window control module JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 377 of 2199

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the rear glass heating grid and to the fuse in the

junction block that feeds the rear window defogger

switch LED indicator. There should be continuity

between the cavity for relay terminal 87 and the rear

glass heating grid and the rear window defogger

switch LED indicator at all times. If OK, go to Step

4. If not OK, repair the open rear window defogger

relay output circuit as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is connected to bat-

tery voltage and should be hot at all times. Check for

battery voltage at the cavity for relay terminal 86. If

OK, go to Step 5. If not OK, repair the open fused

B(+) circuit to the PDC fuse as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. This terminal is pro-

vided with ground by the Body Control Module

(BCM) rear window defogger timer and logic circuitry

to energize the defogger relay. There should be conti-

nuity to the rear window defogger relay control cir-

cuit cavity of the 22-way instrument panel wire

harness connector for the BCM. If OK, use a DRB

scan tool and refer to the Appropriate Diagnostic

Information to test the BCM. If not OK, repair the

open rear window defogger relay control circuit as

required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover

from the instrument panel. Refer to Instrument

Panel System for the procedures.

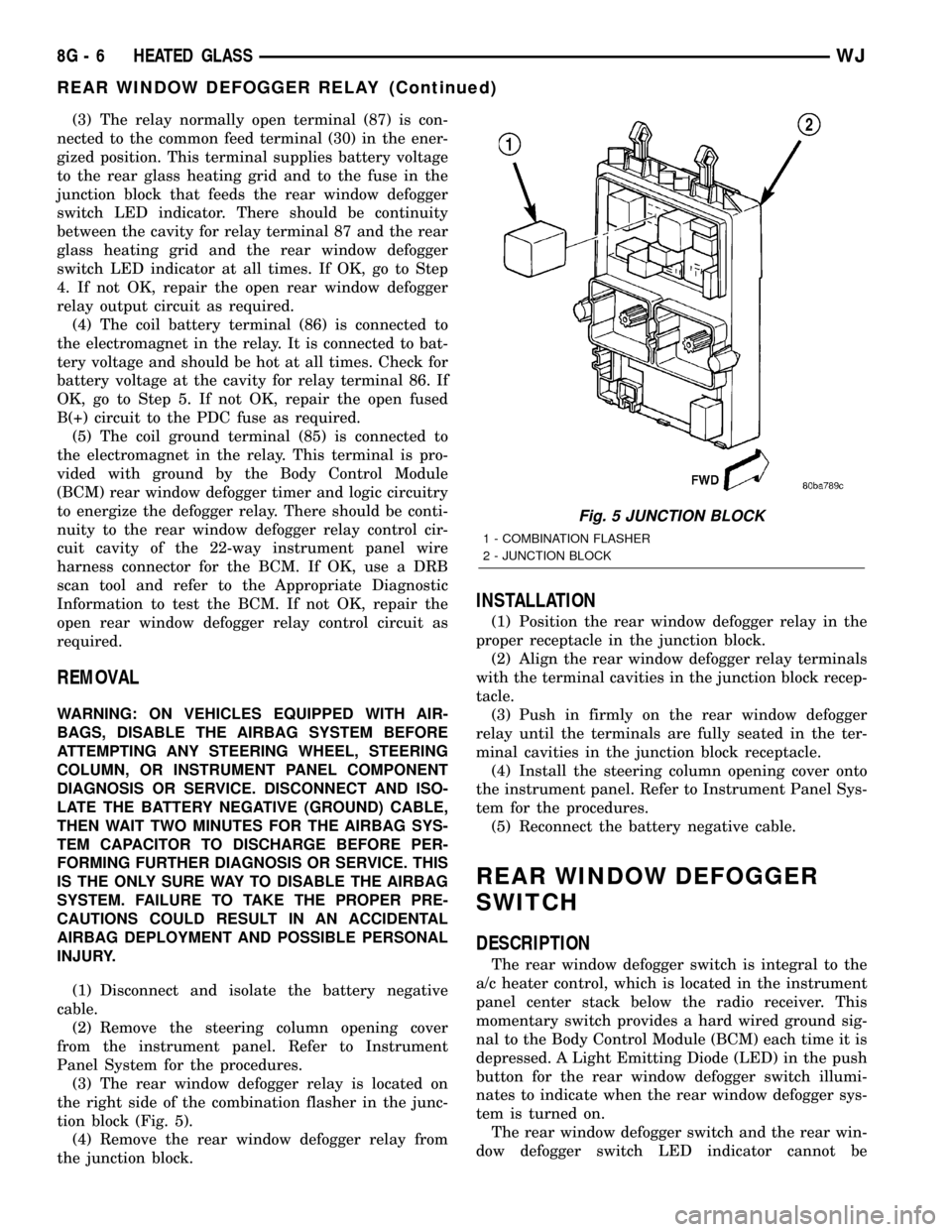

(3) The rear window defogger relay is located on

the right side of the combination flasher in the junc-

tion block (Fig. 5).

(4) Remove the rear window defogger relay from

the junction block.

INSTALLATION

(1) Position the rear window defogger relay in the

proper receptacle in the junction block.

(2) Align the rear window defogger relay terminals

with the terminal cavities in the junction block recep-

tacle.

(3) Push in firmly on the rear window defogger

relay until the terminals are fully seated in the ter-

minal cavities in the junction block receptacle.

