JEEP COMPASS 2016 1.G User Guide

Manufacturer: JEEP, Model Year: 2016, Model line: COMPASS, Model: JEEP COMPASS 2016 1.GPages: 148, PDF Size: 8.42 MB

Page 101 of 148

5. Remove the wheel nuts and pull the wheel and wheel covers, where applicable,off the hub. Install the spare wheel and wheel nuts with the cone shaped end of

the nuts toward the wheel. Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered. Failure to follow this warning may result

in serious injury.

CAUTION!

Be sure to mount the spare tire with the valve stem facing outward. The vehicle

could be damaged if the spare tire is mounted incorrectly.

WARNING!

To avoid possible personal injury, handle the wheel covers with care to avoid

contact with any sharp edges.

NOTE:

The wheel cover is held on the wheel by the wheel nuts. When reinstalling the original

wheel, properly align the wheel cover to the valve stem, place the wheel cover onto

the wheel, then install the wheel nuts.

6. Lower the vehicle by turning the jack screw to the left.

Installing Spare

WHAT TO DO IN EMERGENCIES

99

Page 102 of 148

7. Finish tightening the nuts. Push down on the wrench while at the end of thehandle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct wheel nut torque is 100 ft/lbs (135 N·m).

If you doubt that you have tightened the nuts correctly, have them checked with

a torque wrench by your authorized dealer or service station

8. Remove the wheel blocks and lower the jack until it is free. Release the parking brake. Reassemble the lug wrench to the jack assembly and stow it in the spare

tire area. Secure the assembly using the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the

places provided.

9. Place the deflated (flat) tire in the cargo area, have the tire repaired or replaced as

soon as possible.

WARNING!

A loose tire thrown forward in a collision or hard stop could injure the occupants

in the vehicle. Have the deflated (flat) tire repaired or replaced immediately.

10. Check the spare tire pressure as soon as possible. Correct the tire pressure as required.

11. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

WHAT TO DO IN EMERGENCIES

100

Page 103 of 148

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. Align the valve notch in the wheel cover with the valve stem on the wheel. Installthe cover by hand. Do not use a hammer or excessive force to install the cover.

3. Install the five wheel lug nuts with the cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in

serious injury.

4. Lower the vehicle to the ground by turning the jack handle counterclockwise.

5. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

6. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

Wheel Cover Installation

1 — Valve Stem

2 — Valve Notch

3 — Wheel Lug Nut

4 — Wheel Cover

5 — Mounting Stud

WHAT TO DO IN EMERGENCIES

101

Page 104 of 148

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward thewheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not fully tighten the lug nuts

until the vehicle has been lowered. Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

JUMP-STARTING PROCEDURES

If your vehicle has a discharged battery it can be jump-started using a set of jumper

cables and a battery in another vehicle or by using a portable battery booster pack.

Jump-starting can be dangerous if done improperly so please follow the procedures

in this section carefully.

NOTE:

When using a portable battery booster pack follow the manufacturer’s operating

instructions and precautions.

CAUTION!

Do not use a portable battery booster pack or any other booster source with a

system voltage greater than 12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

WARNING!

Do not attempt jump-starting if the battery is frozen. It could rupture or explode

and cause personal injury.

