Harness JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1549 of 2199

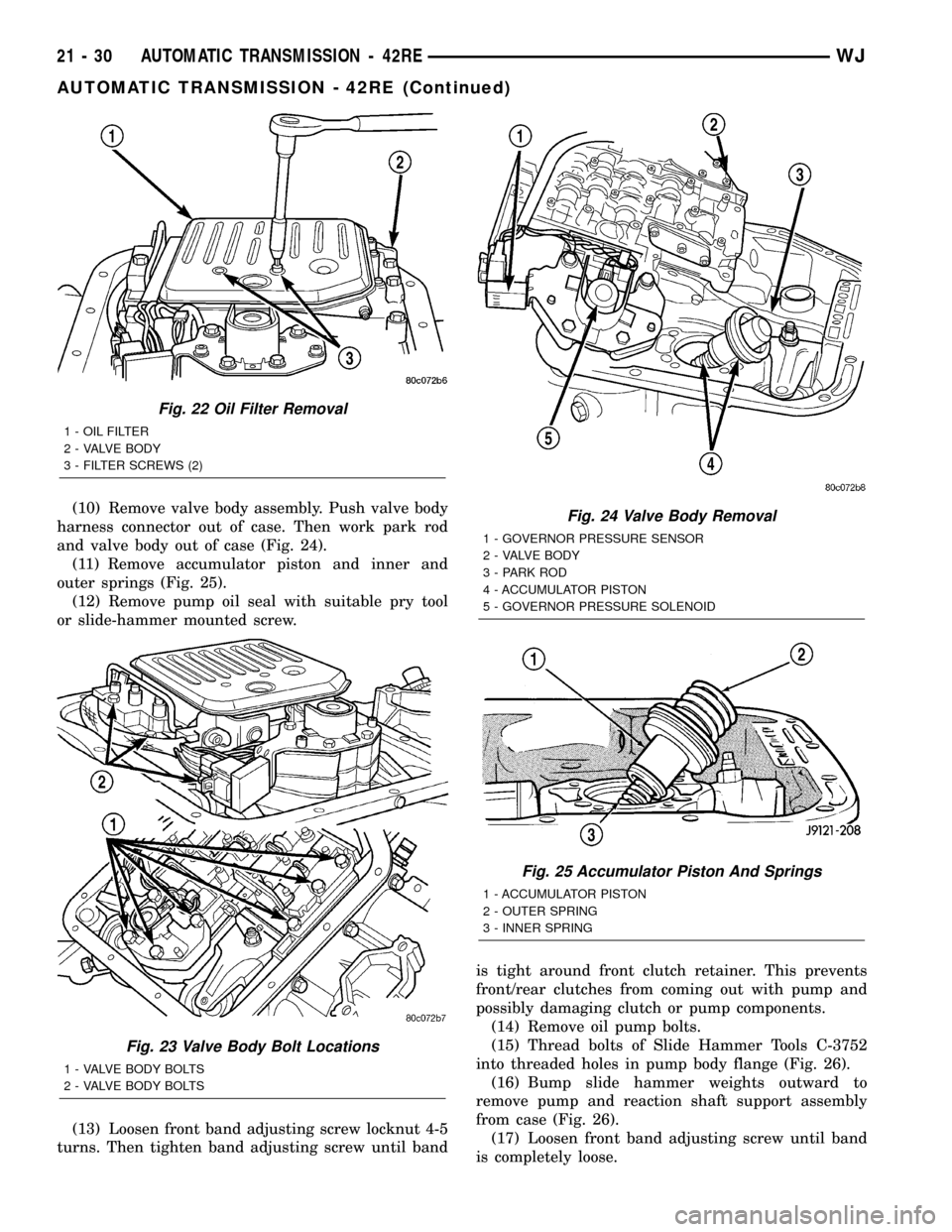

(10) Remove valve body assembly. Push valve body

harness connector out of case. Then work park rod

and valve body out of case (Fig. 24).

