Ignition switch JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 317 of 2199

Frequency (RF) Remote Keyless Entry (RKE)

receiver. The DDM and PDM control and integrate

many functions and features of the vehicle through

both hard wired outputs and messages over the PCI

data bus. The functions and features that the door

modules support or control include the following:

²Automatic Door Lock- The two door modules

provide an automatic door lock feature which locks

the doors when the vehicle is moving. This is a pro-

grammable feature.

²Automatic Door Unlock On Exit- The two

door modules provide an automatic door unlock on

exit feature. This feature will unlock all the doors if

they were locked via the automatic door lock feature

after the vehicle has stopped moving and the driver

door is opened. This is a programmable feature via

the EVIC.

²Customer Programmable Features- Each

door module provides support for certain customer

programmable features that are monitored on the

PCI bus.

²Cylinder Lock Switch Status- The DDM

monitors and transmits the status of the cylinder

lock switch on the driver side front door lock cylin-

der.

²Door Courtesy Lamp Control- Each door

module provides control of its own optional front

door-mounted courtesy lamp.

²Door Lock Inhibit- Each door module pro-

vides a door lock inhibit feature which prevents the

doors from being locked with a power lock switch ifthe key was left in the ignition and a front door is

open.

²Express-Down Window- The DDM provides

an express-down feature for the driver side front door

window only.

²Extended Window Operation- Both door

modules provide an extended power window opera-

tion feature that allows operation of the power win-

dows for 45 seconds following ignition Off or until a

front door is opened.

²Front Door Ajar Switch Status- Each door

module monitors and transmits the status of its own

front door ajar switch.

²Heated Mirrors- Each door module provides

control for its own optional heated outside rear view

mirror.

²Illuminated Entry- Each door module sup-

ports an illuminated entry feature through its own

optional front door-mounted courtesy lamp.

²Memory Mirrors- Each door module provides

control for its own optional memory outside rear view

mirror.

²Memory Switch- The DDM monitors the sta-

tus of the optional memory switch and controls the

illumination of the memory switch ªsetº Light Emit-

ting Diode (LED) indicator and illumination lamps.

²Memory System- The DDM transmits memory

set and recall messages based upon inputs from the

memory switch. If the optional RKE linked to mem-

ory feature is enabled, the DDM will also transmit

memory recall messages based upon memory

requests received from the Remote Keyless Entry

(RKE) system in the PDM. Certain memory system

features are programmable.

²Power Foldaway Mirrors - Export Only-

Each door module provides support for the optional

power foldaway outside mirrors. The DDM also

houses the control switch for this system.

²Power Lock Control- The DDM provides con-

trol for the driver side front door power lock motor,

while the PDM provides control for the power lock

motors of the three remaining doors and the liftgate.

²Power Lock Switch Status- Each door mod-

ule monitors and transmits the status of its own inte-

gral power lock switch.

²Power Window Control- Each door module

provides control for both the front and rear door

power window motors and the rear door power win-

dow switches on the same side of the vehicle.

²Power Window Switch Status- The DDM

monitors and transmits the status of its integral pas-

senger side front and rear power window switches.

²Remote Keyless Entry- The PDM monitors

and transmits the status of the Remote Keyless

Entry (RKE) system and provides support for the

RKE Lock (with the optional horn chirp and park

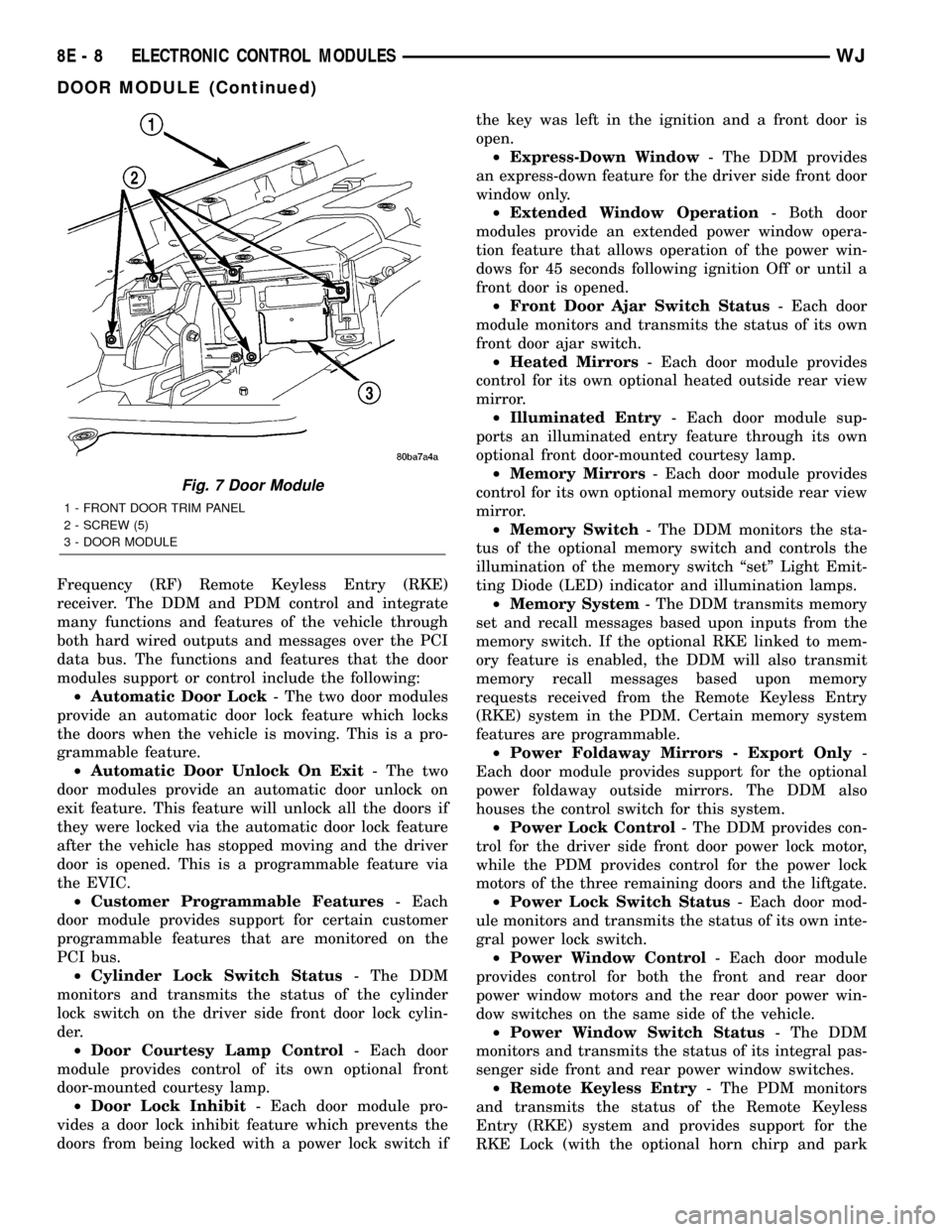

Fig. 7 Door Module

1 - FRONT DOOR TRIM PANEL

2 - SCREW (5)

3 - DOOR MODULE

8E - 8 ELECTRONIC CONTROL MODULESWJ

DOOR MODULE (Continued)

Page 318 of 2199

lamp flash features), Unlock with the optional RKE

unlock, and Panic Mode functions. The optional RKE

features are programmable.

