o2 location JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1549 of 2199

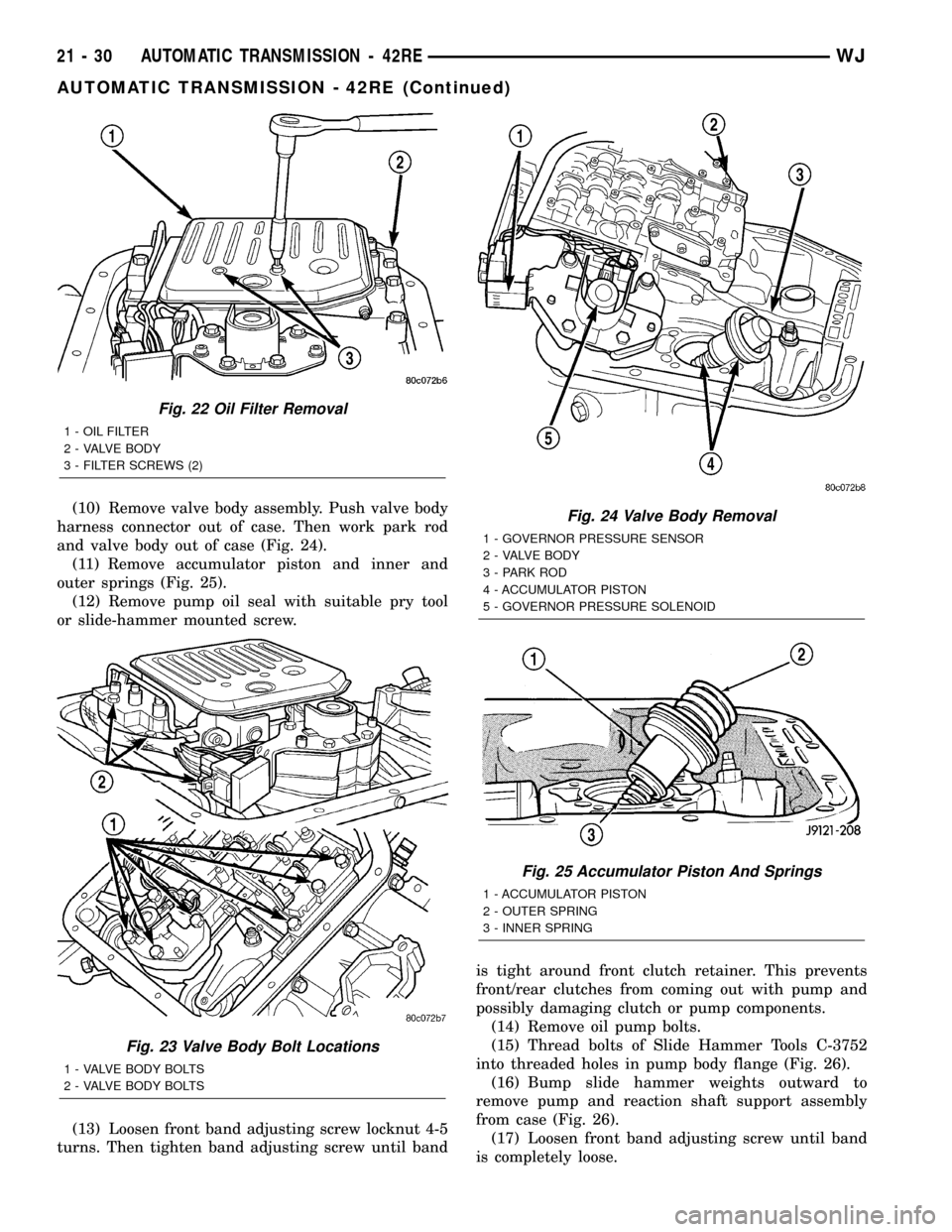

(10) Remove valve body assembly. Push valve body

harness connector out of case. Then work park rod

and valve body out of case (Fig. 24).

(11) Remove accumulator piston and inner and

outer springs (Fig. 25).

(12) Remove pump oil seal with suitable pry tool

or slide-hammer mounted screw.

(13) Loosen front band adjusting screw locknut 4-5

turns. Then tighten band adjusting screw until bandis tight around front clutch retainer. This prevents

front/rear clutches from coming out with pump and

possibly damaging clutch or pump components.

(14) Remove oil pump bolts.

(15) Thread bolts of Slide Hammer Tools C-3752

into threaded holes in pump body flange (Fig. 26).

(16) Bump slide hammer weights outward to

remove pump and reaction shaft support assembly

from case (Fig. 26).

(17) Loosen front band adjusting screw until band

is completely loose.

Fig. 22 Oil Filter Removal

1 - OIL FILTER

2 - VALVE BODY

3 - FILTER SCREWS (2)

