light JEEP GLADIATOR 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GLADIATOR, Model: JEEP GLADIATOR 2023Pages: 448, PDF Size: 17.37 MB

Page 348 of 448

346IN CASE OF EMERGENCY

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, follow the discon -

necting procedure.

Disconnecting The Jumper Cables

1. Disconnect the negative

(-)

end of the jumper

cable from the engine ground of the vehicle

with the discharged battery.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery. 3. Disconnect the positive

(+) end of the jumper

cable from the positive (+) post of the booster

battery.

4. Disconnect the opposite end of the positive (+)

jumper cable from the positive (+) post of the

discharged vehicle.

5. Reinstall the protective cover over the positive (+) post of the discharged vehicle.

If frequent jump starting is required to start your

vehicle you should have the battery and charging

system tested at an authorized dealer.

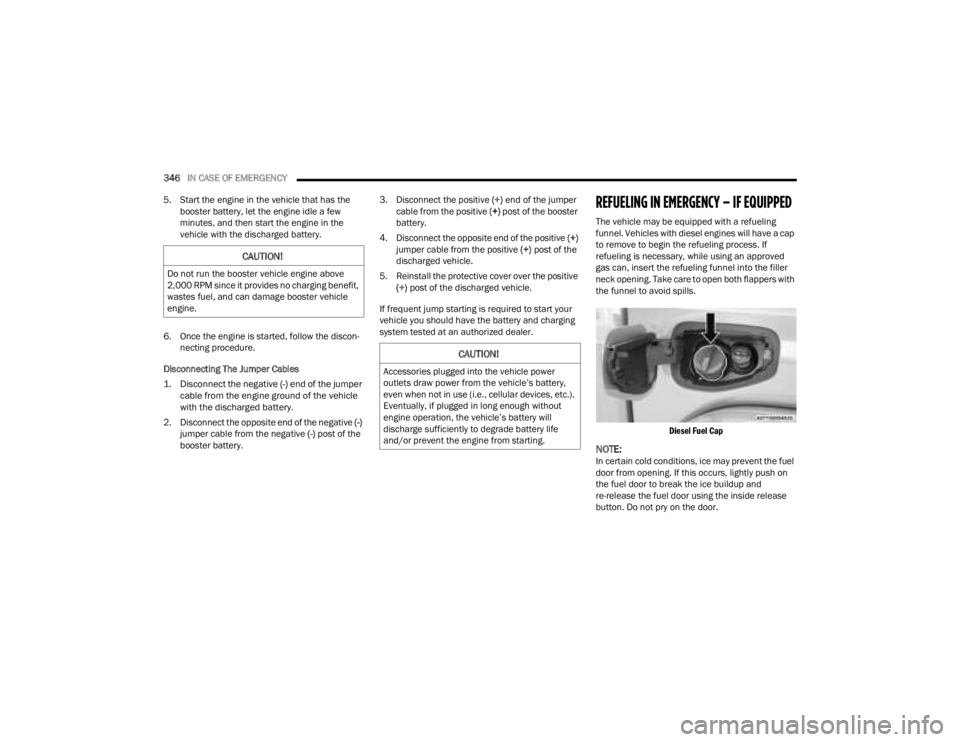

REFUELING IN EMERGENCY – IF EQUIPPED

The vehicle may be equipped with a refueling

funnel. Vehicles with diesel engines will have a cap

to remove to begin the refueling process. If

refueling is necessary, while using an approved

gas can, insert the refueling funnel into the filler

neck opening. Take care to open both flappers with

the funnel to avoid spills.

Diesel Fuel Cap

NOTE:In certain cold conditions, ice may prevent the fuel

door from opening. If this occurs, lightly push on

the fuel door to break the ice buildup and

re-release the fuel door using the inside release

button. Do not pry on the door.

CAUTION!