(4) Install the steering column opening cover onto

the instrument panel. Refer to Instrument Panel Sys-

tem for the procedures.

(5) Reconnect the battery negative cable.

REAR WINDOW DEFOGGER

SWITCH

DESCRIPTION

The rear window defogger switch is integral to the

a/c heater control, which is located in the instrument

panel center stack below the radio receiver. This

momentary switch provides a hard wired ground sig-

nal to the Body Control Module (BCM) each time it is

depressed. A Light Emitting Diode (LED) in the push

button for the rear window defogger switch illumi-

nates to indicate when the rear window defogger sys-

tem is turned on.

The rear window defogger switch and the rear win-

dow defogger switch LED indicator cannot be

Fig. 5 JUNCTION BLOCK

1 - COMBINATION FLASHER

2 - JUNCTION BLOCK

8G - 6 HEATED GLASSWJ

REAR WINDOW DEFOGGER RELAY (Continued)

Page 378 of 2199

repaired and, if faulty or damaged, the entire a/c

heater control must be replaced. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL)

OPERATION

When the rear window defogger switch push but-

ton is depressed, it momentarily closes the rear win-

dow defogger switch sense circuit for the BCM to

ground. The BCM monitors the rear window defogger

switch sense circuit. Each time the BCM rear win-

dow defogger timer and logic circuitry sees another

input from the switch, it toggles a control output to

the rear window defogger relay. Energizing the rear

window defogger relay provides electrical current to

the rear window defogger grid and to the LED indi-

cator in the switch, which lights to indicate when the

defogger system is turned on. A dedicated fuse in the

junction block protects the rear window defogger

relay output circuit to the LED indicator.

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SWITCH

For complete circuit diagrams, refer to the Appro-

priate Wiring Information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the a/c heater control from the instru-

ment panel and disconnect the 11-way (manual tem-

perature control) or 16-way (automatic zone control)

instrument panel wire harness connector from the a/c

heater control receptacle.

(2) Check for continuity between the ground cir-

cuit cavity of the 11-way or 16-way instrument panel

wire harness connector for the a/c heater control and

a good ground. There should be continuity. If OK, go

to Step 3. If not OK, repair the open ground circuit to

ground as required.

(3) Connect two jumper wires to the a/c heater

control 11-way or 16-way connector receptacle. Con-

nect one jumper from the ground circuit terminal inthe 11-way or 16-way a/c heater control connector

receptacle to a good ground. Connect the other

jumper from the fused rear window defogger relay

output circuit terminal of the 11-way or 16-way con-

nector receptacle to a 12-volt battery feed. The rear

window defogger switch LED indicator should light.

If OK, go to Step 4. If not OK, replace the faulty a/c

heater control.

(4) Check for continuity between the ground cir-

cuit and rear window defogger switch sense circuit

terminals of the 11-way or 16-way a/c heater control

connector receptacle. There should be momentary

continuity as the rear window defogger switch push

button is depressed, and then no continuity. If OK, go

to Step 5. If not OK, replace the faulty a/c heater

control.

(5) Disconnect the 22-way instrument panel wire

harness connector from the Body Control Module

(BCM) connector receptacle. Check for continuity

between the rear window defogger switch sense cir-

cuit cavity of the 11-way or 16-way instrument panel

wire harness connector for the a/c heater control and

a good ground. There should be no continuity. If OK,

go to Step 6. If not OK, repair the shorted rear win-

dow defogger switch sense circuit as required.

(6) Check for continuity between the rear window

defogger switch sense circuit cavities of the 11-way or

16-way instrument panel wire harness connector for

the a/c heater control and the 22-way instrument

panel wire harness connector for the BCM. There

should be continuity. If OK, refer to (Refer to 8 -

ELECTRICAL/HEATED GLASS/REAR WINDOW

DEFOGGER RELAY - DIAGNOSIS AND TESTING).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/A/C HEATER CONTROL - REMOVAL)

WJHEATED GLASS 8G - 7

REAR WINDOW DEFOGGER SWITCH (Continued)

Page 439 of 2199

instrument cluster logic circuit, and that logic will

only allow this indicator to operate when the instru-

ment cluster receives a battery current input on the

fused ignition switch output (run-start) circuit.

Therefore, the indicator will always be off when the

ignition switch is in any position except On or Start.

The bulb only illuminates when it is provided a path

to ground by the instrument cluster transistor. The

instrument cluster will turn on the MIL for the fol-

lowing reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the MIL is illuminated for

about three seconds as a bulb test.

²MIL Lamp-On Message- Each time the clus-

ter receives a MIL lamp-on message from the PCM,

the indicator will be illuminated. The indicator can

be flashed on and off, or illuminated solid, as dic-

tated by the PCM message. For some DTC's, if a

problem does not recur, the PCM will send a MIL

lamp-off message automatically. Other DTC's may

require that a fault be repaired and the PCM be

reset before a MIL lamp-off message will be sent. For

more information on the PCM and the DTC set and

reset parameters, (Refer to 25 - EMISSIONS CON-

TROL - OPERATION).

²Communication Error- If the cluster receives

no MIL lamp-on or lamp-off messages from the PCM

for twenty consecutive seconds, the MIL is illumi-

nated by the instrument cluster. The indicator

remains controlled and illuminated by the cluster

until a valid MIL lamp-on or lamp-off message is

received from the PCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the MIL will be turned on

for the duration of the test to confirm the functional-

ity of the bulb and the cluster control circuitry.