Fig. 23 Valve Body Bolt Locations

1 - VALVE BODY BOLTS

2 - VALVE BODY BOLTS

Fig. 24 Valve Body Removal

1 - GOVERNOR PRESSURE SENSOR

2 - VALVE BODY

3 - PARK ROD

4 - ACCUMULATOR PISTON

5 - GOVERNOR PRESSURE SOLENOID

Fig. 25 Accumulator Piston And Springs

1 - ACCUMULATOR PISTON

2 - OUTER SPRING

3 - INNER SPRING

21 - 30 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1556 of 2199

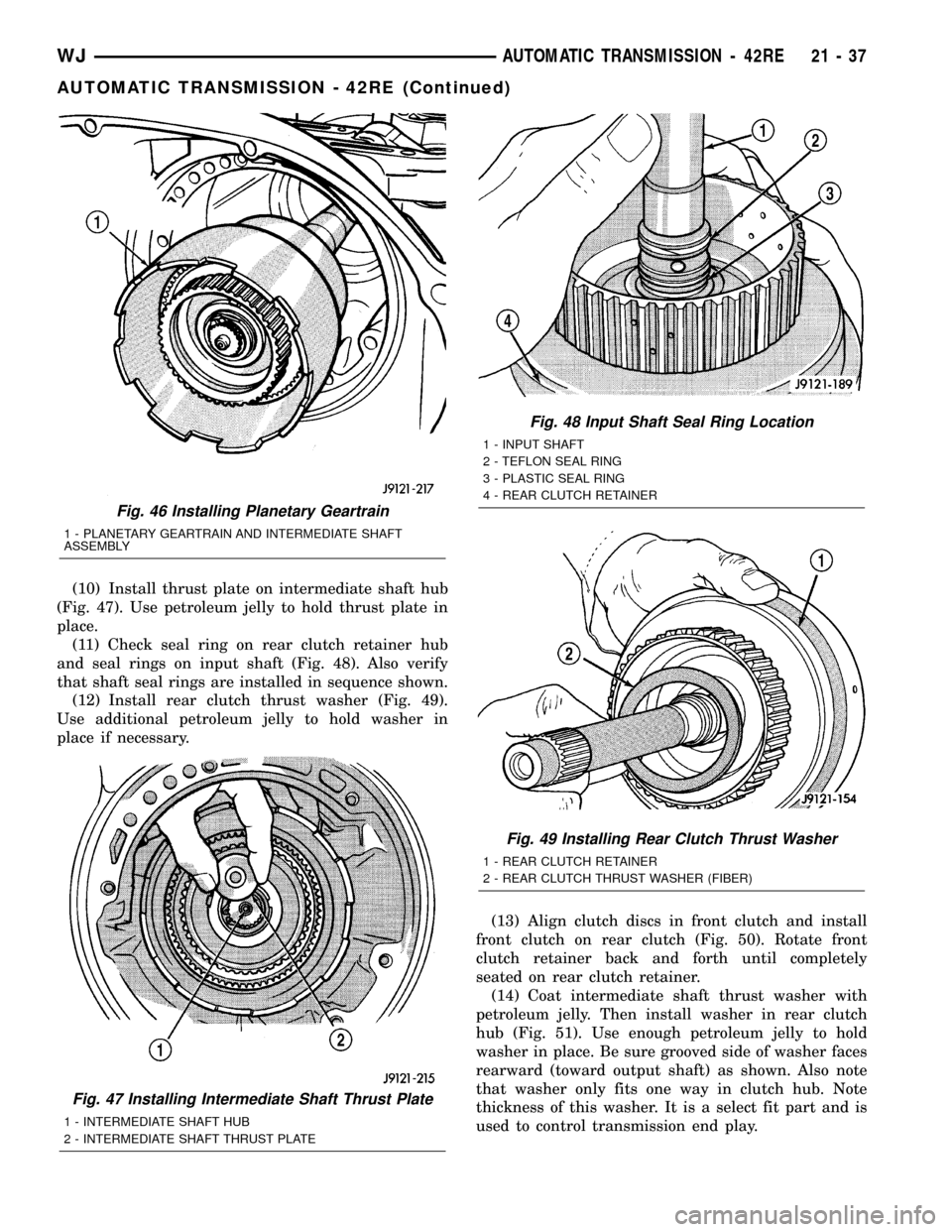

(10) Install thrust plate on intermediate shaft hub

(Fig. 47). Use petroleum jelly to hold thrust plate in

place.

(11) Check seal ring on rear clutch retainer hub

and seal rings on input shaft (Fig. 48). Also verify

that shaft seal rings are installed in sequence shown.

(12) Install rear clutch thrust washer (Fig. 49).

Use additional petroleum jelly to hold washer in

place if necessary.

(13) Align clutch discs in front clutch and install

front clutch on rear clutch (Fig. 50). Rotate front

clutch retainer back and forth until completely

seated on rear clutch retainer.

(14) Coat intermediate shaft thrust washer with

petroleum jelly. Then install washer in rear clutch

hub (Fig. 51). Use enough petroleum jelly to hold

washer in place. Be sure grooved side of washer faces

rearward (toward output shaft) as shown. Also note

that washer only fits one way in clutch hub. Note

thickness of this washer. It is a select fit part and is

used to control transmission end play.

Fig. 46 Installing Planetary Geartrain

1 - PLANETARY GEARTRAIN AND INTERMEDIATE SHAFT

ASSEMBLY

Fig. 47 Installing Intermediate Shaft Thrust Plate

1 - INTERMEDIATE SHAFT HUB

2 - INTERMEDIATE SHAFT THRUST PLATE

Fig. 48 Input Shaft Seal Ring Location

1 - INPUT SHAFT

2 - TEFLON SEAL RING

3 - PLASTIC SEAL RING

4 - REAR CLUTCH RETAINER

Fig. 49 Installing Rear Clutch Thrust Washer

1 - REAR CLUTCH RETAINER

2 - REAR CLUTCH THRUST WASHER (FIBER)

WJAUTOMATIC TRANSMISSION - 42RE 21 - 37

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1581 of 2199

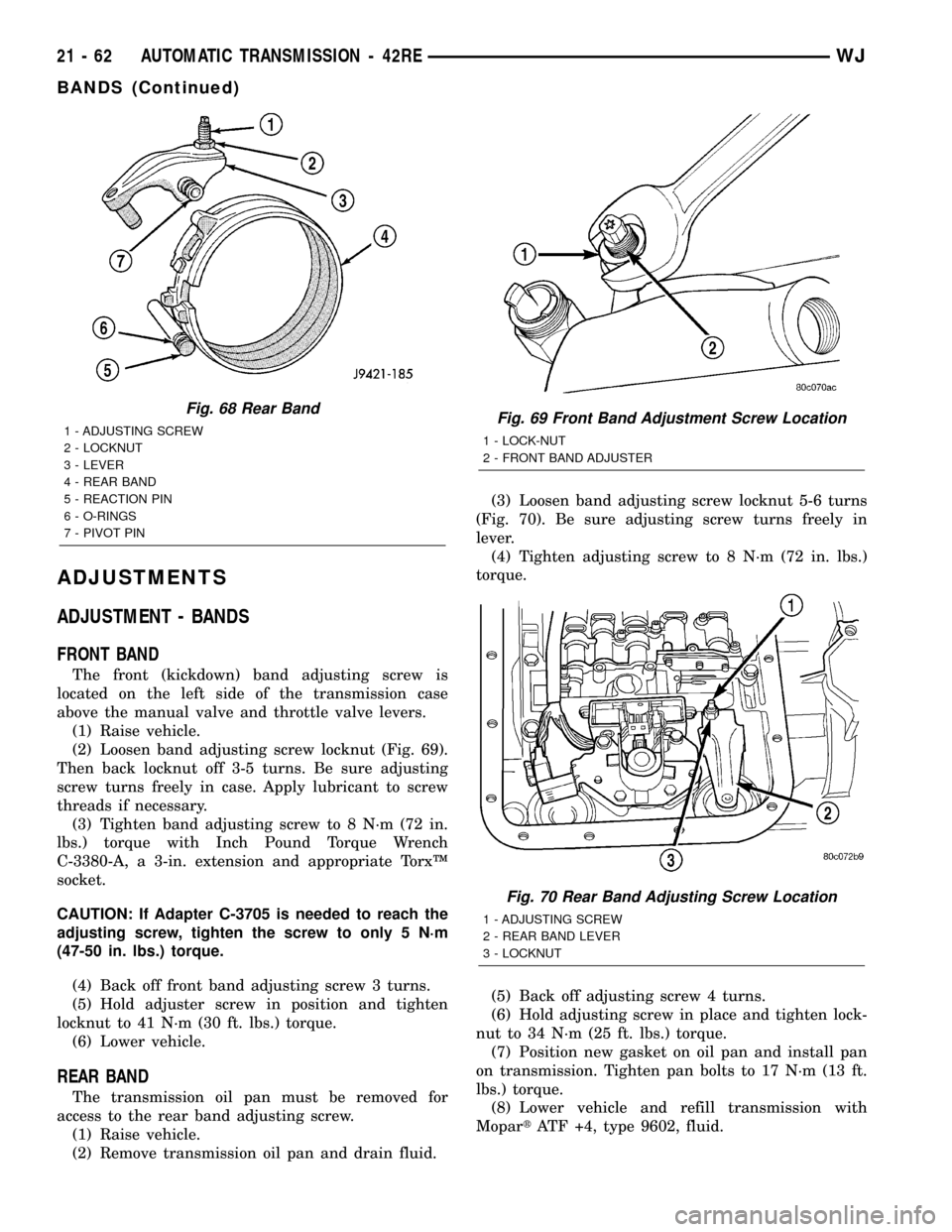

ADJUSTMENTS

ADJUSTMENT - BANDS

FRONT BAND

The front (kickdown) band adjusting screw is

located on the left side of the transmission case

above the manual valve and throttle valve levers.

