Cable JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1364 of 2199

²Cylinder head covers (Refer to 9 - ENGINE/

CYLINDER HEAD/CYLINDER HEAD COVER(S) -

INSTALLATION).

²Oil pan and gasket/windage tray. (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(11) Fill crankcase with proper engine oil to cor-

rect level.

(12) Connect negative cable to battery.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

Before reinstalling used rings or installing new

rings, the ring clearances must be checked.

(1) Wipe the cylinder bore clean.

(2) Insert the ring in the cylinder bore.

NOTE: The ring gap measurement must be made

with the ring positioned at least 12mm (0.50 inch.)

from bottom of cylinder bore.

(3) Using a piston, to ensure that the ring is

squared in the cylinder bore, slide the ring downward

into the cylinder.

(4) Using a feeler gauge check the ring end gap

(Fig. 74). Replace any rings not within specification.

PISTON RING SIDE CLEARANCE

NOTE: Make sure the piston ring grooves are clean

and free of nicks and burrs.

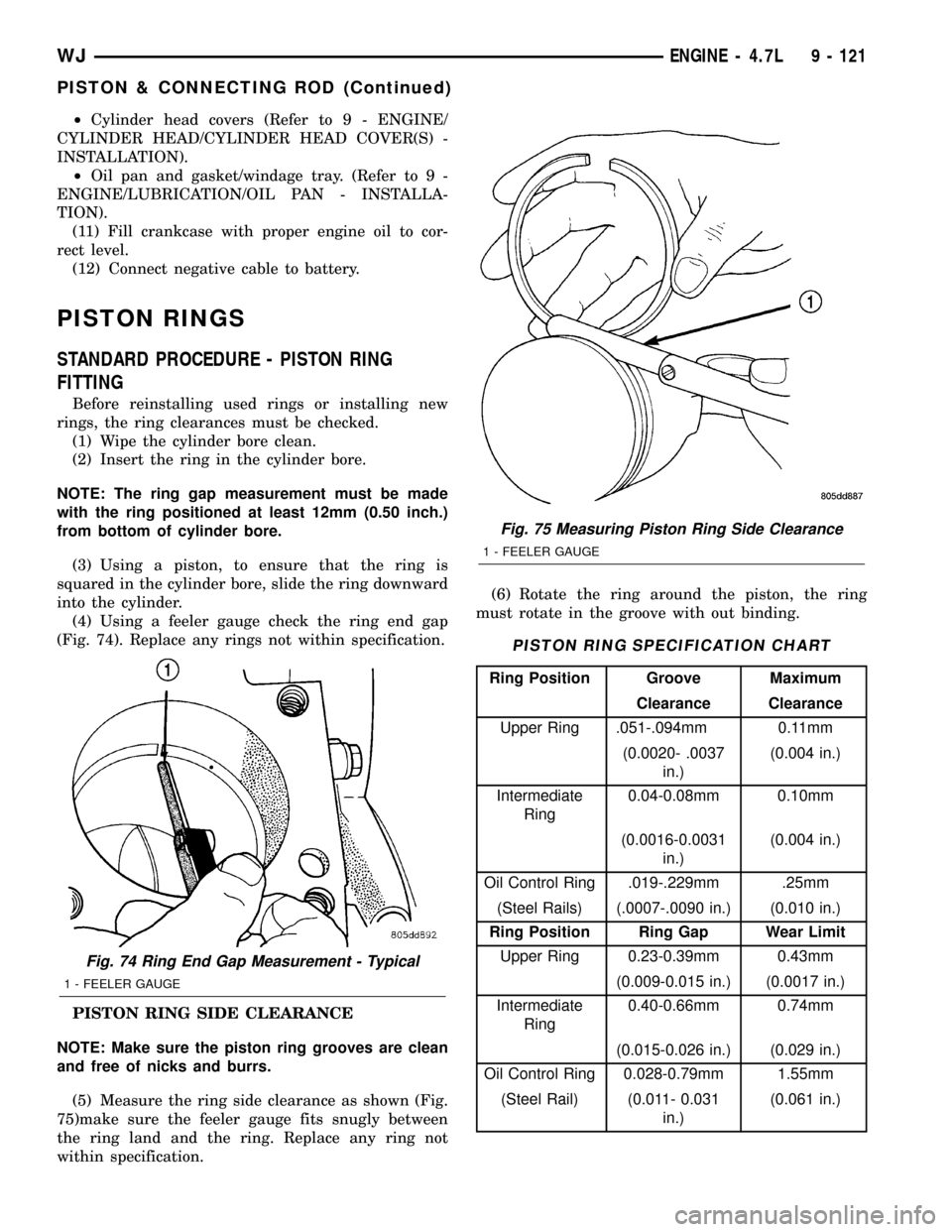

(5) Measure the ring side clearance as shown (Fig.

75)make sure the feeler gauge fits snugly between

the ring land and the ring. Replace any ring not

within specification.(6) Rotate the ring around the piston, the ring

must rotate in the groove with out binding.

PISTON RING SPECIFICATION CHART

Ring Position Groove Maximum

Clearance Clearance

Upper Ring .051-.094mm 0.11mm

(0.0020- .0037

in.)(0.004 in.)

Intermediate

Ring0.04-0.08mm 0.10mm

(0.0016-0.0031

in.)(0.004 in.)

Oil Control Ring .019-.229mm .25mm

(Steel Rails) (.0007-.0090 in.) (0.010 in.)

Ring Position Ring Gap Wear Limit

Upper Ring 0.23-0.39mm 0.43mm

(0.009-0.015 in.) (0.0017 in.)

Intermediate

Ring0.40-0.66mm 0.74mm

(0.015-0.026 in.) (0.029 in.)

Oil Control Ring 0.028-0.79mm 1.55mm

(Steel Rail) (0.011- 0.031

in.)(0.061 in.)

Fig. 74 Ring End Gap Measurement - Typical

1 - FEELER GAUGE

Fig. 75 Measuring Piston Ring Side Clearance

1 - FEELER GAUGE

WJENGINE - 4.7L 9 - 121

PISTON & CONNECTING ROD (Continued)

Page 1365 of 2199

(7) The No. 1 and No. 2 piston rings have a differ-

ent cross section. Ensure No. 2 ring is installed with

manufacturers I.D. mark (Dot) facing up, towards top

of the piston.

NOTE: Piston rings are installed in the following

order:

²Oil ring expander.

²Upper oil ring side rail.

²Lower oil ring side rail.

²No. 2 Intermediate piston ring.

²No. 1 Upper piston ring.

(8) Install the oil ring expander.

(9) Install upper side rail (Fig. 76) by placing one

end between the piston ring groove and the expander

ring. Hold end firmly and press down the portion to

be installed until side rail is in position. Repeat this

step for the lower side rail.

