warning JEEP GLADIATOR 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GLADIATOR, Model: JEEP GLADIATOR 2023Pages: 448, PDF Size: 17.37 MB

Page 194 of 448

192STARTING AND OPERATING

3. Fully insert the gasoline nozzle into the filler pipe. Fill the vehicle with fuel.

4. When the fuel nozzle “clicks” or shuts off, the fuel tank is full. Wait five seconds before

removing the fuel nozzle to allow excess fuel to

drain from nozzle.

5. Remove gasoline nozzle, reinstall fuel cap and close the fuel filler door.

NOTE:

When the fuel nozzle “clicks” or shuts off, the

fuel tank is full.

Tighten the fuel filler cap about a quarter turn

until you hear one click. This is an indication that

the cap is properly tightened.

If the fuel filler cap is not tightened properly, the

MIL will come on. Be sure the cap is tightened

every time the vehicle is refueled.

LOOSE FUEL FILLER CAP MESSAGE

After fuel has been added, the vehicle diagnostic

system can determine if the fuel filler cap is

possibly loose, improperly installed, or damaged. If

the system detects a malfunction, the “gASCAP”

message will display in the odometer display.

Tighten the gas cap until a "clicking" sound is heard. This is an indication that the gas cap is

properly tightened. Push the odometer reset

button to turn the message off. If the problem

persists, the message will appear the next time the

vehicle is started. This might indicate a damaged

cap. If the problem is detected twice in a row, the

system will turn on the MIL. Resolving the problem

will turn the MIL off.

REFUELING THE VEHICLE — DIESEL ENGINE

(IF EQUIPPED)

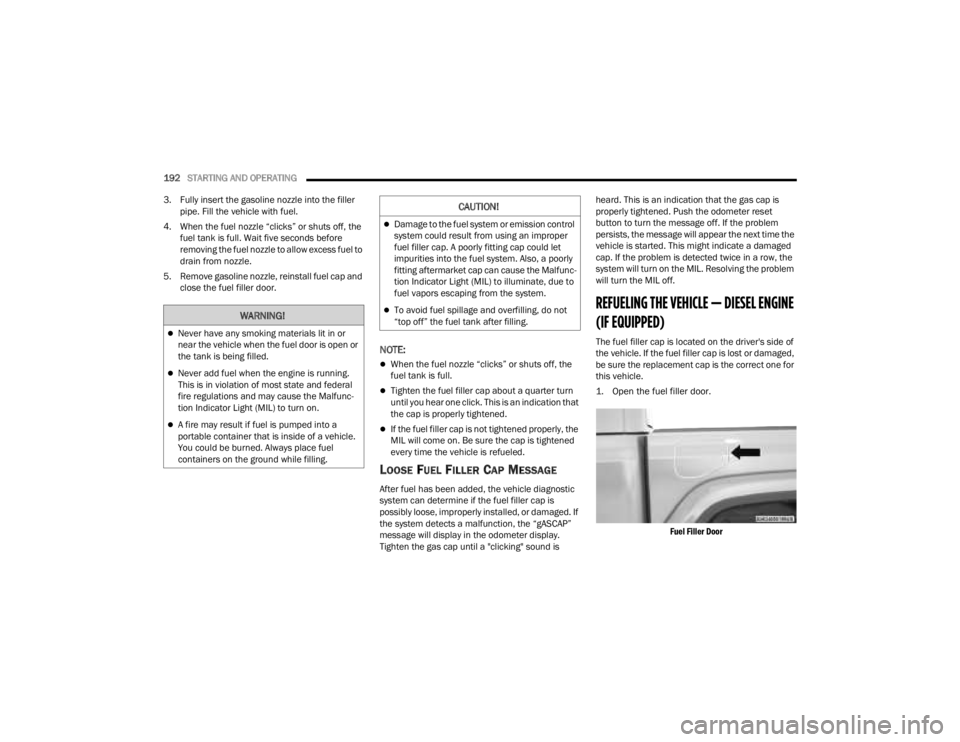

The fuel filler cap is located on the driver's side of

the vehicle. If the fuel filler cap is lost or damaged,

be sure the replacement cap is the correct one for

this vehicle.

1. Open the fuel filler door.

Fuel Filler Door

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light (MIL) to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

CAUTION!

Damage to the fuel system or emission control

system could result from using an improper

fuel filler cap. A poorly fitting cap could let

impurities into the fuel system. Also, a poorly

fitting aftermarket cap can cause the Malfunc -

tion Indicator Light (MIL) to illuminate, due to

fuel vapors escaping from the system.

To avoid fuel spillage and overfilling, do not

“top off” the fuel tank after filling.

