piston JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1388 of 2199

STANDARD PROCEDUREÐMEASURING

TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed.

(1) Remove the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

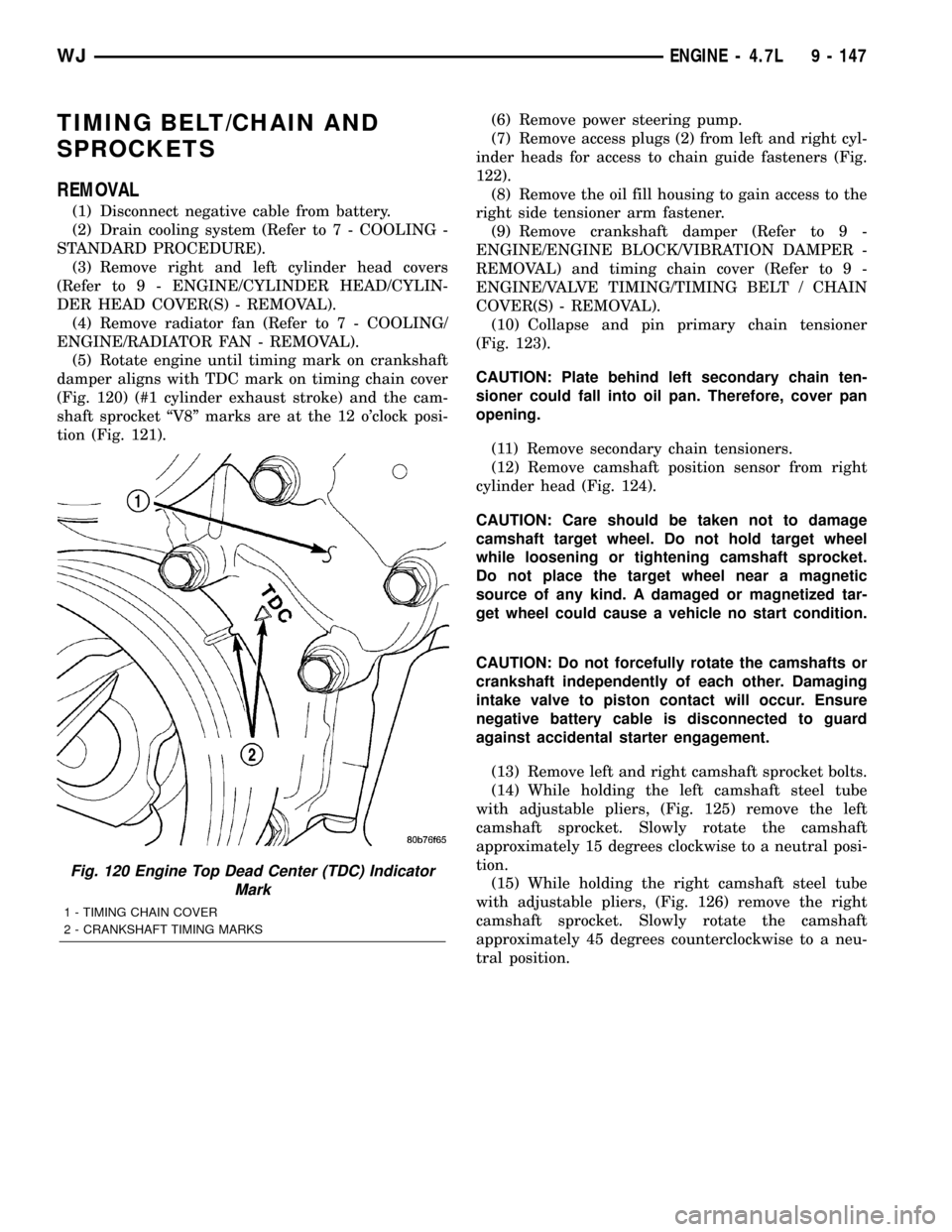

(2) To determine if the secondary timing chains

are worn, rotate the engine clockwise until maximum

tensioner piston extension is obtained. Measure the

distance between the secondary timing chain ten-

sioner housing and the step ledge on the piston (Fig.

116). The measurement at point (A) must be less

than 15mm (0.5906 inches).

(3) If the measurement exceeds the specification

the secondary timing chains are worn and require

replacement. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL).NOTE: If the secondary chains are to be replaced

the primary chain must also be replaced.

