Cable JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 378 of 2199

repaired and, if faulty or damaged, the entire a/c

heater control must be replaced. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL)

OPERATION

When the rear window defogger switch push but-

ton is depressed, it momentarily closes the rear win-

dow defogger switch sense circuit for the BCM to

ground. The BCM monitors the rear window defogger

switch sense circuit. Each time the BCM rear win-

dow defogger timer and logic circuitry sees another

input from the switch, it toggles a control output to

the rear window defogger relay. Energizing the rear

window defogger relay provides electrical current to

the rear window defogger grid and to the LED indi-

cator in the switch, which lights to indicate when the

defogger system is turned on. A dedicated fuse in the

junction block protects the rear window defogger

relay output circuit to the LED indicator.

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SWITCH

For complete circuit diagrams, refer to the Appro-

priate Wiring Information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the a/c heater control from the instru-

ment panel and disconnect the 11-way (manual tem-

perature control) or 16-way (automatic zone control)

instrument panel wire harness connector from the a/c

heater control receptacle.

(2) Check for continuity between the ground cir-

cuit cavity of the 11-way or 16-way instrument panel

wire harness connector for the a/c heater control and

a good ground. There should be continuity. If OK, go

to Step 3. If not OK, repair the open ground circuit to

ground as required.

(3) Connect two jumper wires to the a/c heater

control 11-way or 16-way connector receptacle. Con-

nect one jumper from the ground circuit terminal inthe 11-way or 16-way a/c heater control connector

receptacle to a good ground. Connect the other

jumper from the fused rear window defogger relay

output circuit terminal of the 11-way or 16-way con-

nector receptacle to a 12-volt battery feed. The rear

window defogger switch LED indicator should light.

If OK, go to Step 4. If not OK, replace the faulty a/c

heater control.

(4) Check for continuity between the ground cir-

cuit and rear window defogger switch sense circuit

terminals of the 11-way or 16-way a/c heater control

connector receptacle. There should be momentary

continuity as the rear window defogger switch push

button is depressed, and then no continuity. If OK, go

to Step 5. If not OK, replace the faulty a/c heater

control.

(5) Disconnect the 22-way instrument panel wire

harness connector from the Body Control Module

(BCM) connector receptacle. Check for continuity

between the rear window defogger switch sense cir-

cuit cavity of the 11-way or 16-way instrument panel

wire harness connector for the a/c heater control and

a good ground. There should be no continuity. If OK,

go to Step 6. If not OK, repair the shorted rear win-

dow defogger switch sense circuit as required.

(6) Check for continuity between the rear window

defogger switch sense circuit cavities of the 11-way or

16-way instrument panel wire harness connector for

the a/c heater control and the 22-way instrument

panel wire harness connector for the BCM. There

should be continuity. If OK, refer to (Refer to 8 -

ELECTRICAL/HEATED GLASS/REAR WINDOW

DEFOGGER RELAY - DIAGNOSIS AND TESTING).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/A/C HEATER CONTROL - REMOVAL)

WJHEATED GLASS 8G - 7

REAR WINDOW DEFOGGER SWITCH (Continued)

Page 379 of 2199

HEATED MIRRORS

TABLE OF CONTENTS

page page

HEATED MIRRORS

DESCRIPTION..........................8

OPERATION............................8DIAGNOSIS AND TESTING - HEATED

MIRRORS............................8

HEATED MIRRORS

DESCRIPTION

Electrically heated outside rear view mirrors are

optional equipment on this model. These mirrors fea-

ture an electric heating grid located behind the mir-

ror glass of each power operated outside rear view

mirror. These heating grids consist of a single resis-

tor wire routed in a grid-like pattern and captured

between two thin sheets of plastic. When electrical

current is passed through the resistor wire, it pro-

duces enough heat energy to clear the outside mirror

glass of ice, snow or fog. Battery current is directed

to the outside mirror heating grid only when the rear

window defogger switch is in the On position.

If the outside mirror heating grids and the rear

window heating grid are all inoperative, (Refer to 8 -

ELECTRICAL/HEATED GLASS - DIAGNOSIS AND

TESTING - REAR WINDOW DEFOGGER SYSTEM).

If the outside mirror heating grids are inoperative,

but the rear window heating grid is operating as

designed, (Refer to 8 - ELECTRICAL/HEATED MIR-

RORS - DIAGNOSIS AND TESTING)

The heating grid behind each outside mirror glass

cannot be repaired and, if faulty or damaged, the

entire power mirror unit must be replaced. Refer to

Power Mirrors for the procedures.

OPERATION

The outside mirror heating grids are energized and

de-energized by the Driver Door Module (DDM) and

the Passenger Door Module (PDM) based upon the

rear window defogger switch status. The Body Con-

trol Module (BCM) monitors the rear window defog-ger switch. When the BCM receives an input from

the switch, it sends a defogger switch status message

to the DDM and the PDM over the Programmable

Communications Interface data bus. The DDM and

PDM respond to the defogger switch status messages

by energizing or de-energizing the battery current

feed to their respective outside rear view mirror

heating grids.

DIAGNOSIS AND TESTING - HEATED MIRRORS

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) If both mirror heaters are inoperative, check

for proper operation of the Rear Window Defogger

System. (Refer to 8 - ELECTRICAL/HEATED GLASS

- DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SYSTEM). If Rear Window Defogger

System operates correctly, or if only one mirror

heater is inoperative, go to Step 2.

(2) Disconnect and isolate the battery negative

cable. Remove the front door trim panel on the side

of the inoperative mirror heater. Go to Step 3.

(3) Disconnect the door wire harness connector

from the door module connector receptacle. Check for

continuity between the mirror heater 12 volt supply,

and the mirror heater ground. There should be con-

tinuity. If OK, go to Step 4. If not OK, check for con-

tinuity of the individual circuits between the power

mirror and the door module, and of the mirror heater

grid right at the power mirror.

(4) Use a DRB IIItand (Refer to Appropriate

Diagnostic Information) to test the door module and

the PCI data bus.

8G - 8 HEATED MIRRORSWJ

Page 383 of 2199

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the junction block. If OK, go to

Step 3. If not OK, repair the open fused ignition

switch output (run) circuit to the ignition switch as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the lower center bezel from the instru-

ment panel and disconnect the instrument panel wire

harness connectors from both heated seat switch con-

nector receptacles. Check for continuity between the

ground circuit cavity of the instrument panel wire

harness connector for the inoperative heated seat

switch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the junction block fuse

as required.

