piston JEEP GRAND CHEROKEE 2002 WJ / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1578 of 2199

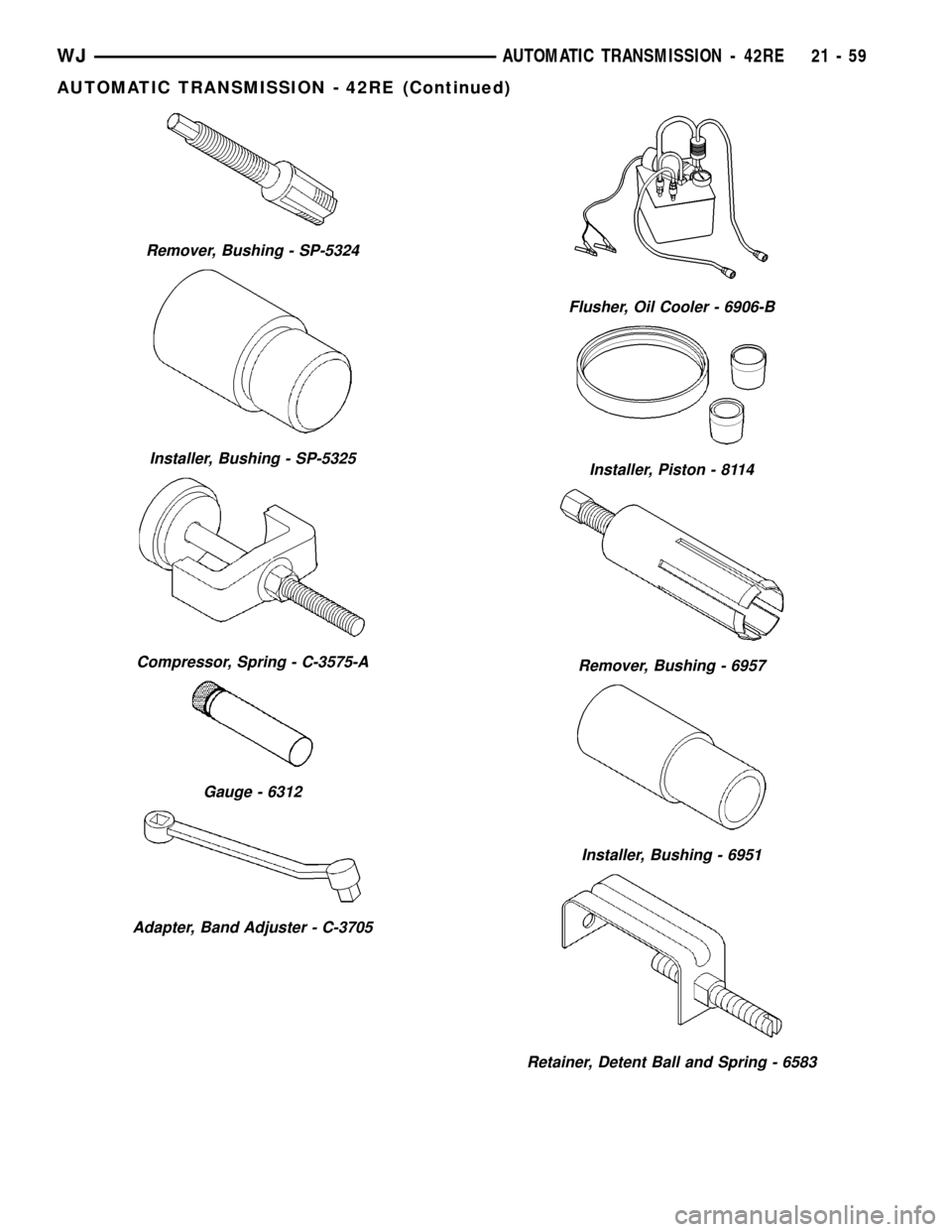

Remover, Bushing - SP-5324

Installer, Bushing - SP-5325

Compressor, Spring - C-3575-A

Gauge - 6312

Adapter, Band Adjuster - C-3705

Flusher, Oil Cooler - 6906-B

Installer, Piston - 8114

Remover, Bushing - 6957

Installer, Bushing - 6951

Retainer, Detent Ball and Spring - 6583

WJAUTOMATIC TRANSMISSION - 42RE 21 - 59

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1579 of 2199

ACCUMULATOR

DESCRIPTION

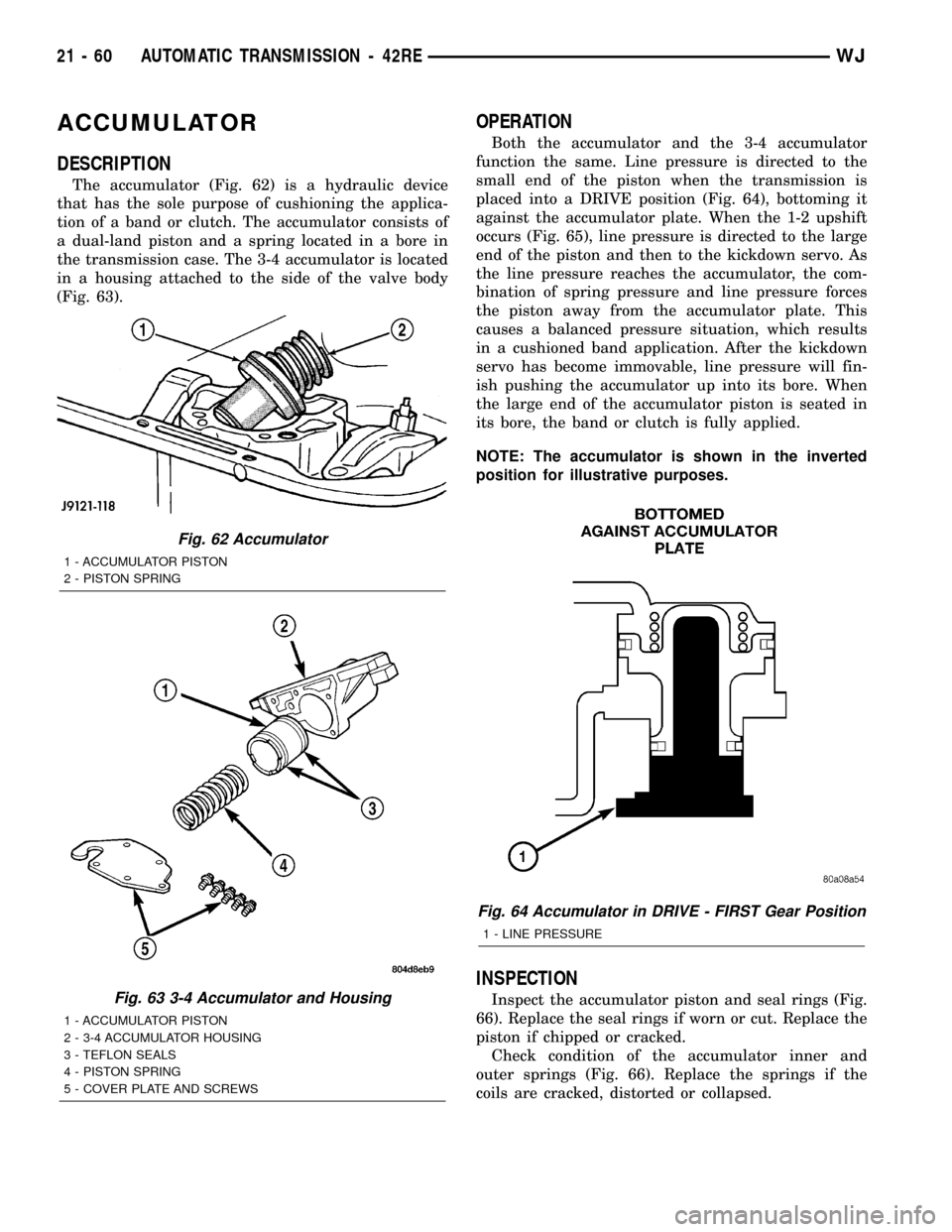

The accumulator (Fig. 62) is a hydraulic device

that has the sole purpose of cushioning the applica-

tion of a band or clutch. The accumulator consists of

a dual-land piston and a spring located in a bore in

the transmission case. The 3-4 accumulator is located

in a housing attached to the side of the valve body

(Fig. 63).

OPERATION

Both the accumulator and the 3-4 accumulator

function the same. Line pressure is directed to the

small end of the piston when the transmission is

placed into a DRIVE position (Fig. 64), bottoming it

against the accumulator plate. When the 1-2 upshift

occurs (Fig. 65), line pressure is directed to the large

end of the piston and then to the kickdown servo. As

the line pressure reaches the accumulator, the com-

bination of spring pressure and line pressure forces

the piston away from the accumulator plate. This

causes a balanced pressure situation, which results

in a cushioned band application. After the kickdown

servo has become immovable, line pressure will fin-

ish pushing the accumulator up into its bore. When

the large end of the accumulator piston is seated in

its bore, the band or clutch is fully applied.

NOTE: The accumulator is shown in the inverted

position for illustrative purposes.

INSPECTION

Inspect the accumulator piston and seal rings (Fig.

66). Replace the seal rings if worn or cut. Replace the

piston if chipped or cracked.

Check condition of the accumulator inner and

outer springs (Fig. 66). Replace the springs if the

coils are cracked, distorted or collapsed.