WHAT TO DO IN EMERGENCIES

102

Page 105 of 148

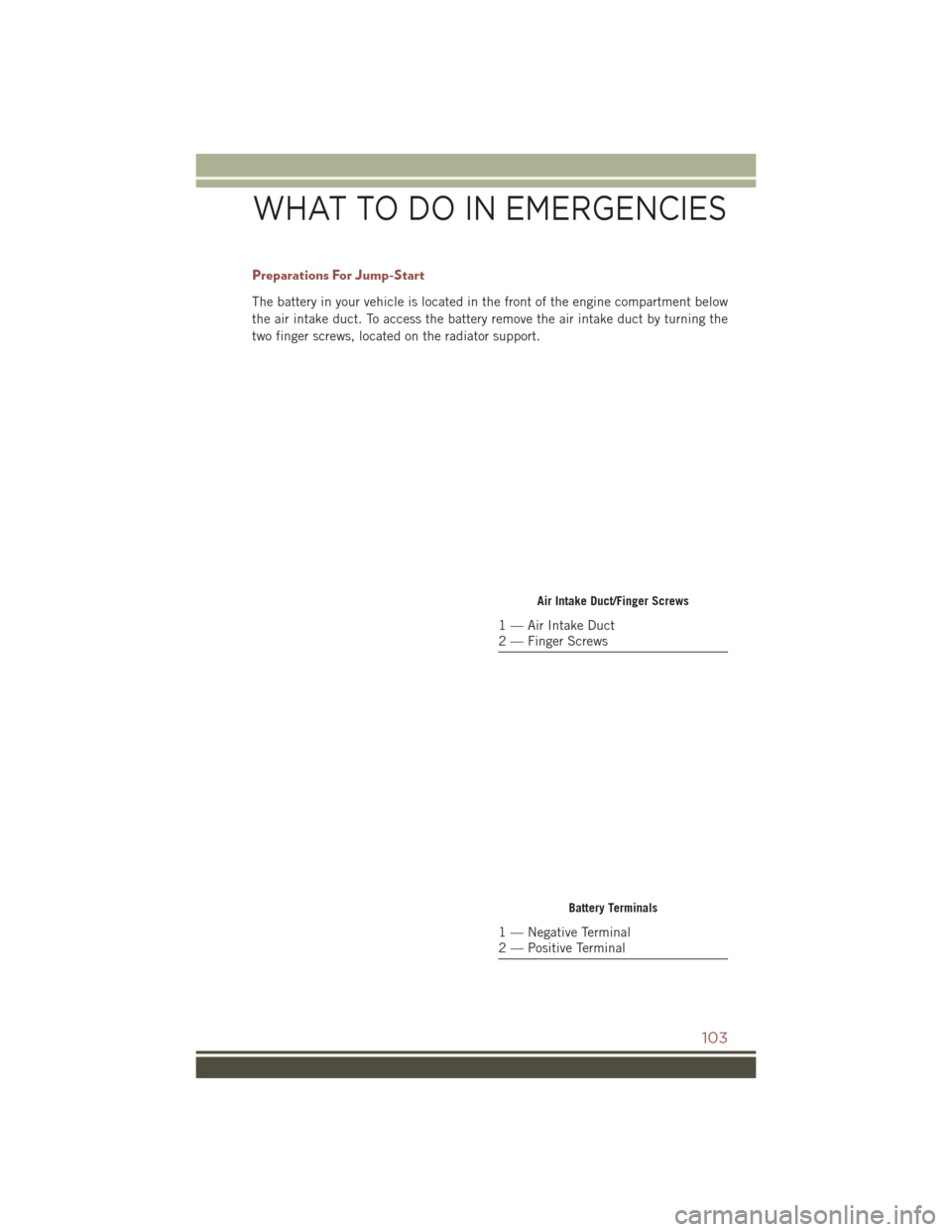

Preparations For Jump-Start

The battery in your vehicle is located in the front of the engine compartment below

the air intake duct. To access the battery remove the air intake duct by turning the

two finger screws, located on the radiator support.

