lock JEEP CJ 1953 Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1953, Model line: CJ, Model: JEEP CJ 1953Pages: 376, PDF Size: 19.96 MB

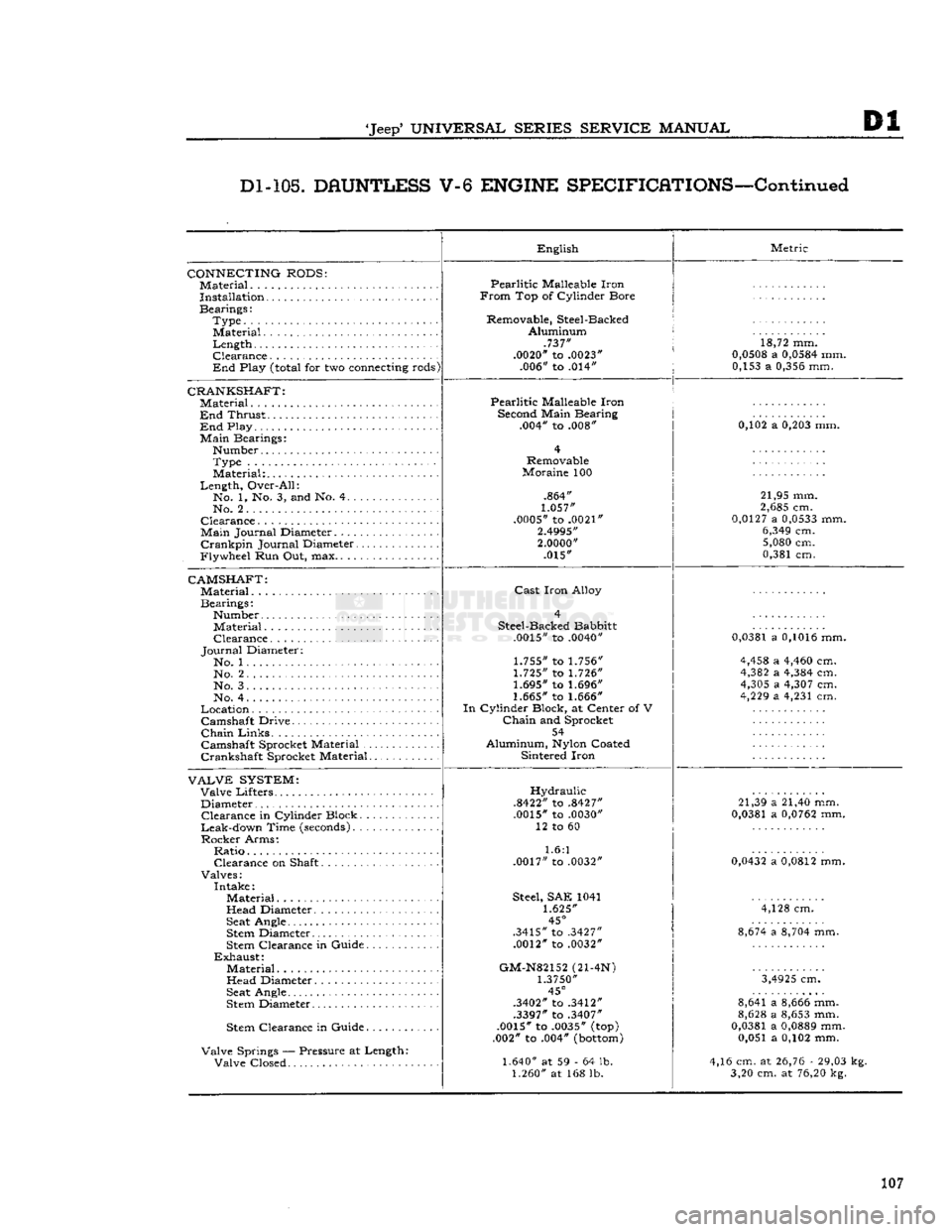

Page 107 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

Dl

Dl-105.

DAUNTLESS

V-6

ENGINE

SPECIFICATIONS—Continued

CONNECTING

RODS:

Material

Installation

Bearings: Type........

Material.

Length Clearance

End

Play

(total

for two

connecting

rods)

CRANKSHAFT:

Material ,

End

Thrust

End

Play

Main

Bearings: Number Type

Material:

Length, Over-All: No. 1, No. 3, and No. 4

No. 2

Clearance

Main

Journal Diameter.

Crankpin

Journal Diameter

Flywheel Run Out, max

CAMSHAFT:

Material

Bearings: Number Material Clearance

Journal

Diameter: No. 1 No. 2

No. 3.

No. 4

Location Camshaft Drive

Chain

Links

Camshaft Sprocket Material

Crankshaft Sprocket Material

VALVE

SYSTEM:

Valve Lifters Diameter Clearance in Cylinder Block

Leak-down Time

(seconds)

Rocker Arms: Ratio Clearance on Shaft

Valves: Intake: Material

Head Diameter

Seat

Angle

Stem

Diameter

Stem

Clearance in Guide

Exhaust:

Material Head Diameter

Seat

Angle

Stem

Diameter

Stem

Clearance in Guide

Valve Springs — Pressure at Length: Valve Closed English

Pearlitic Malleable Iron

From

Top of Cylinder Bore

Removable, Steel-Backed Aluminum .737"

.0020"

to

.0023"

.006" to .014" Metric

18,72 mm.

0,0508

a

0,0584

mm. 0,153 a

0,356

mm.

Pearlitic Malleable Iron

Second

Main Bearing .004" to .008"

Removable

Moraine 100

.864"

1.057"

.0005"

to

.0021"

2.4995"

2.0000"

.015" 0,102 a

0,203

mm.

21,95 mm.

2,685

cm.

0,0127

a

0,0533

mm.

6,349

cm.

5,080

cm.

0,381 cm.

Cast

Iron Alloy

Steel-Backed Babbitt

.0015"

to

.0040"

1.755"

to

1.756"

1.725"

to

1.726"

1.695"

to

1.696"

1.665"

to

1.666"

In

Cylinder Block, at Center of V

Chain

and Sprocket 54

Aluminum,

Nylon

Coated Sintered Iron

0,0381

a

0,1016

mm.

4,458

a

4,460

cm.

4,382

a

4,384

cm.

4,305

a

4,307

cm.

4,229

a 4,231 cm.

Hydraulic

.8422"

to

.8427"

.0015"

to

.0030"

12 to 60

1.6:1

.0017"

to

.0032"

Steel,

SAE 1041

1.625"

45°

.3415"

to

.3427"

.0012"

to

.0032"

GM-N82152

(21-4N)

1.3750"

45°

.3402"

to

.3412"

.3397"

to

.3407"

.0015"

to

.0035"

(top)

.002" to .004"

(bottom)

1.640"

at 59 - 64 lb.

1.260"

at 168 lb. 21,39 a 21,40 mm.

0,0381

a

0,0762

mm.

0,0432

a

0,0812

mm. 4,128 cm.

8,674

a

8,704

mm.

3,4925

cm.

8,641 a

8,666

mm.

8,628

a

8,653

mm.

0,0381

a

0,0889

mm. 0,051 a 0,102 mm.

4,16 cm. at

26,76

-

29,03

kg. 3,20 cm. at

76,20

kg.

107

Page 109 of 376

'Jeep*

UNIVERSAL SERIES SERVICE

MANUAL

E

FUEL

SYSTEM

Contents

SUBJECT

PAR.

GENERAL

E-1 Dash

FUEL

EVAPORATIVE EMISSION

?*^r

CONTROL SYSTEM

..E-2

Canister

.E-3 . Demand Valve E-4

Fuel

Tank.

.E-5

Inspection Test. E-8

Sealed Gas Cap. E-7

Servicing

System E-9

Vapor

Separator or Expansion

Tank

E-6

CARBURETOR

—

HURRICANE F4 ENGINE.

. .

......

..... ,. . .E-10 Accelerating Pump System.............. .E-19 Accelerating Pump Maintenance E-20

Carburetor

Reassembly

E-2

2

Carburetor

Disassembly E-21

Choke

System E-17

Dash

Pot Adjustment E-44

Fast

Idle Adjustment E-18

Float

Adjustment E-12

Float

System. E-ll

High-Speed System . .E-15

Idle

Adjustment .E-14

Low-Speed

System . E-13

Metering Rod Adjustment E-16

CARBURETOR

~r

DAUNTLESS V-6 ENGINE

.E-25

Accelerator Pump Adjustment E-41 Accelerator Pump System. . E-30

Air

Horn Body Assembly E-39

Air

Horn Body Removal and Disassembly.

