Max tire size JEEP GLADIATOR 2023 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: GLADIATOR, Model: JEEP GLADIATOR 2023Pages: 448, PDF Size: 17.37 MB

Page 41 of 448

GETTING TO KNOW YOUR VEHICLE39

2. With the bolts loose, the door can be moved forward by pushing the door handle toward the

front of the vehicle, and/or upward by grabbing

the door handle and lifting towards the roof.

3. Once the gaps between the door and vehicle body are uniform around the entire door,

tighten the door hinge bolts to 20.3 ft· lb /

27.5 N·m (Max Torque: 27.3 ft· lb / 37 N·m).

Upper Door Adjustment

After installation of the half-doors, if water leaks or

wind noise is observed, the seal of the upper

half-door to the door opening may need to be

adjusted.

To determine if the upper half-door needs to be

adjusted, proceed as follows:

1. Determine which door is affected.

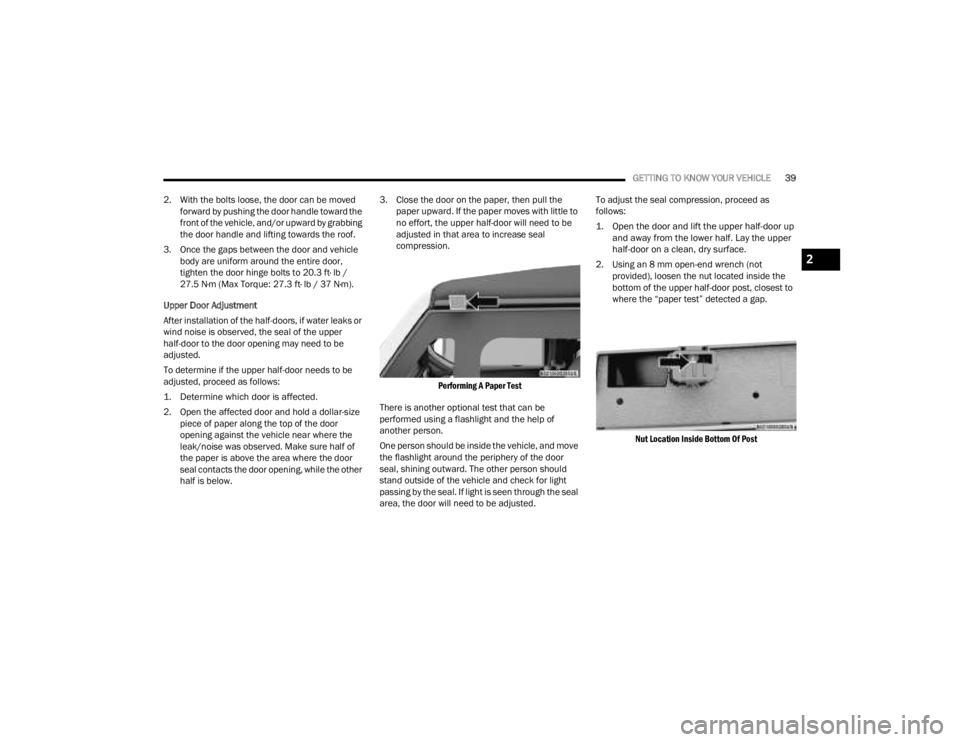

2. Open the affected door and hold a dollar-size piece of paper along the top of the door

opening against the vehicle near where the

leak/noise was observed. Make sure half of

the paper is above the area where the door

seal contacts the door opening, while the other

half is below. 3. Close the door on the paper, then pull the

paper upward. If the paper moves with little to

no effort, the upper half-door will need to be

adjusted in that area to increase seal

compression.

Performing A Paper Test

There is another optional test that can be

performed using a flashlight and the help of

another person.

One person should be inside the vehicle, and move

the flashlight around the periphery of the door

seal, shining outward. The other person should

stand outside of the vehicle and check for light

passing by the seal. If light is seen through the seal

area, the door will need to be adjusted. To adjust the seal compression, proceed as

follows:

1. Open the door and lift the upper half-door up

and away from the lower half. Lay the upper

half-door on a clean, dry surface.