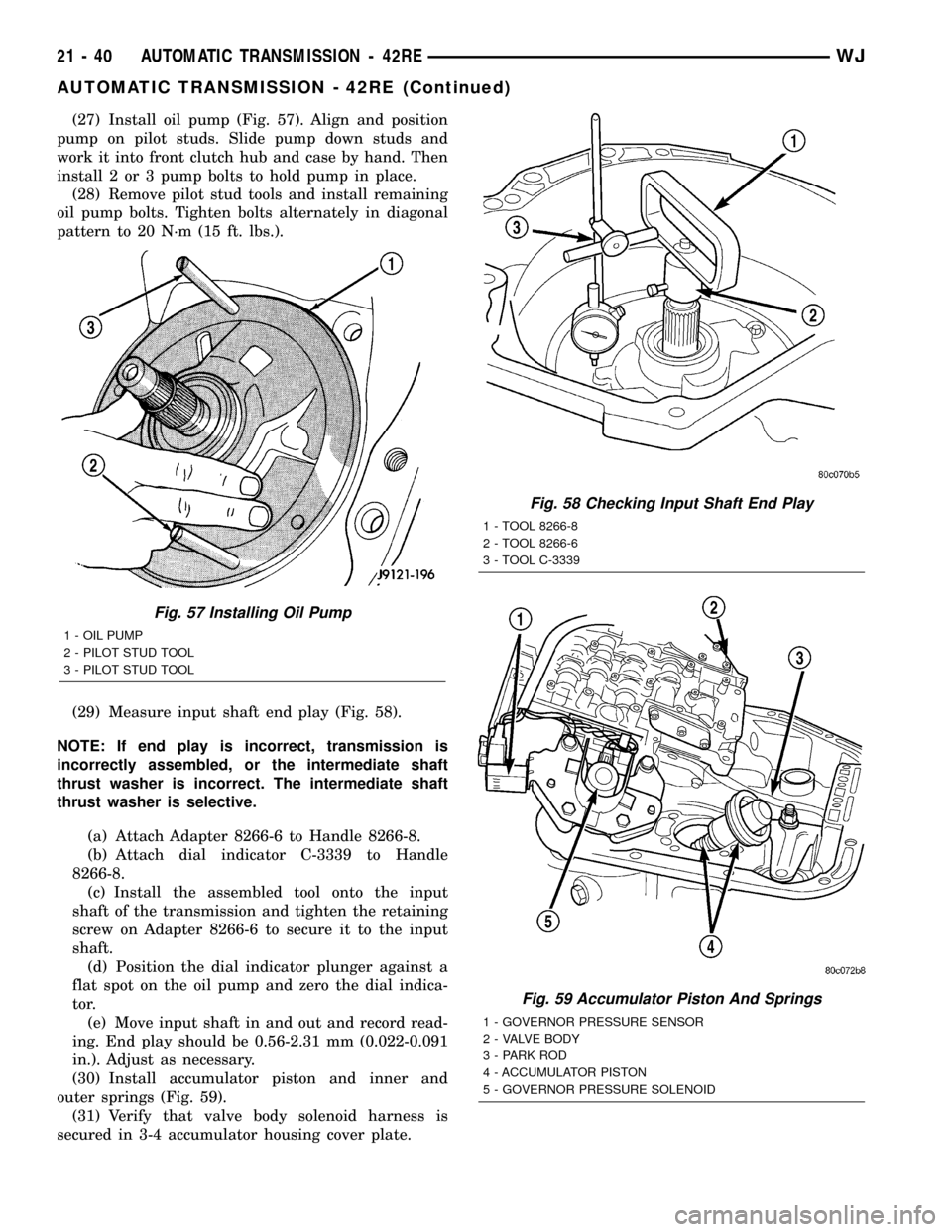

(11) Remove accumulator piston and inner and

outer springs (Fig. 25).

(12) Remove pump oil seal with suitable pry tool

or slide-hammer mounted screw.

(13) Loosen front band adjusting screw locknut 4-5

turns. Then tighten band adjusting screw until bandis tight around front clutch retainer. This prevents

front/rear clutches from coming out with pump and

possibly damaging clutch or pump components.

(14) Remove oil pump bolts.

(15) Thread bolts of Slide Hammer Tools C-3752

into threaded holes in pump body flange (Fig. 26).

(16) Bump slide hammer weights outward to

remove pump and reaction shaft support assembly

from case (Fig. 26).

(17) Loosen front band adjusting screw until band

is completely loose.

Fig. 22 Oil Filter Removal

1 - OIL FILTER

2 - VALVE BODY

3 - FILTER SCREWS (2)

Fig. 23 Valve Body Bolt Locations

1 - VALVE BODY BOLTS

2 - VALVE BODY BOLTS

Fig. 24 Valve Body Removal

1 - GOVERNOR PRESSURE SENSOR

2 - VALVE BODY

3 - PARK ROD

4 - ACCUMULATOR PISTON

5 - GOVERNOR PRESSURE SOLENOID

Fig. 25 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

21 - 30 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1559 of 2199

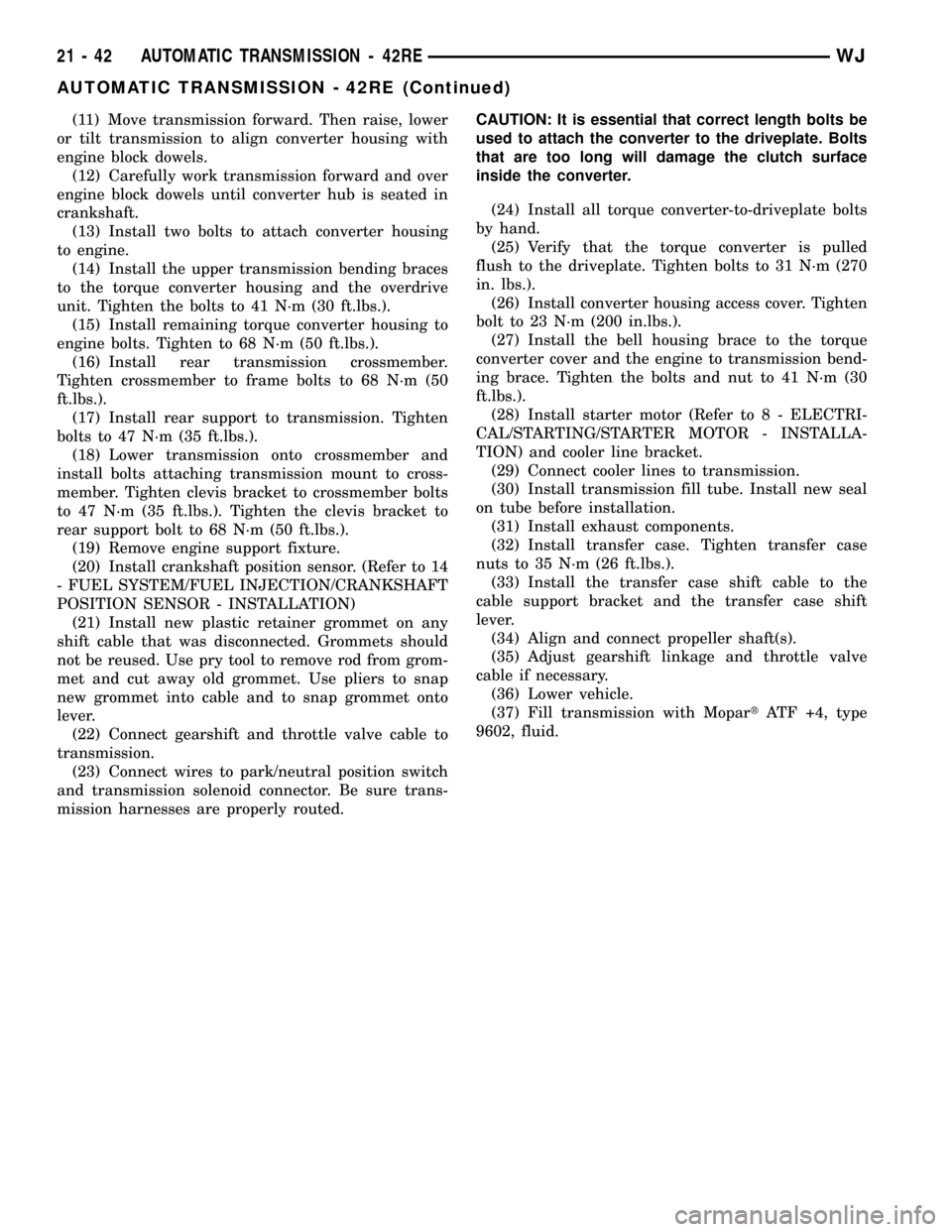

(27) Install oil pump (Fig. 57). Align and position

pump on pilot studs. Slide pump down studs and

work it into front clutch hub and case by hand. Then

install 2 or 3 pump bolts to hold pump in place.

(28) Remove pilot stud tools and install remaining

oil pump bolts. Tighten bolts alternately in diagonal

pattern to 20 N´m (15 ft. lbs.).

(29) Measure input shaft end play (Fig. 58).

NOTE: If end play is incorrect, transmission is

incorrectly assembled, or the intermediate shaft

thrust washer is incorrect. The intermediate shaft

thrust washer is selective.

