Oil JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1155 of 2199

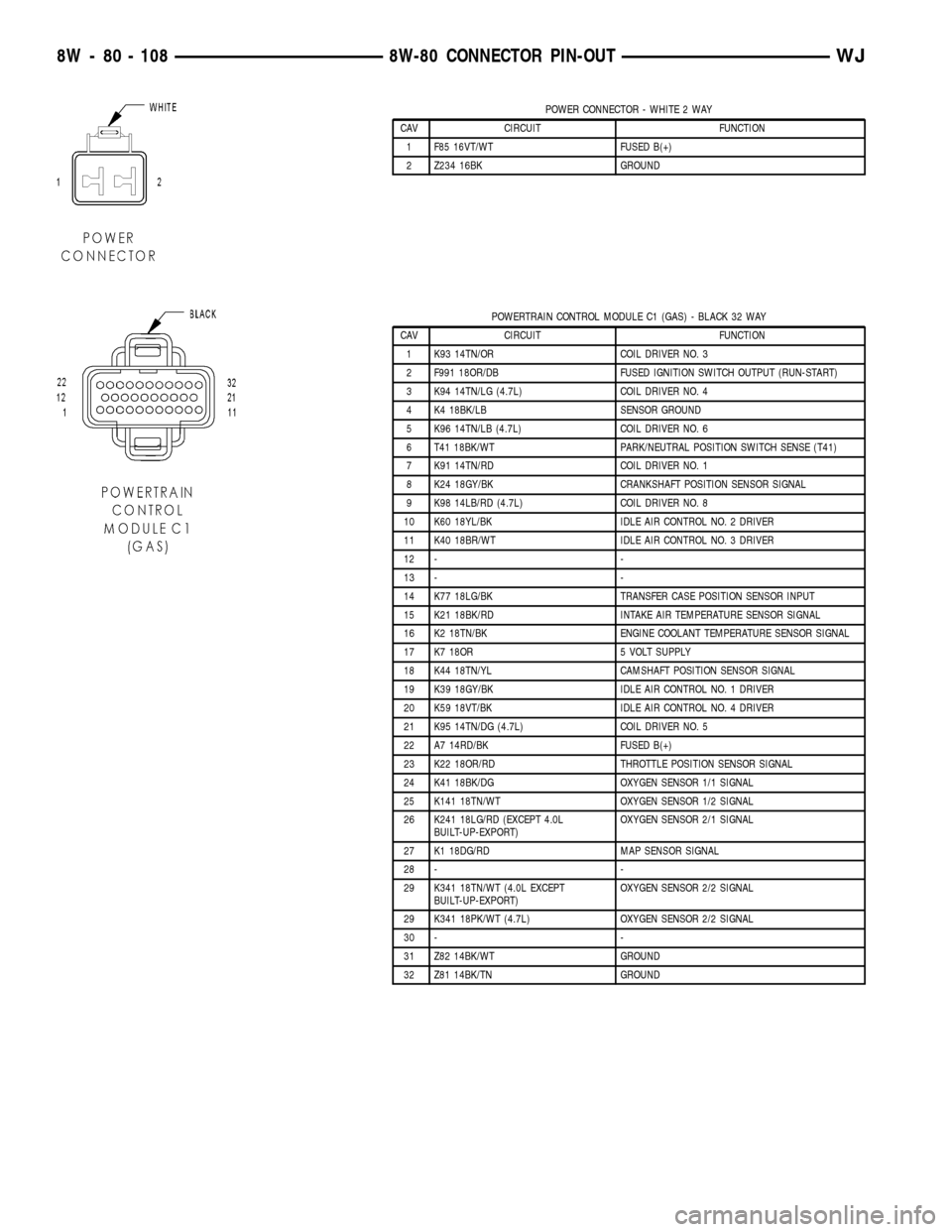

POWER CONNECTOR - WHITE 2 WAY

CAV CIRCUIT FUNCTION

1 F85 16VT/WT FUSED B(+)

2 Z234 16BK GROUND

POWERTRAIN CONTROL MODULE C1 (GAS) - BLACK 32 WAY

CAV CIRCUIT FUNCTION

1 K93 14TN/OR COIL DRIVER NO. 3

2 F991 18OR/DB FUSED IGNITION SWITCH OUTPUT (RUN-START)

3 K94 14TN/LG (4.7L) COIL DRIVER NO. 4

4 K4 18BK/LB SENSOR GROUND

5 K96 14TN/LB (4.7L) COIL DRIVER NO. 6

6 T41 18BK/WT PARK/NEUTRAL POSITION SWITCH SENSE (T41)

7 K91 14TN/RD COIL DRIVER NO. 1

8 K24 18GY/BK CRANKSHAFT POSITION SENSOR SIGNAL

9 K98 14LB/RD (4.7L) COIL DRIVER NO. 8

10 K60 18YL/BK IDLE AIR CONTROL NO. 2 DRIVER

11 K40 18BR/WT IDLE AIR CONTROL NO. 3 DRIVER

12 - -

13 - -

14 K77 18LG/BK TRANSFER CASE POSITION SENSOR INPUT

15 K21 18BK/RD INTAKE AIR TEMPERATURE SENSOR SIGNAL

16 K2 18TN/BK ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

17 K7 18OR 5 VOLT SUPPLY

18 K44 18TN/YL CAMSHAFT POSITION SENSOR SIGNAL

19 K39 18GY/BK IDLE AIR CONTROL NO. 1 DRIVER

20 K59 18VT/BK IDLE AIR CONTROL NO. 4 DRIVER

21 K95 14TN/DG (4.7L) COIL DRIVER NO. 5

22 A7 14RD/BK FUSED B(+)

23 K22 18OR/RD THROTTLE POSITION SENSOR SIGNAL

24 K41 18BK/DG OXYGEN SENSOR 1/1 SIGNAL

25 K141 18TN/WT OXYGEN SENSOR 1/2 SIGNAL

26 K241 18LG/RD (EXCEPT 4.0L

BUILT-UP-EXPORT)OXYGEN SENSOR 2/1 SIGNAL

27 K1 18DG/RD MAP SENSOR SIGNAL

28 - -

29 K341 18TN/WT (4.0L EXCEPT

BUILT-UP-EXPORT)OXYGEN SENSOR 2/2 SIGNAL

29 K341 18PK/WT (4.7L) OXYGEN SENSOR 2/2 SIGNAL

30 - -

31 Z82 14BK/WT GROUND

32 Z81 14BK/TN GROUND

8W - 80 - 108 8W-80 CONNECTOR PIN-OUTWJ

Page 1156 of 2199

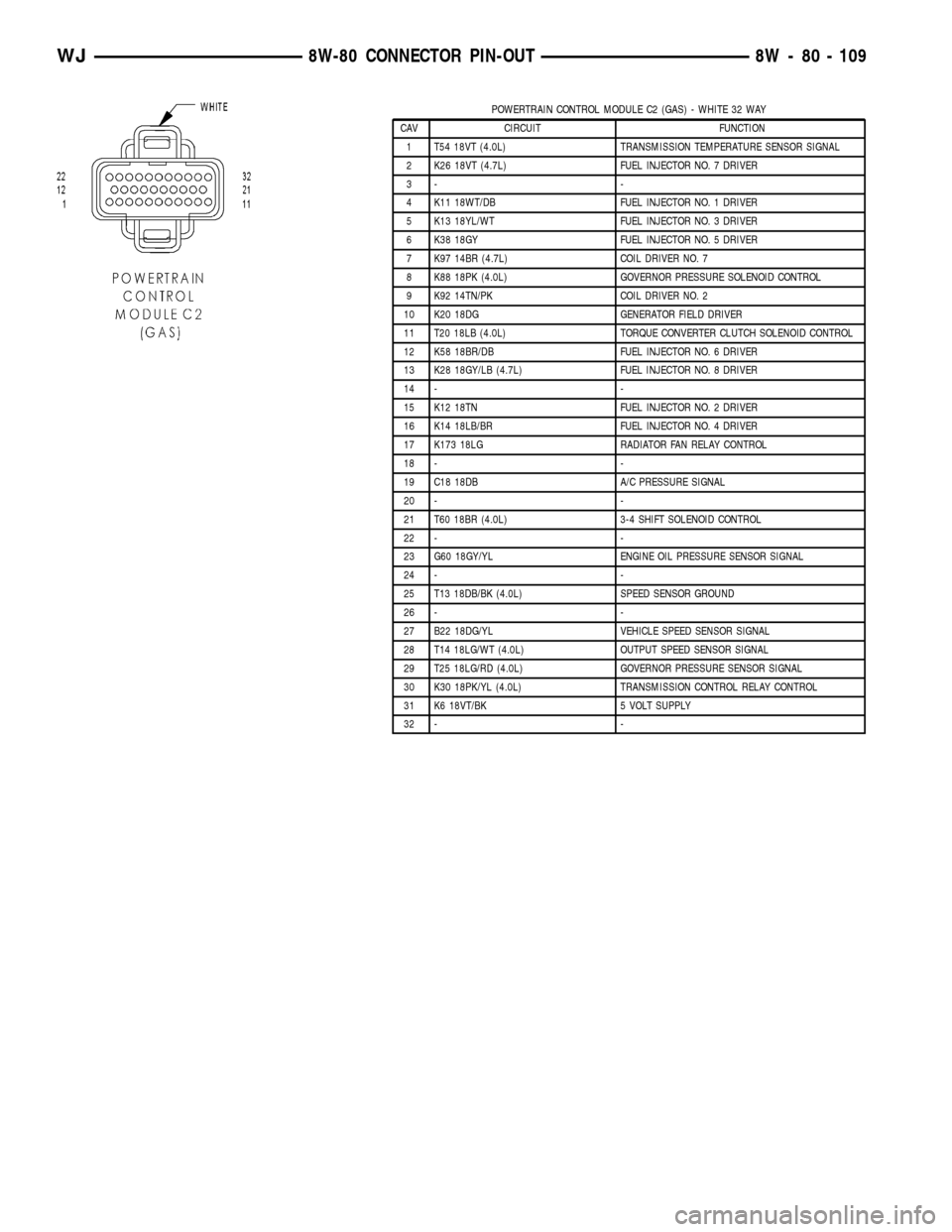

