clock JEEP GLADIATOR 2023 Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GLADIATOR, Model: JEEP GLADIATOR 2023Pages: 448, PDF Size: 17.37 MB

Page 371 of 448

SERVICING AND MAINTENANCE369

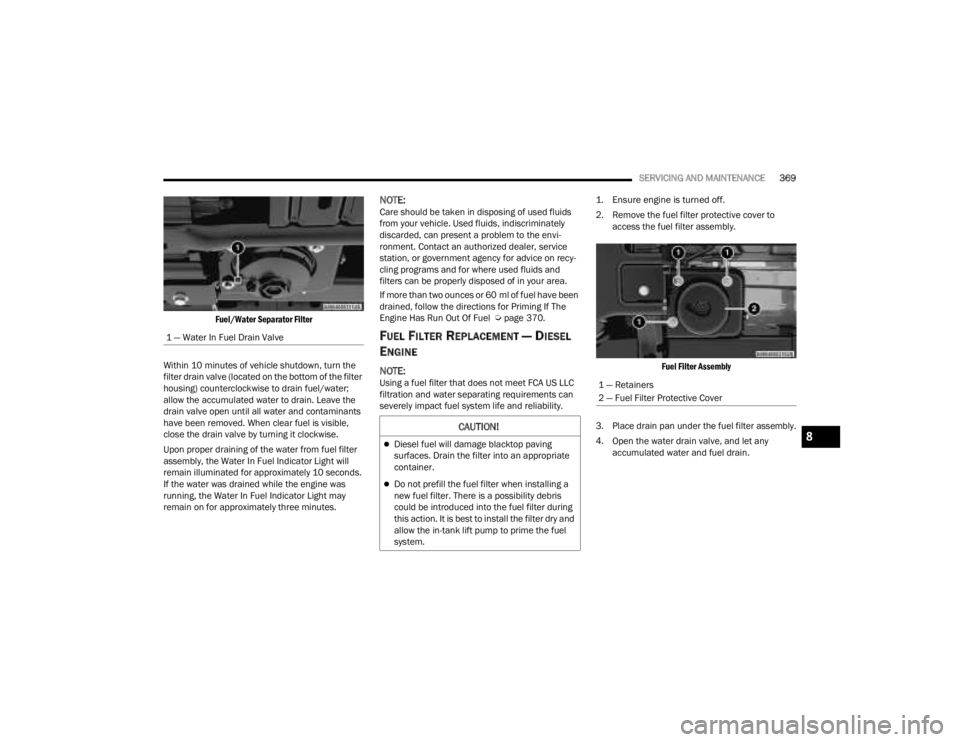

Fuel/Water Separator Filter

Within 10 minutes of vehicle shutdown, turn the

filter drain valve (located on the bottom of the filter

housing) counterclockwise to drain fuel/water;

allow the accumulated water to drain. Leave the

drain valve open until all water and contaminants

have been removed. When clear fuel is visible,

close the drain valve by turning it clockwise.

Upon proper draining of the water from fuel filter

assembly, the Water In Fuel Indicator Light will

remain illuminated for approximately 10 seconds.

If the water was drained while the engine was

running, the Water In Fuel Indicator Light may

remain on for approximately three minutes.

NOTE:Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately

discarded, can present a problem to the envi -

ronment. Contact an authorized dealer, service

station, or government agency for advice on recy -

cling programs and for where used fluids and

filters can be properly disposed of in your area.

If more than two ounces or 60 ml of fuel have been

drained, follow the directions for Priming If The

Engine Has Run Out Of Fuel Ú page 370.

FUEL FILTER REPLACEMENT — DIESEL

E

NGINE

NOTE:Using a fuel filter that does not meet FCA US LLC

filtration and water separating requirements can

severely impact fuel system life and reliability.