²Switch Illumination- Each door module pro-

vides control of the power window and power lock

switch illumination for the front and rear doors on

the same side of the vehicle. The DDM provides con-

trol of the power mirror switch illumination.

²Window Lockout- The DDM monitors and

transmits the status of its integral window lockout

switch to provide the power window lockout feature

and coordinate power window switch knob illumina-

tion.

The door modules are serviced only as complete

units. Many of the features in the vehicle controlled

or supported by the door modules are programmable

using either the Electronic Vehicle Information Cen-

ter (EVIC) user interface, or the DRBIIItscan tool. If

a door module is damaged or faulty, the entire door

module unit must be replaced.

OPERATION

The microprocessor-based DDM and PDM hard-

ware and software monitors integral and hard wired

external switch inputs as well as those resources it

shares with other electronic modules in the vehicle

through its communication over the PCI data bus

network. The internal programming and all of these

inputs allow the DDM or PDM microprocessor to

determine the tasks it needs to perform and their

priorities, as well as both the standard and optional

features that it should provide.

The DDM and PDM are powered by a fused bat-

tery circuit so that they can operate regardless of the

ignition switch position. The DDM and PDM cir-

cuitry is grounded to the chassis beneath the front

seat.

The DDM and PDM can be diagnosed using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

HARD WIRED INPUTS

The hard wired inputs to the door modules include

the following:

²Door ajar switch sense

²Driver door key cylinder switch sense (DDM)

²Fused B(+)

²Ground

²Memory switch mux (DDM)

²Mirror horizontal position signal

²Mirror vertical position signal

²PCI bus

HARD WIRED OUTPUTS

The hard wired outputs of the door modules

include the following:

²Courtesy lamp driver

²Courtesy lamp ground

²Diagnostic out (DDM)

²Door/liftgate lock driver

²Door/liftgate unlock driver

²Door switch illumination (rear power window)

²Front window driver (down)

²Front window driver (up)

²Memory set indicator driver (DDM)

²Memory switch return (DDM)

²Mirror common driver

²Mirror heater ground

²Mirror heater 12V supply

²Rear window driver (down)

²Rear window driver (up)

²Mirror horizontal driver

²Mirror sensor ground

²Mirror vertical driver

²PCI bus

²Switch illumination driver (memory - DDM)

MESSAGING

The door modules use the following messages

received from other electronic modules over the PCI

data bus:

²Accessory Delay Control (PDM)

²Courtesy Lamp Status (BCM)

²Door Ajar Status/Rear Doors (BCM)

²Door Lock Status (DDM/PDM)

²Ignition Switch Position (BCM)

²Key-In Ignition Status (BCM)

²Programmable Features Preferences/Auto Lock/

Auto Unlock/RKE Unlock Sequence/RKE Link to

Memory (EVIC)

²Memory Recall (DDM)

²Rear Window Defogger Relay Status (BCM)

²Vehicle Speed (PCM)

The door modules provide the following messages

to other electronic modules over the PCI data bus:

²Cylinder Lock Switch Status (BCM)

²Door Ajar Status/Front Doors (BCM/DDM/PDM)

²Door Lock Status (DDM/PDM)

²Memory Recall (PDM/MHSM/MSM/Radio)

²Memory Set Switch Status (PDM/MHSM/MSM/

Radio)

²Panic Control (BCM)

²Power Window Switch Status (PDM)

²RKE Status (BCM/DDM)

²Window Lockout Switch Status (PDM)

WJELECTRONIC CONTROL MODULES 8E - 9

DOOR MODULE (Continued)

Page 321 of 2199

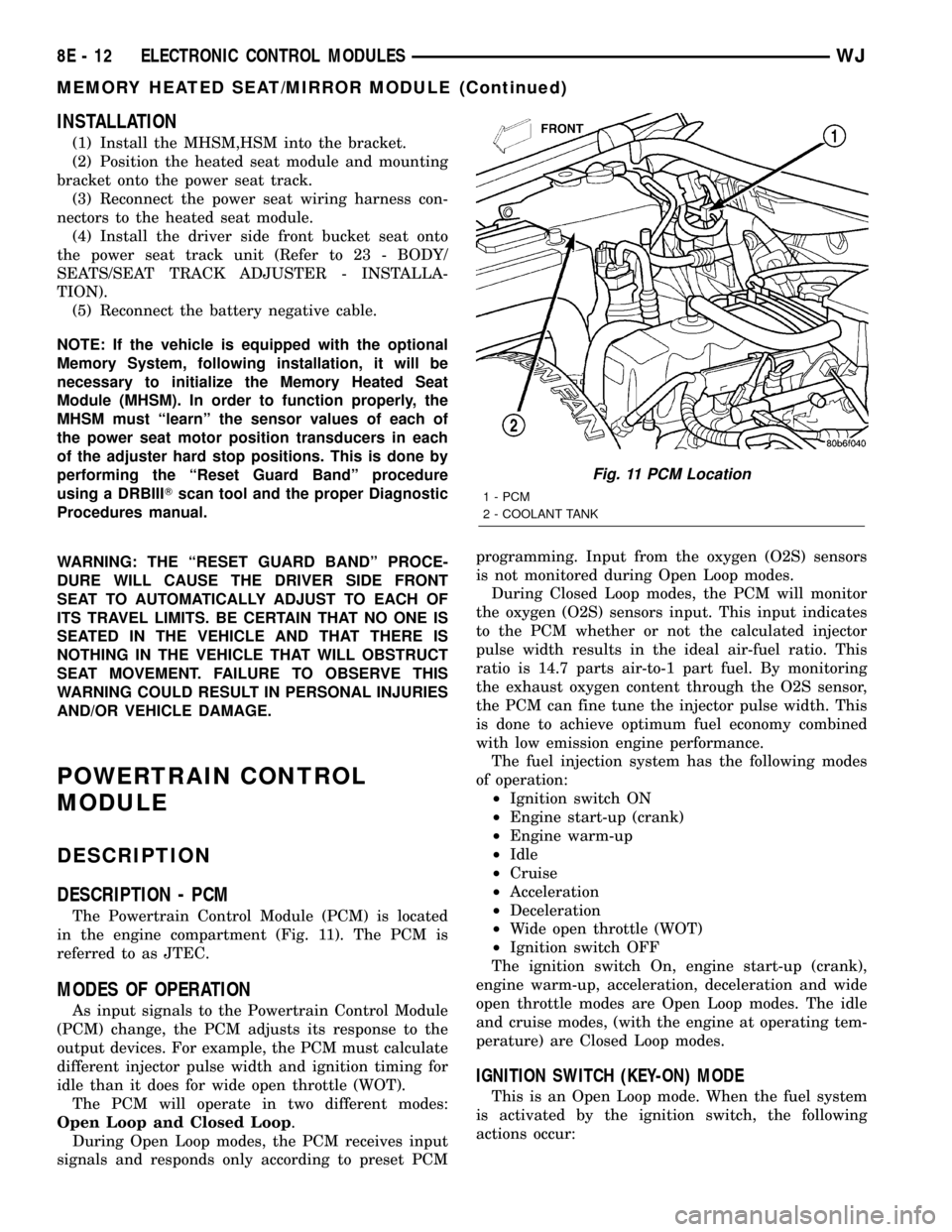

INSTALLATION

(1) Install the MHSM,HSM into the bracket.