E-33

Carburetor

Cleaning and Inspection E-36

Carburetor

Removal E-32

Choke

System E-31

Curb-Idle

Speed and Mixture Adjustment. .E-42

E-1. GENERAL

The

fuel system of the Jeep Universal vehicle,

whether equipped with a Hurricane F4 or Daunt

less

V-6 Engine,

consists

of the fuel tank, fuel lines, fuel pump, carburetor and

air

cleaner.

Fig. E-1, E-2.

Vehicles equipped with a

Fuel

Evaporative

Emis

sion Control System

also

include a

non-vent

pressure and vacuum

sensitive

gas cap, a liquid

expansion and vapor separator tank, a carbon filled vapor

storage

canister, and a vapor purge line. Service information pertaining to the

Fuel

Evap

orative Emission Control System is outlined in

Par.

E-2 through

E-9.

Refer to Figs. E-3 and E-4.

The

most

important

attention

necessary to the fuel

system is to

keep

it clean and free from water. It should be periodically inspected for leaks.

CAUTION—Whenever

a vehicle is to be stored for

an

extended

period, the fuel system should be com

pletely

drained, the

engine

started and allowed to

run

until the carburetor is emptied.

This

will

avoid

oxidization of the fuel, resulting in the formation of

SUBJECT

PAR.

Pot Adjustment .E-44

nal

Carburetor Adjustments.........E-40

Idle

Adjustment

.

E-43 System . . .E-26

Bowl

Body Assembly E-38

Fuel

Bowl Body Disassembly E-34

Idle

System E-27

Main

Metering System E-28

Power System . E-29

Throttle

Body Assembly .E-37

Throttle

Body Removal, and Disassembly. .E-35

FUEL

PUMP

—

HURRICANE F4 ENGINE.

E-45, 54, 60

Cleaning

and Inspection.............

.E-57,

63 Disassembly E-46, 56, 62

Installation E-59, 65

Reassembly

.E-47,

58, 64

Removal

E-55, 61

Testing.

E-49, 50, 51, 52, 53, 66

Vacuum

Pump E-48

FUEL

PUMP

—

DAUNTLESS V-6 ENGINE

E-67

Removal

E-68

AIR CLEANER

—

CARBURETOR

E-69

ACCELERATOR

LINKAGE

.E-70

FUEL

TANK

AND

LINES

E-71

Float

Unit . .E-76

Fuel

Lines E-77

Fuel

Tank

. . .E-72

Fuel

Tank

Cap E-75

Fuel

Tank

Installation. E-74

Fuel

Tank

Removal E-73

SERVICE

DIAGNOSIS

E-78

SPECIFICATIONS.

E-79

gum in the units of the fuel system. Gum formation

is similar to hard varnish and may cause the fuel

pump valves or the carburetor

float

valve to be

come

stuck or the filter screen blocked. Acetone or commercial fuel system cleaners

will

dissolve

gum formation. In

extreme

cases

it

will

be necessary

to dissassemble and clean the fuel system. In

most

cases, however, a

good

commercial fuel system sol

vent

used in accordance with the manufacturer's

instructions or one pint [0,6 ltr.] of

acetone

placed

in

the fuel tank with

about

one gallon [4,5 ltr.]

of

gasoline

will

dissolve

any

deposits

as it

passes

through the system with the

gasoline.

E-2.

FUEL

EVAPORATIVE EMISSION CONTROL SYSTEM

Description and Operation

•

Refer to Figs. E-3 and E-4.

The

Fuel

Evaporative Emission Control System

is

designed

to reduce fuel vapor emission that 109

Page 114 of 376

FUEL

SYSTEM

14261

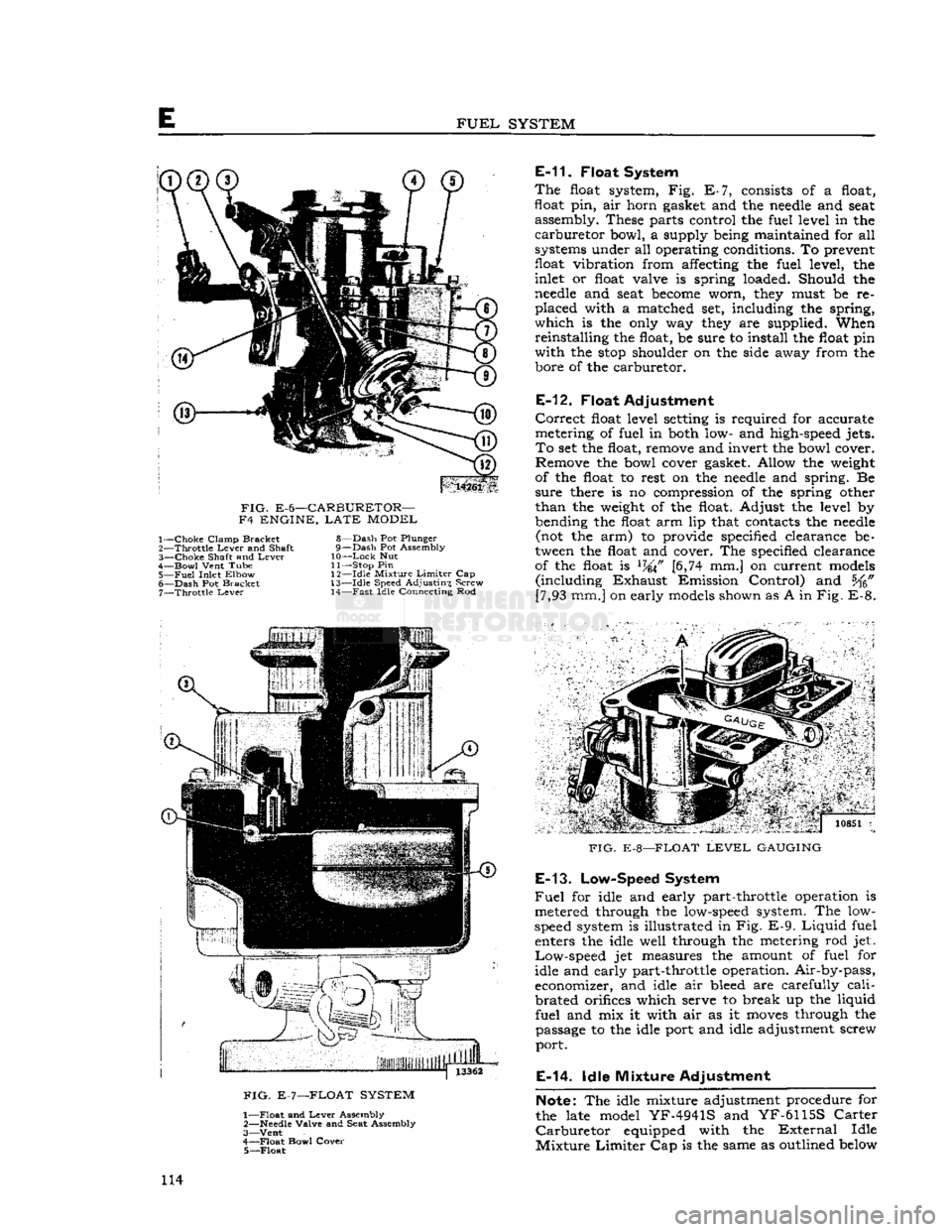

FIG.

E-6—CARBURETOR—

F4 ENGINE,

LATE

MODEL 1—

Choke

Clamp Bracket

2—

Throttle

Lever

and Shaft

3—

Choke

Shaft and

Lever

4—

Bowl

Vent Tube

5—

Fuel

Inlet Elbow

6—

Dash

Pot Bracket 7—

Throttle

Lever

8—

Dash

Pot Plunger

9—

Dash

Pot Assembly

10—

Lock

Nut

11— Stop Pin

1

2—Idle Mixture

Limiter

Cap

13—

Idle

Speed Adjusting Screw 14—

Fast

Idle Connecting Rod

E-11.

Float System

The

float system, Fig. E-7, consists of a float,

float

pin,

air horn gasket and the

needle

and seat assembly. These parts control the fuel level in the

carburetor

bowl, a supply being maintained for all

systems under all operating conditions. To prevent

float

vibration

from affecting the fuel level, the

inlet or float valve is spring loaded. Should the

needle

and seat

become

worn, they must be re

placed

with a matched set, including the spring,

which

is the only way they are supplied. When

reinstalling

the float, be sure to install the float pin

with

the

stop

shoulder on the side away from the bore of the carburetor.

E-12.

Float Adjustment

Correct

float level setting is required for accurate

metering of fuel in both low- and high-speed jets.

To

set the float, remove and invert the bowl cover. Remove the bowl cover gasket. Allow the weight

of the float to rest on the

needle

and spring. Be

sure

there is no compression of the spring other

than

the weight of the float. Adjust the level by

bending the float arm lip that contacts the

needle

(not the arm) to provide specified clearance be

tween the float and cover. The specified clearance of the float is

L74\F

[6,74 mm.] on current models

(including

Exhaust

Emission Control) and [7,93 mm.] on early models shown as A in

Fig.