(1) Raise vehicle.

(2) Loosen band adjusting screw locknut (Fig. 69).

Then back locknut off 3-5 turns. Be sure adjusting

screw turns freely in case. Apply lubricant to screw

threads if necessary.

(3) Tighten band adjusting screw to 8 N´m (72 in.

lbs.) torque with Inch Pound Torque Wrench

C-3380-A, a 3-in. extension and appropriate TorxŸ

socket.

CAUTION: If Adapter C-3705 is needed to reach the

adjusting screw, tighten the screw to only 5 N´m

(47-50 in. lbs.) torque.

(4) Back off front band adjusting screw 3 turns.

(5) Hold adjuster screw in position and tighten

locknut to 41 N´m (30 ft. lbs.) torque.

(6) Lower vehicle.

REAR BAND

The transmission oil pan must be removed for

access to the rear band adjusting screw.

(1) Raise vehicle.

(2) Remove transmission oil pan and drain fluid.(3) Loosen band adjusting screw locknut 5-6 turns

(Fig. 70). Be sure adjusting screw turns freely in

lever.

(4) Tighten adjusting screw to 8 N´m (72 in. lbs.)

torque.

(5) Back off adjusting screw 4 turns.

(6) Hold adjusting screw in place and tighten lock-

nut to 34 N´m (25 ft. lbs.) torque.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 17 N´m (13 ft.

lbs.) torque.

(8) Lower vehicle and refill transmission with

MopartATF +4, type 9602, fluid.

Fig. 68 Rear Band

1 - ADJUSTING SCREW

2 - LOCKNUT

3 - LEVER

4 - REAR BAND

5 - REACTION PIN

6 - O-RINGS

7 - PIVOT PINFig. 69 Front Band Adjustment Screw Location

1 - LOCK-NUT

2 - FRONT BAND ADJUSTER

Fig. 70 Rear Band Adjusting Screw Location

1 - ADJUSTING SCREW

2 - REAR BAND LEVER

3 - LOCKNUT

21 - 62 AUTOMATIC TRANSMISSION - 42REWJ

BANDS (Continued)

Page 1595 of 2199

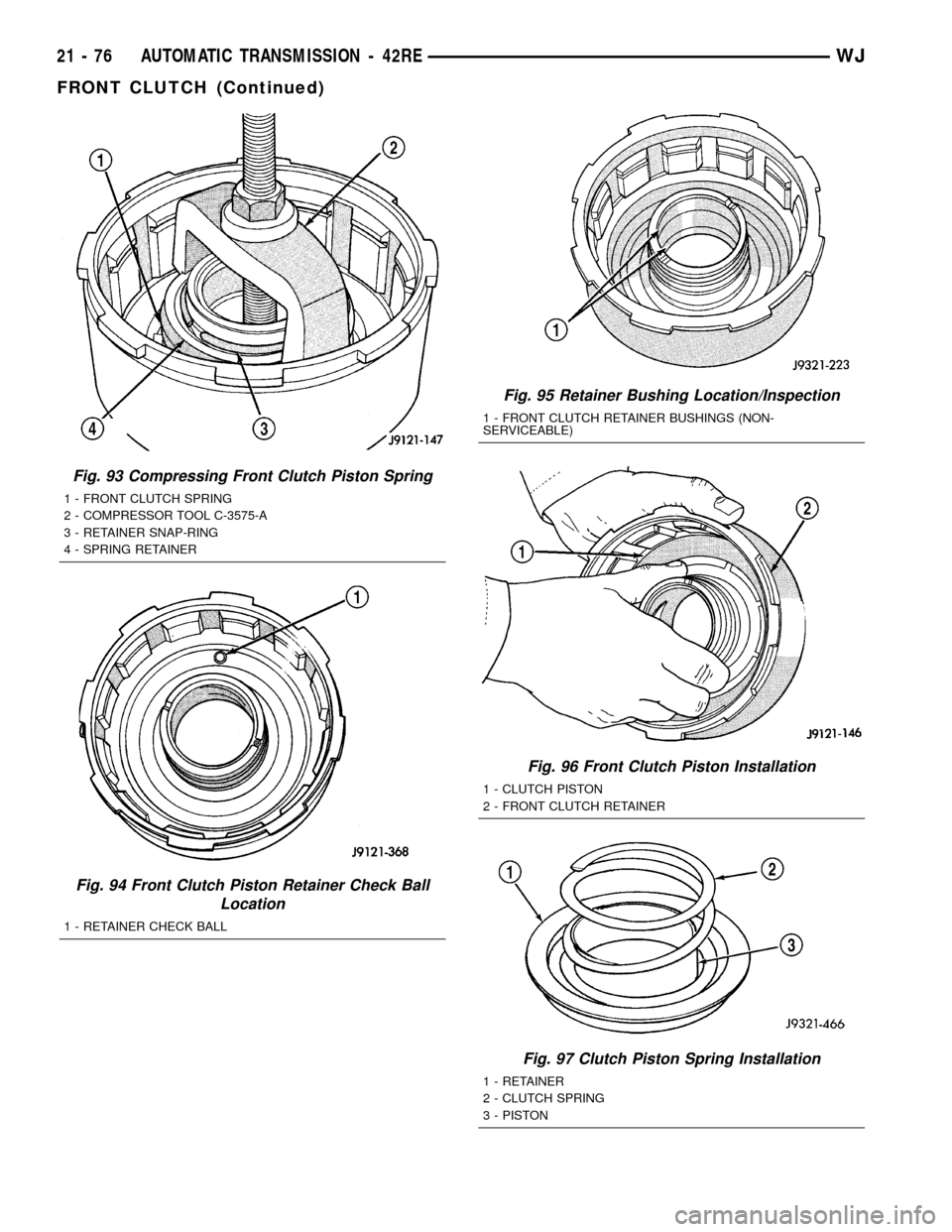

Fig. 93 Compressing Front Clutch Piston Spring

1 - FRONT CLUTCH SPRING

2 - COMPRESSOR TOOL C-3575-A

3 - RETAINER SNAP-RING

4 - SPRING RETAINER

Fig. 94 Front Clutch Piston Retainer Check Ball

Location

1 - RETAINER CHECK BALL

Fig. 95 Retainer Bushing Location/Inspection

1 - FRONT CLUTCH RETAINER BUSHINGS (NON-

SERVICEABLE)