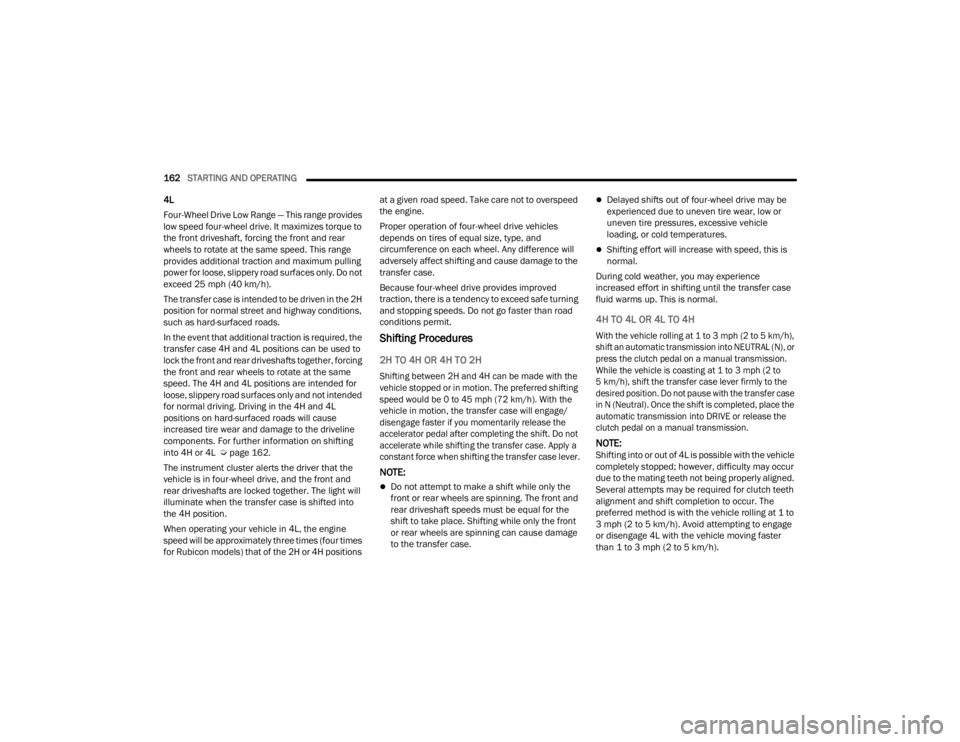

2. Using an 8 mm open-end wrench (not provided), loosen the nut located inside the

bottom of the upper half-door post, closest to

where the “paper test” detected a gap.

Nut Location Inside Bottom Of Post

2

23_JT_OM_EN_USC_t.book Page 39

Page 164 of 448

162STARTING AND OPERATING

4L

Four-Wheel Drive Low Range — This range provides

low speed four-wheel drive. It maximizes torque to

the front driveshaft, forcing the front and rear

wheels to rotate at the same speed. This range

provides additional traction and maximum pulling

power for loose, slippery road surfaces only. Do not

exceed 25 mph (40 km/h).

The transfer case is intended to be driven in the 2H

position for normal street and highway conditions,

such as hard-surfaced roads.

In the event that additional traction is required, the

transfer case 4H and 4L positions can be used to

lock the front and rear driveshafts together, forcing

the front and rear wheels to rotate at the same

speed. The 4H and 4L positions are intended for

loose, slippery road surfaces only and not intended

for normal driving. Driving in the 4H and 4L

positions on hard-surfaced roads will cause

increased tire wear and damage to the driveline

components. For further information on shifting

into 4H or 4L Ú page 162.

The instrument cluster alerts the driver that the

vehicle is in four-wheel drive, and the front and

rear driveshafts are locked together. The light will

illuminate when the transfer case is shifted into

the 4H position.

When operating your vehicle in 4L, the engine

speed will be approximately three times (four times

for Rubicon models) that of the 2H or 4H positions at a given road speed. Take care not to overspeed

the engine.

Proper operation of four-wheel drive vehicles

depends on tires of equal size, type, and

circumference on each wheel. Any difference will

adversely affect shifting and cause damage to the

transfer case.

Because four-wheel drive provides improved

traction, there is a tendency to exceed safe turning

and stopping speeds. Do not go faster than road

conditions permit.

Shifting Procedures

2H TO 4H OR 4H TO 2H

Shifting between 2H and 4H can be made with the

vehicle stopped or in motion. The preferred shifting

speed would be 0 to 45 mph (72 km/h). With the

vehicle in motion, the transfer case will engage/

disengage faster if you momentarily release the

accelerator pedal after completing the shift. Do not

accelerate while shifting the transfer case. Apply a

constant force when shifting the transfer case lever.