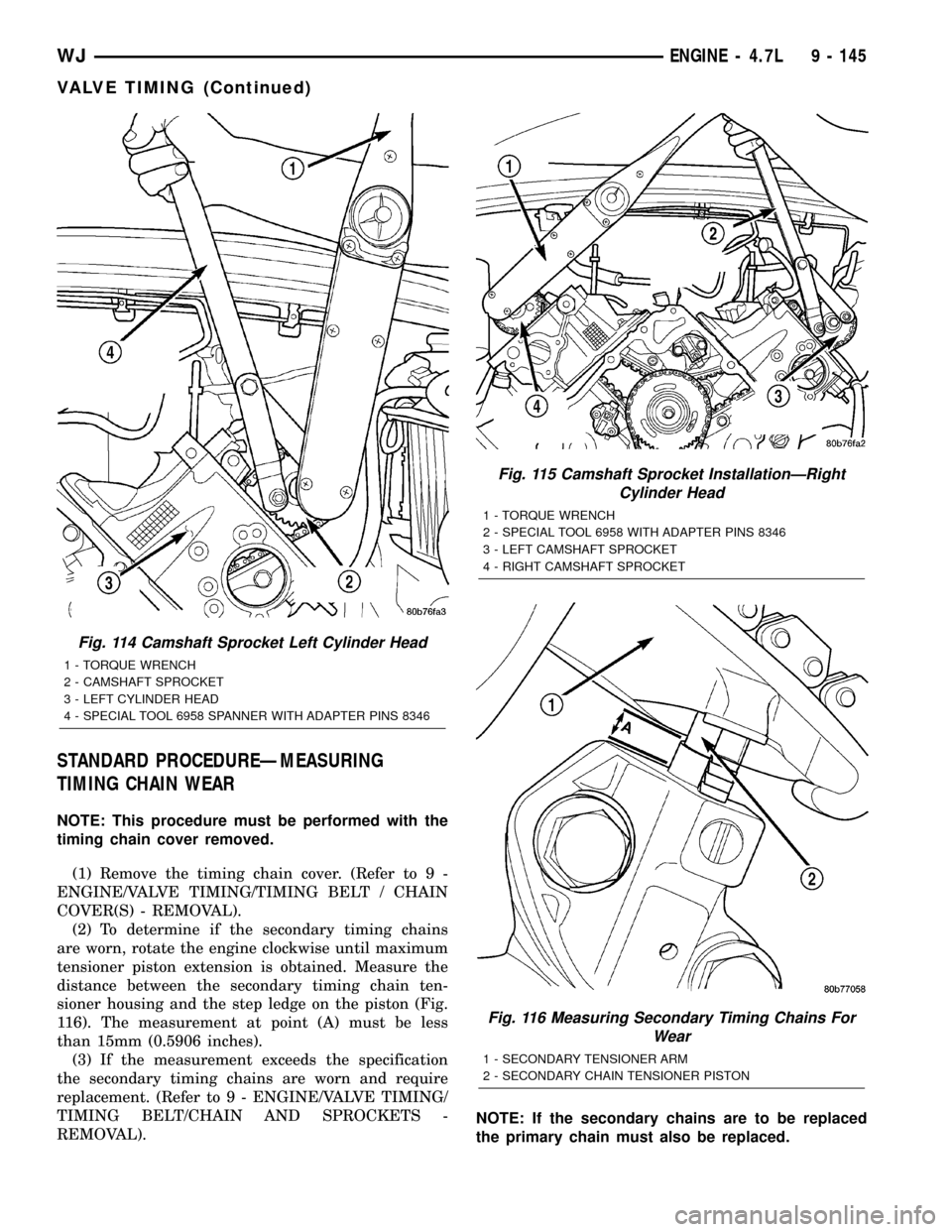

Fig. 114 Camshaft Sprocket Left Cylinder Head

1 - TORQUE WRENCH

2 - CAMSHAFT SPROCKET

3 - LEFT CYLINDER HEAD

4 - SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

Fig. 115 Camshaft Sprocket InstallationÐRight

Cylinder Head

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKET

Fig. 116 Measuring Secondary Timing Chains For

Wear

1 - SECONDARY TENSIONER ARM

2 - SECONDARY CHAIN TENSIONER PISTON

WJENGINE - 4.7L 9 - 145

VALVE TIMING (Continued)

Page 1390 of 2199

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove right and left cylinder head covers

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(4) Remove radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

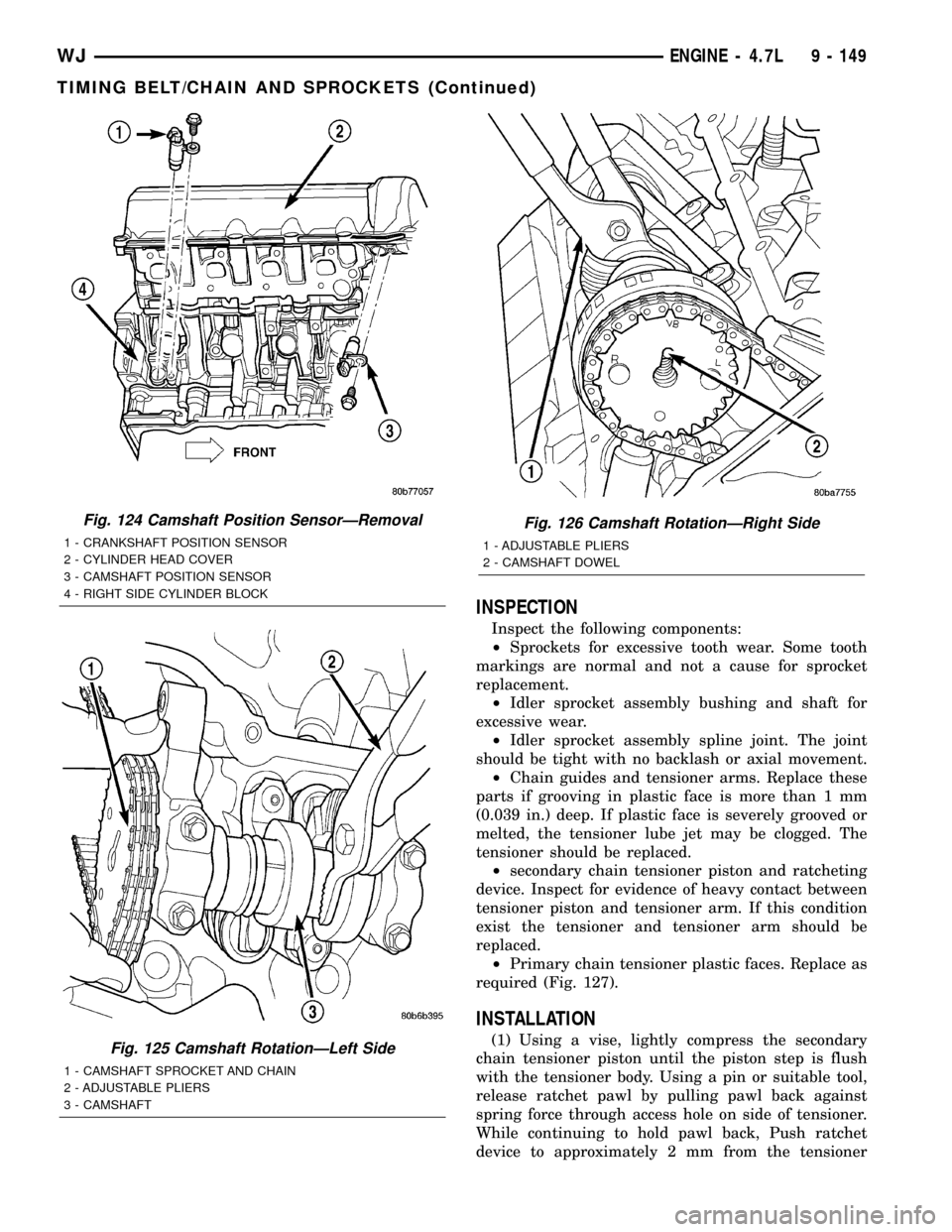

(5) Rotate engine until timing mark on crankshaft

damper aligns with TDC mark on timing chain cover

(Fig. 120) (#1 cylinder exhaust stroke) and the cam-

shaft sprocket ªV8º marks are at the 12 o'clock posi-

tion (Fig. 121).(6) Remove power steering pump.

(7) Remove access plugs (2) from left and right cyl-

inder heads for access to chain guide fasteners (Fig.

122).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(10) Collapse and pin primary chain tensioner

(Fig. 123).

CAUTION: Plate behind left secondary chain ten-

sioner could fall into oil pan. Therefore, cover pan

opening.

(11) Remove secondary chain tensioners.

(12) Remove camshaft position sensor from right

cylinder head (Fig. 124).

CAUTION: Care should be taken not to damage

camshaft target wheel. Do not hold target wheel

while loosening or tightening camshaft sprocket.

Do not place the target wheel near a magnetic

source of any kind. A damaged or magnetized tar-

get wheel could cause a vehicle no start condition.

CAUTION: Do not forcefully rotate the camshafts or

crankshaft independently of each other. Damaging

intake valve to piston contact will occur. Ensure

negative battery cable is disconnected to guard

against accidental starter engagement.

(13) Remove left and right camshaft sprocket bolts.

(14) While holding the left camshaft steel tube

with adjustable pliers, (Fig. 125) remove the left

camshaft sprocket. Slowly rotate the camshaft

approximately 15 degrees clockwise to a neutral posi-

tion.