(10) Install No. 2 intermediate piston ring using a

piston ring installer (Fig. 77).

(11) Install No. 1 upper piston ring using a piston

ring installer (Fig. 77).

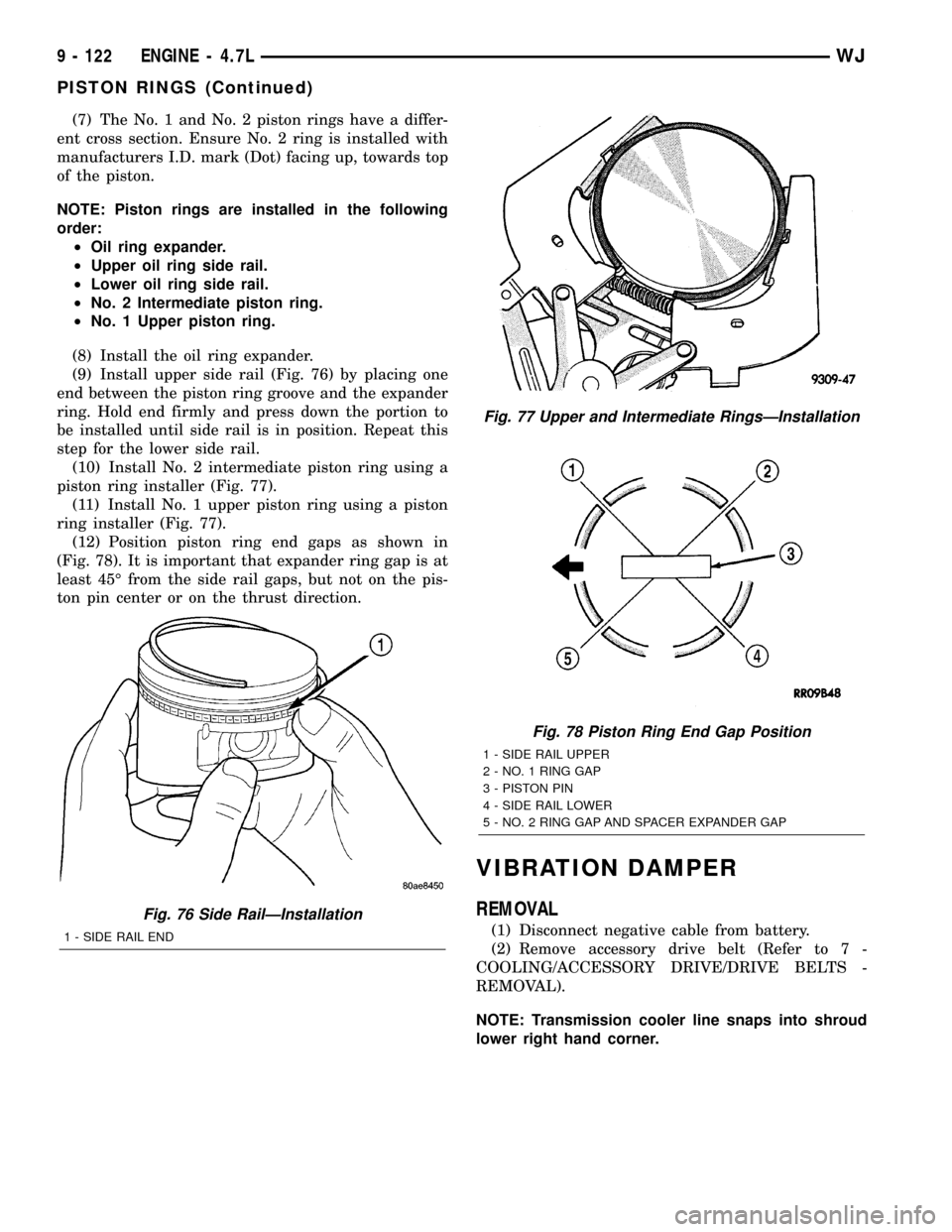

(12) Position piston ring end gaps as shown in

(Fig. 78). It is important that expander ring gap is at

least 45É from the side rail gaps, but not on the pis-

ton pin center or on the thrust direction.

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

NOTE: Transmission cooler line snaps into shroud

lower right hand corner.

Fig. 76 Side RailÐInstallation

1 - SIDE RAIL END

Fig. 77 Upper and Intermediate RingsÐInstallation

Fig. 78 Piston Ring End Gap Position

1 - SIDE RAIL UPPER

2 - NO. 1 RING GAP

3 - PISTON PIN

4 - SIDE RAIL LOWER

5 - NO. 2 RING GAP AND SPACER EXPANDER GAP

9 - 122 ENGINE - 4.7LWJ

PISTON RINGS (Continued)