Fig. 62 Accumulator

1 - ACCUMULATOR PISTON

2 - PISTON SPRING

Fig. 63 3-4 Accumulator and Housing

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

Fig. 64 Accumulator in DRIVE - FIRST Gear Position

1 - LINE PRESSURE

21 - 60 AUTOMATIC TRANSMISSION - 42REWJ

Page 1580 of 2199

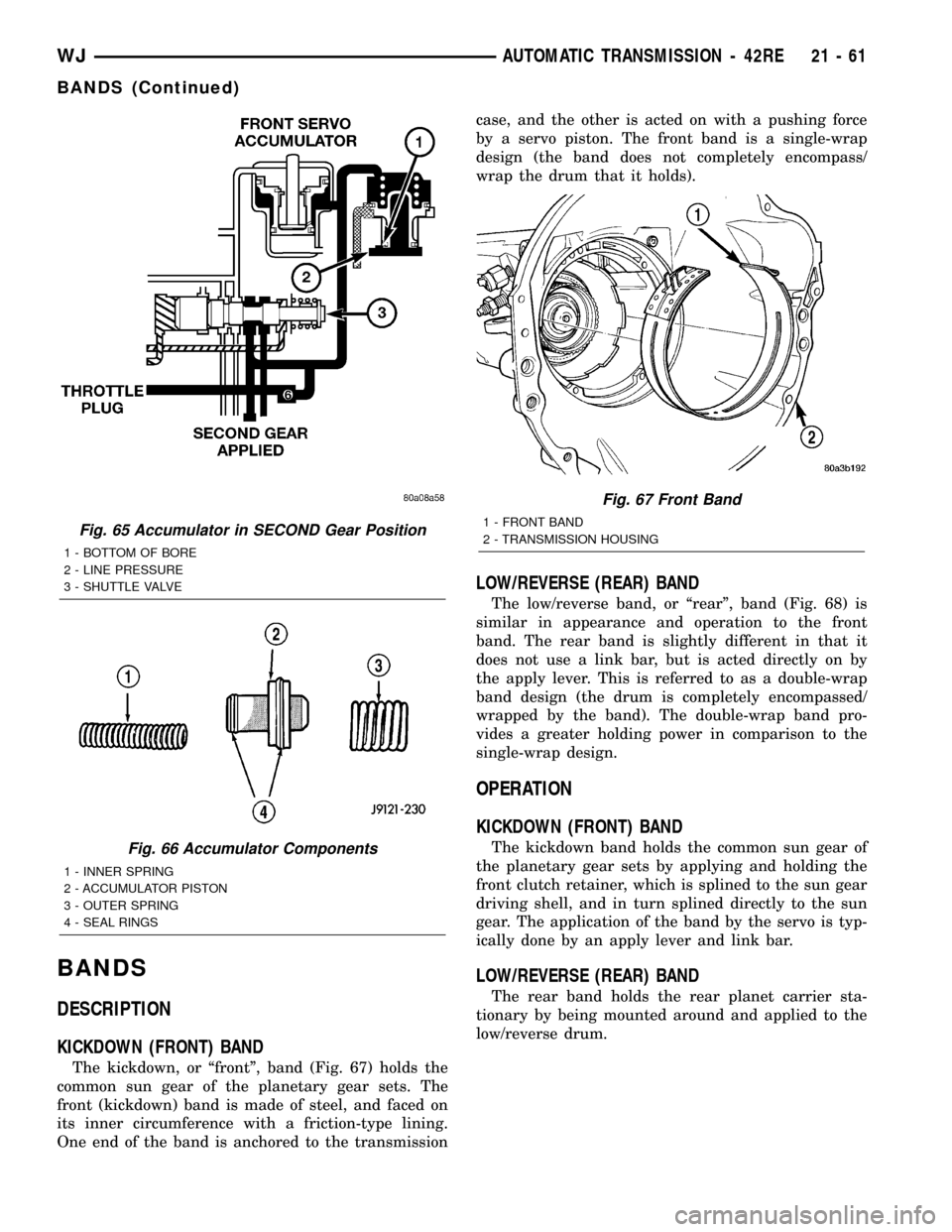

BANDS

DESCRIPTION

KICKDOWN (FRONT) BAND

The kickdown, or ªfrontº, band (Fig. 67) holds the

common sun gear of the planetary gear sets. The

front (kickdown) band is made of steel, and faced on

its inner circumference with a friction-type lining.

One end of the band is anchored to the transmissioncase, and the other is acted on with a pushing force

by a servo piston. The front band is a single-wrap

design (the band does not completely encompass/

wrap the drum that it holds).

LOW/REVERSE (REAR) BAND

The low/reverse band, or ªrearº, band (Fig. 68) is

similar in appearance and operation to the front

band. The rear band is slightly different in that it

does not use a link bar, but is acted directly on by

the apply lever. This is referred to as a double-wrap

band design (the drum is completely encompassed/

wrapped by the band). The double-wrap band pro-

vides a greater holding power in comparison to the

single-wrap design.

OPERATION

KICKDOWN (FRONT) BAND

The kickdown band holds the common sun gear of

the planetary gear sets by applying and holding the

front clutch retainer, which is splined to the sun gear

driving shell, and in turn splined directly to the sun

gear. The application of the band by the servo is typ-

ically done by an apply lever and link bar.

LOW/REVERSE (REAR) BAND

The rear band holds the rear planet carrier sta-

tionary by being mounted around and applied to the

low/reverse drum.

Fig. 65 Accumulator in SECOND Gear Position

1 - BOTTOM OF BORE

2 - LINE PRESSURE

3 - SHUTTLE VALVE

Fig. 66 Accumulator Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 67 Front Band

1 - FRONT BAND

2 - TRANSMISSION HOUSING

WJAUTOMATIC TRANSMISSION - 42RE 21 - 61

BANDS (Continued)