Do not run the booster vehicle engine above

2,000 RPM since it provides no charging benefit,

wastes fuel, and can damage booster vehicle

engine.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

23_JT_OM_EN_USC_t.book Page 346

Page 349 of 448

IN CASE OF EMERGENCY347

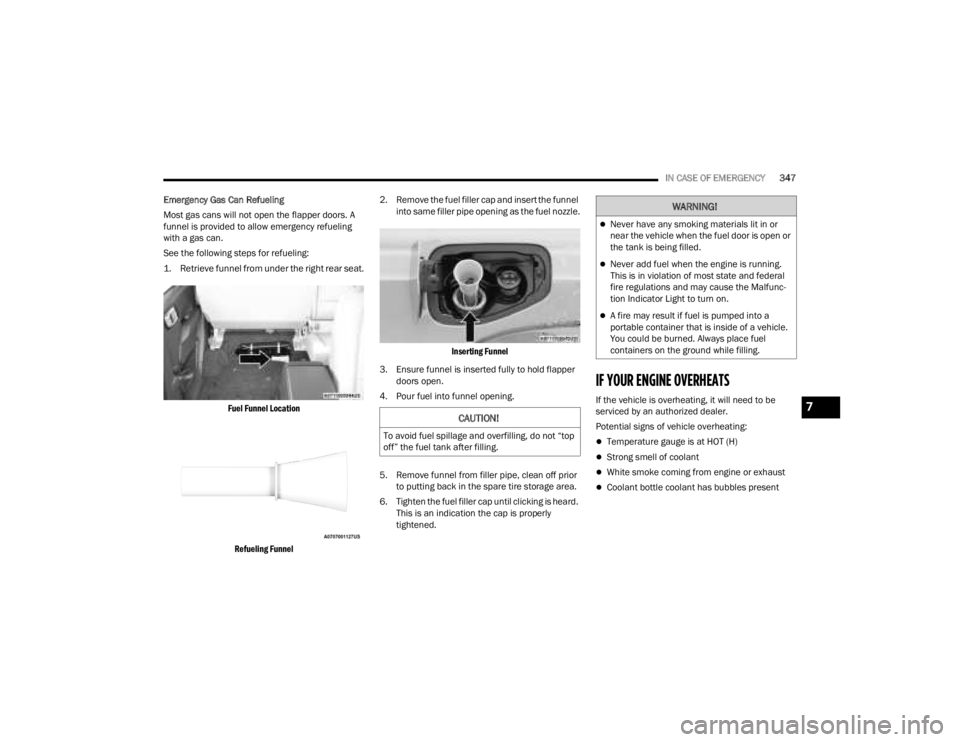

Emergency Gas Can Refueling

Most gas cans will not open the flapper doors. A

funnel is provided to allow emergency refueling

with a gas can.

See the following steps for refueling:

1. Retrieve funnel from under the right rear seat.

Fuel Funnel Location

Refueling Funnel

2. Remove the fuel filler cap and insert the funnel

into same filler pipe opening as the fuel nozzle.

Inserting Funnel

3. Ensure funnel is inserted fully to hold flapper doors open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off prior to putting back in the spare tire storage area.

6. Tighten the fuel filler cap until clicking is heard. This is an indication the cap is properly

tightened.

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be

serviced by an authorized dealer.

Potential signs of vehicle overheating:

Temperature gauge is at HOT (H)

Strong smell of coolant

White smoke coming from engine or exhaust

Coolant bottle coolant has bubbles present

CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

7

23_JT_OM_EN_USC_t.book Page 347

Page 355 of 448

353

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — GASOLINE

ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, or extremely hot or cold ambient

temperatures will influence when the “Change Oil”

or “Oil Change Required” message is displayed.

Have your vehicle serviced as soon as possible,

within the next 500 miles (805 km).

On vehicles equipped with an instrument cluster

display, “Oil Change Required” will be displayed

and a single chime will sound, indicating that an oil

change is necessary. On vehicles not equipped with an instrument

cluster display, “Change Oil” will flash in the

instrument cluster odometer and a single chime

will sound, indicating that an oil change is

necessary.

An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. To reset the system follow the steps

described Ú

page 122.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check the tire pressures and look for unusual

wear or damage, rotate at the first sign of irreg

-

ular wear.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering, and

fill as needed.

Check function of all interior and exterior lights.

8

23_JT_OM_EN_USC_t.book Page 353

Page 359 of 448

SERVICING AND MAINTENANCE357

SCHEDULED SERVICING — DIESEL ENGINE

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, extremely hot or cold ambient

temperatures will influence when the “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km).

An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer, to

reset the message Úpage 121.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km) or

12 months, whichever comes first.