(2) Position the heated seat module and mounting

bracket onto the power seat track.

(3) Reconnect the power seat wiring harness con-

nectors to the heated seat module.

(4) Install the driver side front bucket seat onto

the power seat track unit (Refer to 23 - BODY/

SEATS/SEAT TRACK ADJUSTER - INSTALLA-

TION).

(5) Reconnect the battery negative cable.

NOTE: If the vehicle is equipped with the optional

Memory System, following installation, it will be

necessary to initialize the Memory Heated Seat

Module (MHSM). In order to function properly, the

MHSM must ªlearnº the sensor values of each of

the power seat motor position transducers in each

of the adjuster hard stop positions. This is done by

performing the ªReset Guard Bandº procedure

using a DRBIIITscan tool and the proper Diagnostic

Procedures manual.

WARNING: THE ªRESET GUARD BANDº PROCE-

DURE WILL CAUSE THE DRIVER SIDE FRONT

SEAT TO AUTOMATICALLY ADJUST TO EACH OF

ITS TRAVEL LIMITS. BE CERTAIN THAT NO ONE IS

SEATED IN THE VEHICLE AND THAT THERE IS

NOTHING IN THE VEHICLE THAT WILL OBSTRUCT

SEAT MOVEMENT. FAILURE TO OBSERVE THIS

WARNING COULD RESULT IN PERSONAL INJURIES

AND/OR VEHICLE DAMAGE.

POWERTRAIN CONTROL

MODULE

DESCRIPTION

DESCRIPTION - PCM

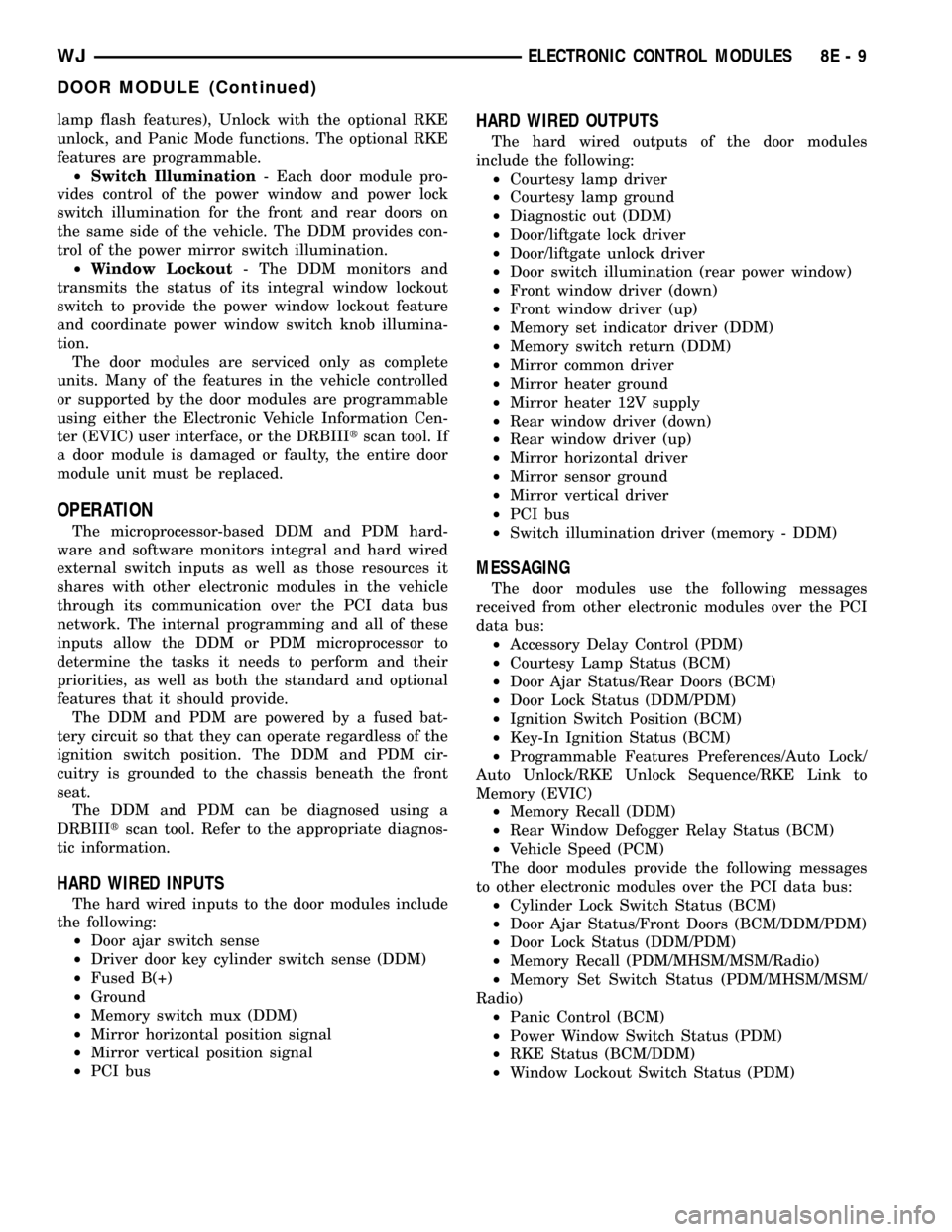

The Powertrain Control Module (PCM) is located

in the engine compartment (Fig. 11). The PCM is

referred to as JTEC.

MODES OF OPERATION

As input signals to the Powertrain Control Module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT).

The PCM will operate in two different modes:

Open Loop and Closed Loop.

During Open Loop modes, the PCM receives input

signals and responds only according to preset PCMprogramming. Input from the oxygen (O2S) sensors

is not monitored during Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensors input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON

²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following

actions occur:

