ECU JEEP COMMANDER 2008 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2008, Model line: COMMANDER, Model: JEEP COMMANDER 2008 1.GPages: 478, PDF Size: 6.97 MB

Page 189 of 478

8. Tachometer

The red segments indicate the maximum permissible

engine revolutions-per-minute (r.p.m. x 1000) for each

gear range. Before reaching the red area, ease up on the

accelerator.

9. Security Alarm System Indicator Light Ð If

Equipped

This light will flash rapidly for approximately 15 seconds

when the vehicle theft alarm is arming. The light will

flash at a slower speed continuously after the alarm is set.

The security light will also come on for about three

seconds when the ignition is first turned on.

10. Oil Pressure Warning Light

This light shows low engine oil pressure. The light

should turn on momentarily when the engine is

started. If the light turns on while driving, stop the

vehicle, and shut off the engine as soon as possible. A

continuous chime will sound when this light turns on.Do not operate the vehicle until the cause is corrected.

This light does not show how much oil is in the engine.

The engine oil level must be checked under the hood.

11. Electronic Stability Program (ESP) Indicator

Light/Traction Control System (TCS) Indicator Light

This indicator light starts to flash as soon as the

tires lose traction and the ESP system becomes

active. The ªESP/TCS Indicator Lightº also

flashes when TCS is active. If the ªESP/TCS

Indicator Lightº begins to flash during acceleration, ease

up on the accelerator and apply as little throttle as

possible. Be sure to adapt your speed and driving to the

prevailing road conditions. The ªESP/TCS Indicator

Lightº will flash any time the ESP or TCS is active and

helping to improve vehicle stability. If the ªESP/TCS

Indicator Lightº is on solid, the ESP system has been

turned off by the driver or a temporary condition exists

that will not allow full ESP function.

UNDERSTANDING YOUR INSTRUMENT PANEL 189

4

Page 197 of 478

Electronic Vehicle Information Center (EVIC)

Displays

When the appropriate conditions exist, the Electronic

Vehicle Information Center (EVIC) displays the following

messages:

²TURN SIGNAL ON

²PERFORM SERVICE

²KEY NOT PROGRAMMED Ð DAMAGED KEY

²KEY NOT PROGRAMMED Ð INVALID KEY

²KEY NOT PROGRAMMED Ð EXCEEDED KEY PRO-

GRAM LIMIT

²PROGRAMMING ACTIVE Ð NEW KEY PRO-

GRAMMED

²SERVICE SECURITY KEY

²INVALID KEY Ð TRY ALTERNATE KEY

²DRIVER/PASSENGER DOOR OPEN (with graphic)

²LEFT/RIGHT REAR DOOR OPEN (with graphic)

²X DOORS OPEN (with graphic)

²LIFTGATE OPEN (with graphic)

²LIFTGATE/DOOR OPEN (with graphic)

²LIFTGATE/DOORS OPEN (with graphic)

²LIFTGLASS OPEN (with graphic)

²HOOD OPEN (with graphic)

²HOOD/DOOR OPEN (with graphic)

²HOOD/DOORS OPEN (with graphic)

²LIFTGATE/HOOD OPEN (with graphic)

²HOOD/GLASS/DOOR OPEN (with graphic)

²HOOD/GLASS/DOORS OPEN (with graphic)

UNDERSTANDING YOUR INSTRUMENT PANEL 197

4

Page 346 of 478

or rear axles has been exceeded but the total load is

within the specified GVWR. If so, weight must be shifted

from front to rear or rear to front as appropriate until the

specified weight limitations are met. Store the heavier

items down low and be sure that the weight is distributed

equally. Stow all loose items securely before driving.

Improper weight distributions can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.

CAUTION!

Do not load your vehicle any heavier than the GVWR

or the maximum front and rear GAWR. If you do,

parts on your vehicle can break, or it can change the

way your vehicle handles. This could cause you to

lose control. Also overloading can shorten the life of

your vehicle.

TRAILER TOWING

In this section you will find safety tips and information

on limits to the type of towing you can reasonably do

with your vehicle. Before towing a trailer carefully re-

view this information to tow your load as efficiently and

safely as possible.

To maintain warranty coverage, follow the requirements

and recommendations in this manual concerning ve-

hicles used for trailer towing.

Common Towing Definitions

The following trailer towing related definitions will assist

you in understanding the following information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your vehicle.