Page 1366 of 2199

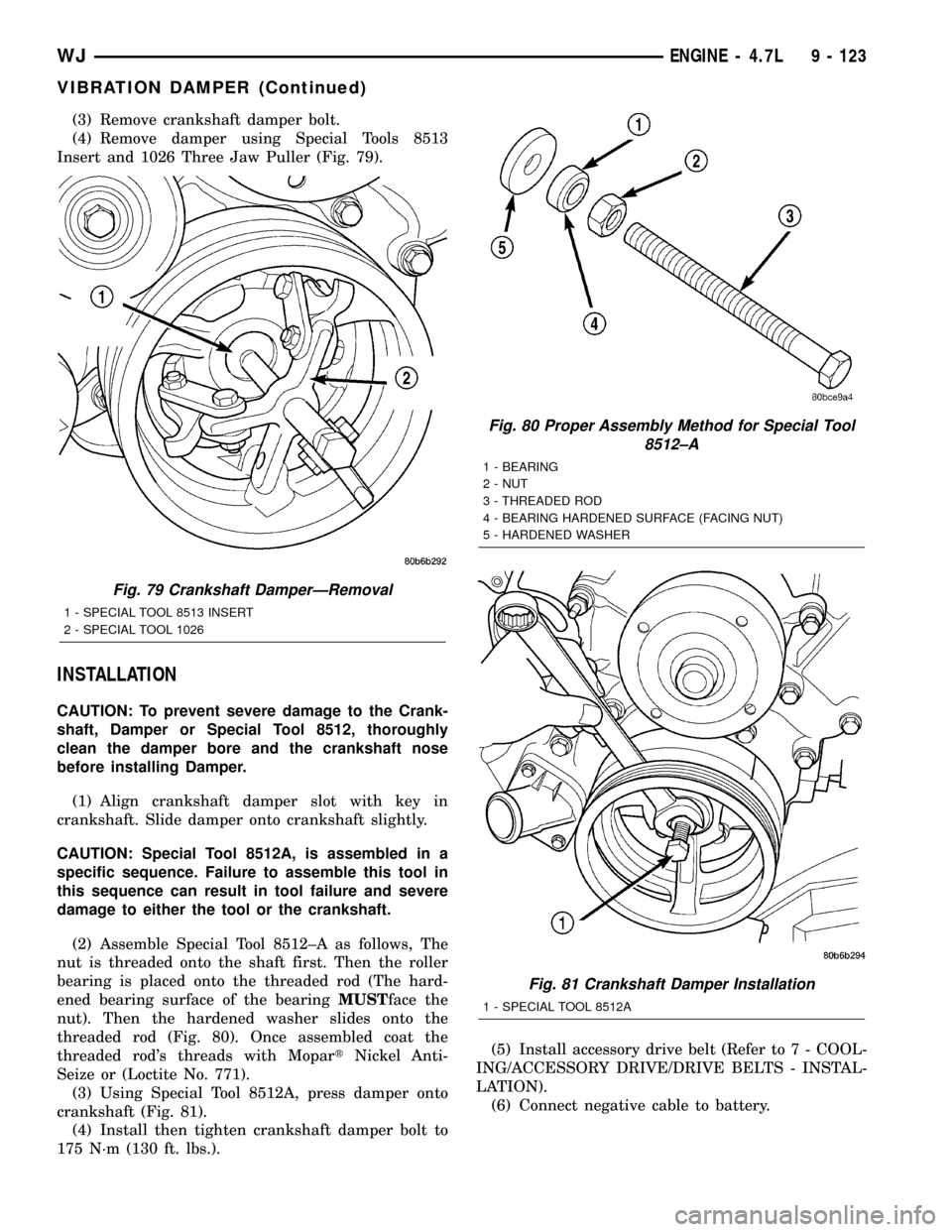

(3) Remove crankshaft damper bolt.

(4) Remove damper using Special Tools 8513

Insert and 1026 Three Jaw Puller (Fig. 79).

INSTALLATION

CAUTION: To prevent severe damage to the Crank-

shaft, Damper or Special Tool 8512, thoroughly

clean the damper bore and the crankshaft nose

before installing Damper.

(1) Align crankshaft damper slot with key in

crankshaft. Slide damper onto crankshaft slightly.

CAUTION: Special Tool 8512A, is assembled in a

specific sequence. Failure to assemble this tool in

this sequence can result in tool failure and severe

damage to either the tool or the crankshaft.

(2) Assemble Special Tool 8512±A as follows, The

nut is threaded onto the shaft first. Then the roller

bearing is placed onto the threaded rod (The hard-

ened bearing surface of the bearingMUSTface the

nut). Then the hardened washer slides onto the

threaded rod (Fig. 80). Once assembled coat the

threaded rod's threads with MopartNickel Anti-

Seize or (Loctite No. 771).

(3) Using Special Tool 8512A, press damper onto

crankshaft (Fig. 81).

(4) Install then tighten crankshaft damper bolt to

175 N´m (130 ft. lbs.).(5) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(6) Connect negative cable to battery.

Fig. 79 Crankshaft DamperÐRemoval

1 - SPECIAL TOOL 8513 INSERT

2 - SPECIAL TOOL 1026

Fig. 80 Proper Assembly Method for Special Tool

8512±A

1 - BEARING

2 - NUT

3 - THREADED ROD

4 - BEARING HARDENED SURFACE (FACING NUT)

5 - HARDENED WASHER

Fig. 81 Crankshaft Damper Installation

1 - SPECIAL TOOL 8512A

WJENGINE - 4.7L 9 - 123

VIBRATION DAMPER (Continued)

Page 1367 of 2199

STRUCTURAL COVER

DESCRIPTION

The structural dust cover is made of die cast alu-

minum and joins the lower half of the transmission

bell housing to the engine bedplate.

OPERATION

The structural cover provides additional power-

train stiffness and reduces noise and vibration.

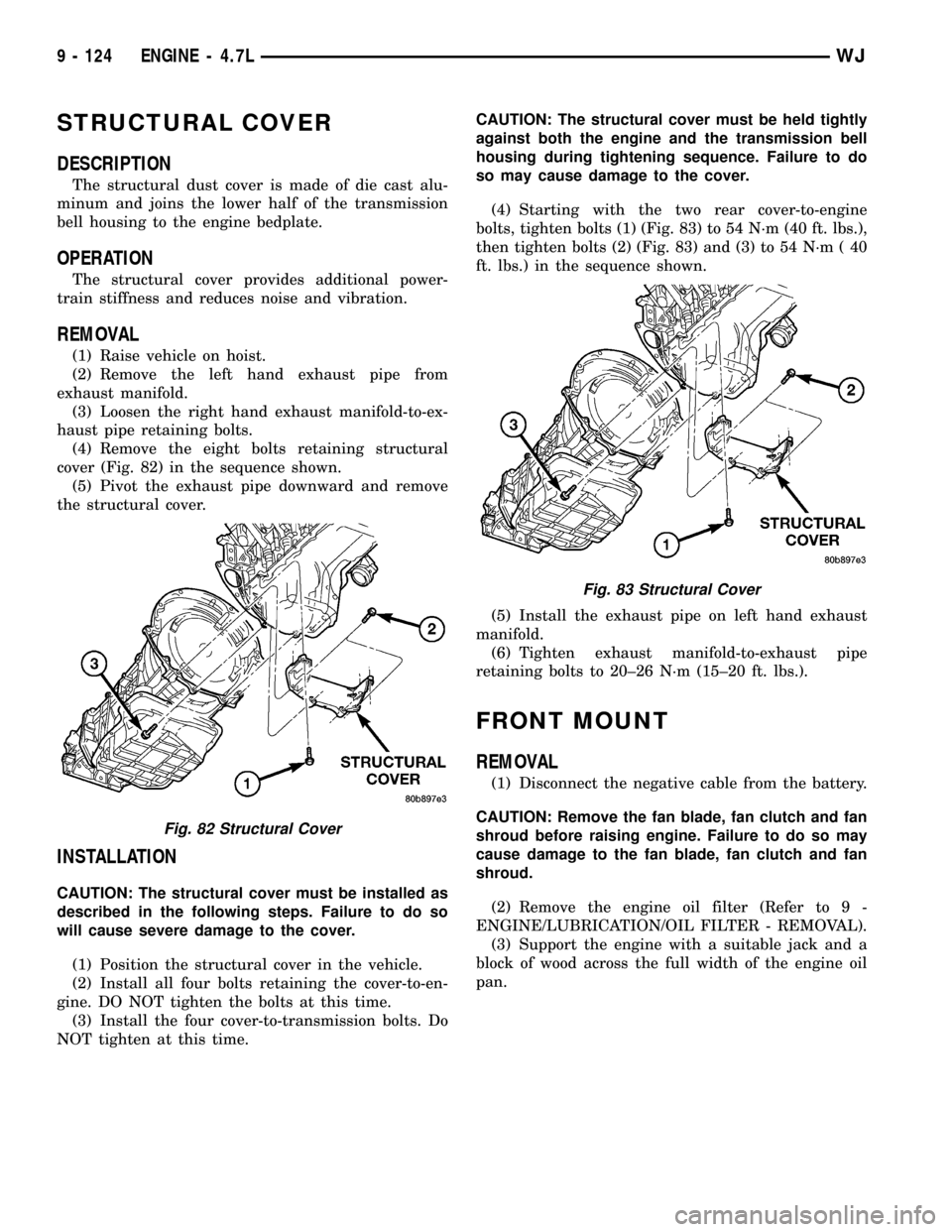

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the left hand exhaust pipe from

exhaust manifold.