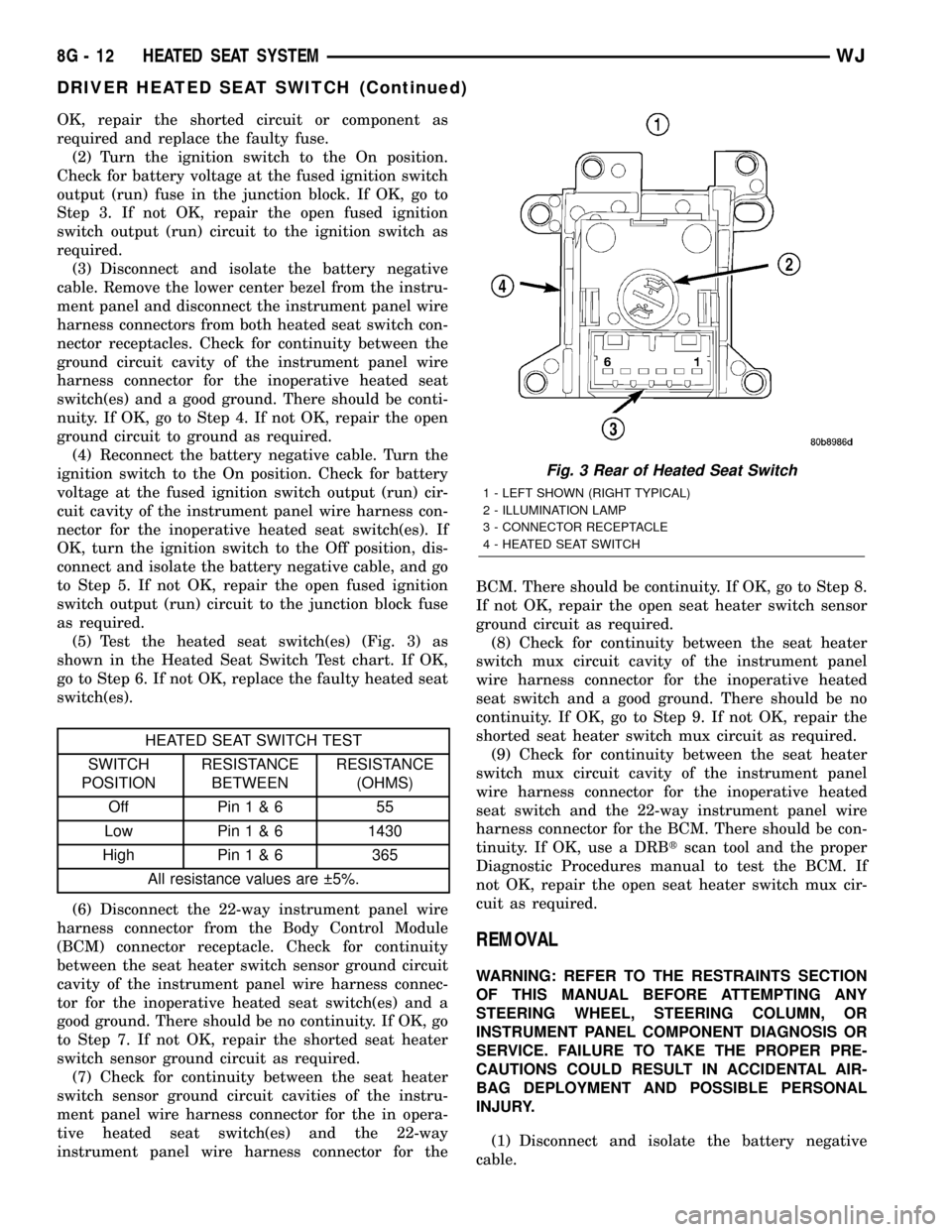

(5) Test the heated seat switch(es) (Fig. 3) as

shown in the Heated Seat Switch Test chart. If OK,

go to Step 6. If not OK, replace the faulty heated seat

switch(es).

HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin1&6 55

Low Pin1&61430

High Pin1&6 365

All resistance values are 5%.

(6) Disconnect the 22-way instrument panel wire

harness connector from the Body Control Module

(BCM) connector receptacle. Check for continuity

between the seat heater switch sensor ground circuit

cavity of the instrument panel wire harness connec-

tor for the inoperative heated seat switch(es) and a

good ground. There should be no continuity. If OK, go

to Step 7. If not OK, repair the shorted seat heater

switch sensor ground circuit as required.

(7) Check for continuity between the seat heater

switch sensor ground circuit cavities of the instru-

ment panel wire harness connector for the in opera-

tive heated seat switch(es) and the 22-way

instrument panel wire harness connector for theBCM. There should be continuity. If OK, go to Step 8.

If not OK, repair the open seat heater switch sensor

ground circuit as required.

(8) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and a good ground. There should be no

continuity. If OK, go to Step 9. If not OK, repair the

shorted seat heater switch mux circuit as required.

(9) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and the 22-way instrument panel wire

harness connector for the BCM. There should be con-

tinuity. If OK, use a DRBtscan tool and the proper

Diagnostic Procedures manual to test the BCM. If

not OK, repair the open seat heater switch mux cir-

cuit as required.

REMOVAL

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

Fig. 3 Rear of Heated Seat Switch

1 - LEFT SHOWN (RIGHT TYPICAL)

2 - ILLUMINATION LAMP

3 - CONNECTOR RECEPTACLE

4 - HEATED SEAT SWITCH

8G - 12 HEATED SEAT SYSTEMWJ

DRIVER HEATED SEAT SWITCH (Continued)

Page 384 of 2199

(2) Remove the center lower bezel from the instru-

ment panel. Refer toInstrument Panel Center

Lower Bezelin the Body section of this manual for

the procedure.

