window circuit JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1137 of 2199

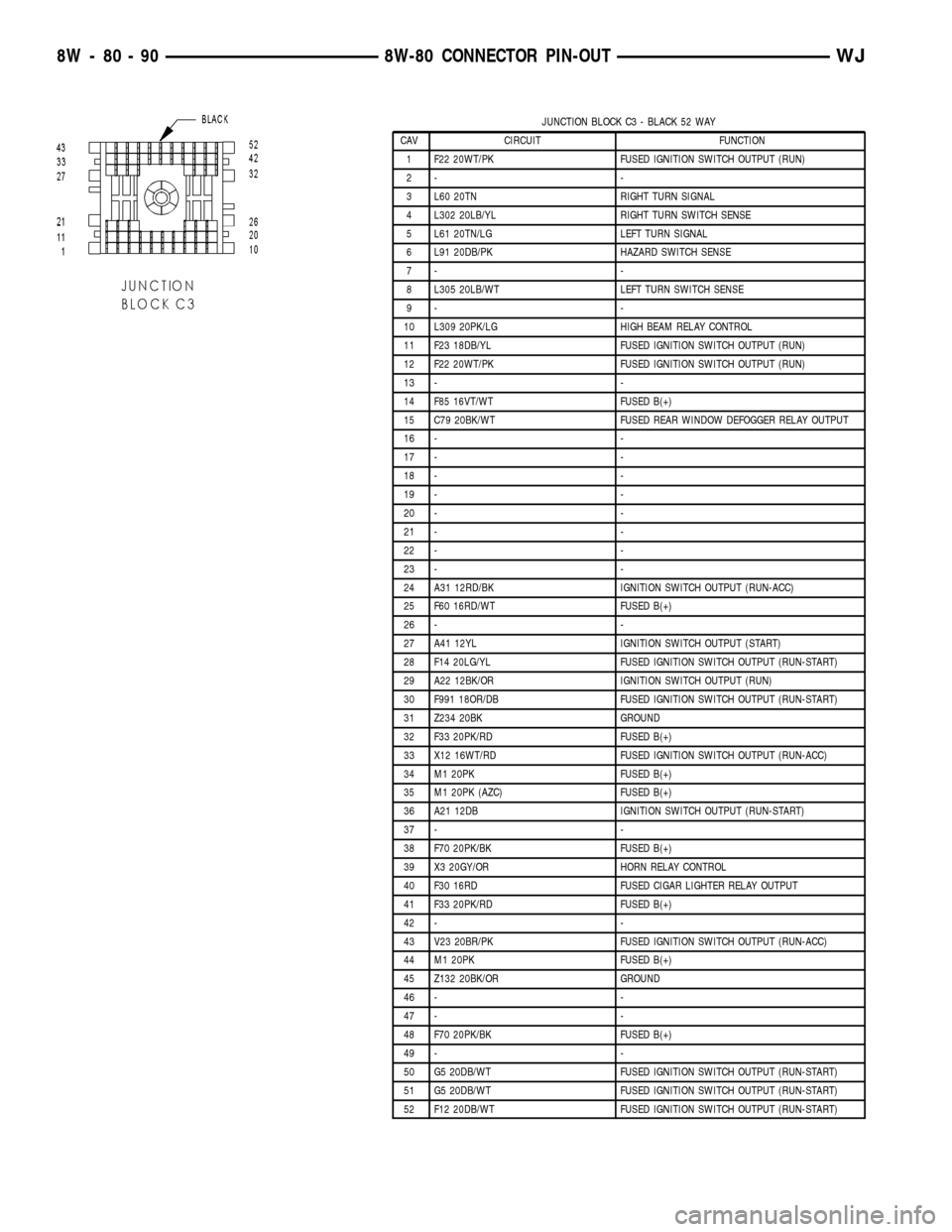

JUNCTION BLOCK C3 - BLACK 52 WAY

CAV CIRCUIT FUNCTION

1 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

2- -

3 L60 20TN RIGHT TURN SIGNAL

4 L302 20LB/YL RIGHT TURN SWITCH SENSE

5 L61 20TN/LG LEFT TURN SIGNAL

6 L91 20DB/PK HAZARD SWITCH SENSE

7- -

8 L305 20LB/WT LEFT TURN SWITCH SENSE

9- -

10 L309 20PK/LG HIGH BEAM RELAY CONTROL

11 F23 18DB/YL FUSED IGNITION SWITCH OUTPUT (RUN)

12 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

13 - -

14 F85 16VT/WT FUSED B(+)

15 C79 20BK/WT FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

16 - -

17 - -

18 - -

19 - -

20 - -

21 - -

22 - -

23 - -

24 A31 12RD/BK IGNITION SWITCH OUTPUT (RUN-ACC)

25 F60 16RD/WT FUSED B(+)

26 - -

27 A41 12YL IGNITION SWITCH OUTPUT (START)

28 F14 20LG/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

29 A22 12BK/OR IGNITION SWITCH OUTPUT (RUN)