Page 1592 of 2199

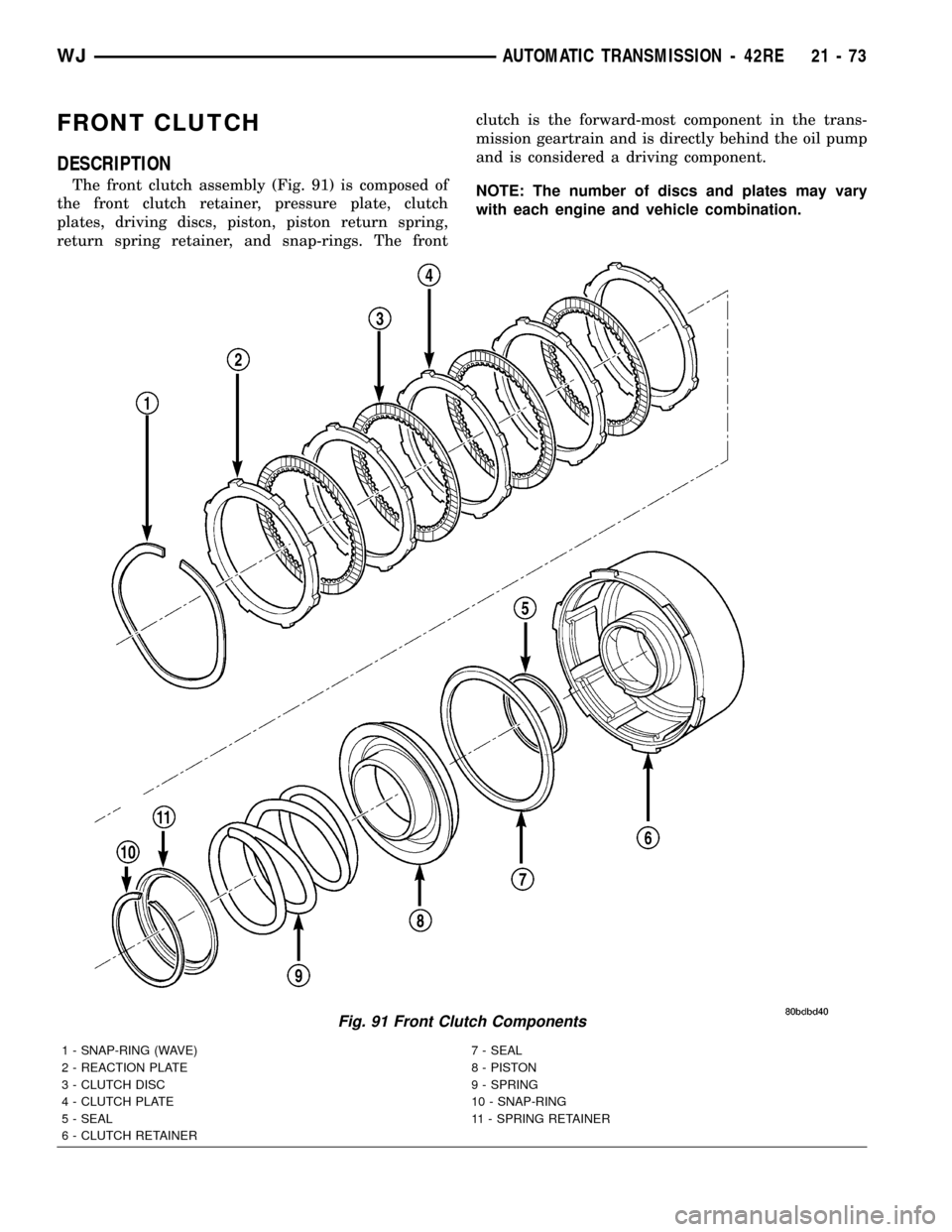

FRONT CLUTCH

DESCRIPTION

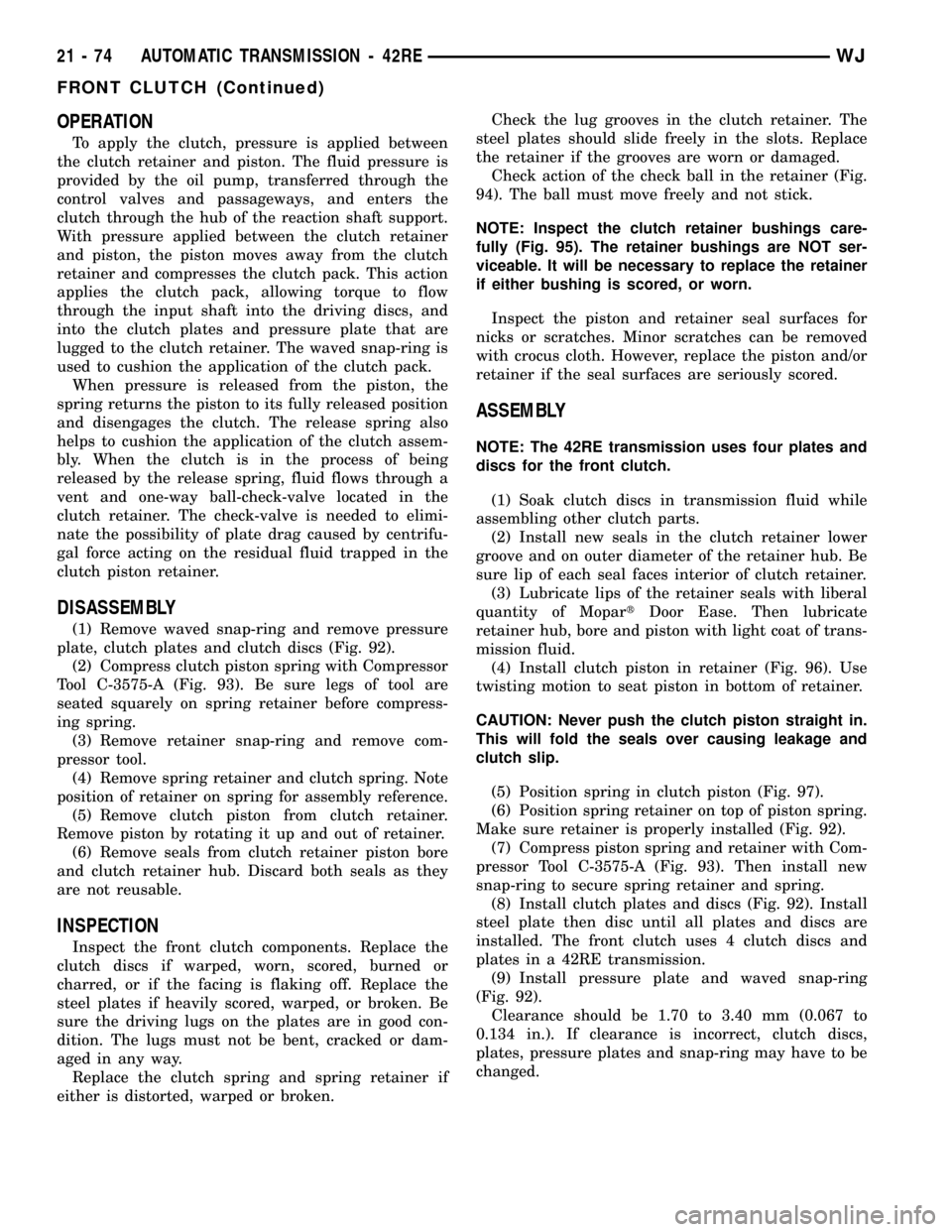

The front clutch assembly (Fig. 91) is composed of

the front clutch retainer, pressure plate, clutch

plates, driving discs, piston, piston return spring,

return spring retainer, and snap-rings. The frontclutch is the forward-most component in the trans-

mission geartrain and is directly behind the oil pump

and is considered a driving component.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

Fig. 91 Front Clutch Components

1 - SNAP-RING (WAVE) 7 - SEAL

2 - REACTION PLATE 8 - PISTON

3 - CLUTCH DISC 9 - SPRING

4 - CLUTCH PLATE 10 - SNAP-RING

5 - SEAL 11 - SPRING RETAINER

6 - CLUTCH RETAINER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 73

Page 1593 of 2199

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved snap-ring is

used to cushion the application of the clutch pack.

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the

clutch retainer. The check-valve is needed to elimi-

nate the possibility of plate drag caused by centrifu-

gal force acting on the residual fluid trapped in the

clutch piston retainer.

DISASSEMBLY

(1) Remove waved snap-ring and remove pressure

plate, clutch plates and clutch discs (Fig. 92).