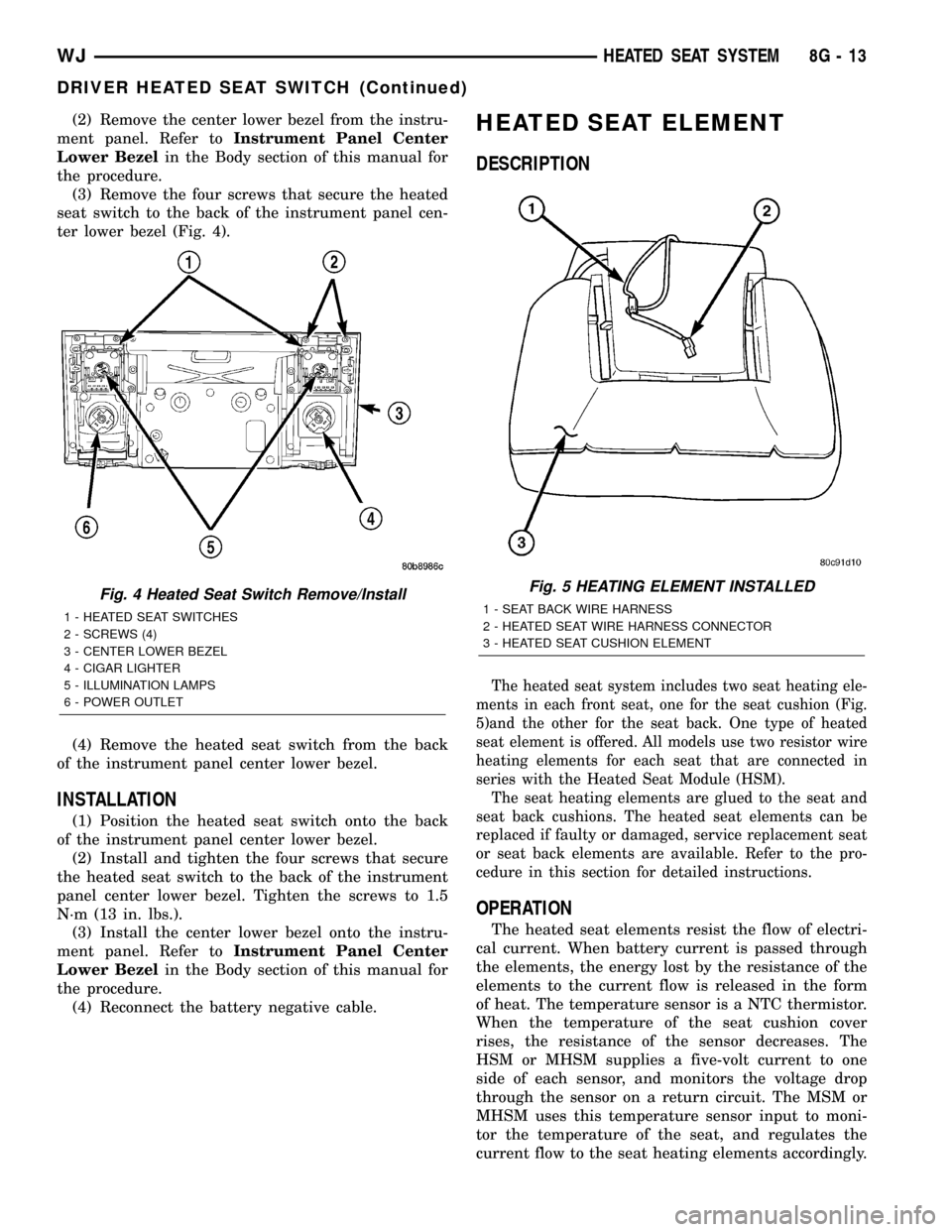

(3) Remove the four screws that secure the heated

seat switch to the back of the instrument panel cen-

ter lower bezel (Fig. 4).

(4) Remove the heated seat switch from the back

of the instrument panel center lower bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center lower bezel.

(2) Install and tighten the four screws that secure

the heated seat switch to the back of the instrument

panel center lower bezel. Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center lower bezel onto the instru-

ment panel. Refer toInstrument Panel Center

Lower Bezelin the Body section of this manual for

the procedure.

(4) Reconnect the battery negative cable.

HEATED SEAT ELEMENT

DESCRIPTION

The heated seat system includes two seat heating ele-

ments in each front seat, one for the seat cushion (Fig.

5)and the other for the seat back. One type of heated

seat element is offered. All models use two resistor wire

heating elements for each seat that are connected in

series with the Heated Seat Module (HSM).

The seat heating elements are glued to the seat and

seat back cushions. The heated seat elements can be

replaced if faulty or damaged, service replacement seat

or seat back elements are available. Refer to the pro-

cedure in this section for detailed instructions.

OPERATION

The heated seat elements resist the flow of electri-

cal current. When battery current is passed through

the elements, the energy lost by the resistance of the

elements to the current flow is released in the form

of heat. The temperature sensor is a NTC thermistor.

When the temperature of the seat cushion cover

rises, the resistance of the sensor decreases. The

HSM or MHSM supplies a five-volt current to one

side of each sensor, and monitors the voltage drop

through the sensor on a return circuit. The MSM or

MHSM uses this temperature sensor input to moni-

tor the temperature of the seat, and regulates the

current flow to the seat heating elements accordingly.

Fig. 4 Heated Seat Switch Remove/Install

1 - HEATED SEAT SWITCHES

2 - SCREWS (4)