30 F991 18OR/DB FUSED IGNITION SWITCH OUTPUT (RUN-START)

31 Z234 20BK GROUND

32 F33 20PK/RD FUSED B(+)

33 X12 16WT/RD FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

34 M1 20PK FUSED B(+)

35 M1 20PK (AZC) FUSED B(+)

36 A21 12DB IGNITION SWITCH OUTPUT (RUN-START)

37 - -

38 F70 20PK/BK FUSED B(+)

39 X3 20GY/OR HORN RELAY CONTROL

40 F30 16RD FUSED CIGAR LIGHTER RELAY OUTPUT

41 F33 20PK/RD FUSED B(+)

42 - -

43 V23 20BR/PK FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

44 M1 20PK FUSED B(+)

45 Z132 20BK/OR GROUND

46 - -

47 - -

48 F70 20PK/BK FUSED B(+)

49 - -

50 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

51 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

52 F12 20DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

8W - 80 - 90 8W-80 CONNECTOR PIN-OUTWJ

Page 1145 of 2199

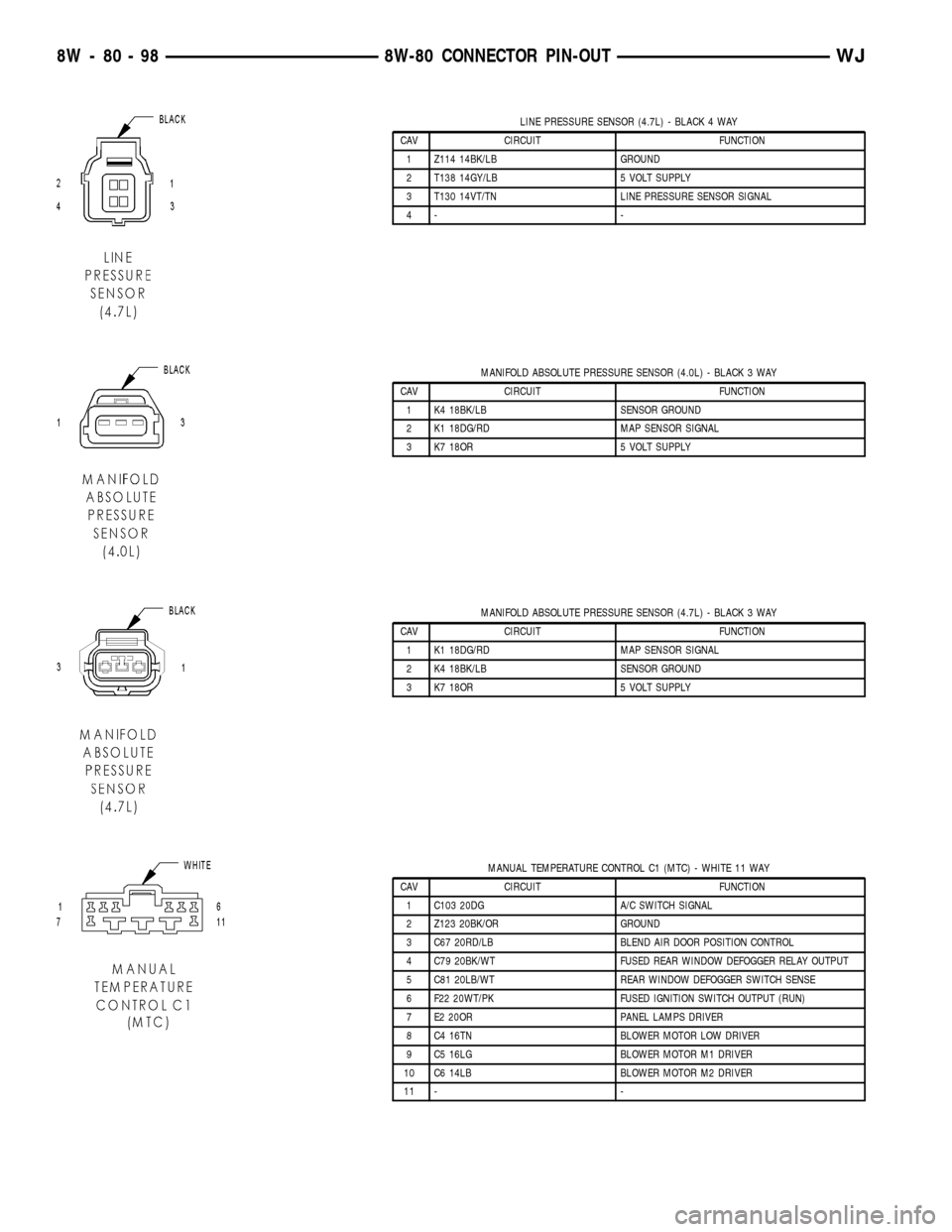

LINE PRESSURE SENSOR (4.7L) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 Z114 14BK/LB GROUND

