check engine light JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 234 of 2199

Carefully remove radiator pressure cap from filler

neck and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck

and examine lower inside sealing seat for nicks,

cracks, paint, dirt and solder residue. Inspect radia-

tor-to- reserve/overflow tank hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of filler neck. If cams are

damaged, seating of pressure cap valve and tester

seal will be affected.

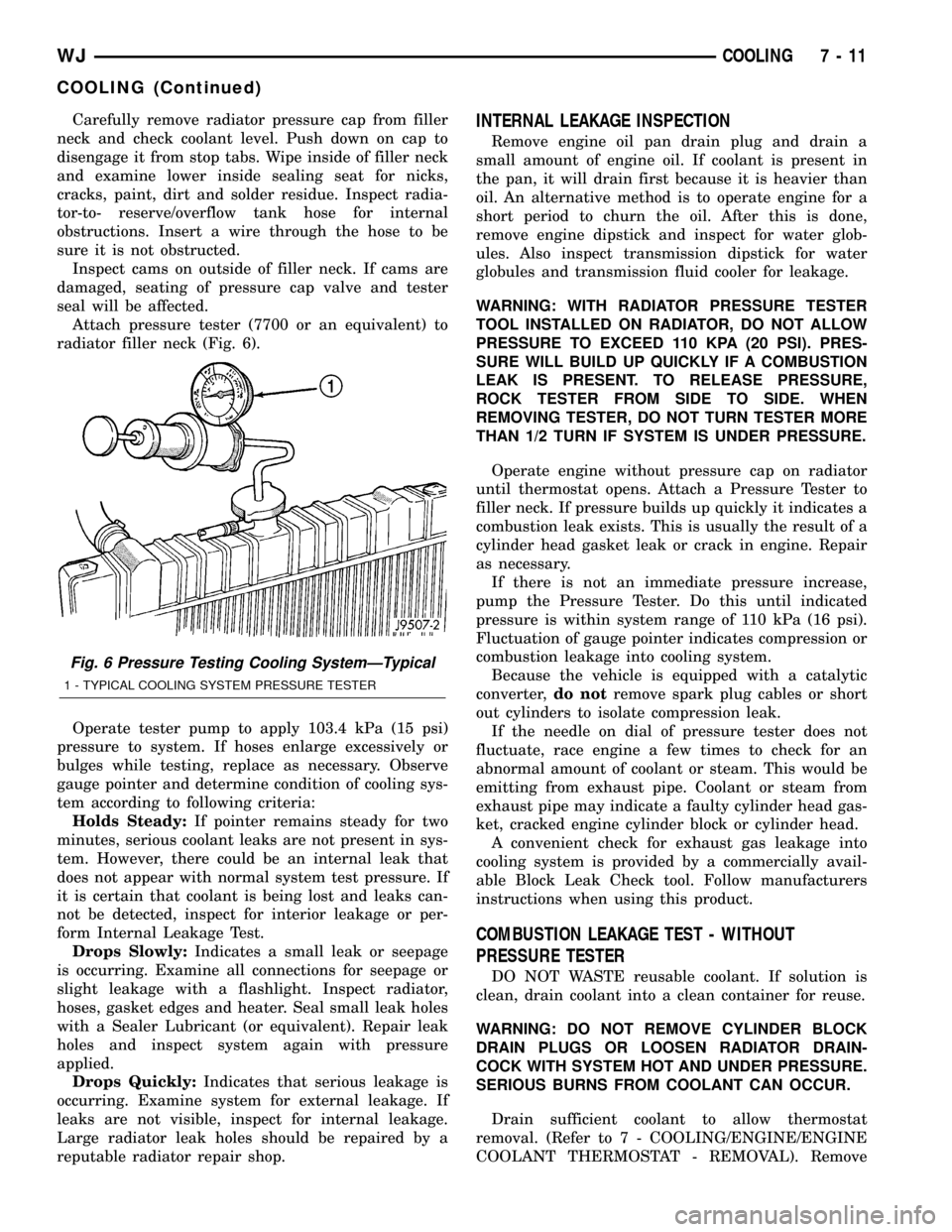

Attach pressure tester (7700 or an equivalent) to

radiator filler neck (Fig. 6).

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-

ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates a

combustion leak exists. This is usually the result of a

cylinder head gasket leak or crack in engine. Repair

as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT - REMOVAL). Remove

Fig. 6 Pressure Testing Cooling SystemÐTypical

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

WJCOOLING 7 - 11

COOLING (Continued)

