head bolt torque JEEP GRAND CHEROKEE 2002 WJ / 2.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1381 of 2199

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install ignition coil towers (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

(10) Install coolant temperature sensor (Refer to 7

- COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - INSTALLATION).

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Install right side engine lifting stud.

(14) Install generator including electrical connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - INSTALLATION).

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Install air conditioning compressor including

electrical connections.

(17) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(19) Install cowl to hood seal (Refer to 23 - BODY/

WEATHERSTRIP/SEALS/COWL WEATHERSTRIP -

INSTALLATION).

(20) Install air cleaner housing and throttle body

resonator. Tighten resonator bolts 4.5 N´m (40 in.

lbs.).

(21) Connect negative cable to battery.

EXHAUST MANIFOLD - LEFT

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nutthat is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

(1) Disconnect negative cable for battery.

(2) Hoist vehicle.

(3) Disconnect exhaust pipe at manifold.

(4) Lower vehicle.

(5) Remove air cleaner housing and tube.

(6) Remove the front two exhaust heat shield

retaining fasteners. Raise vehicle and remove the

fasteners at rear of heat shield.

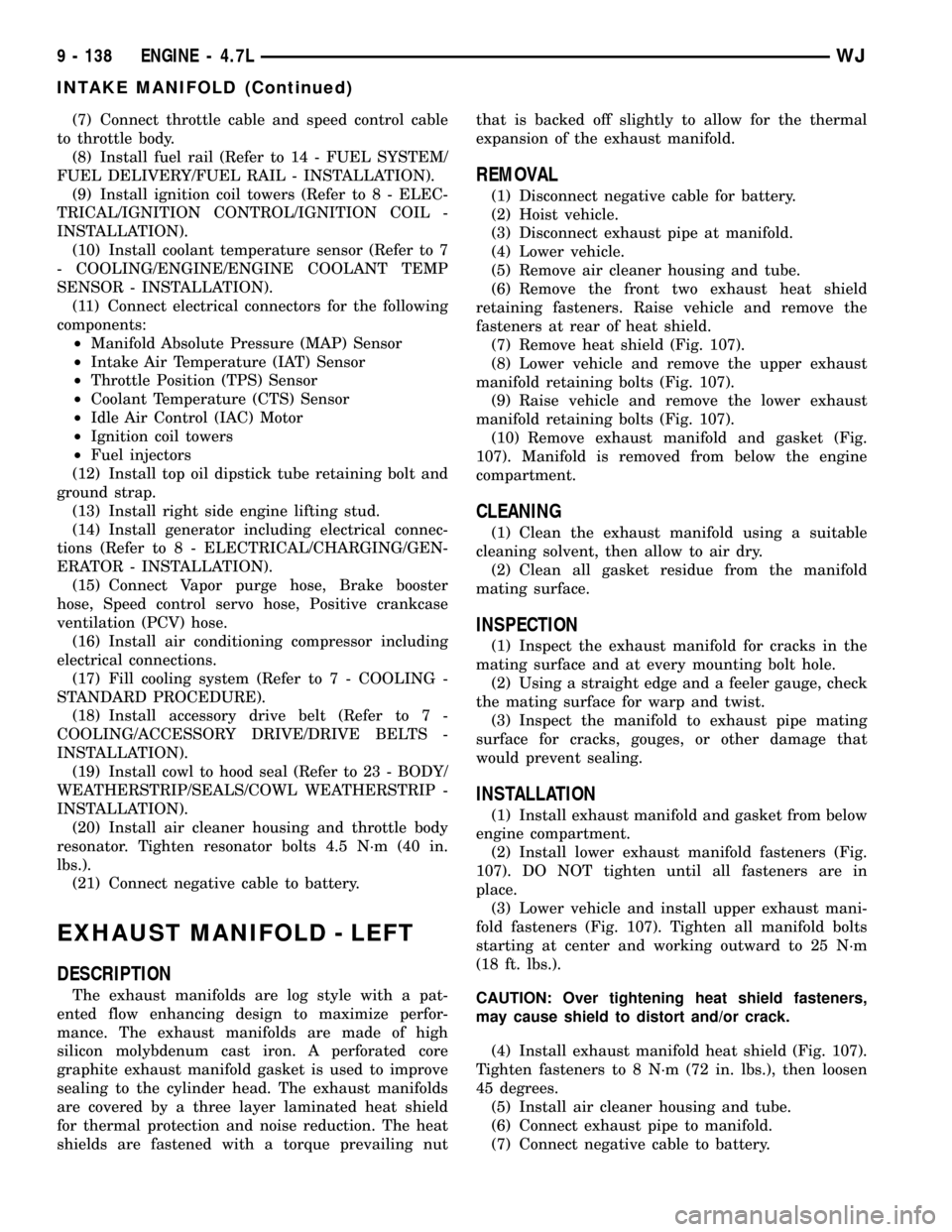

(7) Remove heat shield (Fig. 107).

(8) Lower vehicle and remove the upper exhaust

manifold retaining bolts (Fig. 107).

(9) Raise vehicle and remove the lower exhaust

manifold retaining bolts (Fig. 107).

(10) Remove exhaust manifold and gasket (Fig.

107). Manifold is removed from below the engine

compartment.

CLEANING

(1) Clean the exhaust manifold using a suitable

cleaning solvent, then allow to air dry.

(2) Clean all gasket residue from the manifold

mating surface.

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.

(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners (Fig.

107). DO NOT tighten until all fasteners are in

place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners (Fig. 107). Tighten all manifold bolts

starting at center and working outward to 25 N´m

(18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield (Fig. 107).

Tighten fasteners to 8 N´m (72 in. lbs.), then loosen

45 degrees.

(5) Install air cleaner housing and tube.

(6) Connect exhaust pipe to manifold.

(7) Connect negative cable to battery.

9 - 138 ENGINE - 4.7LWJ

INTAKE MANIFOLD (Continued)

Page 1382 of 2199

EXHAUST MANIFOLD - RIGHT

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

(1) Disconnect negative cable for battery.

(2) Remove battery from vehicle.

(3) Remove Power Distribution Center (PDC) fas-

teners and set aside.

(4) Remove battery tray assembly.