3 - CENTER LOWER BEZEL

4 - CIGAR LIGHTER

5 - ILLUMINATION LAMPS

6 - POWER OUTLET

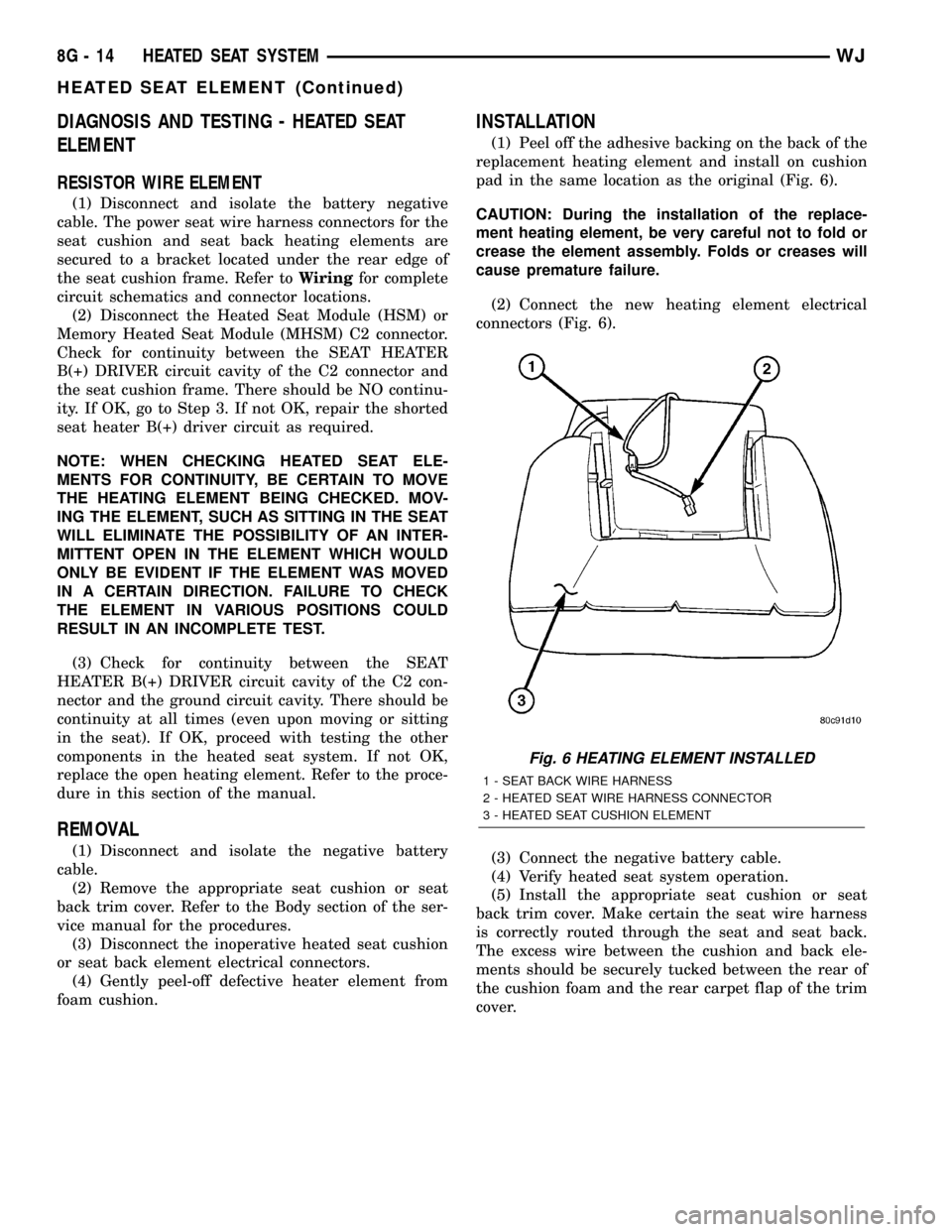

Fig. 5 HEATING ELEMENT INSTALLED

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

WJHEATED SEAT SYSTEM 8G - 13

DRIVER HEATED SEAT SWITCH (Continued)

Page 385 of 2199

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENT

RESISTOR WIRE ELEMENT

(1) Disconnect and isolate the battery negative

cable. The power seat wire harness connectors for the

seat cushion and seat back heating elements are

secured to a bracket located under the rear edge of

the seat cushion frame. Refer toWiringfor complete

circuit schematics and connector locations.

(2) Disconnect the Heated Seat Module (HSM) or

Memory Heated Seat Module (MHSM) C2 connector.

Check for continuity between the SEAT HEATER

B(+) DRIVER circuit cavity of the C2 connector and

the seat cushion frame. There should be NO continu-

ity. If OK, go to Step 3. If not OK, repair the shorted

seat heater B(+) driver circuit as required.

NOTE: WHEN CHECKING HEATED SEAT ELE-

MENTS FOR CONTINUITY, BE CERTAIN TO MOVE

THE HEATING ELEMENT BEING CHECKED. MOV-

ING THE ELEMENT, SUCH AS SITTING IN THE SEAT

WILL ELIMINATE THE POSSIBILITY OF AN INTER-

MITTENT OPEN IN THE ELEMENT WHICH WOULD

ONLY BE EVIDENT IF THE ELEMENT WAS MOVED

IN A CERTAIN DIRECTION. FAILURE TO CHECK

THE ELEMENT IN VARIOUS POSITIONS COULD

RESULT IN AN INCOMPLETE TEST.

(3) Check for continuity between the SEAT

HEATER B(+) DRIVER circuit cavity of the C2 con-

nector and the ground circuit cavity. There should be

continuity at all times (even upon moving or sitting

in the seat). If OK, proceed with testing the other

components in the heated seat system. If not OK,

replace the open heating element. Refer to the proce-

dure in this section of the manual.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate seat cushion or seat

back trim cover. Refer to the Body section of the ser-

vice manual for the procedures.

(3) Disconnect the inoperative heated seat cushion

or seat back element electrical connectors.

(4) Gently peel-off defective heater element from

foam cushion.

INSTALLATION

(1) Peel off the adhesive backing on the back of the

replacement heating element and install on cushion

pad in the same location as the original (Fig. 6).

CAUTION: During the installation of the replace-

ment heating element, be very careful not to fold or

crease the element assembly. Folds or creases will

cause premature failure.

(2) Connect the new heating element electrical

connectors (Fig. 6).

(3) Connect the negative battery cable.

(4) Verify heated seat system operation.

(5) Install the appropriate seat cushion or seat

back trim cover. Make certain the seat wire harness

is correctly routed through the seat and seat back.

The excess wire between the cushion and back ele-

ments should be securely tucked between the rear of

the cushion foam and the rear carpet flap of the trim

cover.

Fig. 6 HEATING ELEMENT INSTALLED

1 - SEAT BACK WIRE HARNESS

2 - HEATED SEAT WIRE HARNESS CONNECTOR

3 - HEATED SEAT CUSHION ELEMENT

8G - 14 HEATED SEAT SYSTEMWJ

HEATED SEAT ELEMENT (Continued)

Page 387 of 2199

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the top of the switch rocker is fully depressed,

the High position is selected and the high position

LED indicator illuminates. When the bottom of the

switch rocker is fully depressed, the Low position is

selected and the low position LED indicator illumi-

nates. When the switch rocker is moved to its neutral

position, Off is selected and both LED indicators are

extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the BCM to indicate the

selected switch position. The BCM monitors the

switch inputs and sends heated seat switch status

messages to the Heated Seat Module (HSM) or the

Memory Heated Seat Module (MHSM) over the Pro-

grammable Communications Interface (PCI) data

bus. The HSM or MHSM responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run)

fuse in the junction block. If OK, go to Step 2. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the junction block. If OK, go to

Step 3. If not OK, repair the open fused ignition

switch output (run) circuit to the ignition switch as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the lower center bezel from the instru-

ment panel and disconnect the instrument panel wire

harness connectors from both heated seat switch con-

nector receptacles. Check for continuity between the

ground circuit cavity of the instrument panel wire

harness connector for the inoperative heated seatswitch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the junction block fuse

as required.