23_JT_OM_EN_USC_t.book Page 192

Page 195 of 448

STARTING AND OPERATING193

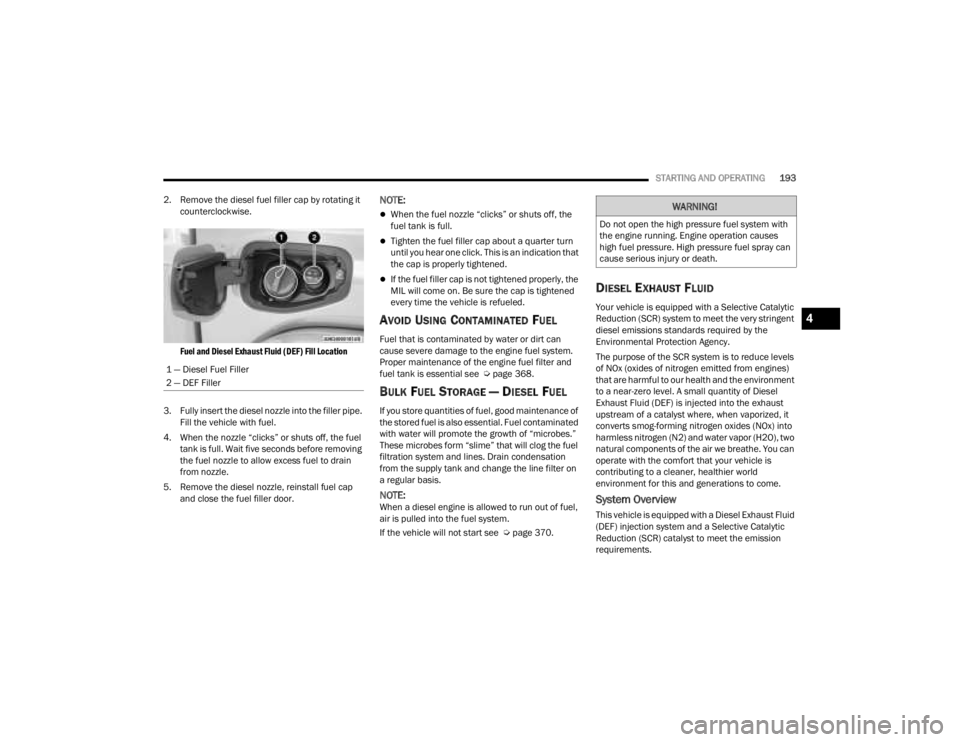

2. Remove the diesel fuel filler cap by rotating it counterclockwise.

Fuel and Diesel Exhaust Fluid (DEF) Fill Location

3. Fully insert the diesel nozzle into the filler pipe. Fill the vehicle with fuel.

4. When the nozzle “clicks” or shuts off, the fuel tank is full. Wait five seconds before removing

the fuel nozzle to allow excess fuel to drain

from nozzle.

5. Remove the diesel nozzle, reinstall fuel cap and close the fuel filler door.

NOTE:

When the fuel nozzle “clicks” or shuts off, the

fuel tank is full.

Tighten the fuel filler cap about a quarter turn

until you hear one click. This is an indication that

the cap is properly tightened.

If the fuel filler cap is not tightened properly, the

MIL will come on. Be sure the cap is tightened

every time the vehicle is refueled.

AVOID USING CONTAMINATED FUEL

Fuel that is contaminated by water or dirt can

cause severe damage to the engine fuel system.

Proper maintenance of the engine fuel filter and

fuel tank is essential see Ú page 368.

BULK FUEL STORAGE — DIESEL FUEL

If you store quantities of fuel, good maintenance of

the stored fuel is also essential. Fuel contaminated

with water will promote the growth of “microbes.”

These microbes form “slime” that will clog the fuel

filtration system and lines. Drain condensation

from the supply tank and change the line filter on

a regular basis.

NOTE:When a diesel engine is allowed to run out of fuel,

air is pulled into the fuel system.

If the vehicle will not start see Ú page 370.

DIESEL EXHAUST FLUID

Your vehicle is equipped with a Selective Catalytic

Reduction (SCR) system to meet the very stringent

diesel emissions standards required by the

Environmental Protection Agency.

The purpose of the SCR system is to reduce levels

of NOx (oxides of nitrogen emitted from engines)

that are harmful to our health and the environment

to a near-zero level. A small quantity of Diesel

Exhaust Fluid (DEF) is injected into the exhaust

upstream of a catalyst where, when vaporized, it

converts smog-forming nitrogen oxides (NOx) into

harmless nitrogen (N2) and water vapor (H2O), two

natural components of the air we breathe. You can

operate with the comfort that your vehicle is

contributing to a cleaner, healthier world

environment for this and generations to come.