2 T138 14GY/LB 5 VOLT SUPPLY

3 T130 14VT/TN LINE PRESSURE SENSOR SIGNAL

4- -

MANIFOLD ABSOLUTE PRESSURE SENSOR (4.0L) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K4 18BK/LB SENSOR GROUND

2 K1 18DG/RD MAP SENSOR SIGNAL

3 K7 18OR 5 VOLT SUPPLY

MANIFOLD ABSOLUTE PRESSURE SENSOR (4.7L) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K1 18DG/RD MAP SENSOR SIGNAL

2 K4 18BK/LB SENSOR GROUND

3 K7 18OR 5 VOLT SUPPLY

MANUAL TEMPERATURE CONTROL C1 (MTC) - WHITE 11 WAY

CAV CIRCUIT FUNCTION

1 C103 20DG A/C SWITCH SIGNAL

2 Z123 20BK/OR GROUND

3 C67 20RD/LB BLEND AIR DOOR POSITION CONTROL

4 C79 20BK/WT FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

5 C81 20LB/WT REAR WINDOW DEFOGGER SWITCH SENSE

6 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

7 E2 20OR PANEL LAMPS DRIVER

8 C4 16TN BLOWER MOTOR LOW DRIVER

9 C5 16LG BLOWER MOTOR M1 DRIVER

10 C6 14LB BLOWER MOTOR M2 DRIVER

11 - -

8W - 80 - 98 8W-80 CONNECTOR PIN-OUTWJ

Page 1149 of 2199

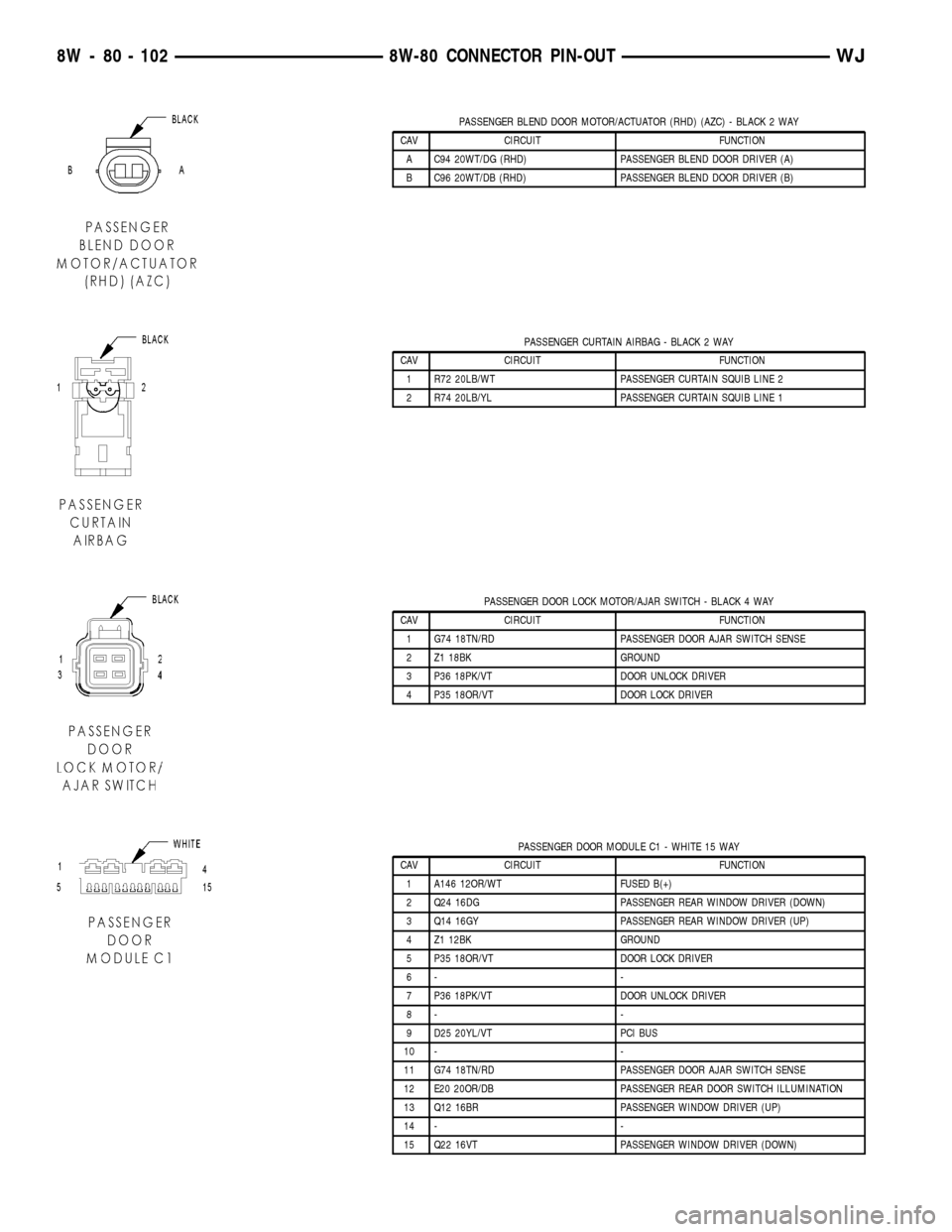

PASSENGER BLEND DOOR MOTOR/ACTUATOR (RHD) (AZC) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

A C94 20WT/DG (RHD) PASSENGER BLEND DOOR DRIVER (A)

B C96 20WT/DB (RHD) PASSENGER BLEND DOOR DRIVER (B)

PASSENGER CURTAIN AIRBAG - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 R72 20LB/WT PASSENGER CURTAIN SQUIB LINE 2

2 R74 20LB/YL PASSENGER CURTAIN SQUIB LINE 1

PASSENGER DOOR LOCK MOTOR/AJAR SWITCH - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 G74 18TN/RD PASSENGER DOOR AJAR SWITCH SENSE

