fuel cap JEEP GLADIATOR 2023 User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GLADIATOR, Model: JEEP GLADIATOR 2023Pages: 448, PDF Size: 17.37 MB

Page 297 of 448

SAFETY295

(Continued)

TPMS Warning Light. Driving the vehicle may cause

the tire pressure to rise to approximately 28 psi

(193 kPa), but the TPMS Warning Light will still be

on. In this situation, the TPMS Warning Light will

turn off only after the tires are inflated to the

vehicle’s recommended cold placard pressure

value.

NOTE:When filling warm tires, the tire pressure may need

to be increased up to an additional 4 psi (28 kPa)

above the recommended cold placard pressure in

order to turn the TPMS Warning Light off.

NOTE:

The TPMS is not intended to replace normal tire

care and maintenance, or to provide warning of

a tire failure or condition.

The TPMS should not be used as a tire pressure

gauge while adjusting your tire pressure, unless

your vehicle is equipped with a Tire Fill Alert

(TFA) system.

Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire

failure. Underinflation also reduces fuel effi

-

ciency and tire tread life, and may affect the

vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsibility

to maintain correct tire pressure using an accu -

rate tire pressure gauge, even if underinflation

has not reached the level to trigger illumination

of the TPMS Warning Light.

Seasonal temperature changes will affect tire

pressure, and the TPMS will monitor the actual

tire pressure in the tire Ú page 432.

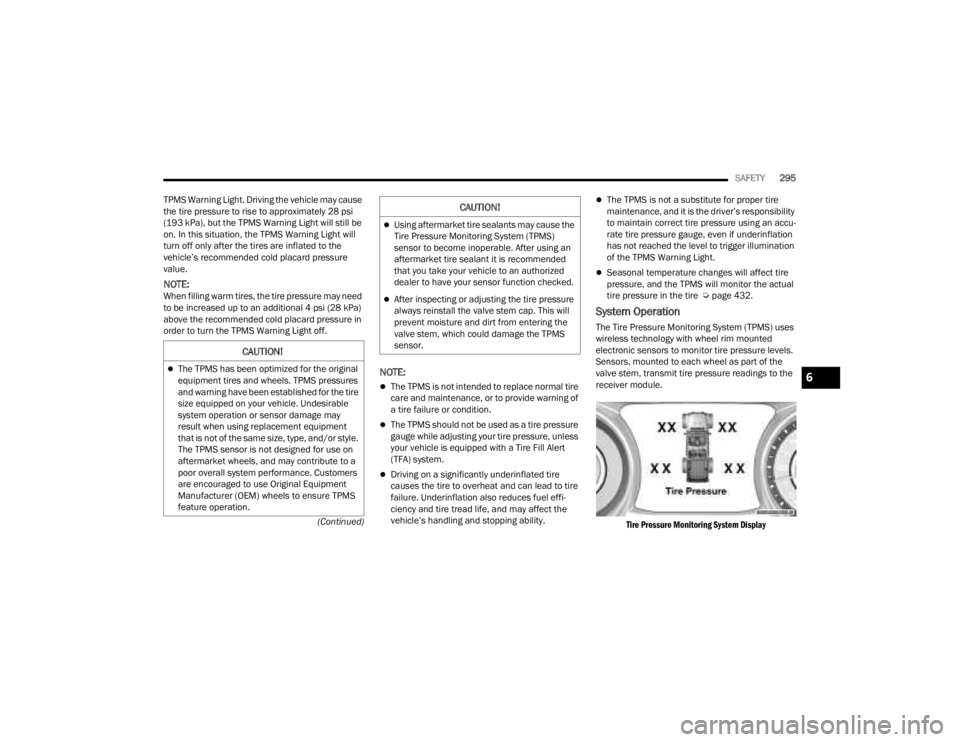

System Operation

The Tire Pressure Monitoring System (TPMS) uses

wireless technology with wheel rim mounted

electronic sensors to monitor tire pressure levels.

Sensors, mounted to each wheel as part of the

valve stem, transmit tire pressure readings to the

receiver module.

Tire Pressure Monitoring System Display

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures

and warning have been established for the tire

size equipped on your vehicle. Undesirable

system operation or sensor damage may

result when using replacement equipment

that is not of the same size, type, and/or style.

