 1970

T

— 1971

Letter

to Designate

Engine

and Compression

Ratio

H—V6-225

9.0 to 1

C.R.

(2 Bbl.

Carb.)

Y—V6-225

9.0 to 1

C.R.

Marine

(Low

Profile)

(2

Bbl.Carb.)

Z—V6-225

9.0 to 1

C.R.

Marine

(High

Profile)

(2 Bbl.

Carb.)

K—V6-225

7.6 to 1

C.R.

(2 Bbl.

Carb.)

L—V6-225

7.4 to 1

C.R.

(2 Bbl.

Carb.)

Market

Domestic

—

Year

"1967"

Engine

J

Day

Plus Chg. If

Any-

Service Engine "S"

Short

Block

"R" -Oversize Bores "B"

Undersize Crank

&

"A"

Rod

Bearings

The

identifying letter or letters follow the

engine

letters are decoded as follows:

A—.010"

Undersize

Main

and Connecting Rod

Bearings

B—.010"

Oversize Pistons

AB—Combination

of A and B

S—Service

Engine

R—Short

Block

All

disassembly and assembly procedures are pre sented in logical order, assuming a complete

engine

overhaul

with

engine

removed from the vehicle.

However,

many of

these

procedures can also be

performed as on-vehicle services if vehicle or

engine

components are removed to gain access to parts

involved.

Note:

Some

engines

are equipped with an exhaust

emission control system. Service information on

the components of this system is given in sec tion F2.

Dl-2.

ENGINE

DESCRIPTION

The

Dauntless V-6

engine

has a displacement of

225 cubic inches. It has a compression ratio of

9.0 to 1, which permits use of regular-grade

gaso

line.

See

Figs.

Dl-1 and Dl-2.

The

cylinder block is made of cast

iron.

Two banks

of cylinders (three cylinders per bank) are cast at a

90-degree

angle. The lower part of the cylinder-

block

extends

below the centerline of the

crank

shaft, forming a continuous flat surface with the

rear

crankshaft main bearing cap and the timing

chain

cover.

This

design allows installation of an

oil

pan with a

one-piece

gasket. The cylinders in

the left bank (as viewed from the driver's seat) are

numbered

1-3-5,

from front to

rear.

The cylinders

in

the right bank are numbered

2-4-6,

from front

to

rear.

The

crankshaft is supported in the cylinder block

by four steel-backed full-precision bearings, all of

which

have an identical diameter.

Crankshaft

main bearings are numbered 1 to 4, front to

rear.

The

thrust

bearing is flanged to maintain crankshaft position and to compensate against crankshaft end

thrust

The No. 2 bearing is the thrust bearing.

The

crankshaft is counterbalanced by weights,

which

are cast integral with the

crank

cheeks. The

weights

are shaped to a contour which

gives

mini

mum

clearance with cylinder barrels and piston

skirts

to conserve space.

Connecting

rods have I-beam sections with

bosses

on each side. Metal is removed, as required, to secure correct weight and balance. The lower end

of each connecting rod has a steel-backed preci

sion bearing. The piston pin is a press fit into the upper end. The outer ends of the piston pin

are

a slide fit in the piston

bosses.

The

full-skirted, aluminum alloy pistons are cam ground and tin plated. Two compression rings and

one oil control ring are installed above the piston

pin.

The cast iron compression rings in the two

upper

grooves

of the piston have a

groove

or bevel cut around the inner

edge

on one side. The

top compression ring is installed with this

groove

or

bevel up. The lower compression ring is installed

with

bevel down. The oil

ring,

in the lower groove,

consists of two thin steel

rails

separated by a

spacer.

It is backed by a hump-type spring-steel

expander.

V-6

engine

cylinder heads are made of cast

iron.

Their

valve

guides

are cast integrally. Right and left cylinder heads are identical and interchange

able. In service, however, it is

good

practice to

install

the cylinder heads on the side from which

they were removed.

The

valves are in line in each head, at an angle

10°

above the centerline of the cylinder bores.

Each

valve has a spring strong enough to ensure

positive valve seating throughout the operating speed range of the engine. The valve rocker arm

mechanism is protected by a

sheet

metal cover.

This

cover is seated on a raised surface of the

cylinder

head. It is gasketed to prevent oil leaks.

The

rocker arms for each bank of cylinders are mounted on a tubular steel shaft, supported on

the cylinder head by brackets. The rocker arms

are

made of aluminum. They have inserts at the

push

rod socket and the valve stem contact face.

The

camshaft is located above the crankshaft be

tween the two cylinder banks; it is supported in

four steel-backed babbitt-metal bearings. The cam shaft is driven at one-half crankshaft speed by

sprockets and a single outside-guide type chain.

Hydraulic

valve lifters and

one-piece

push rods operate overhead rocker arms and valves of both

banks

of cylinders from a single camshaft.

This

system requires no lash adjustment during assem

bly

or in service.