Fig. 96 Front Clutch Piston Installation

1 - CLUTCH PISTON

2 - FRONT CLUTCH RETAINER

Fig. 97 Clutch Piston Spring Installation

1 - RETAINER

2 - CLUTCH SPRING

3 - PISTON

21 - 76 AUTOMATIC TRANSMISSION - 42REWJ

FRONT CLUTCH (Continued)

Page 1607 of 2199

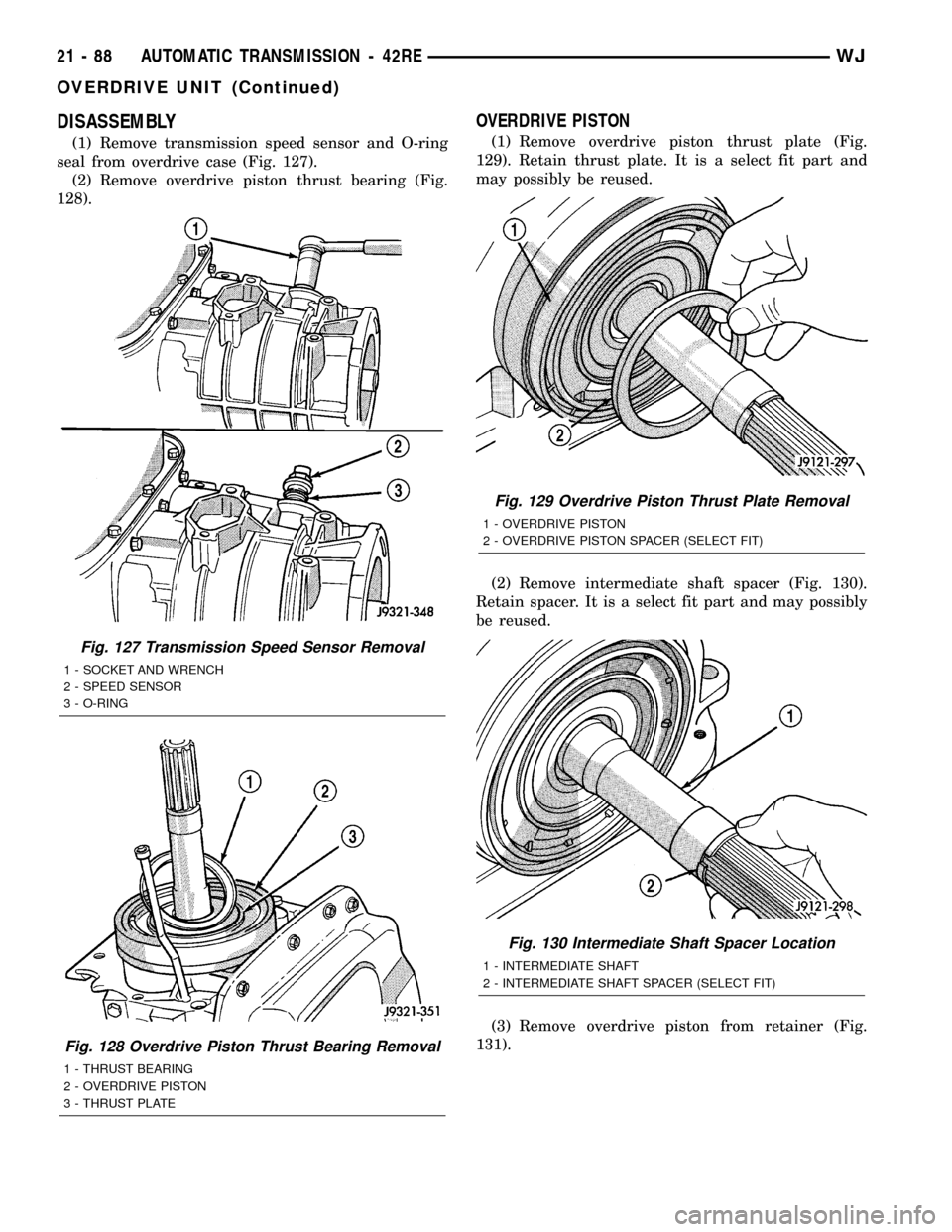

DISASSEMBLY

(1) Remove transmission speed sensor and O-ring

seal from overdrive case (Fig. 127).

(2) Remove overdrive piston thrust bearing (Fig.

128).

OVERDRIVE PISTON

(1) Remove overdrive piston thrust plate (Fig.

129). Retain thrust plate. It is a select fit part and

may possibly be reused.

(2) Remove intermediate shaft spacer (Fig. 130).

Retain spacer. It is a select fit part and may possibly

be reused.

(3) Remove overdrive piston from retainer (Fig.

131).

Fig. 127 Transmission Speed Sensor Removal

1 - SOCKET AND WRENCH

2 - SPEED SENSOR

3 - O-RING

Fig. 128 Overdrive Piston Thrust Bearing Removal

1 - THRUST BEARING

2 - OVERDRIVE PISTON

3 - THRUST PLATE

Fig. 129 Overdrive Piston Thrust Plate Removal

1 - OVERDRIVE PISTON

2 - OVERDRIVE PISTON SPACER (SELECT FIT)

Fig. 130 Intermediate Shaft Spacer Location

1 - INTERMEDIATE SHAFT

2 - INTERMEDIATE SHAFT SPACER (SELECT FIT)

21 - 88 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1624 of 2199

CAUTION: Be sure the shoulder on the inside diam-

eter of the bearing is facing forward.

(8) Verify that splines in overdrive planetary gear

and overrunning clutch hub are aligned with Align-

ment Tool 6227-2. Overdrive unit cannot be installed

if splines are not aligned. If splines have rotated out

of alignment, unit will have to be disassembled to

realign splines.

(9) Carefully slide Alignment Tool 6227-2 out of

overdrive planetary gear and overrunning clutch

splines.

(10) Raise overdrive unit and carefully slide it

straight onto intermediate shaft. Insert park rod into

park lock reaction plug at same time. Avoid tilting

overdrive during installation as this could cause

planetary gear and overrunning clutch splines to

rotate out of alignment. If this occurs, it will be nec-essary to remove and disassemble overdrive unit to

realign splines.

(11) Work overdrive unit forward on intermediate

shaft until seated against transmission case.

(12) Install bolts attaching overdrive unit to trans-

mission unit. Tighten bolts in diagonal pattern to 34

N´m (25 ft-lbs).

(13) Connect the transmission speed sensor and

overdrive wiring connectors.

(14) Install the transfer case, if equipped.