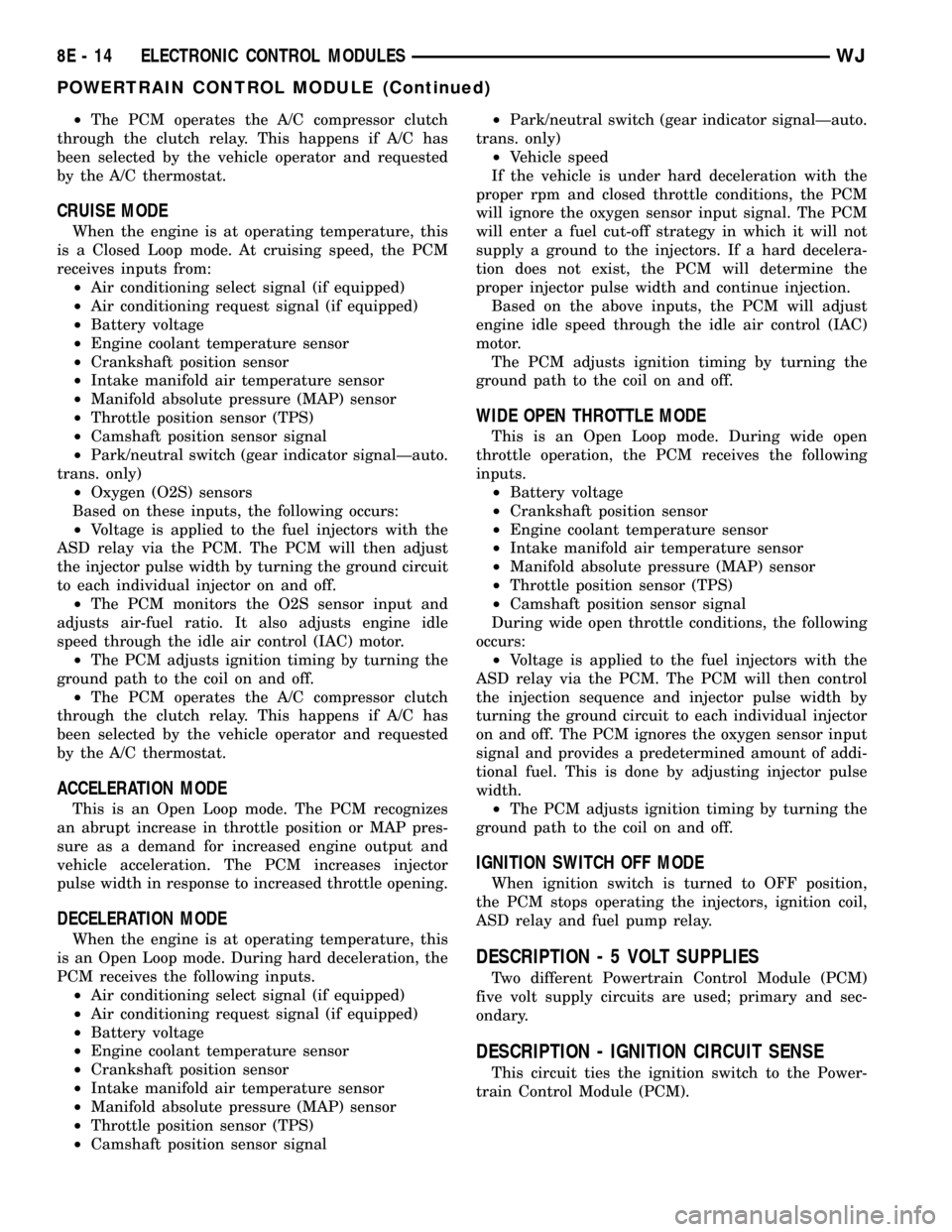

Fig. 11 PCM Location

1 - PCM

2 - COOLANT TANK

8E - 12 ELECTRONIC CONTROL MODULESWJ

MEMORY HEATED SEAT/MIRROR MODULE (Continued)

Page 322 of 2199

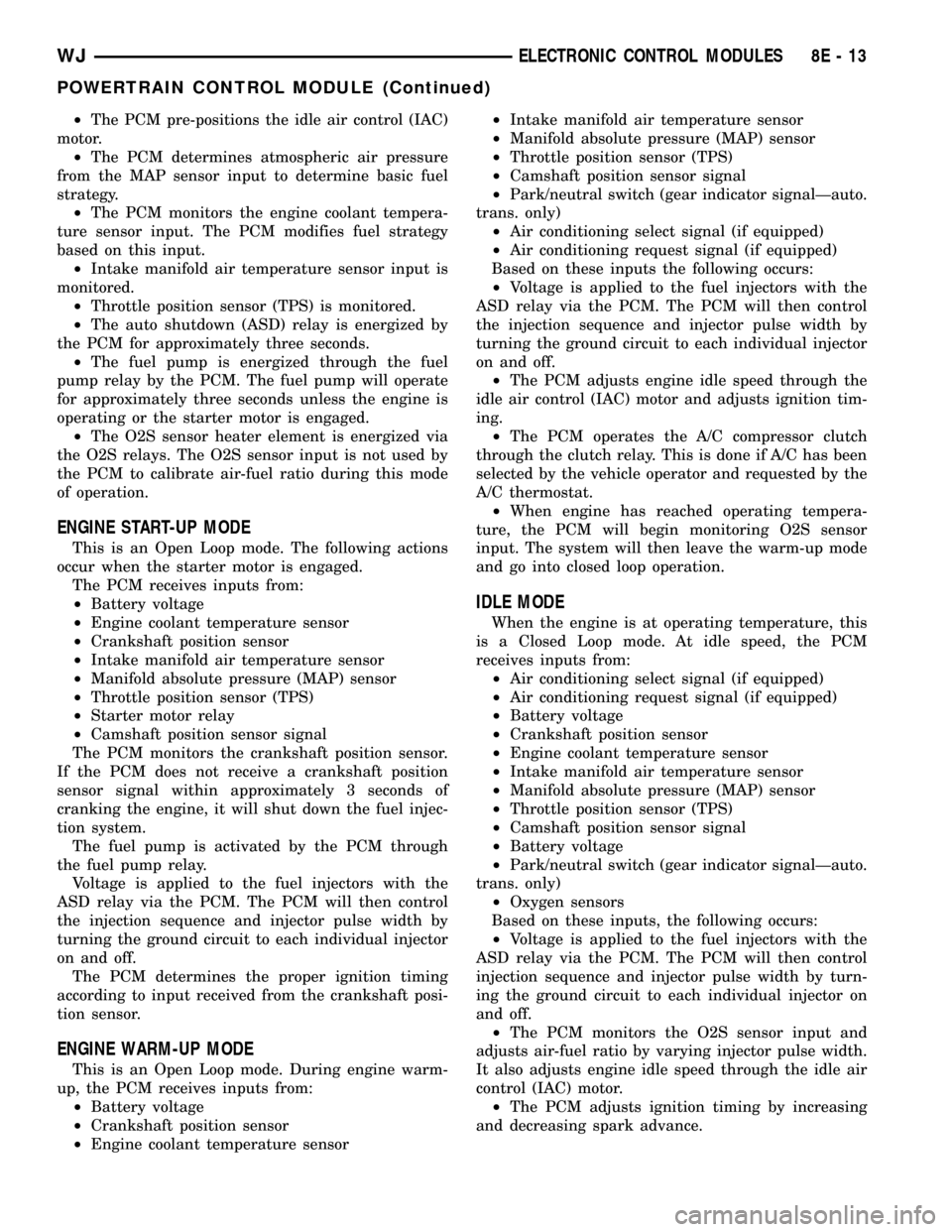

²The PCM pre-positions the idle air control (IAC)

motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant tempera-

ture sensor input. The PCM modifies fuel strategy

based on this input.

²Intake manifold air temperature sensor input is

monitored.

²Throttle position sensor (TPS) is monitored.

²The auto shutdown (ASD) relay is energized by

the PCM for approximately three seconds.