System Overview

This vehicle is equipped with a Diesel Exhaust Fluid

(DEF) injection system and a Selective Catalytic

Reduction (SCR) catalyst to meet the emission

requirements.

1 — Diesel Fuel Filler

2 — DEF Filler

WARNING!

Do not open the high pressure fuel system with

the engine running. Engine operation causes

high fuel pressure. High pressure fuel spray can

cause serious injury or death.

4

23_JT_OM_EN_USC_t.book Page 193

Page 196 of 448

194STARTING AND OPERATING

The DEF injection system consists of the following

components:

DEF tank

DEF pump

DEF injector

Electronically-heated DEF Lines

NOx sensors

Temperature sensors

SCR catalyst

The DEF injection system and SCR catalyst enable

the achievement of diesel emissions

requirements; while maintaining outstanding fuel

economy, drivability, torque and power ratings.

For system messages and warnings see

Ú page 121.

NOTE:

Your vehicle is equipped with a DEF injection

system. You may occasionally hear an audible

clicking noise from under the vehicle at a stop.

This is normal operation.

The DEF pump will run for a period of time after

engine shutdown to purge the DEF system. This

is normal operation and may be audible from

the rear of the vehicle.

Diesel Exhaust Fluid Storage

Diesel Exhaust Fluid (DEF) is considered a very

stable product with a long shelf life. If DEF is kept

in temperatures between 10° and 90°F (-12° and

32°C), it will last a minimum of one year.

DEF is subject to freezing at the lowest

temperatures. For example, DEF may freeze at

temperatures at or below 12°F (-11°C). The

system has been designed to operate in this

environment.

NOTE:When working with DEF, it is important to know

that:

Any containers or parts that come into contact

with DEF must be DEF compatible (plastic or

stainless steel). Copper, brass, aluminum, iron

or non-stainless steel should be avoided as they

are subject to corrosion by DEF.

If DEF is spilled, it should be wiped up

completely.

Adding Diesel Exhaust Fluid

The DEF gauge (located on the instrument cluster

display) will display the level of DEF remaining in

the tank Ú page 121.

NOTE:Driving conditions (altitude, vehicle speed, load,

etc.) will affect the amount of DEF that is used in

your vehicle.

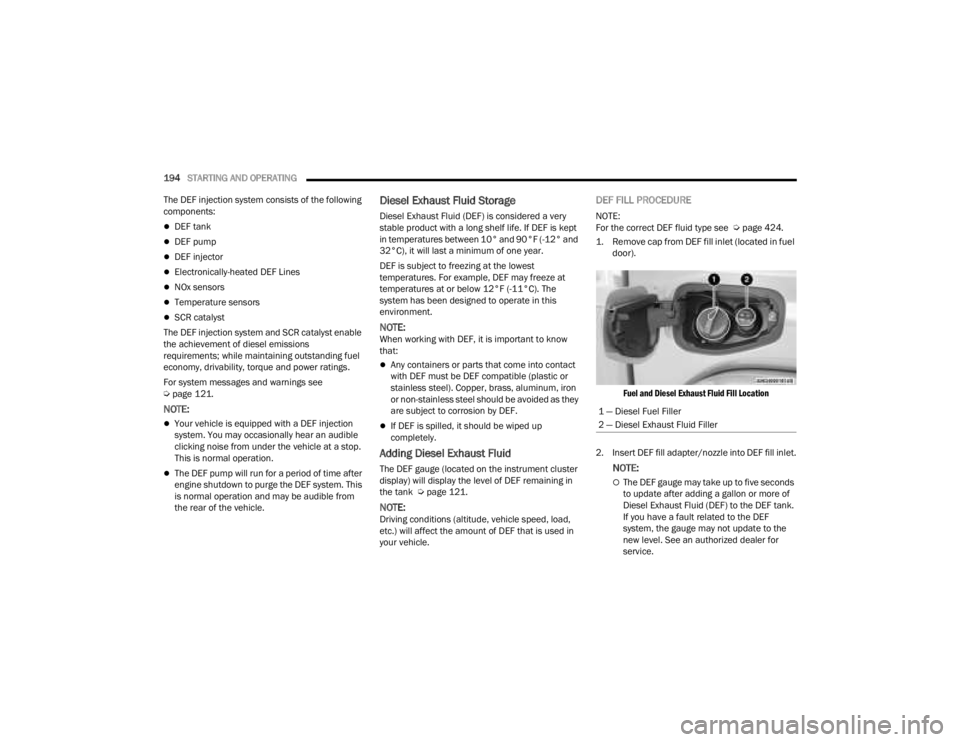

DEF FILL PROCEDURE

NOTE:

For the correct DEF fluid type see Ú page 424.