Engine Oil Filter Replacement

Residual oil in the housing may spill from the

housing when the new filter is installed if the

residual oil is not either removed from the housing

or enough time has not elapsed to allow the oil to

drain back into the engine. When servicing the oil

filter on this engine, open the filter cap

approximately six turns until the cap o-ring is

visible and stop. Wait five minutes with the cap in

this position to allow dirty engine oil to drain back

into the engine. After five minutes, the cap and

filter assembly can be removed and discarded. Once A Month Or Before A Long Trip:Check engine oil level

Check windshield washer fluid level

Check the tire pressures and look for unusual

wear or damage

Check the fluid levels of the coolant reservoir,

brake master cylinder, and fill as needed

Check function of all interior and exterior lights

8

23_JT_OM_EN_USC_t.book Page 357

Page 370 of 448

368SERVICING AND MAINTENANCE

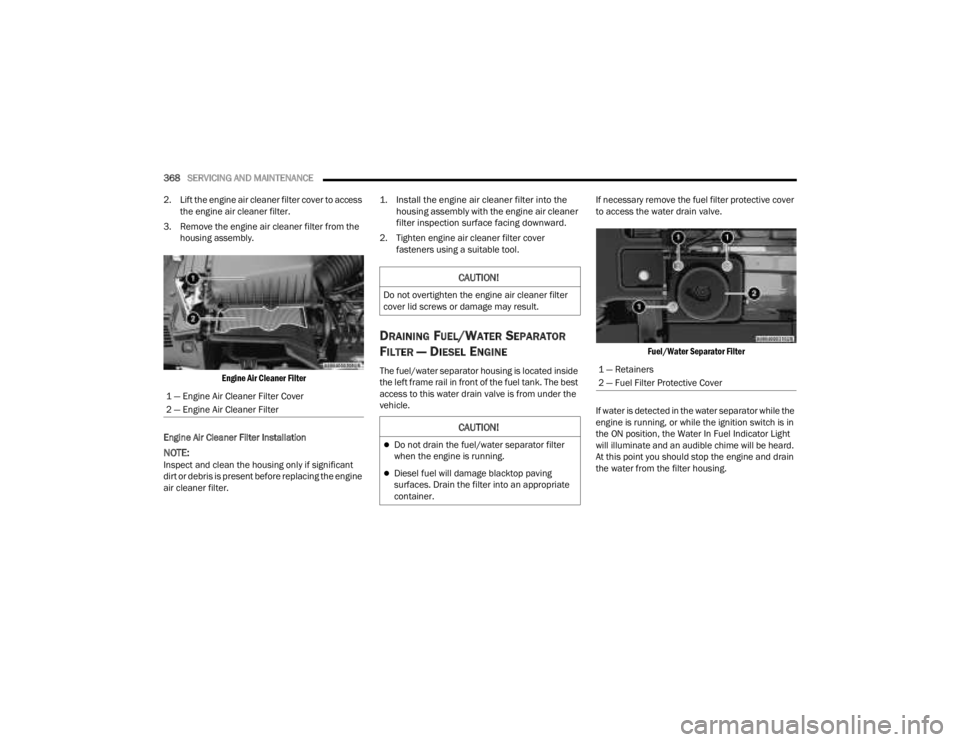

2. Lift the engine air cleaner filter cover to access the engine air cleaner filter.

3. Remove the engine air cleaner filter from the housing assembly.

Engine Air Cleaner Filter

Engine Air Cleaner Filter Installation

NOTE:Inspect and clean the housing only if significant

dirt or debris is present before replacing the engine

air cleaner filter.

1. Install the engine air cleaner filter into the

housing assembly with the engine air cleaner

filter inspection surface facing downward.