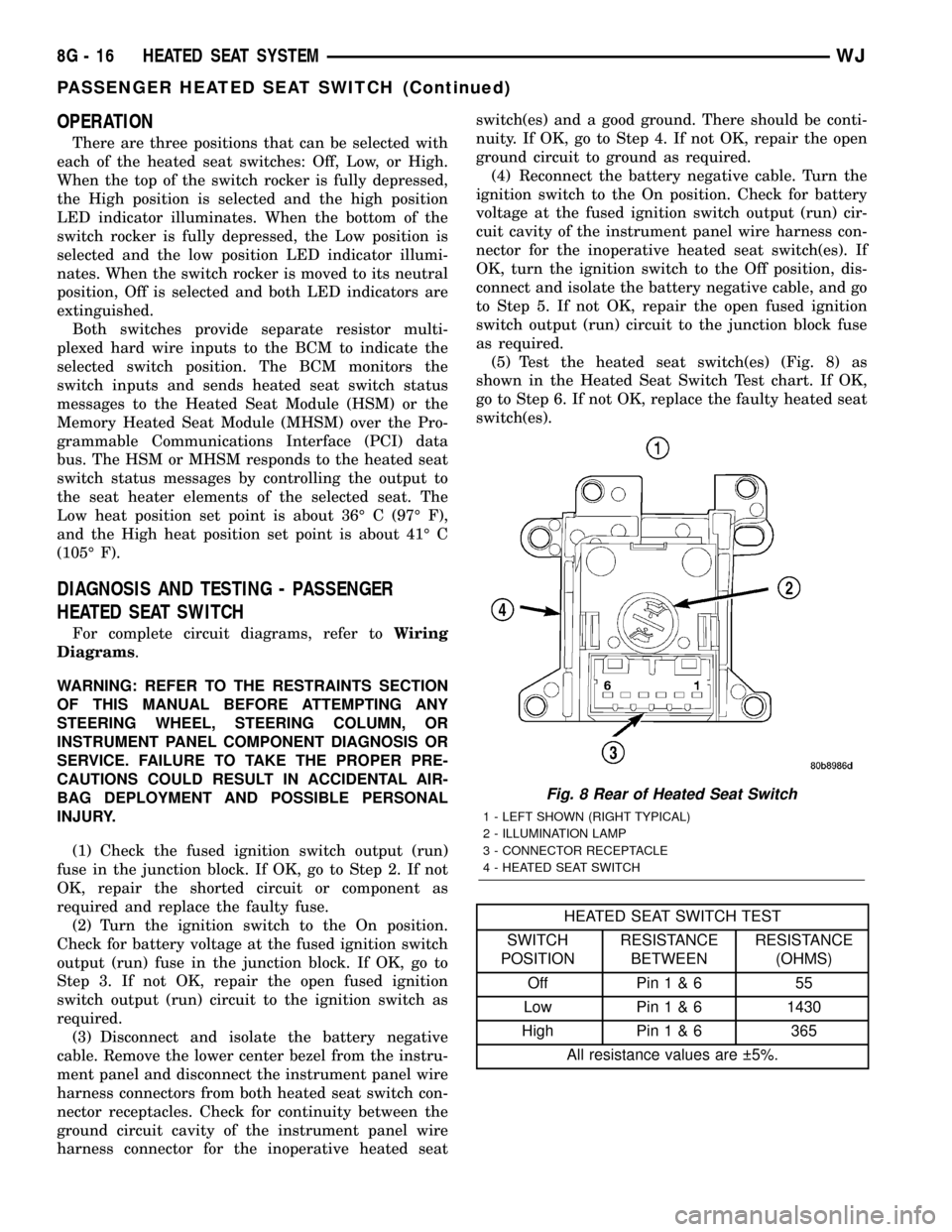

(5) Test the heated seat switch(es) (Fig. 8) as

shown in the Heated Seat Switch Test chart. If OK,

go to Step 6. If not OK, replace the faulty heated seat

switch(es).

HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin1&6 55

Low Pin1&61430

High Pin1&6 365

All resistance values are 5%.

Fig. 8 Rear of Heated Seat Switch

1 - LEFT SHOWN (RIGHT TYPICAL)

2 - ILLUMINATION LAMP

3 - CONNECTOR RECEPTACLE

4 - HEATED SEAT SWITCH

8G - 16 HEATED SEAT SYSTEMWJ

PASSENGER HEATED SEAT SWITCH (Continued)

Page 388 of 2199

(6) Disconnect the 22-way instrument panel wire

harness connector from the Body Control Module

(BCM) connector receptacle. Check for continuity

between the seat heater switch sensor ground circuit

cavity of the instrument panel wire harness connec-

tor for the inoperative heated seat switch(es) and a

good ground. There should be no continuity. If OK, go

to Step 7. If not OK, repair the shorted seat heater

switch sensor ground circuit as required.

(7) Check for continuity between the seat heater

switch sensor ground circuit cavities of the instru-

ment panel wire harness connector for the in opera-

tive heated seat switch(es) and the 22-way

instrument panel wire harness connector for the

BCM. There should be continuity. If OK, go to Step 8.

If not OK, repair the open seat heater switch sensor

ground circuit as required.

(8) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and a good ground. There should be no

continuity. If OK, go to Step 9. If not OK, repair the

shorted seat heater switch mux circuit as required.

(9) Check for continuity between the seat heater

switch mux circuit cavity of the instrument panel

wire harness connector for the inoperative heated

seat switch and the 22-way instrument panel wire

harness connector for the BCM. There should be con-

tinuity. If OK, use a DRBtscan tool and the proper

Diagnostic Procedures manual to test the BCM. If

not OK, repair the open seat heater switch mux cir-

cuit as required.