1. Remove cap from DEF fill inlet (located in fuel door).

Fuel and Diesel Exhaust Fluid Fill Location

2. Insert DEF fill adapter/nozzle into DEF fill inlet.

NOTE:

The DEF gauge may take up to five seconds

to update after adding a gallon or more of

Diesel Exhaust Fluid (DEF) to the DEF tank.

If you have a fault related to the DEF

system, the gauge may not update to the

new level. See an authorized dealer for

service.

1 — Diesel Fuel Filler

2 — Diesel Exhaust Fluid Filler

23_JT_OM_EN_USC_t.book Page 194

Page 198 of 448

196STARTING AND OPERATING

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), front and rear Gross Axle Weight Rating

(GAWR), and Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is included on this

label and indicates the Month, Day and Hour of

manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear Gross Axle

Weight Rating (GAWR). Total load must be limited

so GVWR on front and rear GAWR are not

exceeded.

Payload

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The

front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

Loading

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has not

been exceeded. The weight on the front and rear of

the vehicle should then be determined separately

to be sure that the load is properly distributed over

the front and rear axle. Weighing the vehicle may

show that the GAWR of either the front or rear axles

has been exceeded but the total load is within the

specified GVWR. If so, weight must be shifted from

front to rear or rear to front as appropriate until the

specified weight limitations are met. Store the

heavier items down low and be sure that the

weight is distributed equally. Stow all loose items

securely before driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

WARNING!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR. If

you do, parts on your vehicle can break, or it can

change the way your vehicle handles. This could

cause you to lose control. Overloading can

shorten the life of your vehicle.

23_JT_OM_EN_USC_t.book Page 196

Page 199 of 448

STARTING AND OPERATING197

TRAILER TOWING

In this section you will find safety tips and

information on limits to the type of towing you can

reasonably do with your vehicle. Before towing a

trailer, carefully review this information to tow your

load as efficiently and safely as possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and

recommendations in this manual concerning

vehicles used for trailer towing.

COMMON TOWING DEFINITIONS

The following trailer towing related definitions will

assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be limited

so that you do not exceed the GVWR Ú page 195.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the weight

of all cargo, consumables and equipment

(permanent or temporary) loaded in or on the trailer

in its "loaded and ready for operation" condition.

The recommended way to measure GTW is to put

your fully loaded trailer on a vehicle scale. The

entire weight of the trailer must be supported by

the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total permissible weight of your

vehicle and trailer when weighed in combination.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR Úpage 195.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch

ball by the trailer. You must consider this as part of

the load on your vehicle.

Frontal Area

The frontal area is the maximum height multiplied

by the maximum width of the front of a trailer.

Trailer Sway Control (TSC) — If Equipped

The TSC is a telescoping link that can be installed

between the hitch receiver and the trailer tongue.

It typically provides adjustable friction associated

with the telescoping motion to dampen any

unwanted trailer swaying motions while traveling.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