Page 258 of 2199

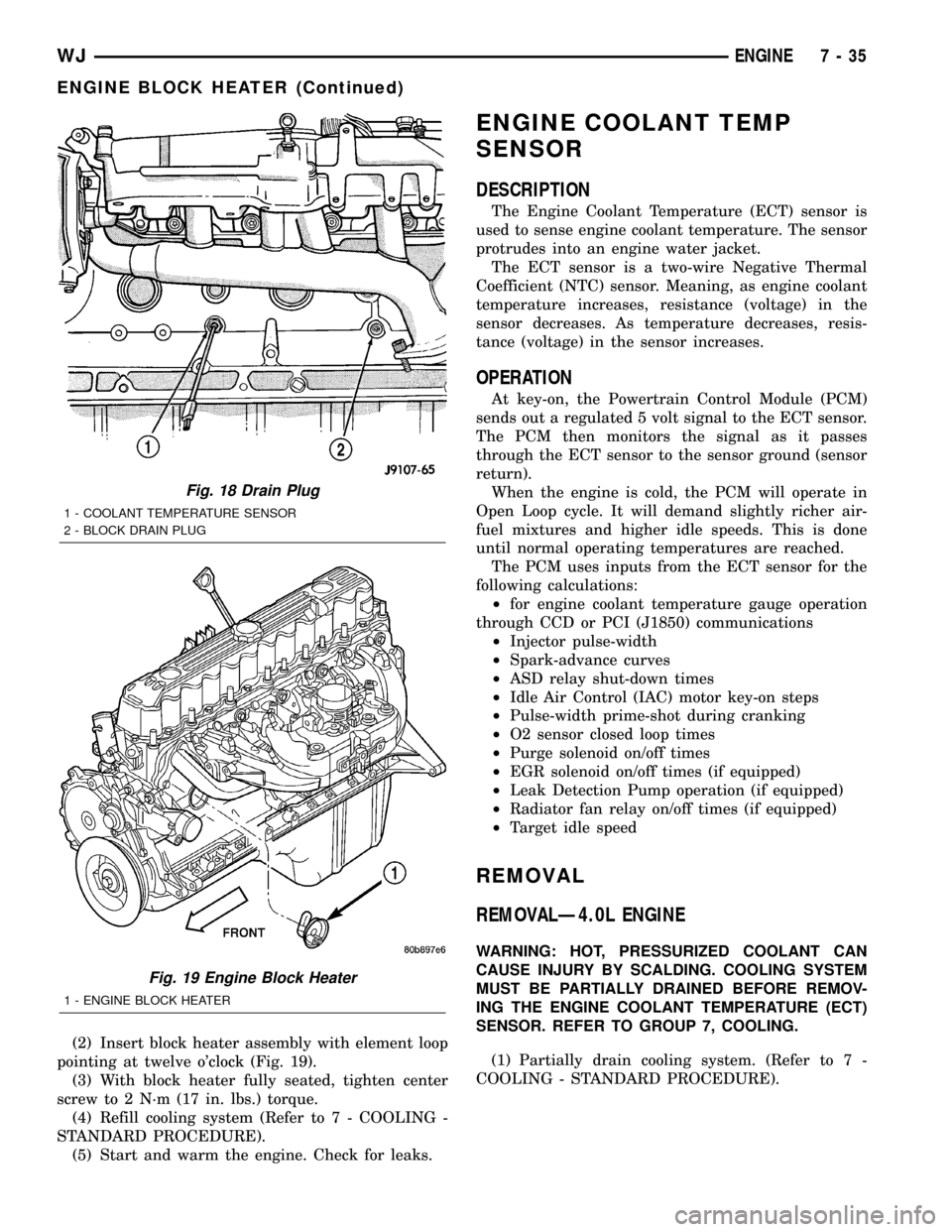

(2) Insert block heater assembly with element loop

pointing at twelve o'clock (Fig. 19).

(3) With block heater fully seated, tighten center

screw to 2 N´m (17 in. lbs.) torque.

(4) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Start and warm the engine. Check for leaks.

ENGINE COOLANT TEMP

SENSOR

DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is

used to sense engine coolant temperature. The sensor

protrudes into an engine water jacket.

The ECT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as engine coolant

temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

At key-on, the Powertrain Control Module (PCM)

sends out a regulated 5 volt signal to the ECT sensor.

The PCM then monitors the signal as it passes

through the ECT sensor to the sensor ground (sensor

return).

When the engine is cold, the PCM will operate in

Open Loop cycle. It will demand slightly richer air-

fuel mixtures and higher idle speeds. This is done

until normal operating temperatures are reached.

The PCM uses inputs from the ECT sensor for the

following calculations:

²for engine coolant temperature gauge operation

through CCD or PCI (J1850) communications

²Injector pulse-width

²Spark-advance curves

²ASD relay shut-down times

²Idle Air Control (IAC) motor key-on steps

²Pulse-width prime-shot during cranking

²O2 sensor closed loop times

²Purge solenoid on/off times

²EGR solenoid on/off times (if equipped)

²Leak Detection Pump operation (if equipped)

²Radiator fan relay on/off times (if equipped)

²Target idle speed

REMOVAL

REMOVALÐ4.0L ENGINE

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE ENGINE COOLANT TEMPERATURE (ECT)

SENSOR. REFER TO GROUP 7, COOLING.

(1) Partially drain cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

Fig. 18 Drain Plug

1 - COOLANT TEMPERATURE SENSOR

2 - BLOCK DRAIN PLUG

Fig. 19 Engine Block Heater

1 - ENGINE BLOCK HEATER

WJENGINE 7 - 35

ENGINE BLOCK HEATER (Continued)

Page 276 of 2199

CAUTION: When installing the serpentine engine

accessory drive belt, the belt MUST be routed cor-

rectly. If not, the engine may overheat due to the

water pump rotating in the wrong direction. Refer to

the Belt Removal and Installtion in this group for

appropriate belt routing. You may also refer to the

Belt Routing Label in the vehicle engine compart-

ment.

Install accessory drive belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(6) Install fan blade and viscous fan drive onto

water pump.

(7) Fill cooling system with coolant and check for

leaks. (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(8) Connect battery cable to battery.

(9) Start and warm the engine. Check for leaks.