The PCM continually monitors each of the many

fuel and emissions system circuits and sensors to

decide whether the system is in good operating con-

dition. The PCM then sends the proper MIL lamp-on

or lamp-off messages to the instrument cluster. If the

MIL fails to light during the bulb test, replace the

bulb with a known good unit. For further diagnosis of

the MIL or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). If the instrument cluster turns on the

MIL after the bulb test, it may indicate that a mal-

function has occurred and that the fuel and emis-

sions system may require service. For proper

diagnosis of the fuel and emissions systems, the

PCM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the

MIL, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.ODOMETER

DESCRIPTION

An odometer and trip odometer are standard

equipment in all instrument clusters. The odometer

and trip odometer information are displayed in a

common electronic, blue-green Vacuum-Fluorescent

Display (VFD), which is located in the lower edge of

the speedometer dial face in the instrument cluster

and, when illuminated, is visible through a small

window cutout in the gauge overlay. However, the

odometer and trip odometer information are not dis-

played simultaneously. The trip odometer reset

switch on the instrument cluster electronic circuit

board toggles the display between odometer and trip

odometer modes by depressing the odometer/trip

odometer switch button that extends through the

lower edge of the cluster lens to the right of the

speedometer.

All odometer and trip odometer distance informa-

tion is stored in the instrument cluster memory. This

distance information can be increased when the

proper inputs are provided to the instrument cluster,

but the distance information cannot be decreased.

The odometer can display values up to 999,999 kilo-

meters (999,999 miles). The odometer will not roll

over, but will latch at the maximum value. The trip

odometer can display values up to 999.9 kilometers

(999.9 miles) before it rolls over to zero. The odome-

ter display does not have a decimal point and will

not show values less than a full unit (kilometer or

mile), the trip odometer display does have a decimal

point and will show tenths of a unit (kilometer or

mile).

The unit of measure for the odometer and trip

odometer display is not shown in the VFD. The unit

of measure for the odometer/trip odometer is selected

at the time that the instrument cluster is manufac-

tured, and cannot be changed. If the instrument clus-

ter has a kilometers-per-hour primary speedometer

scale, the odometer/trip odometer registers kilome-

ters; and, if the cluster features a miles-per-hour pri-

mary speedometer scale, the odometer/trip odometer

registers miles.

During daylight hours (exterior lamps Off) the

VFD is illuminated at full brightness for clear visibil-

ity. At night (exterior lamps are On) the instrument

cluster converts an electronic dimming level message

received from the Body Control Module (BCM) over

the Programmable Communications Interface (PCI)

data bus to a digital dimming level signal for control-

ling the lighting level of the VFD. However, a

ªParadeº mode position of the panel lamps dimmer

control ring on the control stalk of the left (lighting)

multi-function switch allows the VFD to be illumi-

8J - 24 INSTRUMENT CLUSTERWJ

MALFUNCTION INDICATOR LAMP (MIL) (Continued)

Page 508 of 2199

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION.........................11

OPERATION...........................12

DIAGNOSIS AND TESTING - POWER

MIRRORS...........................12

AUTOMATIC DAY/NIGHT MIRROR

DESCRIPTION

DESCRIPTION - REAR VIEW MIRROR.....12

DESCRIPTION - OUTSIDE REAR VIEW

MIRROR............................13

OPERATION

OPERATION - REAR VIEW MIRROR.......13

OPERATION - OUTSIDE REAR VIEW

MIRROR............................13

DIAGNOSIS AND TESTING - AUTOMATIC DAY

/ NIGHT MIRROR......................13POWER FOLD-AWAY MIRROR - EXPORT

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - POWER

FOLD-AWAY MIRROR - EXPORT..........14

REMOVAL.............................14

POWER MIRROR SWITCH

DESCRIPTION.........................15

OPERATION...........................15

SIDEVIEW MIRROR

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - SIDEVIEW

MIRROR............................16

POWER MIRRORS

DESCRIPTION

Driver and passenger side power operated outside

rear view mirrors are standard factory-installed

equipment on this model. The power mirror system

allows the driver to adjust both outside mirrors elec-

trically from the driver seat position by operating a

switch on the driver side front door trim panel. The

power mirror system receives non-switched battery

current through a fuse in the Power Distribution

Center (PDC) so that the power mirrors remain oper-

ational, regardless of the ignition switch position.

The standard equipment power operated outside

rear view mirrors are also equipped with the heated

mirror system, which will only operate when the

ignition switch is in the On position and the rear

window defogger switch is turned on. When the rear

window defogger switch is in the On position, electric

heater grids on the rear window glass and behind

both outside rear view mirror glasses are energized.

These electric heater grids produce heat to help clear

the rear window glass and outside rear view mirrors

of ice, snow, or fog. (Refer to 8 - ELECTRICAL/

HEATED MIRRORS - DESCRIPTION) for more

information on this feature.

A driver side automatic dimming outside mirror

that dims the mirror to reduce the glare of bright

lights approaching the vehicle from behind, and a

memory system that automatically positions the

power mirrors for two different drivers are optionalfactory-installed equipment on this model. (Refer to 8

- ELECTRICAL/POWER MIRRORS/AUTOMATIC

DAY / NIGHT MIRROR - DESCRIPTION) for more

information. (Refer to 8 - ELECTRICAL/POWER

SEATS - DESCRIPTION) for more information.