(3) Loosen the right hand exhaust manifold-to-ex-

haust pipe retaining bolts.

(4) Remove the eight bolts retaining structural

cover (Fig. 82) in the sequence shown.

(5) Pivot the exhaust pipe downward and remove

the structural cover.

INSTALLATION

CAUTION: The structural cover must be installed as

described in the following steps. Failure to do so

will cause severe damage to the cover.

(1) Position the structural cover in the vehicle.

(2) Install all four bolts retaining the cover-to-en-

gine. DO NOT tighten the bolts at this time.

(3) Install the four cover-to-transmission bolts. Do

NOT tighten at this time.CAUTION: The structural cover must be held tightly

against both the engine and the transmission bell

housing during tightening sequence. Failure to do

so may cause damage to the cover.

(4) Starting with the two rear cover-to-engine

bolts, tighten bolts (1) (Fig. 83) to 54 N´m (40 ft. lbs.),

then tighten bolts (2) (Fig. 83) and (3) to 54 N´m ( 40

ft. lbs.) in the sequence shown.

(5) Install the exhaust pipe on left hand exhaust

manifold.

(6) Tighten exhaust manifold-to-exhaust pipe

retaining bolts to 20±26 N´m (15±20 ft. lbs.).

FRONT MOUNT

REMOVAL

(1) Disconnect the negative cable from the battery.

CAUTION: Remove the fan blade, fan clutch and fan

shroud before raising engine. Failure to do so may

cause damage to the fan blade, fan clutch and fan

shroud.

(2) Remove the engine oil filter (Refer to 9 -

ENGINE/LUBRICATION/OIL FILTER - REMOVAL).

(3) Support the engine with a suitable jack and a

block of wood across the full width of the engine oil

pan.

Fig. 82 Structural Cover

Fig. 83 Structural Cover

9 - 124 ENGINE - 4.7LWJ

Page 1375 of 2199

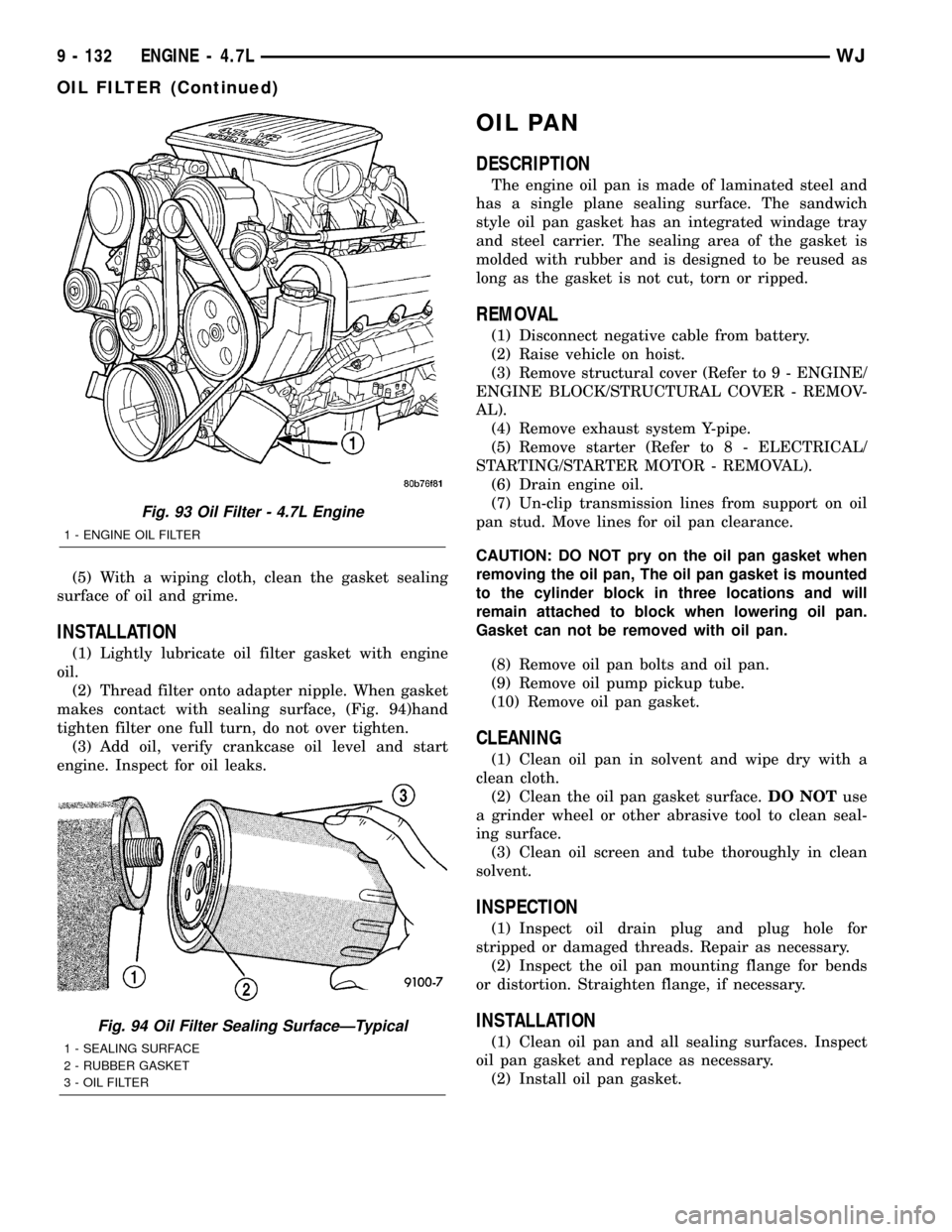

(5) With a wiping cloth, clean the gasket sealing

surface of oil and grime.

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 94)hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

OIL PAN

DESCRIPTION

The engine oil pan is made of laminated steel and

has a single plane sealing surface. The sandwich

style oil pan gasket has an integrated windage tray

and steel carrier. The sealing area of the gasket is

molded with rubber and is designed to be reused as

long as the gasket is not cut, torn or ripped.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - REMOV-

AL).