RADIATOR PRESSURE CAP

DESCRIPTION

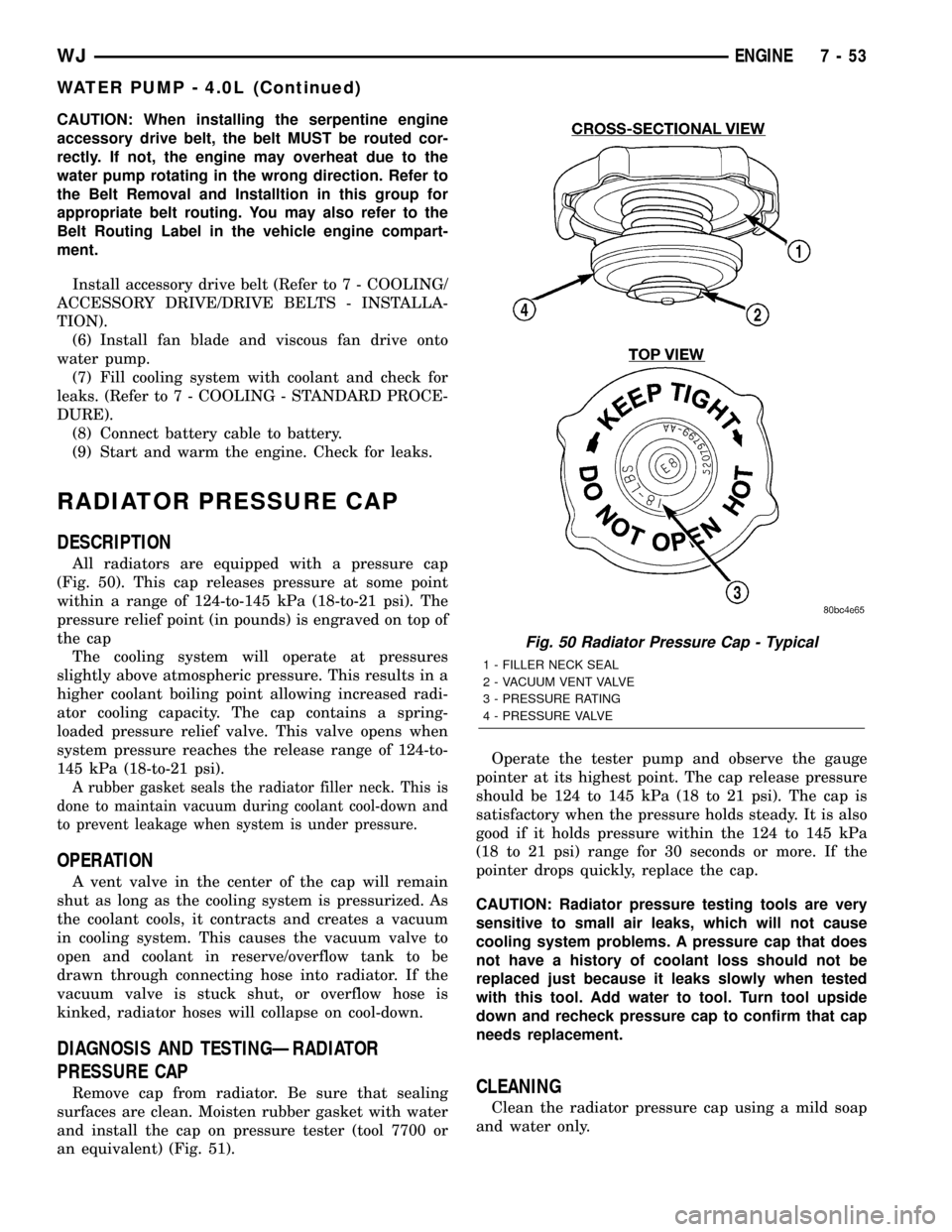

All radiators are equipped with a pressure cap

(Fig. 50). This cap releases pressure at some point

within a range of 124-to-145 kPa (18-to-21 psi). The

pressure relief point (in pounds) is engraved on top of

the cap

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

loaded pressure relief valve. This valve opens when

system pressure reaches the release range of 124-to-

145 kPa (18-to-21 psi).

A rubber gasket seals the radiator filler neck. This is

done to maintain vacuum during coolant cool-down and

to prevent leakage when system is under pressure.

OPERATION

A vent valve in the center of the cap will remain

shut as long as the cooling system is pressurized. As

the coolant cools, it contracts and creates a vacuum

in cooling system. This causes the vacuum valve to

open and coolant in reserve/overflow tank to be

drawn through connecting hose into radiator. If the

vacuum valve is stuck shut, or overflow hose is

kinked, radiator hoses will collapse on cool-down.

DIAGNOSIS AND TESTINGÐRADIATOR

PRESSURE CAP

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install the cap on pressure tester (tool 7700 or

an equivalent) (Fig. 51).Operate the tester pump and observe the gauge

pointer at its highest point. The cap release pressure

should be 124 to 145 kPa (18 to 21 psi). The cap is

satisfactory when the pressure holds steady. It is also

good if it holds pressure within the 124 to 145 kPa

(18 to 21 psi) range for 30 seconds or more. If the

pointer drops quickly, replace the cap.

CAUTION: Radiator pressure testing tools are very

sensitive to small air leaks, which will not cause

cooling system problems. A pressure cap that does

not have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.CLEANING

Clean the radiator pressure cap using a mild soap

and water only.

Fig. 50 Radiator Pressure Cap - Typical

1 - FILLER NECK SEAL

2 - VACUUM VENT VALVE

3 - PRESSURE RATING

4 - PRESSURE VALVE

WJENGINE 7 - 53

WATER PUMP - 4.0L (Continued)

Page 409 of 2199

OPERATION

Battery voltage is supplied to the 8 ignition coils

from the ASD relay. The Powertrain Control Module

(PCM) opens and closes each ignition coil ground cir-

cuit at a determined time for ignition coil operation.

Base ignition timing is not adjustable.By con-

trolling the coil ground circuit, the PCM is able to set

the base timing and adjust the ignition timing

advance. This is done to meet changing engine oper-

ating conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

Because of coil design, spark plug cables (second-

ary cables) are not used.