This group covers the following components of the

power mirror system:

²Power mirrors

²Power mirror switch.

Certain functions and features of the power mirror

system rely upon resources shared with other elec-

tronic modules in the vehicle over the Programmable

Communications Interface (PCI) data bus network.

The PCI data bus network allows the sharing of sen-

sor information. This helps to reduce wire harness

complexity, internal controller hardware, and compo-

nent sensor current loads. At the same time, this sys-

tem provides increased reliability, enhanced

diagnostics, and allows the addition of many new fea-

ture capabilities. For diagnosis of these electronic

modules or of the PCI data bus network, the use of a

DRB scan tool and the proper Diagnostic Procedures

manual are recommended.

The other electronic modules that may affect power

mirror system operation are as follows:

²Body Control Module (BCM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for more information.

²Driver Door Module (DDM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

WJPOWER MIRRORS 8N - 11

Page 512 of 2199

POWER MIRROR SWITCH

DESCRIPTION

Both the right and left power outside mirrors are

controlled by a single multi-function switch unit

located on the driver side front door trim panel. The

power mirror switch unit includes a three-position

rocker selector switch and four momentary direc-

tional push button switches.

The power mirror switch unit is integral to the

Driver Door Module (DDM). The power mirror switch

cannot be repaired or adjusted and, if faulty or dam-

aged, the entire DDM unit must be replaced. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/DRIVER DOOR MODULE - REMOVAL)

for the DDM service procedures.

OPERATION

The power mirror selector switch is moved right

(right mirror control), left (left mirror control), or

center to turn the power outside mirror system off.

When the selector switch is in the right mirror con-

trol or left mirror control position, one of the four

directional control buttons is depressed to control

movement of the selected mirror up, down, right, or

left. When the selector switch is in the Off position,

depressing any of the directional switches will not

change either mirror position.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the power mirror switches.

SIDEVIEW MIRROR

DESCRIPTION

Mechanically folding, power operated outside rear

view mirrors are standard equipment on this model.

Each power mirror housing contains two electric

motors, two drive mechanisms, an electric heating

grid, the mirror glass case and the mirror glass. One

motor and drive controls mirror up-and-down (verti-

cal) movement, and the other controls right-and-left

(horizontal) movement. If the vehicle is equipped

with the optional memory system, each mirror head

also contains two position potentiometers. One posi-

tion potentiometer monitors the vertical mirror

motor, and the other monitors the horizontal mirror

motor.

An optional driver side automatic dimming mirror

is able to automatically change its reflectance level.

This mirror is controlled by the circuitry of the auto-

matic day/night inside rear view mirror. A thin layer

of electrochromic material between two pieces of con-

ductive glass make up the face of the mirror. (Refer

to 8 - ELECTRICAL/POWER MIRRORS/AUTO-MATIC DAY / NIGHT MIRROR - DESCRIPTION) for

more information on this feature.

The power mirror unit cannot be repaired. Only

the mirror glass and glass case are serviced sepa-

rately. The replacement mirror glass is supplied with

an instruction sheet that details the recommended

replacement procedure. If any other component of the

power mirror unit is faulty or damaged, the entire

power mirror unit must be replaced.

OPERATION

Each of the two outside power mirrors includes two

reversible electric motors that are secured within the

power mirror housing. Each motor moves the mirror

case and glass through an integral drive unit. When

a power mirror motor is supplied with battery cur-

rent and ground, it moves the mirror case and glass

through its drive unit in one direction. When the bat-

tery current and ground feeds to the motor are

reversed, it moves the mirror case and glass in the

opposite direction.

The power mirrors are equipped with a standard

equipment electric heating grid that is applied to the

back of each outside rear view mirror glass. When an

electrical current is passed through the resistor wire

of the heating grid, it warms the mirror glass. (Refer

to 8 - ELECTRICAL/HEATED MIRRORS -

DESCRIPTION) for more information on the opera-

tion of the heated mirrors and the rear window

defogger system.

If the driver side mirror is equipped with the auto-

matic dimming outside mirror option, two photocell

sensors on the inside rear view mirror are used to

monitor light levels and adjust the reflectance of both

the inside and driver side outside mirrors. This

change in reflectance helps to reduce the glare of

headlamps approaching the vehicle from the rear.

(Refer to 8 - ELECTRICAL/POWER MIRRORS/AU-

TOMATIC DAY / NIGHT MIRROR - OPERATION)

for more information on this feature.

If the vehicle is equipped with the optional mem-

ory system, the Driver Door Module (DDM) and the

Passenger Door Module (PDM) store the mirror posi-

tion information as monitored through the mirror

motor position potentiometers. When the memory

system requests a recall of the stored mirror position,

the DDM and the PDM are able to duplicate the

stored mirror positions by moving the mirror motors

until the potentiometer readings match the stored

values.