2. Tighten engine air cleaner filter cover fasteners using a suitable tool.

DRAINING FUEL/WATER SEPARATOR

F

ILTER — DIESEL ENGINE

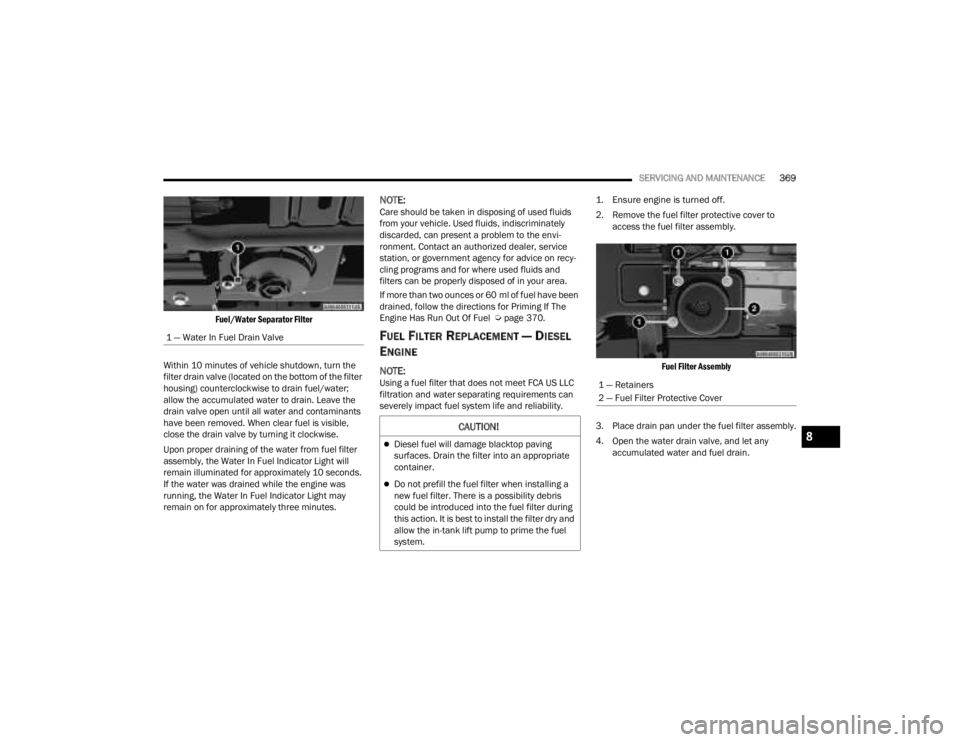

The fuel/water separator housing is located inside

the left frame rail in front of the fuel tank. The best

access to this water drain valve is from under the

vehicle. If necessary remove the fuel filter protective cover

to access the water drain valve.

Fuel/Water Separator Filter

If water is detected in the water separator while the

engine is running, or while the ignition switch is in

the ON position, the Water In Fuel Indicator Light

will illuminate and an audible chime will be heard.

At this point you should stop the engine and drain

the water from the filter housing.

1 — Engine Air Cleaner Filter Cover

2 — Engine Air Cleaner Filter

CAUTION!

Do not overtighten the engine air cleaner filter

cover lid screws or damage may result.

CAUTION!

Do not drain the fuel/water separator filter

when the engine is running.

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appropriate

container.

1 — Retainers

2 — Fuel Filter Protective Cover

23_JT_OM_EN_USC_t.book Page 368

Page 371 of 448

SERVICING AND MAINTENANCE369

Fuel/Water Separator Filter

Within 10 minutes of vehicle shutdown, turn the

filter drain valve (located on the bottom of the filter

housing) counterclockwise to drain fuel/water;

allow the accumulated water to drain. Leave the

drain valve open until all water and contaminants

have been removed. When clear fuel is visible,

close the drain valve by turning it clockwise.

Upon proper draining of the water from fuel filter

assembly, the Water In Fuel Indicator Light will

remain illuminated for approximately 10 seconds.

If the water was drained while the engine was

running, the Water In Fuel Indicator Light may

remain on for approximately three minutes.

NOTE:Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately

discarded, can present a problem to the envi -

ronment. Contact an authorized dealer, service

station, or government agency for advice on recy -

cling programs and for where used fluids and

filters can be properly disposed of in your area.

If more than two ounces or 60 ml of fuel have been

drained, follow the directions for Priming If The

Engine Has Run Out Of Fuel Ú page 370.

FUEL FILTER REPLACEMENT — DIESEL

E

NGINE

NOTE:Using a fuel filter that does not meet FCA US LLC

filtration and water separating requirements can

severely impact fuel system life and reliability.

1. Ensure engine is turned off.

2. Remove the fuel filter protective cover to

access the fuel filter assembly.

Fuel Filter Assembly

3. Place drain pan under the fuel filter assembly.

4. Open the water drain valve, and let any accumulated water and fuel drain.

1 — Water In Fuel Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appropriate

container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter during

this action. It is best to install the filter dry and

allow the in-tank lift pump to prime the fuel

system.

1 — Retainers

2 — Fuel Filter Protective Cover

8

23_JT_OM_EN_USC_t.book Page 369

Page 382 of 448

380SERVICING AND MAINTENANCE

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. For the proper maintenance intervals

Úpage 354.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked whenever the vehicle is serviced, or

immediately if the Brake System Warning Light is

on. If necessary, add fluid to bring level within the

designated marks on the side of the reservoir of

the brake master cylinder. Be sure to clean the top

of the master cylinder area before removing cap.