REMOVAL

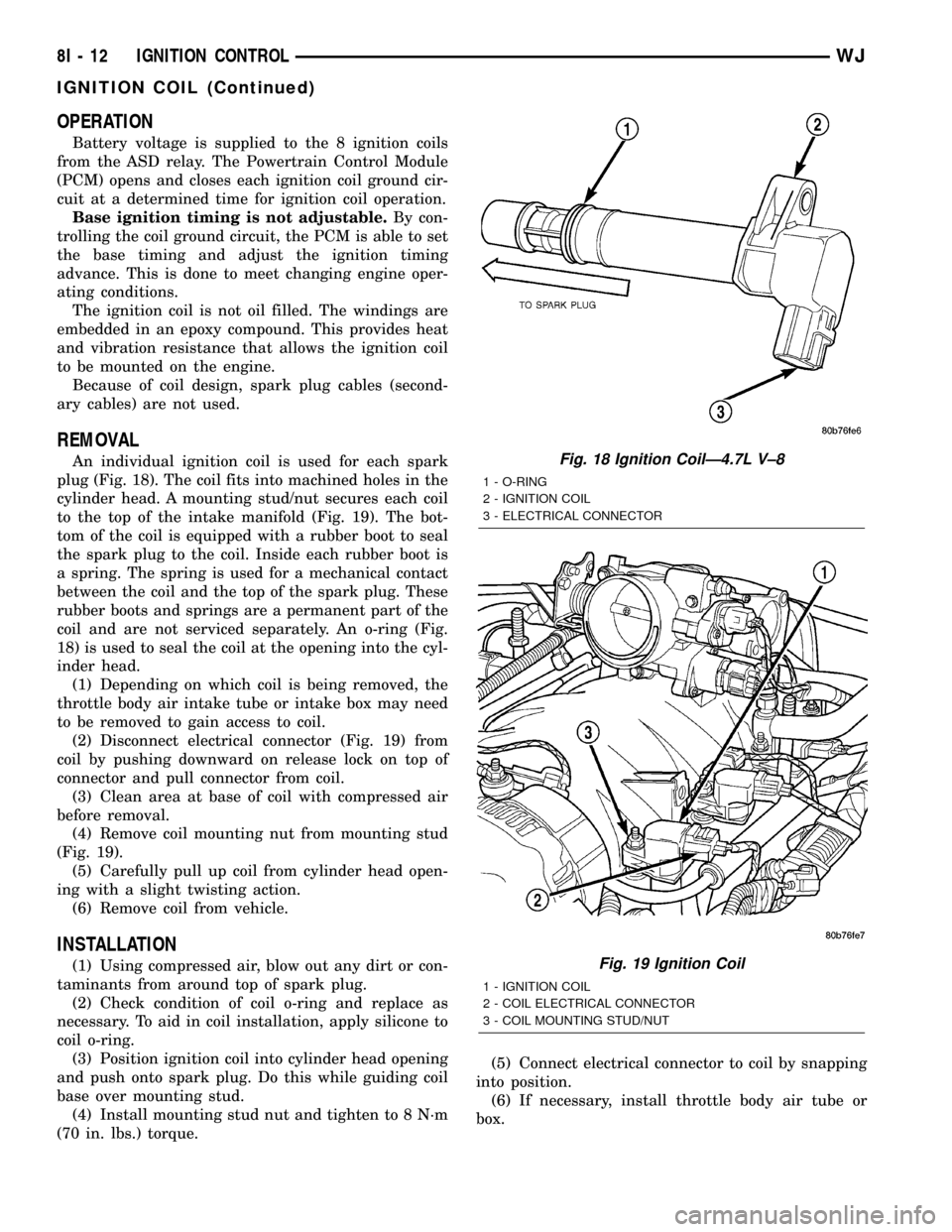

An individual ignition coil is used for each spark

plug (Fig. 18). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 19). The bot-

tom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.

18) is used to seal the coil at the opening into the cyl-

inder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Disconnect electrical connector (Fig. 19) from

coil by pushing downward on release lock on top of

connector and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 19).

(5) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(6) Remove coil from vehicle.

INSTALLATION

(1) Using compressed air, blow out any dirt or con-

taminants from around top of spark plug.

(2) Check condition of coil o-ring and replace as

necessary. To aid in coil installation, apply silicone to

coil o-ring.

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Do this while guiding coil

base over mounting stud.

(4) Install mounting stud nut and tighten to 8 N´m

(70 in. lbs.) torque.(5) Connect electrical connector to coil by snapping

into position.

(6) If necessary, install throttle body air tube or

box.

Fig. 18 Ignition CoilÐ4.7L V±8

1 - O-RING

2 - IGNITION COIL

3 - ELECTRICAL CONNECTOR

Fig. 19 Ignition Coil

1 - IGNITION COIL

2 - COIL ELECTRICAL CONNECTOR

3 - COIL MOUNTING STUD/NUT

8I - 12 IGNITION CONTROLWJ

IGNITION COIL (Continued)

Page 412 of 2199

INSTALLATION

4.7L High-Output Engine Only

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

(1) Thoroughly clean knock sensor mounting holes.

(2) Install sensors (Fig. 22) into cylinder block.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors. The torque for the knock senor bolt is rela-

tively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolts.Bolt

torque is critical.Refer to torque specification.

(4) Install intake manifold. Refer to Engine sec-

tion.

(5) Connect knock sensor pigtail wiring harness to

engine wiring harness near right / rear of intake

manifold (Fig. 23).

SPARK PLUG

DESCRIPTION

Both the 4.0L 6-cylinder and the 4.7L V-8 engine

use resistor type spark plugs. Standard 4.7L V-8

engines are equipped with ªfired in suppressor sealº

type spark plugs using a copper core ground elec-

trode. High-Output (H.O.) 4.7L V-8 engines are

equipped with unique plugs using a platinum rivet

located on the tip of the center electrode.

Because of the use of an aluminum cylinder head

on the 4.7L engine, spark plug torque is very critical.

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.Do not substitute any

other spark plug on the 4.7L H.O. engine. Seri-

ous engine damage may occur.

Plugs on both engines have resistance values rang-

ing from 6,000 to 20,000 ohms (when checked with at

least a 1000 volt spark plug tester).Do not use an

ohmmeter to check the resistance values of thespark plugs. Inaccurate readings will result.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A sin-

gle plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O, Lubrication and Maintenance.

EXCEPT 4.7L H.O. ENGINE :Spark plugs that

have low mileage may be cleaned and reused if not

otherwise defective, carbon or oil fouled. Also refer to

Spark Plug Conditions.4.7L H.O. ENGINE :Never

clean spark plugs on the 4.7L H.O. engine. Damage

to the platinum rivet will result.

CAUTION: EXCEPT 4.7L H.O. ENGINE : Never use a

motorized wire wheel brush to clean the spark

plugs. Metallic deposits will remain on the spark

plug insulator and will cause plug misfire.