(15) While holding the right camshaft steel tube

with adjustable pliers, (Fig. 126) remove the right

camshaft sprocket. Slowly rotate the camshaft

approximately 45 degrees counterclockwise to a neu-

tral position.

Fig. 120 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

WJENGINE - 4.7L 9 - 147

Page 1392 of 2199

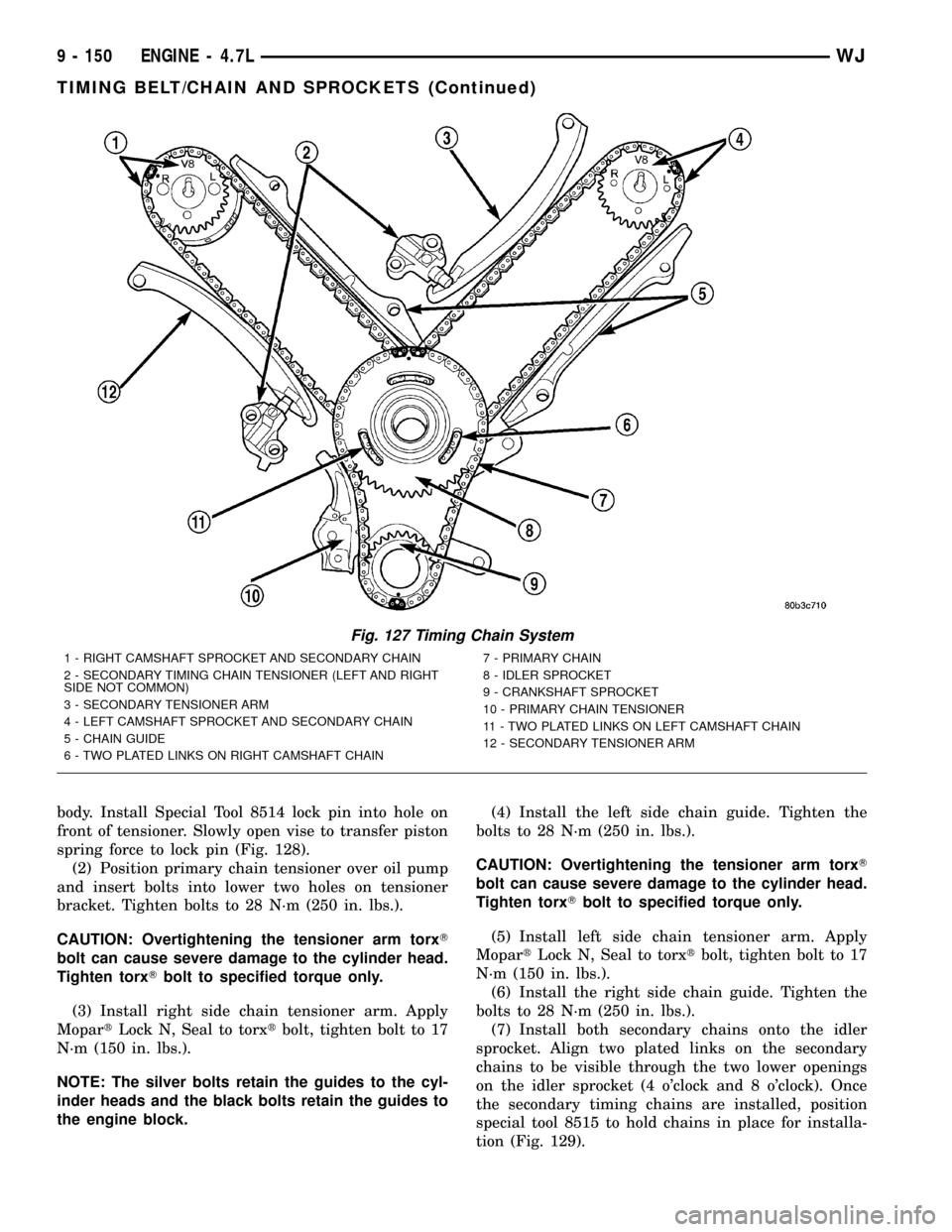

INSPECTION

Inspect the following components:

²Sprockets for excessive tooth wear. Some tooth

markings are normal and not a cause for sprocket

replacement.

²Idler sprocket assembly bushing and shaft for

excessive wear.

²Idler sprocket assembly spline joint. The joint

should be tight with no backlash or axial movement.

²Chain guides and tensioner arms. Replace these

parts if grooving in plastic face is more than 1 mm

(0.039 in.) deep. If plastic face is severely grooved or

melted, the tensioner lube jet may be clogged. The

tensioner should be replaced.

²secondary chain tensioner piston and ratcheting

device. Inspect for evidence of heavy contact between

tensioner piston and tensioner arm. If this condition

exist the tensioner and tensioner arm should be

replaced.

²Primary chain tensioner plastic faces. Replace as

required (Fig. 127).