In

addition to its normal function of a cam follower,

each hydraulic valve lifter also serves as an auto- 76

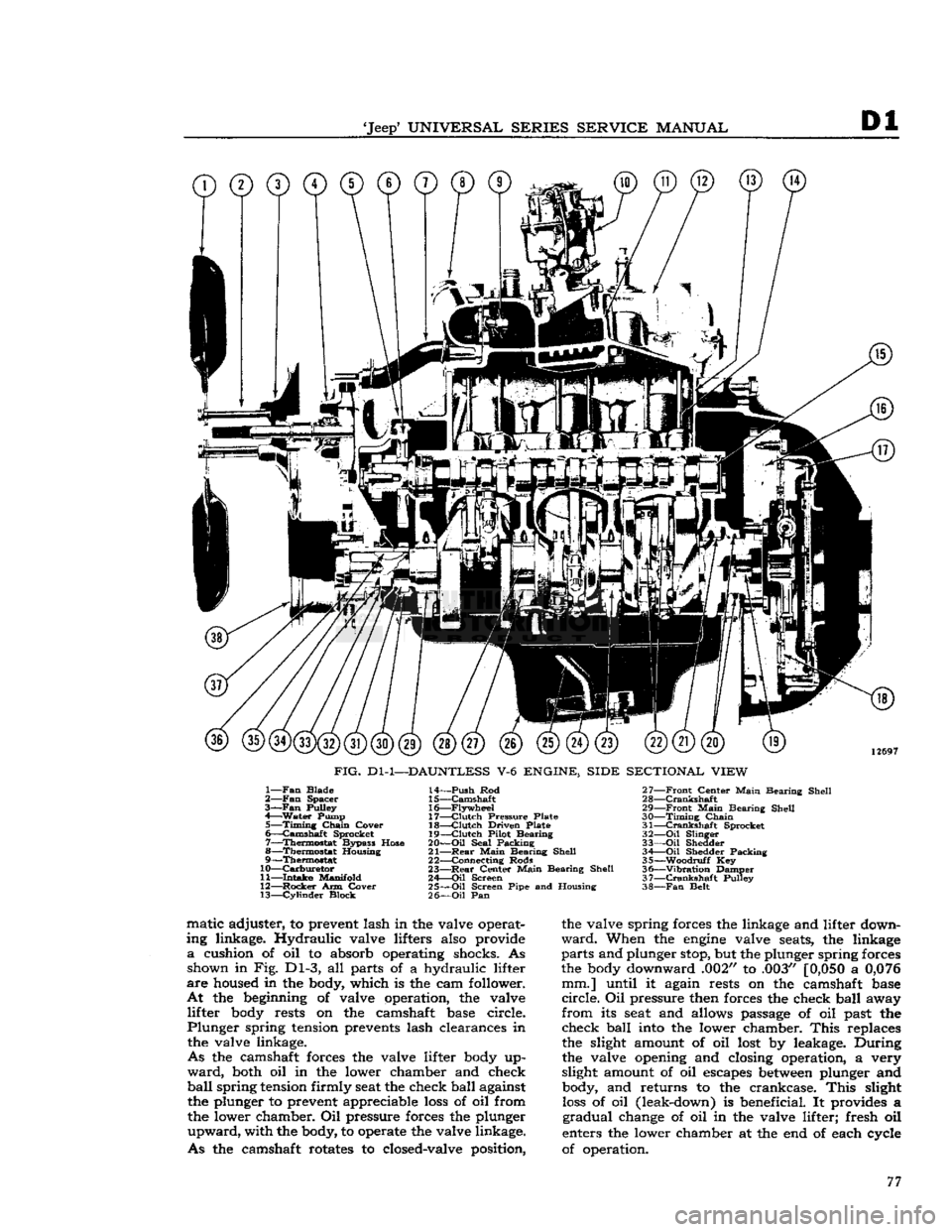

Page 77 of 376

'Jeep'

UNIVERSAL SERIES SERVICE

MANUAL

Dl

©©©©©©©©©

12697

FIG.