NOTE:

Do not attempt to make a shift while only the

front or rear wheels are spinning. The front and

rear driveshaft speeds must be equal for the

shift to take place. Shifting while only the front

or rear wheels are spinning can cause damage

to the transfer case.

Delayed shifts out of four-wheel drive may be

experienced due to uneven tire wear, low or

uneven tire pressures, excessive vehicle

loading, or cold temperatures.

Shifting effort will increase with speed, this is

normal.

During cold weather, you may experience

increased effort in shifting until the transfer case

fluid warms up. This is normal.

4H TO 4L OR 4L TO 4H

With the vehicle rolling at 1 to 3 mph (2 to 5 km/h),

shift an automatic transmission into NEUTRAL (N), or

press the clutch pedal on a manual transmission.

While the vehicle is coasting at 1 to 3 mph (2 to

5 km/h), shift the transfer case lever firmly to the

desired position. Do not pause with the transfer case

in N (Neutral). Once the shift is completed, place the

automatic transmission into DRIVE or release the

clutch pedal on a manual transmission.

NOTE:Shifting into or out of 4L is possible with the vehicle

completely stopped; however, difficulty may occur

due to the mating teeth not being properly aligned.

Several attempts may be required for clutch teeth

alignment and shift completion to occur. The

preferred method is with the vehicle rolling at 1 to

3 mph (2 to 5 km/h). Avoid attempting to engage

or disengage 4L with the vehicle moving faster

than 1 to 3 mph (2 to 5 km/h).

23_JT_OM_EN_USC_t.book Page 162

Page 198 of 448

196STARTING AND OPERATING

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), front and rear Gross Axle Weight Rating

(GAWR), and Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is included on this

label and indicates the Month, Day and Hour of

manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear Gross Axle

Weight Rating (GAWR). Total load must be limited

so GVWR on front and rear GAWR are not

exceeded.

Payload

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The

front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

Loading

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has not

been exceeded. The weight on the front and rear of

the vehicle should then be determined separately

to be sure that the load is properly distributed over

the front and rear axle. Weighing the vehicle may

show that the GAWR of either the front or rear axles

has been exceeded but the total load is within the

specified GVWR. If so, weight must be shifted from

front to rear or rear to front as appropriate until the

specified weight limitations are met. Store the

heavier items down low and be sure that the

weight is distributed equally. Stow all loose items

securely before driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

WARNING!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR. If

you do, parts on your vehicle can break, or it can

change the way your vehicle handles. This could

cause you to lose control. Overloading can

shorten the life of your vehicle.

23_JT_OM_EN_USC_t.book Page 196

Page 199 of 448

STARTING AND OPERATING197

TRAILER TOWING

In this section you will find safety tips and

information on limits to the type of towing you can

reasonably do with your vehicle. Before towing a

trailer, carefully review this information to tow your

load as efficiently and safely as possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and

recommendations in this manual concerning

vehicles used for trailer towing.

COMMON TOWING DEFINITIONS

The following trailer towing related definitions will

assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be limited

so that you do not exceed the GVWR Ú page 195.

Gross Trailer Weight (GTW)

The GTW is the weight of the trailer plus the weight

of all cargo, consumables and equipment

(permanent or temporary) loaded in or on the trailer

in its "loaded and ready for operation" condition.

The recommended way to measure GTW is to put

your fully loaded trailer on a vehicle scale. The

entire weight of the trailer must be supported by

the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total permissible weight of your

vehicle and trailer when weighed in combination.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR Úpage 195.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch

ball by the trailer. You must consider this as part of

the load on your vehicle.

Frontal Area

The frontal area is the maximum height multiplied

by the maximum width of the front of a trailer.

Trailer Sway Control (TSC) — If Equipped

The TSC is a telescoping link that can be installed

between the hitch receiver and the trailer tongue.