2 Z1 18BK GROUND

3 P36 18PK/VT DOOR UNLOCK DRIVER

4 P35 18OR/VT DOOR LOCK DRIVER

PASSENGER DOOR MODULE C1 - WHITE 15 WAY

CAV CIRCUIT FUNCTION

1 A146 12OR/WT FUSED B(+)

2 Q24 16DG PASSENGER REAR WINDOW DRIVER (DOWN)

3 Q14 16GY PASSENGER REAR WINDOW DRIVER (UP)

4 Z1 12BK GROUND

5 P35 18OR/VT DOOR LOCK DRIVER

6- -

7 P36 18PK/VT DOOR UNLOCK DRIVER

8- -

9 D25 20YL/VT PCI BUS

10 - -

11 G74 18TN/RD PASSENGER DOOR AJAR SWITCH SENSE

12 E20 20OR/DB PASSENGER REAR DOOR SWITCH ILLUMINATION

13 Q12 16BR PASSENGER WINDOW DRIVER (UP)

14 - -

15 Q22 16VT PASSENGER WINDOW DRIVER (DOWN)

8W - 80 - 102 8W-80 CONNECTOR PIN-OUTWJ

Page 1150 of 2199

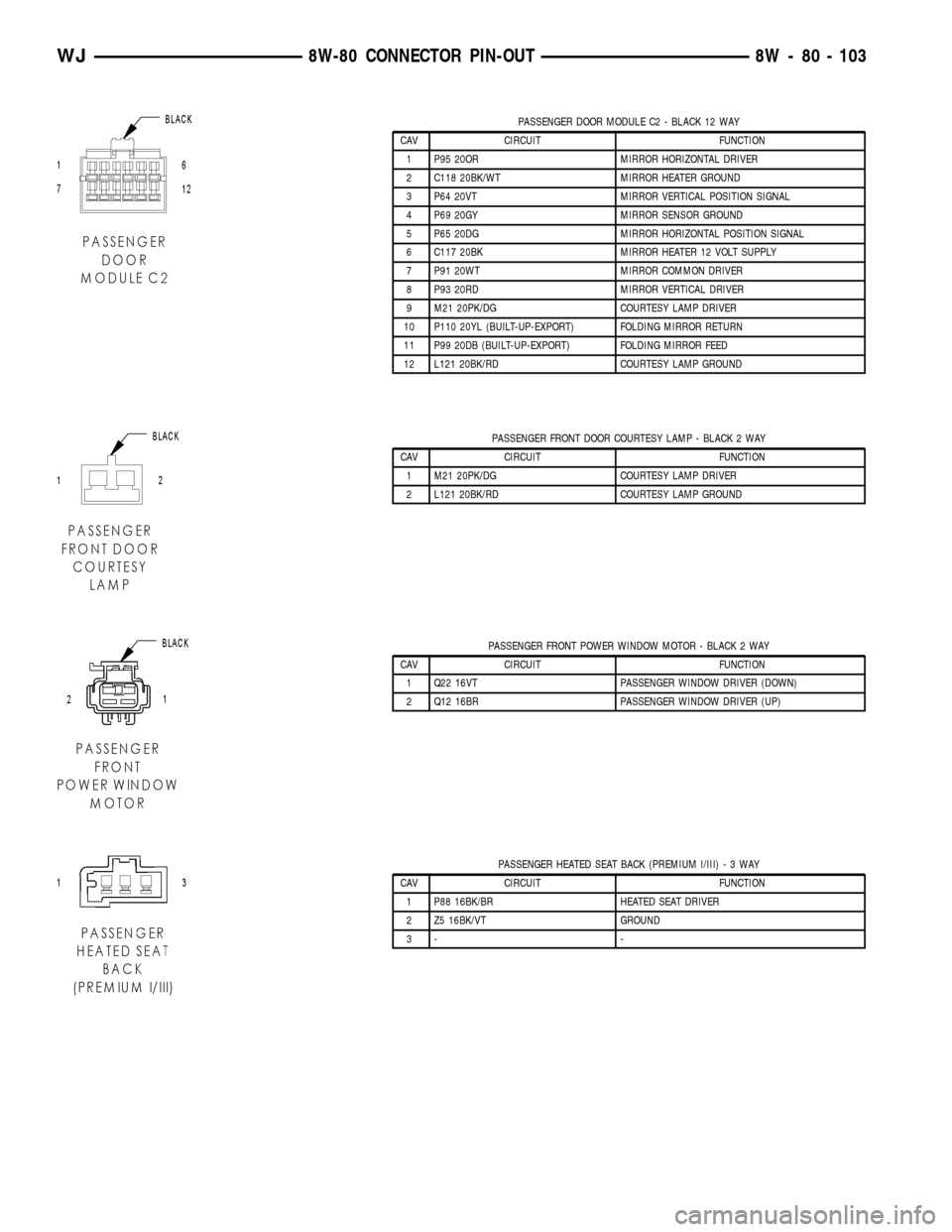

PASSENGER DOOR MODULE C2 - BLACK 12 WAY

CAV CIRCUIT FUNCTION

1 P95 20OR MIRROR HORIZONTAL DRIVER

2 C118 20BK/WT MIRROR HEATER GROUND

3 P64 20VT MIRROR VERTICAL POSITION SIGNAL

4 P69 20GY MIRROR SENSOR GROUND

5 P65 20DG MIRROR HORIZONTAL POSITION SIGNAL

6 C117 20BK MIRROR HEATER 12 VOLT SUPPLY

7 P91 20WT MIRROR COMMON DRIVER

8 P93 20RD MIRROR VERTICAL DRIVER

9 M21 20PK/DG COURTESY LAMP DRIVER

10 P110 20YL (BUILT-UP-EXPORT) FOLDING MIRROR RETURN

11 P99 20DB (BUILT-UP-EXPORT) FOLDING MIRROR FEED

12 L121 20BK/RD COURTESY LAMP GROUND

PASSENGER FRONT DOOR COURTESY LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 M21 20PK/DG COURTESY LAMP DRIVER

2 L121 20BK/RD COURTESY LAMP GROUND

PASSENGER FRONT POWER WINDOW MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q22 16VT PASSENGER WINDOW DRIVER (DOWN)