(5) Remove washer bottle assembly

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

Fig. 107 Exhaust ManifoldÐLeft

ITEM DESCRIPTION TORQUE ITEM DESCRIPTION TORQUE

1 Stud (Qty 2)

25 N´m (18 ft. lbs.)4 Nut (Qty 2) 8 N´m (72 in. lbs.),

then loosen 45

degrees 2 Bolt (Qty 4) 5 Nut (Qty 2)

3 Stud (Qty 2)

WJENGINE - 4.7L 9 - 139

EXHAUST MANIFOLD - LEFT (Continued)

Page 1387 of 2199

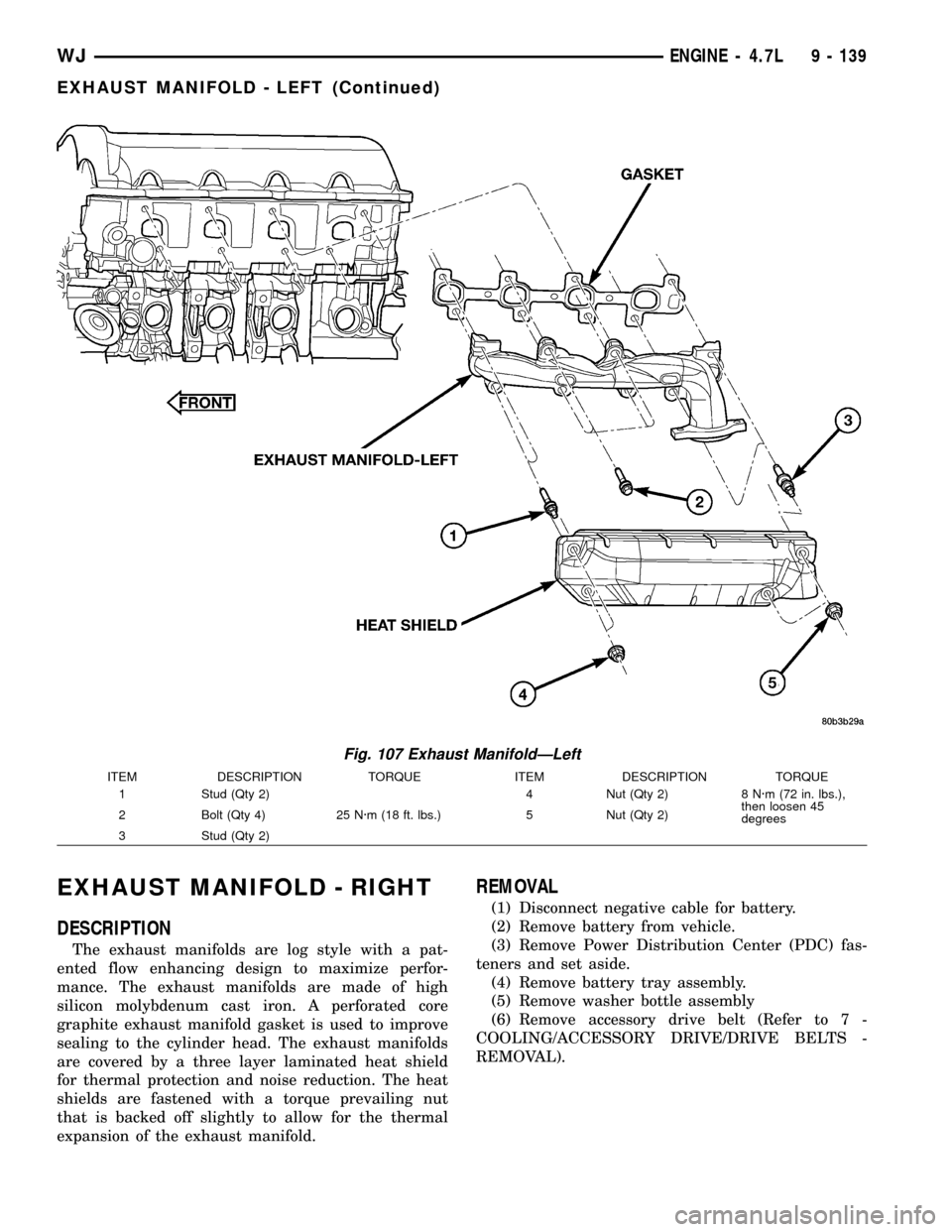

(5) Using a suitable pair of adjustable pliers,

rotate the camshaft until the alignment dowel on the

camshaft is aligned with the slot in the camshaft

drive gear (Fig. 113).

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Fail-

ure to do so may cause over-torqueing of bolt

resulting in bolt failure.

(6) Position the camshaft drive gear onto the cam-

shaft, remove oil from bolt then install the retaining

bolt. Using Special Tools, Spanner Wrench 6958 with

Adapter Pins 8346 and a suitable torque wrench,

Tighten retaining bolt to 122N´m (90 ft. Lbs.) (Fig.

114) (Fig. 115).

(7) Remove special tool 8350.

(8) Rotate the crankshaft two full revolutions, then

reverify that the camshaft drive gear V8 marks are

in fact aligned.

(9) Install the cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

Fig. 112 Securing Timing Chain Tensioners Using Timing Chain Wedge

1 - LEFT CYLINDER HEAD

2 - RIGHT CYLINDER HEAD3 - SPECIAL TOOL 8350 WEDGE

4 - SPECIAL TOOL 8350 WEDGE

Fig. 113 Camshaft Dowel

1 - ADJUSTABLE PLIERS

2 - CAMSHAFT DOWEL

9 - 144 ENGINE - 4.7LWJ

VALVE TIMING (Continued)