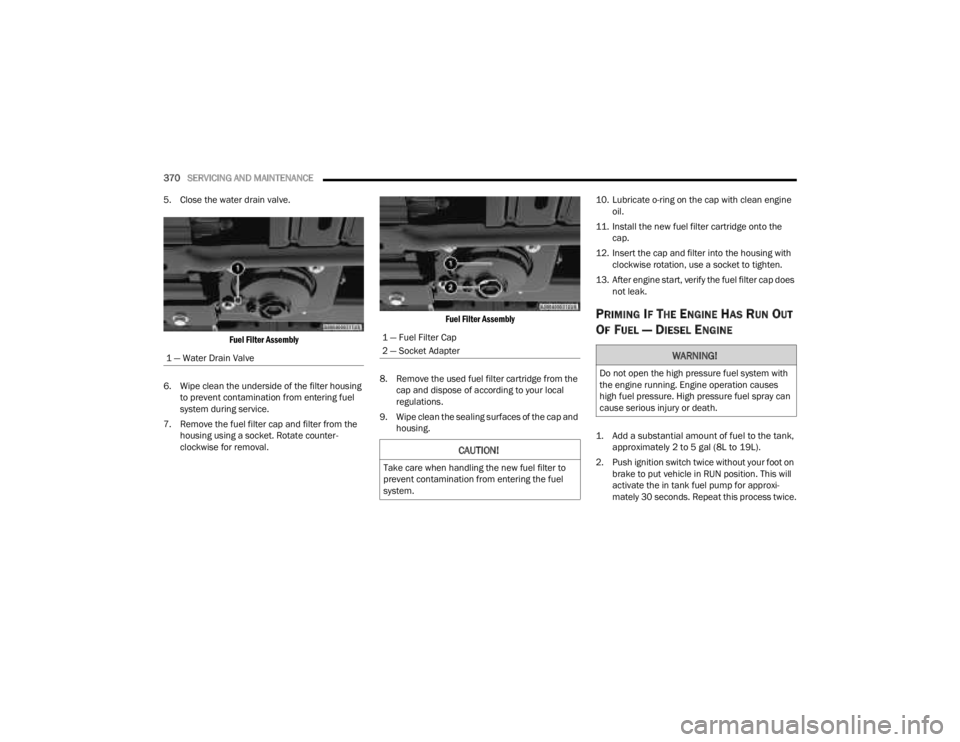

1. Ensure engine is turned off.

2. Remove the fuel filter protective cover to

access the fuel filter assembly.

Fuel Filter Assembly

3. Place drain pan under the fuel filter assembly.

4. Open the water drain valve, and let any accumulated water and fuel drain.

1 — Water In Fuel Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appropriate

container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter during

this action. It is best to install the filter dry and

allow the in-tank lift pump to prime the fuel

system.

1 — Retainers

2 — Fuel Filter Protective Cover

8

23_JT_OM_EN_USC_t.book Page 369

Page 372 of 448

370SERVICING AND MAINTENANCE

5. Close the water drain valve.

Fuel Filter Assembly

6. Wipe clean the underside of the filter housing to prevent contamination from entering fuel

system during service.

7. Remove the fuel filter cap and filter from the housing using a socket. Rotate counter -

clockwise for removal.

Fuel Filter Assembly

8. Remove the used fuel filter cartridge from the cap and dispose of according to your local

regulations.

9. Wipe clean the sealing surfaces of the cap and housing. 10. Lubricate o-ring on the cap with clean engine

oil.

11. Install the new fuel filter cartridge onto the cap.

12. Insert the cap and filter into the housing with clockwise rotation, use a socket to tighten.

13. After engine start, verify the fuel filter cap does not leak.

PRIMING IF THE ENGINE HAS RUN OUT

O

F FUEL — DIESEL ENGINE

1. Add a substantial amount of fuel to the tank,

approximately 2 to 5 gal (8L to 19L).

2. Push ignition switch twice without your foot on brake to put vehicle in RUN position. This will

activate the in tank fuel pump for approxi -

mately 30 seconds. Repeat this process twice.

1 — Water Drain Valve

1 — Fuel Filter Cap

2 — Socket Adapter

CAUTION!

Take care when handling the new fuel filter to

prevent contamination from entering the fuel

system.

WARNING!

Do not open the high pressure fuel system with

the engine running. Engine operation causes

high fuel pressure. High pressure fuel spray can

cause serious injury or death.