Dl-1—DAUNTLESS

V-6

ENGINE, SIDE SECTIONAL VIEW

1—

Fan

Blade

2—

Fan

Spacer

3—Fan

Pulley

4—

Water

Pump 5—

Timing

Chain

Cover

6—

Camshaft

Sprocket

7—

Thermostat

Bypass Hose

8—

Thermostat

Housing

9—

Thermostat

10—

Carburetor

11—

Intake

Manifold

12—

Rocker

Arm Cover 13—

Cylinder

Block 14—

Push

Rod

15—

Camshaft

16—

Flywheel

17—

Clutch

Pressure Plate

18—

Clutch

Driven Plate

19—

Clutch

Pilot Bearing

20—

Oil

Seal Packing

21—

Rear

Main

Bearing Shell

22— Connecting Rods

23—

Rear

Center

Main

Bearing Shell

24—

Oil

Screen

25—

Oil

Screen Pipe and Housing

26—

Oil

Pan 27—

Front

Center

Main

Bearing Shell

28—

Crankshaft

29—

Front

Main

Bearing Shell

30—

Timing

Chain

31—

Crankshaft

Sprocket

32—

Oil

Slinger

33—

Oil

Shedder 34 Oil Shedder Packing

35—

-Woodruff

Key

36—

"Vibration

Damper

37—

Crankshaft

Pulley

38—

Fan

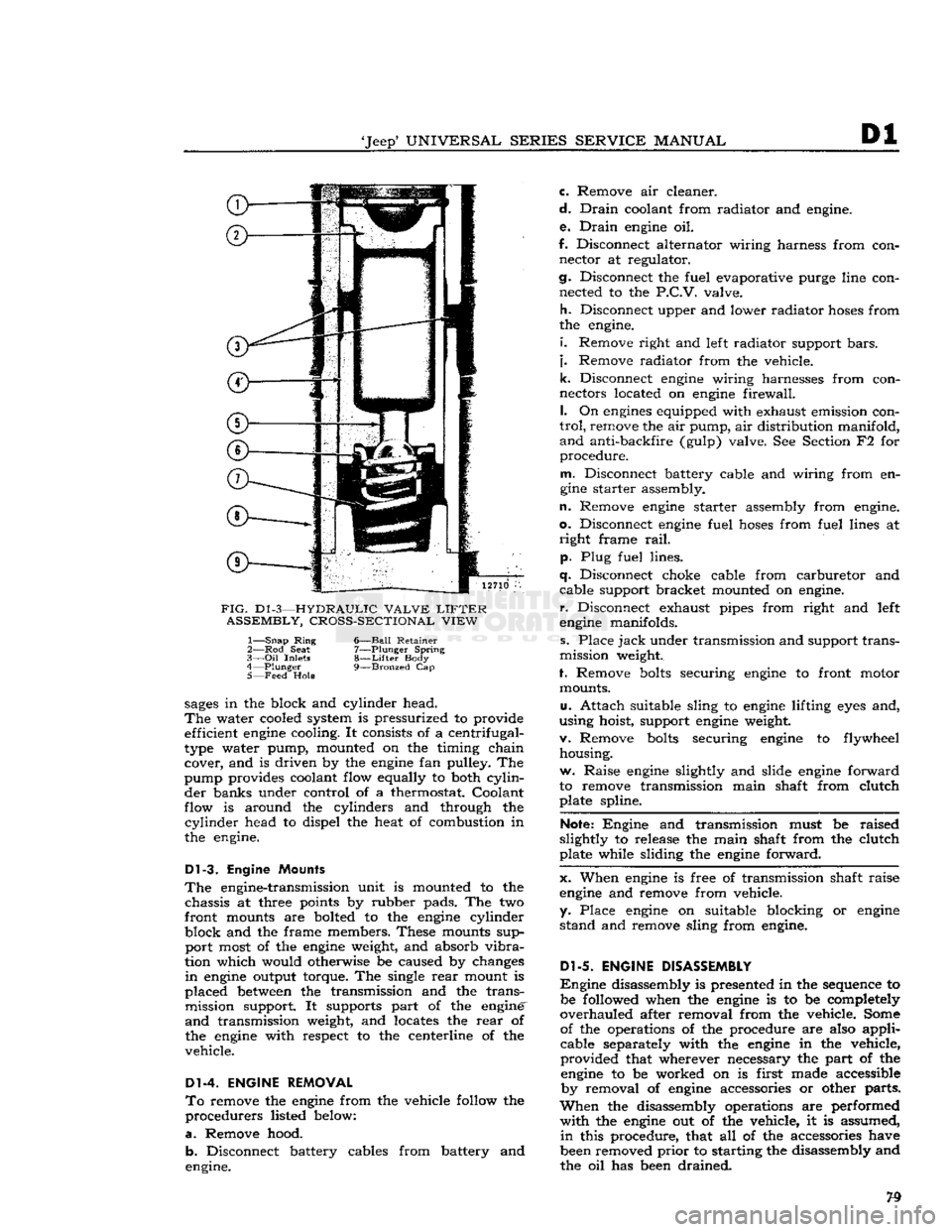

Belt matic adjuster, to prevent lash in the valve operat

ing linkage. Hydraulic valve lifters also provide

a

cushion of oil to absorb operating shocks. As shown in Fig. Dl-3, all parts of a hydraulic lifter

are

housed in the body, which is the cam follower.

At

the beginning of valve operation, the valve lifter body rests on the camshaft base circle.

Plunger

spring tension prevents lash clearances in the valve linkage.

As

the camshaft forces the valve lifter body up

ward,

both oil in the lower chamber and check

ball

spring

tension firmly seat the check ball against the plunger to prevent appreciable

loss

of oil from

the lower chamber. Oil pressure forces the plunger

upward,

with the body, to operate the valve linkage.

As

the camshaft rotates to closed-valve position, the valve spring forces the linkage and lifter down

ward.

When the

engine

valve seats, the linkage

parts

and plunger stop, but the plunger spring forces

the body downward .002" to .003"

[0,050

a

0,076

mm.] until it again rests on the camshaft base

circle.

Oil pressure then forces the check ball away

from

its seat and allows passage of oil past the check ball into the lower chamber.

This

replaces

the slight amount of oil lost by leakage. During

the valve opening and closing operation, a very

slight amount of oil escapes

between

plunger and body, and returns to the crankcase.

This

slight

loss

of oil (leak-down) is beneficial. It provides a

gradual

change of oil in the valve lifter; fresh oil

enters the lower chamber at the end of each cycle

of operation. 77

Page 79 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

Dl

12710

FIG.

D1

-3—HYDRAULIC VALVE

LIFTER

ASSEMBLY, CROSS-SECTIONAL VIEW

1—

Snap

Ring

6—Ball Retainer

2— Rod

Seat

7—Plunger Spring

3—

Oil

Inlets

8—Lifter

Body

4—

Plunger

9—Bronzed

Cap

5— Feed

Hole

sages

in the block and cylinder head.

The

water cooled system is pressurized to provide efficient

engine

cooling. It consists of a centrifugal-

type water pump, mounted on the timing chain cover, and is driven by the

engine

fan pulley. The

pump provides coolant flow equally to both

cylin

der banks under control of a thermostat. Coolant

flow is around the cylinders and through the

cylinder

head to dispel the heat of combustion in

the engine.

Dl-3.

Engine Mounts

The

engine-transmission unit is mounted to the chassis at three points by rubber pads. The two

front mounts are bolted to the

engine

cylinder

block and the frame members. These mounts sup port most of the

engine

weight, and absorb

vibra

tion which would otherwise be caused by changes

in

engine

output torque. The single

rear

mount is

placed

between

the transmission and the trans mission support. It supports part of the engine'

and

transmission weight, and locates the

rear

of

the

engine

with respect to the centerline of the

vehicle.

Dl-4. ENGINE REMOVAL

To

remove the

engine

from the vehicle follow the

procedurers listed below:

a.

Remove hood. b. Disconnect battery cables from battery and

engine. c. Remove air cleaner.

d.

Drain

coolant from radiator and engine.

e.

Drain

engine

oil.

f. Disconnect alternator wiring harness from con nector at regulator.

cj.

Disconnect the fuel evaporative purge line con nected to the

P.C.V.

valve.

h.

Disconnect upper and lower radiator

hoses

from

the engine.

i.

Remove right and left radiator support

bars,

j.

Remove radiator from the vehicle.

k.

Disconnect

engine

wiring harnesses from con

nectors located on

engine

firewall.

I.

On

engines

equipped with exhaust emission con

trol,

remove the air pump, air distribution manifold,

and

anti-backfire (gulp) valve. See Section F2 for

procedure.

m.

Disconnect battery cable and wiring from en

gine

starter assembly.

n.

Remove

engine

starter assembly from engine,

o.

Disconnect

engine

fuel

hoses

from fuel lines at

right

frame

rail,

p. Plug fuel lines.

q.

Disconnect choke cable from carburetor and cable support bracket mounted on engine,

r.

Disconnect exhaust pipes from right and left

engine

manifolds.

s. Place

jack

under transmission and support trans

mission weight.

f. Remove

bolts

securing

engine

to front motor mounts.

u.

Attach suitable sling to

engine

lifting

eyes

and,

using hoist, support

engine

weight.

v. Remove

bolts

securing

engine

to flywheel housing.

w. Raise

engine

slightly and slide

engine

forward

to remove transmission main shaft from clutch plate spline.

Note:

Engine and transmission must be raised

slightly to release the main shaft from the clutch

plate while sliding the

engine

forward.

x. When

engine

is free of transmission shaft raise

engine

and remove from vehicle,

y. Place

engine

on suitable blocking or

engine

stand and remove sling from engine.

Dl-5.

ENGINE DISASSEMBLY

Engine

disassembly is presented in the sequence to be followed when the

engine

is to be completely

overhauled after removal from the vehicle. Some of the operations of the procedure are also applicable separately with the

engine

in the vehicle,

provided that wherever necessary the part of the

engine

to be worked on is first made accessible by removal of

engine

accessories or other parts.