2 Q12 16BR PASSENGER WINDOW DRIVER (UP)

PASSENGER HEATED SEAT BACK (PREMIUM I/III)-3WAY

CAV CIRCUIT FUNCTION

1 P88 16BK/BR HEATED SEAT DRIVER

2 Z5 16BK/VT GROUND

3- -

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 103

Page 1153 of 2199

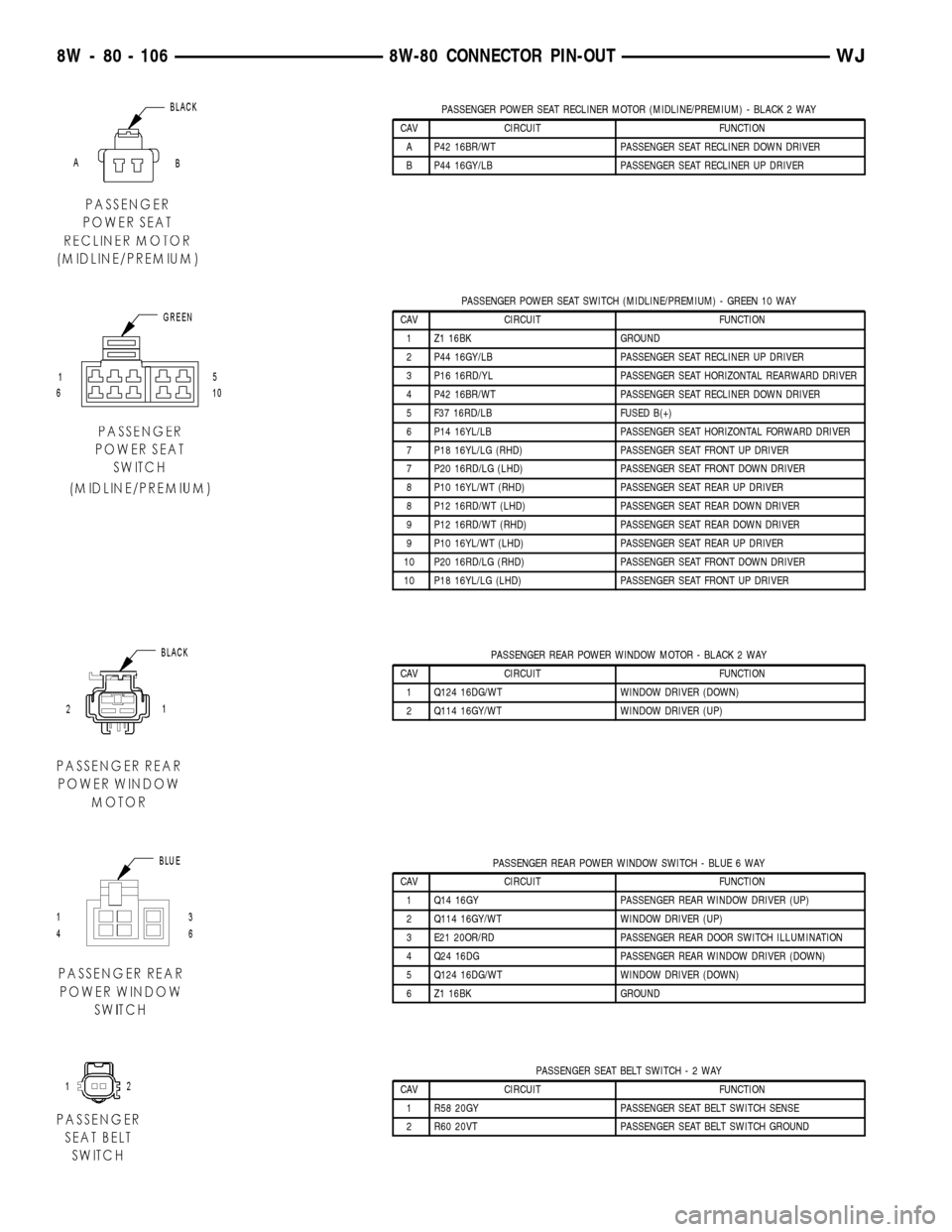

PASSENGER POWER SEAT RECLINER MOTOR (MIDLINE/PREMIUM) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

A P42 16BR/WT PASSENGER SEAT RECLINER DOWN DRIVER

B P44 16GY/LB PASSENGER SEAT RECLINER UP DRIVER

PASSENGER POWER SEAT SWITCH (MIDLINE/PREMIUM) - GREEN 10 WAY

CAV CIRCUIT FUNCTION

1 Z1 16BK GROUND

2 P44 16GY/LB PASSENGER SEAT RECLINER UP DRIVER

3 P16 16RD/YL PASSENGER SEAT HORIZONTAL REARWARD DRIVER

4 P42 16BR/WT PASSENGER SEAT RECLINER DOWN DRIVER

5 F37 16RD/LB FUSED B(+)

6 P14 16YL/LB PASSENGER SEAT HORIZONTAL FORWARD DRIVER

7 P18 16YL/LG (RHD) PASSENGER SEAT FRONT UP DRIVER

7 P20 16RD/LG (LHD) PASSENGER SEAT FRONT DOWN DRIVER

8 P10 16YL/WT (RHD) PASSENGER SEAT REAR UP DRIVER

8 P12 16RD/WT (LHD) PASSENGER SEAT REAR DOWN DRIVER

9 P12 16RD/WT (RHD) PASSENGER SEAT REAR DOWN DRIVER

9 P10 16YL/WT (LHD) PASSENGER SEAT REAR UP DRIVER

10 P20 16RD/LG (RHD) PASSENGER SEAT FRONT DOWN DRIVER

10 P18 16YL/LG (LHD) PASSENGER SEAT FRONT UP DRIVER

PASSENGER REAR POWER WINDOW MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Q124 16DG/WT WINDOW DRIVER (DOWN)