WJPOWER MIRRORS 8N - 15

Page 530 of 2199

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................33

OPERATION...........................34

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................34

POWER WINDOW SWITCH

DESCRIPTION.........................36

OPERATION...........................36

DIAGNOSIS AND TESTING - POWER

WINDOW SWITCH.....................37REMOVAL.............................37

INSTALLATION.........................38

WINDOW MOTOR

DESCRIPTION.........................38

OPERATION...........................38

DIAGNOSIS AND TESTING - WINDOW

MOTOR .............................38

REMOVAL.............................39

INSTALLATION.........................39

POWER WINDOWS

DESCRIPTION

Power operated driver side and passenger side

front and rear door windows are standard factory-in-

stalled equipment on this model. The power window

system allows each of the door windows to be raised

or lowered electrically by operating a switch on the

trim panel for that door. Additionally, the master

switches on the driver side front door trim panel

allow all of the windows to be operated from the

driver seat position. A power window lockout switch

on the driver side front door trim panel will allow the

driver to disable all of the passenger door window

switches.

The power window system functionally operates

when the ignition switch is in the On position. How-

ever, a unique feature of this system will allow the

power windows to be operated for up to forty-five sec-

onds after the ignition switch is turned to the Off

position, or until a front door is opened, whichever

occurs first.

An auto-down feature allows the driver side front

door window to be lowered all the way, even if the

window switch is released. The driver side front door

window switch must be depressed in the down direc-

tion to a second detent to begin an auto-down event.

Depressing the switch again in any direction cancel

the auto-down event and begin movement in the

direction specified.

This group covers the following components of the

power window system:

²Power window switches

²Power window motors.

Certain functions and features of the power win-

dow system rely upon resources shared with other

electronic modules in the vehicle over the Program-mable Communications Interface (PCI) data bus net-

work. The PCI data bus network allows the sharing

of sensor information. This helps to reduce wire har-

ness complexity, internal controller hardware, and

component sensor current loads. At the same time,

this system provides increased reliability, enhanced

diagnostics, and allows the addition of many new fea-

ture capabilities. For diagnosis of these electronic

modules or of the PCI data bus network, the use of a

DRB scan tool and the proper Diagnostic Procedures

manual are recommended.

The other electronic modules that may affect power

window system operation are as follows:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for more information.

²Driver Door Module (DDM)-(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

²Passenger Door Module (PDM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

This group covers diagnosis and service of only the

electrical components in the power window system.

For service of mechanical components, such as the

regulator, lift plate, window tracks, or glass refer to

Body. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds. Follow-

ing are general descriptions of the major components

in the power window system.

WJPOWER WINDOWS 8N - 33

Page 531 of 2199

OPERATION

The power window system includes the Driver

Door Module (DDM) and Passenger Door Module

(PDM), which are mounted in their respective front

door, the rear door power window switches mounted

on the rear doors, and the power window motors

mounted to the window regulator in each door. The

DDM houses four master power window switches, the

power window lockout switch and the control logic for

the driver side front and rear door power windows.

The PDM houses the passenger side front door power

window switch and the control logic for the passenger

side front and rear door power windows.

When a master power window switch on the DDM

is used to operate a passenger side power window,

the DDM sends the window switch actuation mes-

sage to the PDM over the Programmable Communi-

cations Interface (PCI) data bus. The PDM responds

to these messages by sending control outputs to move

the passenger side power window motors. In addi-

tion, when the power window lockout switch in the

DDM is actuated to disable power window operation,

a lockout message is sent to the PDM over the PCI

data bus.

The Body Control Module (BCM) also supports and

controls certain features of the power window sys-

tem. The BCM receives a hard wired input from the

ignition switch. The programming in the BCM allows

it to process the information from this input and

send ignition switch status messages to the DDM

and the PDM over the PCI data bus. The DDM and

PDM use this information and hard wired inputs

from the front door ajar switches to control the light-

ing of the power window switch lamps, and to control

the operation of the power window after ignition-off

feature.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the power window system.

DIAGNOSIS AND TESTING - POWER

WINDOWS

Following are tests that will help to diagnose the

hard wired components and circuits of the power

window system. However, these tests may not prove

conclusive in the diagnosis of this system. In order to

obtain conclusive testing of the power window sys-

tem, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the power window system components must be

checked.The most reliable, efficient, and accurate means to

diagnose the power window system requires the use

of a DRB scan tool and the proper Diagnostic Proce-

dures manual. The DRB scan tool can provide confir-

mation that the PCI data bus is functional, that all

of the electronic modules are sending and receiving

the proper messages on the PCI data bus, and that

the power window motors are being sent the proper

hard wired outputs by the door modules for them to

perform their power window system functions.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

ALL WINDOWS INOPERATIVE

(1) Check the operation of the power lock switch

on the driver side front door. If all of the doors lock

and unlock, but none of the power windows operate,

use a DRB scan tool and the proper Diagnostic Pro-

cedures manual to check the Body Control Module

(BCM), the Driver Door Module (DDM) and the PCI

data bus for proper operation. If not OK, go to Step

2.

(2) Check the operation of the power lock switch

on the passenger side front door. If the passenger

doors lock and unlock, but the driver side front door

does not, go to Step 5. If all of the power locks and

power windows are inoperative from both front doors,

go to Step 3.

(3) Check the fused B(+) fuse in the Power Distri-

bution Center (PDC). If OK, go to Step 4. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(4) Check for battery voltage at the fused B(+) fuse

in the PDC. If OK, go to Step 5. If not OK, repair the

open fused B(+) circuit to the battery as required.