POWERTRAIN CONTROL MODULE C2 (GAS) - WHITE 32 WAY

CAV CIRCUIT FUNCTION

1 T54 18VT (4.0L) TRANSMISSION TEMPERATURE SENSOR SIGNAL

2 K26 18VT (4.7L) FUEL INJECTOR NO. 7 DRIVER

3- -

4 K11 18WT/DB FUEL INJECTOR NO. 1 DRIVER

5 K13 18YL/WT FUEL INJECTOR NO. 3 DRIVER

6 K38 18GY FUEL INJECTOR NO. 5 DRIVER

7 K97 14BR (4.7L) COIL DRIVER NO. 7

8 K88 18PK (4.0L) GOVERNOR PRESSURE SOLENOID CONTROL

9 K92 14TN/PK COIL DRIVER NO. 2

10 K20 18DG GENERATOR FIELD DRIVER

11 T20 18LB (4.0L) TORQUE CONVERTER CLUTCH SOLENOID CONTROL

12 K58 18BR/DB FUEL INJECTOR NO. 6 DRIVER

13 K28 18GY/LB (4.7L) FUEL INJECTOR NO. 8 DRIVER

14 - -

15 K12 18TN FUEL INJECTOR NO. 2 DRIVER

16 K14 18LB/BR FUEL INJECTOR NO. 4 DRIVER

17 K173 18LG RADIATOR FAN RELAY CONTROL

18 - -

19 C18 18DB A/C PRESSURE SIGNAL

20 - -

21 T60 18BR (4.0L) 3-4 SHIFT SOLENOID CONTROL

22 - -

23 G60 18GY/YL ENGINE OIL PRESSURE SENSOR SIGNAL

24 - -

25 T13 18DB/BK (4.0L) SPEED SENSOR GROUND

26 - -

27 B22 18DG/YL VEHICLE SPEED SENSOR SIGNAL

28 T14 18LG/WT (4.0L) OUTPUT SPEED SENSOR SIGNAL

29 T25 18LG/RD (4.0L) GOVERNOR PRESSURE SENSOR SIGNAL

30 K30 18PK/YL (4.0L) TRANSMISSION CONTROL RELAY CONTROL

31 K6 18VT/BK 5 VOLT SUPPLY

32 - -

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 109

Page 1178 of 2199

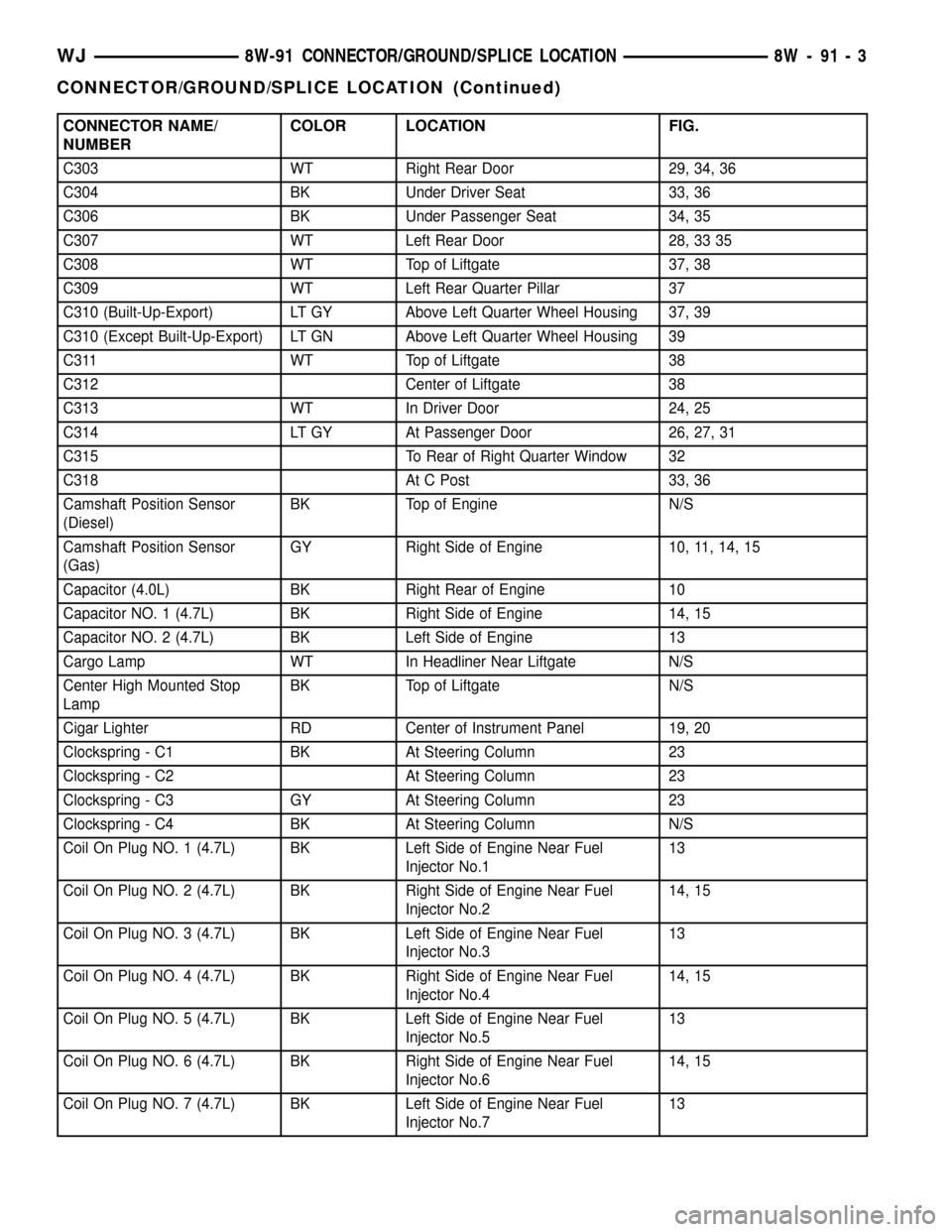

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

C303 WT Right Rear Door 29, 34, 36

C304 BK Under Driver Seat 33, 36

C306 BK Under Passenger Seat 34, 35

C307 WT Left Rear Door 28, 33 35

C308 WT Top of Liftgate 37, 38

C309 WT Left Rear Quarter Pillar 37

C310 (Built-Up-Export) LT GY Above Left Quarter Wheel Housing 37, 39