E-8.

FIG.

E-7—FLOAT SYSTEM

1—

Float

and

Lever

Assembly

2—

Needle

Valve and Seat Assembly

3—

Vent

4—

Float

Bowl Cover 5—

Float

7 '.. j

io8Si

i

FIG.

E-8—FLOAT

LEVEL

GAUGING

E-13.

Low-Speed System

Fuel

for idle and early part-throttle operation is

metered through the low-speed system. The low-

speed system is illustrated in Fig.

E-9.

Liquid

fuel enters the idle well through the metering rod jet.

Low-speed

jet measures the amount of fuel for

idle and early part-throttle operation. Air-by-pass,

economizer, and idle air bleed are carefully

cali

brated

orifices which serve to break up the liquid

fuel

and mix it with air as it

moves

through the passage to the idle port and idle adjustment screw

port.

E-14.

Idle Mixture Adjustment

Note:

The idle mixture adjustment procedure for

the late model

YF-4941S

and

YF-6115S

Carter

Carburetor

equipped with the

External

Idle

Mixture

Limiter

Cap is the same as outlined below 114

Page 115 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

E

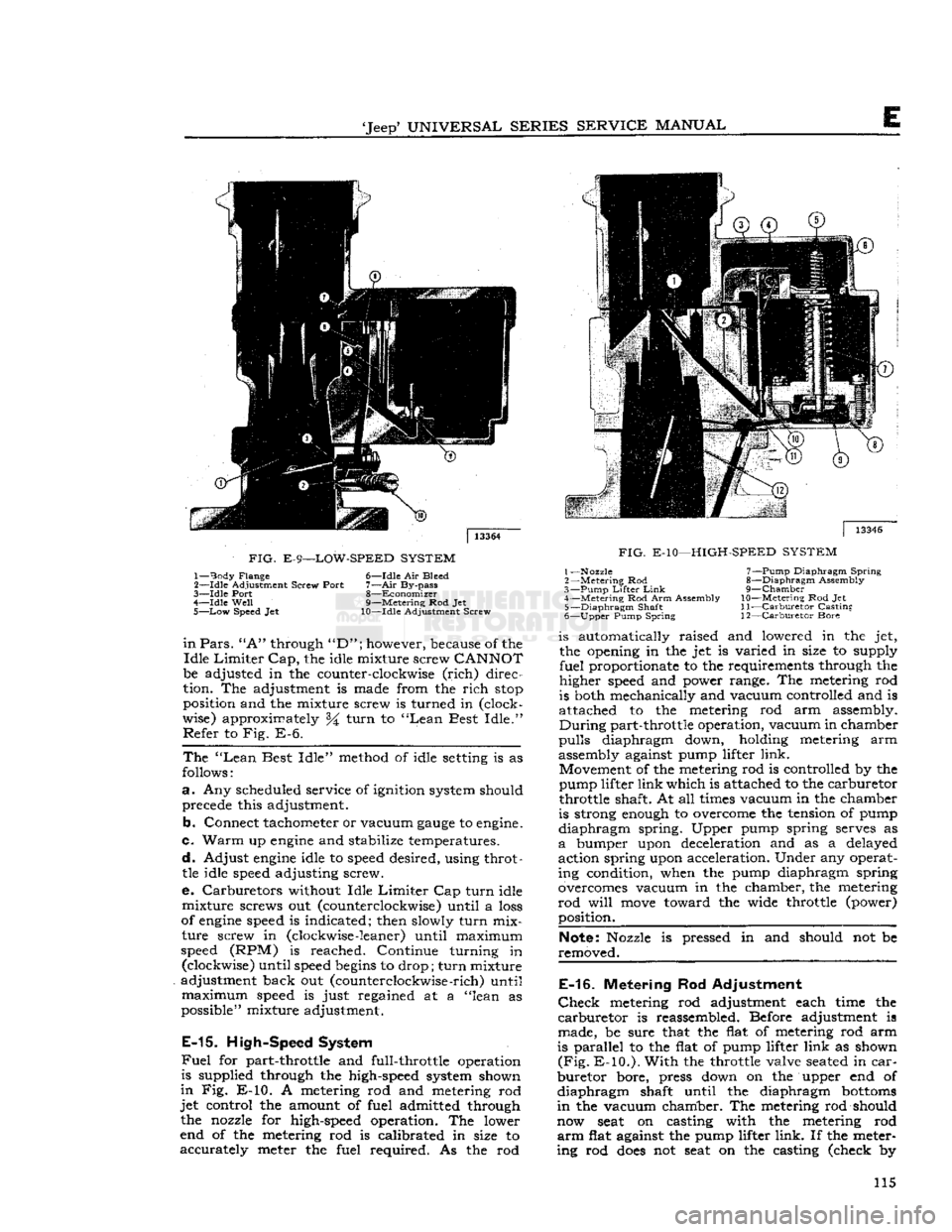

FIG.

E-9—LOW-SPEED

SYSTEM

1—

Body

Flange 6—Idle Air Bleed

2—

-Idle

Adjustment Screw Port

7—Air

By-pass

3—

Idle

Port 8—Economizer

4—

Idle

Well

9—Metering Rod Jet

5—

Low

Speed Jet 10—Idle Adjustment Screw

in

Pars.

"A"

through

"D";

however, because of the

Idle

Limiter

Cap,

the idle mixture screw

CANNOT

be adjusted in the counter-clockwise

(rich)

direc

tion. The adjustment is made from the

rich

stop

position and the mixture screw is turned in (clock

wise) approximately %

turn

to

"Lean

Best

Idle."

Refer

to Fig. E-6.

The

"Lean

Best

Idle"

method of idle

setting

is as

follows:

a.

Any scheduled service of ignition system should precede this adjustment.

b.

Connect tachometer or vacuum

gauge

to

engine.

c.

Warm

up

engine

and stabilize temperatures.

d.

Adjust

engine

idle to

speed

desired, using throttle idle

speed

adjusting screw.

e. Carburetors without Idle

Limiter

Cap

turn

idle

mixture

screws out (counterclockwise) until a

loss

of

engine

speed

is indicated; then slowly

turn

mix

ture

screw in (clockwise

-leaner)

until maximum

speed

(RPM) is reached. Continue turning in (clockwise) until

speed

begins

to drop;

turn

mixture

adjustment back out (counterclockwise

-rich)

until

maximum

speed

is just regained at a "lean as

possible" mixture adjustment.

E-15.

High-Speed System

Fuel

for part-throttle and full-throttle operation

is supplied through the high-speed system shown

in

Fig. E-10. A metering rod and metering rod

jet

control the amount of fuel admitted through the nozzle for high-speed operation. The lower

end of the metering rod is calibrated in size to

accurately

meter the fuel required. As the rod

|

13346

FIG.

E-10—HIGH-SPEED

SYSTEM

1—Nozzle 7—Pump Diaphragm

Spring

2

—Metering

Rod 8—Diaphragm Assembly

3—

Pump

Lifter

Link

9—Chamber

4—

Metering

Rod Arm Assembly

10—Metering

Rod Jet 5—

Diaphragm

Shaft

11—Carburetor

Casting

6—

Upper

Pump Spring 12—Carburetor Bore is automatically raised and lowered in the jet,

the opening in the jet is varied in size to supply

fuel

proportionate to the requirements through the

higher

speed

and power range. The metering rod

is both mechanically and vacuum controlled and is

attached to the metering rod arm assembly.

During

part-throttle operation, vacuum in chamber

pulls

diaphragm down, holding metering arm

assembly against pump lifter

link.

Movement of the metering rod is controlled by the

pump lifter

link

which is attached to the carburetor

throttle shaft. At all

times

vacuum in the chamber

is strong

enough

to overcome the tension of pump

diaphragm

spring. Upper pump spring serves as

a

bumper upon deceleration and as a delayed

action spring upon acceleration. Under any operat ing condition, when the pump diaphragm spring

overcomes vacuum in the chamber, the metering

rod

will

move

toward the wide throttle (power) position.

Note:

Nozzle is pressed in and should not be

removed.

E-16.

Metering Rod Adjustment

Check

metering rod adjustment each time the

carburetor

is reassembled. Before adjustment is

made, be sure that the flat of metering rod arm

is parallel to the flat of pump lifter

link

as shown

(Fig.

E-10.).

With

the throttle valve

seated

in

car

buretor

bore, press down on the upper end of

diaphragm

shaft until the diaphragm

bottoms

in

the vacuum chamber. The metering rod should

now

seat

on casting with the metering rod

arm

flat against the pump lifter

link.