Page 1393 of 2199

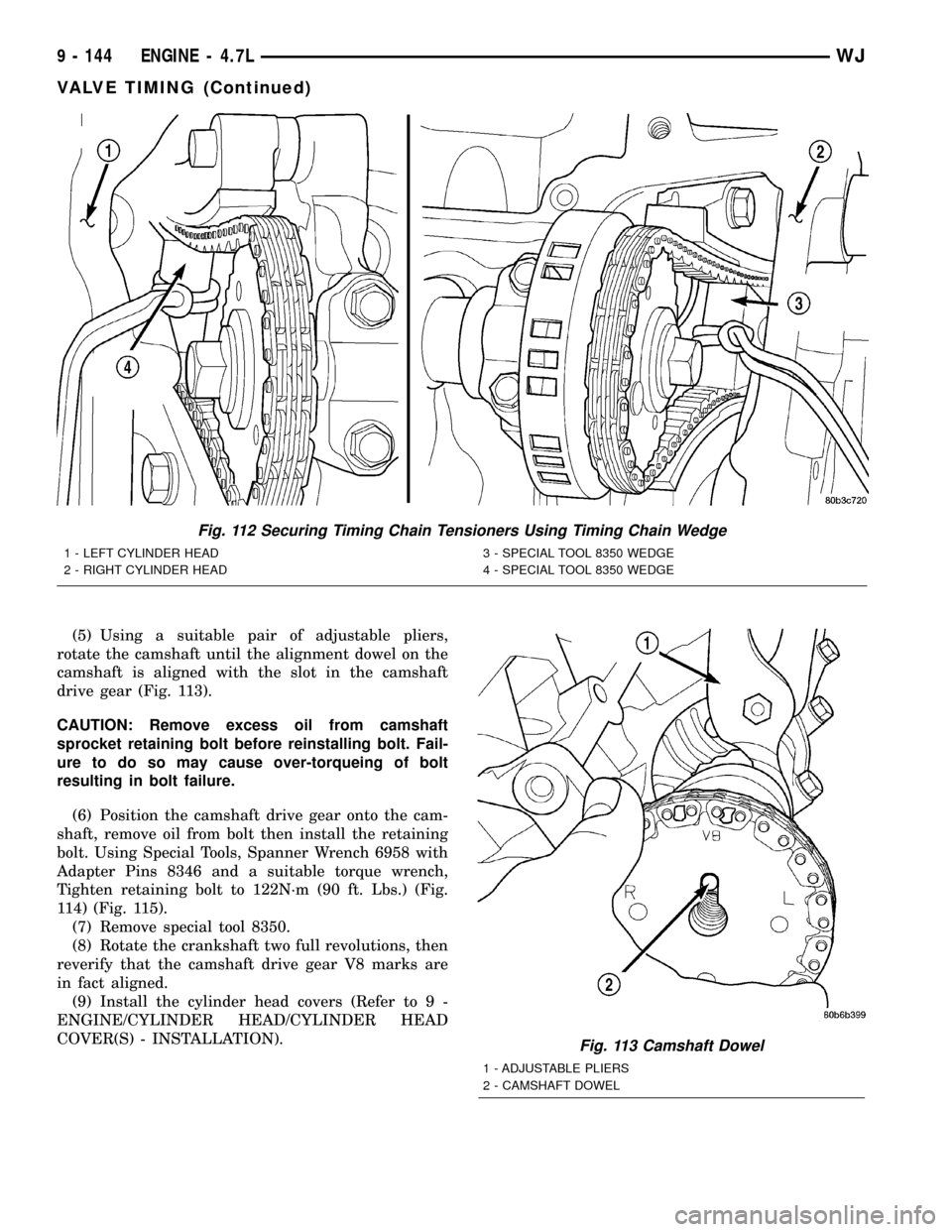

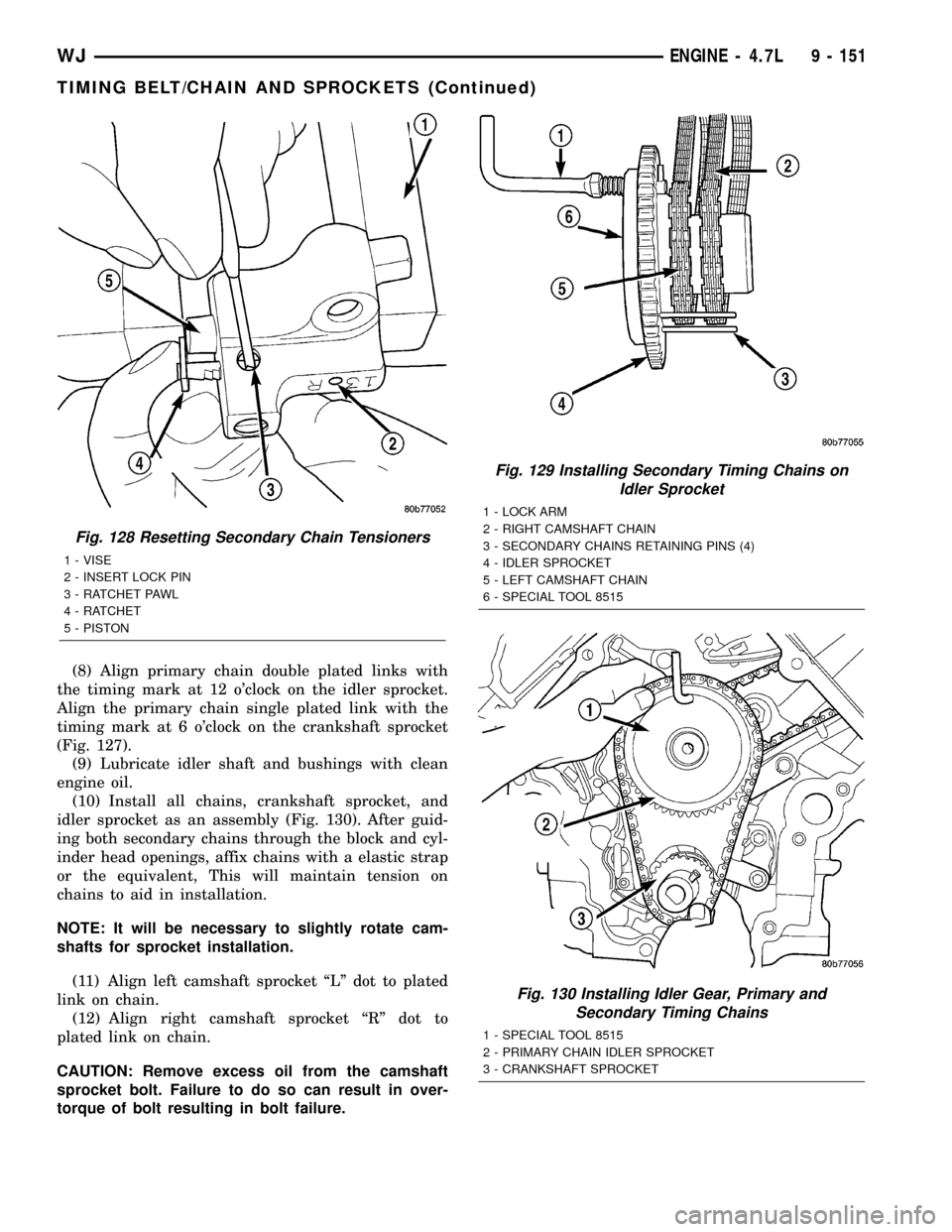

body. Install Special Tool 8514 lock pin into hole on

front of tensioner. Slowly open vise to transfer piston

spring force to lock pin (Fig. 128).