The TPMS sensor is not designed for use on

aftermarket wheels, and may contribute to a

poor overall system performance. Customers

are encouraged to use Original Equipment

Manufacturer (OEM) wheels to ensure TPMS

feature operation.

Using aftermarket tire sealants may cause the

Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended

that you take your vehicle to an authorized

dealer to have your sensor function checked.

After inspecting or adjusting the tire pressure

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the TPMS

sensor.

CAUTION!

6

23_JT_OM_EN_USC_t.book Page 295

Page 348 of 448

346IN CASE OF EMERGENCY

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, follow the discon -

necting procedure.

Disconnecting The Jumper Cables

1. Disconnect the negative

(-)

end of the jumper

cable from the engine ground of the vehicle

with the discharged battery.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery. 3. Disconnect the positive

(+) end of the jumper

cable from the positive (+) post of the booster

battery.

4. Disconnect the opposite end of the positive (+)

jumper cable from the positive (+) post of the

discharged vehicle.

5. Reinstall the protective cover over the positive (+) post of the discharged vehicle.

If frequent jump starting is required to start your

vehicle you should have the battery and charging

system tested at an authorized dealer.

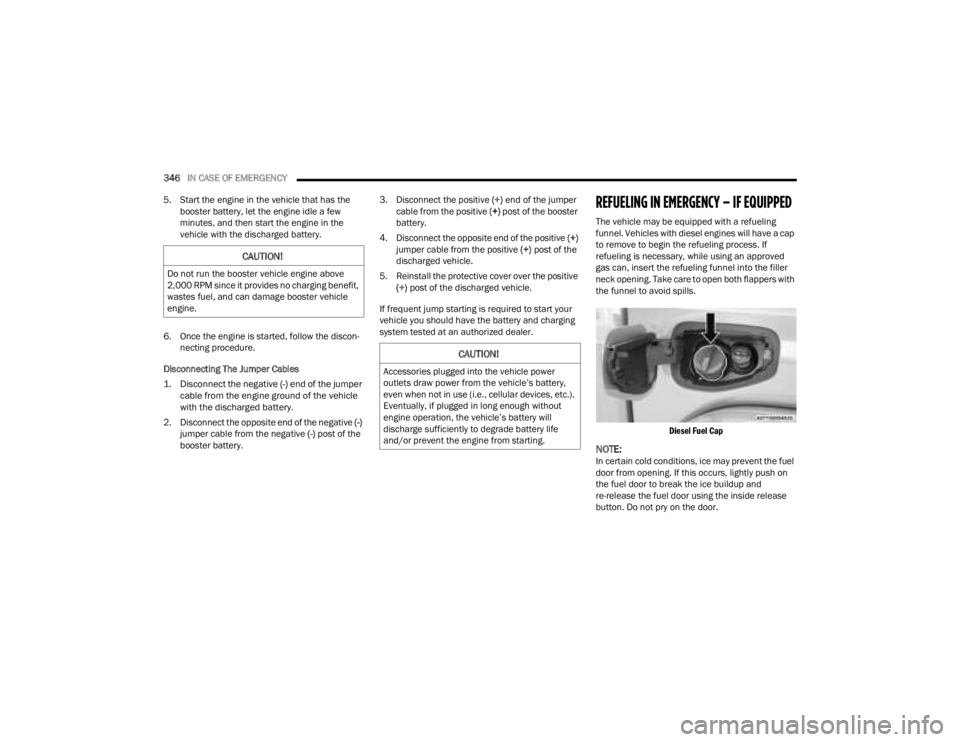

REFUELING IN EMERGENCY – IF EQUIPPED

The vehicle may be equipped with a refueling

funnel. Vehicles with diesel engines will have a cap

to remove to begin the refueling process. If

refueling is necessary, while using an approved

gas can, insert the refueling funnel into the filler

neck opening. Take care to open both flappers with

the funnel to avoid spills.

Diesel Fuel Cap

NOTE:In certain cold conditions, ice may prevent the fuel

door from opening. If this occurs, lightly push on

the fuel door to break the ice buildup and

re-release the fuel door using the inside release

button. Do not pry on the door.

CAUTION!