(5) Disconnect and isolate the battery negative

cable. Remove the trim panel from the driver side

front door. Disconnect the 15-way door wire harness

connector from the DDM connector receptacle. Check

for continuity between the ground circuit cavity of

the 15-way door wire harness connector for the DDM

and a good ground. There should be continuity. If

OK, go to Step 6. If not OK, repair the open ground

circuit to ground as required.

(6) Reconnect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

15-way door wire harness connector for the DDM. If

OK, replace the faulty DDM. If not OK, repair the

open fused B(+) circuit to the fuse in the PDC as

required.

8N - 34 POWER WINDOWSWJ

POWER WINDOWS (Continued)

Page 533 of 2199

and no voltage in the neutral position. If OK,(Refer

to 8 - ELECTRICAL/POWER WINDOWS/WINDOW

MOTOR - DIAGNOSIS AND TESTING). If not OK,

replace the faulty door module.

(9) Check the rear door power window switch con-

tinuity. (Refer to 8 - ELECTRICAL/POWER WIN-

DOWS/POWER WINDOW SWITCH - DIAGNOSIS

AND TESTING). If OK, go to Step 10. If not OK,

replace the faulty rear door power window switch.

(10) Disconnect and isolate the battery negative

cable. Reconnect the door wire harness connector to

the rear door power window switch. Disconnect the

door wire harness connector from the inoperative

power window motor wire harness connector. Check

for continuity between the rear window driver up cir-

cuit cavity of the 15-way door wire harness connector

for the door module and a good ground. Repeat the

check for the rear window driver down circuit. In

each case there should be no continuity. If OK, go to

Step 11. If not OK, repair the shorted rear window

driver up or down circuit as required.

(11) Check for continuity between the rear window

driver up circuit cavities of the 15-way door wire har-

ness connector for the door module and the power

window motor wire harness connector. Repeat the

check for the rear window driver down circuit. In

each case there should be continuity. If OK, go to

Step 12. If not OK, repair the open rear window

driver up or down circuit as required.

NOTE: The door module feeds battery current to

both terminals of the rear door power window

motors when the power window lockout switch is in

the Unlock position, until the master window switch

on the driver side front door is actuated. The door

module feeds ground to both terminals of the rear

door power window motor when the power window

lockout switch is in the Lock position, until the

master window switch on the driver side front door

is actuated.

(12) Reconnect the 15-way door wire harness con-

nector for the door module to the door module con-

nector receptacle. Connect the battery negative cable.

Check for battery voltage at each cavity in the door

wire harness connector for the power window motor.

Each cavity should have battery voltage when the

power window switch is in the neutral position. Each

cavity should also have battery voltage in one other

switch position, either up or down, and zero volts

with the switch in the opposite position. If OK, (Refer

to 8 - ELECTRICAL/POWER WINDOWS/WINDOW

MOTOR - DIAGNOSIS AND TESTING). If not OK,

replace the faulty door module.POWER WINDOW SWITCH

DESCRIPTION

The power window motors are controlled by a two-

way momentary switch mounted on the trim panel of

each passenger door, and four two-way momentary

switches on the driver side front door trim panel. The

driver side front door trim panel also has a two-posi-

tion power window lockout switch. Each power win-

dow switch, except the lockout switch, is illuminated

by a Light-Emitting Diode (LED) that is integral to

the switch paddle.

The front door power window switches and the

power window lockout switch are integral to the

Driver Door Module (DDM) and Passenger Door

Module (PDM). The front door power window

switches and their lamps cannot be adjusted or

repaired and, if faulty or damaged, the entire DDM

or PDM unit must be replaced. The rear door power

window switches and their lamps cannot be adjusted

or repaired but, if faulty or damaged, only the

affected rear door power window switch must be

replaced. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/DRIVER DOOR MODULE -

REMOVAL).

OPERATION

The front door power window switches provide an

up or down (or lock and unlock signal in the case of

the lockout switch) to the door module circuitry. The

Driver Door Module (DDM) circuitry controls the out-

put to the driver side front and rear door power win-

dow motors, and supplies electrical current as

required for the stand-alone operation of the driver

side rear door power window switch. The Passenger

Door Module (PDM) circuitry controls the output to

the passenger side front and rear door power window

motors, and supplies electrical current as required

for the stand-alone operation of the passenger side

rear door power window switch.

When a DDM-integrated master power window

switch for a passenger side window is actuated, or

when the power window lockout switch is actuated to

disable the passenger door power windows, the DDM

circuitry sends a message to the PDM over the Pro-

grammable Communications Interface (PCI) data bus

to control the output to that power window motor(s).

The power window switch for the driver side front

door power window has two detent positions in the

Down direction. The first detent provides normal

power window down operation. If this switch is

depressed to the second detent, the Auto Down cir-

cuitry of the DDM is activated. The Auto-Down cir-

cuitry will automatically move the driver side front

door window to its fully lowered position, even if the

power window switch is released. The Auto-Down

8N - 36 POWER WINDOWSWJ

POWER WINDOWS (Continued)

Page 535 of 2199

INSTALLATION

(1) Position the power window switch to the rear

door trim panel switch receptacle.

(2) Press firmly and evenly on the back of the

power window switch until it snaps into rear door

trim panel switch receptacle.

(3) Install the trim panel onto the rear door. (Refer

to 23 - BODY/DOORS - REAR/TRIM PANEL -

INSTALLATION) for the procedures.