(15) Align and install rear propeller shaft, if nec-

essary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION)

OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER

DESCRIPTION

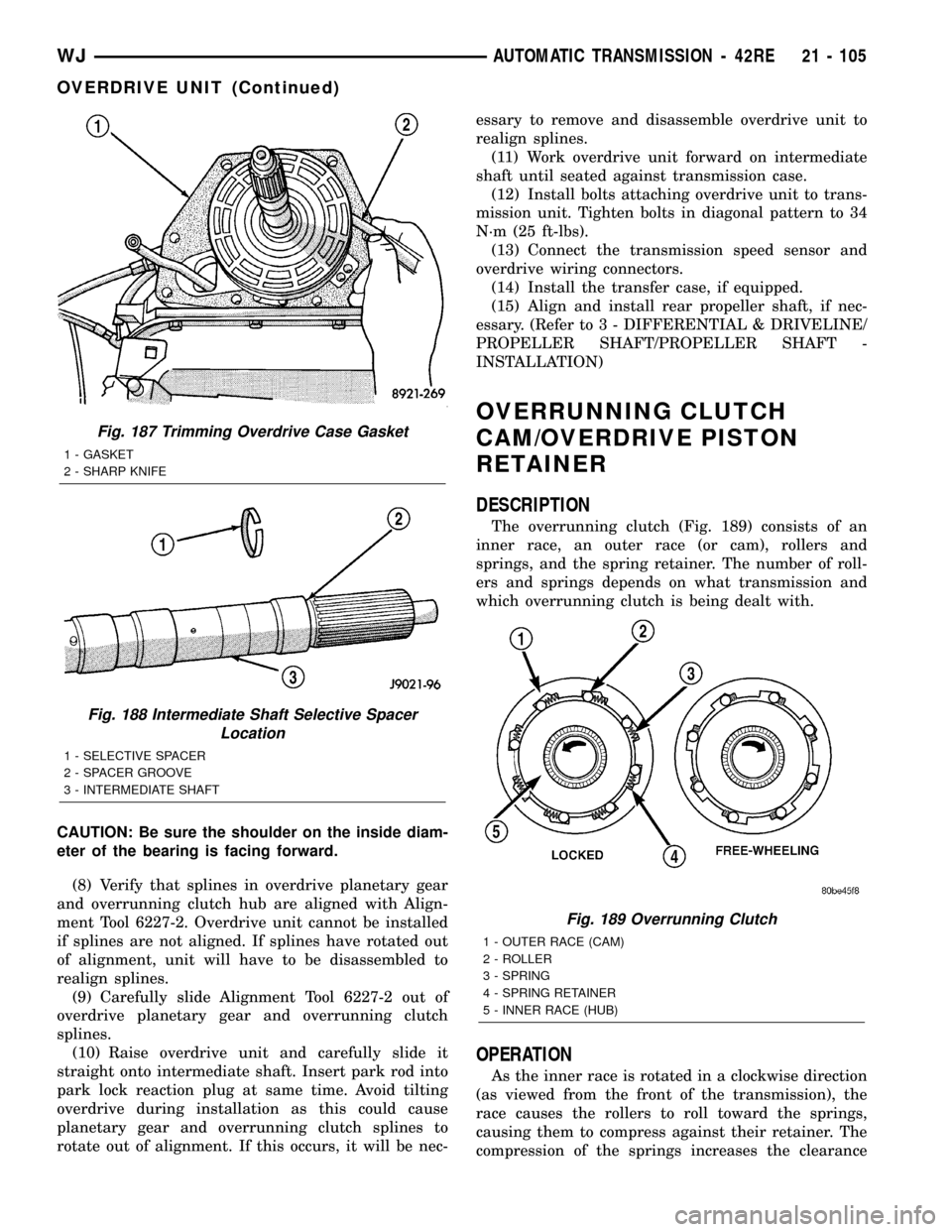

The overrunning clutch (Fig. 189) consists of an

inner race, an outer race (or cam), rollers and

springs, and the spring retainer. The number of roll-

ers and springs depends on what transmission and

which overrunning clutch is being dealt with.

OPERATION

As the inner race is rotated in a clockwise direction

(as viewed from the front of the transmission), the

race causes the rollers to roll toward the springs,

causing them to compress against their retainer. The

compression of the springs increases the clearance

Fig. 187 Trimming Overdrive Case Gasket

1 - GASKET

2 - SHARP KNIFE

Fig. 188 Intermediate Shaft Selective Spacer

Location

1 - SELECTIVE SPACER

2 - SPACER GROOVE

3 - INTERMEDIATE SHAFT

Fig. 189 Overrunning Clutch

1 - OUTER RACE (CAM)

2 - ROLLER

3 - SPRING

4 - SPRING RETAINER

5 - INNER RACE (HUB)

WJAUTOMATIC TRANSMISSION - 42RE 21 - 105

OVERDRIVE UNIT (Continued)

Page 1625 of 2199

between the rollers and cam. This increased clear-

ance between the rollers and cam results in a free-

wheeling condition. When the inner race attempts to

rotate counterclockwise, the action causes the rollers

to roll in the same direction as the race, aided by the

pushing of the springs. As the rollers try to move in

the same direction as the inner race, they are

wedged between the inner and outer races due to the

design of the cam. In this condition, the clutch is

locked and acts as one unit.