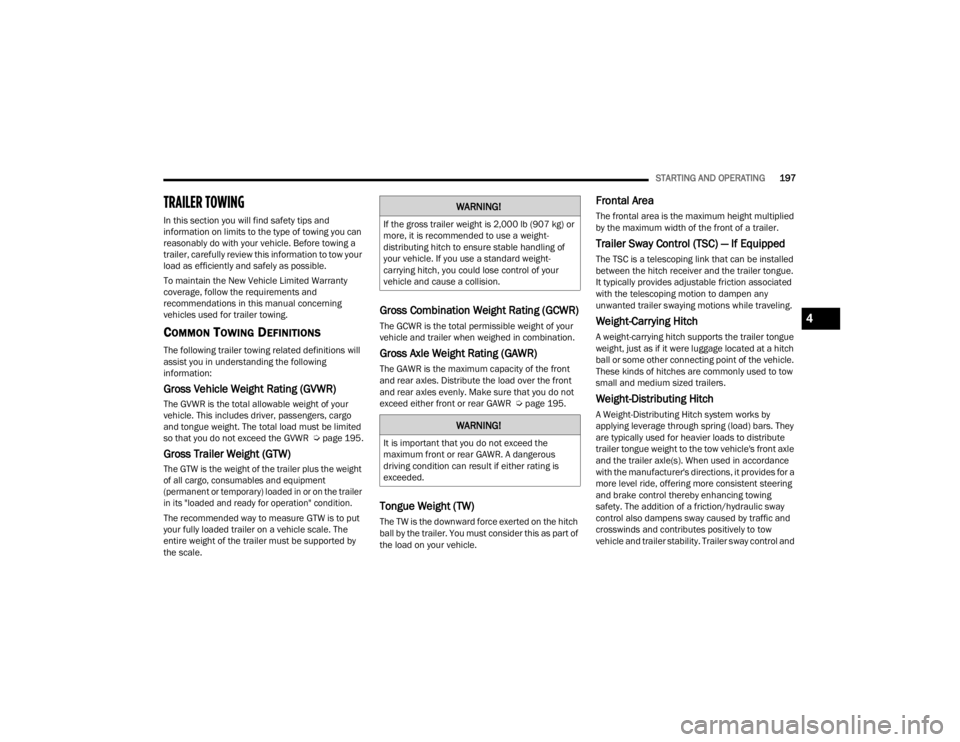

Weight-Distributing Hitch

A Weight-Distributing Hitch system works by

applying leverage through spring (load) bars. They

are typically used for heavier loads to distribute

trailer tongue weight to the tow vehicle's front axle

and the trailer axle(s). When used in accordance

with the manufacturer's directions, it provides for a

more level ride, offering more consistent steering

and brake control thereby enhancing towing

safety. The addition of a friction/hydraulic sway

control also dampens sway caused by traffic and

crosswinds and contributes positively to tow

vehicle and trailer stability. Trailer sway control and

WARNING!

If the gross trailer weight is 2,000 lb (907 kg) or

more, it is recommended to use a weight-

distributing hitch to ensure stable handling of

your vehicle. If you use a standard weight-

carrying hitch, you could lose control of your

vehicle and cause a collision.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded.

4

23_JT_OM_EN_USC_t.book Page 197

Page 200 of 448

198STARTING AND OPERATING

a Weight-Distributing (load equalizing) Hitch are

recommended for heavier Tongue Weights (TW)

and may be required depending on vehicle and

trailer configuration/loading to comply with Gross

Axle Weight Rating (GAWR) requirements.

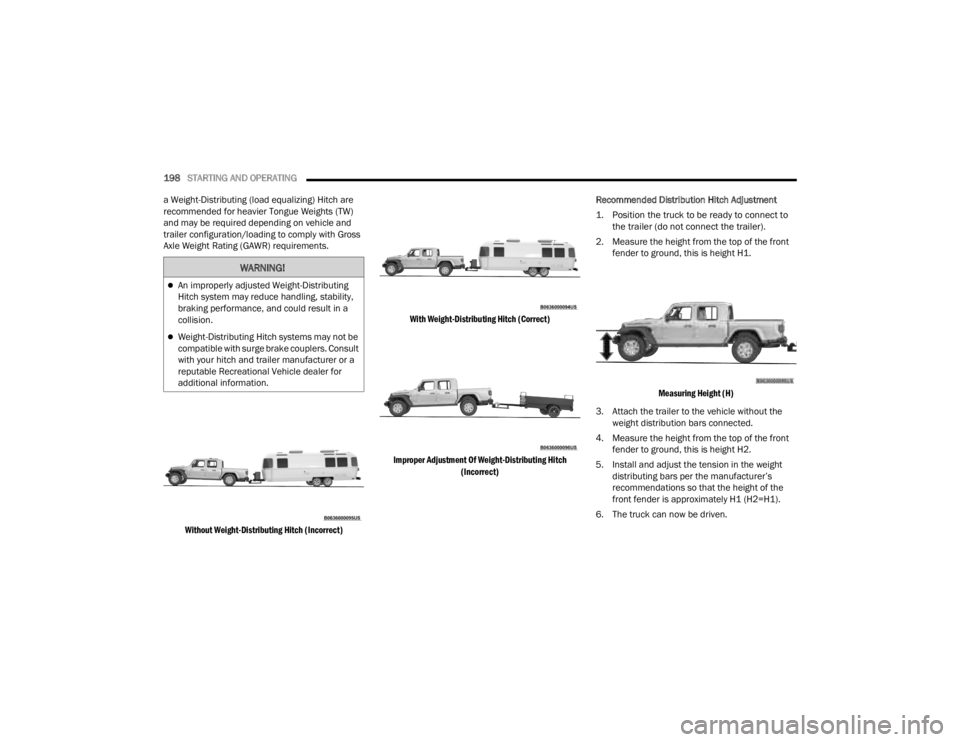

Without Weight-Distributing Hitch (Incorrect) With Weight-Distributing Hitch (Correct)

Improper Adjustment Of Weight-Distributing Hitch (Incorrect)

Recommended Distribution Hitch Adjustment

1. Position the truck to be ready to connect to

the trailer (do not connect the trailer).