If the meter

ing rod

does

not

seat

on the casting (check by 115

Page 117 of 376

'Jeep*

UNIVERSAL

SERIES

SERVICE

MANUAL

E

Note:

The

Carter

YF-6115S Carburetor has a

throttle

return spring

attached

from the carburetor

main

body

to the carburetor

throttle

shaft. The

purpose

of

this

spring is to return the

throttle

to

idle

speed

position

should a linkage failure occur.

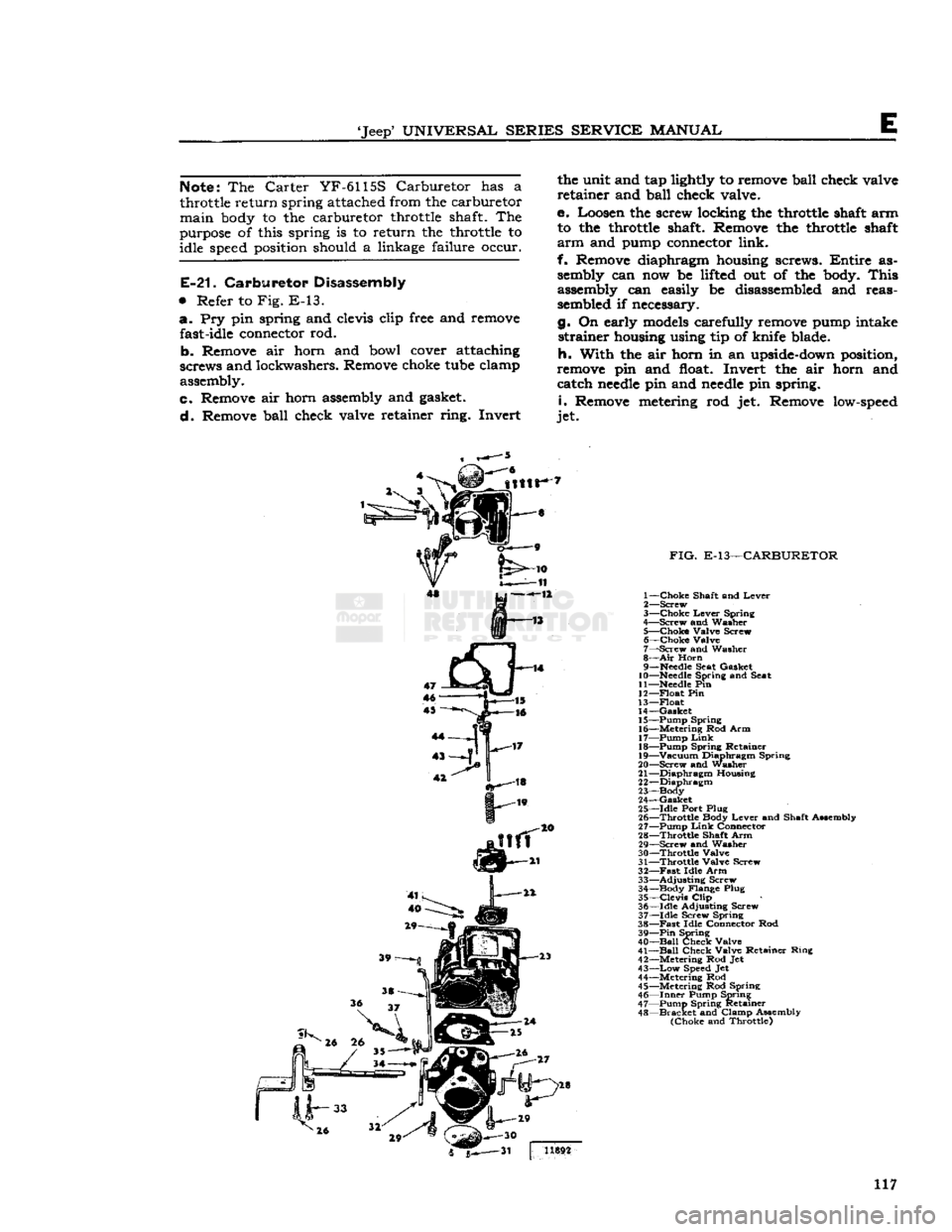

E-21.

Carburetor Disassembly

•

Refer to Fig. E-13. a. Pry pin spring and

clevis

clip

free

and

remove

fast-idle

connector

rod.

b- Remove air horn and bowl

cover

attaching

screws and lockwashers. Remove

choke

tube

clamp

assembly.

c. Remove air horn

assembly

and

gasket.

d. Remove ball check valve retainer ring. Invert the unit and tap

lightly

to

remove

ball check valve

retainer and ball check valve.

e. Loosen the screw locking the

throttle

shaft

arm to the

throttle

shaft. Remove the

throttle

shaft

arm

and

pump

connector

link.

f. Remove diaphragm

housing

screws.

Entire

as

sembly

can now be

lifted

out of the

body.

This

assembly

can easily be

disassembled

and reas

sembled

if necessary.

g. On early

models

carefully

remove

pump

intake strainer

housing

using tip of knife blade.

h. With the air horn in an

upside-down

position,

remove

pin and

float.

Invert the air horn and catch

needle

pin and

needle

pin spring.

i.

Remove

metering

rod jet. Remove

low-speed

jet.

FIG.

E-13—CARBURETOR

1— Choke Shaft and Lever

2— Screw

3— Choke Lever Spring

4— Screw and Washer

5— Choke Valve Screw 6— Choke Valve

7— Screw and Washer

8—

Air

Horn

9—

Needle

Seat Gasket

10—

Needle

Spring and Seat

11—Needle

Pin

12— Float Pin

13— Float

14— Gasket 15— Pump Spring

16— Metering Rod Arm

17— Pump

Link

18— Pump Spring Retainer

19— Vacuum Diaphragm Spring

20— Screw and washer

21— Diaphragm Housing

22— Diaphragm

23—Body

24— Gasket

25— Idle Port Plug

26— Throttle Body Lever and Shaft Assembly

27— Pump

Link

Connector

28— Throttle Shaft Arm 29— Screw and Washer

30— Throttle Valve

31— Throttle Valve Screw

32—

Fast

Idle Arm 33— Adjusting Screw

34— Body Flange Plug

35— Clevis

Clip

36— Idle Adjusting Screw

37— Idle Screw Spring

38—

Fast

Idle Connector Rod 39—

Pin

Spring

40—

Ball

Check Valve

41—

Ball

Check Valve Retainer Ring

42— Metering Rod Jet

43—

Low

Speed

Jet

44— Metering Rod

45— Metering Rod Spring 46—

Inner

Pump Spring

47— Pump Spring Retainer

48—

Bracket

and Clamp Assembly (Choke and Throttle) 5^—31 | 1X892

117

Page 118 of 376

E

FUEL

SYSTEM

Note:

Do not remove pressed-in parts such as

nozzle, pump jet, or antipercolator air bleed.

j.

Remove body flange attaching screws, body flange assembly, and gasket.

k.

Remove idle-adjustment screw, spring, idle

port

rivet, throttle lever assembly, washer, fast

idle arm, throttle plate screws, throttle plate, and throttle shaft.

1. Remove throttle shaft seal by prying out seal

retainer.

Note:

Do not remove pressed-in vacuum passage

orifice.

m.

Remove choke valve screws and choke valve.

Unhook

choke spring and slide shaft from housing,

n.

Wash all parts in carburetor cleaning solution

and

blow out passages with compressed air. Do not immerse diaphragm or seals in cleaning solution.

Inspect

all parts for wear or damage. Always use

new gaskets when reassembling.

E-22.

Carburetor

Reassembly

•

Refer to Fig. E-13.

To

expedite

reassembly, it is advisable to group all

related

parts by the circuit to which they belong.

a.

Install

throttle shaft seal and retainer in flange casting.

b.

Install

fast-idle

arm,

washer, and lever assembly

on throttle shaft. Slide shaft into place and install throttle valve.

c.

Install

idle port rivet plug and idle adjusting

screw

and spring.

d.

Attach flange assembly to body casting. Use new gasket.

e.

Install

low-speed jet assembly.

f.

Early

production models install pump intake

strainer

in pump diaphragm housing and carefully

press into recess.

Note:

If strainer is even slightly damaged, a new

one must be installed.

g.

Install

pump diaphragm assembly in diaphragm housing.

Then,

install pump diaphragm spring

(lower)

and retainer.

h.

Install

pump lifter

link,

metering rod

arm,

upper

pump spring, and retainer.

I.

Install

metering rod jet.

Note:

No gasket is used with this jet.

j.

Install

diaphragm housing attaching screws in

the diaphragm housing, making sure that the

edges

of the diaphragm are not wrinkled.

Lower

into place and tighten screws evenly and securely,

k.

Install

throttle shaft seal, dust seal washer, and

shaft seal spring.

I.

Install

pump connector

link

in the throttle arm

assembly.

Install

throttle shaft arm assembly on

throttle shaft guiding connector

link

in pump lifter

link

hole.