REMOVAL

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

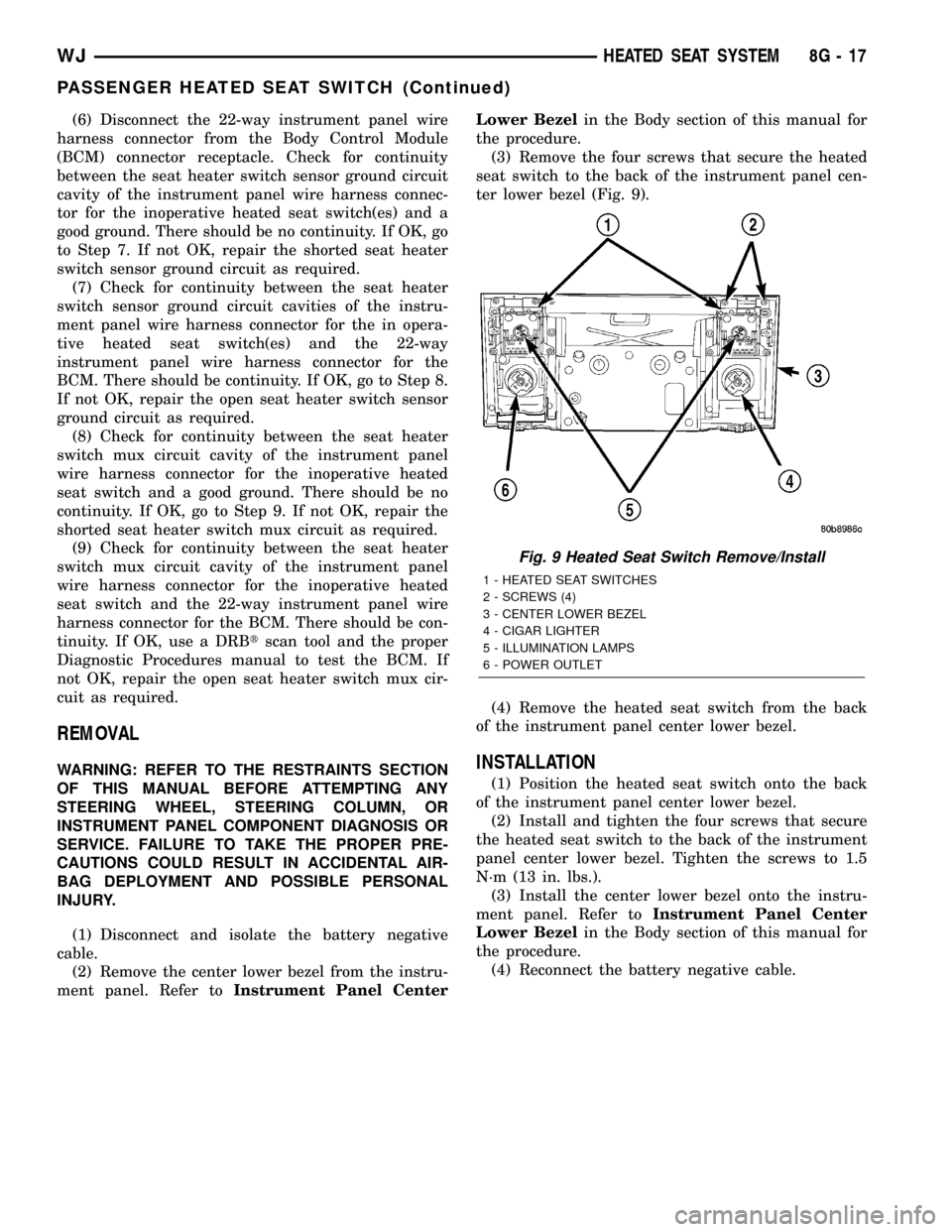

(2) Remove the center lower bezel from the instru-

ment panel. Refer toInstrument Panel CenterLower Bezelin the Body section of this manual for

the procedure.

(3) Remove the four screws that secure the heated

seat switch to the back of the instrument panel cen-

ter lower bezel (Fig. 9).

(4) Remove the heated seat switch from the back

of the instrument panel center lower bezel.INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center lower bezel.

(2) Install and tighten the four screws that secure

the heated seat switch to the back of the instrument

panel center lower bezel. Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center lower bezel onto the instru-

ment panel. Refer toInstrument Panel Center

Lower Bezelin the Body section of this manual for

the procedure.

(4) Reconnect the battery negative cable.

Fig. 9 Heated Seat Switch Remove/Install

1 - HEATED SEAT SWITCHES

2 - SCREWS (4)

3 - CENTER LOWER BEZEL

4 - CIGAR LIGHTER

5 - ILLUMINATION LAMPS

6 - POWER OUTLET

WJHEATED SEAT SYSTEM 8G - 17

PASSENGER HEATED SEAT SWITCH (Continued)

Page 391 of 2199

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds. Following are general descriptions of the

remaining major components in the horn system.

OPERATION

The horn system is activated by a horn switch con-

cealed beneath the driver side airbag module trim

cover in the center of the steering wheel. Depressing

the center of the driver side airbag module trim cover

closes the horn switch. Closing the horn switch acti-

vates the horn relay. The activated horn relay then

switches the battery current needed to energize the

horns.

The BCM can also activate the horn system by

energizing the horn relay through a single hard

wired output circuit. The BCM energizes and de-en-

ergizes the horn relay in response to internal pro-

gramming as well as message inputs received over

the Programmable Communications Interface (PCI)

data bus network. The BCM can energize the horn

relay for a single chirp (RKE lock request), or for

extended operation (RKE panic mode and VTSS

alarm mode).

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the horn system.