When

the disassembly operations are performed

with

the

engine

out of the vehicle, it is assumed,

in

this procedure, that all of the accessories have

been removed

prior

to starting the disassembly and

the oil has been drained.

Page 81 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

Dl

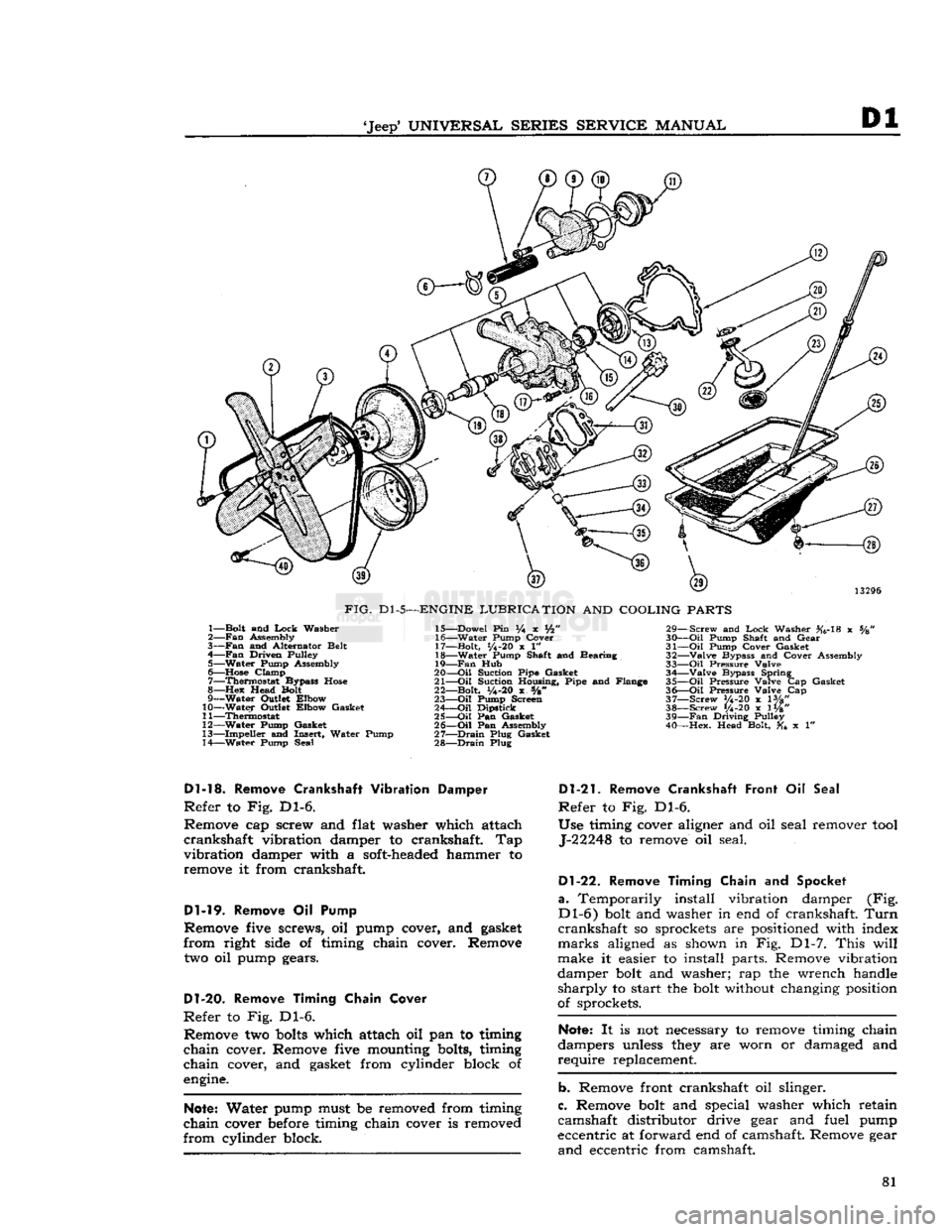

13296

FIG.

Dl-5—ENGINE

LUBRICATION

AND

COOLING

PARTS

1— Bolt and

Lock

Washer

2—

Fan

Assembly

3—

Fan

and Alternator Belt

4—

Fan

Driven Pulley 5— Water Pump Assembly

6—

Hose

Clamp 7— Thermostat Bypass

Hose

8—Hex

Head Bolt

9— Water Outlet Elbow

10— Water Outlet Elbow Gasket

11— Thermostat

12— Water Pump Gasket

13— Impeller and Insert, Water Pump

14— Water Pump Seal 15— Dowel Pin % x Vfc"

16— Water Pump Cover

17— Bolt,

1/4-20

x 1"

18— Water Pump Shaft and Bearing

19—

Fan

Hub

20—

-Oil

Suction Pipe Gasket

21—

Oil

Suction Housing, Pipe and Flange

22— Bolt,

y4-20

x s/8"

23—

Oil

Pump Screen

24—

Oil

Dipstick

25—

Oil

Pan Gasket

26—

Oil

Pan Assembly

27—

Drain

Plug Gasket

28—

Drain

Plug 29— Screw and

Lock

Washer #6-18 x %

30—

Oil

Pump Shaft and Gear

31—

Oil

Pump Cover Gasket

32— Valve Bypass and Cover Assembly

33—

Oil

Pressure Valve 34— Valve Bypass Spring

35—

Oil

Pressure Valve Cap Gasket

36—

Oil

Pressure Valve Cap

37— Screw V4-20 x lVg"

38— Screw 1/4-20 x 1W' 39—

Fan

Driving Pulley

40— Hex. Head Bolt, x 1"

Dl-13.

Remove

Crankshaft

Vibration Damper

Refer

to Fig. Dl-6.

Remove cap screw and flat washer which attach

crankshaft

vibration damper to crankshaft. Tap

vibration

damper with a soft-headed hammer to remove it from crankshaft.

Dl-19.

Remove Oil Pump

Remove five screws, oil pump cover, and gasket

from

right side of timing chain cover. Remove

two oil pump gears.

D1-20.

Remove Timing Chain Cover

Refer

to Fig. Dl-6. Remove two

bolts

which attach oil pan to timing

chain

cover. Remove five mounting bolts, timing

chain

cover, and gasket from cylinder block of

engine.