Do not run the booster vehicle engine above

2,000 RPM since it provides no charging benefit,

wastes fuel, and can damage booster vehicle

engine.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

23_JT_OM_EN_USC_t.book Page 346

Page 349 of 448

IN CASE OF EMERGENCY347

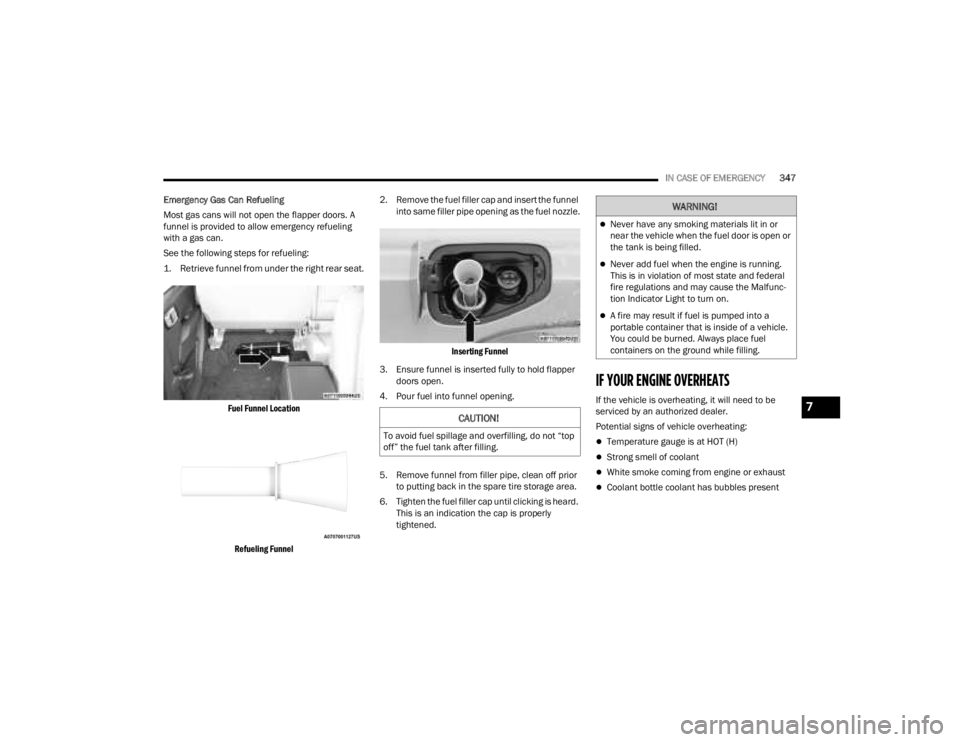

Emergency Gas Can Refueling

Most gas cans will not open the flapper doors. A

funnel is provided to allow emergency refueling

with a gas can.

See the following steps for refueling:

1. Retrieve funnel from under the right rear seat.

Fuel Funnel Location

Refueling Funnel

2. Remove the fuel filler cap and insert the funnel

into same filler pipe opening as the fuel nozzle.

Inserting Funnel

3. Ensure funnel is inserted fully to hold flapper doors open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off prior to putting back in the spare tire storage area.

6. Tighten the fuel filler cap until clicking is heard. This is an indication the cap is properly

tightened.

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be

serviced by an authorized dealer.

Potential signs of vehicle overheating:

Temperature gauge is at HOT (H)

Strong smell of coolant

White smoke coming from engine or exhaust

Coolant bottle coolant has bubbles present

CAUTION!

To avoid fuel spillage and overfilling, do not “top

off” the fuel tank after filling.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