INSTALLATION

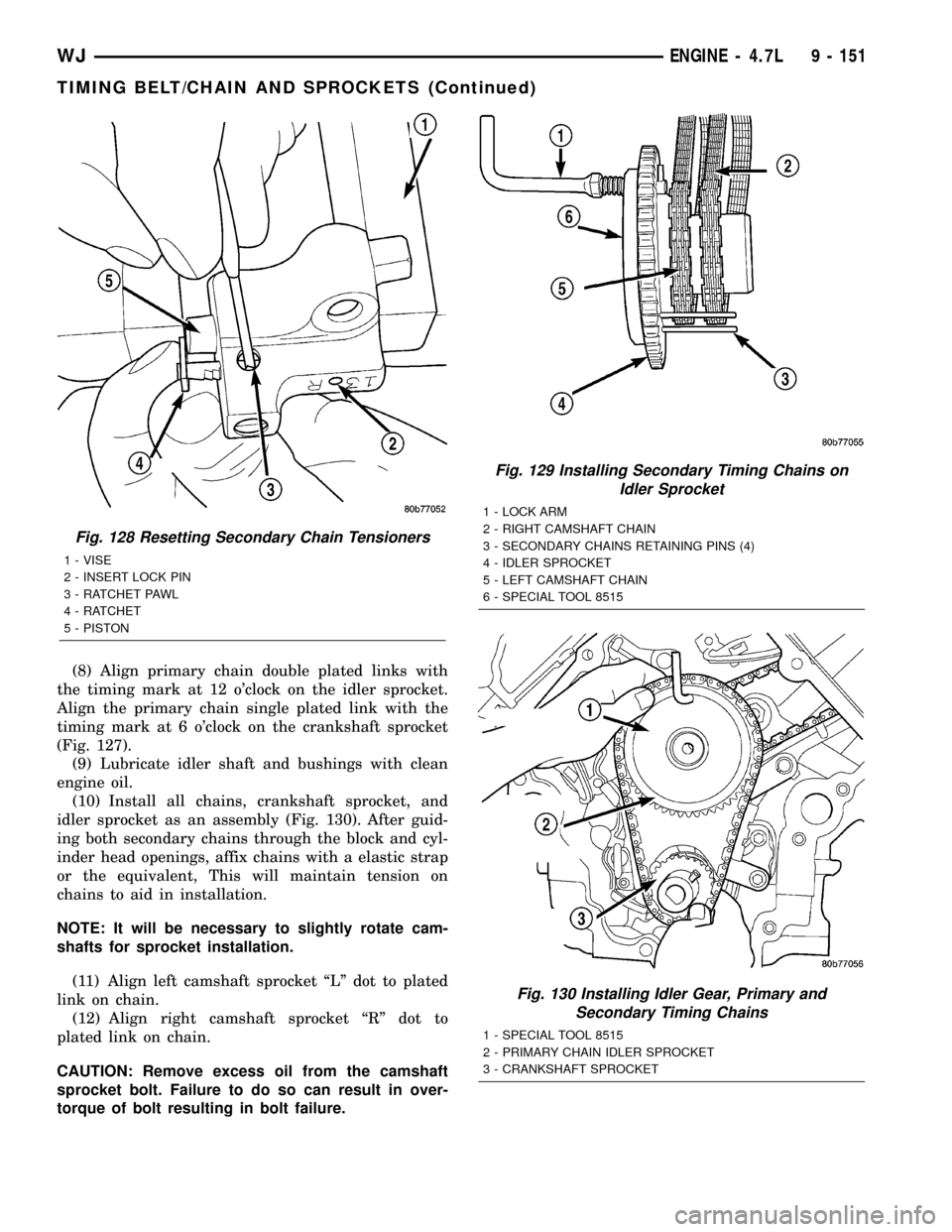

(1) Using a vise, lightly compress the secondary

chain tensioner piston until the piston step is flush

with the tensioner body. Using a pin or suitable tool,

release ratchet pawl by pulling pawl back against

spring force through access hole on side of tensioner.

While continuing to hold pawl back, Push ratchet

device to approximately 2 mm from the tensioner

Fig. 124 Camshaft Position SensorÐRemoval

1 - CRANKSHAFT POSITION SENSOR

2 - CYLINDER HEAD COVER

3 - CAMSHAFT POSITION SENSOR

4 - RIGHT SIDE CYLINDER BLOCK

Fig. 125 Camshaft RotationÐLeft Side

1 - CAMSHAFT SPROCKET AND CHAIN

2 - ADJUSTABLE PLIERS

3 - CAMSHAFT

Fig. 126 Camshaft RotationÐRight Side

1 - ADJUSTABLE PLIERS

2 - CAMSHAFT DOWEL

WJENGINE - 4.7L 9 - 149

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1393 of 2199

body. Install Special Tool 8514 lock pin into hole on

front of tensioner. Slowly open vise to transfer piston

spring force to lock pin (Fig. 128).

(2) Position primary chain tensioner over oil pump

and insert bolts into lower two holes on tensioner

bracket. Tighten bolts to 28 N´m (250 in. lbs.).

CAUTION: Overtightening the tensioner arm torxT

bolt can cause severe damage to the cylinder head.

Tighten torxTbolt to specified torque only.

(3) Install right side chain tensioner arm. Apply

MopartLock N, Seal to torxtbolt, tighten bolt to 17

N´m (150 in. lbs.).

NOTE: The silver bolts retain the guides to the cyl-

inder heads and the black bolts retain the guides to

the engine block.(4) Install the left side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

CAUTION: Overtightening the tensioner arm torxT

bolt can cause severe damage to the cylinder head.

Tighten torxTbolt to specified torque only.

(5) Install left side chain tensioner arm. Apply

MopartLock N, Seal to torxtbolt, tighten bolt to 17

N´m (150 in. lbs.).

(6) Install the right side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

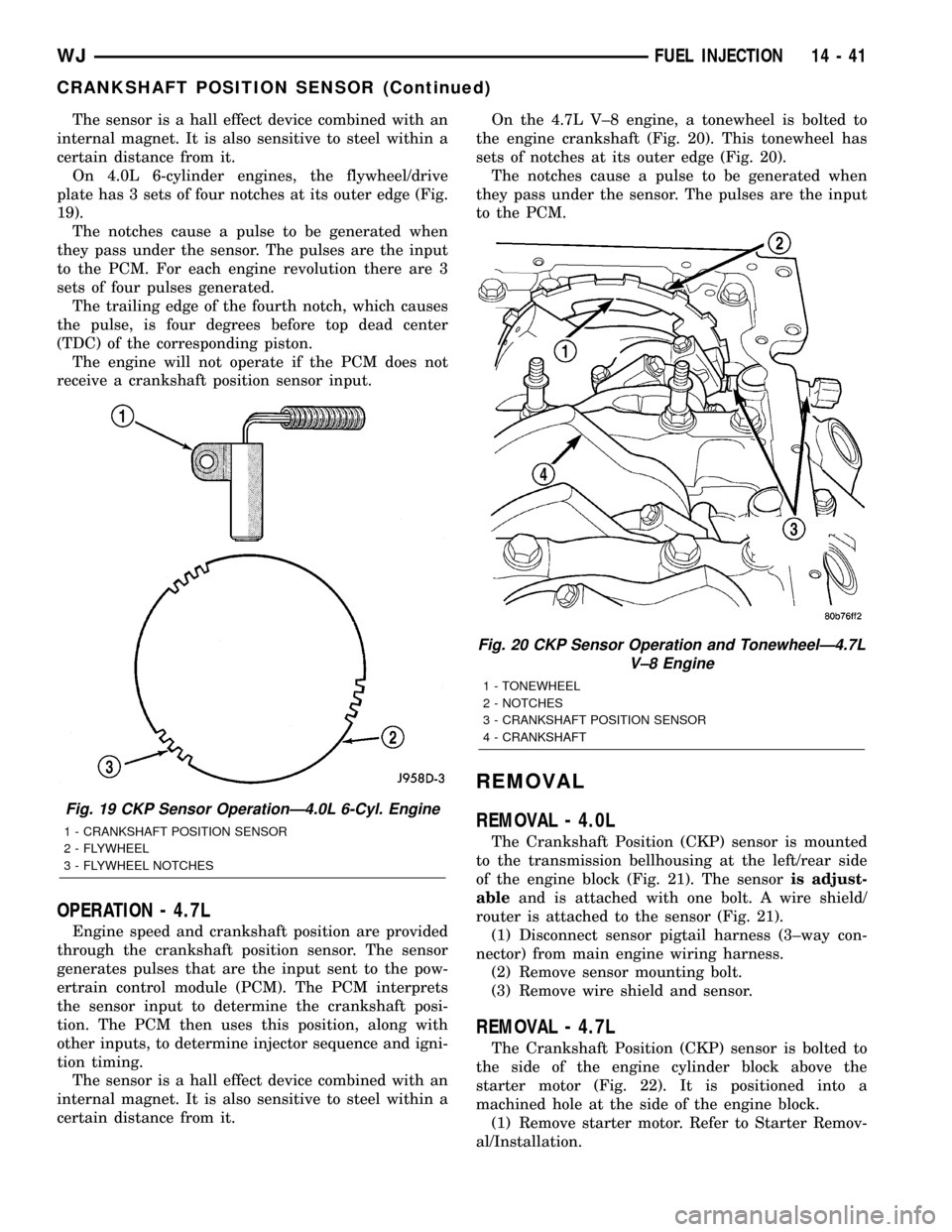

(7) Install both secondary chains onto the idler

sprocket. Align two plated links on the secondary

chains to be visible through the two lower openings

on the idler sprocket (4 o'clock and 8 o'clock). Once

the secondary timing chains are installed, position

special tool 8515 to hold chains in place for installa-

tion (Fig. 129).