CAUTION:

Linkage

must not bind in any throttle

position. If binding occurs,

loosen

clamp screw in

throttle arm, adjust slightly, then retighten screw.

m.

Install

pump check disc, disc retainer, and lock

ring.

n.

Install

metering rod and pin spring. Connect

metering rod spring.

o.

Check

and if necessary correct meter ing rod adjustment. Follow procedure of

Par.

E-16.

p.

Install

needle

seat and gasket assembly, needle,

float

and

float pin. The

stop

shoulder on the float

pin

must be on the side away from the bore of

the carburetor.

q.

Set float level to specifications. Follow pro cedure of

Par.

E-12.

r.

Install

air horn gasket and air horn assembly.

Install

attaching screws, lock washers, and choke

tube clamp assembly. Tighten center screws first,

s. Slide choke shaft and lever assembly into place

and

connect choke lever

spring.

Install

choke valve.

Center

the valve by tapping lightly, then hold in

place with fingers when tightening screws,

t.

Install

fast-idle connector rod with

offset

portion

of rod on top and pin spring on outside.

Install

fast-idle connecting rod spring.

E-23.

Correcting Acceleration

Flat

Spot

Early

production

Carburetor

Models 938-S, 938-

SA,

938-SC

Inasmuch

as a flat

spot

on acceleration or low speed

stumble can

come

from causes other than

car

buretor

malfunction, it is recommended that

engine

tuning be thoroughly checked before attempting

any

actual carburetor work. Make sure that

ignition, compression, and timing are correct and

that fuel pump is supplying enough gas. Also, the F-head

engine

employs a water-heated intake

manifold.

Proper vaporization of the fuel depends

on correct intake manifold temperature. Since this

temperature is controlled by the cooling system

thermostat, include an operational check of the

thermostat when diagnosing the stumble. Operating

temperatures consistently below

155°F.

can cause stumble.

If

the stumble persists, a

YF-938-S,

YF-938-SA,

or

YF-938-SC

carburetor can be converted to a

YF-938-SD

carburetor by installing Special Kit

924161, consisting of a pump discharge check

needle, a metering rod, and a metering rod jet. If this kit is installed, the pump discharge check

needle

replaces the original

ball,

weight, and re

tainer

and the small wire-type retainer used with

the

ball

check assembly must not be reinstalled.

When

installing the kit, check the size of the pump discharge jet, No. 2, Fig. E-14.

Early

production

YF-938S

and

YF-938SA

carburetors have a .025" [0,635 mm.] jet installed. If the carburetor being

converted has a .025" jet it must be opened up to .031" [0,787 mm.] by running a No. 68

drill

through

the jet as shown in

Fig.

E-14.

The jet must be drilled

as it is a pressed in part and cannot be replaced.

Upon

completing the installation of the conversion

kit,

mark

or tag the carburetor to indicate that it

is a

YF-938SD.

118

Page 123 of 376

'Jeep9

UNIVERSAL

SERIES

SERVICE

MANUAL

E

exterior moving parts of a carburetor are

often

responsible for unsatisfactory performance.

For

this

reason,

efficient carburetion depends upon careful cleaning and inspection while servicing.

a.

Thoroughly clean carburetor castings and metal

parts

in carburetor cleaning solvent.

Caution:

Accelerator pump plunger and any fiber

or

rubber parts should never be immersed in

car

buretor

cleaner. Wash pump plunger in cleaning

solvent.

b.

Blow out all passages in the castings with com

pressed air. Dry all parts with compressed air.

Make

sure all jets and passages are clean. Do

not use wire to clean fuel passages or air bleeds.

c.

Check

inlet valve

needle

and seat for wear. If

wear

is noted, the assembly must be replaced.

d.

Check

float hinge pin for wear and check float

for damage.

e.

Check

throttle and choke shaft bores for wear

and

out-of-round.

f. Inspect idle mixture adjustment

needles

for

burrs

or

grooves; replace if damaged.

g. Inspect cup of accelerator pump plunger; re

place if damaged, worn, or hardened. Inspect pump

well

in bowl for wear or scoring.

h.

Check

filter screens for

dirt

or lint.

Clean,

and

if

they remain

clogged,

replace.

i.

If for any reason parts have

become

loose

or

damaged in the cluster assembly, the assembly

must be replaced.

Note:

Use ijew gaskets whenever the carburetor

is disassembled.

E-37.

Throttle Body Assembly

a.

Install

idle mixture adjustment

needles

and

springs in throttle body. Tighten finger-tight, then

unthread

one

turn

as a preliminary adjustment

setting.

Caution:

Do not force idle mixture adjustment

needles

against

seats

or damage may result.

b.

Invert

fuel bowl body and place new throttle

body gasket on bowl. Fasten throttle body to bowl

body with three screws and lockwashers; tighten

securely.

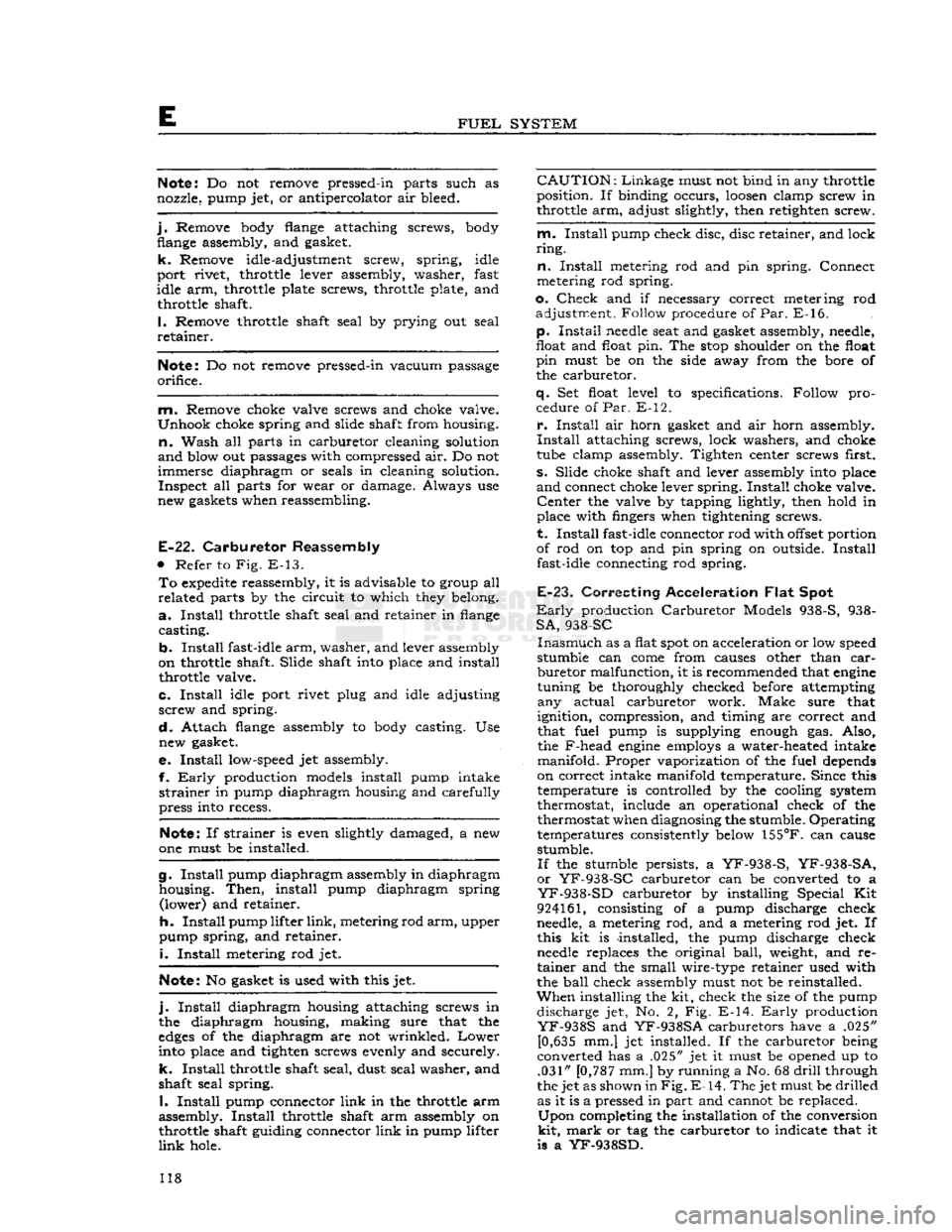

E-38.

Fuel

Bowl Body Assembly

a.

Drop steel discharge check

tall

of accelerator

pump into discharge hole.

Install

pump discharge

spring

and T-shaped retainer. Stake retainer in

place.

Note:

Top of retainer must be flush with flat

surface

of fuel bowl body.

b.

Install

two inserts in main well. Align surface

on lip of insert with flat surface in recess on top

of main well.