(4) Remove exhaust system Y-pipe.

(5) Remove starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

(6) Drain engine oil.

(7) Un-clip transmission lines from support on oil

pan stud. Move lines for oil pan clearance.

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when lowering oil pan.

Gasket can not be removed with oil pan.

(8) Remove oil pan bolts and oil pan.

(9) Remove oil pump pickup tube.

(10) Remove oil pan gasket.

CLEANING

(1) Clean oil pan in solvent and wipe dry with a

clean cloth.

(2) Clean the oil pan gasket surface.DO NOTuse

a grinder wheel or other abrasive tool to clean seal-

ing surface.

(3) Clean oil screen and tube thoroughly in clean

solvent.

INSPECTION

(1) Inspect oil drain plug and plug hole for

stripped or damaged threads. Repair as necessary.

(2) Inspect the oil pan mounting flange for bends

or distortion. Straighten flange, if necessary.

INSTALLATION

(1) Clean oil pan and all sealing surfaces. Inspect

oil pan gasket and replace as necessary.

(2) Install oil pan gasket.

Fig. 93 Oil Filter - 4.7L Engine

1 - ENGINE OIL FILTER

Fig. 94 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

9 - 132 ENGINE - 4.7LWJ

OIL FILTER (Continued)

Page 1376 of 2199

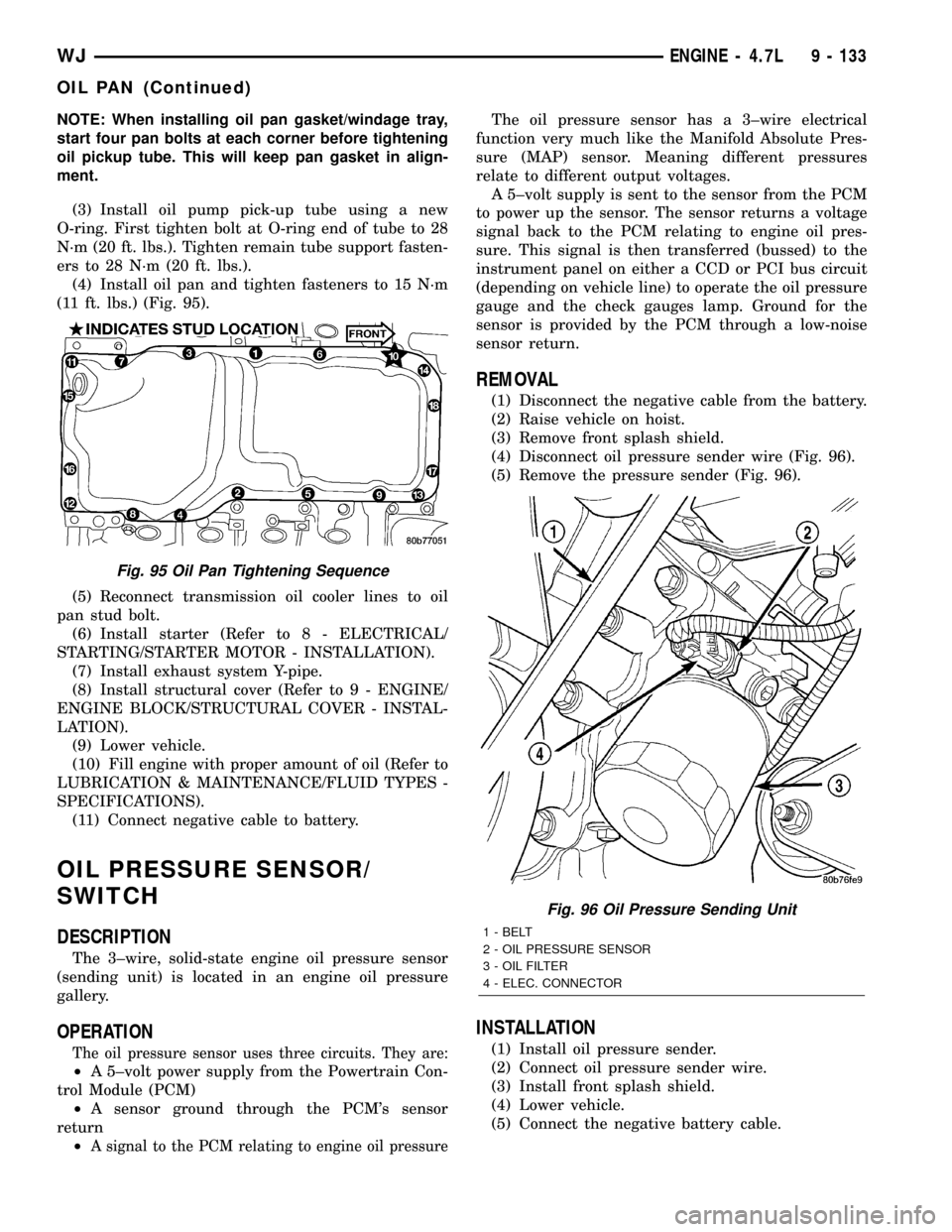

NOTE: When installing oil pan gasket/windage tray,

start four pan bolts at each corner before tightening

oil pickup tube. This will keep pan gasket in align-

ment.

(3) Install oil pump pick-up tube using a new

O-ring. First tighten bolt at O-ring end of tube to 28

N´m (20 ft. lbs.). Tighten remain tube support fasten-

ers to 28 N´m (20 ft. lbs.).

(4) Install oil pan and tighten fasteners to 15 N´m

(11 ft. lbs.) (Fig. 95).

(5) Reconnect transmission oil cooler lines to oil

pan stud bolt.

(6) Install starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - INSTALLATION).

(7) Install exhaust system Y-pipe.

(8) Install structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION).

(9) Lower vehicle.

(10) Fill engine with proper amount of oil (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

(11) Connect negative cable to battery.

OIL PRESSURE SENSOR/

SWITCH

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²

A signal to the PCM relating to engine oil pressure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to the

instrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle on hoist.

(3) Remove front splash shield.

(4) Disconnect oil pressure sender wire (Fig. 96).

(5) Remove the pressure sender (Fig. 96).

INSTALLATION

(1) Install oil pressure sender.

(2) Connect oil pressure sender wire.

(3) Install front splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.

Fig. 95 Oil Pan Tightening Sequence

Fig. 96 Oil Pressure Sending Unit

1 - BELT

2 - OIL PRESSURE SENSOR

3 - OIL FILTER

4 - ELEC. CONNECTOR

WJENGINE - 4.7L 9 - 133

OIL PAN (Continued)

Page 1379 of 2199

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite mate-

rial and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks. Eight studs and

two bolts are used to fasten the intake to the head.