This includes driver, passengers, cargo and tongue

weight. The total load must be limited so that you do not

exceed the GVWR.

346 STARTING AND OPERATING

Page 354 of 478

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

²When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

²Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

hook retainers of the vehicle hitch. Cross the chains

under the trailer tongue and allow enough slack for

turning corners.

²Vehicles with trailers should not be parked on a grade.

When parking, apply the parking brake on the tow

vehicle. Put the tow vehicle transmission in P (Park).

For four-wheel-drive vehicles, make sure the transfer

case is not in N (Neutral). Always, block or9chock9the

trailer wheels.

²GCWR must not be exceeded.

²Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded:

1. GVWR

2. GTW

354 STARTING AND OPERATING

Page 373 of 478

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

6. Remove the lug nuts and wheel.

7. Position the spare wheel/tire on the vehicle and install

the lug nuts with the cone-shaped end toward the wheel.

Lightly tighten the nuts. To avoid the risk of forcing the

vehicle off the jack, do not tighten the nuts fully until the

vehicle has been lowered.

8. Lower the vehicle by turning the jack screw counter

clockwise, and remove the jack and wheel blocks.9. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

nuts until each nut has been tightened twice. Correct

wheel nut tightness is 130 N´m (95 ft. lbs). If in doubt

about the correct tightness, have them checked with a

torque wrench by your authorized dealer or at a service

station.

10. Lower the jack to it's fully closed position.

WARNING!

A loose tire or jack, thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

11. Secure the tire, jack, and tools in their proper loca-

tions.

WHAT TO DO IN EMERGENCIES 373

6

Page 407 of 478

Pay particular attention to the hoses nearest to high heat

sources such as the exhaust manifold. Inspect hose rout-

ing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

Insure nylon tubing in these areas has not melted or

collapsed. Inspect all hose connections such as clamps

and couplings to make sure they are secure and no leaks

are present. Components should be replaced immedi-

ately if there is any evidence of degradation that could

cause failure.

Fuel System Connections

Electronic Fuel Injection high pressure fuel systems are

designed with tubes and special connects, connections

and clamps which have unique material characteristics to

provide adequate sealing and resist attack by deterio-

rated gasoline.You are urged to use only the manufactures-specified

tubes, connections and clamps, or their equivalent in

material and specification, in any fuel system servicing.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Refer to the Maintenance Schedule in Section 8 for

suggested service intervals.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

MAINTAINING YOUR VEHICLE 407

7

Page 408 of 478

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses for evidence of heat and me-

chanical damage. Hard and brittle rubber, cracking, tears,

cuts, abrasion, and excessive swelling suggest deteriora-

tion of the rubber. Particular attention should be made to

examining those hose surfaces nearest to high heat

sources, such as the exhaust manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Often fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before hose is replaced based

on leakage.NOTE:Inspection of brake hoses should be done when-

ever the brake system is serviced and every engine oil

change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Brake Master Cylinder Ð Brake Fluid Level Check

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning lamp shows system failure

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

408 MAINTAINING YOUR VEHICLE

Page 432 of 478

3. Reach through the access hole to access the back of the

front fog light housing on the back of the front fascia.

4. Disconnect the electrical connector.

5. Turn the socket on the back of the housing 1/4 turn

counter clockwise to unlock it.

6. Pull the socket and bulb straight out from the opening

in the housing.