2. Measure the height from the top of the front fender to ground, this is height H1.

Measuring Height (H)

3. Attach the trailer to the vehicle without the weight distribution bars connected.

4. Measure the height from the top of the front fender to ground, this is height H2.

5. Install and adjust the tension in the weight distributing bars per the manufacturer’s

recommendations so that the height of the

front fender is approximately H1 (H2=H1).

6. The truck can now be driven.

WARNING!

An improperly adjusted Weight-Distributing

Hitch system may reduce handling, stability,

braking performance, and could result in a

collision.

Weight-Distributing Hitch systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

23_JT_OM_EN_USC_t.book Page 198

Page 204 of 448

202STARTING AND OPERATING

(Continued)

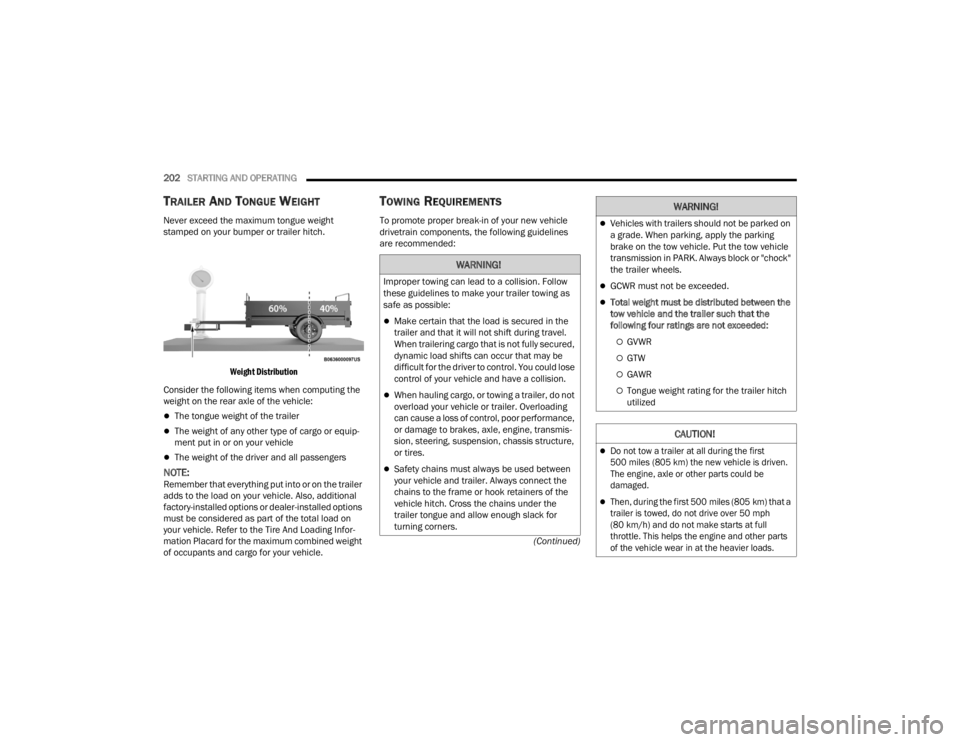

TRAILER AND TONGUE WEIGHT

Never exceed the maximum tongue weight

stamped on your bumper or trailer hitch.

Weight Distribution

Consider the following items when computing the

weight on the rear axle of the vehicle:

The tongue weight of the trailer

The weight of any other type of cargo or equip -

ment put in or on your vehicle

The weight of the driver and all passengers

NOTE:Remember that everything put into or on the trailer

adds to the load on your vehicle. Also, additional

factory-installed options or dealer-installed options

must be considered as part of the total load on

your vehicle. Refer to the Tire And Loading Infor -

mation Placard for the maximum combined weight

of occupants and cargo for your vehicle.

TOWING REQUIREMENTS

To promote proper break-in of your new vehicle

drivetrain components, the following guidelines

are recommended:

WARNING!

Improper towing can lead to a collision. Follow

these guidelines to make your trailer towing as

safe as possible:

Make certain that the load is secured in the

trailer and that it will not shift during travel.

When trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could lose

control of your vehicle and have a collision.

When hauling cargo, or towing a trailer, do not

overload your vehicle or trailer. Overloading

can cause a loss of control, poor performance,

or damage to brakes, axle, engine, transmis -

sion, steering, suspension, chassis structure,

or tires.

Safety chains must always be used between

your vehicle and trailer. Always connect the

chains to the frame or hook retainers of the

vehicle hitch. Cross the chains under the

trailer tongue and allow enough slack for

turning corners.

Vehicles with trailers should not be parked on

a grade. When parking, apply the parking

brake on the tow vehicle. Put the tow vehicle

transmission in PARK. Always block or "chock"

the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between the

tow vehicle and the trailer such that the

following four ratings are not exceeded:

GVWR

GTW

GAWR

Tongue weight rating for the trailer hitch

utilized

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is driven.