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove air cleaner housing and throttle body

resonator (Fig. 104).

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect vapor purge hose, brake booster

hose, speed control servo hose, positive crankcase

ventilation (PCV) hose.

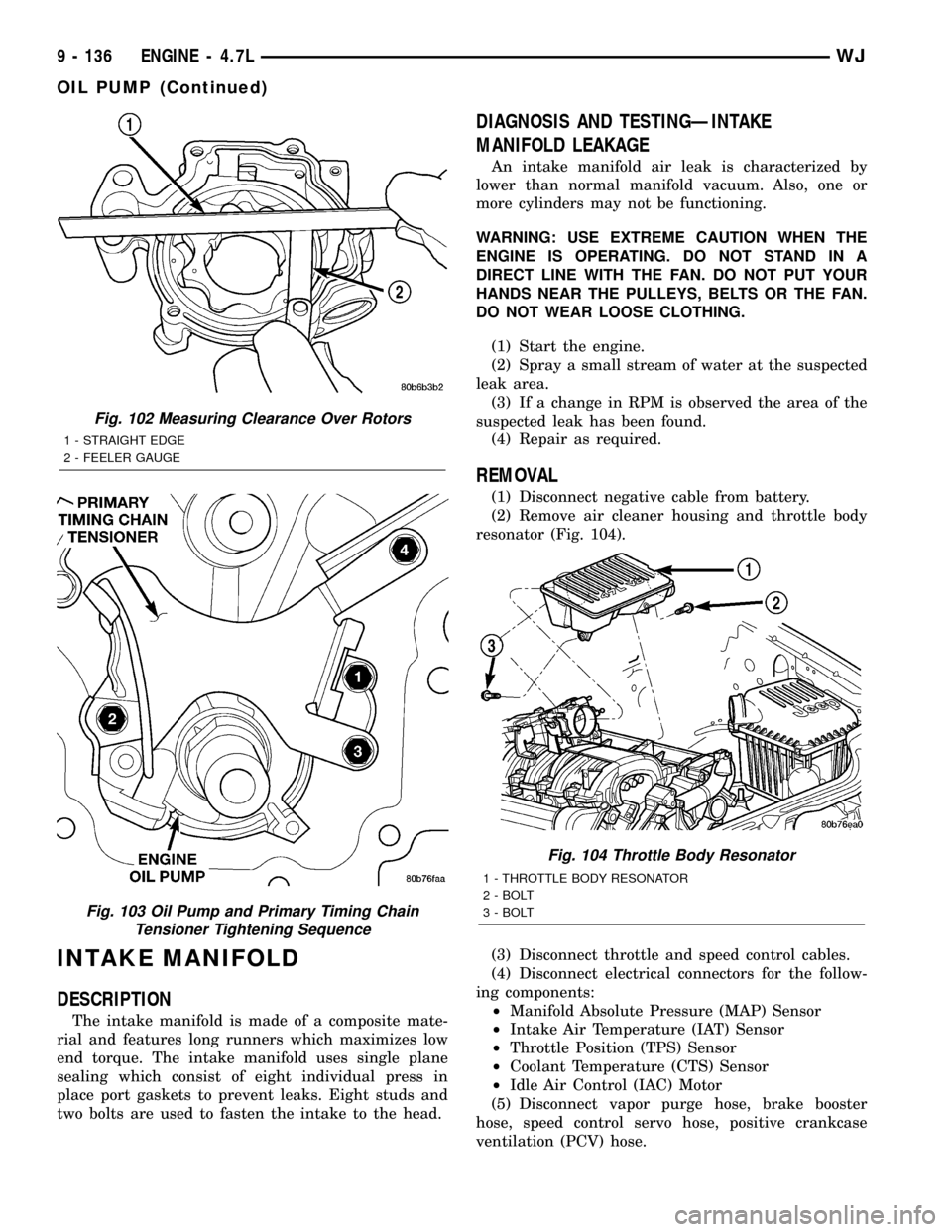

Fig. 102 Measuring Clearance Over Rotors

1 - STRAIGHT EDGE

2 - FEELER GAUGE

Fig. 103 Oil Pump and Primary Timing Chain

Tensioner Tightening Sequence

Fig. 104 Throttle Body Resonator

1 - THROTTLE BODY RESONATOR

2 - BOLT

3 - BOLT

9 - 136 ENGINE - 4.7LWJ

OIL PUMP (Continued)

Page 1380 of 2199

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Disconnect generator electrical connections.

(8) Unbolt the generator and move it away from

the intake manifold for clearance.

(9) Disconnect air conditioning compressor electri-

cal connections.

(10) Unbolt the air conditioning compressor and

move it away from the intake manifold for clearance.

(11) Disconnect left and right radio suppressor

straps.

(12) Disconnect and remove ignition coil towers

(Refer to 8 - ELECTRICAL/IGNITION CONTROL/

IGNITION COIL - REMOVAL).

(13) Remove top oil dipstick tube retaining bolt

and ground strap.

(14) Bleed pressure from fuel system (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE).

(15) Remove fuel rail (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL RAIL - REMOVAL).

(16) Remove throttle body assembly and mounting

bracket.

(17) Drain cooling system below coolant tempera-

ture level (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(18) Remove coolant temperature sensor (Refer to

7 - COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - REMOVAL).

(19) Remove cowl to hood seal. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/COWL WEATHER-

STRIP - REMOVAL).

(20) Remove right side engine lifting stud.