(a) Attach Adapter 8266-6 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-6 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move input shaft in and out and record read-

ing. End play should be 0.56-2.31 mm (0.022-0.091

in.). Adjust as necessary.

(30) Install accumulator piston and inner and

outer springs (Fig. 59).

(31) Verify that valve body solenoid harness is

secured in 3-4 accumulator housing cover plate.

Fig. 57 Installing Oil Pump

1 - OIL PUMP

2 - PILOT STUD TOOL

3 - PILOT STUD TOOL

Fig. 58 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-6

3 - TOOL C-3339

Fig. 59 Accumulator Piston And Springs

1 - GOVERNOR PRESSURE SENSOR

2 - VALVE BODY

3 - PARK ROD

4 - ACCUMULATOR PISTON

5 - GOVERNOR PRESSURE SOLENOID

21 - 40 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1561 of 2199

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(12) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft.

(13) Install two bolts to attach converter housing

to engine.

(14) Install the upper transmission bending braces

to the torque converter housing and the overdrive

unit. Tighten the bolts to 41 N´m (30 ft.lbs.).

(15) Install remaining torque converter housing to

engine bolts. Tighten to 68 N´m (50 ft.lbs.).

(16) Install rear transmission crossmember.

Tighten crossmember to frame bolts to 68 N´m (50

ft.lbs.).

(17) Install rear support to transmission. Tighten

bolts to 47 N´m (35 ft.lbs.).

(18) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member. Tighten clevis bracket to crossmember bolts

to 47 N´m (35 ft.lbs.). Tighten the clevis bracket to

rear support bolt to 68 N´m (50 ft.lbs.).

(19) Remove engine support fixture.

(20) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

(21) Install new plastic retainer grommet on any

shift cable that was disconnected. Grommets should

not be reused. Use pry tool to remove rod from grom-

met and cut away old grommet. Use pliers to snap

new grommet into cable and to snap grommet onto

lever.

(22) Connect gearshift and throttle valve cable to

transmission.

(23) Connect wires to park/neutral position switch

and transmission solenoid connector. Be sure trans-

mission harnesses are properly routed.CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

(24) Install all torque converter-to-driveplate bolts

by hand.

(25) Verify that the torque converter is pulled

flush to the driveplate. Tighten bolts to 31 N´m (270

in. lbs.).

(26) Install converter housing access cover. Tighten

bolt to 23 N´m (200 in.lbs.).

(27) Install the bell housing brace to the torque

converter cover and the engine to transmission bend-

ing brace. Tighten the bolts and nut to 41 N´m (30

ft.lbs.).

(28) Install starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - INSTALLA-

TION) and cooler line bracket.

(29) Connect cooler lines to transmission.

(30) Install transmission fill tube. Install new seal

on tube before installation.

(31) Install exhaust components.

(32) Install transfer case. Tighten transfer case

nuts to 35 N´m (26 ft.lbs.).

(33) Install the transfer case shift cable to the

cable support bracket and the transfer case shift

lever.

(34) Align and connect propeller shaft(s).

(35) Adjust gearshift linkage and throttle valve

cable if necessary.

(36) Lower vehicle.

(37) Fill transmission with MopartATF +4, type

9602, fluid.

21 - 42 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1644 of 2199

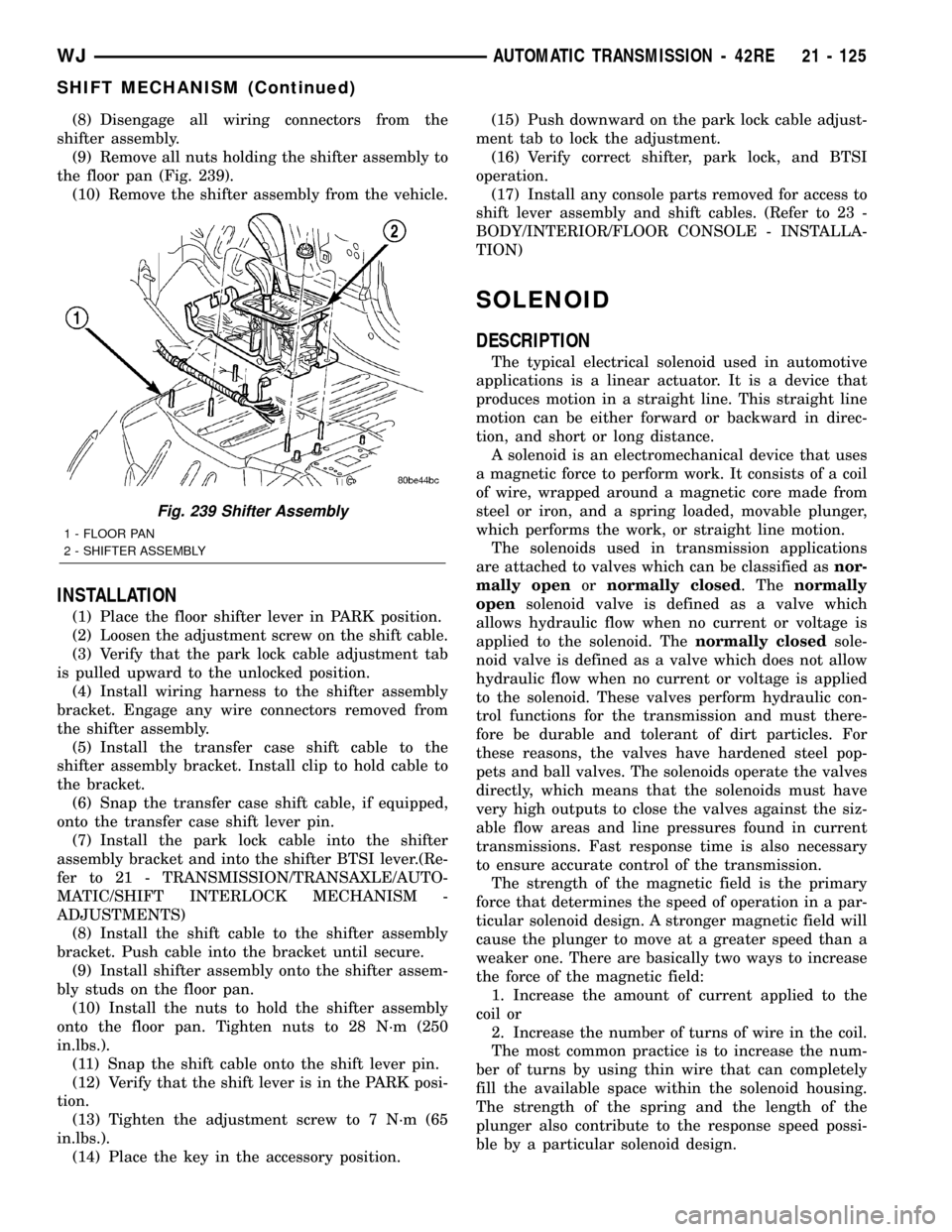

(8) Disengage all wiring connectors from the

shifter assembly.