Note:

Water pump must be removed from timing

chain

cover before timing chain cover is removed

from

cylinder block.

Dl-21.

Remove Crankshaft Front

Oil

Seal

Refer

to Fig. Dl-6.

Use timing cover aligner and oil seal remover

tool

J-22248 to remove oil seal.

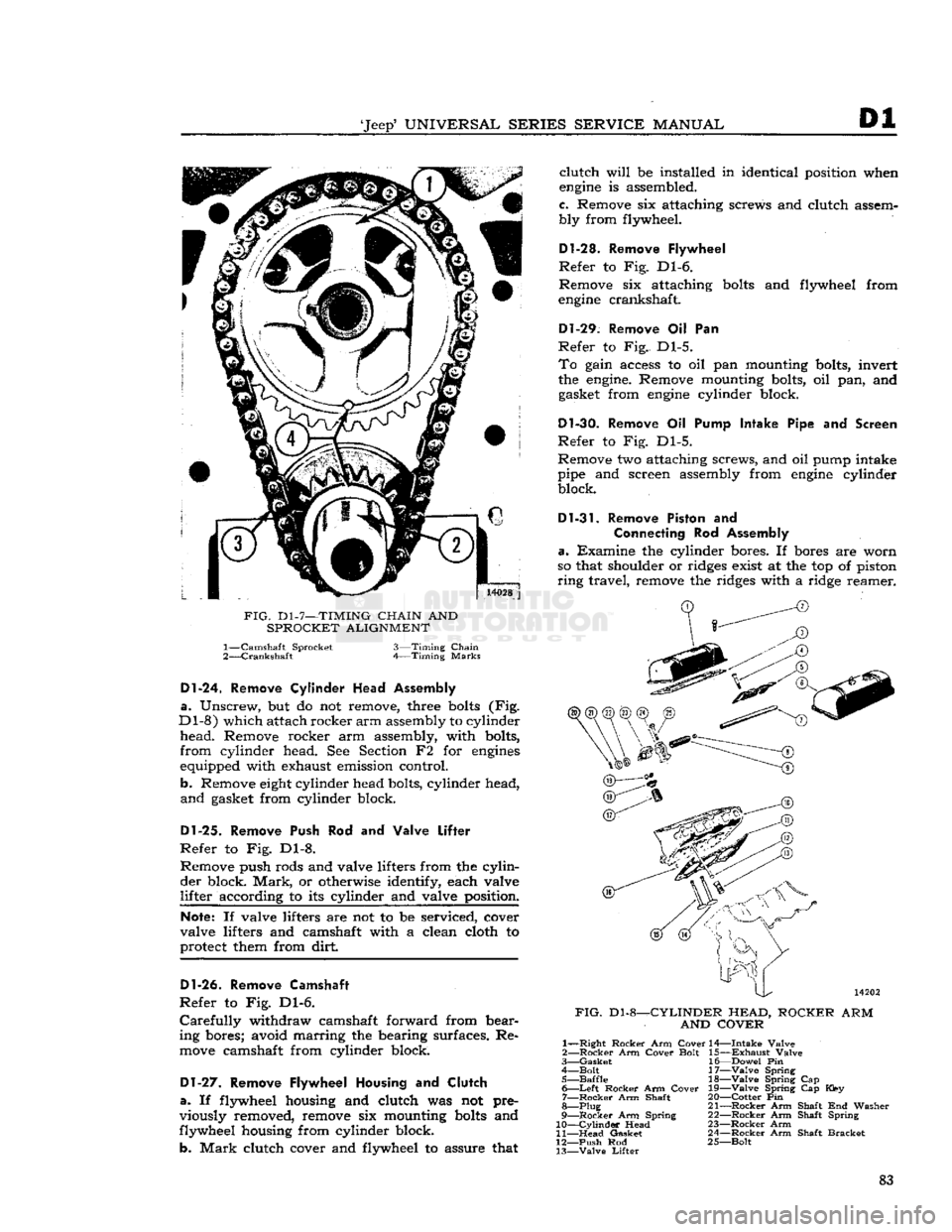

Dl-22.

Remove Timing Chain

and

Spocket

a.

Temporarily install vibration damper (Fig.

Dl-6)

bolt and washer in end of crankshaft.

Turn

crankshaft

so sprockets are positioned with index

marks

aligned as shown in Fig. Dl-7.

This

will

make it easier to install parts. Remove vibration

damper bolt and washer; rap the wrench handle

sharply

to start the bolt without changing position

of sprockets.

Note:

It is not necessary to remove timing chain

dampers unless they are worn or damaged and

require

replacement.

b. Remove front crankshaft oil slinger.

c. Remove bolt and special washer which retain

camshaft distributor drive gear and fuel pump

eccentric at forward end of camshaft. Remove gear

and

eccentric from camshaft. 81

Page 83 of 376

'Jeep'

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

14028

j

FIG.

D1-7—TIMING

CHAIN

AND

SPROCKET ALIGNMENT 1—

Camshaft Sprocket

2—

Crankshaft

3—Timing

Chain

Timing

Marks

Dl-24.

Remove

Cylinder

Head Assembly

a.

Unscrew, but do not remove, three

bolts

(Fig.

Dl-8)

which attach rocker

arm

assembly to cylinder

head.

Remove rocker arm assembly, with bolts,

from

cylinder head. See Section F2 for

engines

equipped with exhaust emission control.

b. Remove

eight

cylinder head bolts, cylinder head,

and

gasket from cylinder block.

Dl-25.

Remove Push Rod and Valve

Lifter

Refer

to Fig. Dl-8. Remove push rods and valve lifters from the

cylin

der

block.

Mark,

or otherwise identify, each valve

lifter

according to its cylinder and valve position.

Note:

If valve lifters are not to be serviced, cover

valve lifters and camshaft with a clean cloth to

protect them from dirt

Dl-26.

Remove Camshaft

Refer

to Fig. Dl-6.

Carefully

withdraw camshaft forward from bear

ing bores; avoid marring the bearing surfaces. Re

move

camshaft from cylinder block.

Dl-27.

Remove Flywheel Housing and

Clutch

a.

If flywheel housing and clutch was not pre

viously removed, remove six mounting

bolts

and

flywheel housing from cylinder block.

b.

Mark

clutch cover and flywheel to assure that

clutch

will

be installed in identical position when

engine

is assembled.

c. Remove six attaching screws and clutch assem

bly from flywheel.