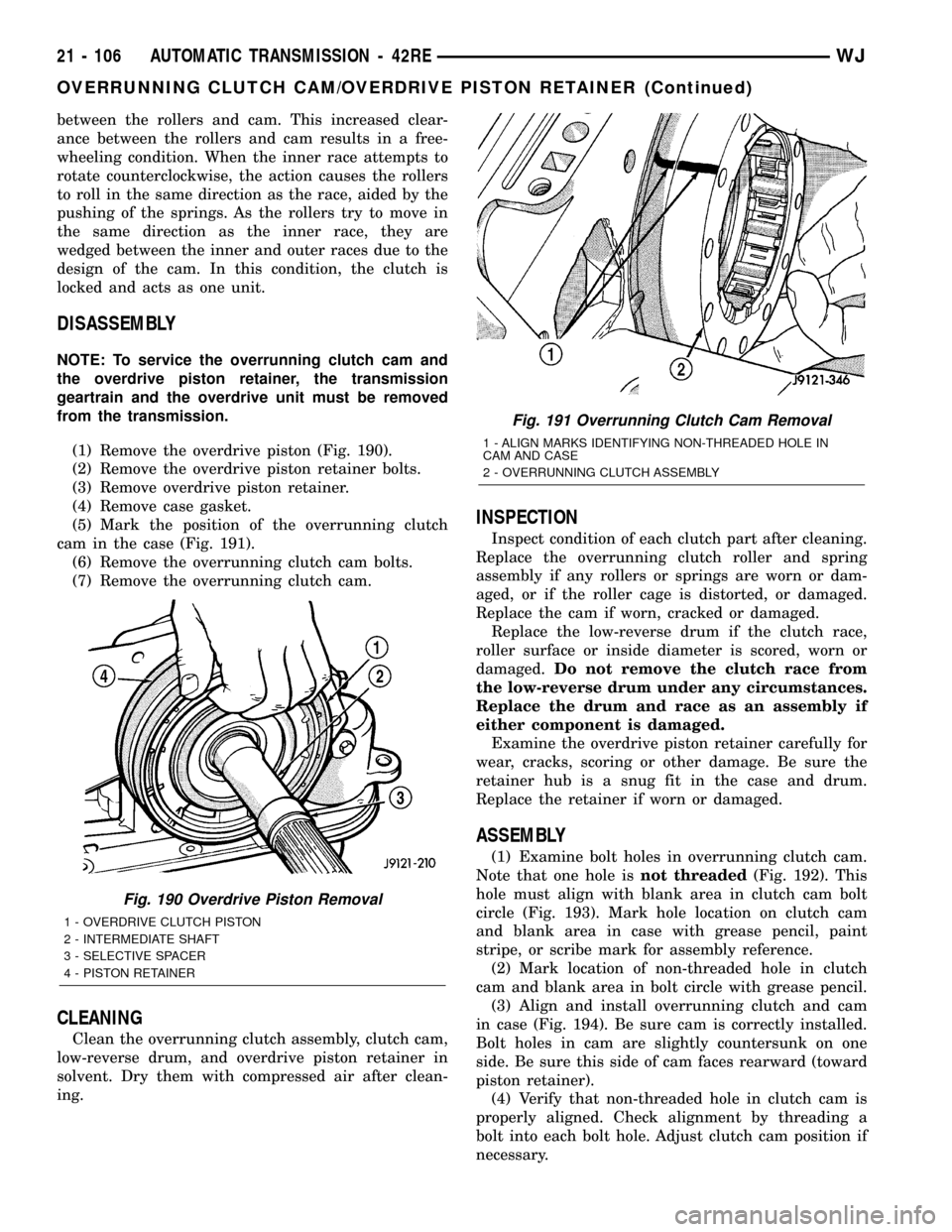

DISASSEMBLY

NOTE: To service the overrunning clutch cam and

the overdrive piston retainer, the transmission

geartrain and the overdrive unit must be removed

from the transmission.

(1) Remove the overdrive piston (Fig. 190).

(2) Remove the overdrive piston retainer bolts.

(3) Remove overdrive piston retainer.

(4) Remove case gasket.

(5) Mark the position of the overrunning clutch

cam in the case (Fig. 191).

(6) Remove the overrunning clutch cam bolts.

(7) Remove the overrunning clutch cam.

CLEANING

Clean the overrunning clutch assembly, clutch cam,

low-reverse drum, and overdrive piston retainer in

solvent. Dry them with compressed air after clean-

ing.

INSPECTION

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring

assembly if any rollers or springs are worn or dam-

aged, or if the roller cage is distorted, or damaged.

Replace the cam if worn, cracked or damaged.

Replace the low-reverse drum if the clutch race,

roller surface or inside diameter is scored, worn or

damaged.Do not remove the clutch race from

the low-reverse drum under any circumstances.

Replace the drum and race as an assembly if

either component is damaged.

Examine the overdrive piston retainer carefully for

wear, cracks, scoring or other damage. Be sure the

retainer hub is a snug fit in the case and drum.

Replace the retainer if worn or damaged.

ASSEMBLY

(1) Examine bolt holes in overrunning clutch cam.

Note that one hole isnot threaded(Fig. 192). This

hole must align with blank area in clutch cam bolt

circle (Fig. 193). Mark hole location on clutch cam

and blank area in case with grease pencil, paint

stripe, or scribe mark for assembly reference.

(2) Mark location of non-threaded hole in clutch

cam and blank area in bolt circle with grease pencil.

(3) Align and install overrunning clutch and cam

in case (Fig. 194). Be sure cam is correctly installed.

Bolt holes in cam are slightly countersunk on one

side. Be sure this side of cam faces rearward (toward

piston retainer).

(4) Verify that non-threaded hole in clutch cam is

properly aligned. Check alignment by threading a

bolt into each bolt hole. Adjust clutch cam position if

necessary.

Fig. 190 Overdrive Piston Removal

1 - OVERDRIVE CLUTCH PISTON

2 - INTERMEDIATE SHAFT

3 - SELECTIVE SPACER

4 - PISTON RETAINER

Fig. 191 Overrunning Clutch Cam Removal

1 - ALIGN MARKS IDENTIFYING NON-THREADED HOLE IN

CAM AND CASE

2 - OVERRUNNING CLUTCH ASSEMBLY

21 - 106 AUTOMATIC TRANSMISSION - 42REWJ

OVERRUNNING CLUTCH CAM/OVERDRIVE PISTON RETAINER (Continued)

Page 1626 of 2199

(5) Install and tighten overrunning clutch cam

bolts to 17 N´m (13 ft. lbs.) torque. Note that clutch

cam bolts are shorter than piston retainer bolts.

(6) Install new gasket at rear of transmission case.

Use petroleum jelly to hold gasket in place. Be sure

to align governor feed holes in gasket with feed pas-

sages in case (Fig. 195). Also install gasket before

overdrive piston retainer. Center hole in gasket is

smaller than retainer and cannot be installed over

retainer.(7) Position overdrive piston retainer on transmis-

sion case and align bolt holes in retainer, gasket and

case (Fig. 196). Then install and tighten retainer

bolts to 17 N´m (13 ft. lbs.) torque.