The engine, axle or other parts could be

damaged.

Then, during the first 500 miles (805 km) that a

trailer is towed, do not drive over 50 mph

(80 km/h) and do not make starts at full

throttle. This helps the engine and other parts

of the vehicle wear in at the heavier loads.

WARNING!

23_JT_OM_EN_USC_t.book Page 202

Page 205 of 448

STARTING AND OPERATING203

Towing Requirements — Tires

Proper tire inflation pressures are essential to

the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For further information Úpage 395.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system

or vacuum system of your vehicle with that of

the trailer. This could cause inadequate braking

and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer with

electronically actuated brakes. When towing a

trailer equipped with a hydraulic surge actuated

brake system, an electronic brake controller is

not required.

NOTE:This vehicle has an aftermarket brake controller

connector under the dash to the left of the brake

pedal. This will be a four pin connector and will be

gray in color.

Trailer brakes are recommended for trailers

over 1,000 lb (453 kg) and required for trailers

in excess of 2,000 lb (907 kg).Towing Requirements — Trailer Lights And

Wiring

Whenever you pull a trailer, regardless of the trailer

size, stop lights and turn signals on the trailer are

required for motoring safety.

The Trailer Tow Package may include a four- and

seven-pin wiring harness. Use a factory approved

trailer harness and connector.

NOTE:Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the

vehicle but you must mate the harness to a trailer

connector. Refer to the following illustrations.

NOTE:

Disconnect the trailer wiring connector from the

vehicle (or any other device plugged into

vehicle’s electrical connectors) before

launching a boat into water.

Be sure to reconnect once clear from water

area.

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your

brake system and cause it to fail. You might

not have brakes when you need them and

could have an accident.

Towing any trailer will increase your stopping

distance. When towing, you should allow for

additional space between your vehicle and the

vehicle in front of you. Failure to do so could

result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do

this could lead to accelerated brake lining wear,

higher brake pedal effort, and longer stopping

distances.

4

23_JT_OM_EN_USC_t.book Page 203

Page 208 of 448

206STARTING AND OPERATING

Shifting Into N (Neutral)

Use the following procedure to prepare your

vehicle for recreational towing.

1. Bring the vehicle to a complete stop on level

ground.

2. Press and hold the brake pedal.

3. Shift the automatic transmission into NEUTRAL or press the clutch pedal on a

manual transmission. 4. Turn the engine off.

5. Shift the transfer case lever into N (Neutral).

6. Start the engine.

7. Shift the transmission into DRIVE or REVERSE.

8. Release the brake pedal (and clutch pedal on

manual transmissions) for five seconds and

ensure that there is no vehicle movement.

9. Repeat steps 7 and 8 with automatic transmission in DRIVE or manual transmission

in first gear.

10. Turn the engine off.

11. Firmly apply the parking brake.

12. Shift the transmission into PARK or place manual transmission in gear (NOT in

NEUTRAL).

13. Attach the vehicle to the tow vehicle using a suitable tow bar.

14. Release the parking brake.Automatic transmissions must be placed in

PARK for recreational towing.

Manual transmissions must be placed in gear

(not in Neutral) for recreational towing.

Before recreational towing, perform the proce -

dure outlined under “Shifting Into N (Neutral)”

to be certain that the transfer case is fully in N

(Neutral). Otherwise, internal damage will

result.

Towing this vehicle in violation of the above

requirements can cause severe transmission

and/or transfer case damage. Damage from

improper towing is not covered under the New

Vehicle Limited Warranty.

Do not use a bumper-mounted clamp-on tow

bar on your vehicle. The bumper face bar will

be damaged.

CAUTION!

WARNING!

You or others could be injured or killed if you

leave the vehicle unattended with the transfer

case in the N (Neutral) position without first fully

engaging the parking brake. The transfer case N

(Neutral) position disengages both the front and

rear driveshafts from the powertrain, and will

allow the vehicle to roll, even if the automatic

transmission is in PARK (or manual transmission

is in gear). The parking brake should always be

applied when the driver is not in the vehicle.

CAUTION!

It is necessary to follow these steps to be certain

that the transfer case is fully in N (Neutral)

before recreational towing to prevent damage to

internal parts.CAUTION!

Damage to the transmission may occur if the

transmission is shifted into PARK with the

transfer case in N (Neutral) and the engine

running. With the transfer case in N (Neutral)

ensure that the engine is OFF before shifting the

transmission into PARK.