(2) Position primary chain tensioner over oil pump

and insert bolts into lower two holes on tensioner

bracket. Tighten bolts to 28 N´m (250 in. lbs.).

CAUTION: Overtightening the tensioner arm torxT

bolt can cause severe damage to the cylinder head.

Tighten torxTbolt to specified torque only.

(3) Install right side chain tensioner arm. Apply

MopartLock N, Seal to torxtbolt, tighten bolt to 17

N´m (150 in. lbs.).

NOTE: The silver bolts retain the guides to the cyl-

inder heads and the black bolts retain the guides to

the engine block.(4) Install the left side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

CAUTION: Overtightening the tensioner arm torxT

bolt can cause severe damage to the cylinder head.

Tighten torxTbolt to specified torque only.

(5) Install left side chain tensioner arm. Apply

MopartLock N, Seal to torxtbolt, tighten bolt to 17

N´m (150 in. lbs.).

(6) Install the right side chain guide. Tighten the

bolts to 28 N´m (250 in. lbs.).

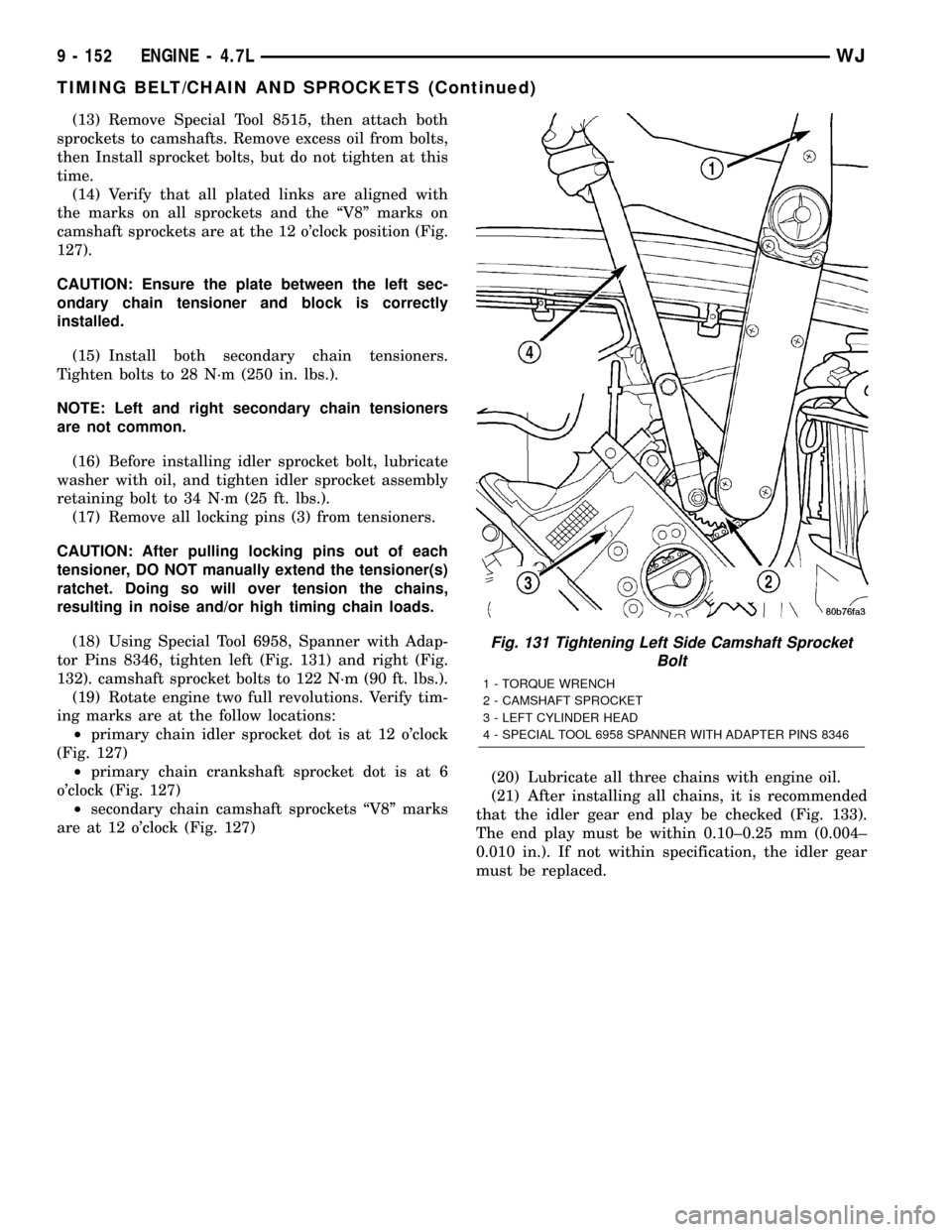

(7) Install both secondary chains onto the idler

sprocket. Align two plated links on the secondary

chains to be visible through the two lower openings

on the idler sprocket (4 o'clock and 8 o'clock). Once

the secondary timing chains are installed, position

special tool 8515 to hold chains in place for installa-

tion (Fig. 129).

Fig. 127 Timing Chain System

1 - RIGHT CAMSHAFT SPROCKET AND SECONDARY CHAIN

2 - SECONDARY TIMING CHAIN TENSIONER (LEFT AND RIGHT

SIDE NOT COMMON)

3 - SECONDARY TENSIONER ARM

4 - LEFT CAMSHAFT SPROCKET AND SECONDARY CHAIN

5 - CHAIN GUIDE

6 - TWO PLATED LINKS ON RIGHT CAMSHAFT CHAIN7 - PRIMARY CHAIN

8 - IDLER SPROCKET

9 - CRANKSHAFT SPROCKET

10 - PRIMARY CHAIN TENSIONER

11 - TWO PLATED LINKS ON LEFT CAMSHAFT CHAIN

12 - SECONDARY TENSIONER ARM

9 - 150 ENGINE - 4.7LWJ

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1394 of 2199

(8) Align primary chain double plated links with

the timing mark at 12 o'clock on the idler sprocket.