7

23_JT_OM_EN_USC_t.book Page 347

Page 372 of 448

370SERVICING AND MAINTENANCE

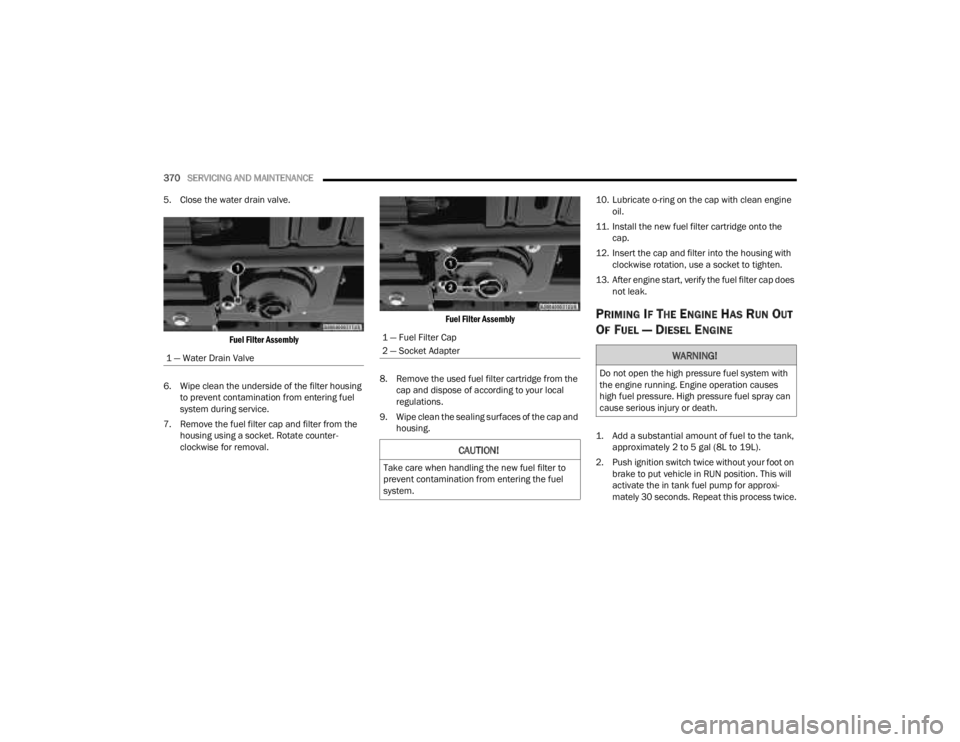

5. Close the water drain valve.

Fuel Filter Assembly

6. Wipe clean the underside of the filter housing to prevent contamination from entering fuel

system during service.

7. Remove the fuel filter cap and filter from the housing using a socket. Rotate counter -

clockwise for removal.

Fuel Filter Assembly

8. Remove the used fuel filter cartridge from the cap and dispose of according to your local

regulations.

9. Wipe clean the sealing surfaces of the cap and housing. 10. Lubricate o-ring on the cap with clean engine

oil.

11. Install the new fuel filter cartridge onto the cap.

12. Insert the cap and filter into the housing with clockwise rotation, use a socket to tighten.

13. After engine start, verify the fuel filter cap does not leak.

PRIMING IF THE ENGINE HAS RUN OUT

O

F FUEL — DIESEL ENGINE

1. Add a substantial amount of fuel to the tank,

approximately 2 to 5 gal (8L to 19L).

2. Push ignition switch twice without your foot on brake to put vehicle in RUN position. This will

activate the in tank fuel pump for approxi -

mately 30 seconds. Repeat this process twice.

1 — Water Drain Valve

1 — Fuel Filter Cap

2 — Socket Adapter

CAUTION!

Take care when handling the new fuel filter to

prevent contamination from entering the fuel

system.

WARNING!

Do not open the high pressure fuel system with

the engine running. Engine operation causes

high fuel pressure. High pressure fuel spray can

cause serious injury or death.

23_JT_OM_EN_USC_t.book Page 370

Page 381 of 448

SERVICING AND MAINTENANCE379

Coolant Level

The coolant bottle provides a quick visual method

for determining that the coolant level is adequate.

With the engine in the off and cold, the level of the

engine coolant (antifreeze) in the bottle should be

between the ranges indicated on the bottle.

The radiator normally remains completely full, so

there is no need to remove the radiator/coolant

pressure cap unless checking for engine coolant

freeze point or replacing coolant. Advise your

service attendant of this. As long as the engine

operating temperature is satisfactory, the coolant

only needs to be checked once a month.

When additional engine coolant is needed to

maintain the proper level, only OAT coolant that

meets the requirements of FCA Material Standard

MS.90032 should be added to the coolant bottle.

Do not overfill.

Cooling System Notes

NOTE:When the vehicle is stopped after a few miles/kilo -

meters of operation, you may observe vapor

coming from the front of the engine compartment.

This is normally a result of moisture from rain,

snow, or high humidity accumulating on the

radiator and being vaporized when the thermostat

opens, allowing hot engine coolant (antifreeze) to

enter the radiator. If an examination of your engine compartment

shows no evidence of radiator or hose leaks, the

vehicle may be safely driven. The vapor will soon

dissipate.

Do not overfill the coolant expansion bottle.