²The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

²The O2S sensor heater element is energized via

the O2S relays. The O2S sensor input is not used by

the PCM to calibrate air-fuel ratio during this mode

of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Starter motor relay

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within approximately 3 seconds of

cranking the engine, it will shut down the fuel injec-

tion system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

The PCM determines the proper ignition timing

according to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the PCM receives inputs from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

Based on these inputs the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

²The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim-

ing.

²The PCM operates the A/C compressor clutch

through the clutch relay. This is done if A/C has been

selected by the vehicle operator and requested by the

A/C thermostat.

²When engine has reached operating tempera-

ture, the PCM will begin monitoring O2S sensor

input. The system will then leave the warm-up mode

and go into closed loop operation.

IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Battery voltage

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

injection sequence and injector pulse width by turn-

ing the ground circuit to each individual injector on

and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio by varying injector pulse width.

It also adjusts engine idle speed through the idle air

control (IAC) motor.

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

WJELECTRONIC CONTROL MODULES 8E - 13

POWERTRAIN CONTROL MODULE (Continued)

Page 323 of 2199

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen (O2S) sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then adjust

the injector pulse width by turning the ground circuit

to each individual injector on and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio. It also adjusts engine idle

speed through the idle air control (IAC) motor.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The PCM recognizes

an abrupt increase in throttle position or MAP pres-

sure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector

pulse width in response to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

PCM receives the following inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Vehicle speed

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply a ground to the injectors. If a hard decelera-

tion does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust

engine idle speed through the idle air control (IAC)

motor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the PCM receives the following

inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off. The PCM ignores the oxygen sensor input

signal and provides a predetermined amount of addi-

tional fuel. This is done by adjusting injector pulse

width.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

DESCRIPTION - 5 VOLT SUPPLIES

Two different Powertrain Control Module (PCM)

five volt supply circuits are used; primary and sec-

ondary.

DESCRIPTION - IGNITION CIRCUIT SENSE

This circuit ties the ignition switch to the Power-

train Control Module (PCM).

8E - 14 ELECTRONIC CONTROL MODULESWJ

POWERTRAIN CONTROL MODULE (Continued)

Page 324 of 2199

DESCRIPTION - POWER GROUNDS

The Powertrain Control Module (PCM) has 2 main

grounds. Both of these grounds are referred to as

power grounds. All of the high-current, noisy, electri-

cal devices are connected to these grounds as well as

all of the sensor returns. The sensor return comes

into the sensor return circuit, passes through noise

suppression, and is then connected to the power

ground.

The power ground is used to control ground cir-

cuits for the following PCM loads:

²Generator field winding

²Fuel injectors

²Ignition coil(s)

²Certain relays/solenoids

²Certain sensors

DESCRIPTION - SENSOR RETURN

The Sensor Return circuits are internal to the Pow-

ertrain Control Module (PCM).

Sensor Return provides a low±noise ground refer-

ence for all engine control system sensors. Refer to

Power Grounds for more information.

OPERATION

OPERATION - PCM

(1) Also refer to Modes of Operation.

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital com-

puter. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro-

vide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant tem-

perature, throttle position, transmission gear selec-

tion (automatic transmission), vehicle speed and the

brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

²A/C request

²Auto shutdown (ASD) sense

²Battery temperature

²Battery voltage

²Brake switch

²J1850 bus circuits

²Camshaft position sensor signal

²Crankshaft position sensor

²Data link connections for DRB scan tool

²Engine coolant temperature sensor

²Five volts (primary)

²Five volts (secondary)

²Fuel level

²Generator (battery voltage) output

²Ignition circuit sense (ignition switch in on/off/

crank/run position)

²Intake manifold air temperature sensor

²Leak detection pump (switch) sense (if equipped)

²Manifold absolute pressure (MAP) sensor

²Oil pressure

²Overdrive/override switch

²Oxygen sensors

²Park/neutral switch (auto. trans. only)

²Power ground

²Sensor return

²Signal ground

²Speed control multiplexed single wire input

²Throttle position sensor

²Transmission governor pressure sensor

²Transmission temperature sensor

²Vehicle speed (from ABS module)

NOTE: PCM Outputs:

²A/C clutch relay

²Auto shutdown (ASD) relay

²J1850 (+/-) circuits for: speedometer, voltmeter,

fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRBIIItscan tool

²EGR valve control solenoid (if equipped)

²EVAP canister purge solenoid

²Fuel injectors

²Fuel pump relay

²Generator field driver (-)

²Generator field driver (+)

²Generator lamp (if equipped)

²Idle air control (IAC) motor

²Ignition coil

²Leak detection pump

WJELECTRONIC CONTROL MODULES 8E - 15

POWERTRAIN CONTROL MODULE (Continued)

Page 325 of 2199

²Malfunction indicator lamp (Check engine lamp).

Driven through J1850 circuits.

²Overdrive indicator lamp (if equipped). Driven

through J1850 circuits.

²Oxygen sensor heater relays (if equipped).

²Radiator cooling fan relay (pulse width modu-

lated)

²Speed control source

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped). Driven through J1850

circuits.

²Transmission convertor clutch circuit

²Transmission 3±4 shift solenoid

²Transmission relay

²Transmission temperature lamp (if equipped)

²Transmission variable force solenoid

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

²supplies a reference voltage for the Throttle

Position Sensor (TPS) sensor.

Secondary 5±volt supply:

²supplies the required 5 volt power source to the

oil pressure sensor.

²supplies the required 5 volt power source for the

Vehicle Speed Sensor (VSS) (if equipped).

²supplies the 5 volt power source to the transmis-

sion pressure sensor (if equipped with an RE auto-

matic transmission).

OPERATION - IGNITION CIRCUIT SENSE

The ignition circuit sense input tells the PCM the

ignition switch has energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the ignition switch when the ignition is in

the RUN or START position. This is referred to as

the9ignition sense9circuit and is used to9wake up9

the PCM.

REMOVAL

USE THE DRBIIItSCAN TOOL TO REPRO-

GRAM THE NEW POWERTRAIN CONTROL

MODULE (PCM) WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE VEHICLES ORIGINAL MILEAGE. IF THIS

STEP IS NOT DONE, A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

The PCM is located on the cowl panel in right/rear

side of engine compartment (Fig. 12).The PCM is located on the cowl panel in right/rear

side of engine compartment (Fig. 12).