C310 (Except Built-Up-Export) LT GN Above Left Quarter Wheel Housing 39

C311 WT Top of Liftgate 38

C312 Center of Liftgate 38

C313 WT In Driver Door 24, 25

C314 LT GY At Passenger Door 26, 27, 31

C315 To Rear of Right Quarter Window 32

C318 At C Post 33, 36

Camshaft Position Sensor

(Diesel)BK Top of Engine N/S

Camshaft Position Sensor

(Gas)GY Right Side of Engine 10, 11, 14, 15

Capacitor (4.0L) BK Right Rear of Engine 10

Capacitor NO. 1 (4.7L) BK Right Side of Engine 14, 15

Capacitor NO. 2 (4.7L) BK Left Side of Engine 13

Cargo Lamp WT In Headliner Near Liftgate N/S

Center High Mounted Stop

LampBK Top of Liftgate N/S

Cigar Lighter RD Center of Instrument Panel 19, 20

Clockspring - C1 BK At Steering Column 23

Clockspring - C2 At Steering Column 23

Clockspring - C3 GY At Steering Column 23

Clockspring - C4 BK At Steering Column N/S

Coil On Plug NO. 1 (4.7L) BK Left Side of Engine Near Fuel

Injector No.113

Coil On Plug NO. 2 (4.7L) BK Right Side of Engine Near Fuel

Injector No.214, 15

Coil On Plug NO. 3 (4.7L) BK Left Side of Engine Near Fuel

Injector No.313

Coil On Plug NO. 4 (4.7L) BK Right Side of Engine Near Fuel

Injector No.414, 15

Coil On Plug NO. 5 (4.7L) BK Left Side of Engine Near Fuel

Injector No.513

Coil On Plug NO. 6 (4.7L) BK Right Side of Engine Near Fuel

Injector No.614, 15

Coil On Plug NO. 7 (4.7L) BK Left Side of Engine Near Fuel

Injector No.713

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1179 of 2199

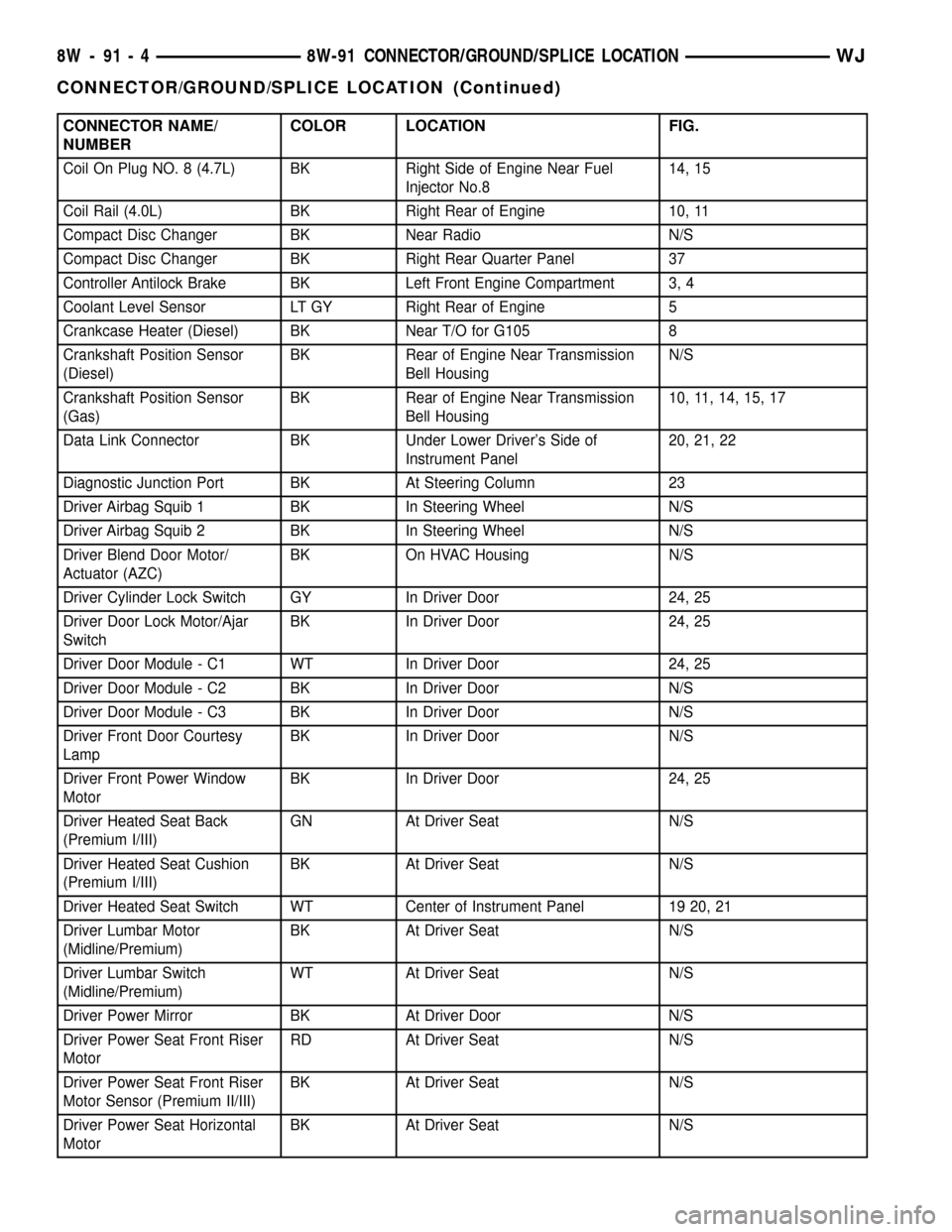

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Coil On Plug NO. 8 (4.7L) BK Right Side of Engine Near Fuel

Injector No.814, 15

Coil Rail (4.0L) BK Right Rear of Engine 10, 11