23_JT_OM_EN_USC_t.book Page 206

Page 210 of 448

208STARTING AND OPERATING

3. After all bolts and nuts have been removed, pull the side step assembly off of the vehicle.

4. To reinstall the side steps align the studs to the body side holes and fasten all nuts on all four

brackets. Then secure all four bolts to the

underbody. Repeat the reassembly procedure

for the other side.

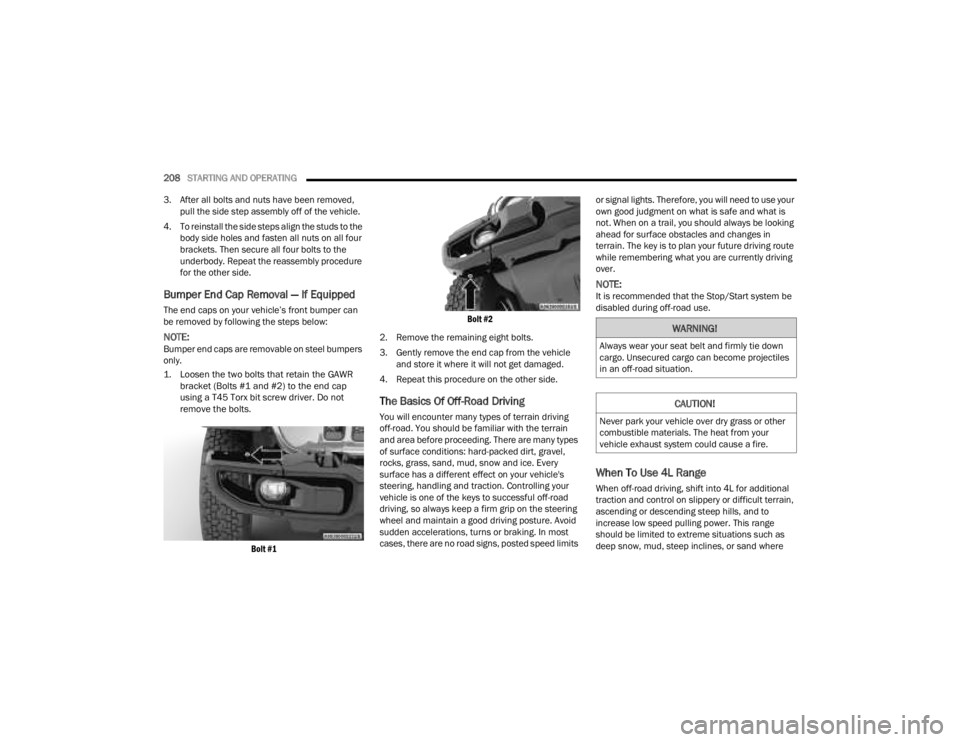

Bumper End Cap Removal — If Equipped

The end caps on your vehicle’s front bumper can

be removed by following the steps below:

NOTE:Bumper end caps are removable on steel bumpers

only.

1. Loosen the two bolts that retain the GAWR bracket (Bolts #1 and #2) to the end cap

using a T45 Torx bit screw driver. Do not

remove the bolts.

Bolt #1 Bolt #2

2. Remove the remaining eight bolts.

3. Gently remove the end cap from the vehicle and store it where it will not get damaged.

4. Repeat this procedure on the other side.

The Basics Of Off-Road Driving

You will encounter many types of terrain driving

off-road. You should be familiar with the terrain

and area before proceeding. There are many types

of surface conditions: hard-packed dirt, gravel,

rocks, grass, sand, mud, snow and ice. Every

surface has a different effect on your vehicle's

steering, handling and traction. Controlling your

vehicle is one of the keys to successful off-road

driving, so always keep a firm grip on the steering

wheel and maintain a good driving posture. Avoid

sudden accelerations, turns or braking. In most

cases, there are no road signs, posted speed limits or signal lights. Therefore, you will need to use your

own good judgment on what is safe and what is

not. When on a trail, you should always be looking

ahead for surface obstacles and changes in

terrain. The key is to plan your future driving route

while remembering what you are currently driving

over.

NOTE:It is recommended that the Stop/Start system be

disabled during off-road use.

When To Use 4L Range

When off-road driving, shift into 4L for additional

traction and control on slippery or difficult terrain,

ascending or descending steep hills, and to

increase low speed pulling power. This range

should be limited to extreme situations such as

deep snow, mud, steep inclines, or sand where

WARNING!

Always wear your seat belt and firmly tie down

cargo. Unsecured cargo can become projectiles

in an off-road situation.

CAUTION!

Never park your vehicle over dry grass or other

combustible materials. The heat from your

vehicle exhaust system could cause a fire.

23_JT_OM_EN_USC_t.book Page 208