(9) Remove all nuts holding the shifter assembly to

the floor pan (Fig. 239).

(10) Remove the shifter assembly from the vehicle.

INSTALLATION

(1) Place the floor shifter lever in PARK position.

(2) Loosen the adjustment screw on the shift cable.

(3) Verify that the park lock cable adjustment tab

is pulled upward to the unlocked position.

(4) Install wiring harness to the shifter assembly

bracket. Engage any wire connectors removed from

the shifter assembly.

(5) Install the transfer case shift cable to the

shifter assembly bracket. Install clip to hold cable to

the bracket.

(6) Snap the transfer case shift cable, if equipped,

onto the transfer case shift lever pin.

(7) Install the park lock cable into the shifter

assembly bracket and into the shifter BTSI lever.(Re-

fer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC/SHIFT INTERLOCK MECHANISM -

ADJUSTMENTS)

(8) Install the shift cable to the shifter assembly

bracket. Push cable into the bracket until secure.

(9) Install shifter assembly onto the shifter assem-

bly studs on the floor pan.

(10) Install the nuts to hold the shifter assembly

onto the floor pan. Tighten nuts to 28 N´m (250

in.lbs.).

(11) Snap the shift cable onto the shift lever pin.

(12) Verify that the shift lever is in the PARK posi-

tion.

(13) Tighten the adjustment screw to 7 N´m (65

in.lbs.).

(14) Place the key in the accessory position.(15) Push downward on the park lock cable adjust-

ment tab to lock the adjustment.

(16) Verify correct shifter, park lock, and BTSI

operation.

(17) Install any console parts removed for access to

shift lever assembly and shift cables. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - INSTALLA-

TION)

SOLENOID

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

Fig. 239 Shifter Assembly

1 - FLOOR PAN

2 - SHIFTER ASSEMBLY

WJAUTOMATIC TRANSMISSION - 42RE 21 - 125

SHIFT MECHANISM (Continued)