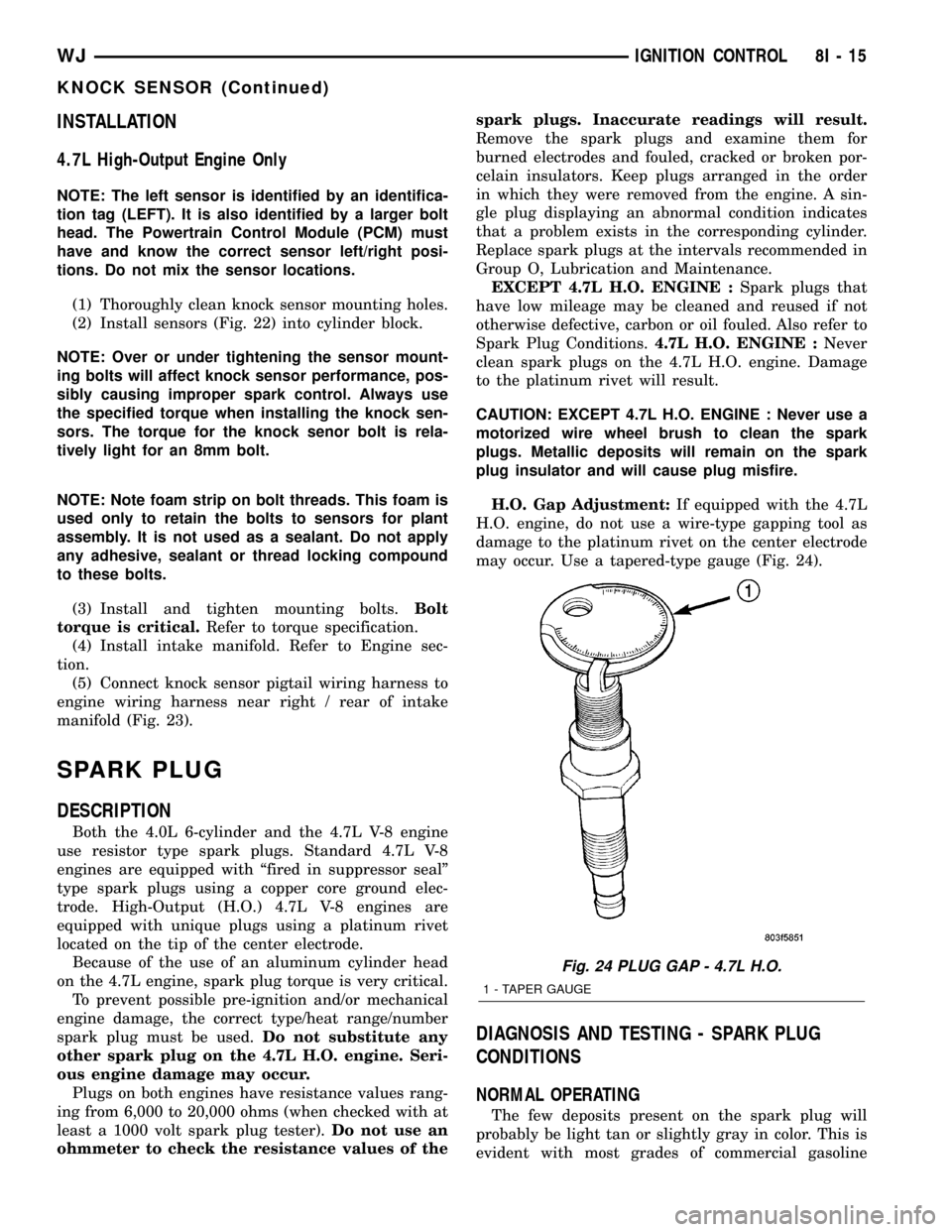

H.O. Gap Adjustment:If equipped with the 4.7L

H.O. engine, do not use a wire-type gapping tool as

damage to the platinum rivet on the center electrode

may occur. Use a tapered-type gauge (Fig. 24).

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

Fig. 24 PLUG GAP - 4.7L H.O.

1 - TAPER GAUGE

WJIGNITION CONTROL 8I - 15

KNOCK SENSOR (Continued)

Page 418 of 2199

EMIC also uses several hard wired inputs in order to

perform its many functions. The EMIC module incor-

porates a blue-green digital Vacuum Fluorescent Dis-

play (VFD) for displaying odometer and trip

odometer information.