Check the freezing point of the coolant in the

radiator and in the coolant expansion bottle. If

determined that more engine coolant needs to

be added to the radiator, the contents of the

coolant expansion bottle must also be protected

against freezing.

If frequent engine coolant additions are

required, the cooling system should be pressure

tested for leaks.

Maintain engine coolant concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corro

-

sion protection of your engine which contains

aluminum components.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. With air

conditioning, keep the front of the condenser

clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat. Other designs may result in unsatisfactory

engine system performance, poor gas mileage,

and increased emissions.

CHARGE AIR COOLER — INTER-COOLER

(D

IESEL ENGINE)

The charge air cooler is positioned in front of the

radiator and the air conditioner condenser. Air

enters the engine through the air cleaner and

passes through the turbocharger, where it is

pressurized. This pressurized air rapidly reaches

high temperature. The air is then directed through

a hose to the charge air cooler and through

another hose to the intake manifold of the engine.

This cooling process enables more efficient

burning of fuel resulting in fewer emissions.

To guarantee optimum performance of the system,

keep the surfaces of the charge air cooler,

condenser and radiator clean and free of debris.

Periodically check the hoses leading to and from

the charge air cooler for cracks or loose clamps

resulting in loss of pressure and reduced engine

performance.

8

23_JT_OM_EN_USC_t.book Page 379

Page 403 of 448

SERVICING AND MAINTENANCE401

To determine the maximum loading conditions of

your vehicle, locate the statement “The combined

weight of occupants and cargo should never

exceed XXX kg or XXX lbs” on the Tire And Loading

Information Placard. The combined weight of

occupants, cargo/luggage and trailer tongue

weight (if applicable) should never exceed the

weight referenced here.

Steps For Determining Correct Load Limit—

(1) Locate the statement “The combined

weight of occupants and cargo should

never exceed XXX kg or XXX lbs.” on your

vehicle's placard.

(2) Determine the combined weight of

the driver and passengers that will be

riding in your vehicle.

(3) Subtract the combined weight of the

driver and passengers from XXX kg or

XXX lbs.

(4) The resulting figure equals the

available amount of cargo and luggage

load capacity. For example, if “XXX”

amount equals 1400 lbs. and there will

be five 150 lbs passengers in your

vehicle, the amount of available cargo and luggage load capacity is 650 lbs.

(1400-750 (5x150) = 650 lbs.)

(5) Determine the combined weight of

luggage and cargo being loaded on the

vehicle. That weight may not safely

exceed the available cargo and luggage

load capacity calculated in Step 4.

(6) If your vehicle will be towing a trailer,

load from your trailer will be transferred

to your vehicle. Consult this manual to

determine how this reduces the

available cargo and luggage load

capacity of your vehicle.

Metric Example For Load Limit

For example, if “XXX” amount equals 635 kg and

there will be five 68 kg passengers in your vehicle,

the amount of available cargo and luggage load

capacity is 295 kg (635-340 (5x68) = 295 kg) as

shown in step 4.

NOTE:

If your vehicle will be towing a trailer, load from

your trailer will be transferred to your vehicle.

The following table shows examples on how to

calculate total load, cargo/luggage, and towing

capacities of your vehicle with varying seating

configurations and number and size of occu

-pants. This table is for illustration purposes only

and may not be accurate for the seating and

load carry capacity of your vehicle.

For the following example, the combined weight

of occupants and cargo should never exceed

865 lbs (392 kg).

TIRES — GENERAL INFORMATION

Tire Pressure

Proper tire inflation pressure is essential to the

safe and satisfactory operation of your vehicle.

Four primary areas are affected by improper tire

pressure:

Safety

Fuel Economy

Tread Wear

Ride Comfort and Vehicle Stability

WARNING!

Overloading of your tires is dangerous.

Overloading can cause tire failure, affect vehicle

handling, and increase your stopping distance.

Use tires of the recommended load capacity for

your vehicle. Never overload them.

8

23_JT_OM_EN_USC_t.book Page 401

Page 404 of 448

402SERVICING AND MAINTENANCE

Safety

Both underinflation and overinflation affect the

stability of the vehicle and can produce a feeling of

sluggish response or over responsiveness in the

steering.

NOTE:

Unequal tire pressures from side to side may

cause erratic and unpredictable steering

response.

Unequal tire pressure from side to side may

cause the vehicle to drift left or right.