Align the primary chain single plated link with the

timing mark at 6 o'clock on the crankshaft sprocket

(Fig. 127).

(9) Lubricate idler shaft and bushings with clean

engine oil.

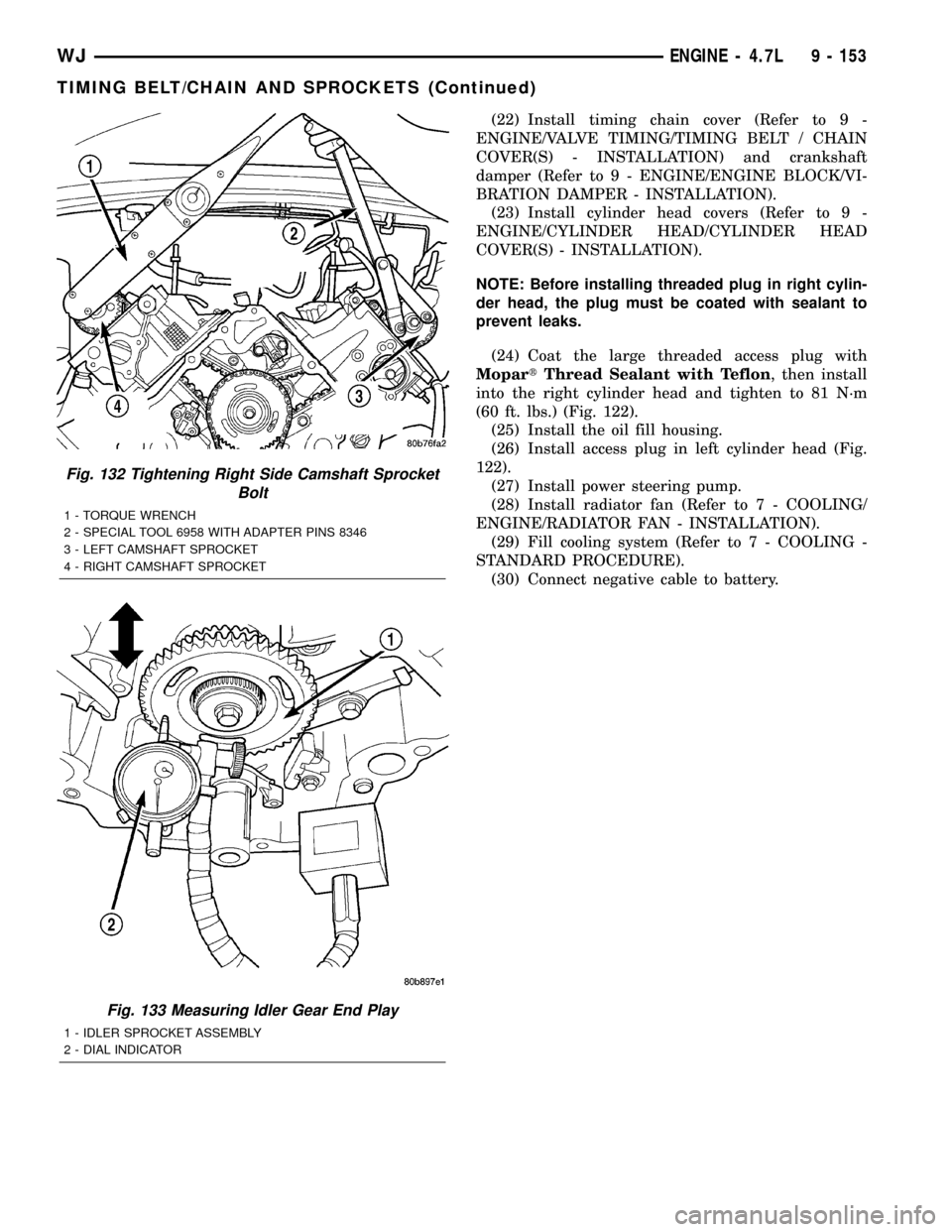

(10) Install all chains, crankshaft sprocket, and

idler sprocket as an assembly (Fig. 130). After guid-

ing both secondary chains through the block and cyl-

inder head openings, affix chains with a elastic strap

or the equivalent, This will maintain tension on

chains to aid in installation.

NOTE: It will be necessary to slightly rotate cam-

shafts for sprocket installation.

(11) Align left camshaft sprocket ªLº dot to plated

link on chain.

(12) Align right camshaft sprocket ªRº dot to

plated link on chain.

CAUTION: Remove excess oil from the camshaft

sprocket bolt. Failure to do so can result in over-

torque of bolt resulting in bolt failure.

Fig. 128 Resetting Secondary Chain Tensioners

1 - VISE

2 - INSERT LOCK PIN

3 - RATCHET PAWL

4 - RATCHET

5 - PISTON

Fig. 129 Installing Secondary Timing Chains on

Idler Sprocket

1 - LOCK ARM

2 - RIGHT CAMSHAFT CHAIN

3 - SECONDARY CHAINS RETAINING PINS (4)

4 - IDLER SPROCKET

5 - LEFT CAMSHAFT CHAIN

6 - SPECIAL TOOL 8515

Fig. 130 Installing Idler Gear, Primary and

Secondary Timing Chains

1 - SPECIAL TOOL 8515

2 - PRIMARY CHAIN IDLER SPROCKET

3 - CRANKSHAFT SPROCKET

WJENGINE - 4.7L 9 - 151

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1395 of 2199

(13) Remove Special Tool 8515, then attach both

sprockets to camshafts. Remove excess oil from bolts,

then Install sprocket bolts, but do not tighten at this

time.

(14) Verify that all plated links are aligned with

the marks on all sprockets and the ªV8º marks on

camshaft sprockets are at the 12 o'clock position (Fig.

127).

CAUTION: Ensure the plate between the left sec-

ondary chain tensioner and block is correctly

installed.

(15) Install both secondary chain tensioners.

Tighten bolts to 28 N´m (250 in. lbs.).

NOTE: Left and right secondary chain tensioners

are not common.

(16) Before installing idler sprocket bolt, lubricate

washer with oil, and tighten idler sprocket assembly

retaining bolt to 34 N´m (25 ft. lbs.).

(17) Remove all locking pins (3) from tensioners.