It typically provides adjustable friction associated

with the telescoping motion to dampen any

unwanted trailer swaying motions while traveling.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

Weight-Distributing Hitch

A Weight-Distributing Hitch system works by

applying leverage through spring (load) bars. They

are typically used for heavier loads to distribute

trailer tongue weight to the tow vehicle's front axle

and the trailer axle(s). When used in accordance

with the manufacturer's directions, it provides for a

more level ride, offering more consistent steering

and brake control thereby enhancing towing

safety. The addition of a friction/hydraulic sway

control also dampens sway caused by traffic and

crosswinds and contributes positively to tow

vehicle and trailer stability. Trailer sway control and

WARNING!

If the gross trailer weight is 2,000 lb (907 kg) or

more, it is recommended to use a weight-

distributing hitch to ensure stable handling of

your vehicle. If you use a standard weight-

carrying hitch, you could lose control of your

vehicle and cause a collision.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded.

4

23_JT_OM_EN_USC_t.book Page 197

Page 398 of 448

396SERVICING AND MAINTENANCE

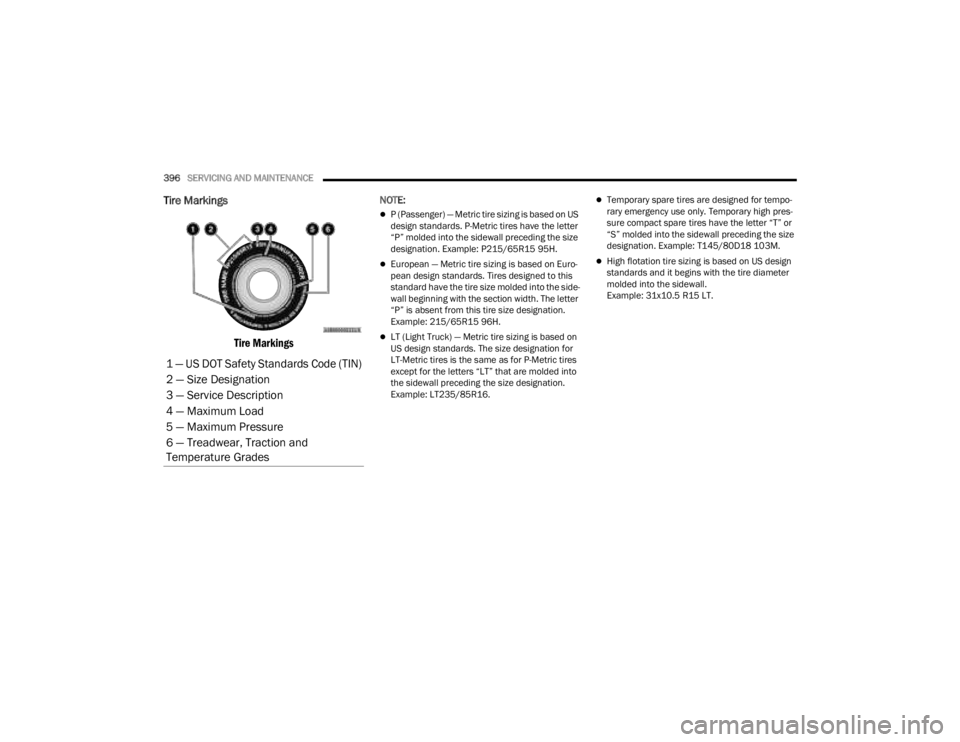

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on Euro -

pean design standards. Tires designed to this

standard have the tire size molded into the side -

wall beginning with the section width. The letter

“P” is absent from this tire size designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on

US design standards. The size designation for

LT-Metric tires is the same as for P-Metric tires

except for the letters “LT” that are molded into

the sidewall preceding the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for tempo -

rary emergency use only. Temporary high pres -

sure compact spare tires have the letter “T” or

“S” molded into the sidewall preceding the size

designation. Example: T145/80D18 103M.

High flotation tire sizing is based on US design

standards and it begins with the tire diameter

molded into the sidewall.

Example: 31x10.5 R15 LT.