Install

venturi cluster with gasket,

and

tighten mounting screws evenly and securely.

Be

certain that center screw is fitted with fiber gasket, and that a special smooth shank screw is

used.

c.

Install

two main metering jets, power valve

gasket and power valve.

d.

Install

small aluminum inlet check

ball

in ac

celerator

pump inlet at

bottom

of pump well. In

sert

pump return spring into well, and center by

pressing spring downward with finger.

e.

Install

pump inlet screen in

bottom

of fuel

bowl.

E-39.

Air

Horn Body

Assembly

a.

Install

choke lever and collar on choke shaft.

Prong

on choke lever must face away from air

horn

body and be on top of choke trip lever.

b.

Install

choke shaft and lever assembly into the

air

horn. Choke rod

hole

in the choke lever must

face fuel inlet side of carburetor.

c.

Install

choke valve plate in choke shaft so that

letters RP

will

face upward in finished carburetor.

Install

two new valve plate attaching screws, but

do not tighten securely until valve plate is centered.

To

center choke valve plate on choke shaft, hold

choke valve tightly closed, then slide choke shaft

inward

to obtain approximately .020" [0,508 mm.]

clearance

between

choke trip lever and choke lever

and

collar assembly. Tighten choke valve screws

securely,

and stake lightly in place. Choke valve

will

be perfectly free in all positions when installed

correctly.

d.

Insert

outer accelerator pump lever and shaft as sembly into air horn body, with lever pointing to

ward

choke shaft.

Install

inner pump arm, with plunger

hole

inward,

and tighten set screw securely.

Position pump plunger assembly on inner pump

arm,

with pump shaft pointing

inward,

and install

retainer.

e.

Install

needle

seat screen on inlet valve seat. In

stall

seat and gasket in air horn body. Tighten seat

securely with a wide-blade screwdriver.

f.

Install

power piston into vacuum cavity.

Lightly

stake piston retainer washer in place. Piston should

travel

freely in cavity.

g.

Install

air horn gasket on air horn body, fitting

gasket over guide pin.

h.

Attach inlet valve

needle

to float.

Carefully

position float and insert float hinge pin. Drop tang

at

rear

of float arm downward toward air horn.

i.

Install

fuel inlet fitting, if removed.

j.

With

air horn assembly inverted, measure the distance from the air horn gasket to top of float

at toe \%£f [27,78 mm.] for standard carburetors

and

\%i [29,36 mm.] for exhaust emission control

equipped carburetors, as shown in Fig. E-23. Use

float level

gauge

J-5127-2. Bend float arm as re

quired

to adjust float level.

k.

With

air horn body held upright, measure dis

tance from gasket to

bottom

of float

pontoon

at outer end. Use a l7/s" [47,625 mm.] float drop

gauge.

Bend float tang, as required, to adjust float

drop.

See Fig. E-24.

I.

Carefully

place air horn body on fuel bowl

body, making certain that the accelerator pump

plunger is properly positioned in the pump well.

Lower

the cover gently, straight down; install air 123

Page 125 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

E

is generally caused by excessive

engine

idle speed

in

combination with retarded ignition timing,

engine

heat soak or the use cf low octane fuel.

Should

engine

dieseling

(engine

running after ignition key is turned off) be experienced on V-6

engine

equipped vehicles, installation of Idle Stop

Valve

Kit

Part

No.

991722

will

correct the

difficulty.

E-43.

Fast

Idle Adjustment

No fast idle speed adjustment is required.

Fast

idle is controlled by the curb idle speed adjustment

screw.

If curb idle speed is correctly set and the choke rod is properly adjusted, fast idle speed

will

be correct;

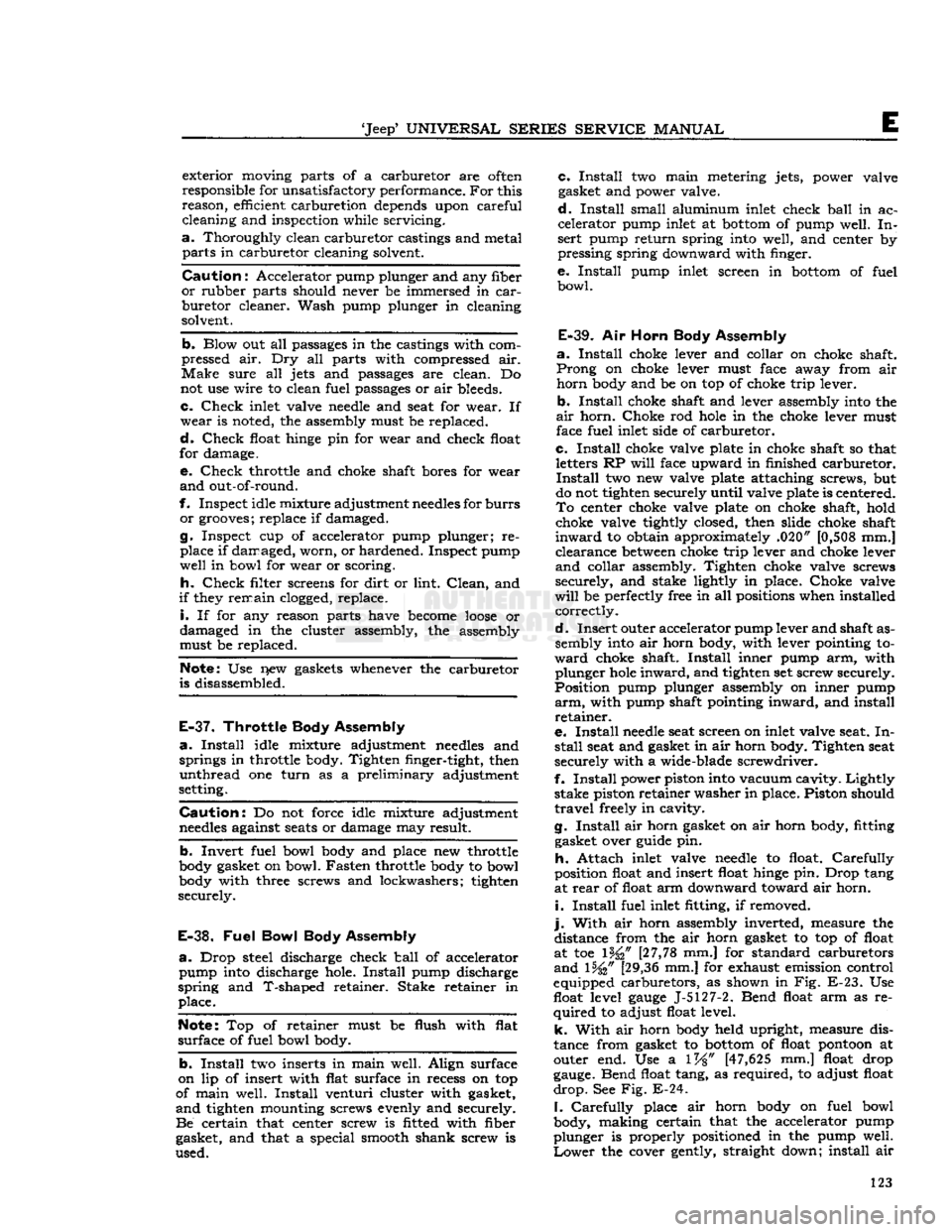

E-44.

Dash Pot Adjustment —

F4

and V-6 Engine

•

Refer to

Figs.

E-27 and E-28. Before adjusting the dash pot, the

engine

idle speed

and

mixture should be correctly adjusted.

With

the

engine

idling at normal operating temperature,

adjust

the dash pot as follows:

The

dash pot adjustment is made with the throttle

set at curb idle (not fast idle). Loosen dash pot lock

nut and

turn

the dash pot assembly until dash pot

plunger contacts the throttle lever without the plunger being depressed.

Then

turn

the dash pot

assembly 2turns against the throttle lever, de pressing the dash pot plunger. Tighten the lock nut

securely. As a final check, open carburetor and

allow throttle to snap closed. Time dash pot delay ing action from the point where the throttle lever

hits the dash pot to the point where the lever

stops

moving. The dash pot should delay or cushion

closing action for two seconds by saying, "One

thousand and one, one thousand and two."

14204

FIG.