7. Pull the base of the bulb straight out of the socket.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

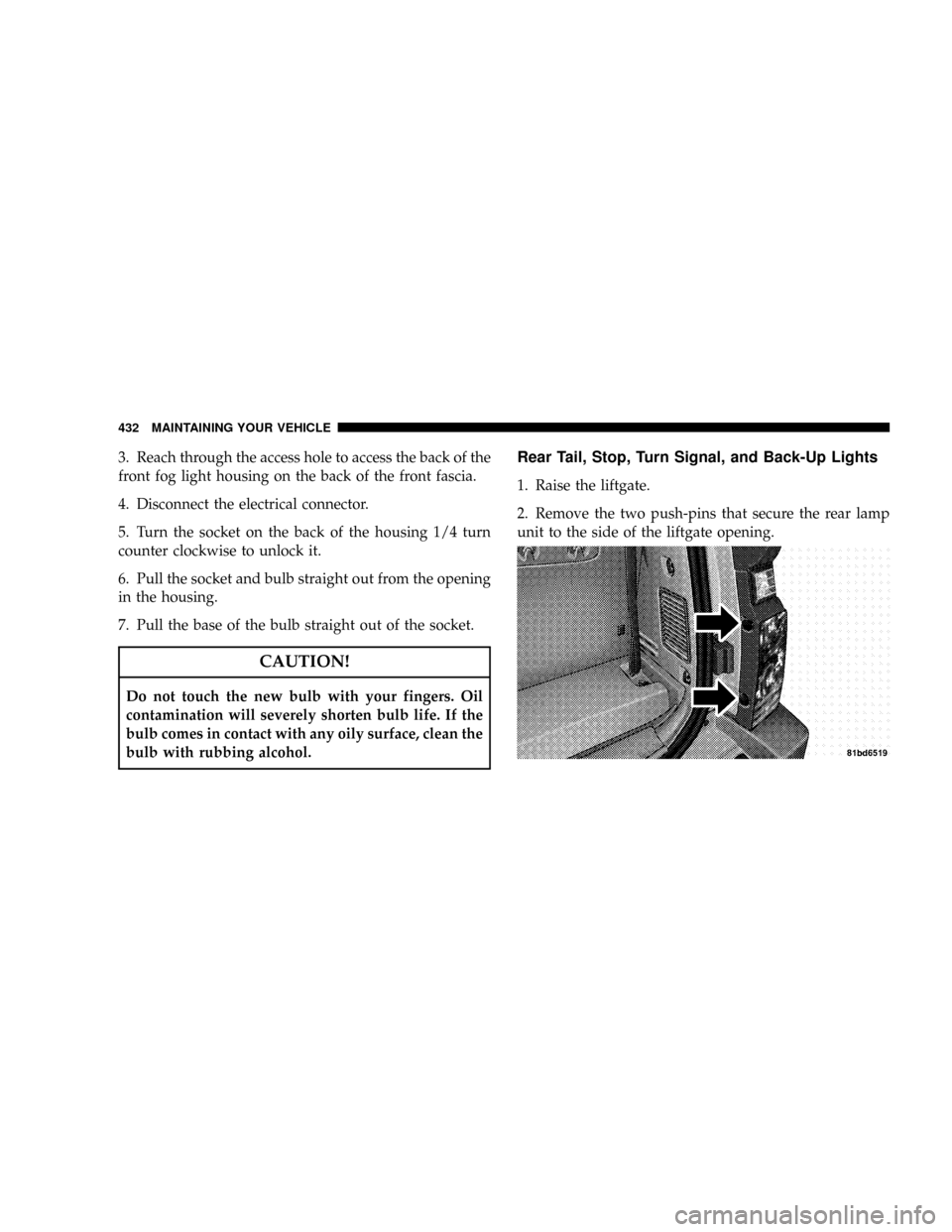

Rear Tail, Stop, Turn Signal, and Back-Up Lights

1. Raise the liftgate.

2. Remove the two push-pins that secure the rear lamp

unit to the side of the liftgate opening.

