check engine light JEEP GRAND CHEROKEE 2002 WJ / 2.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1788 of 2199

position, the clutch will engage after the shift to

third gear, at approximately 56 km/h (35 mph) at

light throttle.

The TCM controls the torque converter by way of

internal logic software. The programming of the soft-

ware provides the TCM with control over the L/R-CC

Solenoid. There are four output logic states that can

be applied as follows:

²No EMCC

²Partial EMCC

²Full EMCC

²Gradual-to-no EMCC

NO EMCC

Under No EMCC conditions, the L/R Solenoid is

OFF. There are several conditions that can result in

NO EMCC operations. No EMCC can be initiated

due to a fault in the transmission or because the

TCM does not see the need for EMCC under current

driving conditions.

PARTIAL EMCC

Partial EMCC operation modulates the L/R Sole-

noid (duty cycle) to obtain partial torque converter

clutch application. Partial EMCC operation is main-

tained until Full EMCC is called for and actuated.

During Partial EMCC some slip does occur. Partial

EMCC will usually occur at low speeds, low load and

light throttle situations.

FULL EMCC

During Full EMCC operation, the TCM increases

the L/R Solenoid duty cycle to full ON after PartialEMCC control brings the engine speed within the

desired slip range of transmission input speed rela-

tive to engine rpm.

GRADUAL-TO-NO EMCC

This operation is to soften the change from Full or

Partial EMCC to No EMCC. This is done at mid-

throttle by decreasing the L/R Solenoid duty cycle.

REMOVAL

(1) Remove transmission and torque converter

from vehicle.

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

INSTALLATION

Check converter hub and drive flats for sharp

edges, burrs, scratches, or nicks. Polish the hub and

flats with 320/400 grit paper or crocus cloth if neces-

sary. Verify that the converter hub o-ring is properly

installed and is free from debris. The hub must be

smooth to avoid damaging the pump seal at installa-

tion.

(1) Lubricate oil pump seal lip with transmission

fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or con-

verter hub o-ring while inserting torque converter

into the front of the transmission.

(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 117). Surface of converter lugs

should be at least 13 mm (1/2 in.) to rear of straight-

edge when converter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

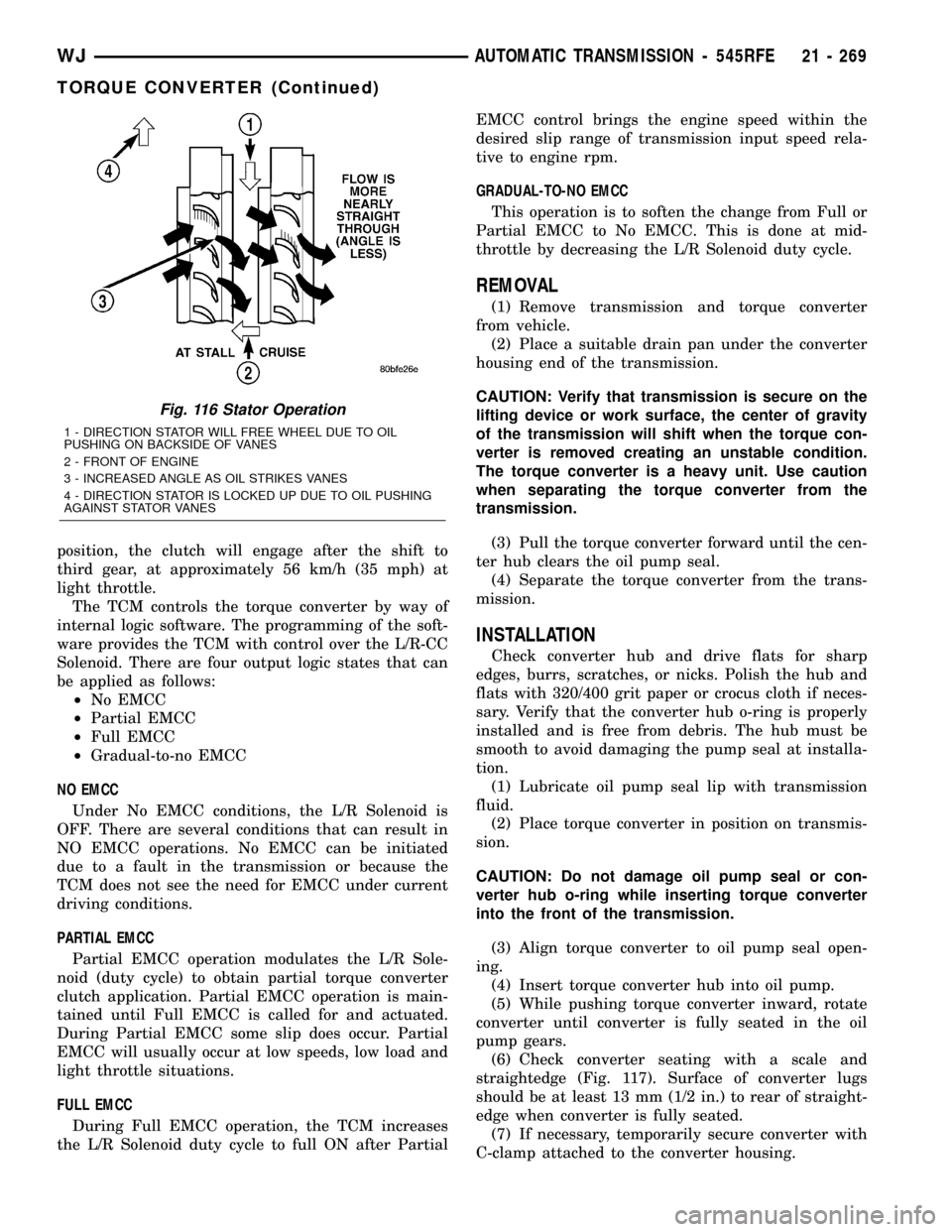

Fig. 116 Stator Operation

1 - DIRECTION STATOR WILL FREE WHEEL DUE TO OIL

PUSHING ON BACKSIDE OF VANES

2 - FRONT OF ENGINE

3 - INCREASED ANGLE AS OIL STRIKES VANES

4 - DIRECTION STATOR IS LOCKED UP DUE TO OIL PUSHING

AGAINST STATOR VANES

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 269

TORQUE CONVERTER (Continued)