CAUTION: After pulling locking pins out of each

tensioner, DO NOT manually extend the tensioner(s)

ratchet. Doing so will over tension the chains,

resulting in noise and/or high timing chain loads.

(18) Using Special Tool 6958, Spanner with Adap-

tor Pins 8346, tighten left (Fig. 131) and right (Fig.

132). camshaft sprocket bolts to 122 N´m (90 ft. lbs.).

(19) Rotate engine two full revolutions. Verify tim-

ing marks are at the follow locations:

²primary chain idler sprocket dot is at 12 o'clock

(Fig. 127)

²primary chain crankshaft sprocket dot is at 6

o'clock (Fig. 127)

²secondary chain camshaft sprockets ªV8º marks

are at 12 o'clock (Fig. 127)(20) Lubricate all three chains with engine oil.

(21) After installing all chains, it is recommended

that the idler gear end play be checked (Fig. 133).

The end play must be within 0.10±0.25 mm (0.004±

0.010 in.). If not within specification, the idler gear

must be replaced.

Fig. 131 Tightening Left Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - CAMSHAFT SPROCKET

3 - LEFT CYLINDER HEAD

4 - SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

9 - 152 ENGINE - 4.7LWJ

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1396 of 2199

(22) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION) and crankshaft

damper (Refer to 9 - ENGINE/ENGINE BLOCK/VI-

BRATION DAMPER - INSTALLATION).

(23) Install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

NOTE: Before installing threaded plug in right cylin-

der head, the plug must be coated with sealant to

prevent leaks.

(24) Coat the large threaded access plug with

MopartThread Sealant with Teflon, then install

into the right cylinder head and tighten to 81 N´m

(60 ft. lbs.) (Fig. 122).

(25) Install the oil fill housing.

(26) Install access plug in left cylinder head (Fig.

122).

(27) Install power steering pump.

(28) Install radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(29) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(30) Connect negative cable to battery.

Fig. 132 Tightening Right Side Camshaft Sprocket

Bolt

1 - TORQUE WRENCH

2 - SPECIAL TOOL 6958 WITH ADAPTER PINS 8346

3 - LEFT CAMSHAFT SPROCKET

4 - RIGHT CAMSHAFT SPROCKET

Fig. 133 Measuring Idler Gear End Play

1 - IDLER SPROCKET ASSEMBLY

2 - DIAL INDICATOR

WJENGINE - 4.7L 9 - 153

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1400 of 2199

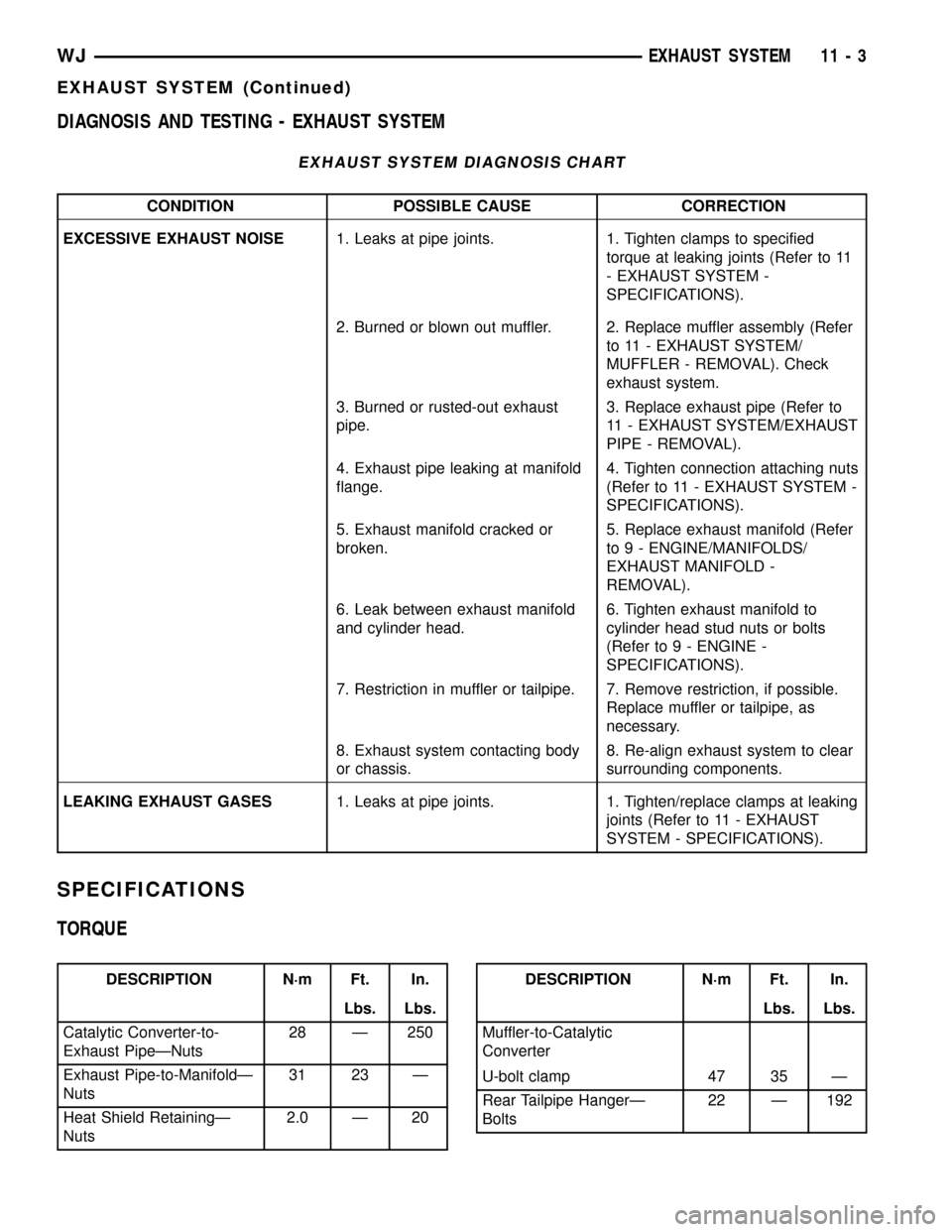

DIAGNOSIS AND TESTING - EXHAUST SYSTEM

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE1. Leaks at pipe joints. 1. Tighten clamps to specified

torque at leaking joints (Refer to 11

- EXHAUST SYSTEM -

SPECIFICATIONS).