Air Intake Duct/Finger Screws

1 — Air Intake Duct

2 — Finger Screws

Battery Terminals

1 — Negative Terminal

2 — Positive Terminal

WHAT TO DO IN EMERGENCIES

103

Page 106 of 148

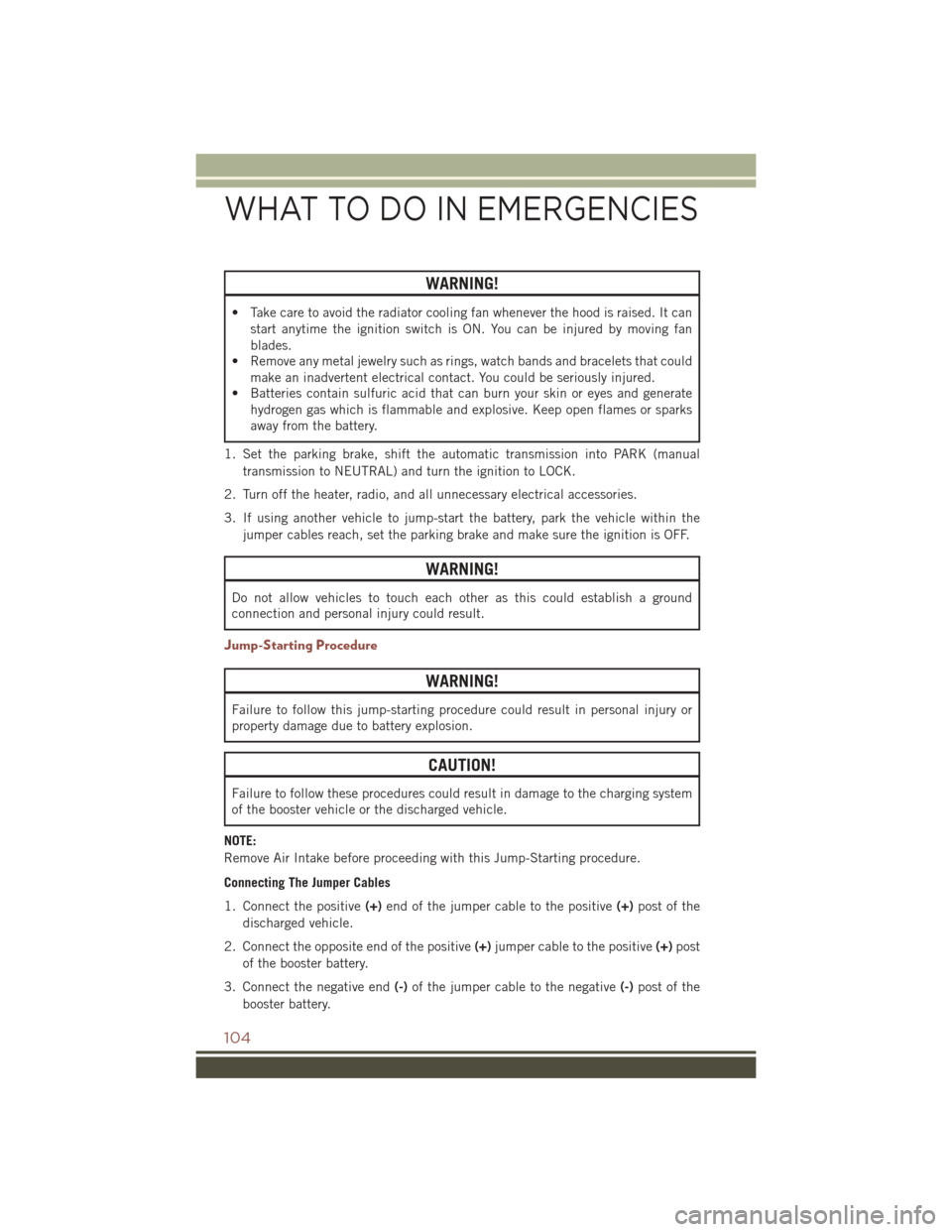

WARNING!

• Take care to avoid the radiator cooling fan whenever the hood is raised. It canstart anytime the ignition switch is ON. You can be injured by moving fan

blades.

• Remove any metal jewelry such as rings, watch bands and bracelets that could

make an inadvertent electrical contact. You could be seriously injured.

• Batteries contain sulfuric acid that can burn your skin or eyes and generate

hydrogen gas which is flammable and explosive. Keep open flames or sparks

away from the battery.

1. Set the parking brake, shift the automatic transmission into PARK (manual transmission to NEUTRAL) and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electrical accessories.

3. If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this could establish a ground

connection and personal injury could result.

Jump-Starting Procedure

WARNING!

Failure to follow this jump-starting procedure could result in personal injury or

property damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result in damage to the charging system

of the booster vehicle or the discharged vehicle.

NOTE:

Remove Air Intake before proceeding with this Jump-Starting procedure.

Connecting The Jumper Cables

1. Connect the positive (+)end of the jumper cable to the positive (+)post of the

discharged vehicle.

2. Connect the opposite end of the positive (+)jumper cable to the positive (+)post

of the booster battery.

3. Connect the negative end (-)of the jumper cable to the negative (-)post of the

booster battery.