Page 2082 of 2199

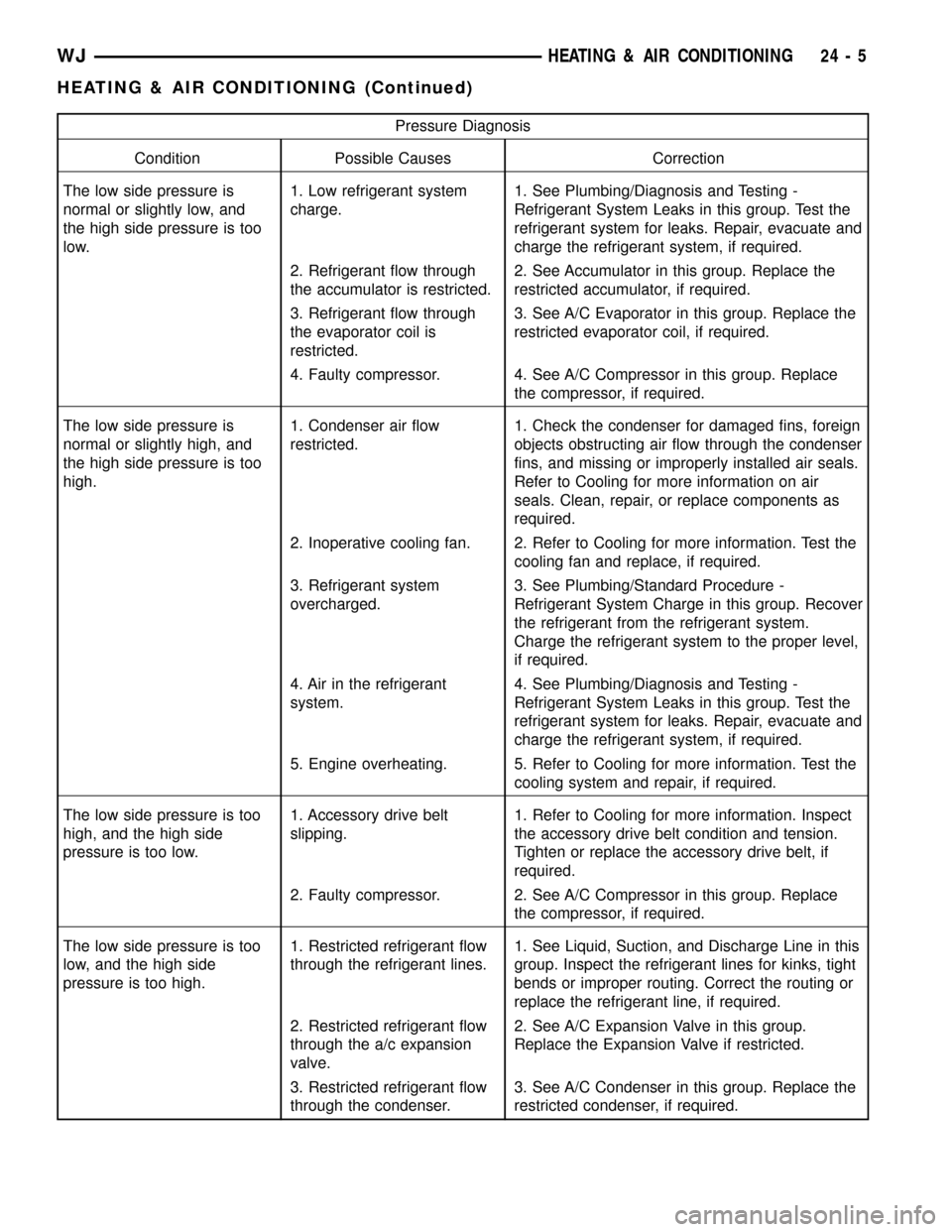

Pressure Diagnosis

Condition Possible Causes Correction

The low side pressure is

normal or slightly low, and

the high side pressure is too

low.1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Refrigerant flow through

the accumulator is restricted.2. See Accumulator in this group. Replace the

restricted accumulator, if required.

3. Refrigerant flow through

the evaporator coil is

restricted.3. See A/C Evaporator in this group. Replace the

restricted evaporator coil, if required.

4. Faulty compressor. 4. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. Condenser air flow

restricted.1. Check the condenser for damaged fins, foreign

objects obstructing air flow through the condenser

fins, and missing or improperly installed air seals.

Refer to Cooling for more information on air

seals. Clean, repair, or replace components as

required.

2. Inoperative cooling fan. 2. Refer to Cooling for more information. Test the

cooling fan and replace, if required.

3. Refrigerant system

overcharged.3. See Plumbing/Standard Procedure -

Refrigerant System Charge in this group. Recover

the refrigerant from the refrigerant system.

Charge the refrigerant system to the proper level,

if required.

4. Air in the refrigerant

system.4. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

5. Engine overheating. 5. Refer to Cooling for more information. Test the

cooling system and repair, if required.

The low side pressure is too

high, and the high side

pressure is too low.1. Accessory drive belt

slipping.1. Refer to Cooling for more information. Inspect

the accessory drive belt condition and tension.

Tighten or replace the accessory drive belt, if

required.

2. Faulty compressor. 2. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid, Suction, and Discharge Line in this

group. Inspect the refrigerant lines for kinks, tight

bends or improper routing. Correct the routing or

replace the refrigerant line, if required.

2. Restricted refrigerant flow

through the a/c expansion

valve.2. See A/C Expansion Valve in this group.

Replace the Expansion Valve if restricted.

3. Restricted refrigerant flow

through the condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

WJHEATING & AIR CONDITIONING 24 - 5

HEATING & AIR CONDITIONING (Continued)

Page 2083 of 2199

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE

Before performing the following tests, refer to Cool-

ing for the procedures to check the radiator coolant

level, serpentine drive belt tension, radiator air flow

and the radiator fan operation. Also be certain that

the accessory vacuum supply line is connected at the

engine intake manifold for the manual temperature

control system.