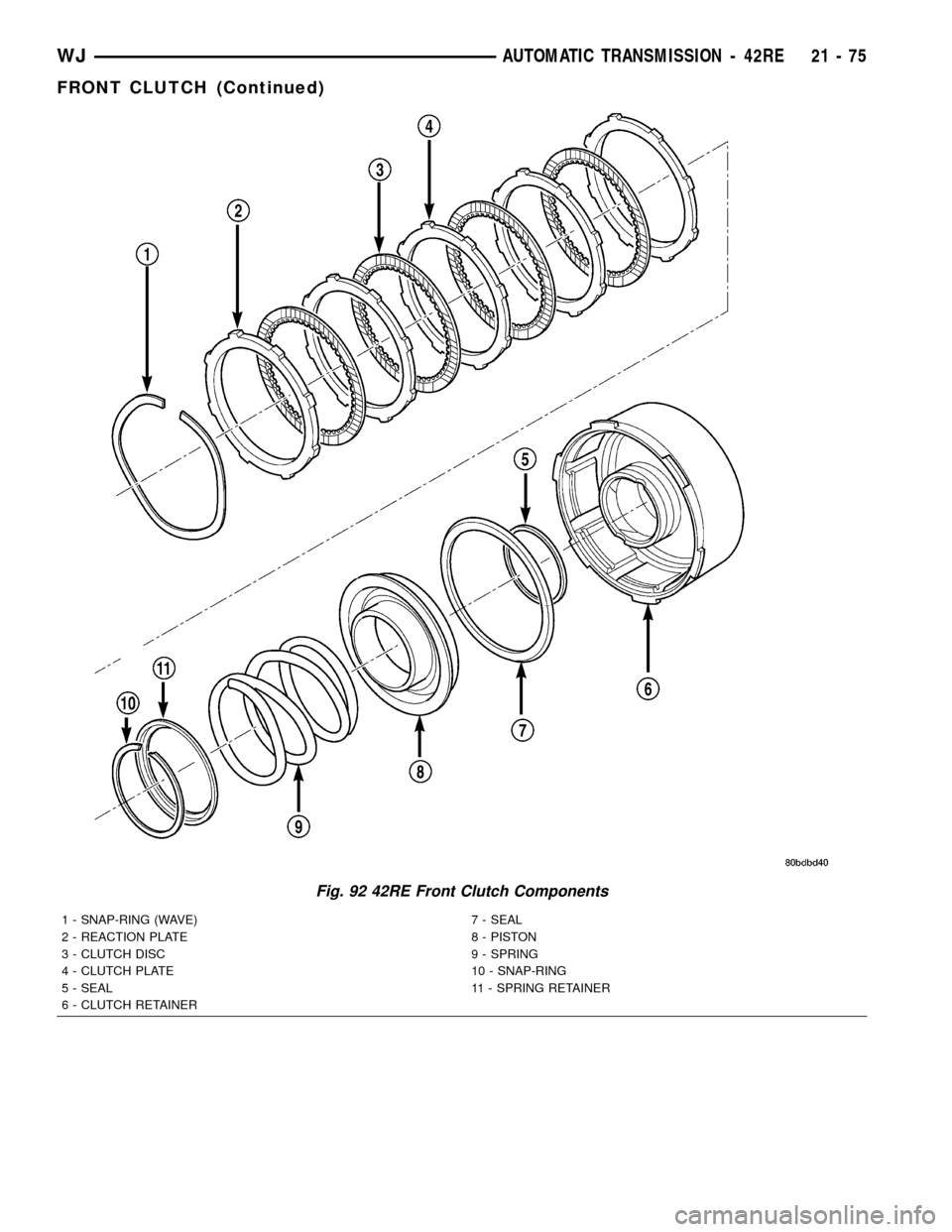

(2) Compress clutch piston spring with Compressor

Tool C-3575-A (Fig. 93). Be sure legs of tool are

seated squarely on spring retainer before compress-

ing spring.

(3) Remove retainer snap-ring and remove com-

pressor tool.

(4) Remove spring retainer and clutch spring. Note

position of retainer on spring for assembly reference.

(5) Remove clutch piston from clutch retainer.

Remove piston by rotating it up and out of retainer.

(6) Remove seals from clutch retainer piston bore

and clutch retainer hub. Discard both seals as they

are not reusable.

INSPECTION

Inspect the front clutch components. Replace the

clutch discs if warped, worn, scored, burned or

charred, or if the facing is flaking off. Replace the

steel plates if heavily scored, warped, or broken. Be

sure the driving lugs on the plates are in good con-

dition. The lugs must not be bent, cracked or dam-

aged in any way.

Replace the clutch spring and spring retainer if

either is distorted, warped or broken.Check the lug grooves in the clutch retainer. The

steel plates should slide freely in the slots. Replace

the retainer if the grooves are worn or damaged.

Check action of the check ball in the retainer (Fig.

94). The ball must move freely and not stick.

NOTE: Inspect the clutch retainer bushings care-

fully (Fig. 95). The retainer bushings are NOT ser-

viceable. It will be necessary to replace the retainer

if either bushing is scored, or worn.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

ASSEMBLY

NOTE: The 42RE transmission uses four plates and

discs for the front clutch.

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seals in the clutch retainer lower

groove and on outer diameter of the retainer hub. Be

sure lip of each seal faces interior of clutch retainer.

(3) Lubricate lips of the retainer seals with liberal

quantity of MopartDoor Ease. Then lubricate

retainer hub, bore and piston with light coat of trans-

mission fluid.

(4) Install clutch piston in retainer (Fig. 96). Use

twisting motion to seat piston in bottom of retainer.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip.

(5) Position spring in clutch piston (Fig. 97).

(6) Position spring retainer on top of piston spring.

Make sure retainer is properly installed (Fig. 92).

(7) Compress piston spring and retainer with Com-

pressor Tool C-3575-A (Fig. 93). Then install new

snap-ring to secure spring retainer and spring.

(8) Install clutch plates and discs (Fig. 92). Install

steel plate then disc until all plates and discs are

installed. The front clutch uses 4 clutch discs and

plates in a 42RE transmission.

(9) Install pressure plate and waved snap-ring

(Fig. 92).

Clearance should be 1.70 to 3.40 mm (0.067 to

0.134 in.). If clearance is incorrect, clutch discs,

plates, pressure plates and snap-ring may have to be

changed.