With disc brakes, fluid level can be expected to fall

as the brake pads wear. Brake fluid level should be

checked when pads are replaced. If the brake fluid

is abnormally low, check the system for leaks.

For further information Ú page 426.

FRONT/REAR AXLE FLUID

For normal service, periodic fluid level checks are

not required. When the vehicle is serviced for other

reasons the exterior surfaces of the axle assembly

should be inspected. If gear oil leakage is

suspected, inspect the fluid level.

Fluid Level Check

Lubricant should be approximately 1/8 inch

(3 mm) below the bottom edge of the oil fill hole.

NOTE:Make sure that the vehicle is level and supported

by the axles.

Adding Fluid

Add lubricant only at the fill hole and only to the

level specified above.

Selection Of Lubricant

Use only the manufacturer’s recommended fluid

Úpage 426.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer recommended brake

fluid Ú page 426. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in a open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

WARNING!

23_JT_OM_EN_USC_t.book Page 380

Page 389 of 448

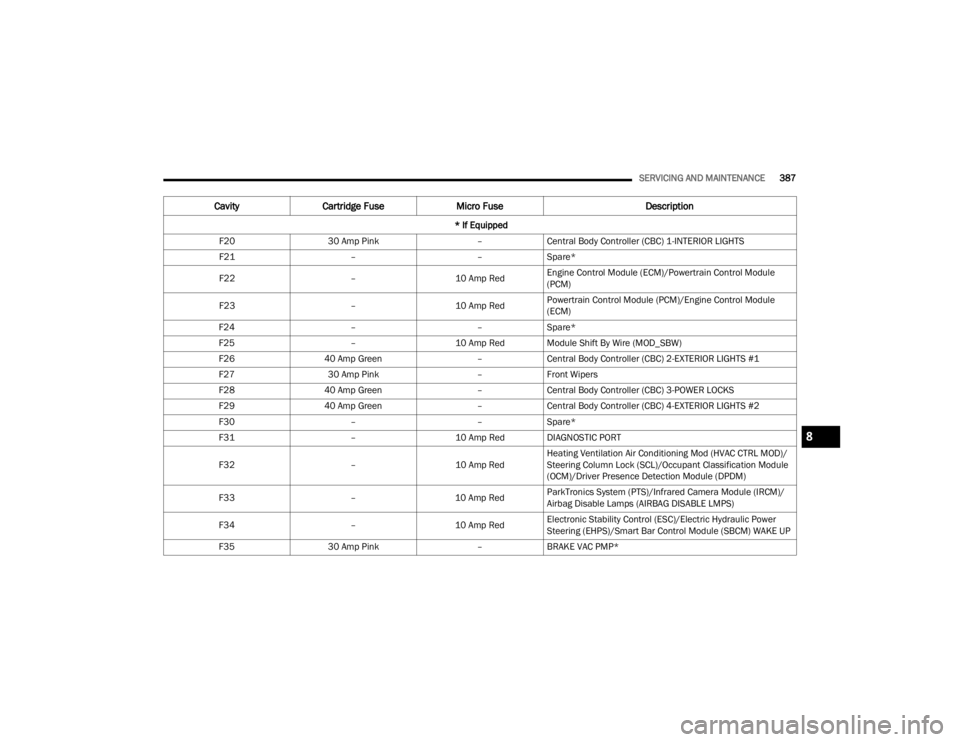

SERVICING AND MAINTENANCE387

F20 30 Amp Pink –Central Body Controller (CBC) 1-INTERIOR LIGHTS

F21 ––Spare*

F22 –10 Amp RedEngine Control Module (ECM)/Powertrain Control Module

(PCM)

F23 –10 Amp RedPowertrain Control Module (PCM)/Engine Control Module

(ECM)

F24 ––Spare*

F25 –10 Amp Red Module Shift By Wire (MOD_SBW)