Fig. 127 Timing Chain System

1 - RIGHT CAMSHAFT SPROCKET AND SECONDARY CHAIN

2 - SECONDARY TIMING CHAIN TENSIONER (LEFT AND RIGHT

SIDE NOT COMMON)

3 - SECONDARY TENSIONER ARM

4 - LEFT CAMSHAFT SPROCKET AND SECONDARY CHAIN

5 - CHAIN GUIDE

6 - TWO PLATED LINKS ON RIGHT CAMSHAFT CHAIN7 - PRIMARY CHAIN

8 - IDLER SPROCKET

9 - CRANKSHAFT SPROCKET

10 - PRIMARY CHAIN TENSIONER

11 - TWO PLATED LINKS ON LEFT CAMSHAFT CHAIN

12 - SECONDARY TENSIONER ARM

9 - 150 ENGINE - 4.7LWJ

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1394 of 2199

(8) Align primary chain double plated links with

the timing mark at 12 o'clock on the idler sprocket.

Align the primary chain single plated link with the

timing mark at 6 o'clock on the crankshaft sprocket

(Fig. 127).

(9) Lubricate idler shaft and bushings with clean

engine oil.

(10) Install all chains, crankshaft sprocket, and

idler sprocket as an assembly (Fig. 130). After guid-

ing both secondary chains through the block and cyl-

inder head openings, affix chains with a elastic strap

or the equivalent, This will maintain tension on

chains to aid in installation.

NOTE: It will be necessary to slightly rotate cam-

shafts for sprocket installation.

(11) Align left camshaft sprocket ªLº dot to plated

link on chain.

(12) Align right camshaft sprocket ªRº dot to

plated link on chain.

CAUTION: Remove excess oil from the camshaft

sprocket bolt. Failure to do so can result in over-

torque of bolt resulting in bolt failure.

Fig. 128 Resetting Secondary Chain Tensioners

1 - VISE

2 - INSERT LOCK PIN

3 - RATCHET PAWL

4 - RATCHET

5 - PISTON

Fig. 129 Installing Secondary Timing Chains on

Idler Sprocket

1 - LOCK ARM

2 - RIGHT CAMSHAFT CHAIN

3 - SECONDARY CHAINS RETAINING PINS (4)

4 - IDLER SPROCKET

5 - LEFT CAMSHAFT CHAIN

6 - SPECIAL TOOL 8515

Fig. 130 Installing Idler Gear, Primary and

Secondary Timing Chains

1 - SPECIAL TOOL 8515

2 - PRIMARY CHAIN IDLER SPROCKET

3 - CRANKSHAFT SPROCKET

WJENGINE - 4.7L 9 - 151

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1460 of 2199

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On 4.0L 6-cylinder engines, the flywheel/drive

plate has 3 sets of four notches at its outer edge (Fig.

19).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM. For each engine revolution there are 3

sets of four pulses generated.

The trailing edge of the fourth notch, which causes

the pulse, is four degrees before top dead center

(TDC) of the corresponding piston.

The engine will not operate if the PCM does not

receive a crankshaft position sensor input.

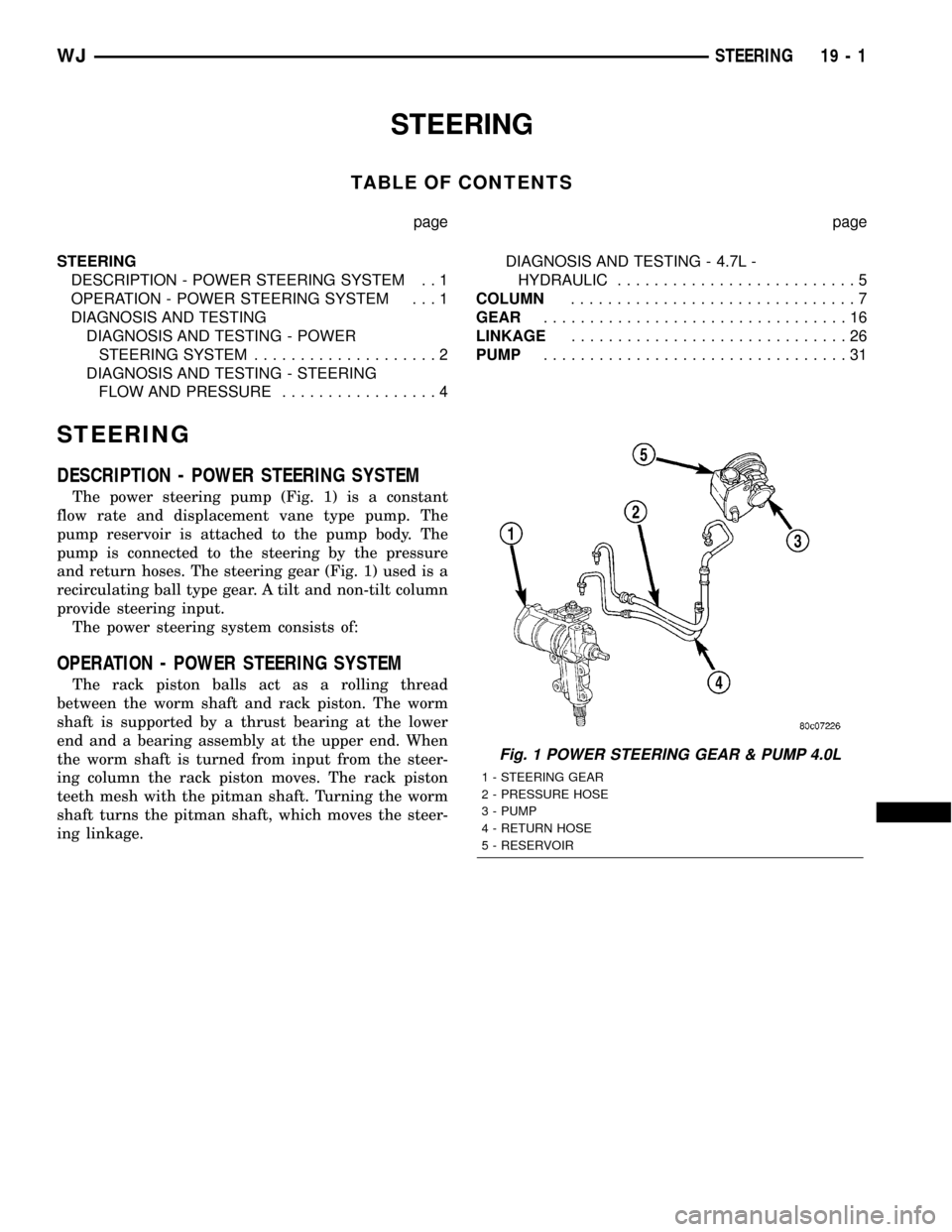

OPERATION - 4.7L

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.On the 4.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft (Fig. 20). This tonewheel has

sets of notches at its outer edge (Fig. 20).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

REMOVAL

REMOVAL - 4.0L

The Crankshaft Position (CKP) sensor is mounted

to the transmission bellhousing at the left/rear side

of the engine block (Fig. 21). The sensoris adjust-

ableand is attached with one bolt. A wire shield/

router is attached to the sensor (Fig. 21).