WHAT TO DO IN EMERGENCIES

104

Page 107 of 148

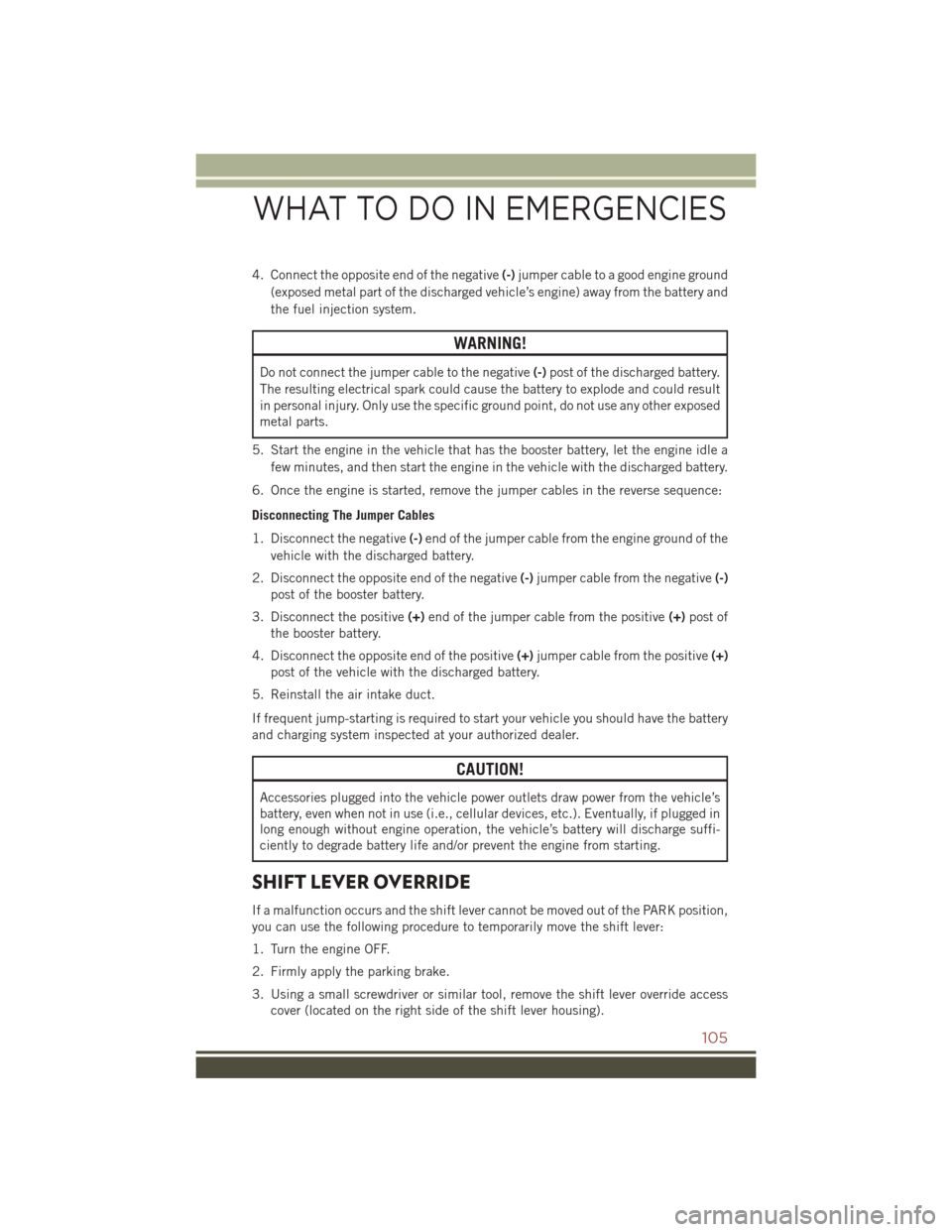

4. Connect the opposite end of the negative(-)jumper cable to a good engine ground

(exposed metal part of the discharged vehicle’s engine) away from the battery and

the fuel injection system.

WARNING!

Do not connect the jumper cable to the negative (-)post of the discharged battery.

The resulting electrical spark could cause the battery to explode and could result

in personal injury. Only use the specific ground point, do not use any other exposed

metal parts.

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few minutes, and then start the engine in the vehicle with the discharged battery.

6. Once the engine is started, remove the jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative (-)end of the jumper cable from the engine ground of the

vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-)jumper cable from the negative (-)

post of the booster battery.

3. Disconnect the positive (+)end of the jumper cable from the positive (+)post of

the booster battery.

4. Disconnect the opposite end of the positive (+)jumper cable from the positive (+)

post of the vehicle with the discharged battery.

5. Reinstall the air intake duct.

If frequent jump-starting is required to start your vehicle you should have the battery

and charging system inspected at your authorized dealer.

CAUTION!