Compact Disc Changer BK Near Radio N/S

Compact Disc Changer BK Right Rear Quarter Panel 37

Controller Antilock Brake BK Left Front Engine Compartment 3, 4

Coolant Level Sensor LT GY Right Rear of Engine 5

Crankcase Heater (Diesel) BK Near T/O for G105 8

Crankshaft Position Sensor

(Diesel)BK Rear of Engine Near Transmission

Bell HousingN/S

Crankshaft Position Sensor

(Gas)BK Rear of Engine Near Transmission

Bell Housing10, 11, 14, 15, 17

Data Link Connector BK Under Lower Driver's Side of

Instrument Panel20, 21, 22

Diagnostic Junction Port BK At Steering Column 23

Driver Airbag Squib 1 BK In Steering Wheel N/S

Driver Airbag Squib 2 BK In Steering Wheel N/S

Driver Blend Door Motor/

Actuator (AZC)BK On HVAC Housing N/S

Driver Cylinder Lock Switch GY In Driver Door 24, 25

Driver Door Lock Motor/Ajar

SwitchBK In Driver Door 24, 25

Driver Door Module - C1 WT In Driver Door 24, 25

Driver Door Module - C2 BK In Driver Door N/S

Driver Door Module - C3 BK In Driver Door N/S

Driver Front Door Courtesy

LampBK In Driver Door N/S

Driver Front Power Window

MotorBK In Driver Door 24, 25

Driver Heated Seat Back

(Premium I/III)GN At Driver Seat N/S

Driver Heated Seat Cushion

(Premium I/III)BK At Driver Seat N/S

Driver Heated Seat Switch WT Center of Instrument Panel 19 20, 21

Driver Lumbar Motor

(Midline/Premium)BK At Driver Seat N/S

Driver Lumbar Switch

(Midline/Premium)WT At Driver Seat N/S

Driver Power Mirror BK At Driver Door N/S

Driver Power Seat Front Riser

MotorRD At Driver Seat N/S

Driver Power Seat Front Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Horizontal

MotorBK At Driver Seat N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1180 of 2199