432 MAINTAINING YOUR VEHICLE

Page 434 of 478

7. Pull the base of the bulb straight out of the socket.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

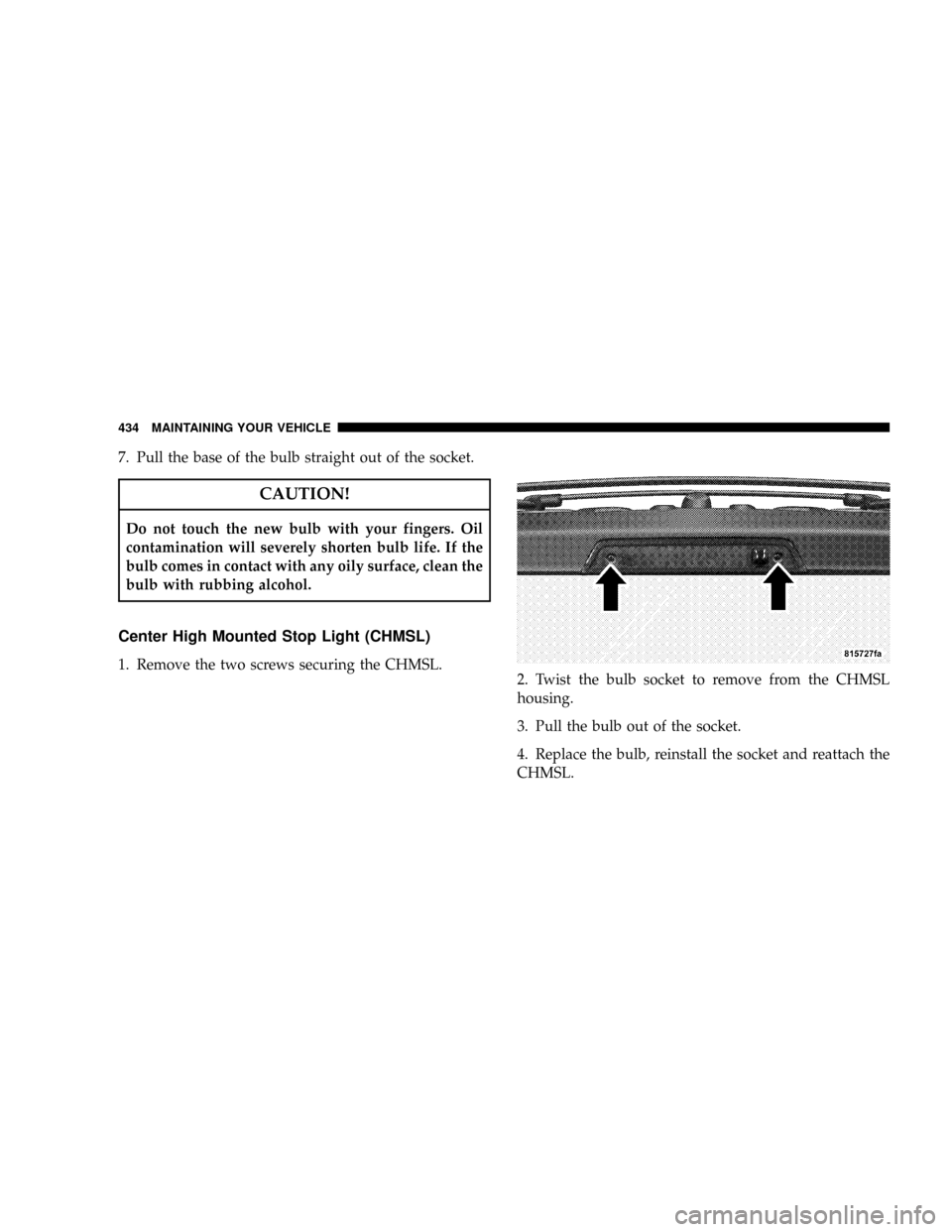

Center High Mounted Stop Light (CHMSL)

1. Remove the two screws securing the CHMSL.

2. Twist the bulb socket to remove from the CHMSL

housing.

3. Pull the bulb out of the socket.

4. Replace the bulb, reinstall the socket and reattach the

CHMSL.

434 MAINTAINING YOUR VEHICLE

Page 458 of 478

ABS (Anti-Lock Brake System)............188,302

Adding Fuel........................... 341

Adding Washer Fluid..................... 177

Adjustable Pedals....................... 135

Air Cleaner, Engine (Engine Air Cleaner Filter) . . . 393

Air Conditioner Maintenance............... 397

Air Conditioning........................ 259

Air Conditioning, Operating Tips............ 269

Air Conditioning, Rear Zone................ 267

Air Conditioning Refrigerant............... 398

Air Conditioning System.................. 259

Air Filter.............................. 393

Air Pressure, Tires....................... 316

Airbag................................ 48

Airbag Deployment....................... 55

Airbag Light.......................57,71,188

Airbag Maintenance....................... 57

Alarm, Panic............................ 24

Alarm (Security Alarm).................20,189Alarm System (Security Alarm)............... 20

Alignment and Balance................... 321

Alterations/Modifications, Vehicle............. 9

Antenna, Satellite Radio................... 250

Antifreeze (Engine Coolant)................ 435

Disposal............................ 405

Anti-Lock Brake System (ABS)............139,302

Anti-Lock Warning Light.................. 188

Anti-Theft System.....................20,189

Appearance Care........................ 415

Assist, Hill Start........................ 148

Audio Systems (Radio).................... 239

Auto Down Power Windows................ 32

Automatic Dimming Mirror................. 78

Automatic Door Locks..................... 29

Automatic Headlights.................... 126

Automatic Temperature Control (ATC)......... 260

Automatic Transmission................283,411

Adding Fluid......................... 412

458 INDEX