21 - 74 AUTOMATIC TRANSMISSION - 42REWJ

FRONT CLUTCH (Continued)

Page 1594 of 2199

Fig. 92 42RE Front Clutch Components

1 - SNAP-RING (WAVE) 7 - SEAL

2 - REACTION PLATE 8 - PISTON

3 - CLUTCH DISC 9 - SPRING

4 - CLUTCH PLATE 10 - SNAP-RING

5 - SEAL 11 - SPRING RETAINER

6 - CLUTCH RETAINER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 75

FRONT CLUTCH (Continued)

Page 1595 of 2199

Fig. 93 Compressing Front Clutch Piston Spring

1 - FRONT CLUTCH SPRING

2 - COMPRESSOR TOOL C-3575-A

3 - RETAINER SNAP-RING

4 - SPRING RETAINER

Fig. 94 Front Clutch Piston Retainer Check Ball

Location

1 - RETAINER CHECK BALL

Fig. 95 Retainer Bushing Location/Inspection

1 - FRONT CLUTCH RETAINER BUSHINGS (NON-

SERVICEABLE)

Fig. 96 Front Clutch Piston Installation

1 - CLUTCH PISTON

2 - FRONT CLUTCH RETAINER

Fig. 97 Clutch Piston Spring Installation

1 - RETAINER

2 - CLUTCH SPRING

3 - PISTON

21 - 76 AUTOMATIC TRANSMISSION - 42REWJ

FRONT CLUTCH (Continued)

Page 1596 of 2199

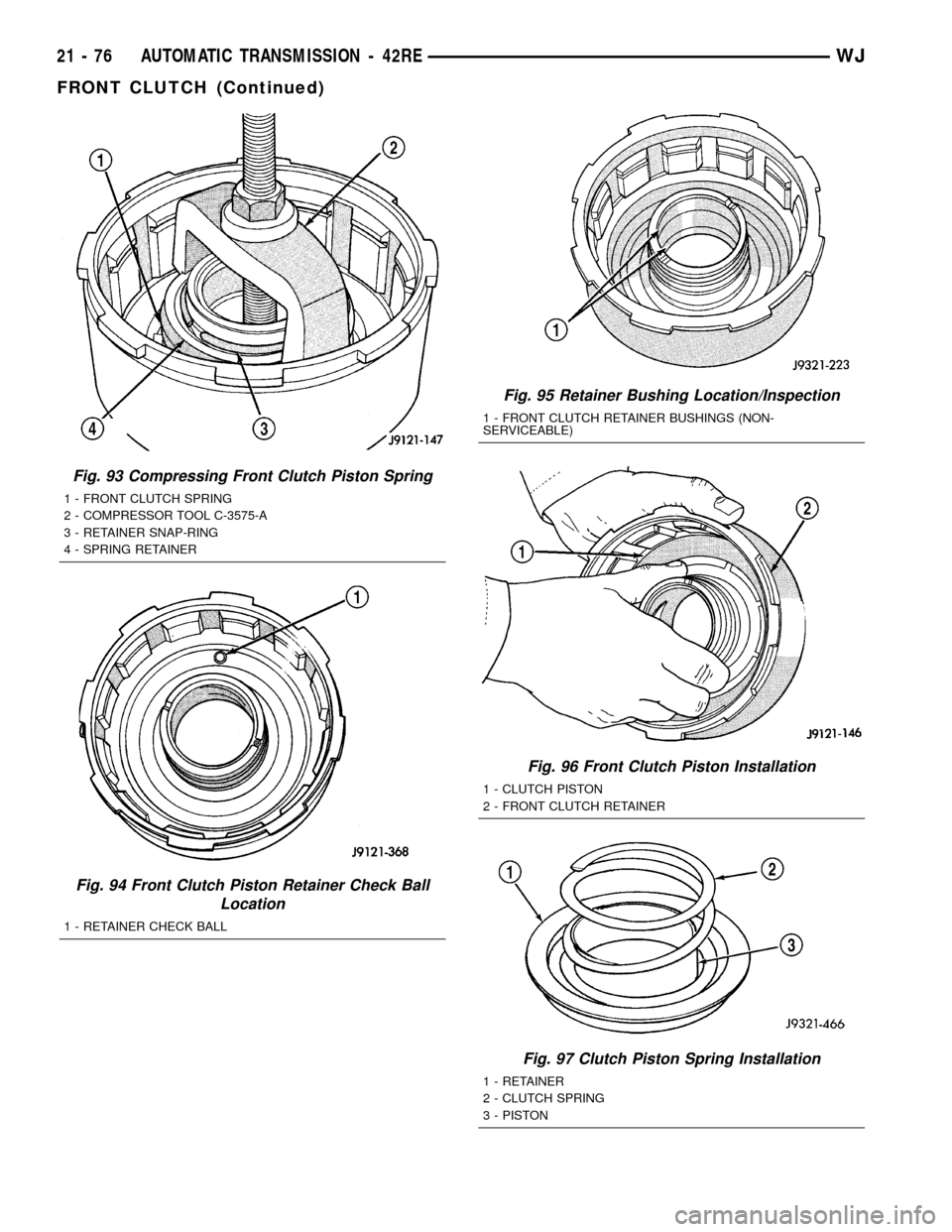

FRONT SERVO

DESCRIPTION

The kickdown servo (Fig. 98) consists of a two-land

piston with an inner piston, a piston rod and guide,

and a return spring. The dual-land piston uses seal

rings on its outer diameters and an O-ring for the

inner piston.

OPERATION

The application of the piston is accomplished by

applying pressure between the two lands of the pis-

ton. The pressure acts against the larger lower land

to push the piston downward, allowing the piston rod

to extend though its guide against the apply lever.

Release of the servo at the 2-3 upshift is accom-

plished by a combination of spring and line pressure,

acting on the bottom of the larger land of the piston.

The small piston is used to cushion the application of

the band by bleeding oil through a small orifice in

the larger piston. The release timing of the kickdown

servo is very important to obtain a smooth but firm

shift. The release has to be very quick, just as the

front clutch application is taking place. Otherwise,

engine runaway or a shift hesitation will occur. To

accomplish this, the band retains its holding capacity

until the front clutch is applied, giving a small

amount of overlap between them.