MAXIMUM HEATER OUTPUT

Engine coolant is delivered to the heater core

through two heater hoses. With the engine idling at

normal operating temperature, set the temperature

control knob in the full hot position, the mode control

switch knob in the floor heat position, and the blower

motor switch knob in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged at the HVAC housing floor

outlets. Compare the test thermometer reading to the

Temperature Reference chart.

Temperature Reference

Ambient Air Temperature15.5É C

(60É F)21.1É C

(70É F)26.6É C

(80É F)32.2É C

(90É F)

Minimum Air Temperature at

Floor Outlet62.2É C

(144É F)63.8É C

(147É F)65.5É C

(150É F)67.2É C

(153É F)

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

OBSTRUCTED COOLANT FLOW

Possible locations or causes of obstructed coolant

flow:

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.

If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS

Possible locations or causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A blend door not functioning properly.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob(s) on the

A/C Heater control panel, the following could require

service:

²The A/C heater control.

²The blend door actuator(s).

²The wire harness circuits for the A/C heater con-

trol or the blend door actuator(s).²The blend door(s).

²Improper engine coolant temperature.

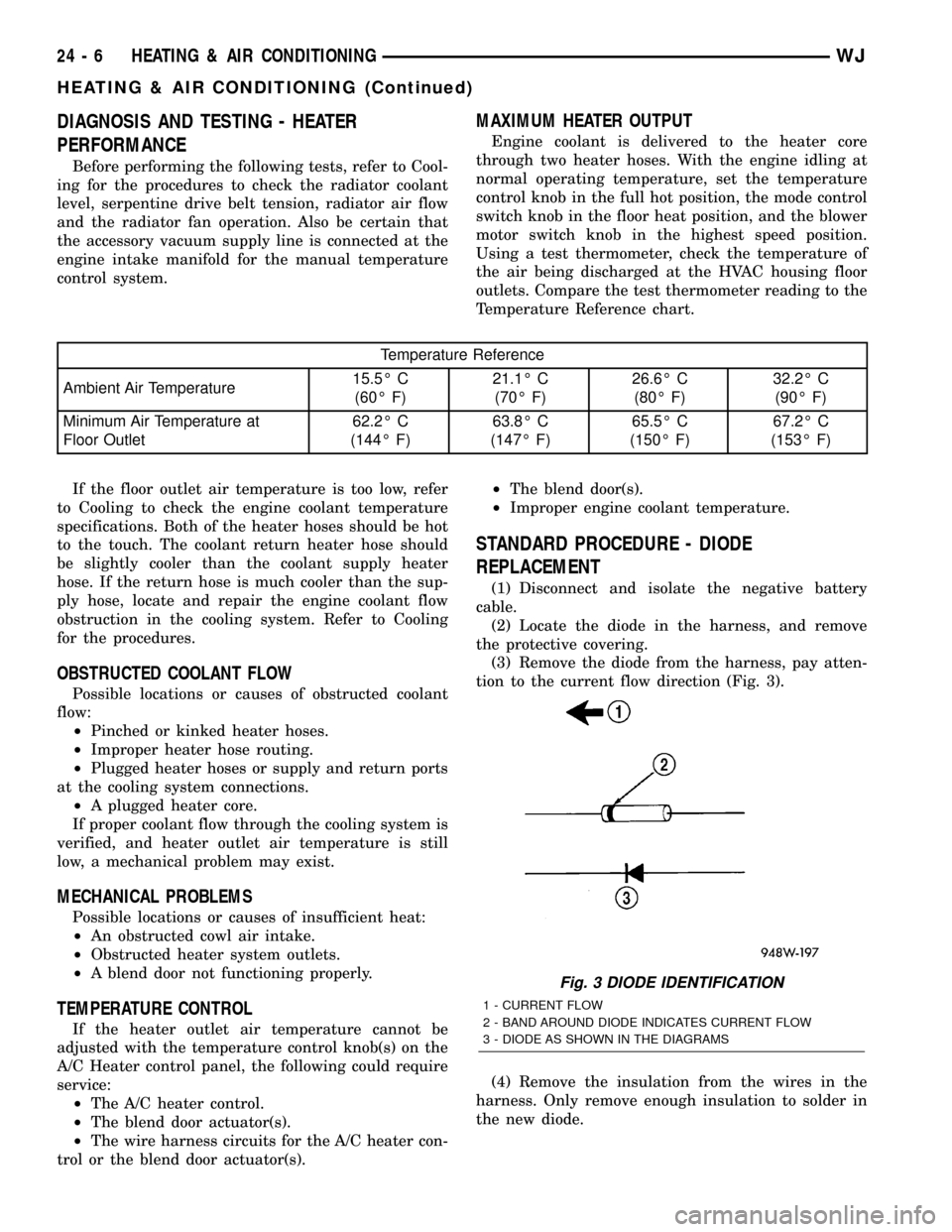

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect and isolate the negative battery

cable.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 3).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