Accessories plugged into the vehicle power outlets draw power from the vehicle’s

battery, even when not in use (i.e., cellular devices, etc.). Eventually, if plugged in

long enough without engine operation, the vehicle’s battery will discharge suffi-

ciently to degrade battery life and/or prevent the engine from starting.

SHIFT LEVER OVERRIDE

If a malfunction occurs and the shift lever cannot be moved out of the PARK position,

you can use the following procedure to temporarily move the shift lever:

1. Turn the engine OFF.

2. Firmly apply the parking brake.

3. Using a small screwdriver or similar tool, remove the shift lever override access cover (located on the right side of the shift lever housing).

WHAT TO DO IN EMERGENCIES

105

Page 108 of 148

4. Turn the ignition switch to the ACC or ON/RUN position, but do not start theengine.

5. Press and maintain firm pressure on the brake pedal.

6. Insert the screwdriver or similar tool into the access port, and push and hold the override release lever forward.

7. Move the shift lever to the NEUTRAL position.

8. The vehicle may then be started in NEUTRAL.

9. Reinstall the shift lever override access cover.

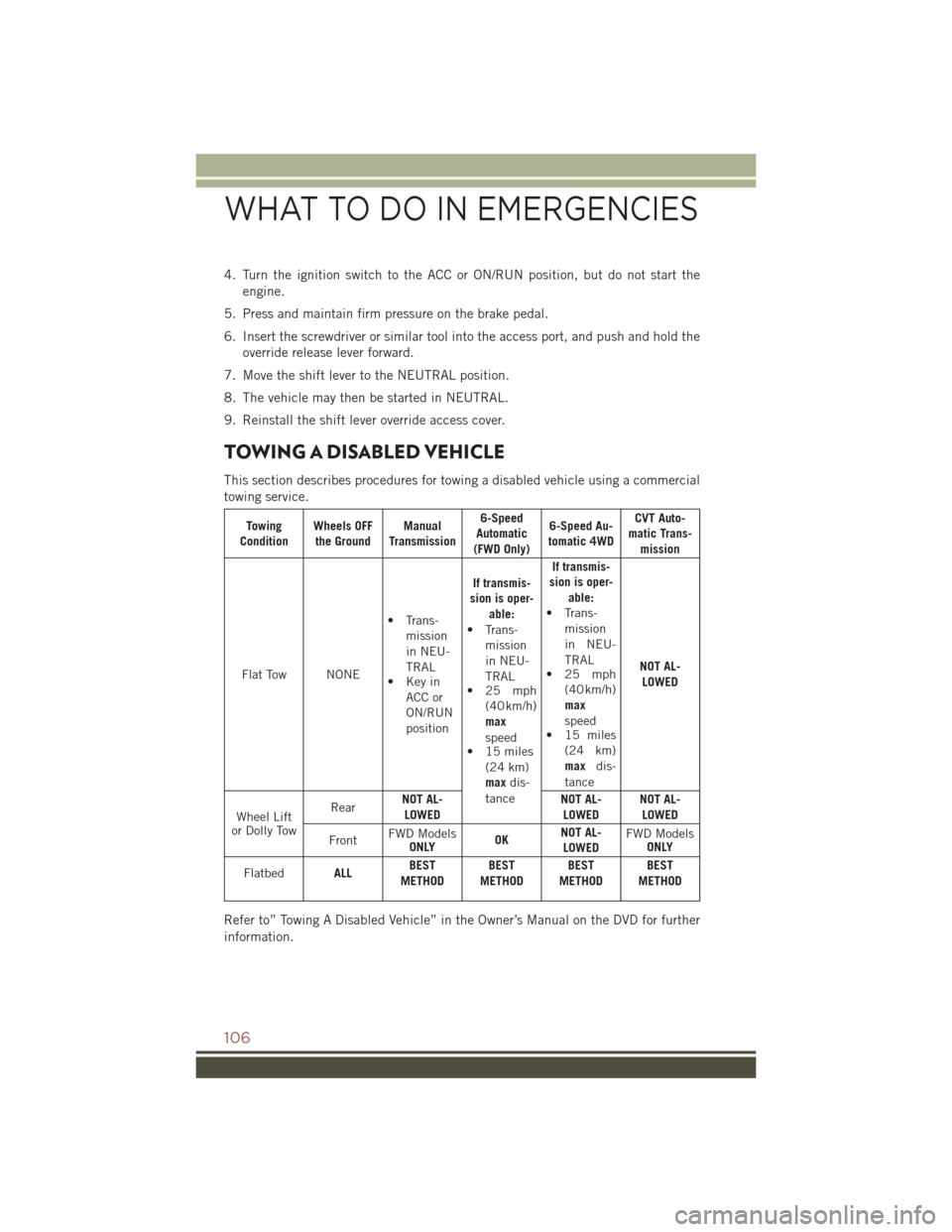

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial

towing service.