Page 1657 of 2199

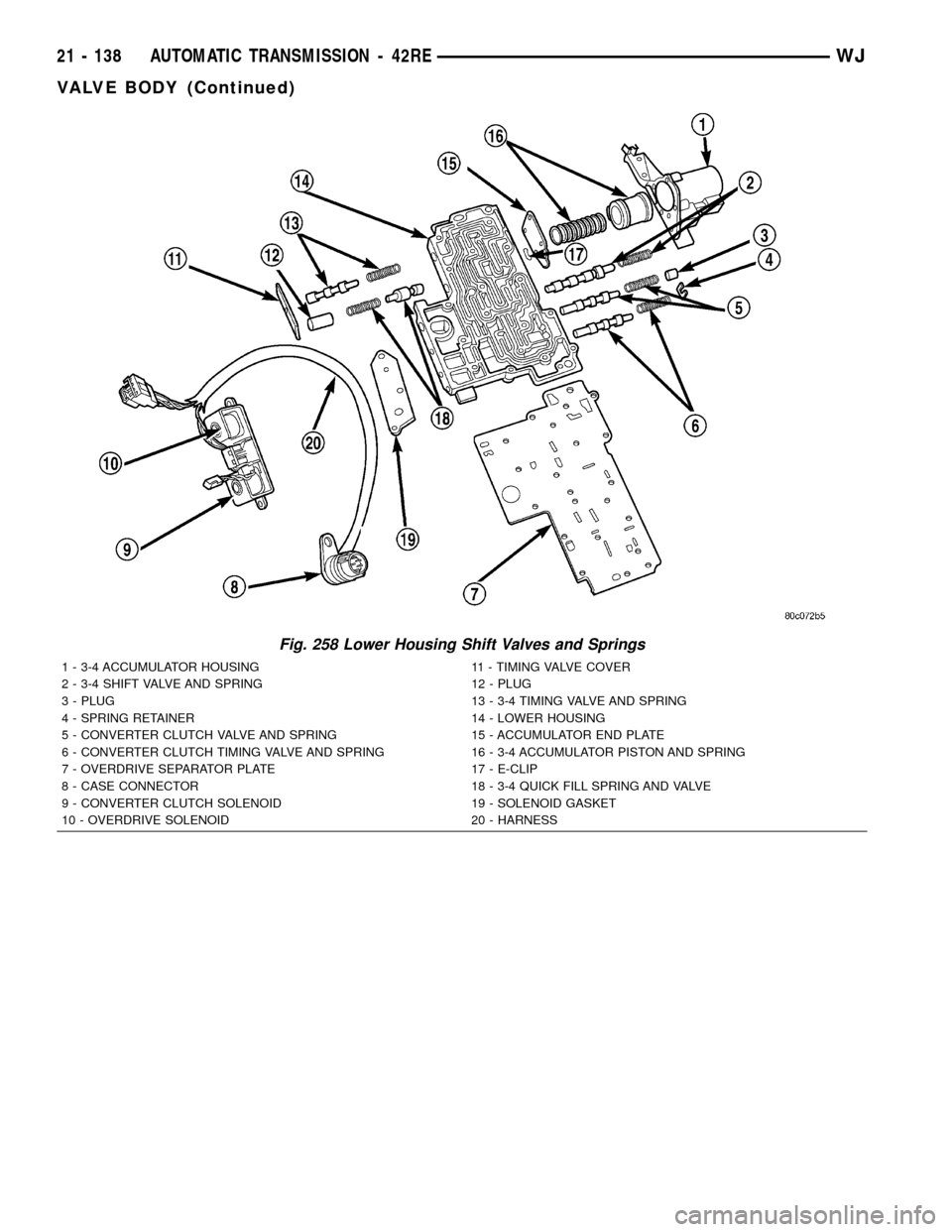

Fig. 258 Lower Housing Shift Valves and Springs

1 - 3-4 ACCUMULATOR HOUSING 11 - TIMING VALVE COVER

2 - 3-4 SHIFT VALVE AND SPRING 12 - PLUG

3 - PLUG 13 - 3-4 TIMING VALVE AND SPRING

4 - SPRING RETAINER 14 - LOWER HOUSING

5 - CONVERTER CLUTCH VALVE AND SPRING 15 - ACCUMULATOR END PLATE

6 - CONVERTER CLUTCH TIMING VALVE AND SPRING 16 - 3-4 ACCUMULATOR PISTON AND SPRING

7 - OVERDRIVE SEPARATOR PLATE 17 - E-CLIP

8 - CASE CONNECTOR 18 - 3-4 QUICK FILL SPRING AND VALVE

9 - CONVERTER CLUTCH SOLENOID 19 - SOLENOID GASKET

10 - OVERDRIVE SOLENOID 20 - HARNESS

21 - 138 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1673 of 2199

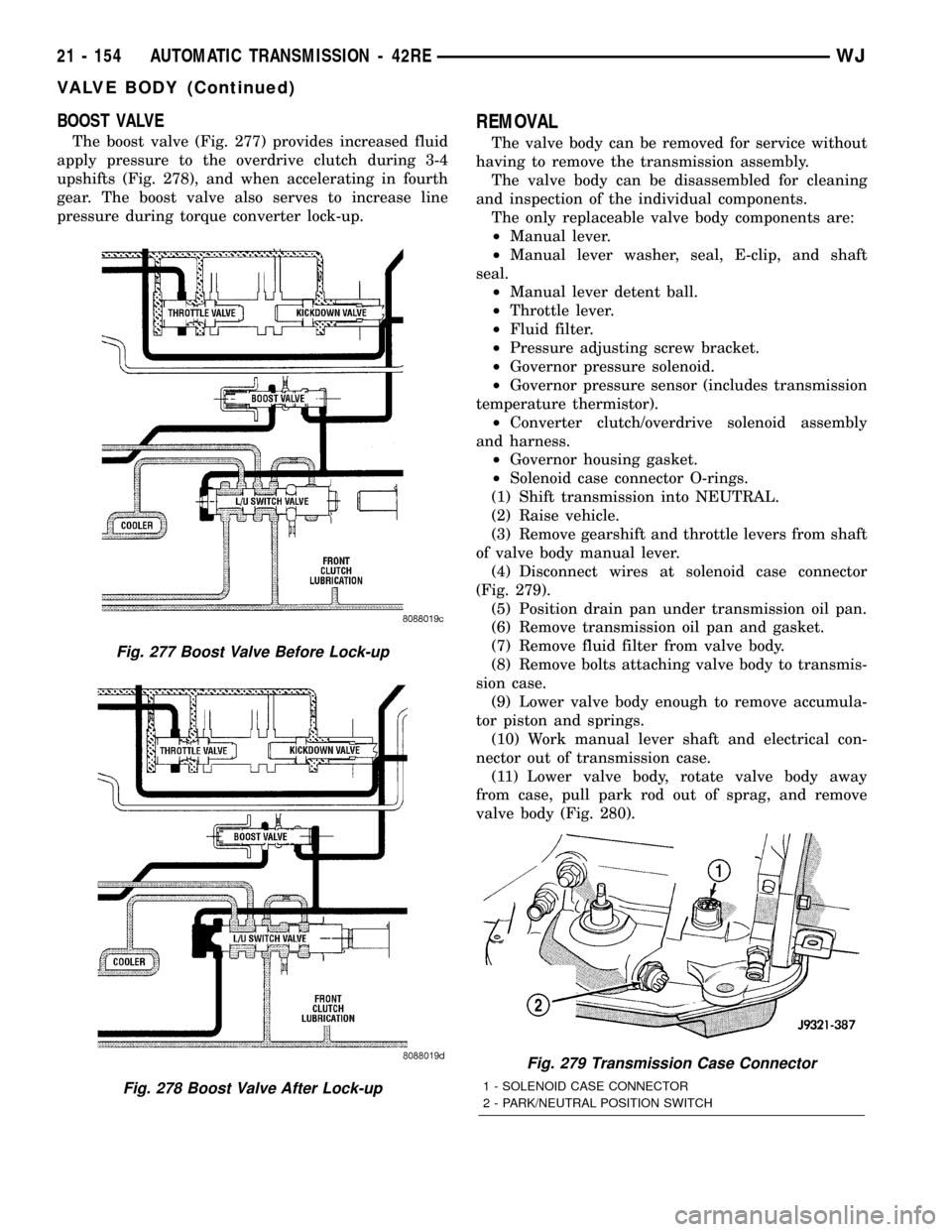

BOOST VALVE

The boost valve (Fig. 277) provides increased fluid

apply pressure to the overdrive clutch during 3-4

upshifts (Fig. 278), and when accelerating in fourth

gear. The boost valve also serves to increase line

pressure during torque converter lock-up.

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components.

The only replaceable valve body components are:

²Manual lever.

²Manual lever washer, seal, E-clip, and shaft

seal.

²Manual lever detent ball.

²Throttle lever.

²Fluid filter.

²Pressure adjusting screw bracket.

²Governor pressure solenoid.

²Governor pressure sensor (includes transmission

temperature thermistor).

²Converter clutch/overdrive solenoid assembly

and harness.

²Governor housing gasket.

²Solenoid case connector O-rings.

(1) Shift transmission into NEUTRAL.

(2) Raise vehicle.

(3) Remove gearshift and throttle levers from shaft

of valve body manual lever.

(4) Disconnect wires at solenoid case connector

(Fig. 279).

(5) Position drain pan under transmission oil pan.

(6) Remove transmission oil pan and gasket.

(7) Remove fluid filter from valve body.

(8) Remove bolts attaching valve body to transmis-

sion case.

(9) Lower valve body enough to remove accumula-

tor piston and springs.

(10) Work manual lever shaft and electrical con-

nector out of transmission case.