Fig. 3 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

24 - 6 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2111 of 2199

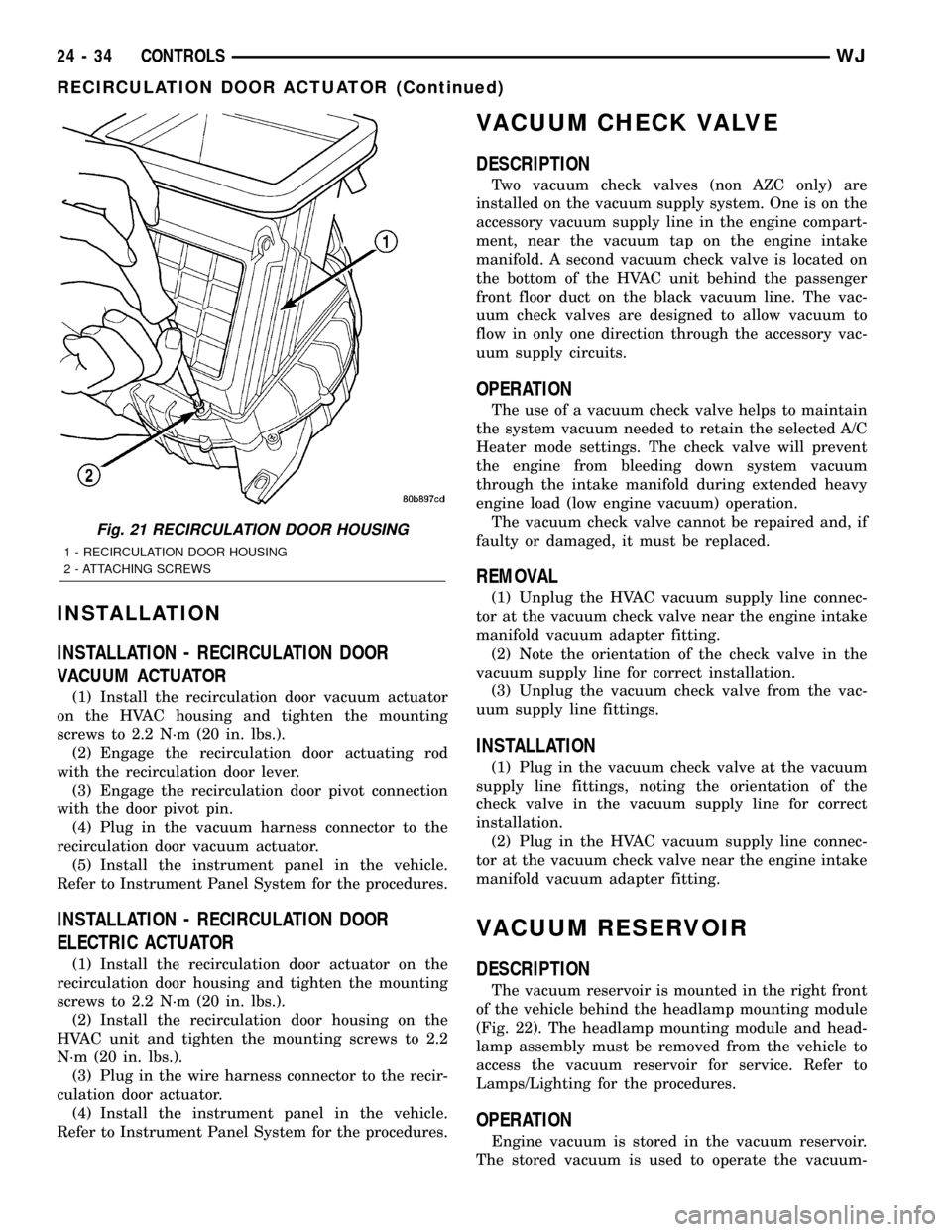

INSTALLATION

INSTALLATION - RECIRCULATION DOOR

VACUUM ACTUATOR

(1) Install the recirculation door vacuum actuator

on the HVAC housing and tighten the mounting

screws to 2.2 N´m (20 in. lbs.).

(2) Engage the recirculation door actuating rod

with the recirculation door lever.

(3) Engage the recirculation door pivot connection

with the door pivot pin.

(4) Plug in the vacuum harness connector to the

recirculation door vacuum actuator.

(5) Install the instrument panel in the vehicle.

Refer to Instrument Panel System for the procedures.

INSTALLATION - RECIRCULATION DOOR

ELECTRIC ACTUATOR

(1) Install the recirculation door actuator on the

recirculation door housing and tighten the mounting

screws to 2.2 N´m (20 in. lbs.).

(2) Install the recirculation door housing on the

HVAC unit and tighten the mounting screws to 2.2

N´m (20 in. lbs.).

(3) Plug in the wire harness connector to the recir-

culation door actuator.

(4) Install the instrument panel in the vehicle.

Refer to Instrument Panel System for the procedures.

VACUUM CHECK VALVE

DESCRIPTION

Two vacuum check valves (non AZC only) are

installed on the vacuum supply system. One is on the

accessory vacuum supply line in the engine compart-

ment, near the vacuum tap on the engine intake

manifold. A second vacuum check valve is located on

the bottom of the HVAC unit behind the passenger

front floor duct on the black vacuum line. The vac-

uum check valves are designed to allow vacuum to

flow in only one direction through the accessory vac-

uum supply circuits.

OPERATION

The use of a vacuum check valve helps to maintain

the system vacuum needed to retain the selected A/C

Heater mode settings. The check valve will prevent

the engine from bleeding down system vacuum

through the intake manifold during extended heavy

engine load (low engine vacuum) operation.

The vacuum check valve cannot be repaired and, if

faulty or damaged, it must be replaced.

REMOVAL

(1) Unplug the HVAC vacuum supply line connec-

tor at the vacuum check valve near the engine intake

manifold vacuum adapter fitting.

(2) Note the orientation of the check valve in the

vacuum supply line for correct installation.

(3) Unplug the vacuum check valve from the vac-

uum supply line fittings.

INSTALLATION

(1) Plug in the vacuum check valve at the vacuum

supply line fittings, noting the orientation of the

check valve in the vacuum supply line for correct

installation.

(2) Plug in the HVAC vacuum supply line connec-

tor at the vacuum check valve near the engine intake

manifold vacuum adapter fitting.

VACUUM RESERVOIR

DESCRIPTION

The vacuum reservoir is mounted in the right front

of the vehicle behind the headlamp mounting module

(Fig. 22). The headlamp mounting module and head-

lamp assembly must be removed from the vehicle to

access the vacuum reservoir for service. Refer to

Lamps/Lighting for the procedures.

OPERATION

Engine vacuum is stored in the vacuum reservoir.