DIAGNOSIS AND TESTING - HORN SYSTEM

In most cases, any problem involving continually

sounding horns can be quickly alleviated by removing

the horn relay from the Power Distribution Center

(PDC). Refer to Horn Relay for the proper removal

procedure. Refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

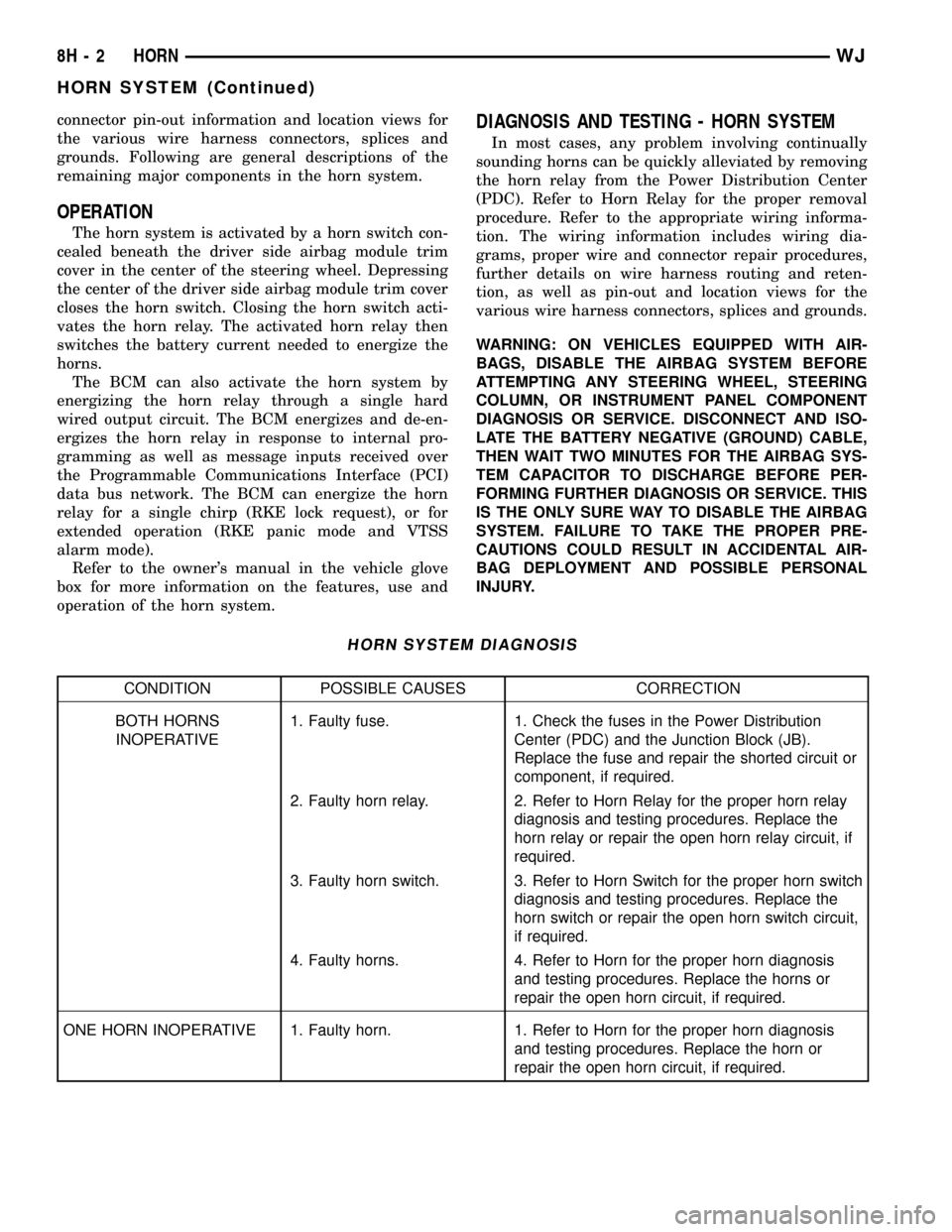

HORN SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

BOTH HORNS

INOPERATIVE1. Faulty fuse. 1. Check the fuses in the Power Distribution

Center (PDC) and the Junction Block (JB).

Replace the fuse and repair the shorted circuit or

component, if required.

2. Faulty horn relay. 2. Refer to Horn Relay for the proper horn relay

diagnosis and testing procedures. Replace the

horn relay or repair the open horn relay circuit, if

required.

3. Faulty horn switch. 3. Refer to Horn Switch for the proper horn switch

diagnosis and testing procedures. Replace the

horn switch or repair the open horn switch circuit,

if required.

4. Faulty horns. 4. Refer to Horn for the proper horn diagnosis

and testing procedures. Replace the horns or

repair the open horn circuit, if required.

ONE HORN INOPERATIVE 1. Faulty horn. 1. Refer to Horn for the proper horn diagnosis

and testing procedures. Replace the horn or

repair the open horn circuit, if required.

8H - 2 HORNWJ

HORN SYSTEM (Continued)

Page 392 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

HORN SOUNDS

CONTINUOUSLY1. Faulty horn relay. 1. Refer to Horn Relay for the proper horn relay

diagnosis and testing procedures. Replace the

horn relay or repair the shorted horn relay control

circuit, if required.

2. Faulty horn switch. 2. Refer to Horn Switch for the proper horn switch

diagnosis and testing procedures. Replace the

horn switch or repair the shorted horn switch

circuit, if required.

HORN

DESCRIPTION

The dual electromagnetic diaphragm-type horns

are standard equipment on this model. Both horns

are secured to a mounting bracket. The mounting

bracket is secured with a screw to the back side of

the right extension of the radiator closure assembly,

just ahead of the right front wheel house and below

the front wheel house extension. The two horns are

connected in parallel. Each horn is grounded through

its wire harness connector and circuit to an eyelet

secured to the right inner fender shield near the bat-

tery, and receives battery feed through the closed

contacts of the horn relay.

The horns cannot be repaired or adjusted and, if

faulty or damaged, they must be individually

replaced.

OPERATION

Within the two halves of the molded plastic horn

housing are a flexible diaphragm, a plunger, an elec-

tromagnetic coil and a set of contact points. The dia-

phragm is secured in suspension around its

perimeter by the mating surfaces of the horn hous-

ing. The plunger is secured to the center of the dia-

phragm and extends into the center of the

electromagnet. The contact points control the current

flow through the electromagnet.

When the horn is energized, electrical current

flows through the closed contact points to the electro-

magnet. The resulting electromagnetic field draws

the plunger and diaphragm toward it until that

movement mechanically opens the contact points.

When the contact points open, the electromagnetic

field collapses allowing the plunger and diaphragm to

return to their relaxed positions and closing the con-

tact points again. This cycle continues repeating at a

very rapid rate producing the vibration and move-

ment of air that creates the sound that is directed

through the horn outlet.

DIAGNOSIS AND TESTING - HORN

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect the wire harness connector(s) from

the horn connector receptacle(s). Measure the resis-

tance between the ground circuit cavity of the horn(s)

wire harness connector(s) and a good ground. There

should be no measurable resistance. If OK, go to Step

2. If not OK, repair the open ground circuit to ground

as required.

(2) Check for battery voltage at the horn relay out-

put circuit cavity of the horn(s) wire harness connec-

tor(s). There should be zero volts. If OK, go to Step 3.

If not OK, repair the shorted horn relay output cir-

cuit or replace the faulty horn relay as required.

(3) Depress the horn switch. There should now be

battery voltage at the horn relay output circuit cavity

of the horn(s) wire harness connector(s). If OK,

replace the faulty horns. If not OK, repair the open

horn relay output circuit to the horn relay as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support the vehicle.

(3) Remove the lower front half of the inner liner

from the right front fender wheel house. (Refer to 23

- BODY/EXTERIOR/FRONT FENDER - REMOVAL).