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and

Temperature Grades

23_JT_OM_EN_USC_t.book Page 396

Page 399 of 448

SERVICING AND MAINTENANCE397

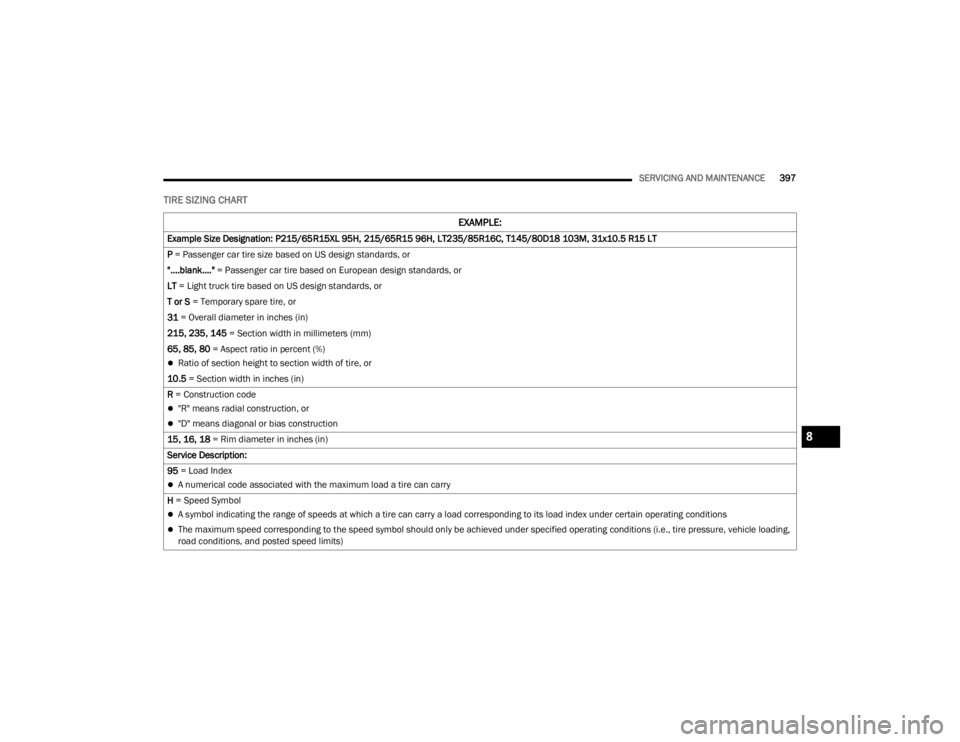

TIRE SIZING CHART

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire, or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading,

road conditions, and posted speed limits)

8

23_JT_OM_EN_USC_t.book Page 397

Page 400 of 448

398SERVICING AND MAINTENANCE

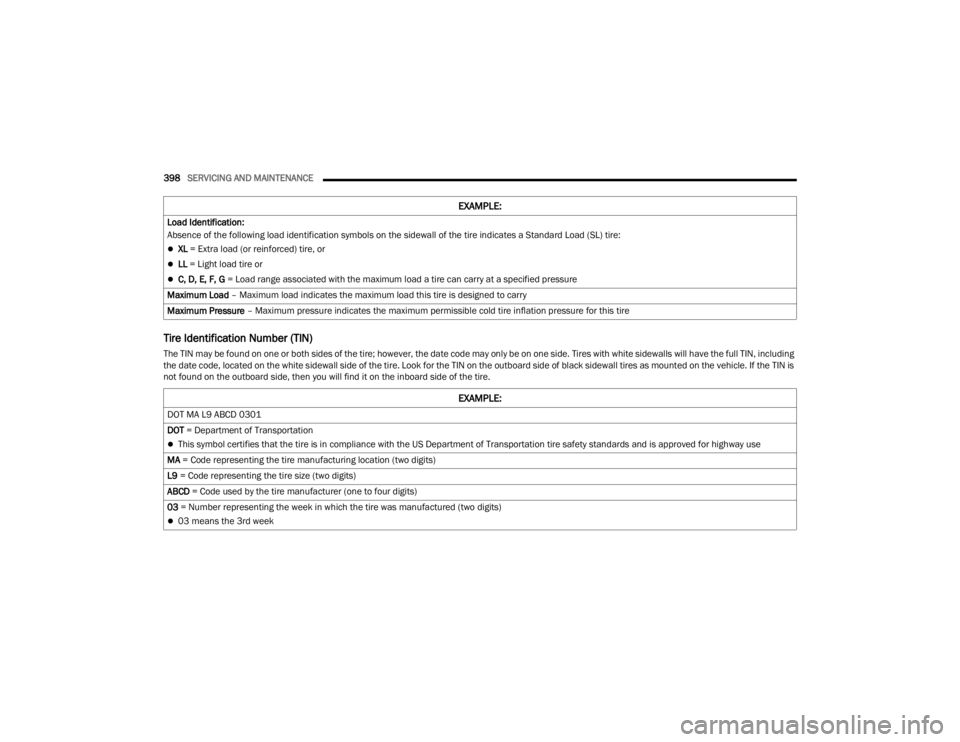

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white sidewalls will have the full TIN, including

the date code, located on the white sidewall side of the tire. Look for the TIN on the outboard side of black sidewall tires as mounted on the vehicle. If the TIN is

not found on the outboard side, then you will find it on the inboard side of the tire.Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL

= Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

03 means the 3rd week

23_JT_OM_EN_USC_t.book Page 398

Page 401 of 448

SERVICING AND MAINTENANCE399

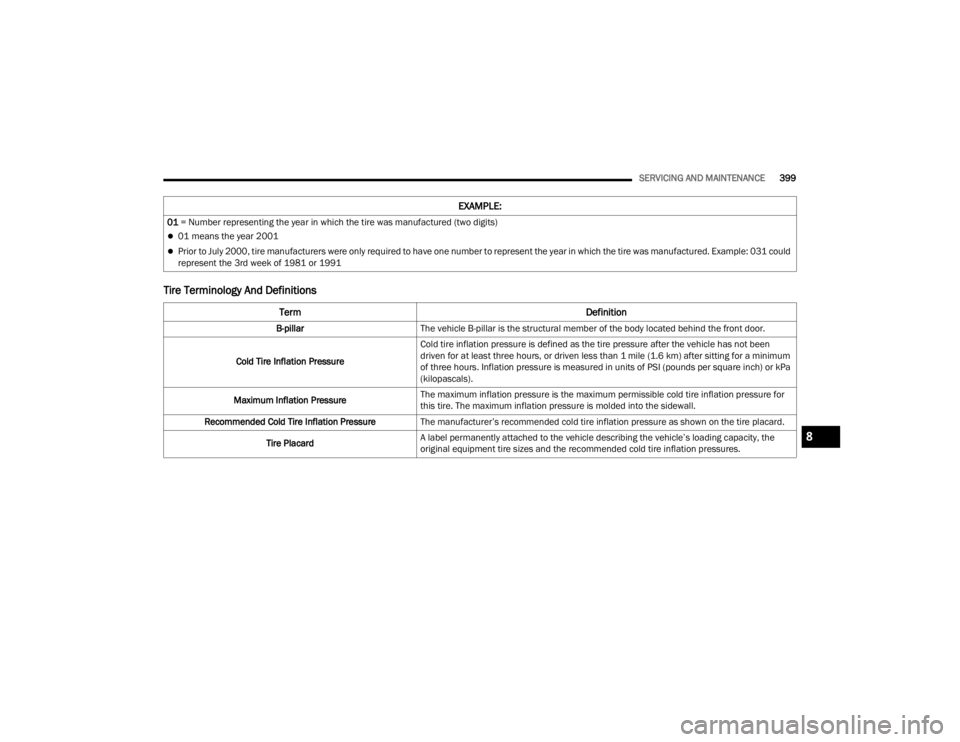

Tire Terminology And Definitions

01 = Number representing the year in which the tire was manufactured (two digits)

01 means the year 2001

Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was manufactured. Example: 031 could

represent the 3rd week of 1981 or 1991

Term Definition

B-pillarThe vehicle B-pillar is the structural member of the body located behind the front door.

Cold Tire Inflation Pressure Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been

driven for at least three hours, or driven less than 1 mile (1.6 km) after sitting for a minimum

of three hours. Inflation pressure is measured in units of PSI (pounds per square inch) or kPa

(kilopascals).

Maximum Inflation Pressure The maximum inflation pressure is the maximum permissible cold tire inflation pressure for

this tire. The maximum inflation pressure is molded into the sidewall.

Recommended Cold Tire Inflation Pressure The manufacturer’s recommended cold tire inflation pressure as shown on the tire placard.

Tire Placard A label permanently attached to the vehicle describing the vehicle’s loading capacity, the

original equipment tire sizes and the recommended cold tire inflation pressures.