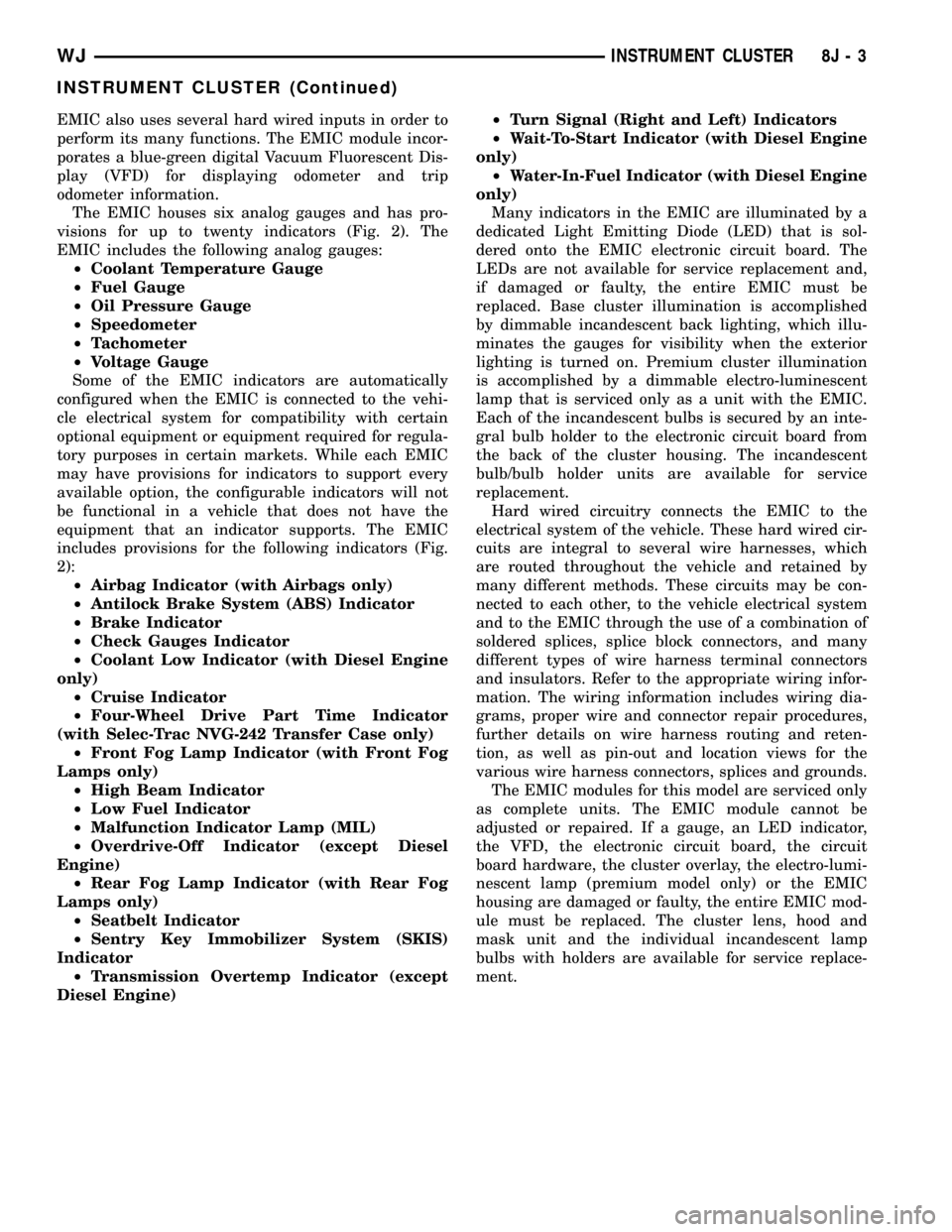

The EMIC houses six analog gauges and has pro-

visions for up to twenty indicators (Fig. 2). The

EMIC includes the following analog gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

2):

²Airbag Indicator (with Airbags only)

²Antilock Brake System (ABS) Indicator

²Brake Indicator

²Check Gauges Indicator

²Coolant Low Indicator (with Diesel Engine

only)

²Cruise Indicator

²Four-Wheel Drive Part Time Indicator

(with Selec-Trac NVG-242 Transfer Case only)

²Front Fog Lamp Indicator (with Front Fog

Lamps only)

²High Beam Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Overdrive-Off Indicator (except Diesel

Engine)

²Rear Fog Lamp Indicator (with Rear Fog

Lamps only)

²Seatbelt Indicator

²Sentry Key Immobilizer System (SKIS)

Indicator

²Transmission Overtemp Indicator (except

Diesel Engine)²Turn Signal (Right and Left) Indicators

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Many indicators in the EMIC are illuminated by a

dedicated Light Emitting Diode (LED) that is sol-

dered onto the EMIC electronic circuit board. The

LEDs are not available for service replacement and,

if damaged or faulty, the entire EMIC must be

replaced. Base cluster illumination is accomplished

by dimmable incandescent back lighting, which illu-

minates the gauges for visibility when the exterior

lighting is turned on. Premium cluster illumination

is accomplished by a dimmable electro-luminescent

lamp that is serviced only as a unit with the EMIC.

Each of the incandescent bulbs is secured by an inte-

gral bulb holder to the electronic circuit board from

the back of the cluster housing. The incandescent

bulb/bulb holder units are available for service

replacement.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator,

the VFD, the electronic circuit board, the circuit

board hardware, the cluster overlay, the electro-lumi-

nescent lamp (premium model only) or the EMIC

housing are damaged or faulty, the entire EMIC mod-

ule must be replaced. The cluster lens, hood and

mask unit and the individual incandescent lamp

bulbs with holders are available for service replace-

ment.

WJINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)

Page 419 of 2199

OPERATION

The ElectroMechanical Instrument Cluster (EMIC)

is designed to allow the vehicle operator to monitor

the conditions of many of the vehicle components and

operating systems. The gauges and indicators in the

EMIC provide valuable information about the various

standard and optional powertrains, fuel and emis-

sions systems, cooling systems, lighting systems,

safety systems and many other convenience items.

The EMIC is installed in the instrument panel so

that all of these monitors can be easily viewed by the

vehicle operator when driving, while still allowing

relative ease of access for service. The microproces-

sor-based EMIC hardware and software uses various

inputs to control the gauges and indicators visible on

the face of the cluster. Some of these inputs are hard

wired, but most are in the form of electronic mes-

sages that are transmitted by other electronic mod-ules over the Programmable Communications

Interface (PCI) data bus network. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

The EMIC microprocessor smooths the input data

using algorithms to provide gauge readings that are

accurate, stable and responsive to operating condi-

tions. These algorithms are designed to provide

gauge readings during normal operation that are con-

sistent with customer expectations. However, when

abnormal conditions exist, such as low or high bat-

tery voltage, low oil pressure or high coolant temper-

ature, the algorithm can drive the gauge pointer to

an extreme position and the microprocessor turns on

the Check Gauges indicator to provide a distinct

visual indication of a problem to the vehicle operator.

The instrument cluster circuitry also sends electronic

chime tone request messages over the PCI data bus

to the Body Control Module (BCM) when it monitors

Fig. 2 EMIC Gauges & Indicators

1 - BRAKE INDICATOR 15 - TRANSMISSION OVERTEMP INDICATOR

2 - REAR FOG LAMP INDICATOR 16 - PART TIME 4WD INDICATOR

3 - WATER-IN-FUEL INDICATOR 17 - CHECK GAUGES INDICATOR

4 - VOLTAGE GAUGE 18 - ENGINE TEMPERATURE GAUGE

5 - LEFT TURN INDICATOR 19 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

6 - TACHOMETER 20 - ODOMETER/TRIP ODOMETER DISPLAY

7 - HIGH BEAM INDICATOR 21 - WAIT-TO-START INDICATOR

8 - AIRBAG INDICATOR 22 - OVERDRIVE-OFF INDICATOR

9 - SPEEDOMETER 23 - SEATBELT INDICATOR

10 - RIGHT TURN INDICATOR 24 - ABS INDICATOR

11 - OIL PRESSURE GAUGE 25 - FUEL GAUGE

12 - SKIS INDICATOR 26 - FRONT FOG LAMP INDICATOR

13 - MALFUNCTION INDICATOR LAMP (MIL) 27 - LOW FUEL INDICATOR

14 - CRUISE INDICATOR 28 - COOLANT LOW INDICATOR

8J - 4 INSTRUMENT CLUSTERWJ

INSTRUMENT CLUSTER (Continued)

Page 432 of 2199

lens is serviced as a unit with the instrument cluster

lens, hood and mask unit.