(1) Disconnect sensor pigtail harness (3±way con-

nector) from main engine wiring harness.

(2) Remove sensor mounting bolt.

(3) Remove wire shield and sensor.

REMOVAL - 4.7L

The Crankshaft Position (CKP) sensor is bolted to

the side of the engine cylinder block above the

starter motor (Fig. 22). It is positioned into a

machined hole at the side of the engine block.

(1) Remove starter motor. Refer to Starter Remov-

al/Installation.

Fig. 19 CKP Sensor OperationÐ4.0L 6-Cyl. Engine

1 - CRANKSHAFT POSITION SENSOR

2 - FLYWHEEL

3 - FLYWHEEL NOTCHES

Fig. 20 CKP Sensor Operation and TonewheelÐ4.7L

V±8 Engine

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

WJFUEL INJECTION 14 - 41

CRANKSHAFT POSITION SENSOR (Continued)

Page 1478 of 2199

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION - POWER STEERING SYSTEM . . 1

OPERATION - POWER STEERING SYSTEM . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM....................2

DIAGNOSIS AND TESTING - STEERING

FLOW AND PRESSURE.................4DIAGNOSIS AND TESTING - 4.7L -

HYDRAULIC..........................5

COLUMN...............................7

GEAR.................................16

LINKAGE..............................26

PUMP.................................31

STEERING

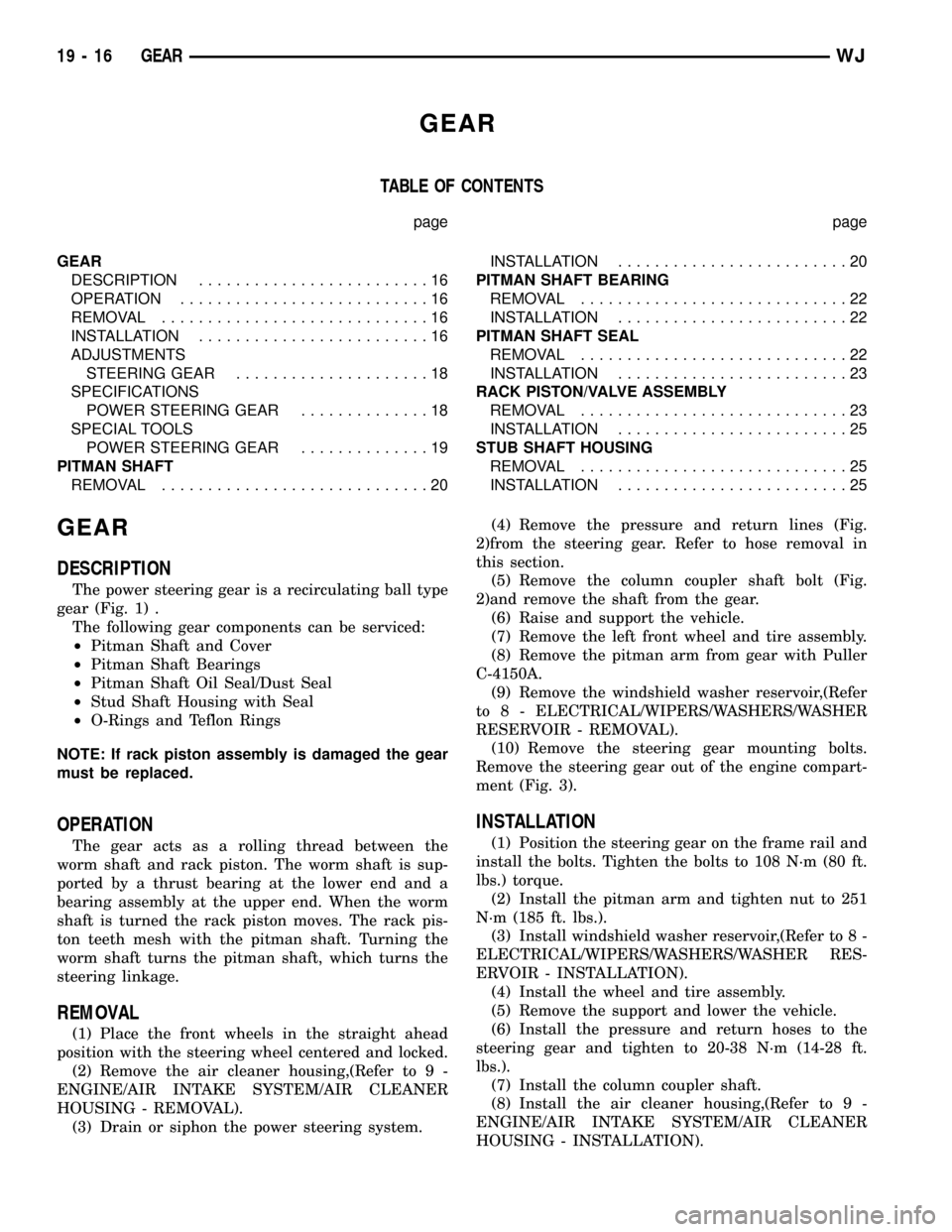

DESCRIPTION - POWER STEERING SYSTEM

The power steering pump (Fig. 1) is a constant

flow rate and displacement vane type pump. The

pump reservoir is attached to the pump body. The

pump is connected to the steering by the pressure

and return hoses. The steering gear (Fig. 1) used is a

recirculating ball type gear. A tilt and non-tilt column

provide steering input.

The power steering system consists of:

OPERATION - POWER STEERING SYSTEM

The rack piston balls act as a rolling thread

between the worm shaft and rack piston. The worm

shaft is supported by a thrust bearing at the lower

end and a bearing assembly at the upper end. When

the worm shaft is turned from input from the steer-

ing column the rack piston moves. The rack piston

teeth mesh with the pitman shaft. Turning the worm

shaft turns the pitman shaft, which moves the steer-

ing linkage.