2. Burned or blown out muffler. 2. Replace muffler assembly (Refer

to 11 - EXHAUST SYSTEM/

MUFFLER - REMOVAL). Check

exhaust system.

3. Burned or rusted-out exhaust

pipe.3. Replace exhaust pipe (Refer to

11 - EXHAUST SYSTEM/EXHAUST

PIPE - REMOVAL).

4. Exhaust pipe leaking at manifold

flange.4. Tighten connection attaching nuts

(Refer to 11 - EXHAUST SYSTEM -

SPECIFICATIONS).

5. Exhaust manifold cracked or

broken.5. Replace exhaust manifold (Refer

to 9 - ENGINE/MANIFOLDS/

EXHAUST MANIFOLD -

REMOVAL).

6. Leak between exhaust manifold

and cylinder head.6. Tighten exhaust manifold to

cylinder head stud nuts or bolts

(Refer to 9 - ENGINE -

SPECIFICATIONS).

7. Restriction in muffler or tailpipe. 7. Remove restriction, if possible.

Replace muffler or tailpipe, as

necessary.

8. Exhaust system contacting body

or chassis.8. Re-align exhaust system to clear

surrounding components.

LEAKING EXHAUST GASES1. Leaks at pipe joints. 1. Tighten/replace clamps at leaking

joints (Refer to 11 - EXHAUST

SYSTEM - SPECIFICATIONS).

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Catalytic Converter-to-

Exhaust PipeÐNuts28 Ð 250

Exhaust Pipe-to-ManifoldÐ

Nuts31 23 Ð

Heat Shield RetainingÐ

Nuts2.0 Ð 20DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Muffler-to-Catalytic

Converter

U-bolt clamp 47 35 Ð

Rear Tailpipe HangerÐ

Bolts22 Ð 192

WJEXHAUST SYSTEM 11 - 3

EXHAUST SYSTEM (Continued)

Page 1437 of 2199

(9) Disconnect speed control cable at throttle body

(if equipped). Refer to Speed Control Cable.

(10) Disconnect automatic transmission cable at

throttle body (if equipped).

(11) Remove cable routing bracket at intake mani-

fold.

(12) Clean dirt/debris from each fuel injector at

intake manifold.

(13) Remove fuel rail mounting nuts/bolts (Fig.

24).

(14) Remove fuel rail by gently rocking until all

fuel injectors have cleared machined holes at intake

manifold.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

INSTALLATION

INSTALLATION - 4.7L

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(3) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(4) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.(5) Pushrightside of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.

Pushleftfuel rail down until injectors have bot-

tomed on cylinder head shoulder.

(6) Install 4 fuel rail mounting bolts and tighten to

27 N´m (20 ft. lbs.).

(7) Install ignition coils. Refer to Ignition Coil

Removal/Installation.

(8) Connect electrical connectors to throttle body.

(9) Connect electrical connectors to MAP and IAT

sensors.

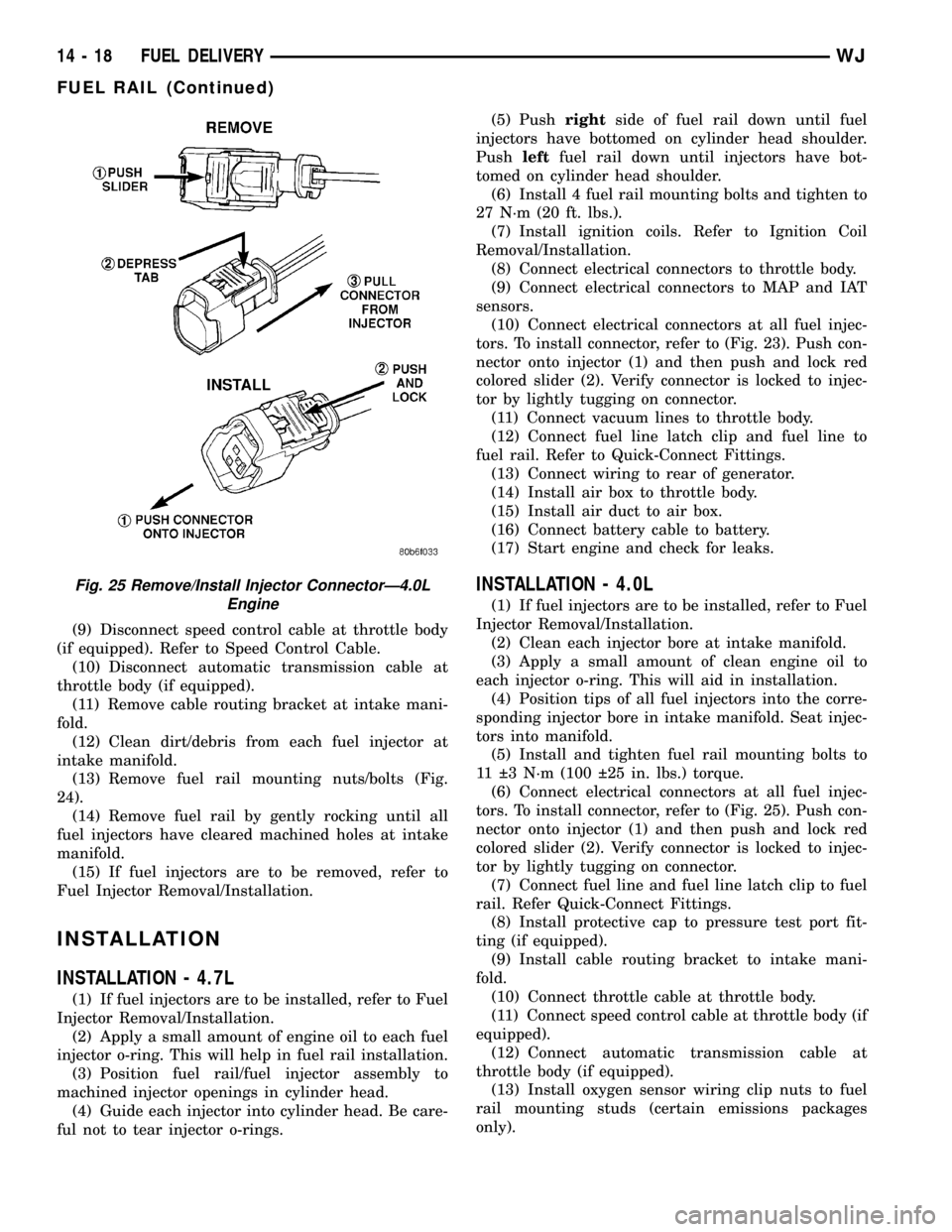

(10) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 23). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(11) Connect vacuum lines to throttle body.