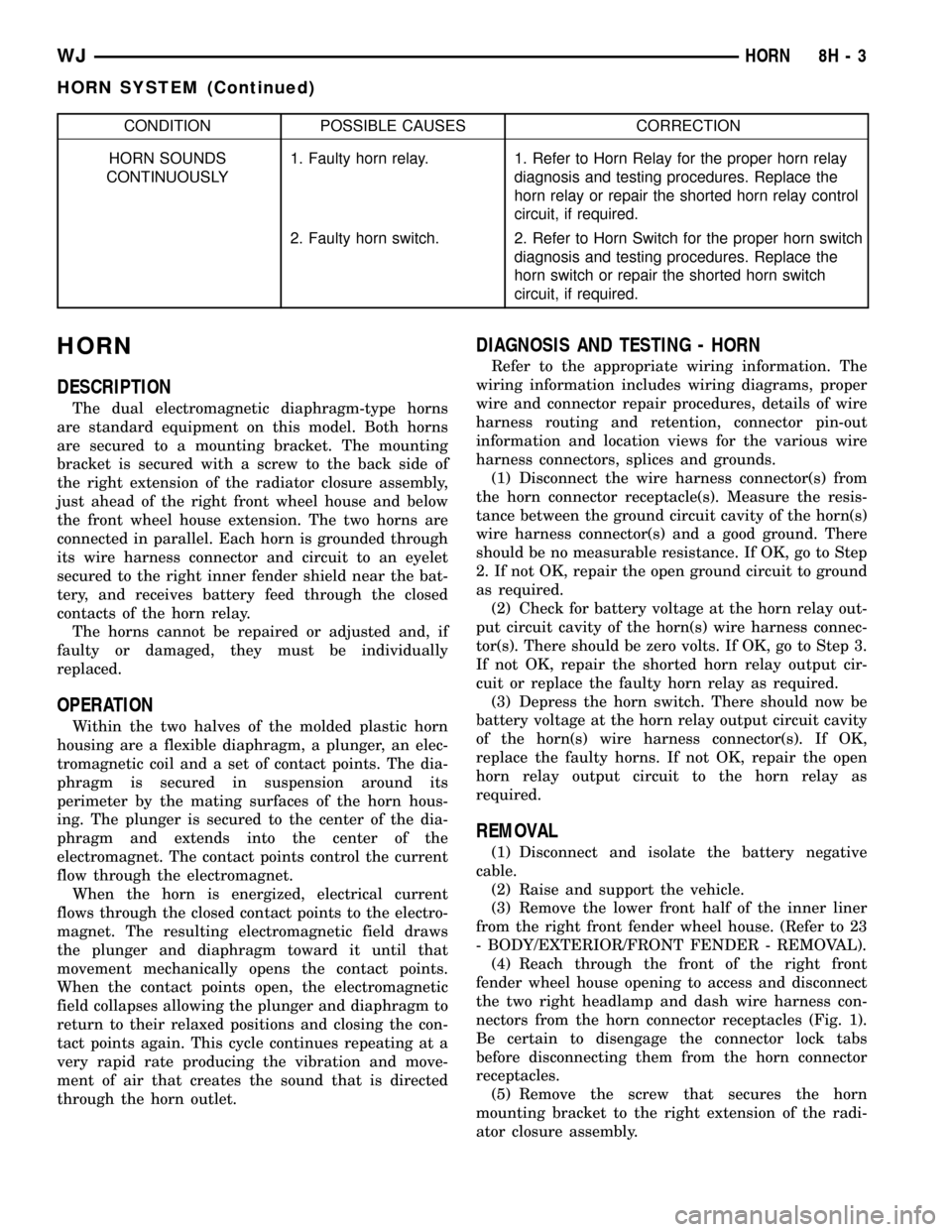

(4) Reach through the front of the right front

fender wheel house opening to access and disconnect

the two right headlamp and dash wire harness con-

nectors from the horn connector receptacles (Fig. 1).

Be certain to disengage the connector lock tabs

before disconnecting them from the horn connector

receptacles.

(5) Remove the screw that secures the horn

mounting bracket to the right extension of the radi-

ator closure assembly.

WJHORN 8H - 3

HORN SYSTEM (Continued)

Page 393 of 2199

(6) Remove both horns and the mounting bracket

from the right extension of the radiator closure

assembly as a unit.

INSTALLATION

(1) Position both horns and the mounting bracket

onto the right extension of the radiator closure

assembly as a unit.

(2) Install and tighten the screw that secures the

horn mounting bracket to the right extension of the

radiator closure assembly. Tighten the screw to 11.3

N´m (100 in. lbs.).

(3) Reconnect the two right headlamp and dash

wire harness connectors to the horn connector recep-

tacles. Be certain to engage the connector lock tabs

after reconnecting them to the horn connector recep-

tacles.

(4) Install the lower front half of the inner liner to

the right front fender wheel house. (Refer to 23 -

BODY/EXTERIOR/FRONT FENDER - INSTALLA-

TION) for the procedure.

(5) Lower the vehicle.

(6) Reconnect the battery negative cable.

HORN RELAY

DESCRIPTION

The horn relay is a electromechanical device that

switches battery current to the horn when the horn

switch grounds the relay coil. The horn relay is

located in the Power Distribution Center (PDC) inthe engine compartment. If a problem is encountered

with a continuously sounding horn, it can usually be

quickly resolved by removing the horn relay from the

PDC until further diagnosis is completed. See the

fuse and relay layout label affixed to the inside sur-

face of the PDC cover for horn relay identification

and location.

The horn relay is a International Standards Orga-

nization (ISO) micro-relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The ISO micro-relay terminal functions

are the same as a conventional ISO relay. However,

the ISO micro-relay terminal pattern (or footprint) is

different, the current capacity is lower, and the phys-

ical dimensions are smaller than those of the conven-

tional ISO relay.

The horn relay cannot be repaired or adjusted and,

if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - HORN RELAY

The horn relay (Fig. 2) is located in the Power Dis-

tribution Center (PDC) between the battery and the

right inner fender shield on the passenger side of the

engine compartment. If a problem is encountered

with a continuously sounding horn, it can usually be

quickly resolved by removing the horn relay from the

PDC until further diagnosis is completed. See the

fuse and relay layout label affixed to the inside sur-

face of the PDC cover for horn relay identification

and location. For complete circuit diagrams, refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

Fig. 1 Horns Remove/Install

1 - RADIATOR CLOSURE ASSEMBLY

2 - HORNS AND MOUNTING BRACKET

3 - RIGHT HEADLAMP AND DASH WIRE HARNESS

CONNECTORS

8H - 4 HORNWJ

HORN (Continued)