(4) Reconnect the battery negative cable.

WINDOW MOTOR

DESCRIPTION

Power operated front and rear door windows are

standard equipment on this model. Each door has a

permanent magnet reversible electric motor with an

integral right angle gearbox mechanism that oper-

ates the window regulator. In addition, each power

window motor is equipped with an integral self-reset-

ting circuit breaker to protect the motor from over-

loads.

The power window motor gearbox housing is

secured to the window regulator drum housing with

screws. The window regulators used in all four doors

are single vertical post cable-and-drum type. A

molded plastic slider guided by the post is driven by

the regulator cables. The slider raises and lowers the

window glass through a steel lift plate attachment.

Front and rear glass channels within each door guide

and stabilize each end of the glass.

The power window motor and gearbox assembly

cannot be repaired and, if faulty or damaged, the

entire power window motor and gearbox unit must be

replaced. The window regulators are available for

service. (Refer to 23 - BODY/DOOR - FRONT/WIN-

DOW REGULATOR - REMOVAL) or (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

REMOVAL) for the regulator service procedures.

OPERATION

A positive and negative battery connection to the

two motor terminals will cause the power window

motor to rotate in one direction. Reversing the cur-

rent through these same two connections will cause

the motor to rotate in the opposite direction.

When the power window motor operates, it rotates

the regulator cable drum through its gearbox. The

window regulator cable drum is connected through

two cables to the plastic slider on the vertical post.

As the cable drum rotates, it lets cable out on one

side of the drum, and takes cable in on the other side

of the drum. The changes in cable length move the

slider up or down the vertical post, raising or lower-

ing the window glass.If the window regulator or window glass bind,

encounter obstructions, or reach their travel limits it

overloads the power window motor. The overloading

condition causes the power window motor self-reset-

ting circuit breaker to open, which stops the motor

from running.

DIAGNOSIS AND TESTING - WINDOW MOTOR

Before you proceed with this diagnosis, confirm

proper switch operation. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/DRIVER

DOOR MODULE - OPERATION) or (Refer to 8 -

ELECTRICAL/POWER WINDOWS/POWER WIN-

DOW SWITCH - OPERATION). For complete circuit

diagrams, refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

(1) Remove the trim panel from the door with the

inoperative power window. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL) or

(Refer to 23 - BODY/DOORS - REAR/TRIM PANEL -

REMOVAL) for the procedures.

(2) Disconnect the door wire harness connector

from the power window motor wire harness connec-

tor. Apply battery current to one cavity of the power

window motor wire harness connector, and apply

ground to the other cavity of the connector. The

power window motor should operate in one direction.

Remember, if the window is in the full up or full

down position, the motor will not operate in that

direction by design. If OK, go to Step 3. If not OK,

replace the faulty power window motor.

(3) Reverse the battery and ground connections to

the two cavities of the power window motor wire har-

ness connector. The power window motor should now

operate in the other direction. Remember, if the win-

dow is in the full up or full down position, the motor

will not operate in that direction by design. If OK, go

to Step 4. If not OK, replace the faulty power window

motor.

(4) If the power window motor operates in both

directions, check the operation of the window glass

and regulator mechanism through its complete up

and down travel. There should be no binding or stick-

ing of the window glass or regulator mechanism

through the entire travel range. If not OK, (Refer to

23 - BODY/DOOR - FRONT/WINDOW REGULATOR

- REMOVAL) or (Refer to 23 - BODY/DOORS -

REAR/WINDOW REGULATOR - REMOVAL) to

check for proper installation or damage of the win-

dow glass mounting and operating hardware.

8N - 38 POWER WINDOWSWJ

POWER WINDOW SWITCH (Continued)

Page 574 of 2199

NOTE: Vehicles equipped with a three-point center

seat belt have the center seat belt lower anchor

secured to the right buckle anchor plate with a

screw instead of the center lap belt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/REAR CENTER SEAT

BELT & RETRACTOR - INSTALLATION).

(3) Fold the rear seat cushion back into the seat-

ing position.