Fig. 1 POWER STEERING GEAR & PUMP 4.0L

1 - STEERING GEAR

2 - PRESSURE HOSE

3 - PUMP

4 - RETURN HOSE

5 - RESERVOIR

WJSTEERING 19 - 1

Page 1493 of 2199

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

ADJUSTMENTS

STEERING GEAR.....................18

SPECIFICATIONS

POWER STEERING GEAR..............18

SPECIAL TOOLS

POWER STEERING GEAR..............19

PITMAN SHAFT

REMOVAL.............................20INSTALLATION.........................20

PITMAN SHAFT BEARING

REMOVAL.............................22

INSTALLATION.........................22

PITMAN SHAFT SEAL

REMOVAL.............................22

INSTALLATION.........................23

RACK PISTON/VALVE ASSEMBLY

REMOVAL.............................23

INSTALLATION.........................25

STUB SHAFT HOUSING

REMOVAL.............................25

INSTALLATION.........................25

GEAR

DESCRIPTION

The power steering gear is a recirculating ball type

gear (Fig. 1) .

The following gear components can be serviced:

²Pitman Shaft and Cover

²Pitman Shaft Bearings

²Pitman Shaft Oil Seal/Dust Seal

²Stud Shaft Housing with Seal

²O-Rings and Teflon Rings

NOTE: If rack piston assembly is damaged the gear

must be replaced.

OPERATION

The gear acts as a rolling thread between the

worm shaft and rack piston. The worm shaft is sup-

ported by a thrust bearing at the lower end and a

bearing assembly at the upper end. When the worm

shaft is turned the rack piston moves. The rack pis-

ton teeth mesh with the pitman shaft. Turning the

worm shaft turns the pitman shaft, which turns the

steering linkage.

REMOVAL

(1) Place the front wheels in the straight ahead

position with the steering wheel centered and locked.

(2) Remove the air cleaner housing,(Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

(3) Drain or siphon the power steering system.(4) Remove the pressure and return lines (Fig.

2)from the steering gear. Refer to hose removal in

this section.

(5) Remove the column coupler shaft bolt (Fig.

2)and remove the shaft from the gear.

(6) Raise and support the vehicle.

(7) Remove the left front wheel and tire assembly.

(8) Remove the pitman arm from gear with Puller

C-4150A.

(9) Remove the windshield washer reservoir,(Refer

to 8 - ELECTRICAL/WIPERS/WASHERS/WASHER

RESERVOIR - REMOVAL).

(10) Remove the steering gear mounting bolts.

Remove the steering gear out of the engine compart-

ment (Fig. 3).

INSTALLATION

(1) Position the steering gear on the frame rail and

install the bolts. Tighten the bolts to 108 N´m (80 ft.

lbs.) torque.

(2) Install the pitman arm and tighten nut to 251

N´m (185 ft. lbs.).

(3) Install windshield washer reservoir,(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WASHER RES-

ERVOIR - INSTALLATION).

(4) Install the wheel and tire assembly.

(5) Remove the support and lower the vehicle.

(6) Install the pressure and return hoses to the

steering gear and tighten to 20-38 N´m (14-28 ft.

lbs.).

(7) Install the column coupler shaft.

(8) Install the air cleaner housing,(Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

19 - 16 GEARWJ

Page 1494 of 2199

(9) Fill the power steering pump (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

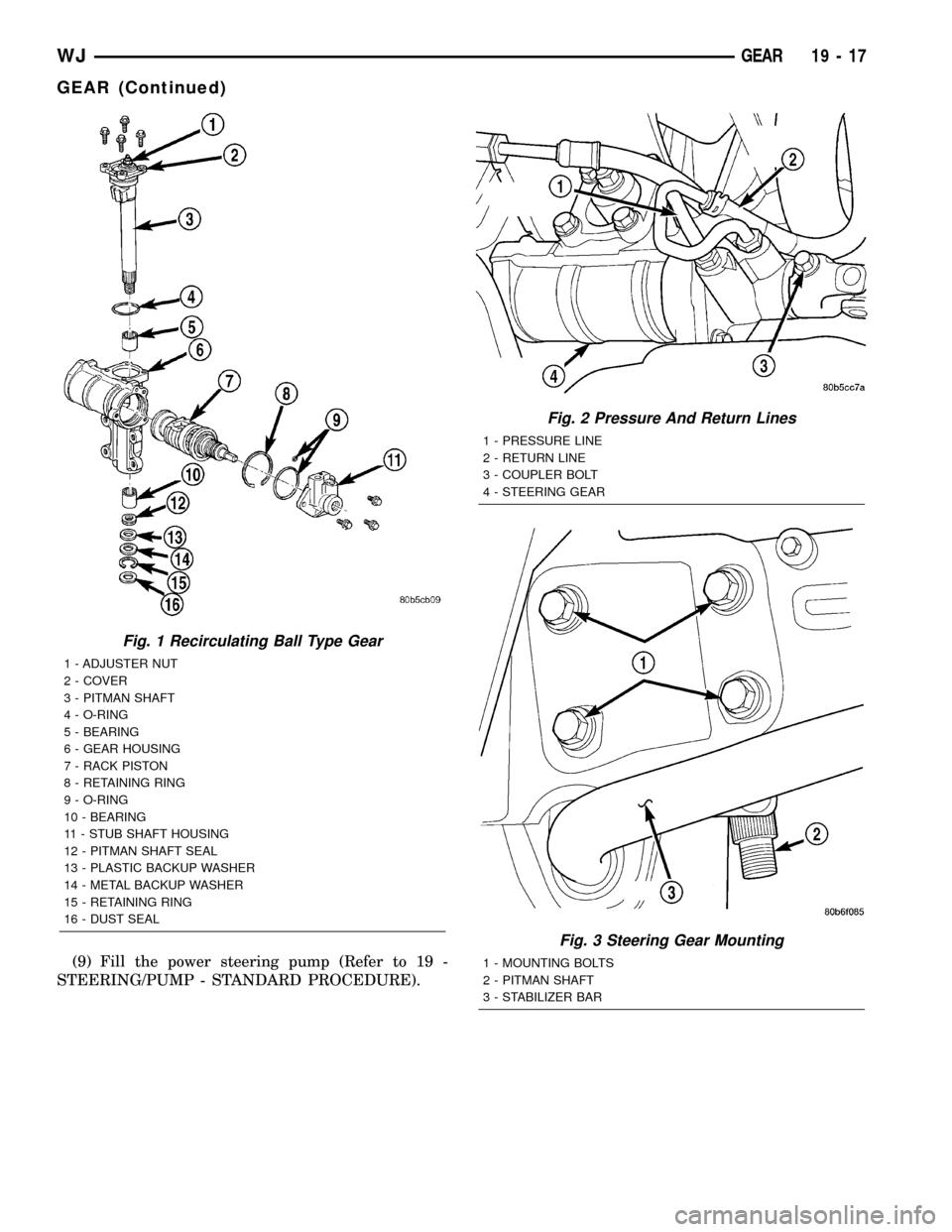

Fig. 1 Recirculating Ball Type Gear

1 - ADJUSTER NUT

2 - COVER

3 - PITMAN SHAFT

4 - O-RING

5 - BEARING

6 - GEAR HOUSING

7 - RACK PISTON

8 - RETAINING RING

9 - O-RING

10 - BEARING

11 - STUB SHAFT HOUSING

12 - PITMAN SHAFT SEAL

13 - PLASTIC BACKUP WASHER

14 - METAL BACKUP WASHER

15 - RETAINING RING

16 - DUST SEAL

Fig. 2 Pressure And Return Lines

1 - PRESSURE LINE

2 - RETURN LINE

3 - COUPLER BOLT

4 - STEERING GEAR

Fig. 3 Steering Gear Mounting

1 - MOUNTING BOLTS

2 - PITMAN SHAFT

3 - STABILIZER BAR

WJGEAR 19 - 17

GEAR (Continued)

Page 1500 of 2199

(9) Remove pitman shaft oil seal from the housing

with a Puller 7794-A and Slide Hammer C-637 (Fig.