D1-28. Remove Flywheel

Refer

to Fig. Dl-6.

Remove six attaching

bolts

and flywheel from

engine

crankshaft.

Dl-29.

Remove Oil Pan

Refer

to Fig. Dl-5.

To

gain access to oil pan mounting bolts, invert

the

engine.

Remove mounting bolts, oil pan, and gasket from

engine

cylinder block.

Dl-30.

Remove Oil Pump Intake Pipe and Screen

Refer

to Fig. Dl-5.

Remove two attaching screws, and oil pump intake

pipe and screen assembly from

engine

cylinder block.

Dl-31.

Remove Piston and

Connecting

Rod Assembly

a.

Examine the cylinder bores. If bores are worn

so that shoulder or ridges exist at the top of piston

ring

travel, remove the ridges with a ridge reamer.

FIG.

Dl-8-

-CYLINDER HEAD,

AND COVER

ROCKER

ARM

1—

—Right

Rocker

Arm

Cover

2—

Rocker

Arm

Cover

Bolt

3—

Gasket

4—

Bolt

5—

Baffle

6—

Left

Rocker

Arm

Cover

7—

Rocker

Arm Shaft

8—Plug

9—

Rocker

Arm Spring

10—

Cylinder

Head

11—

Head

Gasket

12—

Push

Rod

13—

Valve

Lifter

14—

Intake

Valve

15—

Exhaust

Valve

16—

Dowel

Pin

17—

Valve

Spring 18—

Valve

Spring Cap

19—

Valve

Spring Cap Key

20—

Cotter

Pin

21—

Rocker

Arm Shaft End Washer

22—

Rocker

Arm Shaft Spring

23—

Rocker

Arm

24—

Rocker

Arm Shaft

Bracket

25—

Bolt

83

Page 85 of 376

'Jeep*

UNIVERSAL

SERIES SERVICE

MANUAL

Dl

12713

FIG.

Dl-11—MEASURING

TELESCOPE GAUGE

1—

Telescope

Gauge

2—

Micrometer

may

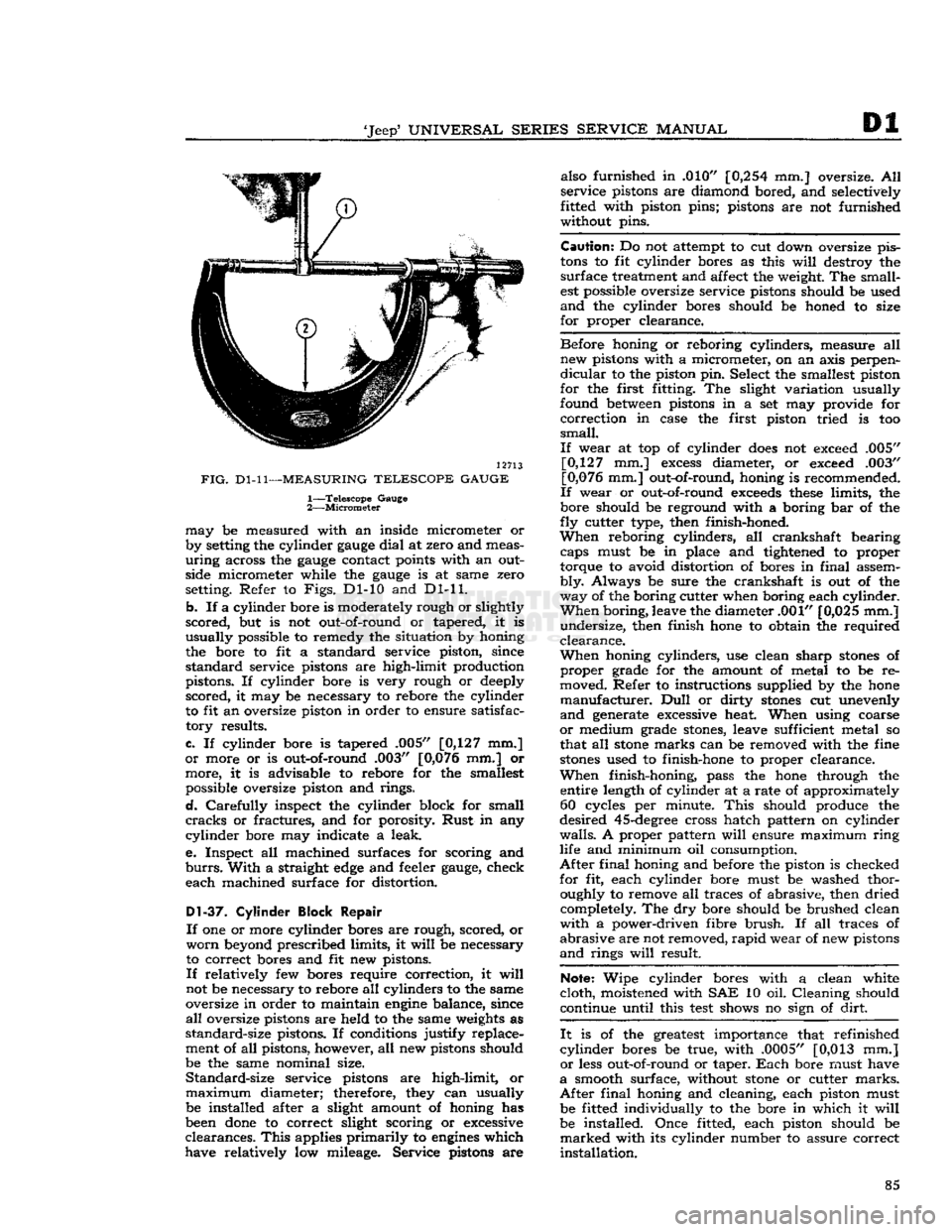

be measured with an inside micrometer or

by setting the cylinder

gauge

dial

at zero and meas

uring

across the

gauge

contact points with an outside micrometer while the

gauge

is at same zero

setting. Refer to

Figs.

Dl-10 and Dl-11.

b.

If a cylinder bore is moderately rough or slightly

scored,

but is not out-of-round or tapered, it is

usually

possible to remedy the situation by honing

the bore to fit a standard service piston, since

standard

service pistons are high-limit production

pistons. If cylinder bore is very rough or deeply

scored,

it may be necessary to rebore the cylinder

to fit an oversize piston in order to ensure satisfac

tory

results.

c.