E-27—DASH

POT

ADJUSTMENT—V6

ENGINE

1—

Throttle

Lever

3—Dash Pot

2—

Plunger

4—Lock

Nut

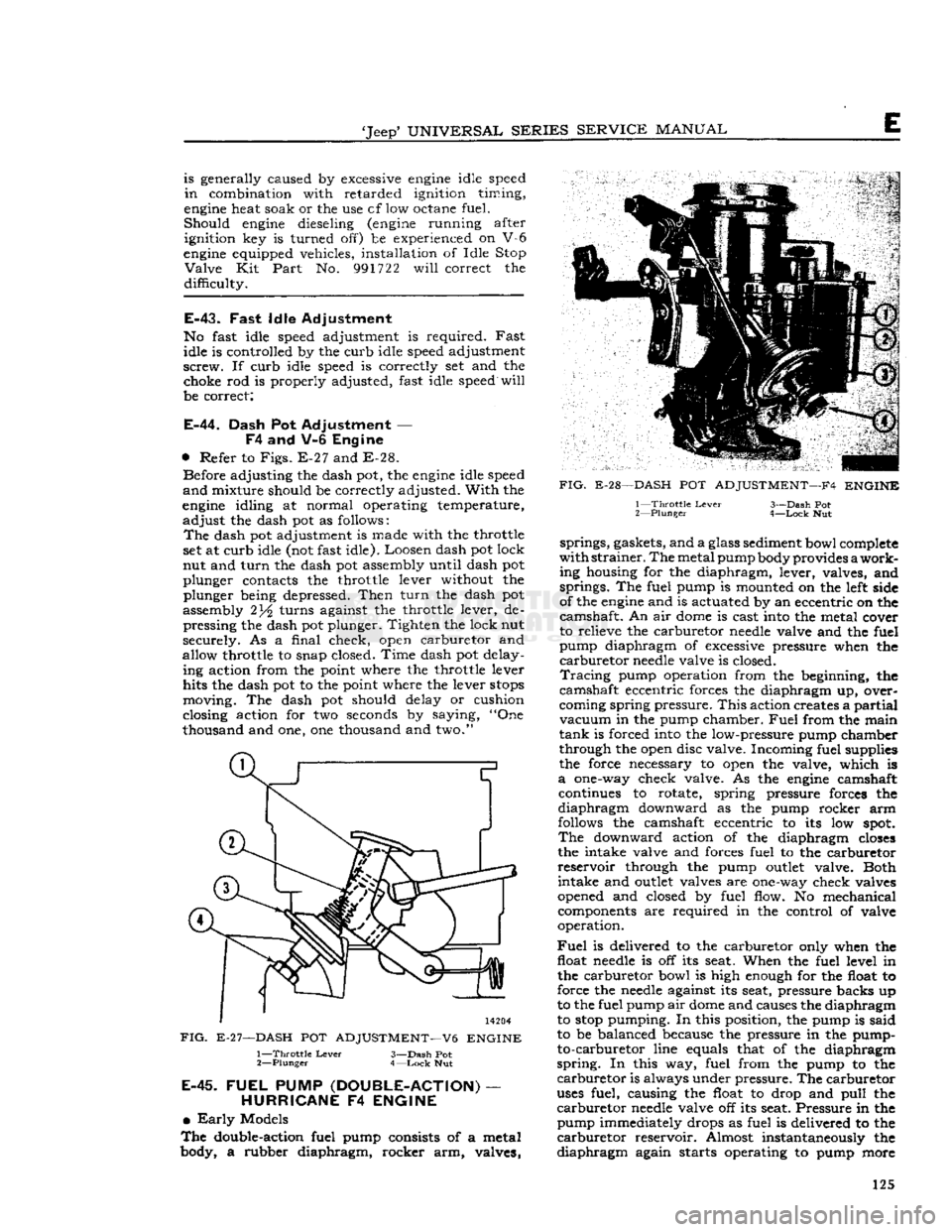

E-45.

FUEL

PUMP

(DOUBLE-ACTION)

—

HURRICANE

F4

ENGINE

•

Early

Models

The

double-action fuel pump consists of a metal

body, a rubber diaphragm, rocker arm, valves,

FIG.

E-28—DASH

POT

ADJUSTMENT—F4

ENGINE

1—

Throttle

Lever

3—Dash Pot

2—

Plunger

4—Lock

Nut springs, gaskets, and a glass sediment bowl complete

with

strainer.

The

metal pump body provides

a

work

ing housing for the diaphragm, lever, valves, and springs. The fuel pump is mounted on the left side

of the

engine

and is actuated by an eccentric on the

camshaft. An air

dome

is cast into the metal cover

to relieve the carburetor

needle

valve and the fuel

pump diaphragm of excessive pressure when the

carburetor

needle

valve is closed.

Tracing

pump operation from the beginning, the

camshaft eccentric forces the diaphragm up, over

coming spring pressure.

This

action creates a

partial

vacuum

in the pump chamber.

Fuel

from the main

tank

is forced into the low-pressure pump chamber

through the open disc valve. Incoming fuel supplies

the force necessary to open the valve, which is

a

one-way check valve. As the

engine

camshaft continues to rotate, spring pressure forces the

diaphragm

downward as the pump rocker arm

follows the camshaft eccentric to its low

spot.

The

downward action of the diaphragm

closes

the intake valve and forces fuel to the carburetor

reservoir

through the pump

outlet

valve. Both intake and

outlet

valves are one-way check valves

opened and closed by fuel flow. No mechanical components are required in the control of valve

operation.

Fuel

is delivered to the carburetor only when the float

needle

is off its seat. When the fuel level in the carburetor bowl is high enough for the float to

force the

needle

against its seat, pressure backs up

to the fuel pump air

dome

and causes the diaphragm

to

stop

pumping. In this position, the pump is said

to be balanced because the pressure in the pump- to-carburetor line equals that of the diaphragm

spring.

In this way, fuel from the pump to the

carburetor

is always under pressure. The carburetor

uses

fuel, causing the float to drop and

pull

the

carburetor

needle

valve off its seat. Pressure in the pump immediately drops as fuel is delivered to the

carburetor

reservoir. Almost instantaneously the

diaphragm

again starts operating to pump more 125

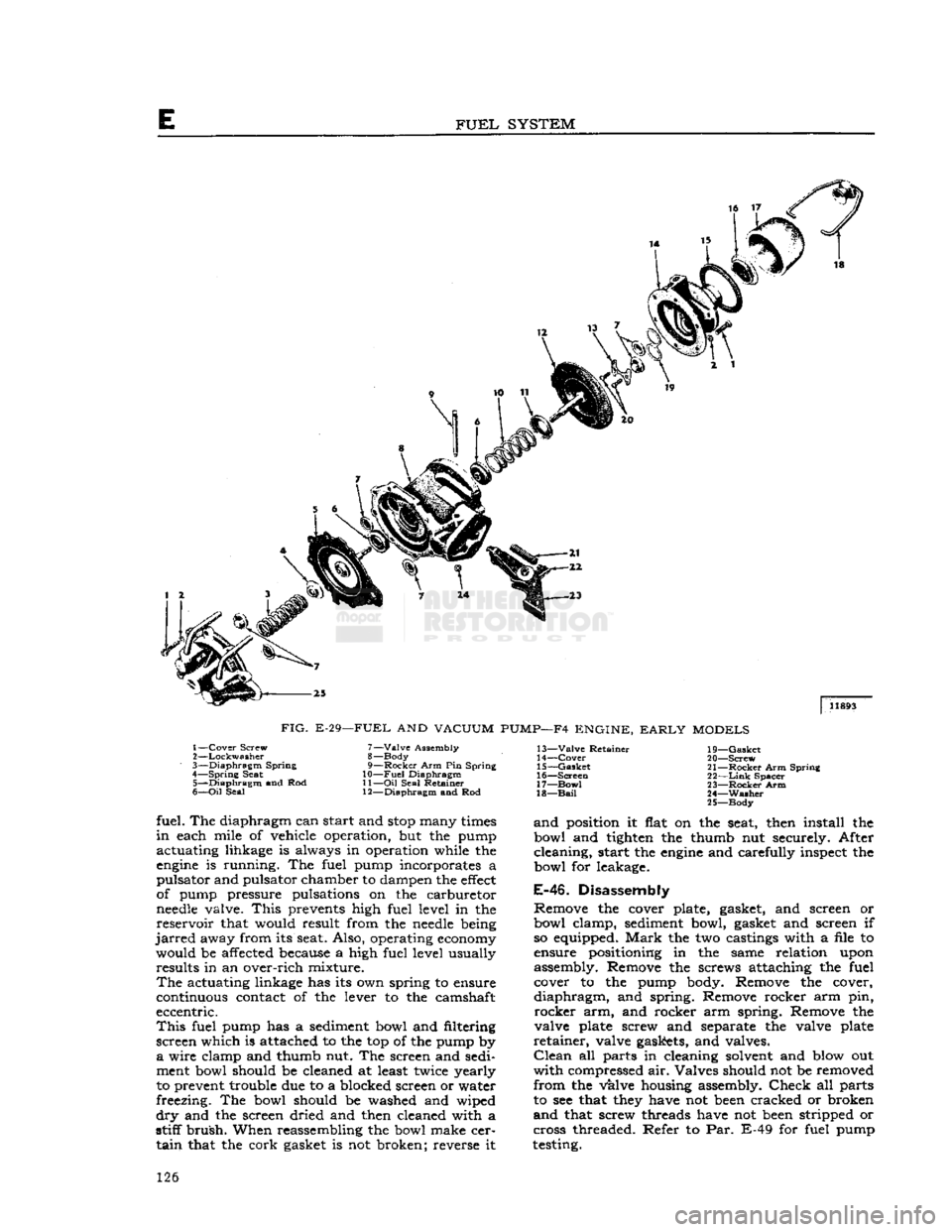

Page 126 of 376

FUEL

SYSTEM

|

11893

FIG.