23_JT_OM_EN_USC_t.book Page 370

Page 395 of 448

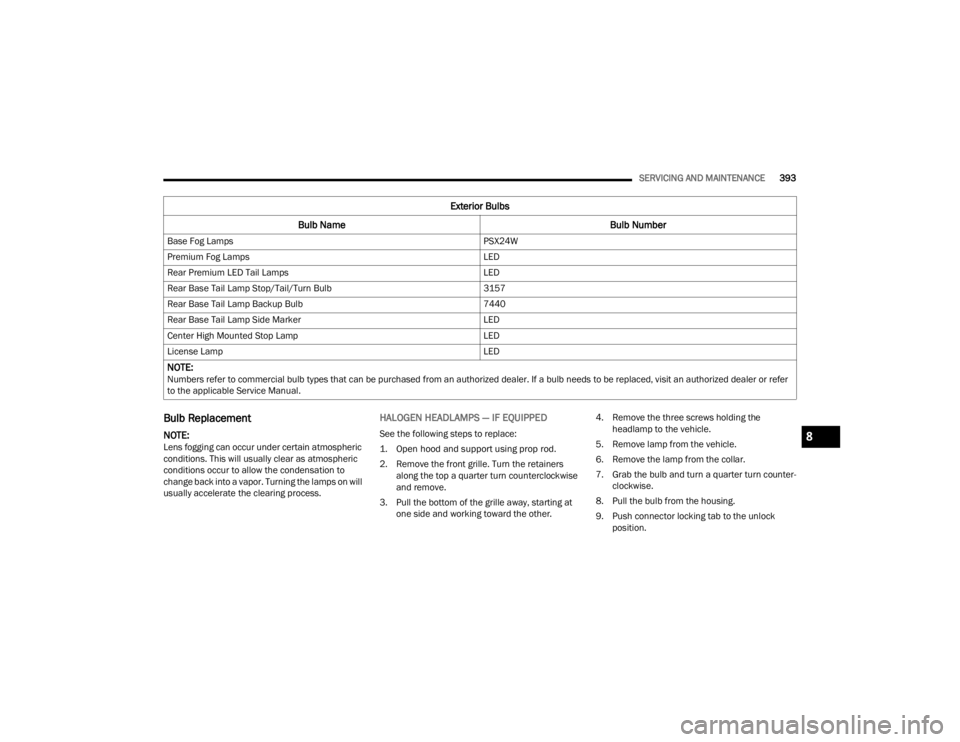

SERVICING AND MAINTENANCE393

Bulb Replacement

NOTE:Lens fogging can occur under certain atmospheric

conditions. This will usually clear as atmospheric

conditions occur to allow the condensation to

change back into a vapor. Turning the lamps on will

usually accelerate the clearing process.

HALOGEN HEADLAMPS — IF EQUIPPED

See the following steps to replace:

1. Open hood and support using prop rod.

2. Remove the front grille. Turn the retainers

along the top a quarter turn counterclockwise

and remove.

3. Pull the bottom of the grille away, starting at one side and working toward the other. 4. Remove the three screws holding the

headlamp to the vehicle.

5. Remove lamp from the vehicle.

6. Remove the lamp from the collar.

7. Grab the bulb and turn a quarter turn counter -

clockwise.

8. Pull the bulb from the housing.

9. Push connector locking tab to the unlock position.

Base Fog Lamps

PSX24W

Premium Fog Lamps LED

Rear Premium LED Tail Lamps LED

Rear Base Tail Lamp Stop/Tail/Turn Bulb 3157

Rear Base Tail Lamp Backup Bulb 7440

Rear Base Tail Lamp Side Marker LED

Center High Mounted Stop Lamp LED

License Lamp LED

NOTE: Numbers refer to commercial bulb types that can be purchased from an authorized dealer. If a bulb needs to be replaced, visit an authorized dealer or refer

to the applicable Service Manual.

Exterior Bulbs

Bulb Name Bulb Number

8

23_JT_OM_EN_USC_t.book Page 393

Page 396 of 448

394SERVICING AND MAINTENANCE

10. Remove connector from bulb.

11. Push connector onto new bulb base, and push the connector locking tab to the lock position.

12. Reinstall bulb housing. Rotate the bulb a quarter turn clockwise.

NOTE:We recommend seeing an authorized dealer for

service.