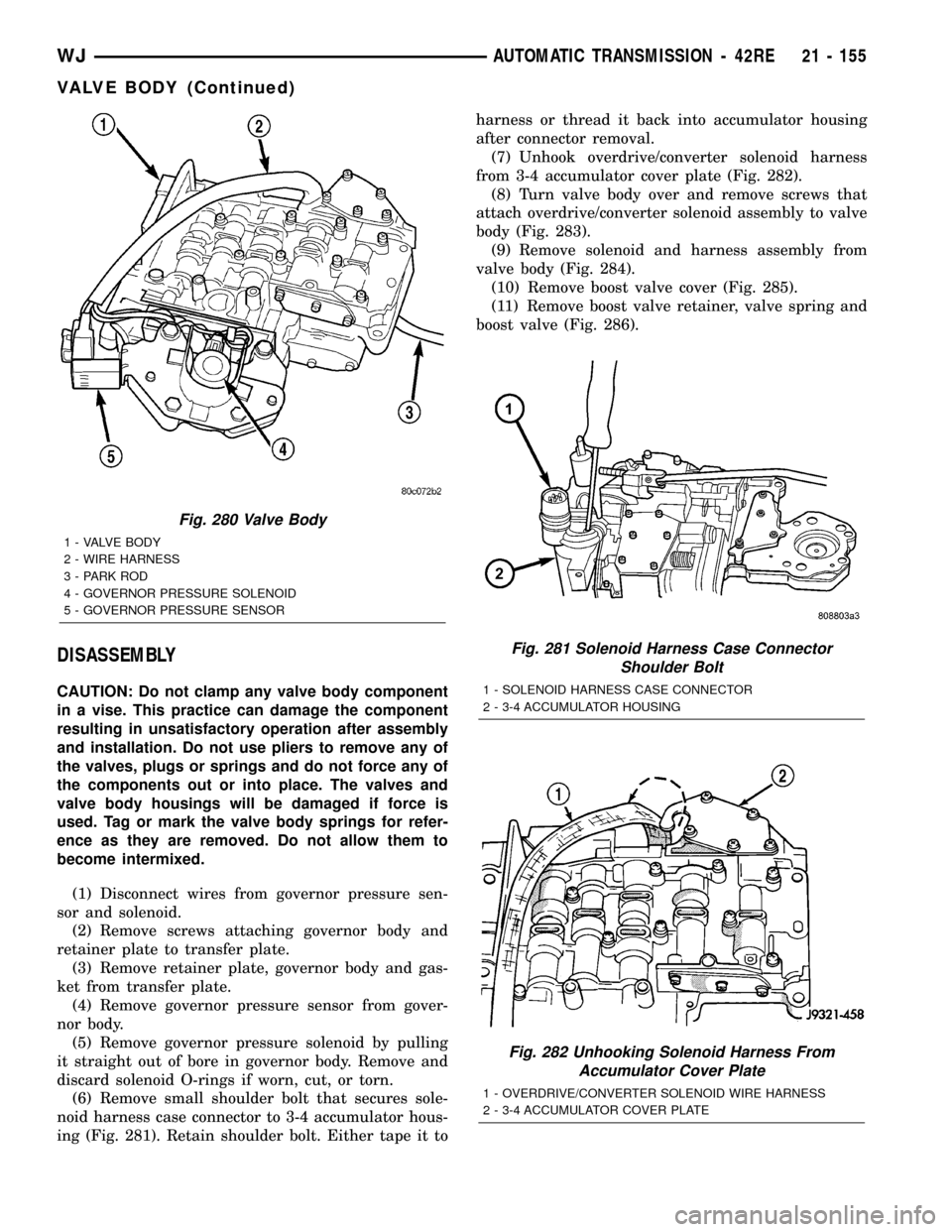

(11) Lower valve body, rotate valve body away

from case, pull park rod out of sprag, and remove

valve body (Fig. 280).

Fig. 277 Boost Valve Before Lock-up

Fig. 278 Boost Valve After Lock-up

Fig. 279 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - PARK/NEUTRAL POSITION SWITCH

21 - 154 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1674 of 2199

DISASSEMBLY

CAUTION: Do not clamp any valve body component

in a vise. This practice can damage the component

resulting in unsatisfactory operation after assembly

and installation. Do not use pliers to remove any of

the valves, plugs or springs and do not force any of

the components out or into place. The valves and

valve body housings will be damaged if force is

used. Tag or mark the valve body springs for refer-

ence as they are removed. Do not allow them to

become intermixed.

(1) Disconnect wires from governor pressure sen-

sor and solenoid.

(2) Remove screws attaching governor body and

retainer plate to transfer plate.

(3) Remove retainer plate, governor body and gas-

ket from transfer plate.

(4) Remove governor pressure sensor from gover-

nor body.

(5) Remove governor pressure solenoid by pulling

it straight out of bore in governor body. Remove and

discard solenoid O-rings if worn, cut, or torn.

(6) Remove small shoulder bolt that secures sole-

noid harness case connector to 3-4 accumulator hous-

ing (Fig. 281). Retain shoulder bolt. Either tape it toharness or thread it back into accumulator housing

after connector removal.