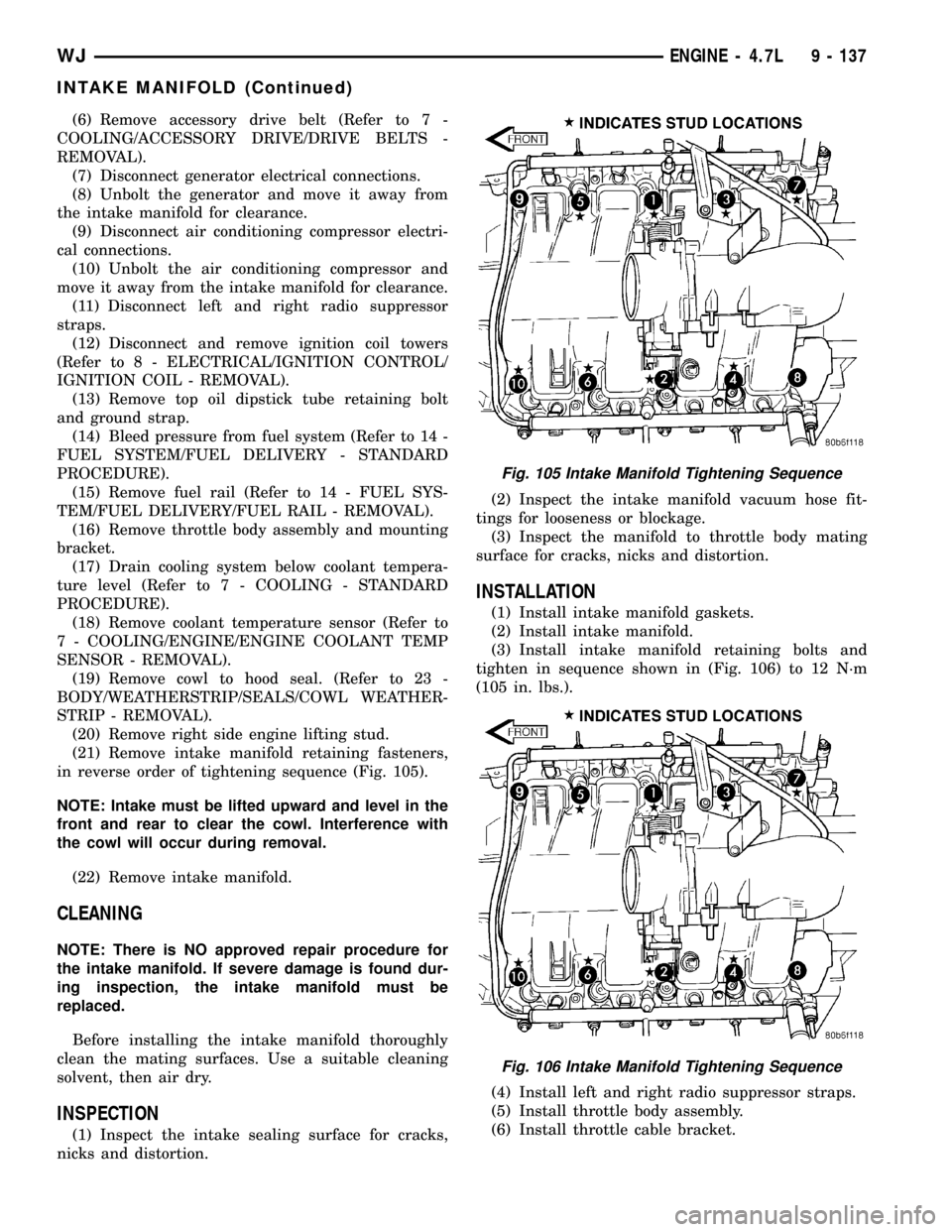

(21) Remove intake manifold retaining fasteners,

in reverse order of tightening sequence (Fig. 105).

NOTE: Intake must be lifted upward and level in the

front and rear to clear the cowl. Interference with

the cowl will occur during removal.

(22) Remove intake manifold.

CLEANING

NOTE: There is NO approved repair procedure for

the intake manifold. If severe damage is found dur-

ing inspection, the intake manifold must be

replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

(3) Install intake manifold retaining bolts and

tighten in sequence shown in (Fig. 106) to 12 N´m

(105 in. lbs.).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Install throttle cable bracket.

Fig. 105 Intake Manifold Tightening Sequence

Fig. 106 Intake Manifold Tightening Sequence

WJENGINE - 4.7L 9 - 137

INTAKE MANIFOLD (Continued)

Page 1381 of 2199

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install ignition coil towers (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

(10) Install coolant temperature sensor (Refer to 7

- COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - INSTALLATION).

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Install right side engine lifting stud.

(14) Install generator including electrical connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - INSTALLATION).

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Install air conditioning compressor including

electrical connections.

(17) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(19) Install cowl to hood seal (Refer to 23 - BODY/

WEATHERSTRIP/SEALS/COWL WEATHERSTRIP -

INSTALLATION).

(20) Install air cleaner housing and throttle body

resonator. Tighten resonator bolts 4.5 N´m (40 in.

lbs.).

(21) Connect negative cable to battery.

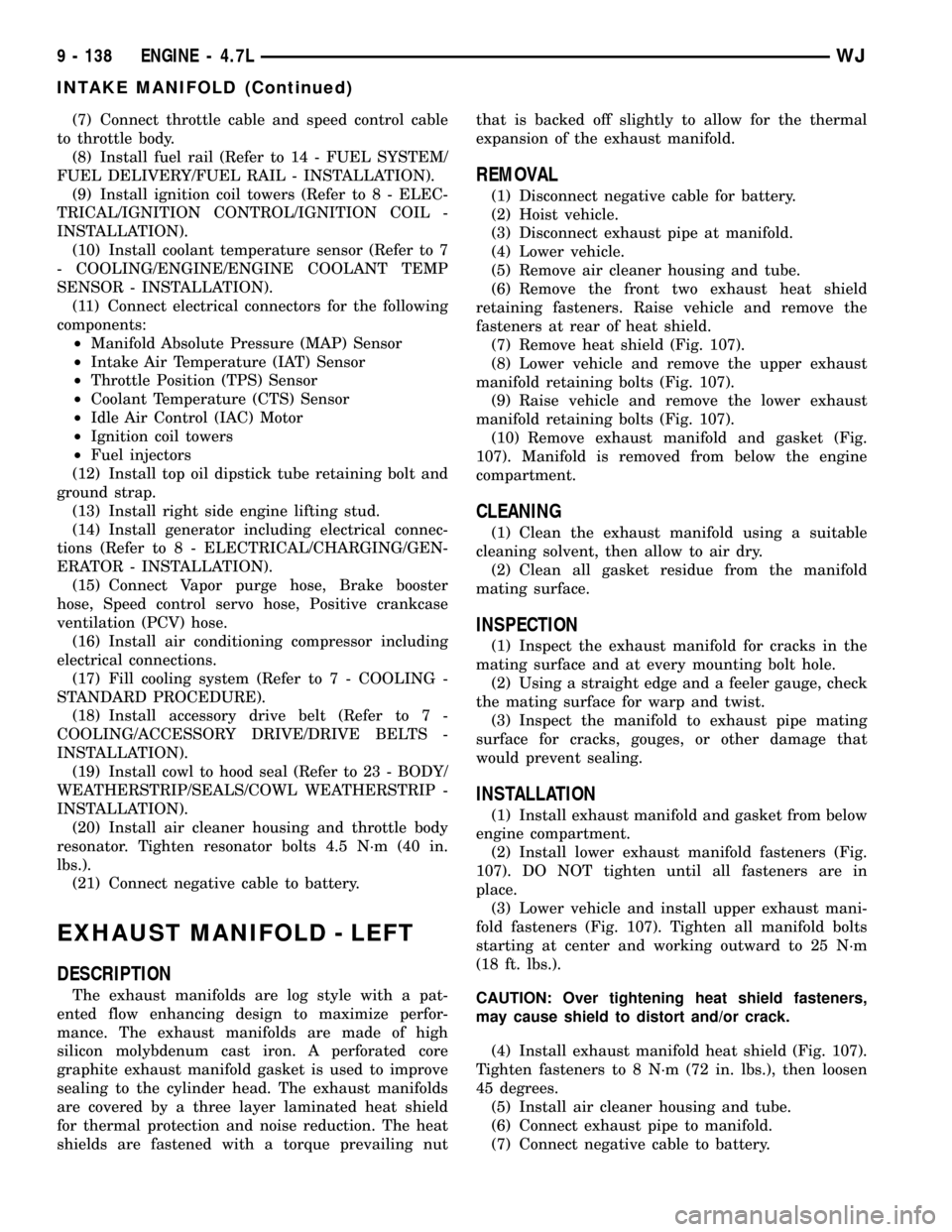

EXHAUST MANIFOLD - LEFT

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nutthat is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