F26 40 Amp Green –Central Body Controller (CBC) 2-EXTERIOR LIGHTS #1

F27 30 Amp Pink –Front Wipers

F28 40 Amp Green –Central Body Controller (CBC) 3-POWER LOCKS

F29 40 Amp Green –Central Body Controller (CBC) 4-EXTERIOR LIGHTS #2

F30 ––Spare*

F31 –10 Amp Red DIAGNOSTIC PORT

F32 –10 Amp RedHeating Ventilation Air Conditioning Mod (HVAC CTRL MOD)/

Steering Column Lock (SCL)/Occupant Classification Module

(OCM)/Driver Presence Detection Module (DPDM)

F33 –10 Amp RedParkTronics System (PTS)/Infrared Camera Module (IRCM)/

Airbag Disable Lamps (AIRBAG DISABLE LMPS)

F34 –10 Amp RedElectronic Stability Control (ESC)/Electric Hydraulic Power

Steering (EHPS)/Smart Bar Control Module (SBCM) WAKE UP

F35 30 Amp Pink –BRAKE VAC PMP*

Cavity Cartridge Fuse Micro Fuse Description

* If Equipped

8

23_JT_OM_EN_USC_t.book Page 387

Page 390 of 448

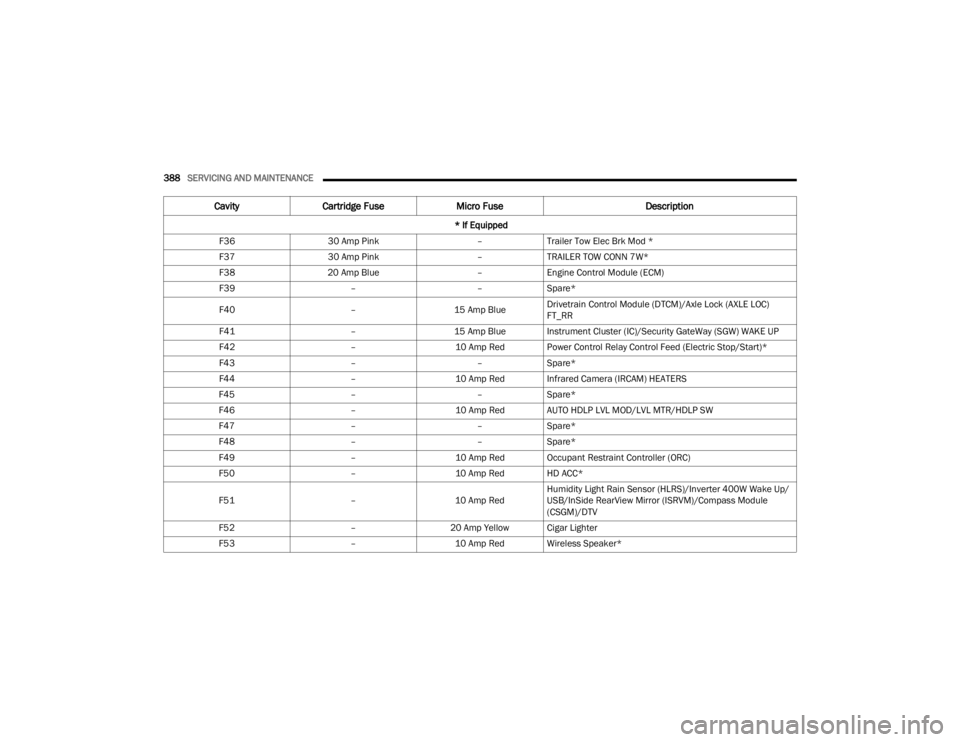

388SERVICING AND MAINTENANCE

F36 30 Amp Pink –Trailer Tow Elec Brk Mod *

F37 30 Amp Pink –TRAILER TOW CONN 7W*

F38 20 Amp Blue –Engine Control Module (ECM)

F39 ––Spare*

F40 –15 Amp BlueDrivetrain Control Module (DTCM)/Axle Lock (AXLE LOC)

FT_RR

F41 –15 Amp Blue Instrument Cluster (IC)/Security GateWay (SGW) WAKE UP

F42 –10 Amp Red Power Control Relay Control Feed (Electric Stop/Start)*

F43 ––Spare*

F44 –10 Amp Red Infrared Camera (IRCAM) HEATERS

F45 ––Spare*

F46 –10 Amp Red AUTO HDLP LVL MOD/LVL MTR/HDLP SW

F47 ––Spare*

F48 ––Spare*

F49 –10 Amp Red Occupant Restraint Controller (ORC)