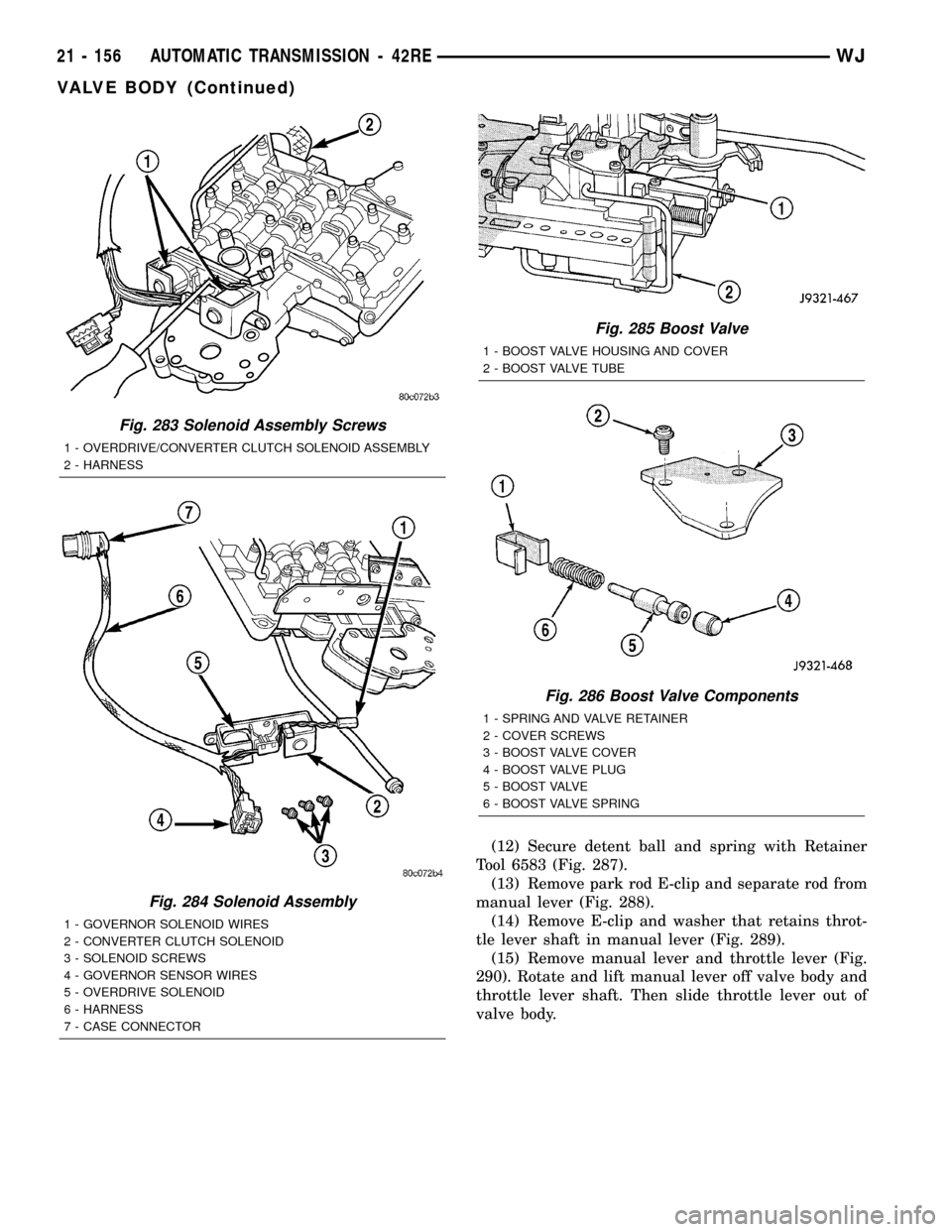

(7) Unhook overdrive/converter solenoid harness

from 3-4 accumulator cover plate (Fig. 282).

(8) Turn valve body over and remove screws that

attach overdrive/converter solenoid assembly to valve

body (Fig. 283).

(9) Remove solenoid and harness assembly from

valve body (Fig. 284).

(10) Remove boost valve cover (Fig. 285).

(11) Remove boost valve retainer, valve spring and

boost valve (Fig. 286).

Fig. 280 Valve Body

1 - VALVE BODY

2 - WIRE HARNESS

3 - PARK ROD

4 - GOVERNOR PRESSURE SOLENOID

5 - GOVERNOR PRESSURE SENSOR

Fig. 281 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

Fig. 282 Unhooking Solenoid Harness From

Accumulator Cover Plate

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

WJAUTOMATIC TRANSMISSION - 42RE 21 - 155

VALVE BODY (Continued)

Page 1675 of 2199

(12) Secure detent ball and spring with Retainer

Tool 6583 (Fig. 287).

(13) Remove park rod E-clip and separate rod from

manual lever (Fig. 288).

(14) Remove E-clip and washer that retains throt-

tle lever shaft in manual lever (Fig. 289).

(15) Remove manual lever and throttle lever (Fig.

290). Rotate and lift manual lever off valve body and

throttle lever shaft. Then slide throttle lever out of

valve body.

Fig. 283 Solenoid Assembly Screws

1 - OVERDRIVE/CONVERTER CLUTCH SOLENOID ASSEMBLY

2 - HARNESS

Fig. 284 Solenoid Assembly

1 - GOVERNOR SOLENOID WIRES

2 - CONVERTER CLUTCH SOLENOID

3 - SOLENOID SCREWS

4 - GOVERNOR SENSOR WIRES

5 - OVERDRIVE SOLENOID

6 - HARNESS

7 - CASE CONNECTOR

Fig. 285 Boost Valve

1 - BOOST VALVE HOUSING AND COVER

2 - BOOST VALVE TUBE

Fig. 286 Boost Valve Components

1 - SPRING AND VALVE RETAINER

2 - COVER SCREWS

3 - BOOST VALVE COVER

4 - BOOST VALVE PLUG

5 - BOOST VALVE

6 - BOOST VALVE SPRING

21 - 156 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1684 of 2199

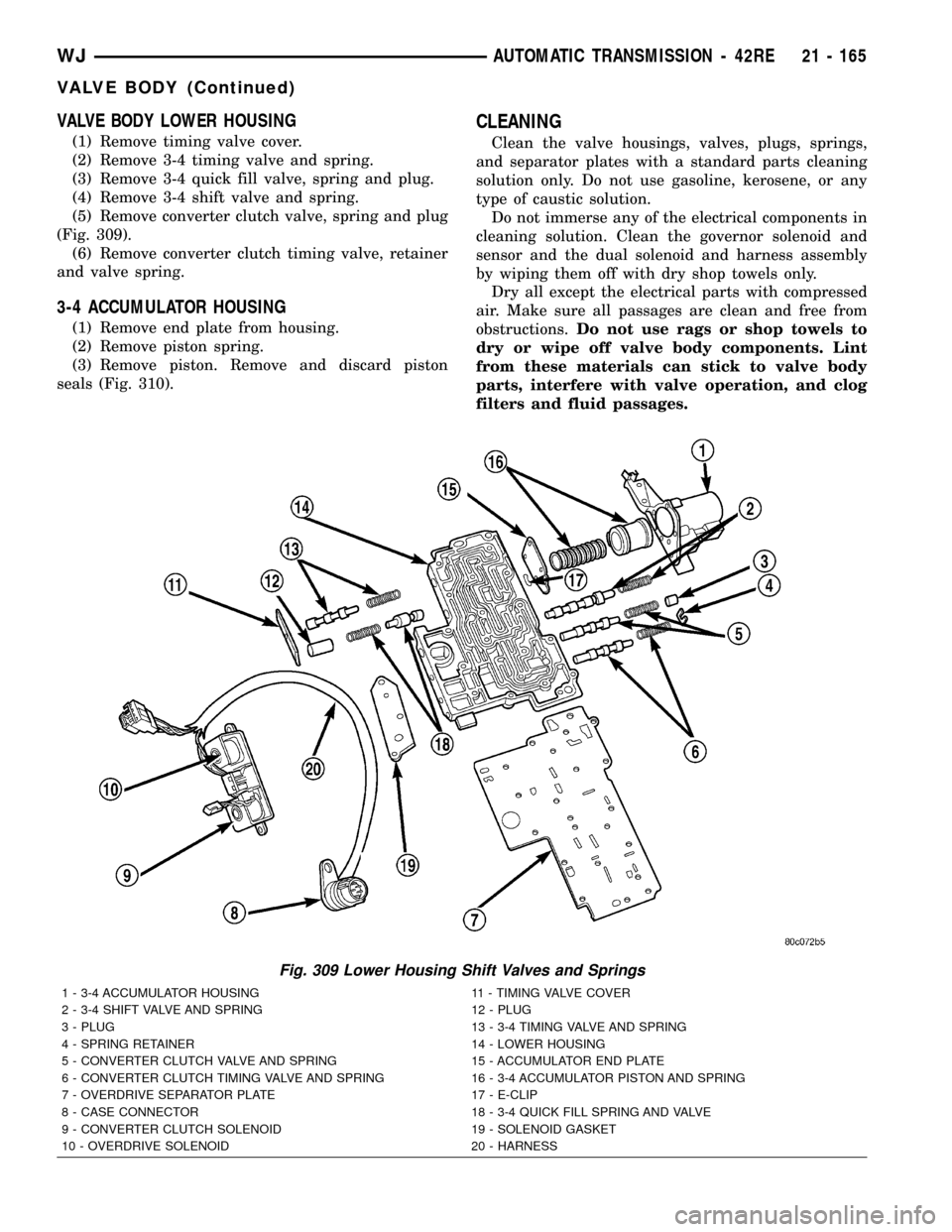

VALVE BODY LOWER HOUSING

(1) Remove timing valve cover.