Fuel Economy

Underinflated tires will increase tire rolling

resistance resulting in higher fuel consumption.

Tread Wear

Improper cold tire inflation pressures can cause

abnormal wear patterns and reduced tread life,

resulting in the need for earlier tire replacement.

Ride Comfort And Vehicle Stability

Proper tire inflation contributes to a comfortable

ride. Overinflation produces a jarring and

uncomfortable ride.

Tire Inflation Pressures

The proper cold tire inflation pressure is listed on

the driver's side B-pillar or rear edge of the driver's

side door.

At least once a month:

Check and adjust tire pressure with a good

quality pocket-type pressure gauge. Do not

make a visual judgment when determining proper inflation. Tires may look properly inflated

even when they are underinflated.

Inspect tires for signs of tire wear or visible

damage.

Inflation pressures specified on the placard are

always “cold tire inflation pressure”. Cold tire

inflation pressure is defined as the tire pressure

after the vehicle has not been driven for at least

three hours, or driven less than 1 mile (1.6 km)

after sitting for a minimum of three hours. The cold

tire inflation pressure must not exceed the

maximum inflation pressure molded into the tire

sidewall.

Check tire pressures more often if subject to a

wide range of outdoor temperatures, as tire

pressures vary with temperature changes.

Tire pressures change by approximately 1 psi

(7 kPa) per 12°F (7°C) of air temperature change.

Keep this in mind when checking tire pressure

inside a garage, especially in the Winter.WARNING!

Improperly inflated tires are dangerous and

can cause collisions.

Underinflation increases tire flexing and can

result in overheating and tire failure.

Overinflation reduces a tire's ability to cushion

shock. Objects on the road and chuckholes

can cause damage that result in tire failure.

Overinflated or underinflated tires can affect

vehicle handling and can fail suddenly,

resulting in loss of vehicle control.

Unequal tire pressures can cause steering

problems. You could lose control of your

vehicle.

Unequal tire pressures from one side of the

vehicle to the other can cause the vehicle to

drift to the right or left.

Always drive with each tire inflated to the

recommended cold tire inflation pressure.

CAUTION!

After inspecting or adjusting the tire pressure,

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the valve stem.

23_JT_OM_EN_USC_t.book Page 402

Page 425 of 448

TECHNICAL SPECIFICATIONS423

Fuel Water Separation — Must Use

Mopar® Approved Fuel Filter Elements

Biodiesel fuel has a natural affinity to water and

water accelerates microbial growth. Your Mopar®

filtration system is designed to provide adequate

fuel water separation capabilities.

Fuel In Oil Dilution — Must Adhere To

Required Oil Change Interval

Fuel dilution of lubricating oil has been observed

with the use of biodiesel fuel. Fuel in oil must not

exceed 5%. To ensure this limit is met your oil

change interval must be maintained within the

suggested schedule. The regular use of biodiesel

between 6% and 20% requires intervals shorter

than the outlined 10,000 miles (16,000 km) and must not exceed the suggested schedule. When

routinely operating on biodiesel between 6% and

20%, oil and filter replacement intervals must not

exceed 8,000 miles (13,000 km) or six months,

which ever comes first.

Biodiesel Fuel Filter Change Intervals

The use of biodiesel requires more frequent fuel

filter change intervals. When operating on

biodiesel between 6% and 20%, fuel filter

replacement intervals should be every second oil

change, and must not exceed 16,000 miles

(25,750 km).

NOTE:Under no circumstances should oil change

intervals exceed 8,000 miles (12,875 km) or six

months, if regular operation occurs with 6% - 20%

biodiesel blends. Under no circumstances should

fuel filter replacement intervals exceed every

second oil change and must not exceed

16,000 miles (25,750 km), if regular operation

occurs with 6% - 20% biodiesel blends. Failure to

comply with these Oil Change and fuel filter

requirements for vehicles operating on biodiesel

blends up to B20 may result in premature engine

wear. Such wear is not covered by the New Vehicle

Limited Warranty. The engine may suffer severe

damage if operated with concentrations of

biodiesel higher than 20%.