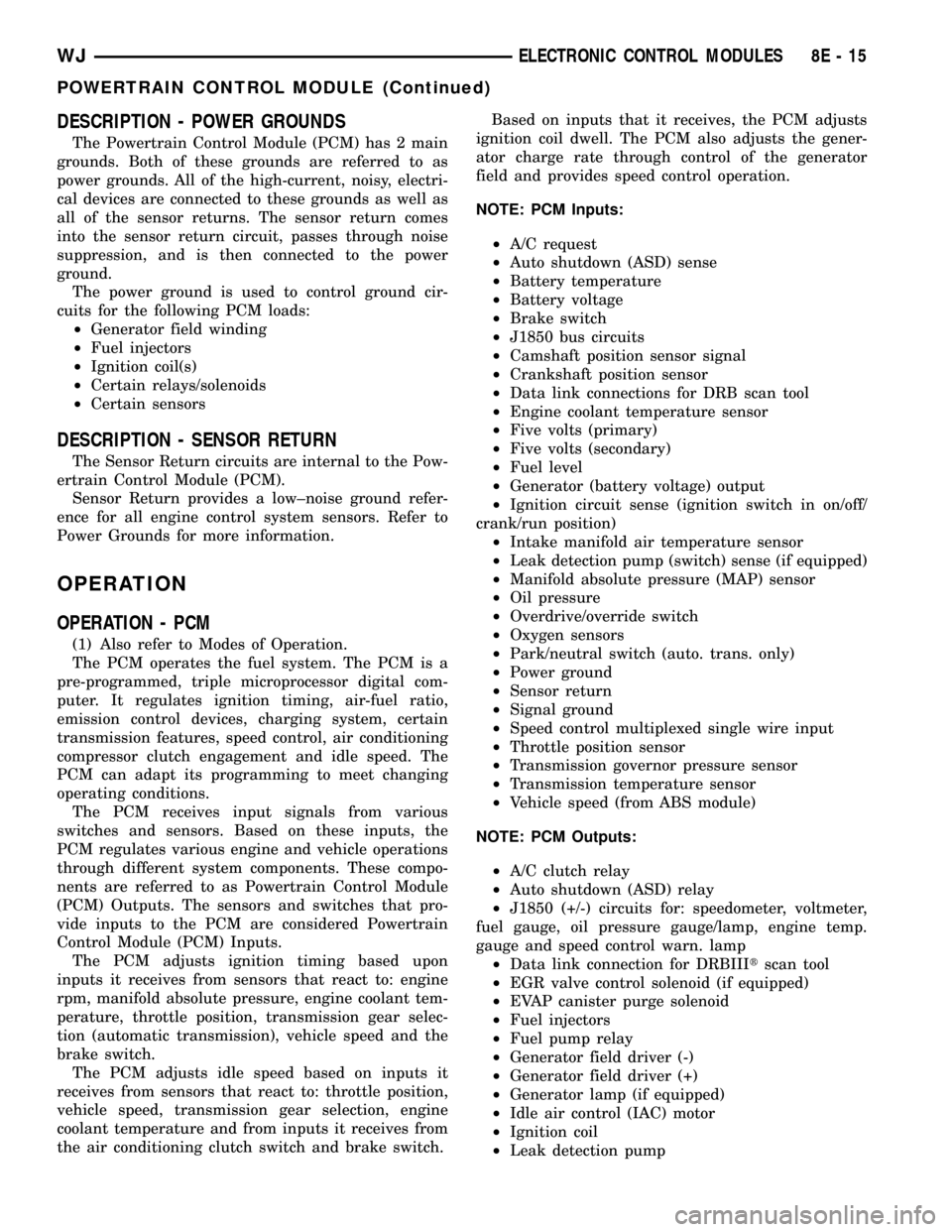

To avoid possible voltage spike damage to PCM,

ignition key must be off, and negative battery cable

must be disconnected before unplugging PCM connec-

tors.

(1) Disconnect negative battery cable at battery.

Fig. 12 Powertrain Control Module (PCM) Location

1 - PCM

2 - COOLANT TANK

Fig. 13 Powertrain Control Module (PCM) 32±Way

Connectors

1 - 3 32±WAY CONNECTORS

2 - PCM/BRACKET ASSEMBLY

3 - BRACKET NUTS (3)

8E - 16 ELECTRONIC CONTROL MODULESWJ

POWERTRAIN CONTROL MODULE (Continued)

Page 327 of 2199

sponder through a tuned antenna ring integral to the

SKIM housing. If this antenna ring is not mounted

properly around the ignition lock cylinder housing,

communication problems between the SKIM and the

transponder may arise. These communication prob-

lems will result in Sentry Key transponder-related

faults. The SKIM also communicates over the Pro-

grammable Communications Interface (PCI) data bus

with the Powertrain Control Module (PCM), the Elec-

troMechanical Instrument Cluster (EMIC), the Body

Control Module (BCM), and/or the DRBIIItscan tool.

The SKIM retains in memory the ID numbers of

any Sentry Key transponder that is programmed into

it. A maximum of eight transponders can be pro-

grammed into the SKIM. For added system security,

each SKIM is programmed with a unique Secret Key

code. This code is stored in memory, sent over the

PCI data bus to the PCM, and is encoded to the tran-

sponder of every Sentry Key that is programmed into

the SKIM. Another security code, called a PIN, is

used to gain access to the SKIM Secured Access

Mode. The Secured Access Mode is required during

service to perform the SKIS initialization and Sentry

Key transponder programming procedures. The

SKIM also stores the Vehicle Identification Number

(VIN) in its memory, which it learns through a PCI

data bus message from the PCM during SKIS initial-

ization.

In the event that a SKIM replacement is required,

the Secret Key code can be transferred to the new

SKIM from the PCM using the DRBIIItscan tool

and the SKIS replacement procedure. Proper comple-

tion of the SKIS initialization will allow the existing

Sentry Keys to be programmed into the new SKIM so

that new keys will not be required. In the event that

the original Secret Key code cannot be recovered,

SKIM replacement will also require new Sentry

Keys. The DRBIIItscan tool will alert the technician

during the SKIS replacement procedure if new Sen-

try Keys are required.

When the ignition switch is turned to the On posi-

tion, the SKIM transmits an RF signal to the tran-

sponder in the ignition key. The SKIM then waits for

an RF signal response from the transponder. If the

response received identifies the key as valid, the

SKIM sends a valid key message to the PCM over

the PCI data bus. If the response received identifies

the key as invalid, or if no response is received from

the key transponder, the SKIM sends an invalid key

message to the PCM. The PCM will enable or disable

engine operation based upon the status of the SKIM

messages. It is important to note that the default

condition in the PCM is an invalid key; therefore, if

no message is received from the SKIM by the PCM,

the engine will be disabled and the vehicle immobi-

lized after two seconds of running.The SKIM also sends indicator light status mes-

sages to the EMIC over the PCI data bus to tell the

EMIC how to operate the SKIS indicator. This indi-

cator light status message tells the EMIC to turn the

indicator on for about three seconds each time the

ignition switch is turned to the On position as a bulb

test. After completion of the bulb test, the SKIM

sends indicator light status messages to the EMIC to

turn the indicator off, turn the indicator on, or to

flash the indicator on and off. If the SKIS indicator

lamp flashes or stays on solid after the bulb test, it

signifies a SKIS fault. If the SKIM detects a system

malfunction and/or the SKIS has become inoperative,

the SKIS indicator will stay on solid. If the SKIM

detects an invalid key or if a key transponder-related

fault exists, the SKIS indicator will flash. If the vehi-

cle is equipped with the Customer Learn transponder

programming feature, the SKIM will also send mes-

sages to the EMIC to flash the SKIS indicator lamp,

and to the BCM to generate a single audible chime

tone whenever the Customer Learn programming

mode is being utilized. (Refer to 8 - ELECTRICAL/

VEHICLE THEFT SECURITY - STANDARD PRO-

CEDURE - SENTRY KEY TRANSPONDER

PROGRAMMING).