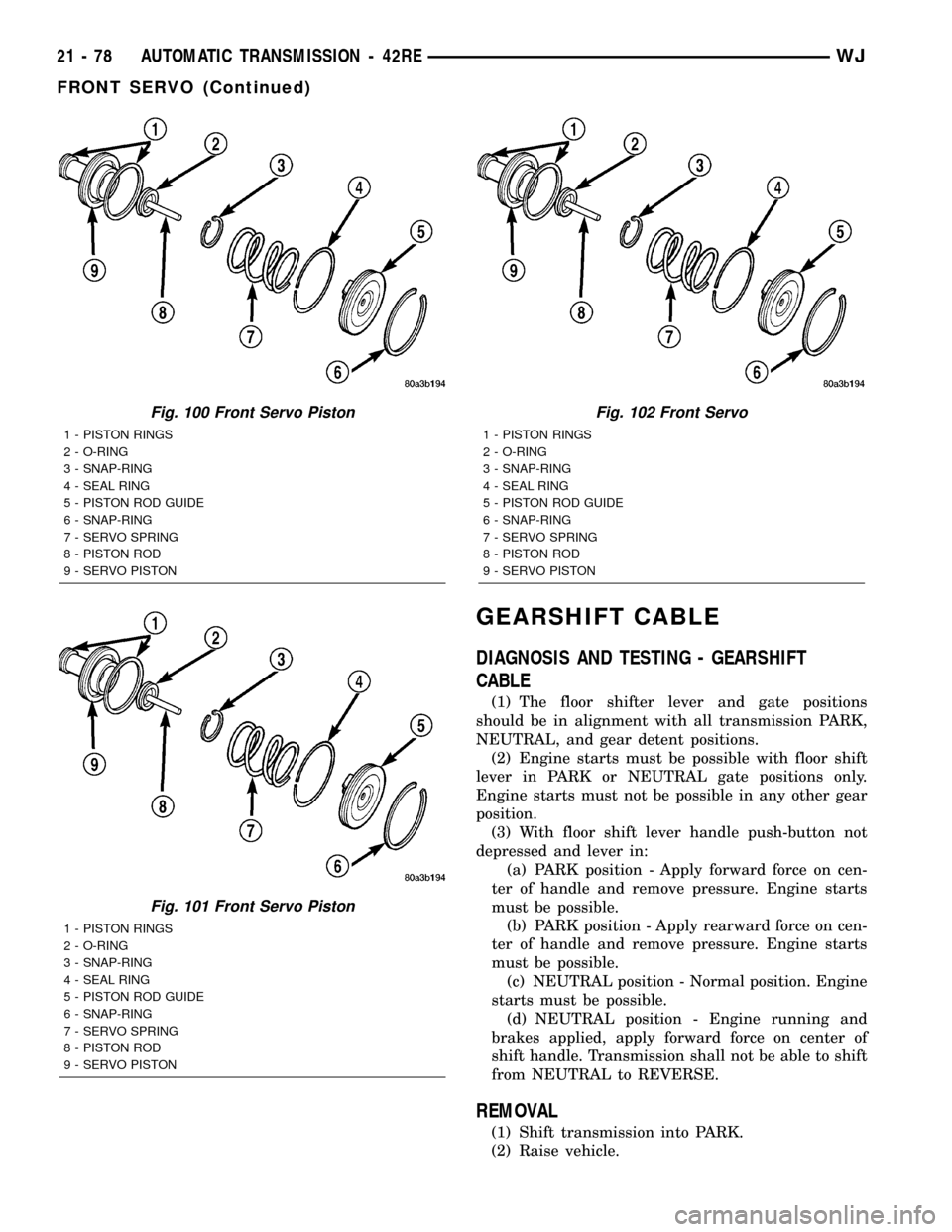

DISASSEMBLY

(1) Remove seal ring from rod guide (Fig. 99).(2) Remove small snap-ring from servo piston rod.

Then remove piston rod, spring and washer from pis-

ton.

(3) Remove and discard servo component o-ring

and seal rings.

CLEANING

Clean the servo piston components (Fig. 100) with

solvent and dry them with compressed air.

INSPECTION

Inspect the servo components (Fig. 101). Replace

the springs if collapsed, distorted or broken. Replace

the guide, rod and piston if cracked, bent, or worn.

Discard the servo snap-ring if distorted or warped.

Check the servo piston bore for wear. If the bore is

severely scored, or damaged, it will be necessary to

replace the case.

Replace any servo component if doubt exists about

condition. Do not reuse suspect parts.

ASSEMBLY

Clean and inspect front servo components.

(1) Lubricate new o-ring and seal rings with petro-

leum jelly and install them on piston, guide and rod.

(2) Install rod in piston. Install spring and washer

on rod. Compress spring and install snap-ring (Fig.

102).

Fig. 98 Front Servo

1 - VENT

2 -PISTON ROD

3 - PISTON

4 - SPRING

5 - RELEASE PRESSURE

6 - APPLY PRESSURE

Fig. 99 Front Servo

1 - PISTON RINGS

2 - O-RING

3 - SNAP-RING

4 - SEAL RING

5 - PISTON ROD GUIDE

6 - SNAP-RING

7 - SERVO SPRING

8 - PISTON ROD

9 - SERVO PISTON

WJAUTOMATIC TRANSMISSION - 42RE 21 - 77

Page 1597 of 2199

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE

(1) The floor shifter lever and gate positions

should be in alignment with all transmission PARK,

NEUTRAL, and gear detent positions.

(2) Engine starts must be possible with floor shift

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gear

position.

(3) With floor shift lever handle push-button not

depressed and lever in:

(a) PARK position - Apply forward force on cen-

ter of handle and remove pressure. Engine starts

must be possible.

(b) PARK position - Apply rearward force on cen-

ter of handle and remove pressure. Engine starts

must be possible.

(c) NEUTRAL position - Normal position. Engine

starts must be possible.

(d) NEUTRAL position - Engine running and

brakes applied, apply forward force on center of

shift handle. Transmission shall not be able to shift

from NEUTRAL to REVERSE.

REMOVAL

(1) Shift transmission into PARK.

(2) Raise vehicle.