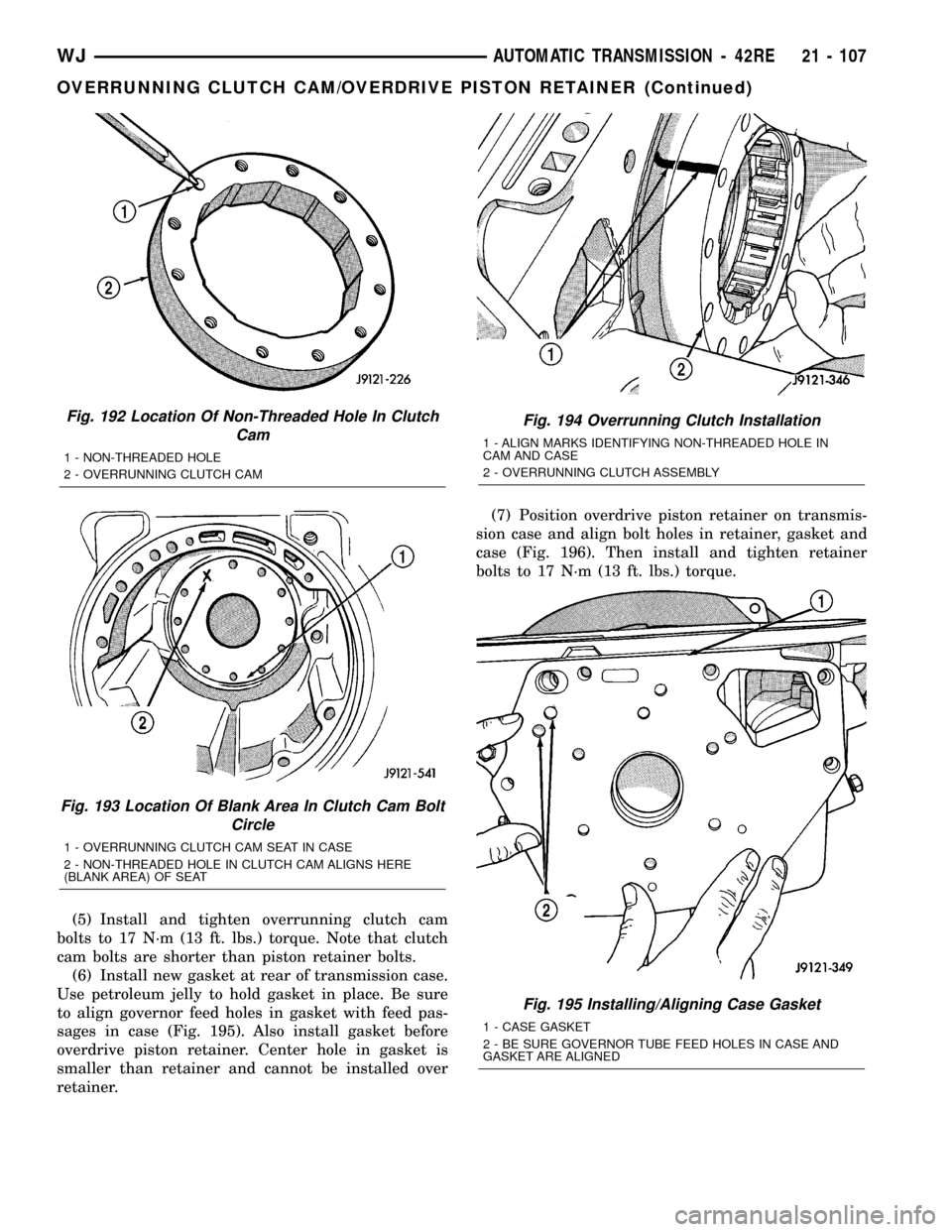

Fig. 192 Location Of Non-Threaded Hole In Clutch

Cam

1 - NON-THREADED HOLE

2 - OVERRUNNING CLUTCH CAM

Fig. 193 Location Of Blank Area In Clutch Cam Bolt

Circle

1 - OVERRUNNING CLUTCH CAM SEAT IN CASE

2 - NON-THREADED HOLE IN CLUTCH CAM ALIGNS HERE

(BLANK AREA) OF SEAT

Fig. 194 Overrunning Clutch Installation

1 - ALIGN MARKS IDENTIFYING NON-THREADED HOLE IN

CAM AND CASE

2 - OVERRUNNING CLUTCH ASSEMBLY

Fig. 195 Installing/Aligning Case Gasket

1 - CASE GASKET

2 - BE SURE GOVERNOR TUBE FEED HOLES IN CASE AND

GASKET ARE ALIGNED

WJAUTOMATIC TRANSMISSION - 42RE 21 - 107

OVERRUNNING CLUTCH CAM/OVERDRIVE PISTON RETAINER (Continued)

Page 1632 of 2199

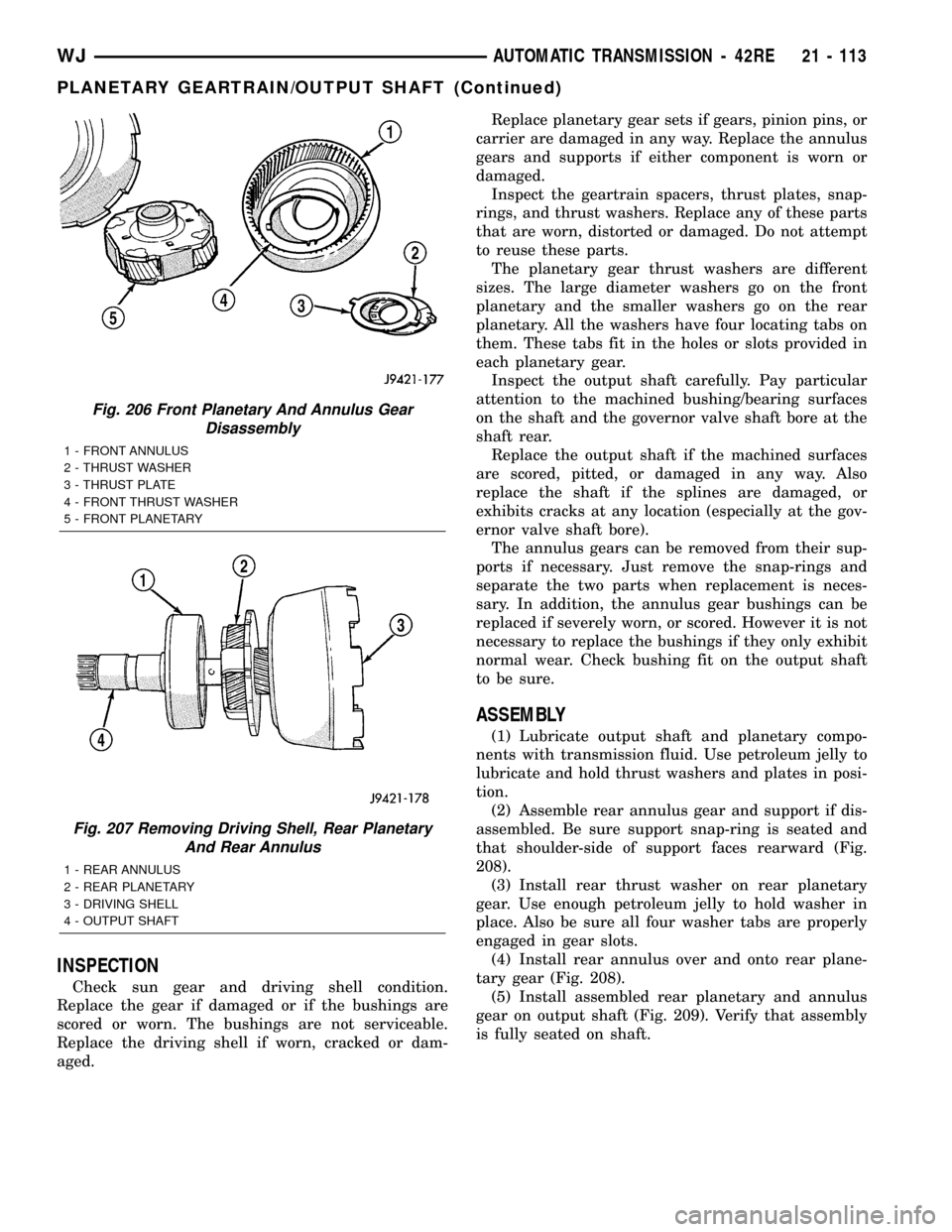

INSPECTION

Check sun gear and driving shell condition.