If cylinder bore is tapered .005" [0,127 mm.]

or

more or is out-of-round .003" [0,076 mm.] or

more,

it is advisable to rebore for the smallest possible oversize piston and rings.

d.

Carefully

inspect the cylinder block for small

cracks

or fractures, and for porosity.

Rust

in any

cylinder

bore may indicate a leak.

e.

Inspect all machined surfaces for scoring and

burrs.

With

a straight

edge

and feeler

gauge,

check

each

machined surface for distortion.

D1-37.

Cylinder Block Repair

If

one or more cylinder bores are rough, scored, or

worn

beyond prescribed limits, it

will

be necessary

to correct bores and fit new pistons.

If

relatively few bores require correction, it

will

not be necessary to rebore all cylinders to the same

oversize in order to maintain

engine

balance, since

all

oversize pistons are held to the same weights as

standard-size

pistons. If conditions justify replace

ment of all pistons, however, all new pistons should

be the same nominal size.

Standard-size

service pistons are high-limit, or

maximum

diameter; therefore, they can usually be installed after a slight amount of honing has

been

done

to correct slight scoring or excessive

clearances.

This

applies

primarily

to

engines

which

have relatively low mileage. Service pistons are also furnished in .010"

[0,254

mm.] oversize. All

service

pistons are diamond bored, and selectively

fitted with piston pins; pistons are not furnished

without pins.

Caution:

Do not attempt to cut down oversize pis

tons

to fit cylinder bores as this

will

destroy the

surface

treatment and affect the weight. The small

est possible oversize service pistons should be used

and

the cylinder bores should be honed to size

for

proper clearance.

Before

honing or reboring cylinders, measure all new pistons with a micrometer, on an axis perpen

dicular

to the piston pin. Select the smallest piston

for

the first fitting. The slight variation usually

found between pistons in a set may provide for

correction

in case the first piston tried is too

small.

If

wear at top of cylinder

does

not exceed .005" [0,127 mm.]

excess

diameter, or exceed .003"

[0,076 mm.] out-of-round, honing is recommended.

If

wear or out-of-round

exceeds

these

limits, the

bore should be reground with a boring bar of the

fly

cutter type, then finish-honed.

When

reboring cylinders, all crankshaft bearing caps must be in place and tightened to proper

torque to avoid distortion of bores in

final

assem

bly.

Always be sure the crankshaft is out of the

way

of the boring cutter when boring each cylinder.

When

boring, leave the diameter .001" [0,025 mm.]

undersize,

then finish hone to obtain the required

clearance.

When

honing cylinders, use clean sharp

stones

of

proper

grade for the amount of metal to be re

moved. Refer to instructions supplied by the hone

manufacturer.

Dull

or dirty

stones

cut unevenly

and

generate excessive heat. When using coarse

or

medium grade

stones,

leave sufficient metal so

that all

stone

marks can be removed with the fine

stones

used to finish-hone to proper clearance.

When

finish-honing, pass the hone through the entire length of cylinder at a rate of approximately 60 cycles per minute.

This

should produce the

desired

45-degree

cross hatch pattern on cylinder

walls.

A proper pattern

will

ensure maximum

ring

life and minimum oil consumption.

After

final

honing and before the piston is checked

for

fit, each cylinder bore must be washed thor oughly to remove all traces of abrasive, then dried completely. The dry bore should be brushed clean

with

a power-driven fibre

brush.

If all traces of

abrasive

are not removed,

rapid

wear of new pistons

and

rings

will

result.

Note:

Wipe cylinder bores with a clean white

cloth,

moistened with SAE 10 oil. Cleaning should

continue until this

test

shows no sign of

dirt.

It

is of the greatest importance that refinished

cylinder

bores be true, with .0005" [0,013 mm.]

or

less out-of-round or taper.

Each

bore must have

a

smooth surface, without

stone

or cutter

marks.

After

final

honing and cleaning, each piston must be fitted individually to the bore in which it

will

be installed. Once fitted, each piston should be

marked

with its cylinder number to assure correct

installation.

85

Page 86 of 376

Dl

DAUNTLESS

V-6

ENGINE

Dl-38.

Crankshaft

Cleaning

Clean

the crankshaft thoroughly with a suitable

cleaning solvent.

Clean

drilled oil

passages

in its

journals

with a small rifle brush to remove all

sludge

or gum deposits; dry

passages

with com

pressed air.

Dl-39.

Crankshaft

Inspection

and

Repair

If

the crankshaft has not

been

removed from the

cylinder

block for inspection, disconnect two con necting rods at a time from crankshaft. Inspect

the bearings and crankpin journals. While turning

crankshaft,

it is necessary to temporarily reconnect

the rods to crankshaft to avoid possibility of dam aging the journals through contact with uncon

nected rods.

Inspect the crankpins visually for excessive or ir

regular

wear, and for scoring. Use an

outside

micrometer to check crankpins for out-of-round.

Standard

crankpin

diameter is

2.0000"

[5,080

cm.].

If

crankpins are more than .0015"

[0,0381

mm.]

out-of-round, new bearings cannot be

expected

to

have satisfactory life.

If

the crankshaft has

been

removed from the

cyl

inder

block for inspection support it on V-blocks

at its main bearing journals 1 and 4. Inspect the

main

bearing journals visually for excessive or ir

regular

wear, and for scoring. Standard main bear

ing

journal

diameter is 2.4995"

[6,349

cm.].

Total

indicator readings at each

journal

should not ex

ceed .003"

[0,076

mm.].

Check

run out at all four journals and

note

high

spot

(maximum eccentricity) of each

journal.

High

spot

of each

journal

should

come

at the same

angular

location. If high

spots

do not coincide,

crankshaft

is misaligned and unsatisfactory for

service.

If

crankpin or main bearing journals are scored,

ridged, or out-of-round, the crankshaft must be replaced or reground to a standard undersize bear

ing diameter to ensure satisfactory life of bearings. Slight roughness can be removed with a fine grit

polishing cloth thoroughly

wetted

with

engine

oil.

Burrs

can

be

honed with a fine oil

stone,

so long as

bearing clearances

will

remain within specified

limits.

Dl-40.