F50 –10 Amp Red HD ACC*

F51 –10 Amp RedHumidity Light Rain Sensor (HLRS)/Inverter 400W Wake Up/

USB/InSide RearView Mirror (ISRVM)/Compass Module

(CSGM)/DTV

F52 –20 Amp Yellow Cigar Lighter

F53 –10 Amp Red Wireless Speaker*

CavityCartridge Fuse Micro Fuse Description

* If Equipped

23_JT_OM_EN_USC_t.book Page 388

Page 396 of 448

394SERVICING AND MAINTENANCE

10. Remove connector from bulb.

11. Push connector onto new bulb base, and push the connector locking tab to the lock position.

12. Reinstall bulb housing. Rotate the bulb a quarter turn clockwise.

NOTE:We recommend seeing an authorized dealer for

service.

FRONT PARK/TURN SIGNAL

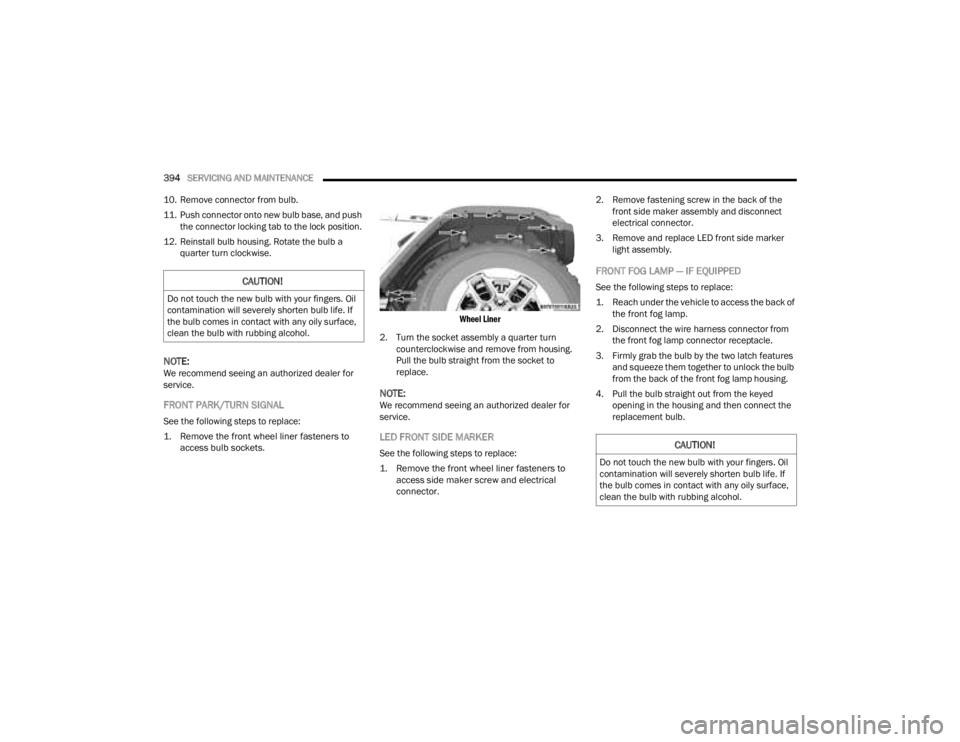

See the following steps to replace:

1. Remove the front wheel liner fasteners to access bulb sockets.

Wheel Liner

2. Turn the socket assembly a quarter turn counterclockwise and remove from housing.

Pull the bulb straight from the socket to

replace.

NOTE:We recommend seeing an authorized dealer for

service.

LED FRONT SIDE MARKER

See the following steps to replace:

1. Remove the front wheel liner fasteners to access side maker screw and electrical

connector.

2. Remove fastening screw in the back of the

front side maker assembly and disconnect

electrical connector.

3. Remove and replace LED front side marker light assembly.

FRONT FOG LAMP — IF EQUIPPED

See the following steps to replace:

1. Reach under the vehicle to access the back of the front fog lamp.

2. Disconnect the wire harness connector from the front fog lamp connector receptacle.

3. Firmly grab the bulb by the two latch features and squeeze them together to unlock the bulb

from the back of the front fog lamp housing.

4. Pull the bulb straight out from the keyed opening in the housing and then connect the

replacement bulb.CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If

the bulb comes in contact with any oily surface,

clean the bulb with rubbing alcohol.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If

the bulb comes in contact with any oily surface,

clean the bulb with rubbing alcohol.

23_JT_OM_EN_USC_t.book Page 394