The stored vacuum is used to operate the vacuum-

Fig. 21 RECIRCULATION DOOR HOUSING

1 - RECIRCULATION DOOR HOUSING

2 - ATTACHING SCREWS

24 - 34 CONTROLSWJ

RECIRCULATION DOOR ACTUATOR (Continued)

Page 2183 of 2199

CCV HOSE

DIAGNOSIS AND TESTING - CCV SYSTEM -

4.0L

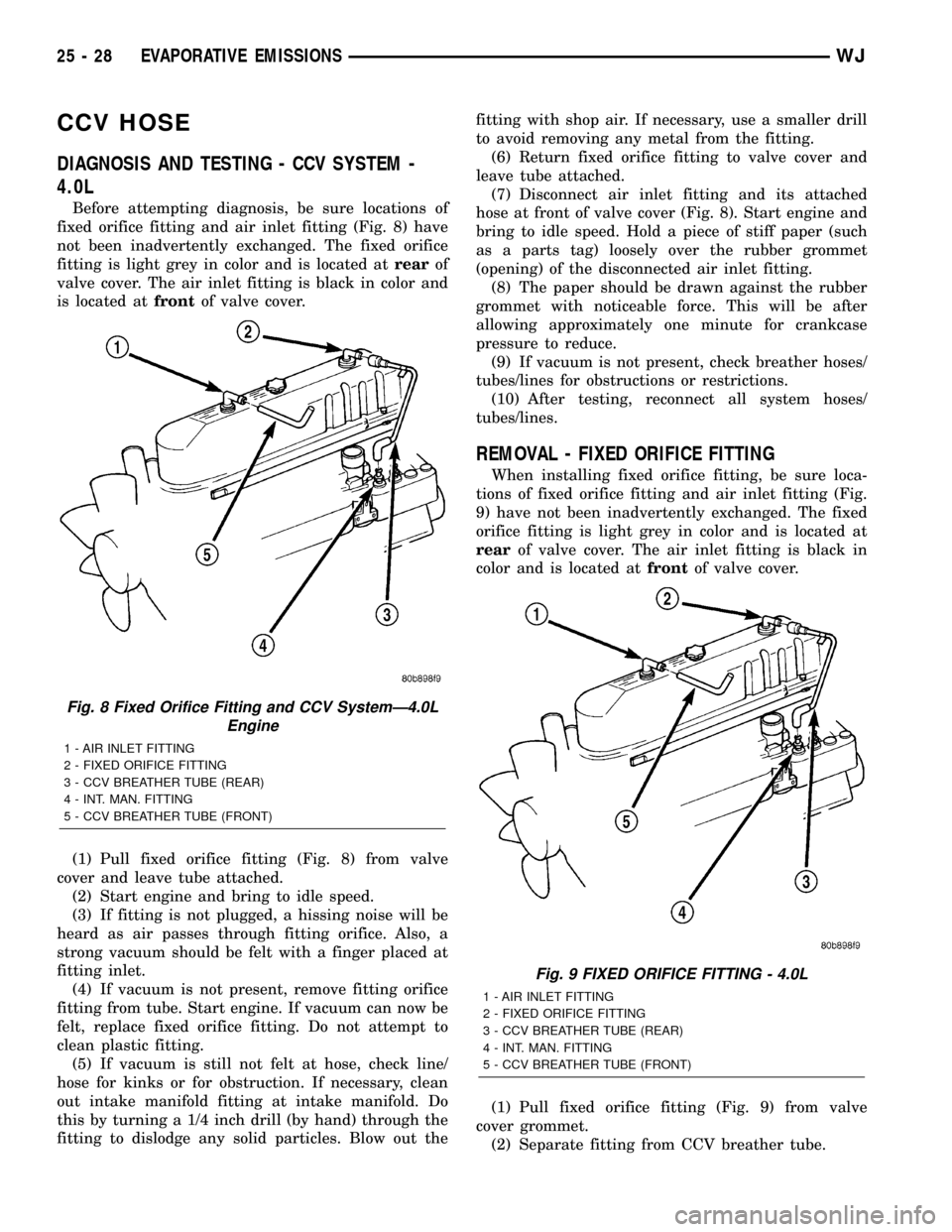

Before attempting diagnosis, be sure locations of

fixed orifice fitting and air inlet fitting (Fig. 8) have

not been inadvertently exchanged. The fixed orifice

fitting is light grey in color and is located atrearof

valve cover. The air inlet fitting is black in color and

is located atfrontof valve cover.

(1) Pull fixed orifice fitting (Fig. 8) from valve

cover and leave tube attached.

(2) Start engine and bring to idle speed.

(3) If fitting is not plugged, a hissing noise will be

heard as air passes through fitting orifice. Also, a

strong vacuum should be felt with a finger placed at

fitting inlet.

(4) If vacuum is not present, remove fitting orifice

fitting from tube. Start engine. If vacuum can now be

felt, replace fixed orifice fitting. Do not attempt to

clean plastic fitting.

(5) If vacuum is still not felt at hose, check line/

hose for kinks or for obstruction. If necessary, clean

out intake manifold fitting at intake manifold. Do

this by turning a 1/4 inch drill (by hand) through the

fitting to dislodge any solid particles. Blow out thefitting with shop air. If necessary, use a smaller drill

to avoid removing any metal from the fitting.

(6) Return fixed orifice fitting to valve cover and

leave tube attached.

(7) Disconnect air inlet fitting and its attached

hose at front of valve cover (Fig. 8). Start engine and

bring to idle speed. Hold a piece of stiff paper (such

as a parts tag) loosely over the rubber grommet

(opening) of the disconnected air inlet fitting.

(8) The paper should be drawn against the rubber

grommet with noticeable force. This will be after

allowing approximately one minute for crankcase

pressure to reduce.

(9) If vacuum is not present, check breather hoses/

tubes/lines for obstructions or restrictions.

(10) After testing, reconnect all system hoses/

tubes/lines.

REMOVAL - FIXED ORIFICE FITTING

When installing fixed orifice fitting, be sure loca-

tions of fixed orifice fitting and air inlet fitting (Fig.

9) have not been inadvertently exchanged. The fixed

orifice fitting is light grey in color and is located at

rearof valve cover. The air inlet fitting is black in

color and is located atfrontof valve cover.

(1) Pull fixed orifice fitting (Fig. 9) from valve

cover grommet.

(2) Separate fitting from CCV breather tube.