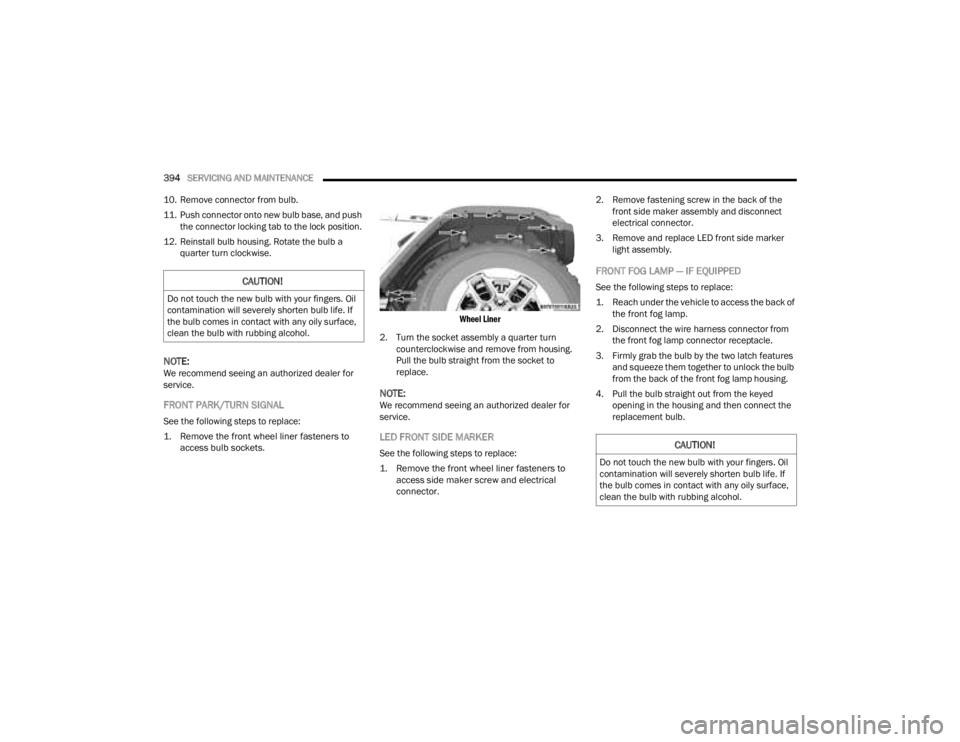

FRONT PARK/TURN SIGNAL

See the following steps to replace:

1. Remove the front wheel liner fasteners to access bulb sockets.

Wheel Liner

2. Turn the socket assembly a quarter turn counterclockwise and remove from housing.

Pull the bulb straight from the socket to

replace.

NOTE:We recommend seeing an authorized dealer for

service.

LED FRONT SIDE MARKER

See the following steps to replace:

1. Remove the front wheel liner fasteners to access side maker screw and electrical

connector.

2. Remove fastening screw in the back of the

front side maker assembly and disconnect

electrical connector.

3. Remove and replace LED front side marker light assembly.

FRONT FOG LAMP — IF EQUIPPED

See the following steps to replace:

1. Reach under the vehicle to access the back of the front fog lamp.

2. Disconnect the wire harness connector from the front fog lamp connector receptacle.

3. Firmly grab the bulb by the two latch features and squeeze them together to unlock the bulb

from the back of the front fog lamp housing.

4. Pull the bulb straight out from the keyed opening in the housing and then connect the

replacement bulb.CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If

the bulb comes in contact with any oily surface,

clean the bulb with rubbing alcohol.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If

the bulb comes in contact with any oily surface,

clean the bulb with rubbing alcohol.

23_JT_OM_EN_USC_t.book Page 394

Page 397 of 448

SERVICING AND MAINTENANCE395

LED Front Fog Lamp

If your vehicle is equipped with LED fog lamps they

are replaced as an assembly.

NOTE:We recommend seeing an authorized dealer for

service.