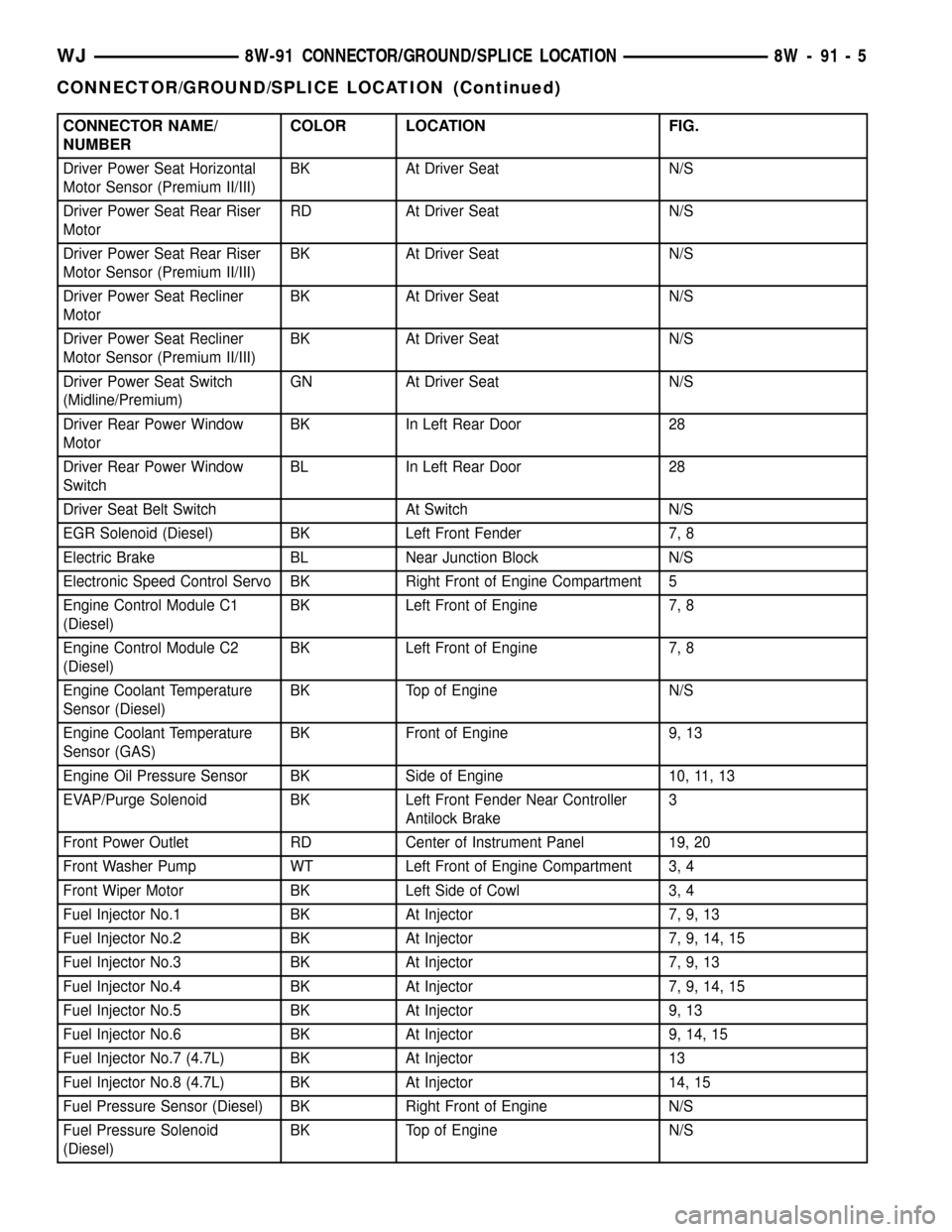

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Driver Power Seat Horizontal

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Rear Riser

MotorRD At Driver Seat N/S

Driver Power Seat Rear Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Recliner

MotorBK At Driver Seat N/S

Driver Power Seat Recliner

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Switch

(Midline/Premium)GN At Driver Seat N/S

Driver Rear Power Window

MotorBK In Left Rear Door 28

Driver Rear Power Window

SwitchBL In Left Rear Door 28

Driver Seat Belt Switch At Switch N/S

EGR Solenoid (Diesel) BK Left Front Fender 7, 8

Electric Brake BL Near Junction Block N/S

Electronic Speed Control Servo BK Right Front of Engine Compartment 5

Engine Control Module C1

(Diesel)BK Left Front of Engine 7, 8

Engine Control Module C2

(Diesel)BK Left Front of Engine 7, 8

Engine Coolant Temperature

Sensor (Diesel)BK Top of Engine N/S

Engine Coolant Temperature

Sensor (GAS)BK Front of Engine 9, 13

Engine Oil Pressure Sensor BK Side of Engine 10, 11, 13

EVAP/Purge Solenoid BK Left Front Fender Near Controller

Antilock Brake3

Front Power Outlet RD Center of Instrument Panel 19, 20

Front Washer Pump WT Left Front of Engine Compartment 3, 4

Front Wiper Motor BK Left Side of Cowl 3, 4

Fuel Injector No.1 BK At Injector 7, 9, 13

Fuel Injector No.2 BK At Injector 7, 9, 14, 15

Fuel Injector No.3 BK At Injector 7, 9, 13

Fuel Injector No.4 BK At Injector 7, 9, 14, 15

Fuel Injector No.5 BK At Injector 9, 13

Fuel Injector No.6 BK At Injector 9, 14, 15

Fuel Injector No.7 (4.7L) BK At Injector 13

Fuel Injector No.8 (4.7L) BK At Injector 14, 15

Fuel Pressure Sensor (Diesel) BK Right Front of Engine N/S

Fuel Pressure Solenoid

(Diesel)BK Top of Engine N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 5

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1181 of 2199

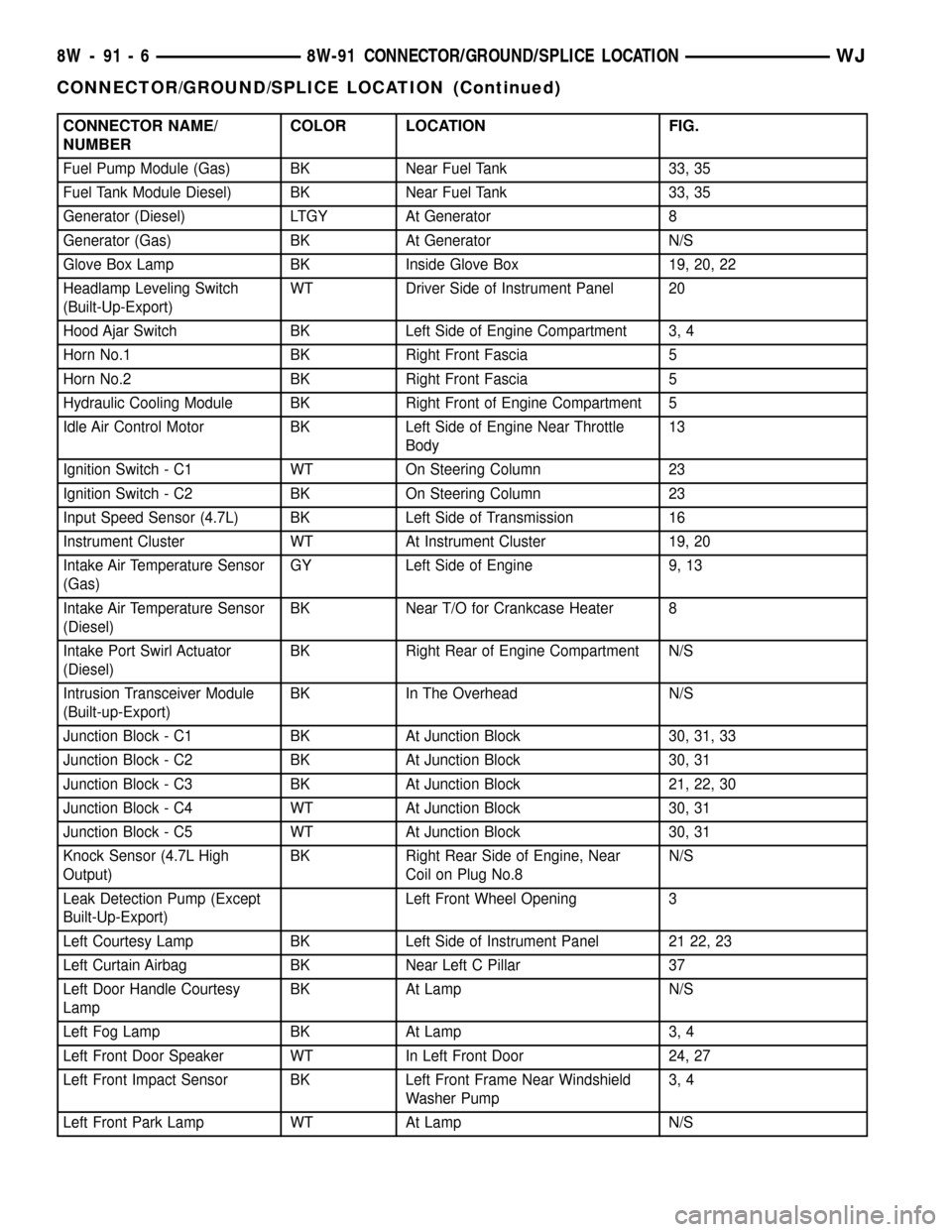

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Fuel Pump Module (Gas) BK Near Fuel Tank 33, 35