OPERATION

The check gauges indicator gives an indication to

the vehicle operator when certain instrument cluster

gauge readings reflect a condition requiring immedi-

ate attention. This indicator is controlled by a tran-

sistor on the instrument cluster circuit board based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) over the Programmable Communica-

tions Interface (PCI) data bus. The check gauges

indicator Light Emitting Diode (LED) is completely

controlled by the instrument cluster logic circuit, and

that logic will only allow this indicator to operate

when the instrument cluster receives a battery cur-

rent input on the fused ignition switch output (run-

start) circuit. Therefore, the indicator will always be

off when the ignition switch is in any position except

On or Start. The LED only illuminates when it is

provided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

check gauges indicator for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the check gauges indicator

is illuminated for about three seconds as a bulb test.

²Engine Temperature High/Critical Message

- Each time the cluster receives a message from the

PCM indicating the engine coolant temperature is

high or critical [above about 127É C (261É F) for gas-

oline engines except Gulf Coast Country (GCC), 129É

C (264É F) for GCC gasoline engines, and 118É C

(244É F) for diesel engines], the check gauges indica-

tor is illuminated. The indicator remains illuminated

until the cluster receives a message indicating the

engine coolant temperature is not high or critical

[about 125É C (255É F) or below for all gasoline

engines, or 115É C (239É F) for all diesel engines].

²Engine Oil Pressure Low Message- Each

time the cluster receives a message from the PCM

indicating the engine oil pressure is about 0.28

kg/cm or lower (about 4 psi or lower), the check

gauges indicator is illuminated. The indicator

remains illuminated until the cluster receives a mes-

sage from the PCM indicating that the engine oil

pressure is about 0.56 kg/cm or higher (about 8 psi

or higher). The cluster will only turn the indicator on

in response to an engine oil pressure low message if

the ignition switch is in the On position and the

engine speed is 300 rpm or greater.

²System Voltage Low Message- Each time the

cluster receives a message from the PCM indicating

a low system voltage condition (system voltage is

about eleven volts or lower), the check gauges indica-

tor is illuminated. The indicator remains illuminateduntil the cluster receives a message from the PCM

indicating there is no low system voltage condition

(system voltage is above about eleven volts, but lower

than about sixteen volts).

²System Voltage High Message- Each time

the cluster receives a message from the PCM indicat-

ing a high system voltage condition (system voltage

is about sixteen volts or higher), the check gauges

indicator is illuminated. The indicator remains illu-

minated until the cluster receives a message from

the PCM indicating there is no high system voltage

condition (system voltage is below about sixteen

volts, but higher than about eleven volts).

²Actuator Test- Each time the cluster is put

through the actuator test, the check gauges indicator

will be turned on for the duration of the test to con-

firm the functionality of the LED and the cluster con-

trol circuitry.

The PCM continually monitors the engine temper-

ature, oil pressure, and electrical system voltage,

then sends the proper messages to the instrument

cluster. For further diagnosis of the check gauges

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the PCM, the PCI

data bus, or the electronic message inputs to the

instrument cluster that control the check gauges

indicator, a DRBIIItscan tool is required. Refer to

the appropriate diagnostic information.

COOLANT LOW INDICATOR

DESCRIPTION

A coolant low indicator is only found in the instru-

ment clusters of vehicles equipped with an optional

diesel engine. The coolant low indicator should not be

confused with the coolant level low indication pro-

vided by the Electronic Vehicle Information Center

(EVIC) of vehicles equipped with a gasoline engine,

although they do perform the same function. The

coolant low indicator is located in the lower left cor-

ner of the instrument cluster, to the left of the

tachometer. The coolant low indicator consists of an

International Control and Display Symbol icon for

ªLow Coolantº imprinted on an amber lens. The lens

is located behind a cutout in the opaque layer of the

instrument cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. The icon appears

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when the indicator

is illuminated from behind by a replaceable incandes-

cent bulb and bulb holder unit located on the instru-

ment cluster electronic circuit board. When the

WJINSTRUMENT CLUSTER 8J - 17

CHECK GAUGES INDICATOR (Continued)

Page 441 of 2199

Base cluster gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. Premium cluster gauge illumination is pro-

vided by an integral electro-luminescent lamp that is

serviced as a unit with the instrument cluster. The

oil pressure gauge is serviced as a unit with the

instrument cluster.

OPERATION

The oil pressure gauge gives an indication to the

vehicle operator of the engine oil pressure. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

oil pressure gauge is an air core magnetic unit that

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (run-start) circuit whenever the igni-

tion switch is in the On or Start positions. The clus-

ter is programmed to move the gauge needle back to

the low end of the scale after the ignition switch is

turned to the Off position. The instrument cluster

circuitry controls the gauge needle position and pro-

vides the following features:

²Engine Oil Pressure Normal Message- Each

time the cluster receives a message from the PCM

indicating the engine oil pressure is within the nor-

mal operating range [above 0.28 kg/cm (above 4

psi), the gauge needle is moved to the relative pres-

sure position of the gauge scale.

²Engine Oil Pressure Low Message- Each

time the cluster receives a message from the PCM

indicating the engine oil pressure is about 0.28

kg/cm or lower (about 4 psi or lower), the gauge

needle is moved to the far left (low) end of the gauge

scale. The gauge needle remains at the low end of

the scale until the cluster receives a message from

the PCM indicating that the engine oil pressure is

about 0.56 kg/cm or higher (about 8 psi or higher).

