fuel type JEEP COMPASS 2017 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: COMPASS, Model: JEEP COMPASS 2017 2.GPages: 429, PDF Size: 3.46 MB

Page 200 of 429

engine fails to start, the starter will disengage automati-

cally in 10 seconds. If this occurs, turn the ignition switch

to the LOCK position, wait 10 to 15 seconds, then repeat

the “Normal Starting” procedure.

Normal Starting

Normal starting of either a cold or a warm engine does not

require pumping or pressing the accelerator pedal. Simply

turn the ignition switch to the START position and release

when the engine starts. If the engine fails to start within 15

seconds, turn the ignition switch to the OFF position, wait

10 to 15 seconds, then repeat the “Normal Starting” proce-

dure.

WARNING!

Do not attempt to push or tow your vehicle to get it

started. Vehicles equipped with an automatic transmis-

sion cannot be started this way. Unburned fuel could

enter the catalytic converter and once the engine has

started, ignite and damage the converter and vehicle. If

the vehicle has a discharged battery, booster cables

may be used to obtain a start from another vehicle.

This type of start can be dangerous if done improperly,

(Continued)

WARNING!(Continued)

so follow the procedure carefully. Refer to “Jump-

Starting” in “In Case Of Emergency” for further infor-

mation.

Extreme Cold Weather (Below –22°F Or �30°C)

To ensure reliable starting at these temperatures, use of an

externally powered electric engine block heater (available

from your authorized dealer) is recommended.

If Engine Fails To Start

If the engine fails to start after you have followed the

“Normal Starting” and “Extreme Cold Weather” proce-

dures, it may be flooded. Press the accelerator pedal all the

way to the floor and hold it there. Crank the engine for no

more than 15 seconds. This should clear any excess fuel in

case the engine is flooded. Leave the ignition key in the ON

position, release the accelerator pedal and repeat the “Nor-

mal Starting” procedure.

WARNING!

Never pour fuel or other flammable liquid into the

throttle body air inlet opening in an attempt to start the

(Continued)

198 STARTING AND OPERATING

Page 290 of 429

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If you

have any doubt about your ability to perform a service

job, take your vehicle to a competent mechanic.

Engine Oil

Change Engine Oil

The oil change indicator system will remind you that it is

time to take your vehicle in for scheduled maintenance.

Refer to the “Maintenance Plan” for further information.

NOTE:Under no circumstances should oil change inter-

vals exceed 10,000 miles (16,000 km), twelve months or 350

hours of engine run time, whichever comes first. The 350

hours of engine run or idle time is generally only a concern

for fleet customers.

Engine Oil Selection

For best performance and maximum protection under all

types of operating conditions, the manufacturer only rec-

ommends engine oils that are API Certified and meet the

requirements of FCA Material Standard MS-6395.

American Petroleum Institute (API) Engine Oil

Identification Symbol

This symbol means that the oil has

been certified by the American Pe-

troleum Institute (API). The manu-

facturer only recommends API Cer-

tified engine oils.

This symbol certifies 0W-20, 5W-20,

0W-30, 5W-30 and 10W-30 engine

oils.

CAUTION!

Do not use chemical flushes in your engine oil as the

chemicals can damage your engine. Such damage is not

covered by the New Vehicle Limited Warranty.

Engine Oil Viscosity (SAE Grade) — 2.0L, 2.4L

Engine

MOPAR SAE 5W-20 engine oil approved to FCA Material

Standard MS-6395 such as Pennzoil, Shell Helix or equiva-

lent is recommended for all operating temperatures. This

engine oil improves low temperature starting and vehicle

fuel economy.

288 SERVICING AND MAINTENANCE

Page 316 of 429

Fuel Economy

Underinflated tires will increase tire rolling resistance

resulting in higher fuel consumption.

Tread Wear

Improper cold tire inflation pressures can cause abnormal

wear patterns and reduced tread life, resulting in the need

for earlier tire replacement.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a comfortable ride.

Over-inflation produces a jarring and uncomfortable ride.

Tire Inflation Pressures

The proper cold tire inflation pressure is listed on the

driver’s side B-Pillar or rear edge of the driver’s side door.

At least once a month:

•Check and adjust tire pressure with a good quality

pocket-type pressure gauge. Do not make a visual

judgement when determining proper inflation. Tires

may look properly inflated even when they are under-

inflated.

• Inspect tires for signs of tire wear or visible damage.

CAUTION!

After inspecting or adjusting the tire pressure, always

reinstall the valve stem cap. This will prevent moisture

and dirt from entering the valve stem, which could

damage the valve stem.

Inflation pressures specified on the placard are always

“cold tire inflation pressure”. Cold tire inflation pressure is

defined as the tire pressure after the vehicle has not been

driven for at least three hours, or driven less than 1 mile

(1.6 km) after sitting for a minimum of three hours. The

cold tire inflation pressure must not exceed the maximum

inflation pressure molded into the tire sidewall.

Check tire pressures more often if subject to a wide range

of outdoor temperatures, as tire pressures vary with tem-

perature changes.

Tire pressures change by approximately 1 psi (7 kPa) per

12°F (7°C) of air temperature change. Keep this in mind

when checking tire pressure inside a garage, especially in

the Winter.