Fuel Tank Module Diesel) BK Near Fuel Tank 33, 35

Generator (Diesel) LTGY At Generator 8

Generator (Gas) BK At Generator N/S

Glove Box Lamp BK Inside Glove Box 19, 20, 22

Headlamp Leveling Switch

(Built-Up-Export)WT Driver Side of Instrument Panel 20

Hood Ajar Switch BK Left Side of Engine Compartment 3, 4

Horn No.1 BK Right Front Fascia 5

Horn No.2 BK Right Front Fascia 5

Hydraulic Cooling Module BK Right Front of Engine Compartment 5

Idle Air Control Motor BK Left Side of Engine Near Throttle

Body13

Ignition Switch - C1 WT On Steering Column 23

Ignition Switch - C2 BK On Steering Column 23

Input Speed Sensor (4.7L) BK Left Side of Transmission 16

Instrument Cluster WT At Instrument Cluster 19, 20

Intake Air Temperature Sensor

(Gas)GY Left Side of Engine 9, 13

Intake Air Temperature Sensor

(Diesel)BK Near T/O for Crankcase Heater 8

Intake Port Swirl Actuator

(Diesel)BK Right Rear of Engine Compartment N/S

Intrusion Transceiver Module

(Built-up-Export)BK In The Overhead N/S

Junction Block - C1 BK At Junction Block 30, 31, 33

Junction Block - C2 BK At Junction Block 30, 31

Junction Block - C3 BK At Junction Block 21, 22, 30

Junction Block - C4 WT At Junction Block 30, 31

Junction Block - C5 WT At Junction Block 30, 31

Knock Sensor (4.7L High

Output)BK Right Rear Side of Engine, Near

Coil on Plug No.8N/S

Leak Detection Pump (Except

Built-Up-Export)Left Front Wheel Opening 3

Left Courtesy Lamp BK Left Side of Instrument Panel 21 22, 23

Left Curtain Airbag BK Near Left C Pillar 37

Left Door Handle Courtesy

LampBK At Lamp N/S

Left Fog Lamp BK At Lamp 3, 4

Left Front Door Speaker WT In Left Front Door 24, 27

Left Front Impact Sensor BK Left Front Frame Near Windshield

Washer Pump3, 4

Left Front Park Lamp WT At Lamp N/S

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1187 of 2199

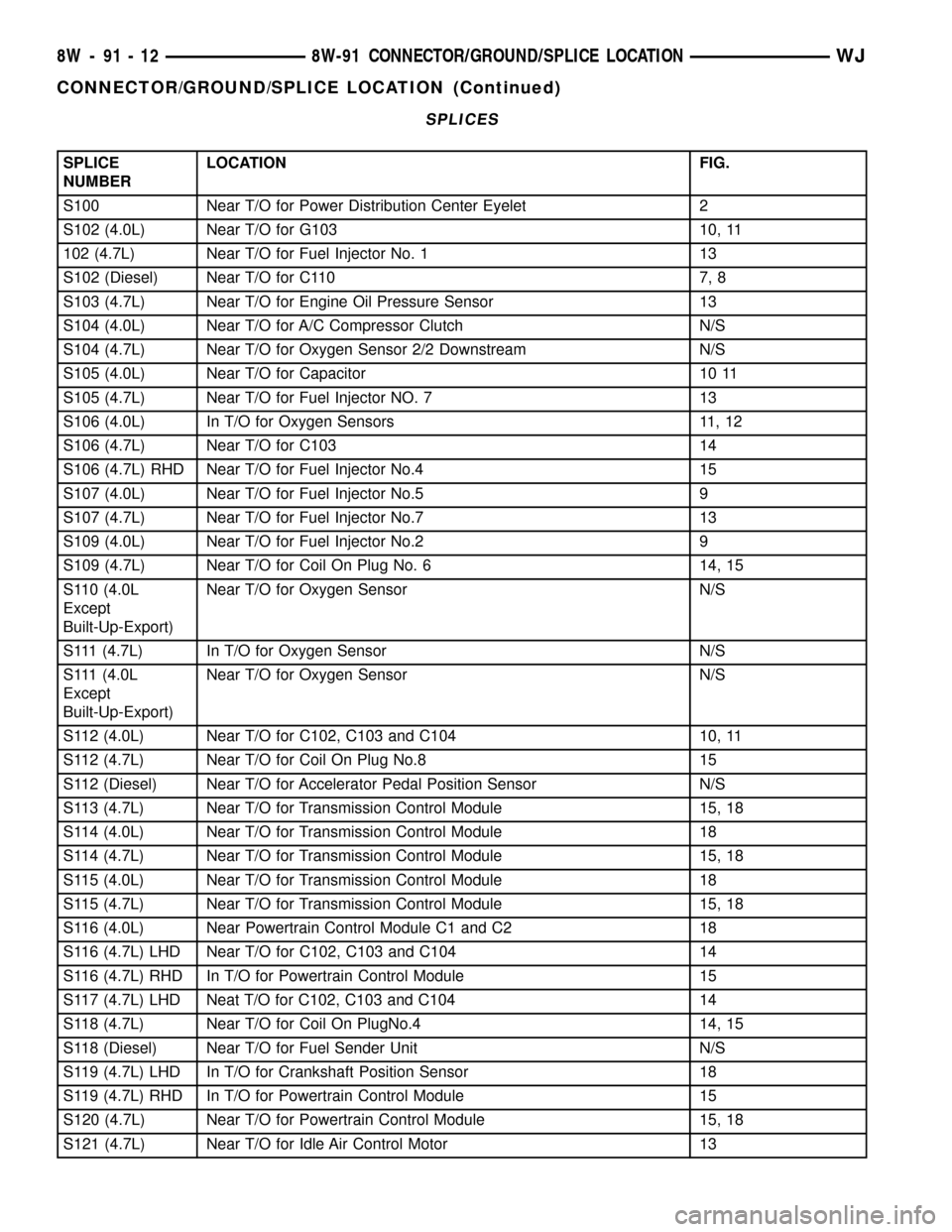

SPLICES

SPLICE

NUMBERLOCATION FIG.