Fig. 8 Fixed Orifice Fitting and CCV SystemÐ4.0L

Engine

1 - AIR INLET FITTING

2 - FIXED ORIFICE FITTING

3 - CCV BREATHER TUBE (REAR)

4 - INT. MAN. FITTING

5 - CCV BREATHER TUBE (FRONT)

Fig. 9 FIXED ORIFICE FITTING - 4.0L

1 - AIR INLET FITTING

2 - FIXED ORIFICE FITTING

3 - CCV BREATHER TUBE (REAR)

4 - INT. MAN. FITTING

5 - CCV BREATHER TUBE (FRONT)

25 - 28 EVAPORATIVE EMISSIONSWJ

Page 2187 of 2199

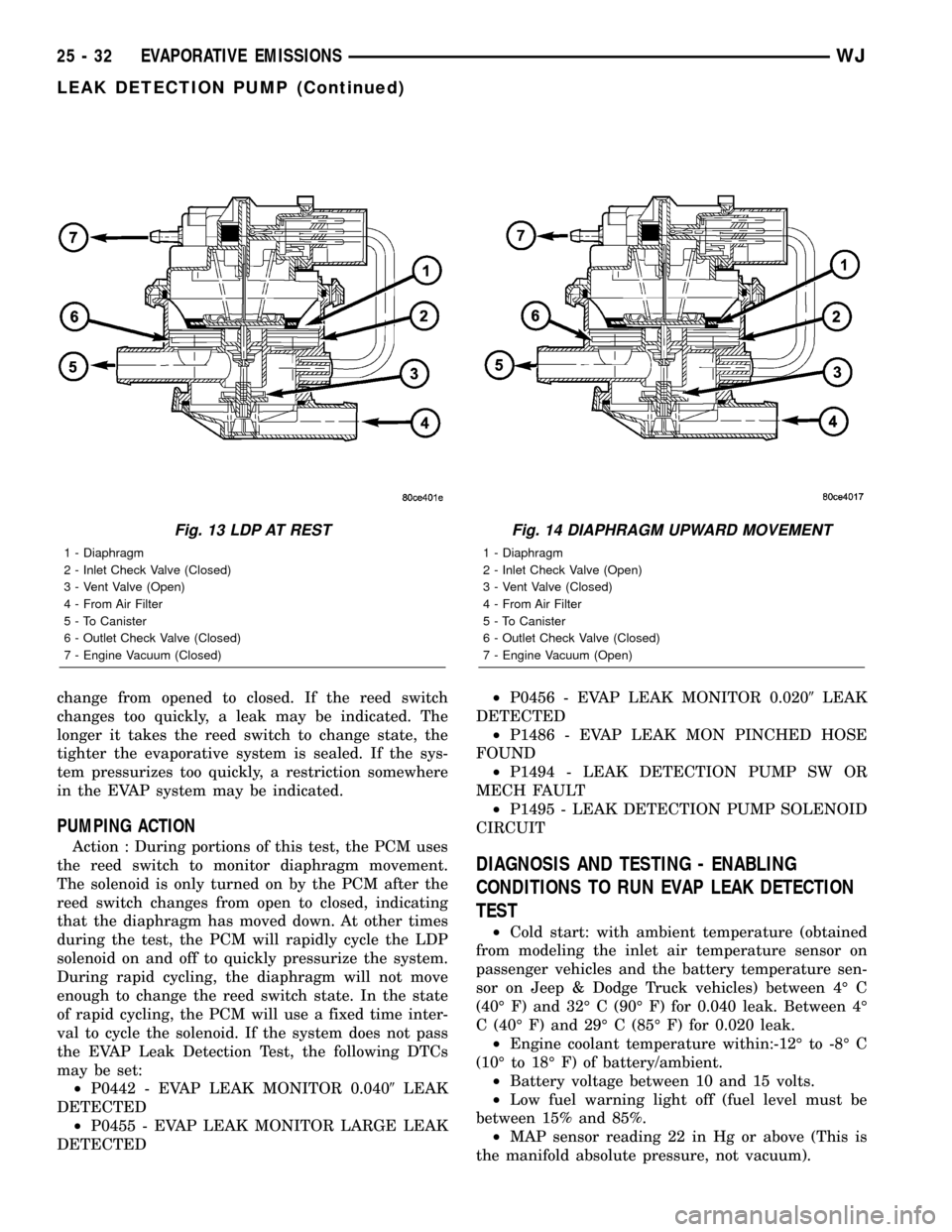

change from opened to closed. If the reed switch

changes too quickly, a leak may be indicated. The

longer it takes the reed switch to change state, the

tighter the evaporative system is sealed. If the sys-

tem pressurizes too quickly, a restriction somewhere

in the EVAP system may be indicated.

PUMPING ACTION

Action : During portions of this test, the PCM uses

the reed switch to monitor diaphragm movement.

The solenoid is only turned on by the PCM after the

reed switch changes from open to closed, indicating

that the diaphragm has moved down. At other times

during the test, the PCM will rapidly cycle the LDP

solenoid on and off to quickly pressurize the system.

During rapid cycling, the diaphragm will not move

enough to change the reed switch state. In the state

of rapid cycling, the PCM will use a fixed time inter-

val to cycle the solenoid. If the system does not pass

the EVAP Leak Detection Test, the following DTCs

may be set:

²P0442 - EVAP LEAK MONITOR 0.0409LEAK

DETECTED

²P0455 - EVAP LEAK MONITOR LARGE LEAK

DETECTED²P0456 - EVAP LEAK MONITOR 0.0209LEAK

DETECTED

²P1486 - EVAP LEAK MON PINCHED HOSE

FOUND

²P1494 - LEAK DETECTION PUMP SW OR

MECH FAULT

²P1495 - LEAK DETECTION PUMP SOLENOID

CIRCUIT

DIAGNOSIS AND TESTING - ENABLING

CONDITIONS TO RUN EVAP LEAK DETECTION

TEST

²Cold start: with ambient temperature (obtained

from modeling the inlet air temperature sensor on

passenger vehicles and the battery temperature sen-

sor on Jeep & Dodge Truck vehicles) between 4É C

(40É F) and 32É C (90É F) for 0.040 leak. Between 4É

C (40É F) and 29É C (85É F) for 0.020 leak.

²Engine coolant temperature within:-12É to -8É C

(10É to 18É F) of battery/ambient.

²Battery voltage between 10 and 15 volts.

²Low fuel warning light off (fuel level must be

between 15% and 85%.

²MAP sensor reading 22 in Hg or above (This is

the manifold absolute pressure, not vacuum).