E-29—FUEL

AND

VACUUM

PUMP—F4

ENGINE,

EARLY

MODELS

1—

Cover

Screw

2—

Lockwasher

3—

Diaphragm

Spring

4—

Spring

Seat 5—

Diaphragm

and Rod

6—

Oil

Seal 7—

Valve

Assembly

8— Body

9—

Rocker

Arm Pin Spring

10—

Fuel

Diaphragm

11—

Oil

Seal Retainer

12—

Diaphragm

and Rod 13—

Valve

Retainer

14—

Cover

15—

Gasket

16—

Screen

17—

Bow!

18—

Bail

19—

Gasket

20—

Screw

21—

Rocker

Arm Spring

22—

Link

Spacer

23—

Rocker

Arm

24—

Washer

25—

Body

fuel. The diaphragm can start and

stop

many

times

in

each mile of vehicle operation, but the pump

actuating lihkage is always in operation while the

engine

is running. The fuel pump incorporates a

pulsator and pulsator chamber to dampen the

effect

of pump pressure pulsations on the carburetor

needle

valve.

This

prevents high fuel level in the

reservoir

that would result from the

needle

being

jarred

away from its seat. Also, operating

economy

would be affected because a high fuel level usually results in an over-rich mixture.

The

actuating linkage has its own spring to ensure

continuous contact of the lever to the camshaft

eccentric.

This

fuel pump has a sediment bowl and filtering

screen which is attached to the top of the pump by

a

wire clamp and thumb nut. The screen and sedi

ment bowl should be cleaned at least twice yearly

to prevent trouble due to a blocked screen or water

freezing. The bowl should be washed and wiped

dry

and the screen dried and then cleaned with a

stiff

brush.

When reassembling the bowl make cer

tain

that the cork gasket is not broken; reverse it

and

position it flat on the seat, then install the

bowl and tighten the thumb nut securely. After

cleaning, start the

engine

and carefully inspect the

bowl for leakage.

E-46.

Disassembly

Remove the cover plate, gasket, and screen or

bowl clamp, sediment bowl, gasket and screen if so equipped.

Mark

the two castings with a file to

ensure positioning in the same relation upon

assembly. Remove the screws attaching the fuel cover to the pump body. Remove the cover,

diaphragm,

and spring. Remove rocker arm pin,

rocker

arm, and rocker arm spring. Remove the

valve plate screw and separate the valve plate

retainer,

valve gaskets, and valves.

Clean

all parts in cleaning solvent and blow out

with

compressed air. Valves should not be removed

from

the valve housing assembly.

Check

all parts

to see that

they

have not

been

cracked or broken

and

that screw threads have not

been

stripped or

cross threaded. Refer to Par. E-49 for fuel pump

testing. 126

Page 127 of 376

'Jeep'

UNIVERSAL

SERIES

SERVICE

MANUAL

E

E-47.

Reassembly

•

Refer to Fig. E-29.

Install

the valve gaskets, valves, valve retainer and

secure them with the valve retainer screws. Make

sure that the inlet and

outlet

valves are in their proper positions. Place the diaphragm spring re

tainer in position on the diaphragm

pull

rod

and

install diaphragm spring. Position the

dia

phragm assembly in pump

body

and attach the

cover to pump body, with file marks aligned, with

the six attaching screws. Do not draw the screws

up tight.

Install

rocker arm spring, rocker arm

pin

washers, rocker arm and rocker arm pin.

With

rocker

arm positioned on the diaphragm rod, draw

the six pump

body

screws up evenly and securely.

Install

the filter screen, cork gasket and sediment

bowl and secure them firmly with the thumb screw

on the bowl clamp.

E-48.

Vacuum

Pump

The

double-action fuel pump resembles two single-

action pumps placed one

above

the other. A single

fuel pump rocker arm actuates the two separate diaphragms. One diaphragm is part of the fuel

delivery pump and operates as described in Par.

E-45.

The other diaphragm is part of the vacuum

pump and operates as described here.

As

the actuating lever forces the diaphragm upward against spring pressure, air is forced through the

outlet

port

into

the

engine's

intake manifold. On

the return stroke, spring pressure forces the

dia

phragm downward, creating a

partial

vacuum and

opening the inlet valve. In this manner, air is pumped out of the windshield wiper motor and

into

the intake manifold. When the wiper motor is shut off, manifold vacuum holds the diaphragm against its spring so that the

full

motion of the actuating

lever is not accompanied by a

complete

up-and-

down motion of the diaphragm.

When

the windshield wiper motor is turned on, but manifold vacuum is greater than the vacuum

created by the

booster

pump, air

flows

from the

wiper motor through both valves of the vacuum

booster.

As manifold vacuum drops off as a result

of the

engine

operating under low

speed

and high load, the vacuum created by the vacuum

booster

will

be greater than

engine

intake manifold vacuum

and

the pump

will

operate the wiper motor when the wiper control switch is turned on.

•

Refer to Fig. E-29. Remove the

eight

cover attaching screws and

lockwashers, and remove the cover, diaphragm

spring

and spring seat. Detach the diaphragm rod

from the rocker arm and remove the diaphragm.

The

valve assemblies are pressed

into

the cover

and

body

and lightly staked. They may be removed

with the point of a knife blade. If installing new valves be sure the inlet and

outlet

valves are

correctly positioned and stake them lightly with

a

small punch.

Assemble the vacuum pump in the reverse order

of disassembly, drawing the cover attaching screws up evenly and tightly.

E-49.

Fuel

Pump

Testing

Four

tests

are presented in following paragraphs to

test

for proper operation of the fuel pump. In addi

tion, check the following:

a.

Check

for secure mounting of the fuel pump.

The

rocker arm may be working the entire pump

up and down, rather than just the pump

dia

phragms.

b. Remove and clean the fuel sediment bowl.

c.

Check

all fuel lines.

E-50.

Volume

Check

To

measure fuel pump capacity (amount of fuel

delivered in a given time) disconnect the pump-to-

carburetor

line at the carburetor end. Place the

open

end of the line in a suitable container.

Start

the

engine

and operate at normal idle speed.

Delivery

should be one quart U.S. [1 ltr.] within

one minute.

E-51.

Pressure

Check

To

measure fuel pump pressure (force of fuel de

livery)

disconnect the pump-to-carburetor line

at the carburetor end. Plug a pressure

gauge

and T-fitting

into

the

open

end of this line and

into

the

carburetor.

Start

the

engine

and operate at normal

idle speed. Pressure should be 2J4 to 3% psi.

[0,716

a

0,264

kg-cm2] at 1800 rpm. and at 16"

[406 mm.]

above

the

outlet.

E-52.

Vacuum

Check

To

measure fuel pump vacuum (pull of. the pump

at the inlet side) disconnect the pump-to-fuel-tank

line at the fuel pump. Attach a vacuum

gauge

to the fuel pump inlet.

Start

the

engine,

accelerate to

specified speed, and hold this

engine

speed

while

taking a

gauge

reading. Permissible

gauge

reading

is 8* [203 mm.] of mercury [Hg] at 1200 rpm. and

10j^'

[267 mm.] at 1800 rpm.

E-53.

Vacuum

Booster

Check

To

test

the condition of the vacuum

booster

pump,

disconnect both inlet and

outlet

lines at the pump.

Attach

a vacuum

gauge

to the windshield wiper

connection at the pump.

Start

the

engine,

accelerate

to

2000

rpm., and hold this

engine

speed

while taking a

gauge

reading. Permissible

gauge

reading

is 10* to 14" [254 a 356 cm.] of mercury [Hg].

E-54.'

FUEL

PUMP

(SINGLE-ACTION)

—

HURRICANE

F4

ENGINE

•

Early

Models.

Vehicles with electric windshield wiper motors are

equipped with a single-action fuel pump (Fig.

E-30).

The fuel pump cam lever is activated by an eccentric on the

engine

camshaft. When the

car

buretor float

needle

valve closes, accumulation of

fuel in the pump

extends

the diaphragm spring.

This

action causes the rocker arm linkage to be

come

inoperative until the pressure on the

dia

phragm and spring is reduced. The fuel pump dis

charge pressure is thus controlled by the diaphragm

spring.

This

provides a steady supply of fuel to the

carburetor

at a fairly constant pressure. 127