SEAT BELT SWITCH

DESCRIPTION

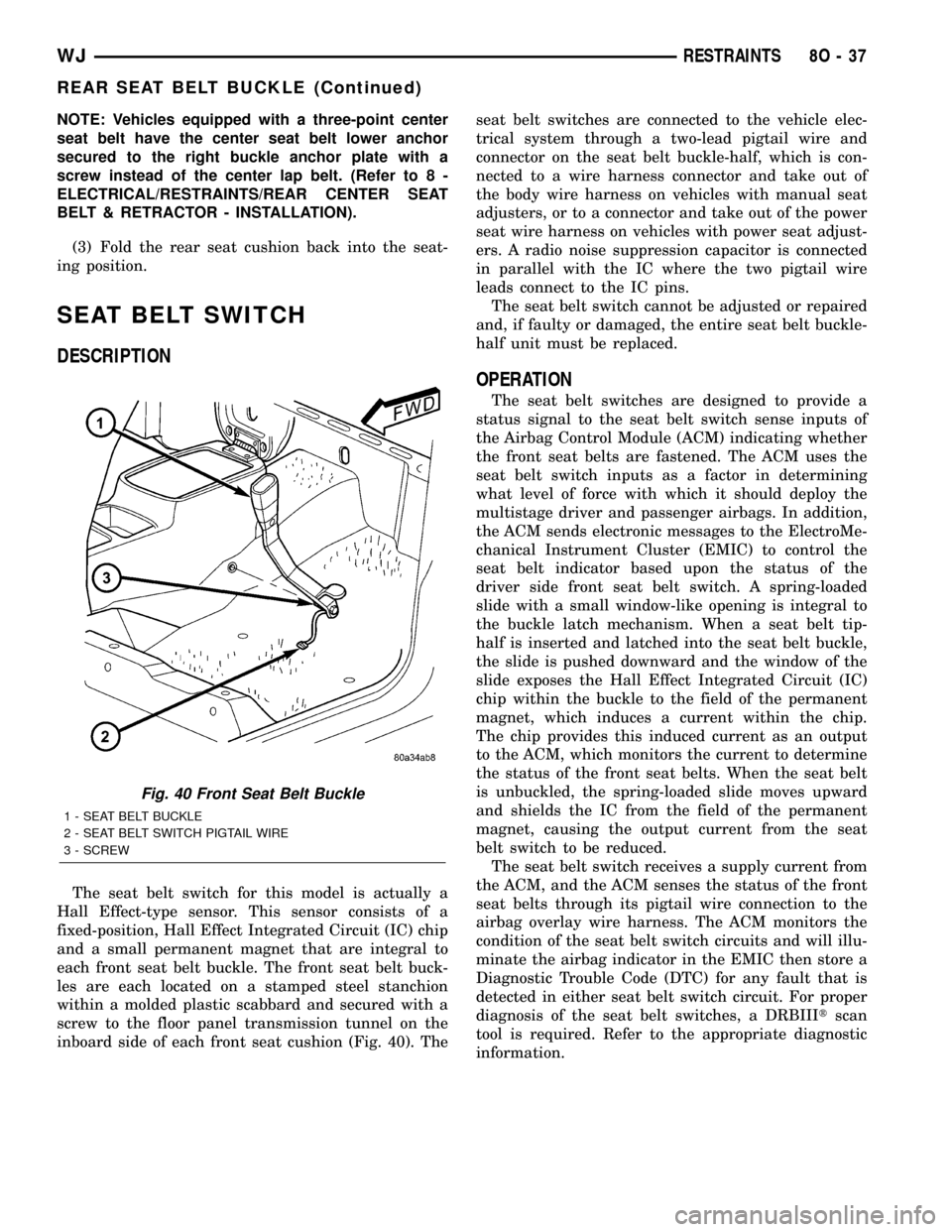

The seat belt switch for this model is actually a

Hall Effect-type sensor. This sensor consists of a

fixed-position, Hall Effect Integrated Circuit (IC) chip

and a small permanent magnet that are integral to

each front seat belt buckle. The front seat belt buck-

les are each located on a stamped steel stanchion

within a molded plastic scabbard and secured with a

screw to the floor panel transmission tunnel on the

inboard side of each front seat cushion (Fig. 40). Theseat belt switches are connected to the vehicle elec-

trical system through a two-lead pigtail wire and

connector on the seat belt buckle-half, which is con-

nected to a wire harness connector and take out of

the body wire harness on vehicles with manual seat

adjusters, or to a connector and take out of the power

seat wire harness on vehicles with power seat adjust-

ers. A radio noise suppression capacitor is connected

in parallel with the IC where the two pigtail wire

leads connect to the IC pins.

The seat belt switch cannot be adjusted or repaired

and, if faulty or damaged, the entire seat belt buckle-

half unit must be replaced.

OPERATION

The seat belt switches are designed to provide a

status signal to the seat belt switch sense inputs of

the Airbag Control Module (ACM) indicating whether

the front seat belts are fastened. The ACM uses the

seat belt switch inputs as a factor in determining

what level of force with which it should deploy the

multistage driver and passenger airbags. In addition,

the ACM sends electronic messages to the ElectroMe-

chanical Instrument Cluster (EMIC) to control the

seat belt indicator based upon the status of the

driver side front seat belt switch. A spring-loaded

slide with a small window-like opening is integral to

the buckle latch mechanism. When a seat belt tip-

half is inserted and latched into the seat belt buckle,

the slide is pushed downward and the window of the

slide exposes the Hall Effect Integrated Circuit (IC)

chip within the buckle to the field of the permanent

magnet, which induces a current within the chip.

The chip provides this induced current as an output

to the ACM, which monitors the current to determine

the status of the front seat belts. When the seat belt

is unbuckled, the spring-loaded slide moves upward

and shields the IC from the field of the permanent

magnet, causing the output current from the seat

belt switch to be reduced.

The seat belt switch receives a supply current from

the ACM, and the ACM senses the status of the front

seat belts through its pigtail wire connection to the

airbag overlay wire harness. The ACM monitors the

condition of the seat belt switch circuits and will illu-

minate the airbag indicator in the EMIC then store a

Diagnostic Trouble Code (DTC) for any fault that is

detected in either seat belt switch circuit. For proper

diagnosis of the seat belt switches, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

Fig. 40 Front Seat Belt Buckle

1 - SEAT BELT BUCKLE

2 - SEAT BELT SWITCH PIGTAIL WIRE

3 - SCREW

WJRESTRAINTS 8O - 37

REAR SEAT BELT BUCKLE (Continued)