(12) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(13) Connect wiring to rear of generator.

(14) Install air box to throttle body.

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

INSTALLATION - 4.0L

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean each injector bore at intake manifold.

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Position tips of all fuel injectors into the corre-

sponding injector bore in intake manifold. Seat injec-

tors into manifold.

(5) Install and tighten fuel rail mounting bolts to

11 3 N´m (100 25 in. lbs.) torque.

(6) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 25). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(7) Connect fuel line and fuel line latch clip to fuel

rail. Refer Quick-Connect Fittings.

(8) Install protective cap to pressure test port fit-

ting (if equipped).

(9) Install cable routing bracket to intake mani-

fold.

(10) Connect throttle cable at throttle body.

(11) Connect speed control cable at throttle body (if

equipped).

(12) Connect automatic transmission cable at

throttle body (if equipped).

(13) Install oxygen sensor wiring clip nuts to fuel

rail mounting studs (certain emissions packages

only).

Fig. 25 Remove/Install Injector ConnectorÐ4.0L

Engine

14 - 18 FUEL DELIVERYWJ

FUEL RAIL (Continued)

Page 1462 of 2199

(5) Push sensor against flywheel/drive plate. With

sensor pushed against flywheel/drive plate, tighten

mounting bolt to 7 N´m (60 in. lbs.) torque.

(6) Route sensor wiring harness into wire shield.

(7) Connect sensor pigtail harness electrical con-

nector to main wiring harness.

INSTALLATION - 4.7L

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking action. Do not twist sensor into position as

damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Install starter motor. Refer to Starter Removal/

Installation.

FUEL INJECTOR

DESCRIPTION

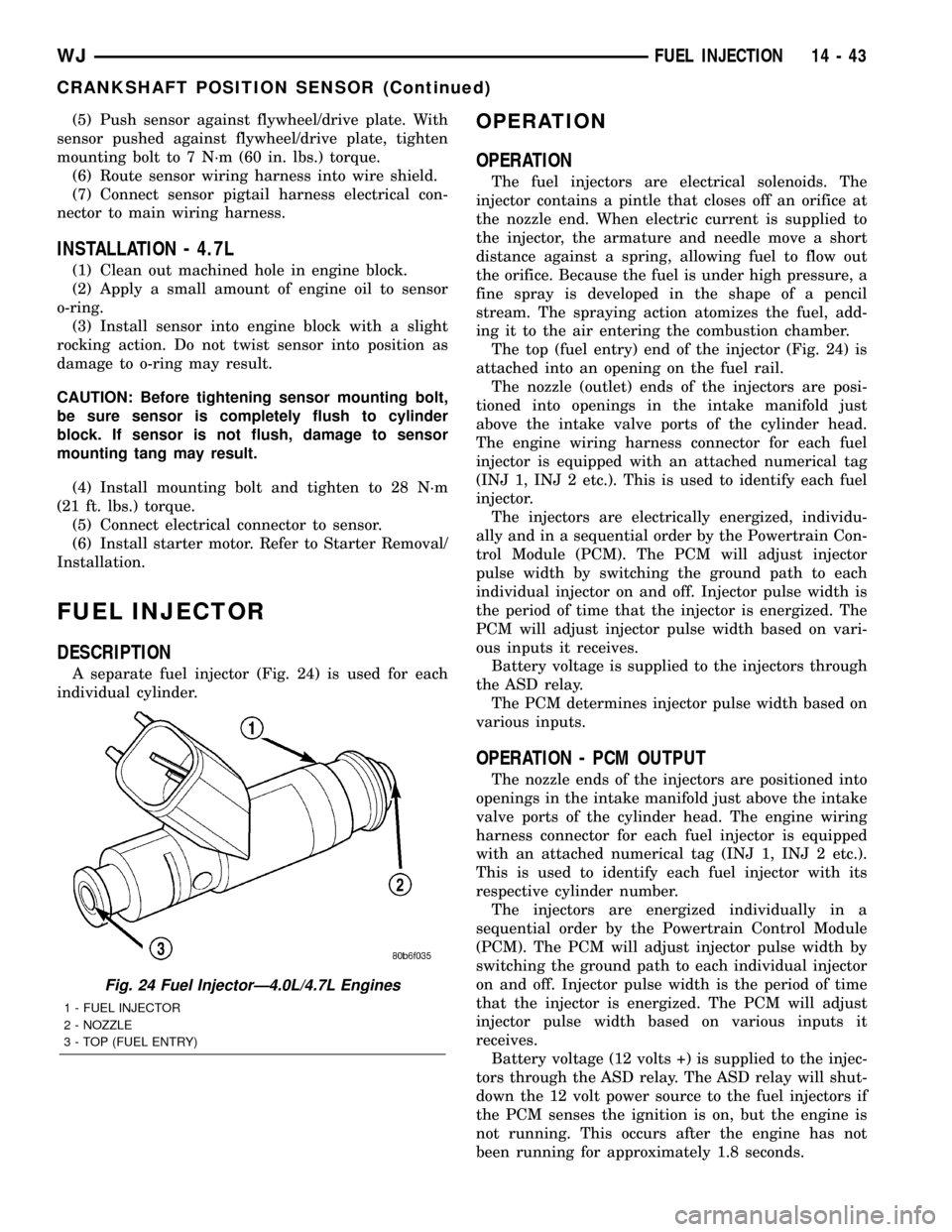

A separate fuel injector (Fig. 24) is used for each

individual cylinder.

OPERATION

OPERATION

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The top (fuel entry) end of the injector (Fig. 24) is

attached into an opening on the fuel rail.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are electrically energized, individu-

ally and in a sequential order by the Powertrain Con-

trol Module (PCM). The PCM will adjust injector

pulse width by switching the ground path to each

individual injector on and off. Injector pulse width is

the period of time that the injector is energized. The

PCM will adjust injector pulse width based on vari-

ous inputs it receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

Fig. 24 Fuel InjectorÐ4.0L/4.7L Engines

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

WJFUEL INJECTION 14 - 43

CRANKSHAFT POSITION SENSOR (Continued)