2 Q114 16GY/WT WINDOW DRIVER (UP)

PASSENGER REAR POWER WINDOW SWITCH - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q14 16GY PASSENGER REAR WINDOW DRIVER (UP)

2 Q114 16GY/WT WINDOW DRIVER (UP)

3 E21 20OR/RD PASSENGER REAR DOOR SWITCH ILLUMINATION

4 Q24 16DG PASSENGER REAR WINDOW DRIVER (DOWN)

5 Q124 16DG/WT WINDOW DRIVER (DOWN)

6 Z1 16BK GROUND

PASSENGER SEAT BELT SWITCH-2WAY

CAV CIRCUIT FUNCTION

1 R58 20GY PASSENGER SEAT BELT SWITCH SENSE

2 R60 20VT PASSENGER SEAT BELT SWITCH GROUND

8W - 80 - 106 8W-80 CONNECTOR PIN-OUTWJ

Page 2094 of 2199

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

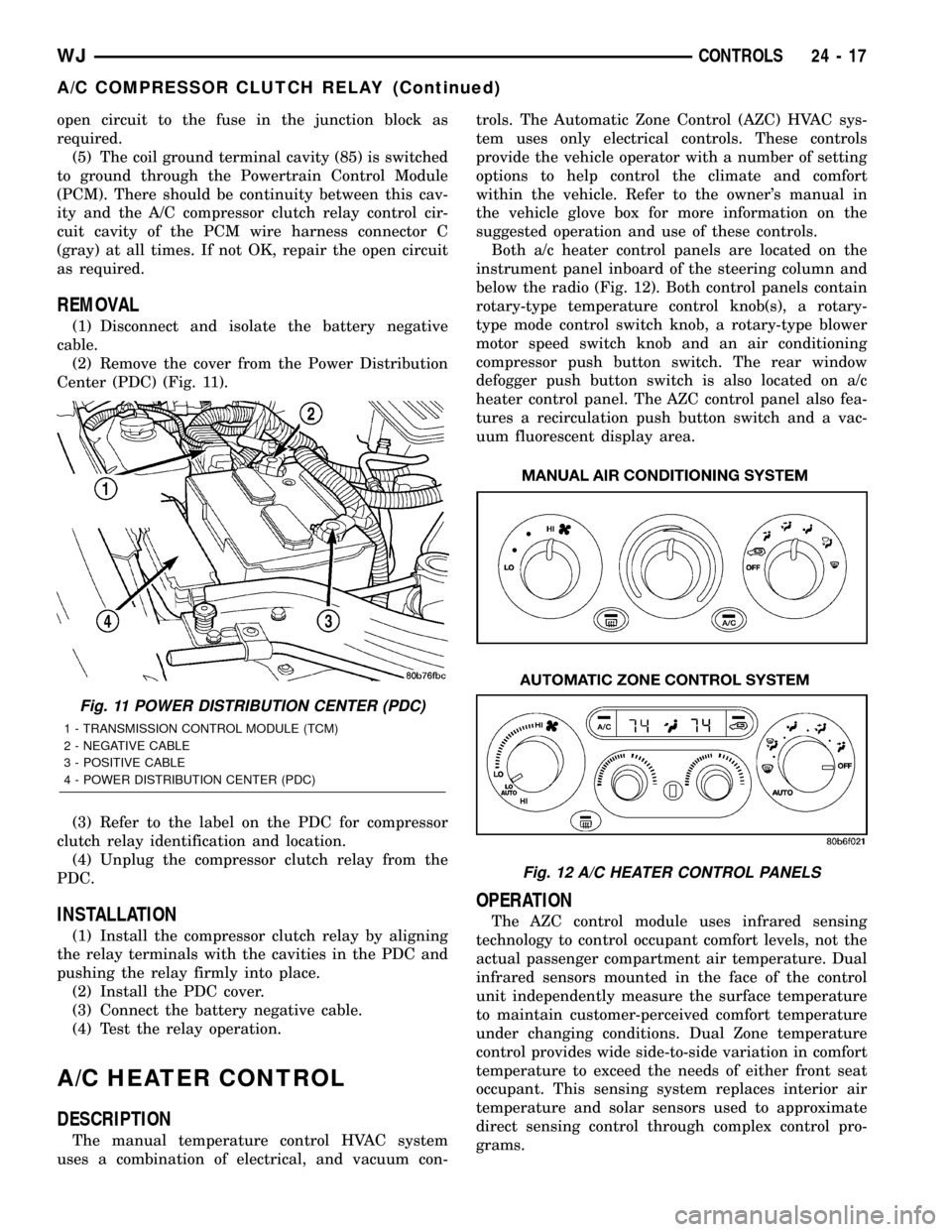

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2106 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the a/c heater control from the instrument

panel. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS/A/C HEATER CONTROL -

REMOVAL) Check for continuity between the ground

circuit cavity of the a/c heater control wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 3. If not OK, repair the open

circuit to ground as required.