S100 Near T/O for Power Distribution Center Eyelet 2

S102 (4.0L) Near T/O for G103 10, 11

102 (4.7L) Near T/O for Fuel Injector No. 1 13

S102 (Diesel) Near T/O for C110 7, 8

S103 (4.7L) Near T/O for Engine Oil Pressure Sensor 13

S104 (4.0L) Near T/O for A/C Compressor Clutch N/S

S104 (4.7L) Near T/O for Oxygen Sensor 2/2 Downstream N/S

S105 (4.0L) Near T/O for Capacitor 10 11

S105 (4.7L) Near T/O for Fuel Injector NO. 7 13

S106 (4.0L) In T/O for Oxygen Sensors 11, 12

S106 (4.7L) Near T/O for C103 14

S106 (4.7L) RHD Near T/O for Fuel Injector No.4 15

S107 (4.0L) Near T/O for Fuel Injector No.5 9

S107 (4.7L) Near T/O for Fuel Injector No.7 13

S109 (4.0L) Near T/O for Fuel Injector No.2 9

S109 (4.7L) Near T/O for Coil On Plug No. 6 14, 15

S110 (4.0L

Except

Built-Up-Export)Near T/O for Oxygen Sensor N/S

S111 (4.7L) In T/O for Oxygen Sensor N/S

S111 (4.0L

Except

Built-Up-Export)Near T/O for Oxygen Sensor N/S

S112 (4.0L) Near T/O for C102, C103 and C104 10, 11

S112 (4.7L) Near T/O for Coil On Plug No.8 15

S112 (Diesel) Near T/O for Accelerator Pedal Position Sensor N/S

S113 (4.7L) Near T/O for Transmission Control Module 15, 18

S114 (4.0L) Near T/O for Transmission Control Module 18

S114 (4.7L) Near T/O for Transmission Control Module 15, 18

S115 (4.0L) Near T/O for Transmission Control Module 18

S115 (4.7L) Near T/O for Transmission Control Module 15, 18

S116 (4.0L) Near Powertrain Control Module C1 and C2 18

S116 (4.7L) LHD Near T/O for C102, C103 and C104 14

S116 (4.7L) RHD In T/O for Powertrain Control Module 15

S117 (4.7L) LHD Neat T/O for C102, C103 and C104 14

S118 (4.7L) Near T/O for Coil On PlugNo.4 14, 15

S118 (Diesel) Near T/O for Fuel Sender Unit N/S

S119 (4.7L) LHD In T/O for Crankshaft Position Sensor 18

S119 (4.7L) RHD In T/O for Powertrain Control Module 15

S120 (4.7L) Near T/O for Powertrain Control Module 15, 18

S121 (4.7L) Near T/O for Idle Air Control Motor 13

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1227 of 2199

the same time, the power distribution system was

designed to provide ready access to these electrical

distribution points for the vehicle technician to use

when conducting diagnosis and repair of faulty cir-

cuits. The power distribution system can also prove

useful for the sourcing of additional electrical circuits

that may be required to provide the electrical current

needed to operate accessories that the vehicle owner

may choose to have installed in the aftermarket.

NOTE: DO NOT ATTEMPT TO SWAP POWER DIS-

TRIBUTION CENTERS FROM ONE VEHICLE TO

ANOTHER. MOST OF THESE ASSEMBLIES ARE

VEHICLE FEATURE SPECIFIC AND THEREFORE

NOT INTERCHANGEABLE. ALWAYS USE THE COR-

RECT PART NUMBERED ASSEMBLY WHEN DIAG-

NOSING OR REPLACING A POWER DISTRIBUTION

CENTER.

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

CIGAR LIGHTER OUTLET

DESCRIPTION

A cigar lighter outlet is standard equipment on

this model. On models equipped with the optional

Smoker's Package, the cigar lighter knob and heating

element are included. On models without the Smok-

er's Package, the cigar lighter outlet is equipped with

a snap fit plastic cap and is treated as an extra

accessory power outlet. The cigar lighter outlet is

installed in the instrument panel center lower bezel,

which is located near the bottom of the instrument

panel center stack area, below the heater and air

conditioner controls. The cigar lighter outlet is

secured by a snap fit within the center lower bezel.The cigar lighter outlet, plastic cap and the knob

and heating element unit are available for service

replacement. These components cannot be repaired

and, if faulty or damaged, they must be replaced.

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or outlet shell. The receptacle shell is

connected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The cigar lighter receives battery voltage from a fuse

in the junction block when the ignition switch is in

the Accessory or On positions.

The cigar lighter knob and heating element are

encased within a spring-loaded housing, which also

features a sliding protective heat shield. When the

knob and heating element are inserted in the outlet

shell, the heating element resistor coil is grounded

through its housing to the outlet shell. If the cigar

lighter knob is pushed inward, the heat shield slides

up toward the knob exposing the heating element,

and the heating element extends from the housing

toward the insulated contact in the bottom of the

outlet shell.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottom

of the outlet shell. These clips engage and hold the

heating element against the insulated contact long

enough for the resistor coil to heat up. When the

heating element is engaged with the contact, battery

current can flow through the resistor coil to ground,

causing the resistor coil to heat.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element caus-

ing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heat-

ing element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the outlet shell, the protective heat

shield slides downward on the housing so that the

heating element is recessed and shielded around its

circumference for safety.

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET

For complete circuit diagrams, refer toHorn/Ci-

gar Lighter/Power Outletin Wiring Diagrams.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused B(+) fuse in

Terminal Pick Kit 6680

8W - 97 - 2 8W-97 POWER DISTRIBUTIONWJ

POWER DISTRIBUTION (Continued)