Fig. 100 Front Servo Piston

1 - PISTON RINGS

2 - O-RING

3 - SNAP-RING

4 - SEAL RING

5 - PISTON ROD GUIDE

6 - SNAP-RING

7 - SERVO SPRING

8 - PISTON ROD

9 - SERVO PISTON

Fig. 101 Front Servo Piston

1 - PISTON RINGS

2 - O-RING

3 - SNAP-RING

4 - SEAL RING

5 - PISTON ROD GUIDE

6 - SNAP-RING

7 - SERVO SPRING

8 - PISTON ROD

9 - SERVO PISTON

Fig. 102 Front Servo

1 - PISTON RINGS

2 - O-RING

3 - SNAP-RING

4 - SEAL RING

5 - PISTON ROD GUIDE

6 - SNAP-RING

7 - SERVO SPRING

8 - PISTON ROD

9 - SERVO PISTON

21 - 78 AUTOMATIC TRANSMISSION - 42REWJ

FRONT SERVO (Continued)

Page 1605 of 2199

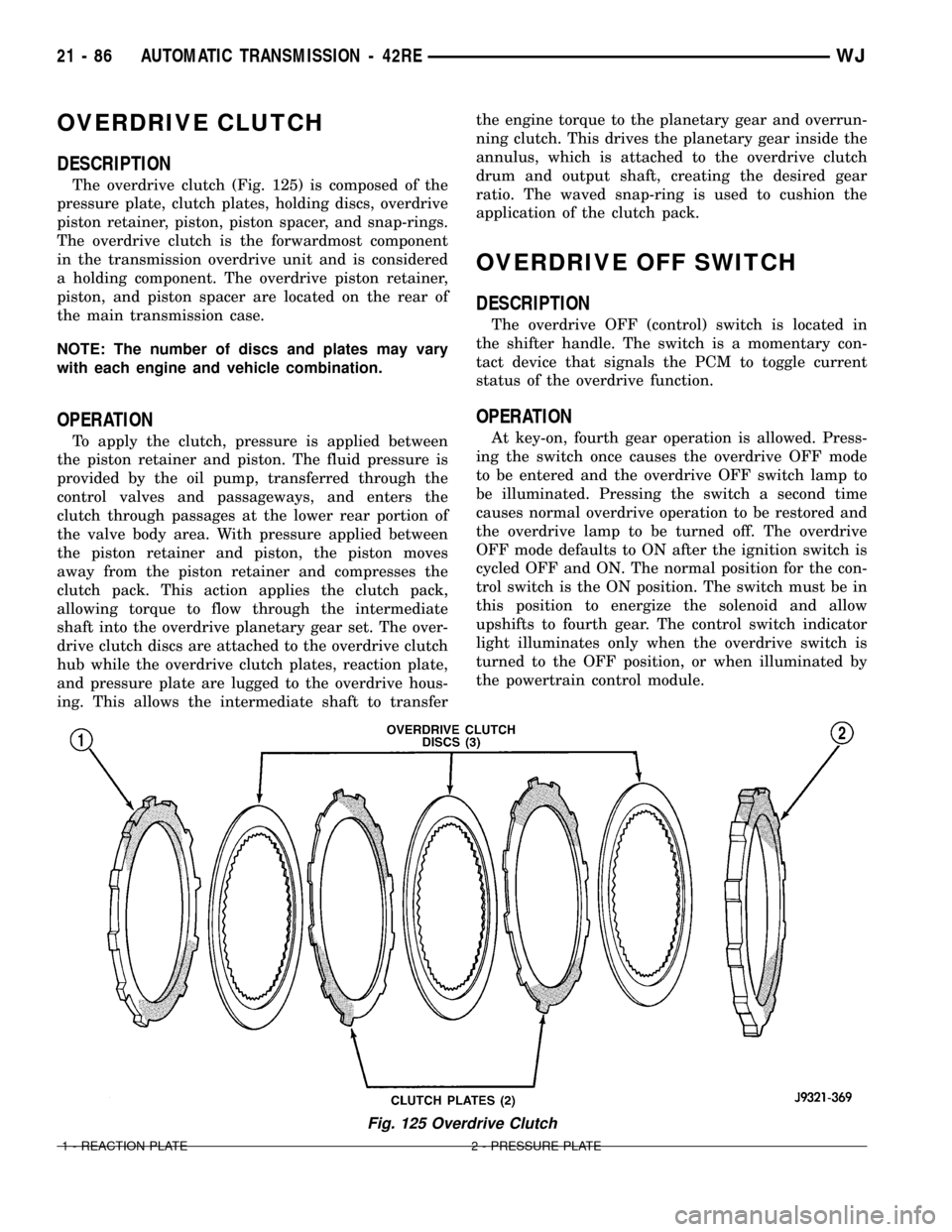

OVERDRIVE CLUTCH

DESCRIPTION

The overdrive clutch (Fig. 125) is composed of the

pressure plate, clutch plates, holding discs, overdrive

piston retainer, piston, piston spacer, and snap-rings.

The overdrive clutch is the forwardmost component

in the transmission overdrive unit and is considered

a holding component. The overdrive piston retainer,

piston, and piston spacer are located on the rear of

the main transmission case.

NOTE: The number of discs and plates may vary

with each engine and vehicle combination.

OPERATION

To apply the clutch, pressure is applied between

the piston retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through passages at the lower rear portion of

the valve body area. With pressure applied between

the piston retainer and piston, the piston moves

away from the piston retainer and compresses the

clutch pack. This action applies the clutch pack,

allowing torque to flow through the intermediate

shaft into the overdrive planetary gear set. The over-

drive clutch discs are attached to the overdrive clutch

hub while the overdrive clutch plates, reaction plate,

and pressure plate are lugged to the overdrive hous-

ing. This allows the intermediate shaft to transferthe engine torque to the planetary gear and overrun-

ning clutch. This drives the planetary gear inside the

annulus, which is attached to the overdrive clutch

drum and output shaft, creating the desired gear

ratio. The waved snap-ring is used to cushion the

application of the clutch pack.

OVERDRIVE OFF SWITCH

DESCRIPTION

The overdrive OFF (control) switch is located in

the shifter handle. The switch is a momentary con-

tact device that signals the PCM to toggle current

status of the overdrive function.

OPERATION

At key-on, fourth gear operation is allowed. Press-

ing the switch once causes the overdrive OFF mode

to be entered and the overdrive OFF switch lamp to

be illuminated. Pressing the switch a second time

causes normal overdrive operation to be restored and

the overdrive lamp to be turned off. The overdrive

OFF mode defaults to ON after the ignition switch is

cycled OFF and ON. The normal position for the con-

trol switch is the ON position. The switch must be in

this position to energize the solenoid and allow

upshifts to fourth gear. The control switch indicator

light illuminates only when the overdrive switch is

turned to the OFF position, or when illuminated by

the powertrain control module.

Fig. 125 Overdrive Clutch

1 - REACTION PLATE 2 - PRESSURE PLATE

21 - 86 AUTOMATIC TRANSMISSION - 42REWJ