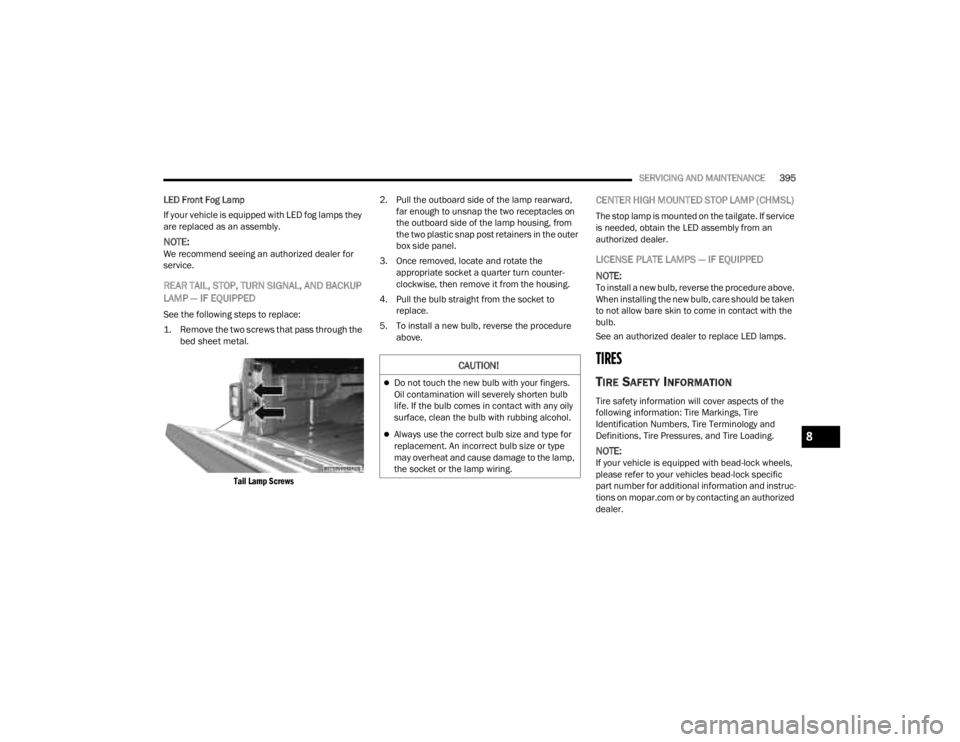

REAR TAIL, STOP, TURN SIGNAL, AND BACKUP

LAMP — IF EQUIPPED

See the following steps to replace:

1. Remove the two screws that pass through the bed sheet metal.

Tail Lamp Screws

2. Pull the outboard side of the lamp rearward,

far enough to unsnap the two receptacles on

the outboard side of the lamp housing, from

the two plastic snap post retainers in the outer

box side panel.

3. Once removed, locate and rotate the appropriate socket a quarter turn counter -

clockwise, then remove it from the housing.

4. Pull the bulb straight from the socket to replace.

5. To install a new bulb, reverse the procedure above.

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

The stop lamp is mounted on the tailgate. If service

is needed, obtain the LED assembly from an

authorized dealer.

LICENSE PLATE LAMPS — IF EQUIPPED

NOTE:

To install a new bulb, reverse the procedure above.

When installing the new bulb, care should be taken

to not allow bare skin to come in contact with the

bulb.

See an authorized dealer to replace LED lamps.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

NOTE:If your vehicle is equipped with bead-lock wheels,

please refer to your vehicles bead-lock specific

part number for additional information and instruc -

tions on mopar.com or by contacting an authorized

dealer.

CAUTION!

Do not touch the new bulb with your fingers.

Oil contamination will severely shorten bulb

life. If the bulb comes in contact with any oily

surface, clean the bulb with rubbing alcohol.