Towing

Condition Wheels OFF

the Ground Manual

Transmission 6-Speed

Automatic

(FWD Only) 6-Speed Au-

tomatic 4WD CVT Auto-

matic Trans- mission

Flat Tow NONE • Trans-

mission

in NEU-

TRAL

• Key in

ACC or

ON/RUN

position If transmis-

sion is oper- able:

• Trans- mission

in NEU-

TRAL

• 25 mph

(40 km/h)

max

speed

• 15 miles

(24 km)

max dis-

tance If transmis-

sion is oper- able:

• Trans- mission

in NEU-

TRAL

• 25 mph

(40 km/h)

max

speed

• 15 miles

(24 km)

max dis-

tance NOT AL-

LOWED

Wheel Lift

or Dolly Tow Rear

NOT AL-

LOWED NOT AL-

LOWED NOT AL-

LOWED

Front FWD Models

ONLY OKNOT AL-

LOWED FWD Models

ONLY

Flatbed ALLBEST

METHOD BEST

METHOD BEST

METHOD BEST

METHOD

Refer to” Towing A Disabled Vehicle” in the Owner’s Manual on the DVD for further

information.

WHAT TO DO IN EMERGENCIES

106

Page 109 of 148

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or snow, it can often be moved using a

rocking motion. Turn the steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between DRIVE and REVERSE (with

automatic transmission) or 2nd gear and REVERSE (with manual transmission),

while gently pressing the accelerator. Use the least amount of accelerator pedal

pressure that will maintain the rocking motion, without spinning the wheels, or racing

the engine.

CAUTION!

Racing the engine or spinning the wheels may lead to transmission overheating

and failure. Allow the engine to idle with the transmission in NEUTRAL for at least

one minute after every five rocking-motion cycles. This will minimize overheating

and reduce the risk of clutch or transmission failure during prolonged efforts to

free a stuck vehicle.

NOTE:

Push the "ESC Off" switch, to place the Electronic Stability Control (ESC) system in

"Partial Off" mode, before rocking the vehicle. Refer to “Electronic Brake Control” in

“Starting And Operating” in the Owner’s Manual on the DVD for further information.

Once the vehicle has been freed, push the "ESC Off" switch again to restore "ESC On"

mode.

CAUTION!

• When “rocking” a stuck vehicle by shifting between DRIVE/2nd gear and REVERSE, do not spin the wheels faster than 15 mph (24 km/h), or drivetrain

damage may result.

• Revving the engine or spinning the wheels too fast may lead to transmission

overheating and failure. It can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmission shifting occurring).

WARNING!

Fast spinning tires can be dangerous. Forces generated by excessive wheel speeds

may cause damage, or even failure, of the axle and tires. A tire could explode and

injure someone. Do not spin your vehicle's wheels faster than 30 mph (48 km/h)

or for longer than 30 seconds continuously without stopping when you are stuck

and do not let anyone near a spinning wheel, no matter what the speed.

WHAT TO DO IN EMERGENCIES

107

Page 110 of 148

ENHANCED ACCIDENT RESPONSE SYSTEM (EARS)

This vehicle is equipped with an Enhanced Accident Response System.

Please refer to “Supplemental Restraint System (SRS) — Air Bags” in “Getting

Started” in this guide for further information on the Enhanced Accident Response

System (EARS) function.

EVENT DATA RECORDER (EDR)

This vehicle is equipped with an event data recorder (EDR). The main purpose of an

EDR is to record, in certain crash or near crash-like situations, such as an air bag

deployment or hitting a road obstacle, data that will assist in understanding how a

vehicle’s systems performed.

Please refer to “Supplemental Restraint System (SRS) — Air Bags” in “Getting

Started” in this guide for further information on the Event Data Recorder (EDR).

WHAT TO DO IN EMERGENCIES

108