The SKIS performs a self-test each time the igni-

tion switch is turned to the On position, and will

store fault information in the form of Diagnostic

Trouble Codes (DTC's) in SKIM memory if a system

malfunction is detected. The SKIM can be diagnosed,

and any stored DTC's can be retrieved using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

8E - 18 ELECTRONIC CONTROL MODULESWJ

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 328 of 2199

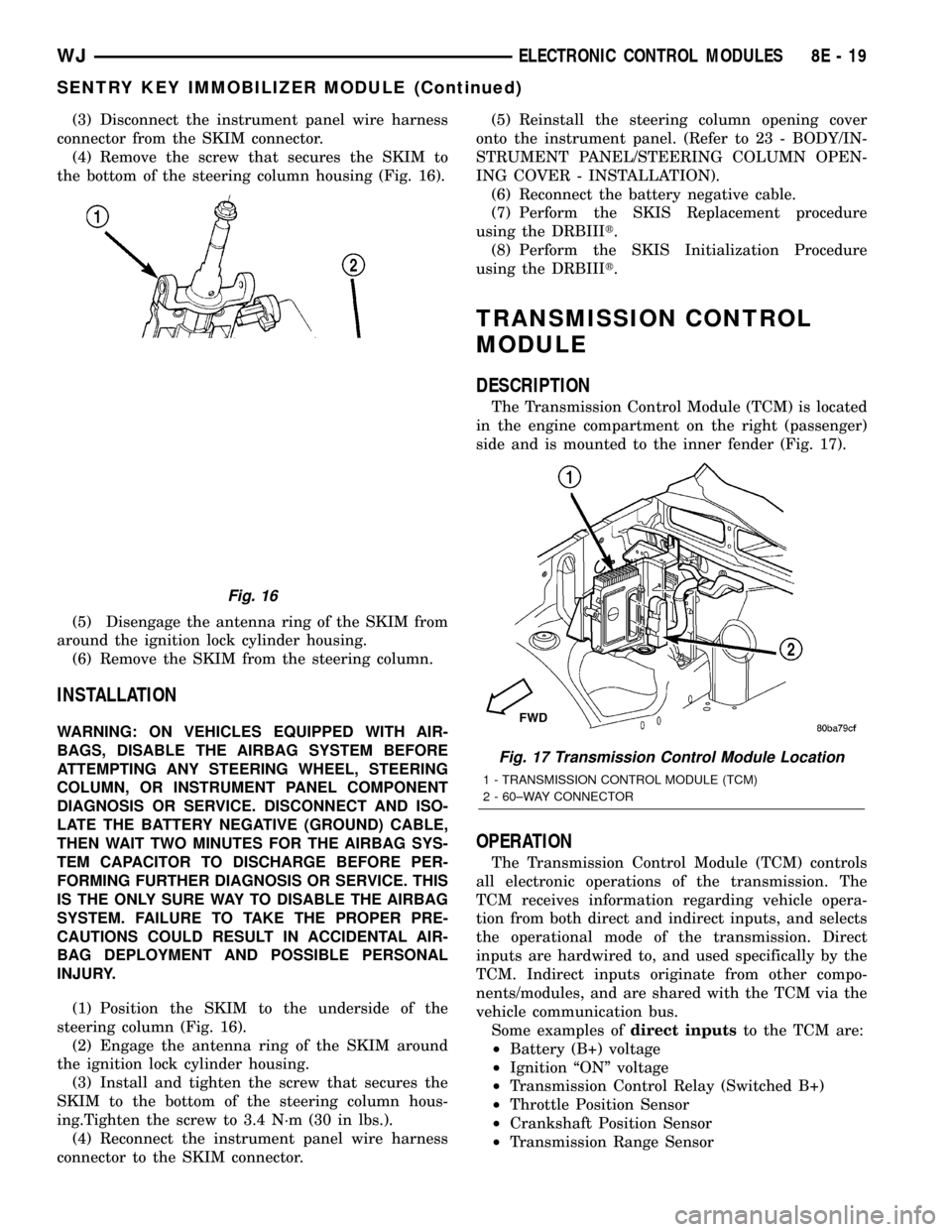

(3) Disconnect the instrument panel wire harness

connector from the SKIM connector.

(4) Remove the screw that secures the SKIM to

the bottom of the steering column housing (Fig. 16).

(5) Disengage the antenna ring of the SKIM from

around the ignition lock cylinder housing.

(6) Remove the SKIM from the steering column.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the SKIM to the underside of the

steering column (Fig. 16).

(2) Engage the antenna ring of the SKIM around

the ignition lock cylinder housing.

(3) Install and tighten the screw that secures the

SKIM to the bottom of the steering column hous-

ing.Tighten the screw to 3.4 N´m (30 in lbs.).

(4) Reconnect the instrument panel wire harness

connector to the SKIM connector.(5) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(6) Reconnect the battery negative cable.

(7) Perform the SKIS Replacement procedure

using the DRBIIIt.

(8) Perform the SKIS Initialization Procedure

using the DRBIIIt.

TRANSMISSION CONTROL

MODULE

DESCRIPTION

The Transmission Control Module (TCM) is located

in the engine compartment on the right (passenger)

side and is mounted to the inner fender (Fig. 17).

OPERATION

The Transmission Control Module (TCM) controls

all electronic operations of the transmission. The

TCM receives information regarding vehicle opera-

tion from both direct and indirect inputs, and selects

the operational mode of the transmission. Direct

inputs are hardwired to, and used specifically by the

TCM. Indirect inputs originate from other compo-

nents/modules, and are shared with the TCM via the

vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

Fig. 16

Fig. 17 Transmission Control Module Location

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - 60±WAY CONNECTOR

WJELECTRONIC CONTROL MODULES 8E - 19

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 344 of 2199

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.005 to 0.035 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to thirty-five milliamperes are needed to

enable the memory functions for the Powertrain Con-

trol Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.

A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the Power Distribution Center (PDC). This will

reduce battery discharging.Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes. See the Electronic Module Igni-

tion-Off Draw Table for more information.