Example: If garage temperature = 68°F (20°C) and the

outside temperature = 32°F (0°C) then the cold tire inflation

314 SERVICING AND MAINTENANCE

Page 414 of 429

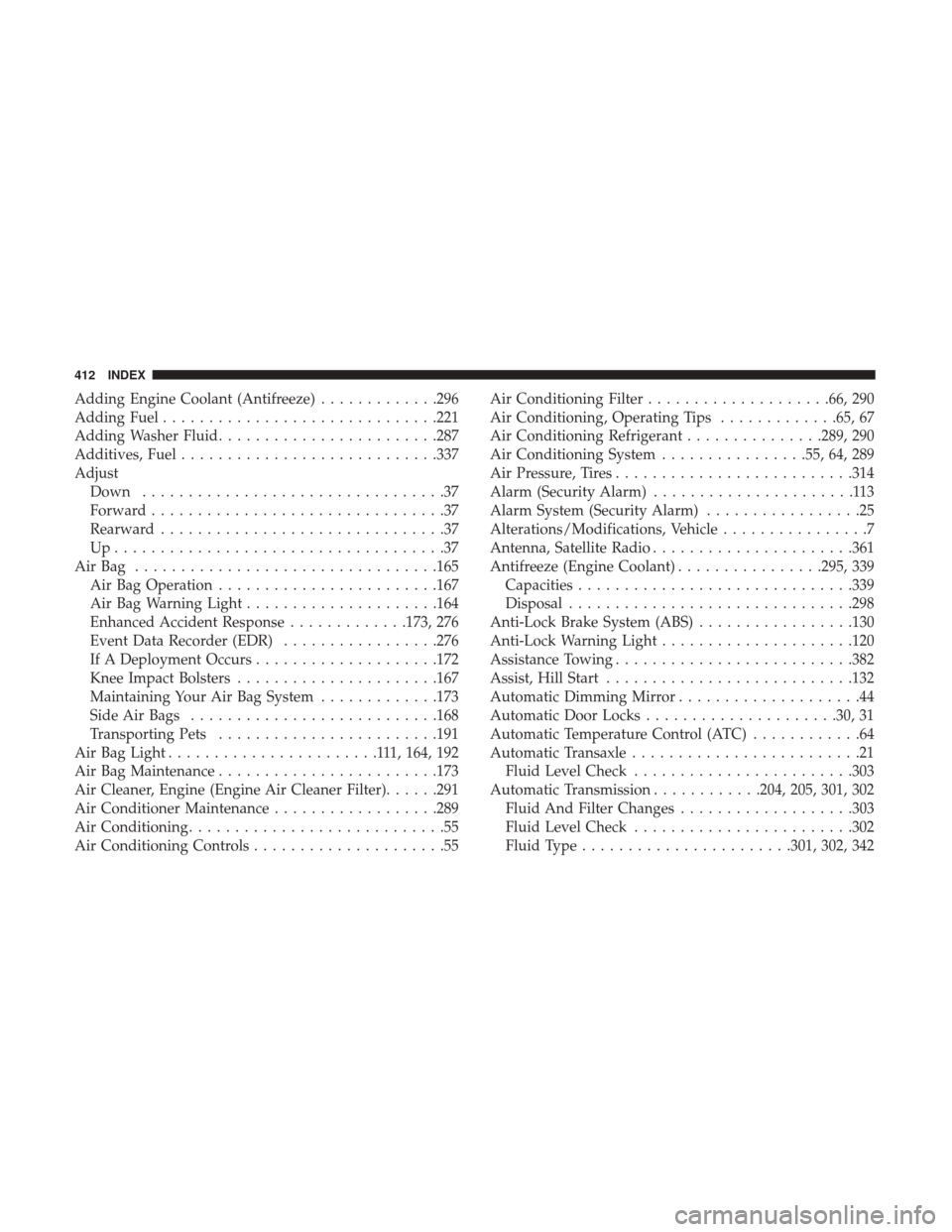

Adding Engine Coolant (Antifreeze).............296

Adding Fuel ............................. .221

Adding Washer Fluid ........................287

Additives, Fuel ............................337

Adjust Down .................................37

Forward ................................37

Rearward ...............................37

Up....................................37

AirBag ................................ .165

Air Bag Operation ........................167

Air Bag Warning Light .....................164

Enhanced Accident Response .............173, 276

Event Data Recorder (EDR) .................276

If A Deployment Occurs ....................172

Knee Impact Bolsters ..................... .167

Maintaining Your Air Bag System .............173

Side Air Bags .......................... .168

Transporting Pets ........................191

Air Bag Light .......................111, 164, 192

Air Bag Maintenance ........................173

Air Cleaner, Engine (Engine Air Cleaner Filter) ......291

Air Conditioner Maintenance ..................289

Air Conditioning ............................55

Air Conditioning Controls .....................55 Air Conditioning Filter

....................66, 290

Air Conditioning, Operating Tips .............65, 67

Air Conditioning Refrigerant ...............289, 290

Air Conditioning System ................55, 64, 289

Air Pressure, Tires ..........................314

Alarm (Security Alarm) ......................113

Alarm System (Security Alarm) .................25

Alterations/Modifications, Vehicle ................7

Antenna, Satellite Radio ..................... .361

Antifreeze (Engine Coolant) ................295, 339

Capacities ............................. .339

Disposal ...............................298

Anti-Lock Brake System (ABS) .................130

Anti-Lock Warning Light .....................120

Assistance T owing.........................

.382

Assist, Hill Start .......................... .132

Automatic Dimming Mirror ....................44

Automatic Door Locks .....................30, 31

Automatic Temperature Control (ATC) ............64

Automatic Transaxle .........................21

Fluid Level Check ........................303

Automatic Transmission ............204, 205, 301, 302

Fluid And Filter Changes ...................303

Fluid Level Check ........................302

Fluid Type .......................301, 302, 342

412 INDEX