EXAMPLE:

8

23_JT_OM_EN_USC_t.book Page 399

Page 402 of 448

400SERVICING AND MAINTENANCE

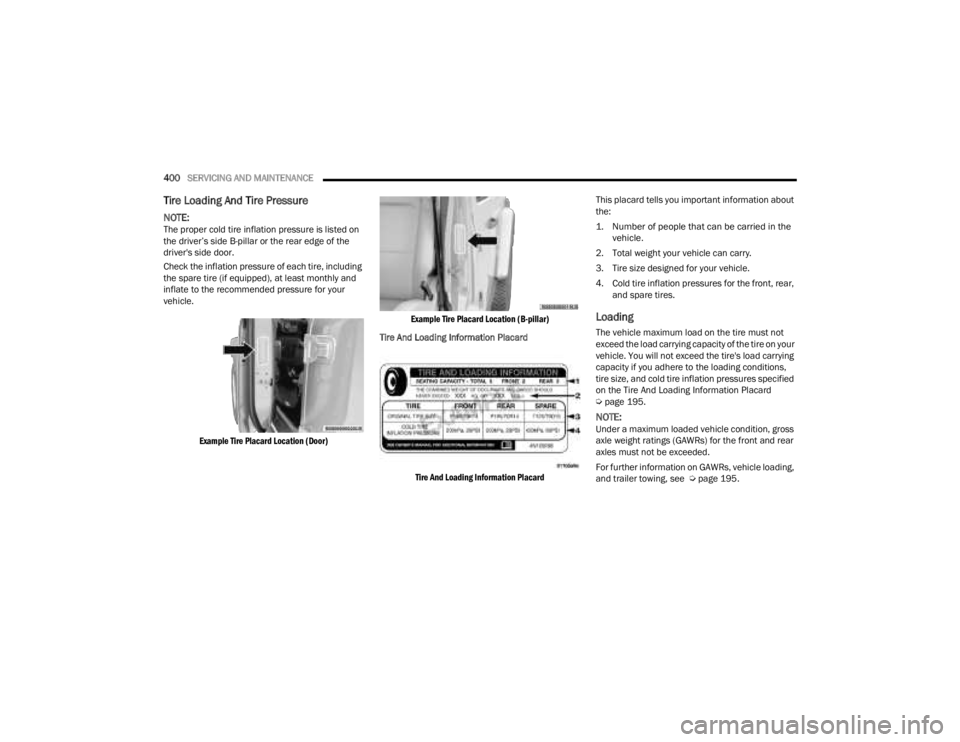

Tire Loading And Tire Pressure

NOTE:The proper cold tire inflation pressure is listed on

the driver’s side B-pillar or the rear edge of the

driver's side door.

Check the inflation pressure of each tire, including

the spare tire (if equipped), at least monthly and

inflate to the recommended pressure for your

vehicle.