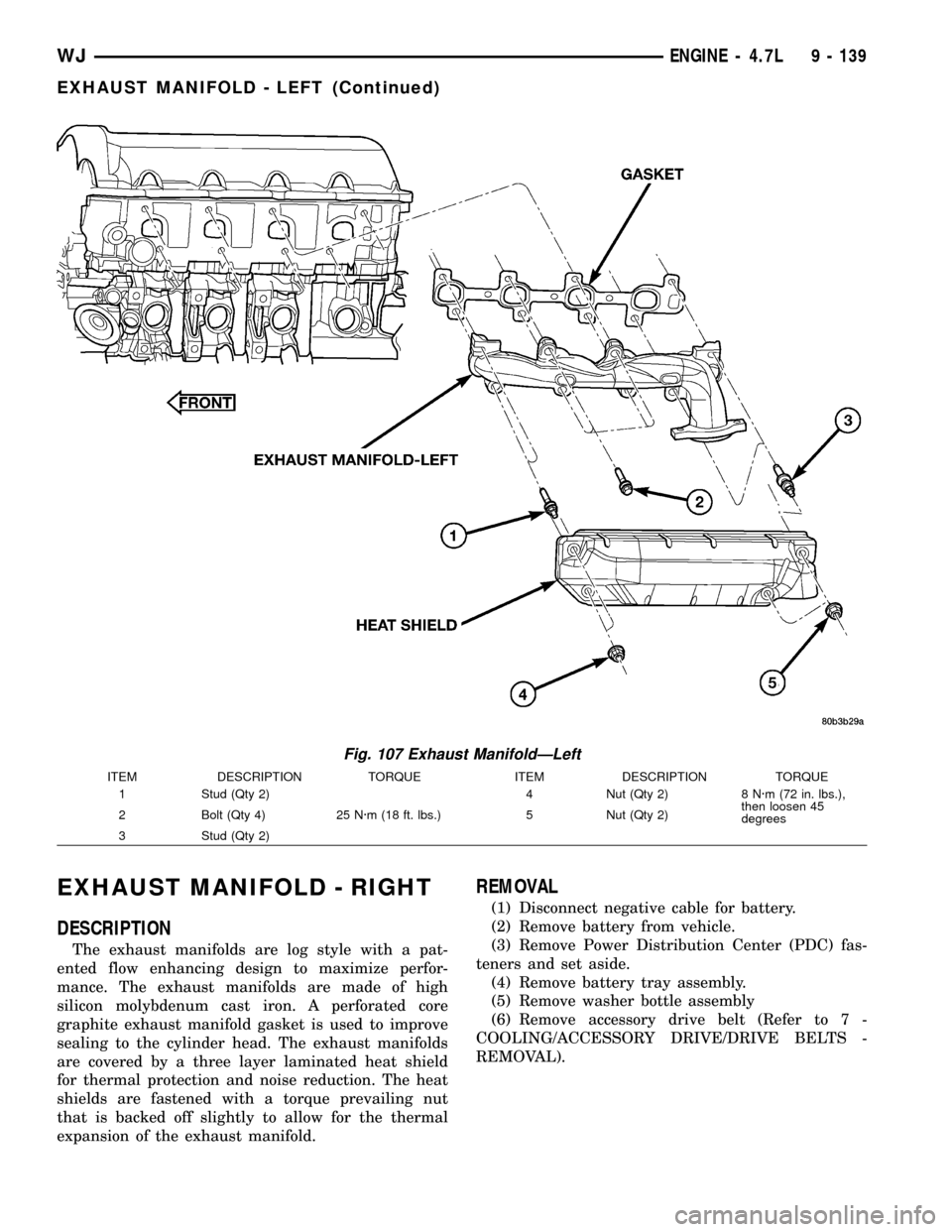

REMOVAL

(1) Disconnect negative cable for battery.

(2) Hoist vehicle.

(3) Disconnect exhaust pipe at manifold.

(4) Lower vehicle.

(5) Remove air cleaner housing and tube.

(6) Remove the front two exhaust heat shield

retaining fasteners. Raise vehicle and remove the

fasteners at rear of heat shield.

(7) Remove heat shield (Fig. 107).

(8) Lower vehicle and remove the upper exhaust

manifold retaining bolts (Fig. 107).

(9) Raise vehicle and remove the lower exhaust

manifold retaining bolts (Fig. 107).

(10) Remove exhaust manifold and gasket (Fig.

107). Manifold is removed from below the engine

compartment.

CLEANING

(1) Clean the exhaust manifold using a suitable

cleaning solvent, then allow to air dry.

(2) Clean all gasket residue from the manifold

mating surface.

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.

(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners (Fig.

107). DO NOT tighten until all fasteners are in

place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners (Fig. 107). Tighten all manifold bolts

starting at center and working outward to 25 N´m

(18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield (Fig. 107).

Tighten fasteners to 8 N´m (72 in. lbs.), then loosen

45 degrees.

(5) Install air cleaner housing and tube.

(6) Connect exhaust pipe to manifold.

(7) Connect negative cable to battery.

9 - 138 ENGINE - 4.7LWJ

INTAKE MANIFOLD (Continued)

Page 1382 of 2199

EXHAUST MANIFOLD - RIGHT

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

(1) Disconnect negative cable for battery.

(2) Remove battery from vehicle.

(3) Remove Power Distribution Center (PDC) fas-

teners and set aside.

(4) Remove battery tray assembly.

(5) Remove washer bottle assembly

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

Fig. 107 Exhaust ManifoldÐLeft

ITEM DESCRIPTION TORQUE ITEM DESCRIPTION TORQUE

1 Stud (Qty 2)

25 N´m (18 ft. lbs.)4 Nut (Qty 2) 8 N´m (72 in. lbs.),

then loosen 45

degrees 2 Bolt (Qty 4) 5 Nut (Qty 2)

3 Stud (Qty 2)

WJENGINE - 4.7L 9 - 139

EXHAUST MANIFOLD - LEFT (Continued)