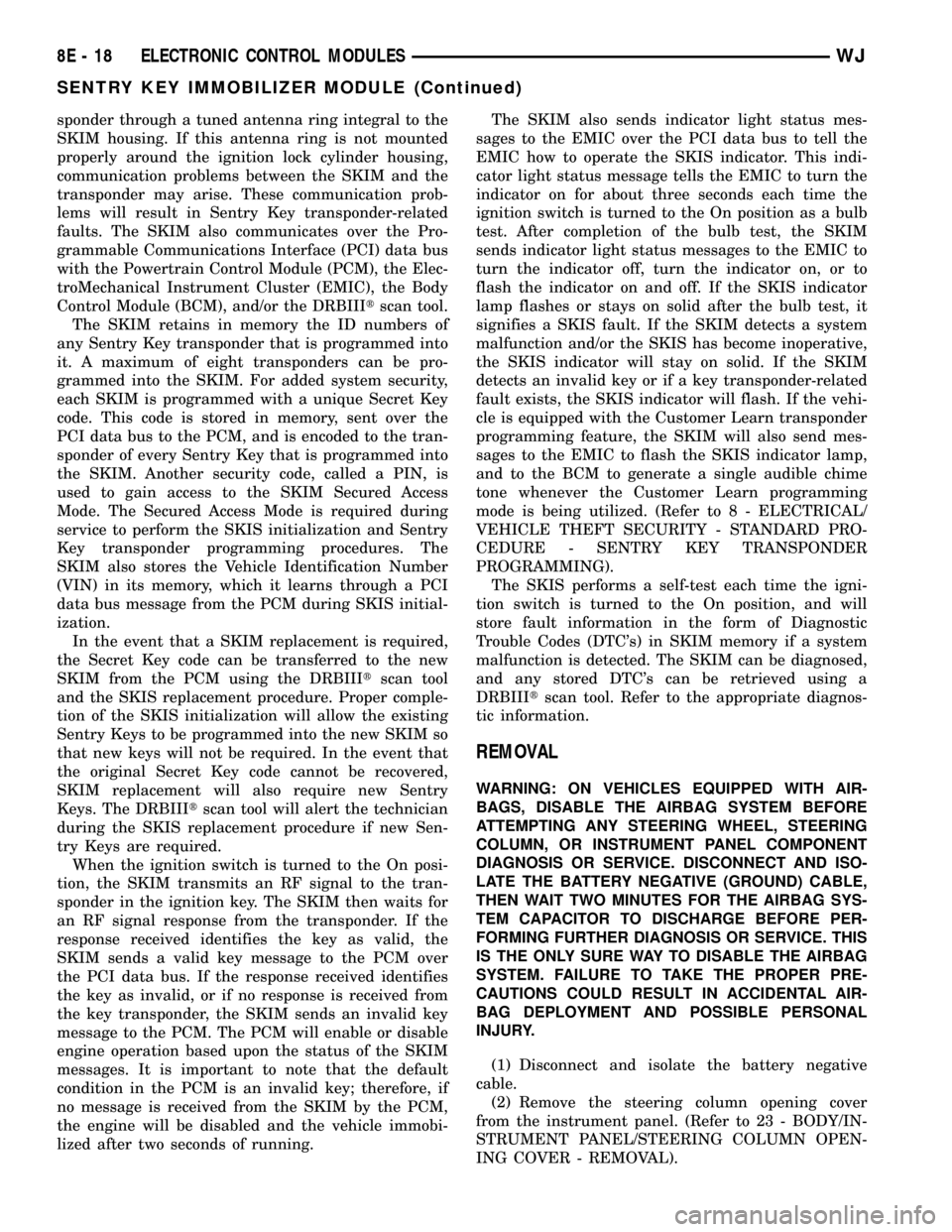

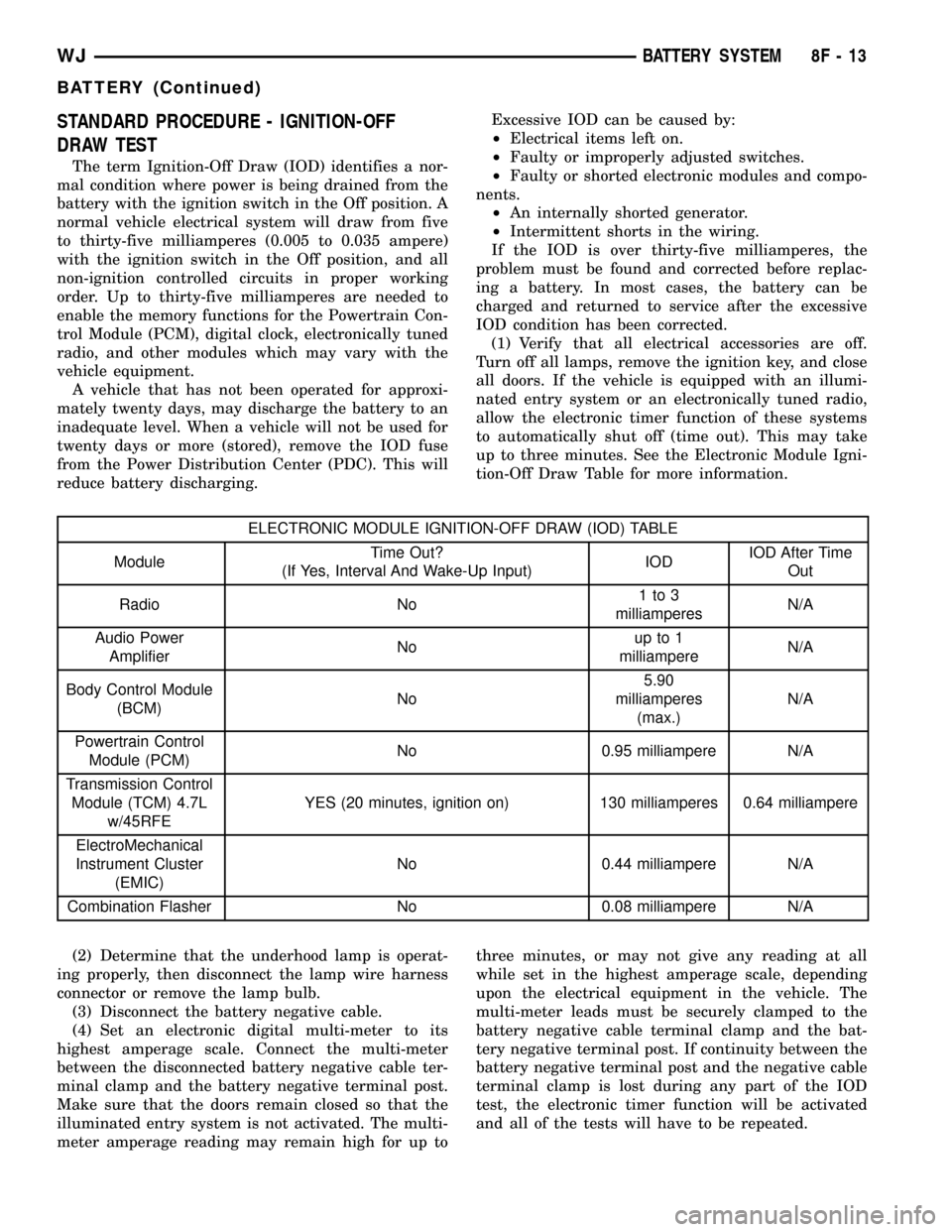

ELECTRONIC MODULE IGNITION-OFF DRAW (IOD) TABLE

ModuleTime Out?

(If Yes, Interval And Wake-Up Input)IODIOD After Time

Out

Radio No1to3

milliamperesN/A

Audio Power

AmplifierNoup to 1

milliampereN/A

Body Control Module

(BCM)No5.90

milliamperes

(max.)N/A

Powertrain Control

Module (PCM)No 0.95 milliampere N/A

Transmission Control

Module (TCM) 4.7L

w/45RFEYES (20 minutes, ignition on) 130 milliamperes 0.64 milliampere

ElectroMechanical

Instrument Cluster

(EMIC)No 0.44 milliampere N/A

Combination Flasher No 0.08 milliampere N/A

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect the lamp wire harness

connector or remove the lamp bulb.

(3) Disconnect the battery negative cable.

(4) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up tothree minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

WJBATTERY SYSTEM 8F - 13

BATTERY (Continued)