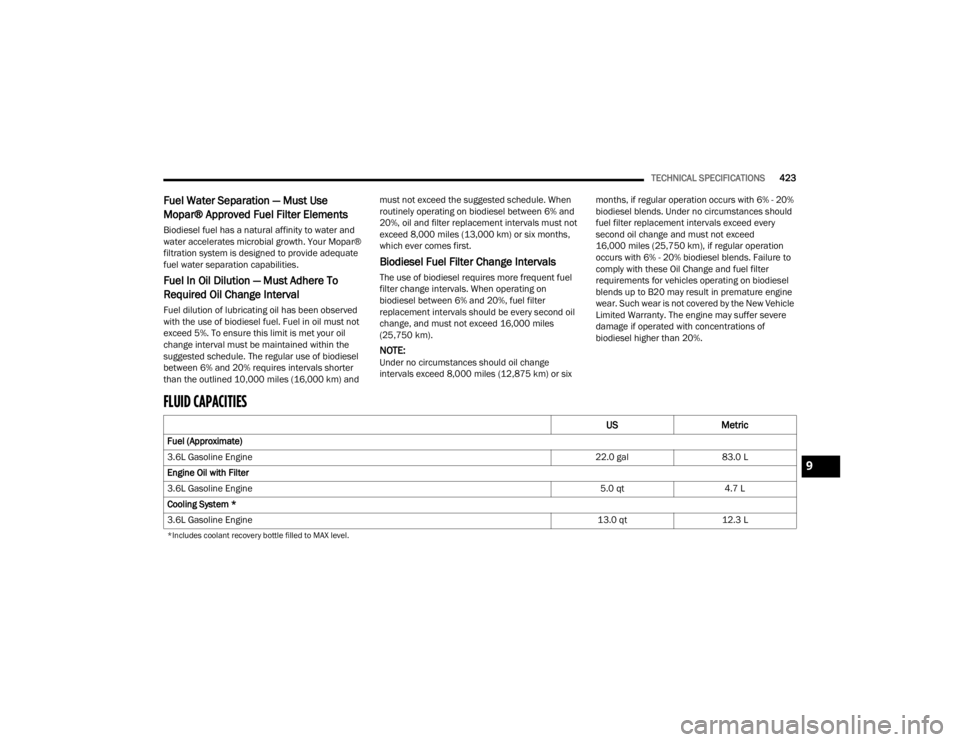

FLUID CAPACITIES

US

Metric

Fuel (Approximate)

3.6L Gasoline Engine 22.0 gal83.0 L

Engine Oil with Filter

3.6L Gasoline Engine 5.0 qt4.7 L

Cooling System *

3.6L Gasoline Engine 13.0 qt12.3 L

*Includes coolant recovery bottle filled to MAX level.

9

23_JT_OM_EN_USC_t.book Page 423

Page 436 of 448

434

Belts, Seat

..................................................... 329Blind Spot Monitoring.................................... 287Bluetooth Connecting To A Particular Mobile Phone Or Audio Device After Pairing

................248Body Mechanism Lubrication........................ 374B-Pillar Location............................................. 400Brake Assist System...................................... 280Brake Control System.................................... 280Brake Fluid.......................................... 380, 426Brake System...................................... 380, 418Anti-Lock (ABS).......................................... 418Fluid Check............................................... 380Master Cylinder......................................... 380Parking...................................................... 152Warning Light............................................ 132Brake/Transmission Interlock....................... 157Bulb Replacement............................... 392, 393Bulbs, Light.......................................... 330, 392Bumper End Cap Removal............................. 208

C

Camera, Rear................................................ 189Capacities, Fluid............................................ 423Caps, FillerFuel........................................................... 191Oil (Engine)................................................ 362Radiator (Coolant Pressure)...................... 378Car Washes................................................... 412Carbon Monoxide Warning............................ 331

Carpet Safety Information............................. 414Carpeting...................................................... 415CD................................................................. 242Cellular Phone.............................................. 276Center High Mounted Stop Light................... 395Certification Label......................................... 195Chains, Tire................................................... 408Charge Air Cooler.......................................... 379Chart, Tire Sizing........................................... 397Checking Your Vehicle For Safety................. 328Checks, Safety.............................................. 328Child Restraint.............................................. 318Child RestraintsBooster Seats........................................... 321Child Seat Installation.............................. 327How To Stow An unused ALR Seat Belt.... 325Infant And Child Restraints....................... 320Locating The LATCH Anchorages.............. 324Lower Anchors And Tethers For Children.. 322Older Children And Child Restraints......... 320Seating Positions...................................... 321Clean Air Gasoline......................................... 419CleaningWheels..................................................... 407Climate Control................................................ 61Automatic.................................................... 62Manual........................................................ 64CNG And LP Fuel System Modifications........ 420Cold Weather Operation............................... 146Compact Spare Tire...................................... 406