7).

(10) Drop Driver 8277 through the top bearing and

align the driver up with the lower bearing. (Fig. 9).

Install Handle C-4171 into the driver and remove the

lower bearing.

(11) Turn the gear over and remover the upper

bearing with Driver 8277 and Handle C-4171.

INSTALLATION

(1) Install upper pitman shaft bearing, with Driver

8294 and Handle C-4171 (Fig. 10). Drive bearing into

housing until the driver bottoms out.

NOTE: Install upper pitman shaft bearing with the

part number/letters facing the driver.

(2) Install lower pitman shaft bearing with the

other side Driver 8294 and Handle C-4171 (Fig. 11).

Drive bearing into housing until the bearing shoulder

is seated against the housing.

(3) Coat the oil seal and backup washers withspe-

cial greasesupplied with the new seal.

(4) Install the oil seal with Driver 8294 and Han-

dle C-4171.

(5) Install plastic backup washer.

NOTE: The plastic backup washer has a lip on the

inside diameter that faces down towards the oil

seal.

(6) Install metal backup washer.

(7) Install the retainer ring with snap ring pliers.

(8) Coat the dust seal withspecial greasesup-

plied with the new seal.

(9) Install dust seal with Driver 8294 and Handle

C-4171.

(10) Install new pitman shaft cover o-ring.

(11) Install pitman shaft assembly into the hous-

ing.

(12) Install cover bolts and tighten to 62 N´m (46

ft. lbs.).

(13) Perform over-center rotation torque adjust-

ment.

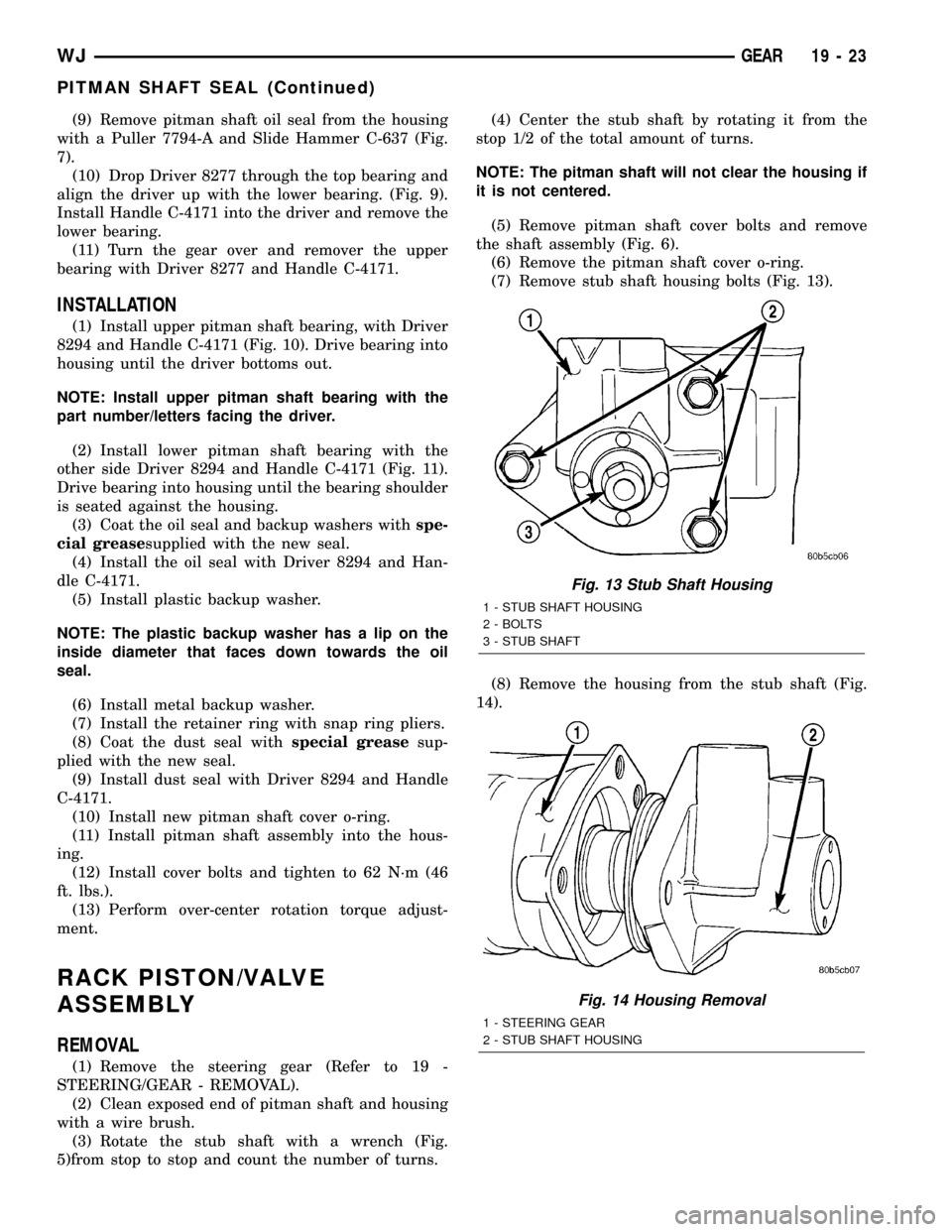

RACK PISTON/VALVE

ASSEMBLY

REMOVAL

(1) Remove the steering gear (Refer to 19 -

STEERING/GEAR - REMOVAL).

(2) Clean exposed end of pitman shaft and housing

with a wire brush.

(3) Rotate the stub shaft with a wrench (Fig.

5)from stop to stop and count the number of turns.(4) Center the stub shaft by rotating it from the

stop 1/2 of the total amount of turns.

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(5) Remove pitman shaft cover bolts and remove

the shaft assembly (Fig. 6).

(6) Remove the pitman shaft cover o-ring.

(7) Remove stub shaft housing bolts (Fig. 13).

(8) Remove the housing from the stub shaft (Fig.

14).

Fig. 13 Stub Shaft Housing

1 - STUB SHAFT HOUSING

2 - BOLTS

3 - STUB SHAFT

Fig. 14 Housing Removal

1 - STEERING GEAR

2 - STUB SHAFT HOUSING

WJGEAR 19 - 23

PITMAN SHAFT SEAL (Continued)