Fig. 13 LDP AT REST

1 - Diaphragm

2 - Inlet Check Valve (Closed)

3 - Vent Valve (Open)

4 - From Air Filter

5 - To Canister

6 - Outlet Check Valve (Closed)

7 - Engine Vacuum (Closed)

Fig. 14 DIAPHRAGM UPWARD MOVEMENT

1 - Diaphragm

2 - Inlet Check Valve (Open)

3 - Vent Valve (Closed)

4 - From Air Filter

5 - To Canister

6 - Outlet Check Valve (Closed)

7 - Engine Vacuum (Open)

25 - 32 EVAPORATIVE EMISSIONSWJ

LEAK DETECTION PUMP (Continued)

Page 2193 of 2199

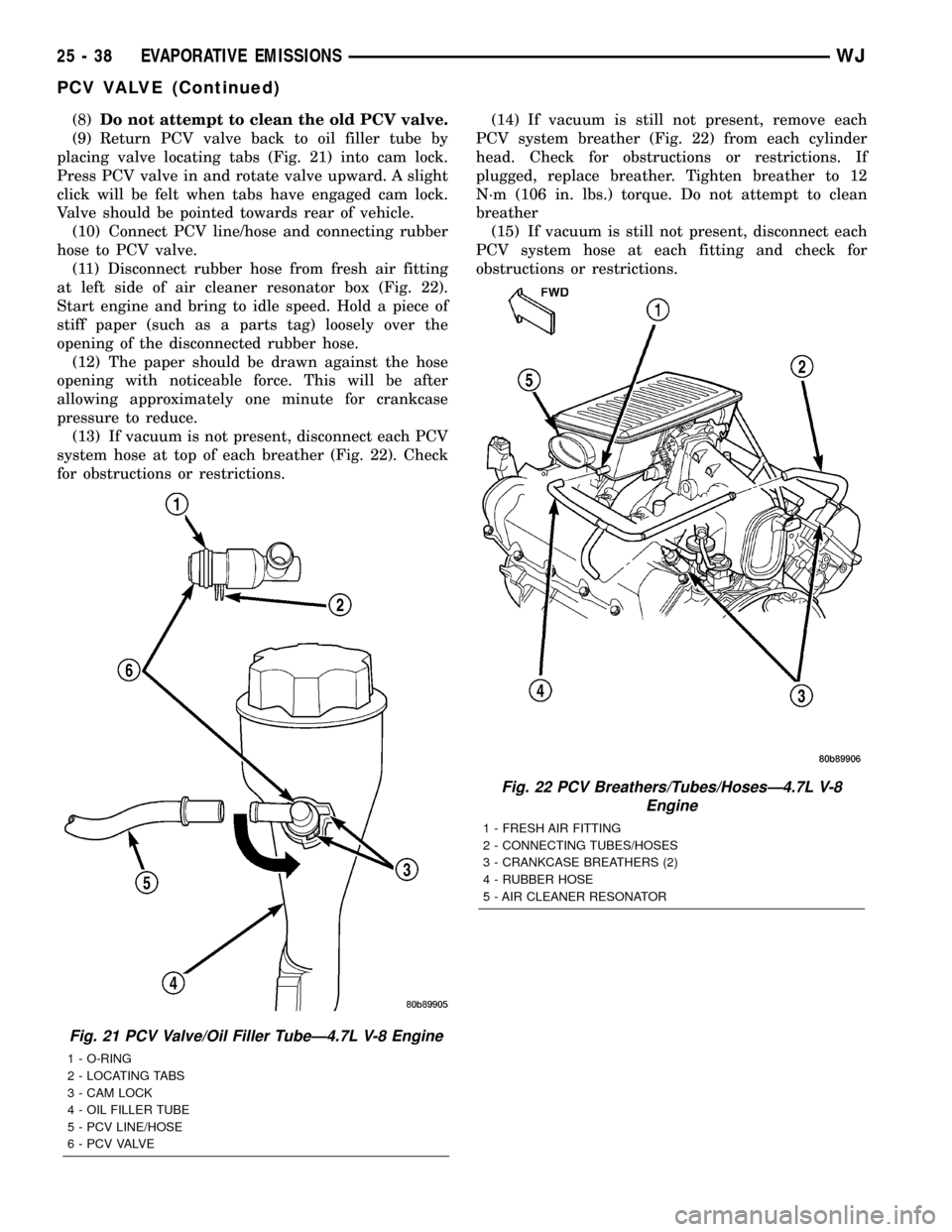

(8)Do not attempt to clean the old PCV valve.

(9) Return PCV valve back to oil filler tube by

placing valve locating tabs (Fig. 21) into cam lock.

Press PCV valve in and rotate valve upward. A slight

click will be felt when tabs have engaged cam lock.

Valve should be pointed towards rear of vehicle.

(10) Connect PCV line/hose and connecting rubber

hose to PCV valve.

(11) Disconnect rubber hose from fresh air fitting

at left side of air cleaner resonator box (Fig. 22).

Start engine and bring to idle speed. Hold a piece of

stiff paper (such as a parts tag) loosely over the

opening of the disconnected rubber hose.

(12) The paper should be drawn against the hose

opening with noticeable force. This will be after

allowing approximately one minute for crankcase

pressure to reduce.

(13) If vacuum is not present, disconnect each PCV

system hose at top of each breather (Fig. 22). Check

for obstructions or restrictions.(14) If vacuum is still not present, remove each

PCV system breather (Fig. 22) from each cylinder

head. Check for obstructions or restrictions. If

plugged, replace breather. Tighten breather to 12

N´m (106 in. lbs.) torque. Do not attempt to clean

breather

(15) If vacuum is still not present, disconnect each

PCV system hose at each fitting and check for

obstructions or restrictions.