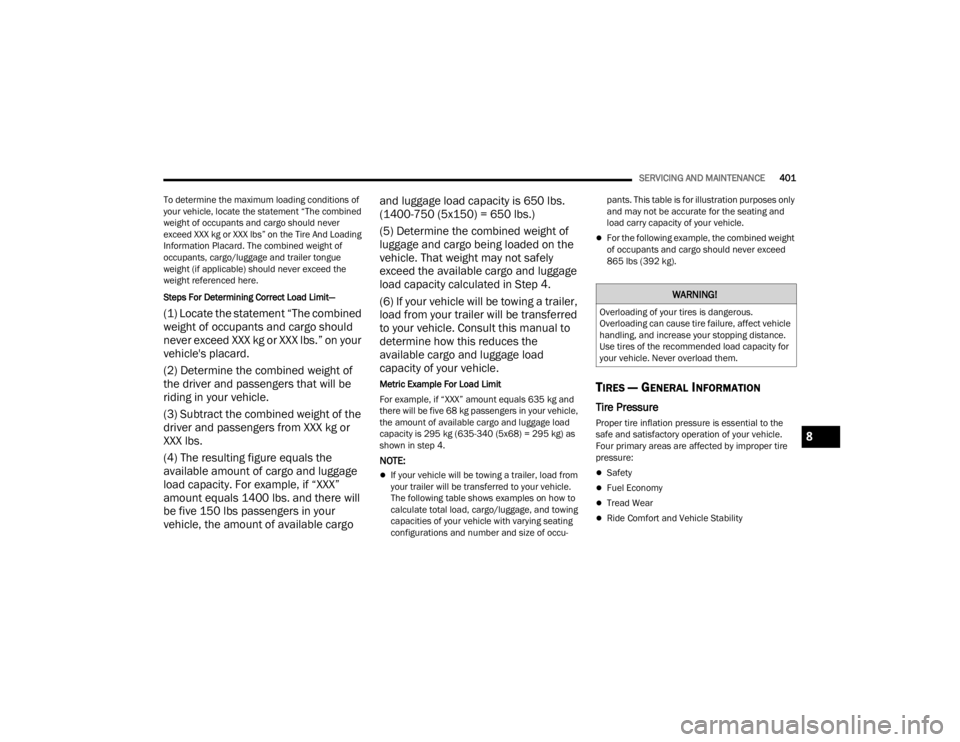

Example Tire Placard Location (Door) Example Tire Placard Location (B-pillar)

Tire And Loading Information Placard

Tire And Loading Information Placard

This placard tells you important information about

the:

1. Number of people that can be carried in the

vehicle.

2. Total weight your vehicle can carry.

3. Tire size designed for your vehicle.

4. Cold tire inflation pressures for the front, rear, and spare tires.

Loading

The vehicle maximum load on the tire must not

exceed the load carrying capacity of the tire on your

vehicle. You will not exceed the tire's load carrying

capacity if you adhere to the loading conditions,

tire size, and cold tire inflation pressures specified

on the Tire And Loading Information Placard

Úpage 195.

NOTE:Under a maximum loaded vehicle condition, gross

axle weight ratings (GAWRs) for the front and rear

axles must not be exceeded.

For further information on GAWRs, vehicle loading,

and trailer towing, see Ú page 195.

23_JT_OM_EN_USC_t.book Page 400

Page 403 of 448

SERVICING AND MAINTENANCE401

To determine the maximum loading conditions of

your vehicle, locate the statement “The combined

weight of occupants and cargo should never

exceed XXX kg or XXX lbs” on the Tire And Loading

Information Placard. The combined weight of

occupants, cargo/luggage and trailer tongue

weight (if applicable) should never exceed the

weight referenced here.

Steps For Determining Correct Load Limit—

(1) Locate the statement “The combined

weight of occupants and cargo should

never exceed XXX kg or XXX lbs.” on your

vehicle's placard.

(2) Determine the combined weight of

the driver and passengers that will be

riding in your vehicle.

(3) Subtract the combined weight of the

driver and passengers from XXX kg or

XXX lbs.

(4) The resulting figure equals the

available amount of cargo and luggage

load capacity. For example, if “XXX”

amount equals 1400 lbs. and there will

be five 150 lbs passengers in your

vehicle, the amount of available cargo and luggage load capacity is 650 lbs.

(1400-750 (5x150) = 650 lbs.)

(5) Determine the combined weight of

luggage and cargo being loaded on the

vehicle. That weight may not safely

exceed the available cargo and luggage

load capacity calculated in Step 4.

(6) If your vehicle will be towing a trailer,

load from your trailer will be transferred

to your vehicle. Consult this manual to

determine how this reduces the

available cargo and luggage load

capacity of your vehicle.

Metric Example For Load Limit

For example, if “XXX” amount equals 635 kg and

there will be five 68 kg passengers in your vehicle,

the amount of available cargo and luggage load

capacity is 295 kg (635-340 (5x68) = 295 kg) as

shown in step 4.

NOTE:

If your vehicle will be towing a trailer, load from

your trailer will be transferred to your vehicle.

The following table shows examples on how to

calculate total load, cargo/luggage, and towing

capacities of your vehicle with varying seating

configurations and number and size of occu

-pants. This table is for illustration purposes only

and may not be accurate for the seating and

load carry capacity of your vehicle.

For the following example, the combined weight

of occupants and cargo should never exceed

865 lbs (392 kg).

TIRES — GENERAL INFORMATION

Tire Pressure

Proper tire inflation pressure is essential to the

safe and satisfactory operation of your vehicle.

Four primary areas are affected by improper tire

pressure:

Safety

Fuel Economy

Tread Wear

Ride Comfort and Vehicle Stability

WARNING!

Overloading of your tires is dangerous.

Overloading can cause tire failure, affect vehicle

handling, and increase your stopping distance.

Use tires of the recommended load capacity for

your vehicle. Never overload them.

8

23_JT_OM_EN_USC_t.book Page 401