Crankshaft

Main

Bearings

A

crankshaft bearing consists of two halves which

are

neither alike nor interchangeable. One half is

carried

in the corresponding main bearing cap; the

other half is located

between

the crankshaft and

cylinder

block. The upper (cylinder block) half

of the bearing is grooved to supply oil to the con necting rod bearings, while the lower (bearing cap)

half

of the bearing is not grooved. The two bearing

halves must not be interchanged. All crankshaft

bearings

except

the thrust bearing and the

rear

main

bearing are identical. The thrust bearing (No. 2) is longer and it is flanged to take

crank

shaft end thrust. When the bearing halves are

placed in cylinder block and bearing cap, the

ends

extend slightly beyond the parting surfaces. When

cap

bolts

are tightened, the halves are clamped

tightly in place to ensure positive seating and to

prevent turning. The

ends

of bearing halves must never be filed flush with parting surface of

crank

case or bearing cap.

Crankshaft

bearings are the precision type which

do not require reaming to size or other fitting.

Shims

are not provided for adjustment since worn

bearings are readily replaced with new bearings of proper size. Bearings for service replacement are

furnished

in standard size and undersizes. Under no circumstances should crankshaft bearing caps

be filed to adjust for wear in old bearings.

Dl-41.

Crankshaft

Main

Bearing

Cleaning

and

Inspection

Clean

main bearing surfaces. Inspect the bearings

visually

for excessive or uneven wear, scoring, and

flaking.

Visibly worn or damaged bearings must

be replaced. It is necessary to check

radial

clear ance of each new or used crankshaft main bearing

before installation.

This

can be

done

by either of two methods, which are described in

Pars.

Dl-42

and

Dl-43.

a.

The desired

radial

clearance of a new bearing

is .0005" to .0021"

[0,0127

a

0,0534

mm.].

b. Replacement bearings are furnished in standard

size, and in several undersizes, including undersizes

for reground journals. If a new bearing is to be installed, try a standard size; then try each under

size in turn until one is found that

meets

the

specified clearance limits.

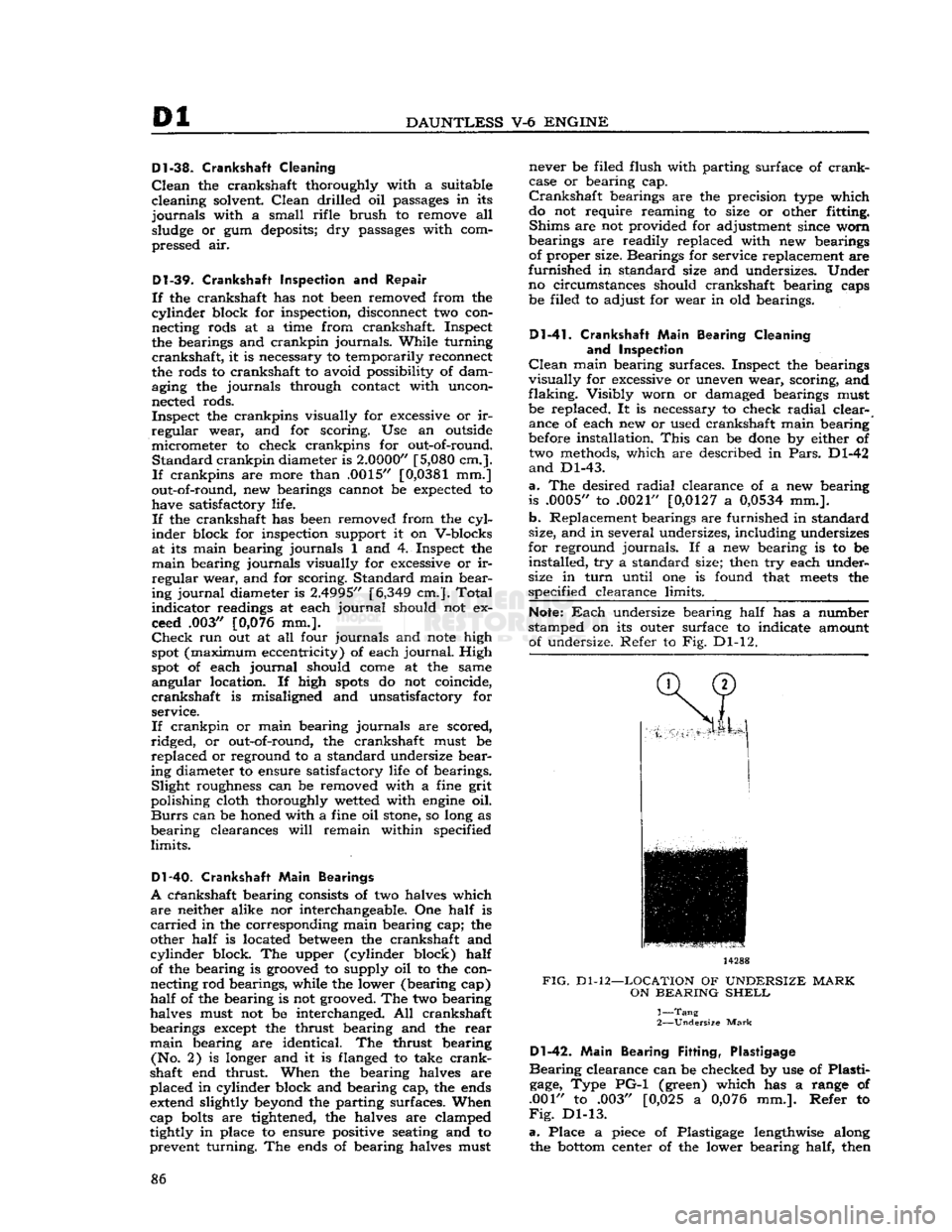

Note:

Each

undersize bearing half has a number

stamped on its outer surface to indicate amount of undersize. Refer to Fig. Dl-12. 14288

FIG.

Dl-12—LOCATION

OF

UNDERSIZE

MARK

ON

BEARING

SHELL

1—

Tang

2—

Undersize

Mark

Dl-42.

Main

Bearing

Fitting,

Plastigage

Bearing

clearance can be checked by use of Plasti

gage,

Type PG-1 (green) which has a range of

.001" to .003" [0,025 a

0,076

mm.]. Refer to

Fig.

Dl-13.

a.

Place a piece of Plastigage lengthwise along the

bottom

center of the lower bearing half, then 86