Fig. 21 PCV Valve/Oil Filler TubeÐ4.7L V-8 Engine

1 - O-RING

2 - LOCATING TABS

3 - CAM LOCK

4 - OIL FILLER TUBE

5 - PCV LINE/HOSE

6 - P C V VA LV E

Fig. 22 PCV Breathers/Tubes/HosesÐ4.7L V-8

Engine

1 - FRESH AIR FITTING

2 - CONNECTING TUBES/HOSES

3 - CRANKCASE BREATHERS (2)

4 - RUBBER HOSE

5 - AIR CLEANER RESONATOR

25 - 38 EVAPORATIVE EMISSIONSWJ

PCV VALVE (Continued)

Page 2194 of 2199

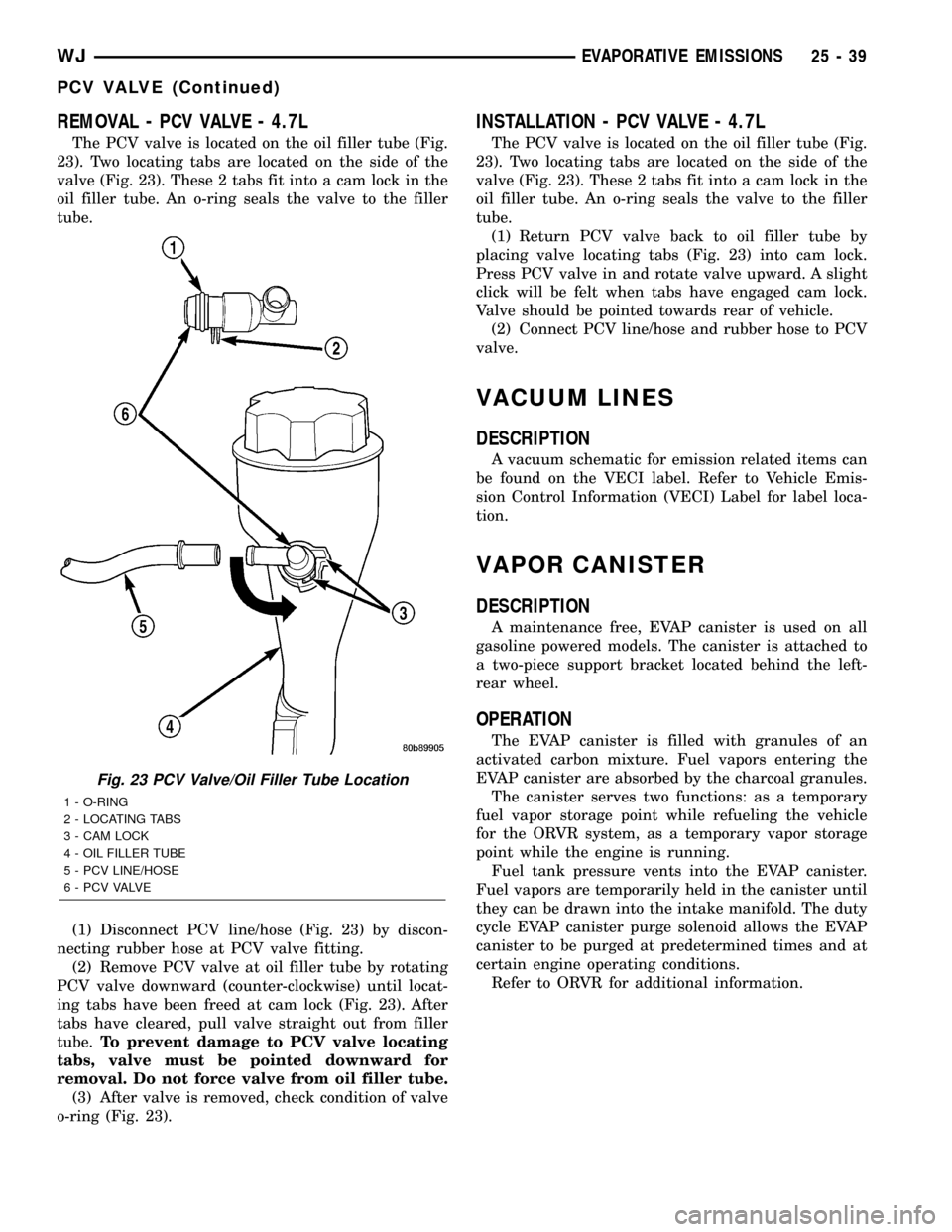

REMOVAL - PCV VALVE - 4.7L

The PCV valve is located on the oil filler tube (Fig.

23). Two locating tabs are located on the side of the

valve (Fig. 23). These 2 tabs fit into a cam lock in the

oil filler tube. An o-ring seals the valve to the filler

tube.

(1) Disconnect PCV line/hose (Fig. 23) by discon-

necting rubber hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward (counter-clockwise) until locat-

ing tabs have been freed at cam lock (Fig. 23). After

tabs have cleared, pull valve straight out from filler

tube.To prevent damage to PCV valve locating

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 23).

INSTALLATION - PCV VALVE - 4.7L

The PCV valve is located on the oil filler tube (Fig.

23). Two locating tabs are located on the side of the

valve (Fig. 23). These 2 tabs fit into a cam lock in the

oil filler tube. An o-ring seals the valve to the filler

tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs (Fig. 23) into cam lock.

Press PCV valve in and rotate valve upward. A slight

click will be felt when tabs have engaged cam lock.

Valve should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

VACUUM LINES

DESCRIPTION

A vacuum schematic for emission related items can

be found on the VECI label. Refer to Vehicle Emis-

sion Control Information (VECI) Label for label loca-

tion.

VAPOR CANISTER

DESCRIPTION

A maintenance free, EVAP canister is used on all

gasoline powered models. The canister is attached to

a two-piece support bracket located behind the left-

rear wheel.

OPERATION

The EVAP canister is filled with granules of an

activated carbon mixture. Fuel vapors entering the

EVAP canister are absorbed by the charcoal granules.

The canister serves two functions: as a temporary

fuel vapor storage point while refueling the vehicle

for the ORVR system, as a temporary vapor storage

point while the engine is running.

Fuel tank pressure vents into the EVAP canister.

Fuel vapors are temporarily held in the canister until

they can be drawn into the intake manifold. The duty

cycle EVAP canister purge solenoid allows the EVAP

canister to be purged at predetermined times and at

certain engine operating conditions.

Refer to ORVR for additional information.

Fig. 23 PCV Valve/Oil Filler Tube Location

1 - O-RING

2 - LOCATING TABS

3 - CAM LOCK

4 - OIL FILLER TUBE

5 - PCV LINE/HOSE

6 - P C V VA LV E

WJEVAPORATIVE EMISSIONS 25 - 39

PCV VALVE (Continued)