Always use the correct bulb size and type for

replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp,

the socket or the lamp wiring.8

23_JT_OM_EN_USC_t.book Page 395

Page 418 of 448

416SERVICING AND MAINTENANCE

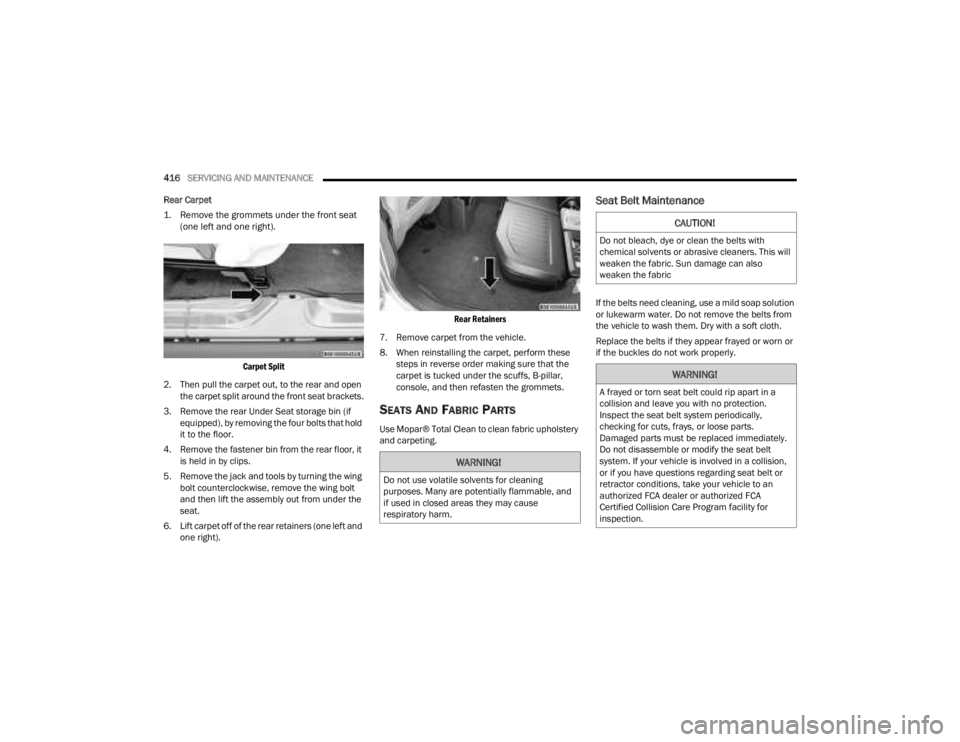

Rear Carpet

1. Remove the grommets under the front seat (one left and one right).

Carpet Split

2. Then pull the carpet out, to the rear and open the carpet split around the front seat brackets.

3. Remove the rear Under Seat storage bin (if equipped), by removing the four bolts that hold

it to the floor.

4. Remove the fastener bin from the rear floor, it is held in by clips.

5. Remove the jack and tools by turning the wing bolt counterclockwise, remove the wing bolt

and then lift the assembly out from under the

seat.

6. Lift carpet off of the rear retainers (one left and one right).

Rear Retainers

7. Remove carpet from the vehicle.

8. When reinstalling the carpet, perform these steps in reverse order making sure that the

carpet is tucked under the scuffs, B-pillar,

console, and then refasten the grommets.

SEATS AND FABRIC PARTS

Use Mopar® Total Clean to clean fabric upholstery

and carpeting.

Seat Belt Maintenance

If the belts need cleaning, use a mild soap solution

or lukewarm water. Do not remove the belts from

the vehicle to wash them. Dry with a soft cloth.

Replace the belts if they appear frayed or worn or

if the buckles do not work properly.

WARNING!

Do not use volatile solvents for cleaning

purposes. Many are potentially flammable, and

if used in closed areas they may cause

respiratory harm.

CAUTION!

Do not bleach, dye or clean the belts with

chemical solvents or abrasive cleaners. This will

weaken the fabric. Sun damage can also

weaken the fabric

WARNING!

A frayed or torn seat belt could rip apart in a

collision and leave you with no protection.

Inspect the seat belt system periodically,

checking for cuts, frays, or loose parts.

Damaged parts must be replaced immediately.

Do not disassemble or modify the seat belt

system. If your vehicle is involved in a collision,

or if you have questions regarding seat belt or

retractor conditions, take your vehicle to an

authorized FCA dealer or authorized FCA

Certified Collision Care Program facility for

inspection.

23_JT_OM_EN_USC_t.book Page 416