²Communication Error- If the cluster fails to

receive an engine oil pressure message, it will hold

the gauge needle at the last indication for about

twelve seconds or until a new engine oil pressure

message is received, whichever occurs first. After

twelve seconds, the cluster will return the gauge nee-

dle to the low end of the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back in order

to confirm the functionality of the gauge and the

cluster control circuitry.

The PCM continually monitors the engine oil pres-

sure sensor to determine the engine oil pressure. ThePCM then sends the proper engine oil pressure mes-

sages to the instrument cluster. For further diagnosis

of the oil pressure gauge or the instrument cluster

circuitry that controls the gauge, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). If the instrument cluster turns on

the check gauges indicator due to a low oil pressure

gauge reading, it may indicate that the engine or the

engine oiling system requires service. For proper

diagnosis of the engine oil pressure sensor, the PCM,

the PCI data bus, or the electronic message inputs to

the instrument cluster that control the oil pressure

gauge, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

OVERDRIVE OFF INDICATOR

DESCRIPTION

An overdrive off indicator is standard equipment

on all gasoline engine instrument clusters. The over-

drive off indicator is located in the lower edge of the

tachometer gauge dial face in the instrument cluster.

The overdrive off indicator consists of the words ªO/D

OFFº imprinted on an amber lens. The lens is

located behind a cutout in the opaque layer of the

tachometer gauge dial face overlay. The dark outer

layer of the gauge dial face overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. The words ªO/D OFFº appear silhouetted

against an amber field through the translucent outer

layer of the gauge dial face overlay when the indica-

tor is illuminated from behind by a replaceable

incandescent bulb and bulb holder unit located on

the instrument cluster electronic circuit board. When

the exterior lighting is turned On, the illumination

intensity of the overdrive off indicator is dimmable,

which is adjusted using the panel lamps dimmer con-

trol ring on the control stalk of the left multi-func-

tion switch. The overdrive off indicator lens is

serviced as a unit with the instrument cluster.

OPERATION

The overdrive off indicator gives an indication to

the vehicle operator when the Off position of the

overdrive off switch has been selected, disabling the

electronically controlled overdrive feature of the auto-

matic transmission. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster over the Programmable

Communications Interface (PCI) data bus. These

messages are sent by the Powertrain Control Module

(PCM) or by the Transmission Control Module

(TCM), depending on the model of the automatic

transmission. The overdrive off indicator bulb is com-

8J - 26 INSTRUMENT CLUSTERWJ

OIL PRESSURE GAUGE (Continued)

Page 450 of 2199

ing the system voltage is high (system voltage is

about sixteen volts or higher), the gauge needle is

moved to the relative voltage position in the red zone

of the gauge scale and the check gauges indicator is

illuminated. The gauge needle remains in the red

zone and the check gauges indicator remains illumi-

nated until the cluster receives a message from the

PCM indicating there is no high system voltage con-

dition (system voltage is below about sixteen volts,

but higher than about eleven volts).

²Communication Error- If the cluster fails to

receive a system voltage message, it will hold the

gauge needle at the last indication for about twelve

seconds, until a new message is received, or until the

ignition switch is turned to the Off position, which-

ever occurs first. After twelve seconds, the cluster

will return the gauge needle to the low end of the

gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back to con-

firm the functionality of the gauge and the cluster

control circuitry.

The PCM continually monitors the system voltage

to control the generator output. The PCM then sends

the proper system voltage messages to the instru-

ment cluster. For further diagnosis of the voltage

gauge or the instrument cluster circuitry that con-

trols the gauge, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING). If

the instrument cluster turns on the check gauges

indicator due to a system voltage low or high condi-

tion, it may indicate that the charging system

requires service. For proper diagnosis of the charging

system, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the volt-

age gauge, a DRBIIItscan tool is required. Refer to

the appropriate diagnostic information.

WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is only found in the

instrument clusters of vehicles equipped with an

optional diesel engine. The wait-to-start indicator is

located near the lower edge of the tachometer gauge

dial face, to the right of center. The wait-to-start

indicator consists of an International Control and

Display Symbol icon for ªDiesel Preheatº imprinted

on an amber lens. The lens is located behind a cutout

in the opaque layer of the tachometer gauge dial face

overlay. The dark outer layer of the gauge dial face

overlay prevents the icon from being clearly visible

when the indicator is not illuminated. The icon

appears silhouetted against an amber field throughthe translucent outer layer of the gauge dial face

overlay when the indicator is illuminated from

behind by a replaceable incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. The wait-to-start indicator lens

is serviced as a unit with the instrument cluster.

OPERATION

The wait-to-start indicator gives an indication to

the vehicle operator when the diesel engine glow

plugs are energized in their preheat operating mode.

This indicator is controlled by a transistor on the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus. The wait-to-start indicator

bulb is completely controlled by the instrument clus-

ter logic circuit, and that logic will only allow this

indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is in

any position except On or Start. The bulb only illu-

minates when it is switched to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the wait-to-start indicator for the following

reasons:

²Wait-To-Start Indicator Lamp-On Message-

Each time the cluster receives a wait-to-start indica-

tor lamp-on message from the PCM indicating the

glow plugs are heating and the driver must wait to

start the engine, the wait-to-start indicator will be

illuminated. The indicator remains illuminated until

the cluster receives a wait-to-start indicator lamp-off

message, or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the wait-to-start indicator

will be turned on for the duration of the test to con-

firm the functionality of the bulb and the cluster con-

trol circuitry.

The PCM continually monitors the ambient tem-

perature and the glow plug pre-heater circuits to

determine how long the glow plugs must be heated in

the pre-heat operating mode. The PCM then sends

the proper wait-to-start indicator lamp-on and lamp-

off messages to the instrument cluster. If the wait-to-

start indicator fails to light during the actuator test,

replace the bulb with a known good unit. For further

diagnosis of the wait-to-start indicator or the instru-

ment cluster circuitry that controls the indicator,

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). For proper

diagnosis of the glow plug pre-heater control circuits,

the PCM, the PCI data bus, or the electronic message

WJINSTRUMENT CLUSTER 8J - 35

VOLTAGE GAUGE (Continued)