(2) Remove 3-4 timing valve and spring.

(3) Remove 3-4 quick fill valve, spring and plug.

(4) Remove 3-4 shift valve and spring.

(5) Remove converter clutch valve, spring and plug

(Fig. 309).

(6) Remove converter clutch timing valve, retainer

and valve spring.

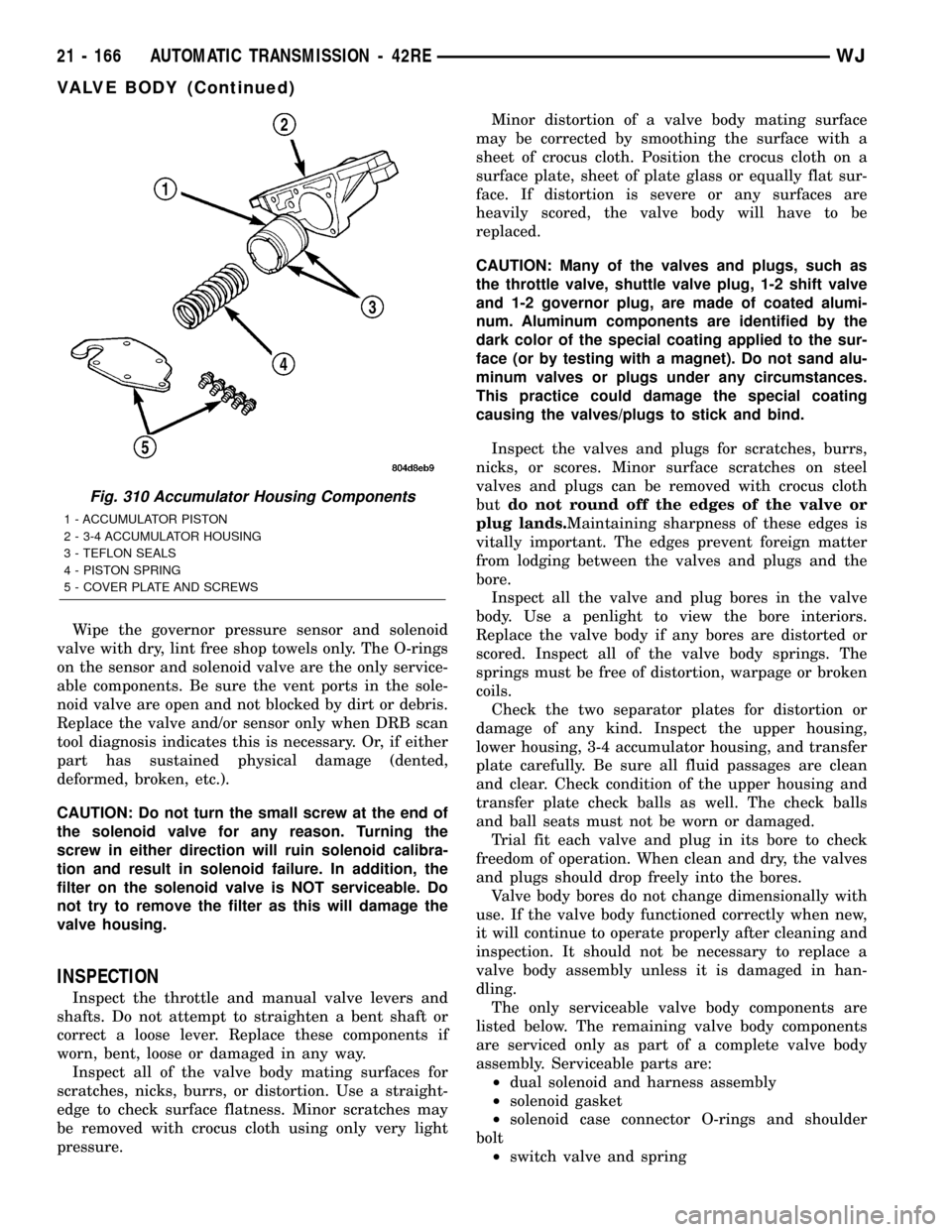

3-4 ACCUMULATOR HOUSING

(1) Remove end plate from housing.

(2) Remove piston spring.

(3) Remove piston. Remove and discard piston

seals (Fig. 310).

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Fig. 309 Lower Housing Shift Valves and Springs

1 - 3-4 ACCUMULATOR HOUSING 11 - TIMING VALVE COVER

2 - 3-4 SHIFT VALVE AND SPRING 12 - PLUG

3 - PLUG 13 - 3-4 TIMING VALVE AND SPRING

4 - SPRING RETAINER 14 - LOWER HOUSING

5 - CONVERTER CLUTCH VALVE AND SPRING 15 - ACCUMULATOR END PLATE

6 - CONVERTER CLUTCH TIMING VALVE AND SPRING 16 - 3-4 ACCUMULATOR PISTON AND SPRING

7 - OVERDRIVE SEPARATOR PLATE 17 - E-CLIP

8 - CASE CONNECTOR 18 - 3-4 QUICK FILL SPRING AND VALVE

9 - CONVERTER CLUTCH SOLENOID 19 - SOLENOID GASKET

10 - OVERDRIVE SOLENOID 20 - HARNESS

WJAUTOMATIC TRANSMISSION - 42RE 21 - 165

VALVE BODY (Continued)

Page 1685 of 2199

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if either

part has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, the

filter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

Valve body bores do not change dimensionally with

use. If the valve body functioned correctly when new,

it will continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

The only serviceable valve body components are

listed below. The remaining valve body components

are serviced only as part of a complete valve body

assembly. Serviceable parts are:

²dual solenoid and harness assembly

²solenoid gasket

²solenoid case connector O-rings and shoulder

bolt

²switch valve and spring

Fig. 310 Accumulator Housing Components

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 166 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)