Page 1239 of 2199

The cigar lighter relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

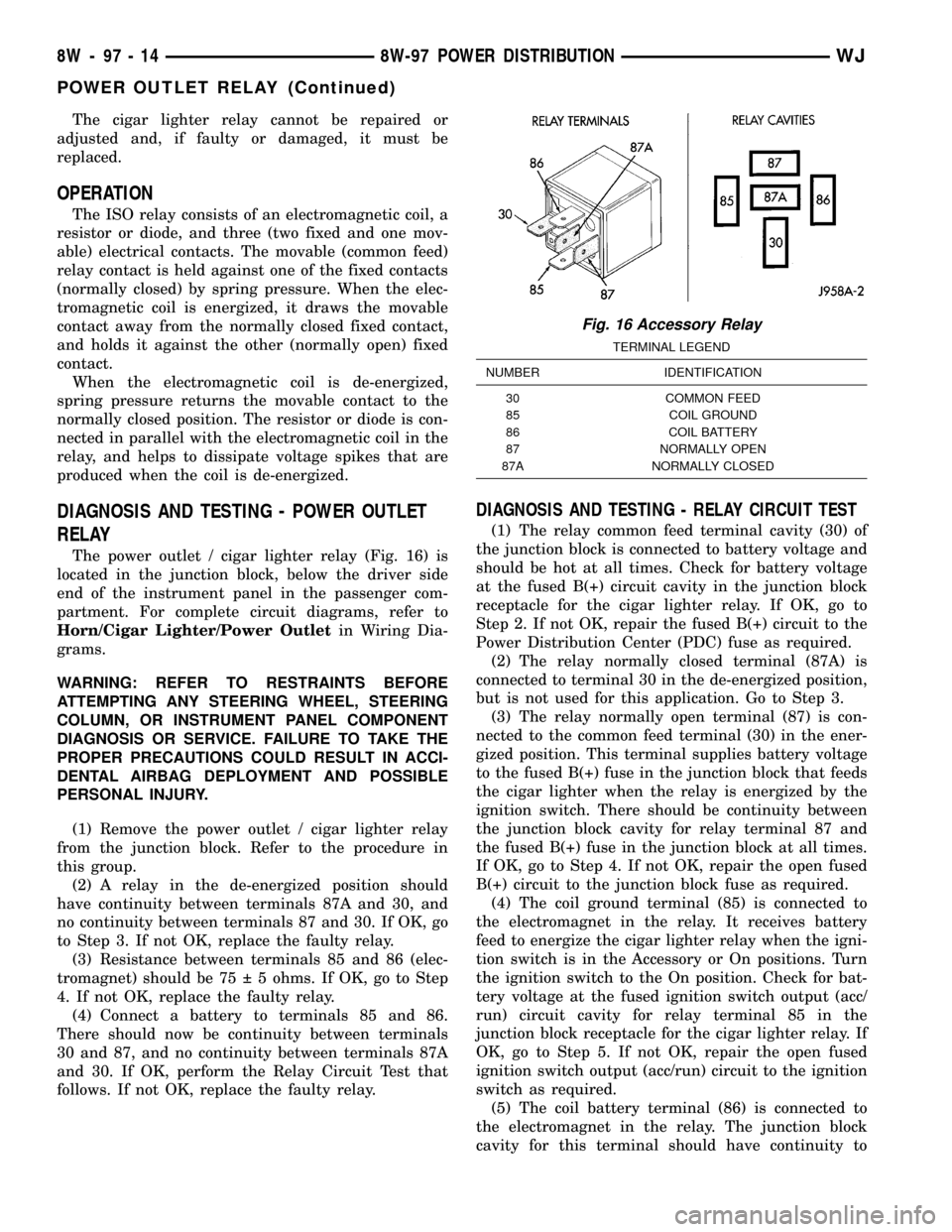

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - POWER OUTLET

RELAY

The power outlet / cigar lighter relay (Fig. 16) is

located in the junction block, below the driver side

end of the instrument panel in the passenger com-

partment. For complete circuit diagrams, refer to

Horn/Cigar Lighter/Power Outletin Wiring Dia-

grams.

WARNING: REFER TO RESTRAINTS BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the power outlet / cigar lighter relay

from the junction block. Refer to the procedure in

this group.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

DIAGNOSIS AND TESTING - RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the junction block is connected to battery voltage and

should be hot at all times. Check for battery voltage

at the fused B(+) circuit cavity in the junction block

receptacle for the cigar lighter relay. If OK, go to

Step 2. If not OK, repair the fused B(+) circuit to the

Power Distribution Center (PDC) fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the fused B(+) fuse in the junction block that feeds

the cigar lighter when the relay is energized by the

ignition switch. There should be continuity between

the junction block cavity for relay terminal 87 and

the fused B(+) fuse in the junction block at all times.

If OK, go to Step 4. If not OK, repair the open fused

B(+) circuit to the junction block fuse as required.

(4) The coil ground terminal (85) is connected to

the electromagnet in the relay. It receives battery

feed to energize the cigar lighter relay when the igni-

tion switch is in the Accessory or On positions. Turn

the ignition switch to the On position. Check for bat-

tery voltage at the fused ignition switch output (acc/

run) circuit cavity for relay terminal 85 in the

junction block receptacle for the cigar lighter relay. If

OK, go to Step 5. If not OK, repair the open fused

ignition switch output (acc/run) circuit to the ignition

switch as required.

(5) The coil battery terminal (86) is connected to

the electromagnet in the relay. The junction block

cavity for this terminal should have continuity to

Fig. 16 Accessory Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8W - 97 - 14 8W-97 POWER DISTRIBUTIONWJ

POWER OUTLET RELAY (Continued)

Page 1244 of 2199

ENGINE

TABLE OF CONTENTS

page page

ENGINE - 4.0L............................ 1ENGINE - 4.7L........................... 61

ENGINE - 4.0L

TABLE OF CONTENTS

page page

ENGINE - 4.0L

DESCRIPTION..........................2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION............3

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - PERFORMANCE............4

DIAGNOSIS AND TESTINGÐ ENGINE

DIAGNOSIS - MECHANICAL..............6

DIAGNOSIS AND TESTINGÐCYLINDER

COMPRESSION PRESSURE..............8

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE.......8

DIAGNOSIS AND TESTINGÐREAR SEAL

AREA LEAKS..........................9

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-

PLACE GASKETS AND SEALERS..........9

STANDARD PROCEDURE - REPAIR

DAMAGED OR WORN THREADS.........10

STANDARD PROCEDUREÐHYDROSTATIC

LOCK...............................10

STANDARD PROCEDURE - CYLINDER

BORE HONING.......................10

STANDARD PROCEDURE - ENGINE CORE

AND OIL GALLERY PLUGS..............11

REMOVAL.............................11

INSTALLATION.........................13

SPECIFICATIONS

ENGINE - 4.0L........................14

TORQUE - 4.0L ENGINE................17

AIR CLEANER ELEMENT

REMOVAL - 4.0L........................18

INSTALLATION - 4.0L....................19

AIR CLEANER HOUSING

REMOVAL - 4.0L........................19

INSTALLATION - 4.0L....................19CYLINDER HEAD

DESCRIPTION.........................19

REMOVAL.............................19

CLEANING............................21

INSPECTION..........................21

INSTALLATION.........................21

CYLINDER HEAD COVER(S)

DESCRIPTION.........................22

REMOVAL.............................22

CLEANING............................23

INSPECTION..........................23

INSTALLATION.........................23

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION.........................23

STANDARD PROCEDURE - VALVE SERVICE . . 23

REMOVAL.............................25

INSTALLATION.........................25

ROCKER ARM / ADJUSTER ASSEMBLY

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................26

CLEANING............................26

INSPECTION..........................27

INSTALLATION.........................27

VALVE STEM SEALS

DESCRIPTION.........................27

VALVE SPRINGS

DESCRIPTION.........................28

STANDARD PROCEDURE - VALVE SPRING

TENSION TEST.......................28

REMOVAL.............................28

INSTALLATION.........................29

ENGINE BLOCK

CLEANING............................30

INSPECTION..........................30

CAMSHAFT & BEARINGS

DESCRIPTION.........................30

WJENGINE 9 - 1