Connected Services...................................... 258Connected Services FAQ............................... 272Connected Services Features....................... 261Connected Services, Getting Started............ 260Connected Services, Introduction................. 258ConnectorUCI...............................................................71Universal Consumer Interface (UCI).............71Console............................................................69Floor............................................................69Contract, Service........................................... 430Controls........................................................ 234Cooling Pressure Cap (Radiator Cap)............ 378Cooling System............................................. 377Adding Coolant (Antifreeze)...................... 378Coolant Level............................................ 379Cooling Capacity....................................... 423Disposal Of Used Coolant......................... 378Drain, Flush, And Refill............................. 377Inspection........................................ 377, 379Points To Remember................................ 379Pressure Cap............................................ 378Radiator Cap............................................. 378Selection Of Coolant (Antifreeze)......................... 377, 423, 424Corrosion Protection..................................... 411Cruise Control (Speed

Control)............................. 139, 140, 141, 173Customer Assistance.................................... 428Cybersecurity................................................ 214

23_JT_OM_EN_USC_t.book Page 434

Page 437 of 448

435

D

Daytime Running Lights

................................... 57Defroster, Windshield.................................... 329De-Icer, Remote Start...................................... 22Deleting A Phone........................................... 248Diesel Exhaust Fluid............................ 193, 371Diesel Fuel..................................................... 421Diesel Fuel Requirements............................. 421Bulk Storage Of......................................... 193Diesel Fuel System, Re-Priming..................... 370Dimmer Control Switch.................................... 60Dimmer Switch Headlight..................................................... 57DipsticksOil (Engine)................................................ 364Disable Vehicle Towing.................................. 350Disc Drive...................................................... 242Disconnecting................................................ 248DisposalAntifreeze (Engine Coolant)....................... 378Disturb........................................................... 251Do Not Use E-85 In Non-Flex Fuel Vehicles... 420Door Ajar Light............................................... 133Door Frame................................................... 104Installation................................................ 104Removal.................................................... 104Door LocksAutomatic.................................................... 27Door Off Mirror Kit........................................... 34

Doors............................................................... 24Removal............................................... 28, 32Removal, Front............................................ 28Removal, Rear............................................. 32Drag & Drop.................................................. 232Draining Fuel/Water Separator Filter............ 368Driver Memory Presets................................. 240Driver’s Seat Back Tilt............................... 43, 44Driving.......................................................... 207Driving Tips................................................... 207

E

Electric Brake Control System....................... 280Anti-Lock Brake System............................ 279Electronic Roll Mitigation................. 280, 286Electric Remote Mirrors................................... 52Electrical Outlet, Auxiliary (Power Outlet)......... 77Electrical Power Outlets................................... 77Electronic Speed Control (Cruise Control)..... 173Electronic Stability Control

(ESC)........................................... 135, 136, 281EmergencyIn Case Of................................................. 332SOS Emergency Call................................. 332Emergency Brake.......................................... 152Emergency Braking....................................... 293Emergency Gas Can Refueling...................... 346

Emergency, In Case OfJacking...................................................... 335Jump Starting........................................... 343Tow Hooks................................................ 351Engine........................................................... 362Air Cleaner................................................ 366Block Heater............................................. 148Break-In Recommendations..................... 151Checking Oil Level.................................... 364Compartment.................................. 362, 363Compartment Identification............. 362, 363Coolant (Antifreeze).................................. 424Cooling...................................................... 377Exhaust Gas Caution................................ 331Fails To Start............................................. 147Flooded, Starting...................................... 147Fuel Requirements................................... 423Idling......................................................... 150Jump Starting........................................... 343Oil...........................................365, 423, 424Oil Filler Cap............................................. 362Oil Filter.................................................... 366Oil Reset................................................... 122Oil Selection..................................... 365, 423Oil Synthetic.............................................. 366Overheating.............................................. 347Starting..................................................... 144Enhanced Accident Response

Feature................................................ 317, 352

11

23_JT_OM_EN_USC_t.book Page 435