(3) With the a/c heater control wire harness con-

nector unplugged, place the a/c heater mode control

switch knob in any position except the Off position.

Check for continuity between the ground circuit ter-

minal and each of the blower motor driver circuit ter-

minals of the a/c heater control as you move the

blower motor switch knob to each of the four speed

positions. There should be continuity at each driver

circuit terminal in only one blower motor switch

speed position. If OK, test and repair the blower

driver circuits between the a/c heater control connec-

tor and the blower motor resistor as required. If not

OK, replace the faulty a/c heater control unit.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTALAIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blower motor switch cannot be adjusted or

repaired, and if faulty or damaged, the a/c heater

control must be replaced. (Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - REMOVAL)

IN-CAR TEMPERATURE

SENSOR

DESCRIPTION

Models equipped with the optional Automatic Zone

Control (AZC) system use automatic dual zone tem-

perature control with infrared sensing technology.

The temperature sensor is located in the center

instrument panel, between the dual temperature

knobs of the AZC.

OPERATION

The Automatic Zone Control uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

The infrared temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, the

AZC head must be replaced.

NOTE: The infrared sensor window may be perma-

nently damaged if any type of cosmetic vinyl dress-

ings are allowed to contact the lens. Avoid spraying

or wiping this area with any cleaner or conditioner.

This may result in impaired temperature sensing

and control.

REMOVAL

The infrared temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, the

AZC head must be replaced. (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/A/C HEATER

CONTROL - REMOVAL)

WJCONTROLS 24 - 29

BLOWER MOTOR SWITCH (Continued)

Page 2174 of 2199

and deteriorate engine performance, driveability and

fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S's sensor strategy is based on the fact that

as a catalyst deteriorates, its oxygen storage capacity

and its efficiency are both reduced. By monitoring

the oxygen storage capacity of a catalyst, its effi-

ciency can be indirectly calculated. The upstream

O2S is used to detect the amount of oxygen in the

exhaust gas before the gas enters the catalytic con-

verter. The PCM calculates the A/F mixture from the

output of the O2S. A low voltage indicates high oxy-

gen content (lean mixture). A high voltage indicates a

low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL will be illu-

minated.

DESCRIPTION - TRIP DEFINITION

The term ªTripº has different meanings depending

on what the circumstances are. If the MIL (Malfunc-

tion Indicator Lamp) is OFF, a Trip is defined as

when the Oxygen Sensor Monitor and the Catalyst

Monitor have been completed in the same drive cycle.

When any Emission DTC is set, the MIL on the

dash is turned ON. When the MIL is ON, it takes 3

good trips to turn the MIL OFF. In this case, itdepends on what type of DTC is set to know what a

ªTripº is.

For the Fuel Monitor or Mis-Fire Monitor (contin-

uous monitor), the vehicle must be operated in the

ªSimilar Condition Windowº for a specified amount of

time to be considered a Good Trip.

If a Non-Contiuous OBDII Monitor fails twice in a

row and turns ON the MIL, re-running that monitor

which previously failed, on the next start-up and

passing the monitor, is considered to be a Good Trip.

These will include the following:

²Oxygen Sensor

²Catalyst Monitor

²Purge Flow Monitor

²Leak Detection Pump Monitor (if equipped)

²EGR Monitor (if equipped)

²Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII

Monitor), a Good Trip is considered to be when the

Oxygen Sensor Monitor and Catalyst Monitor have

been completed; or 2 Minutes of engine run time if

the Oxygen Sensor Monitor or Catalyst Monitor have

been stopped from running.

It can take up to 2 Failures in a row to turn on the

MIL. After the MIL is ON, it takes 3 Good Trips to

turn the MIL OFF. After the MIL is OFF, the PCM

will self-erase the DTC after 40 Warm-up cycles. A

Warm-up cycle is counted when the ECT (Engine

Coolant Temperature Sensor) has crossed 160ÉF and

has risen by at least 40ÉF since the engine has been

started.

DESCRIPTION - COMPONENT MONITORS

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (MIL) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum if

the TPS indicates a small throttle opening.

All open/short circuit checks or any component that

has an associated limp in will set a fault after 1 trip

with the malfunction present. Components without

WJEMISSIONS CONTROL 25 - 19

EMISSIONS CONTROL (Continued)