Replace the gear if damaged or if the bushings are

scored or worn. The bushings are not serviceable.

Replace the driving shell if worn, cracked or dam-

aged.Replace planetary gear sets if gears, pinion pins, or

carrier are damaged in any way. Replace the annulus

gears and supports if either component is worn or

damaged.

Inspect the geartrain spacers, thrust plates, snap-

rings, and thrust washers. Replace any of these parts

that are worn, distorted or damaged. Do not attempt

to reuse these parts.

The planetary gear thrust washers are different

sizes. The large diameter washers go on the front

planetary and the smaller washers go on the rear

planetary. All the washers have four locating tabs on

them. These tabs fit in the holes or slots provided in

each planetary gear.

Inspect the output shaft carefully. Pay particular

attention to the machined bushing/bearing surfaces

on the shaft and the governor valve shaft bore at the

shaft rear.

Replace the output shaft if the machined surfaces

are scored, pitted, or damaged in any way. Also

replace the shaft if the splines are damaged, or

exhibits cracks at any location (especially at the gov-

ernor valve shaft bore).

The annulus gears can be removed from their sup-

ports if necessary. Just remove the snap-rings and

separate the two parts when replacement is neces-

sary. In addition, the annulus gear bushings can be

replaced if severely worn, or scored. However it is not

necessary to replace the bushings if they only exhibit

normal wear. Check bushing fit on the output shaft

to be sure.

ASSEMBLY

(1) Lubricate output shaft and planetary compo-

nents with transmission fluid. Use petroleum jelly to

lubricate and hold thrust washers and plates in posi-

tion.

(2) Assemble rear annulus gear and support if dis-

assembled. Be sure support snap-ring is seated and

that shoulder-side of support faces rearward (Fig.

208).

(3) Install rear thrust washer on rear planetary

gear. Use enough petroleum jelly to hold washer in

place. Also be sure all four washer tabs are properly

engaged in gear slots.

(4) Install rear annulus over and onto rear plane-

tary gear (Fig. 208).

(5) Install assembled rear planetary and annulus

gear on output shaft (Fig. 209). Verify that assembly

is fully seated on shaft.

Fig. 206 Front Planetary And Annulus Gear

Disassembly

1 - FRONT ANNULUS

2 - THRUST WASHER

3 - THRUST PLATE

4 - FRONT THRUST WASHER

5 - FRONT PLANETARY

Fig. 207 Removing Driving Shell, Rear Planetary

And Rear Annulus

1 - REAR ANNULUS

2 - REAR PLANETARY

3 - DRIVING SHELL

4 - OUTPUT SHAFT

WJAUTOMATIC TRANSMISSION - 42RE 21 - 113

PLANETARY GEARTRAIN/OUTPUT SHAFT (Continued)

Page 1650 of 2199

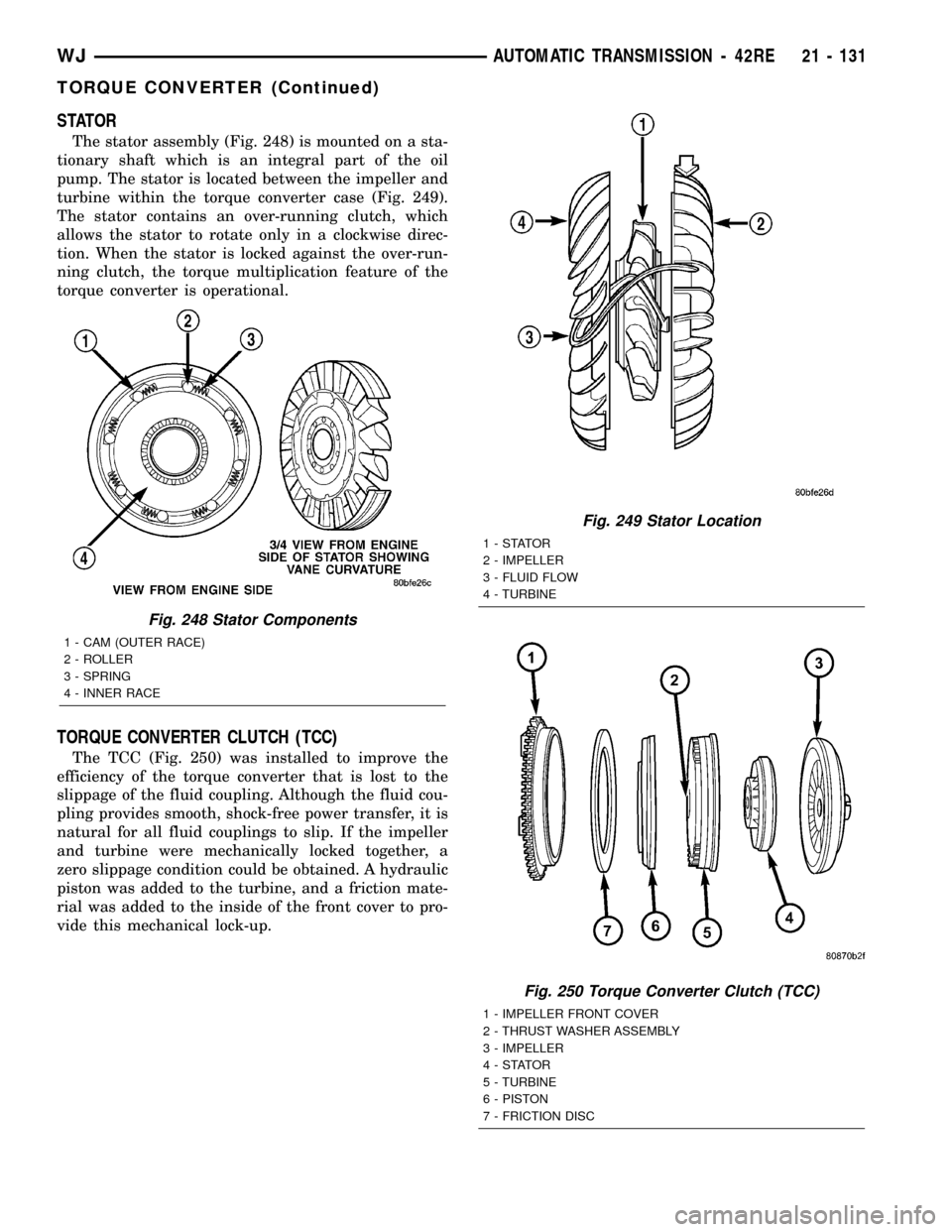

STATOR

The stator assembly (Fig. 248) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 249).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 250) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston was added to the turbine, and a friction mate-

rial was added to the inside of the front cover to pro-

vide this mechanical lock-up.

Fig. 248 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 249 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 250 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

WJAUTOMATIC TRANSMISSION - 42RE 21 - 131

TORQUE CONVERTER (Continued)