head bolt torque JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1266 of 2199

CLEANING

Remove any original sealer from the cover sealing

surface of the engine cylinder head and clean the

surface using a fabric cleaner.

Remove all residue from the sealing surface using

a clean, dry cloth.

INSPECTION

Inspect the engine cylinder head cover for cracks.

Replace the cover, if cracked.

The original dark grey gasket material should

NOT be removed. If sections of the gasket material

are missing or are compressed, replace the engine

cylinder head cover. However, sections with minor

damage such as small cracks, cuts or chips may be

repaired with a hand held applicator. The new mate-

rial must be smoothed over to maintain gasket

height. Allow the gasket material to cure prior to

engine cylinder head cover installation.

INSTALLATION

The cylinder head cover is isolated from the cylin-

der head via grommets and a reusable molded rubber

gasket. The grommet and limiter are retained in the

cylinder head cover.

(1) If a replacement cover is installed, transfer the

CCV valve grommet and oil filler cap from the origi-

nal cover to the replacement cover.

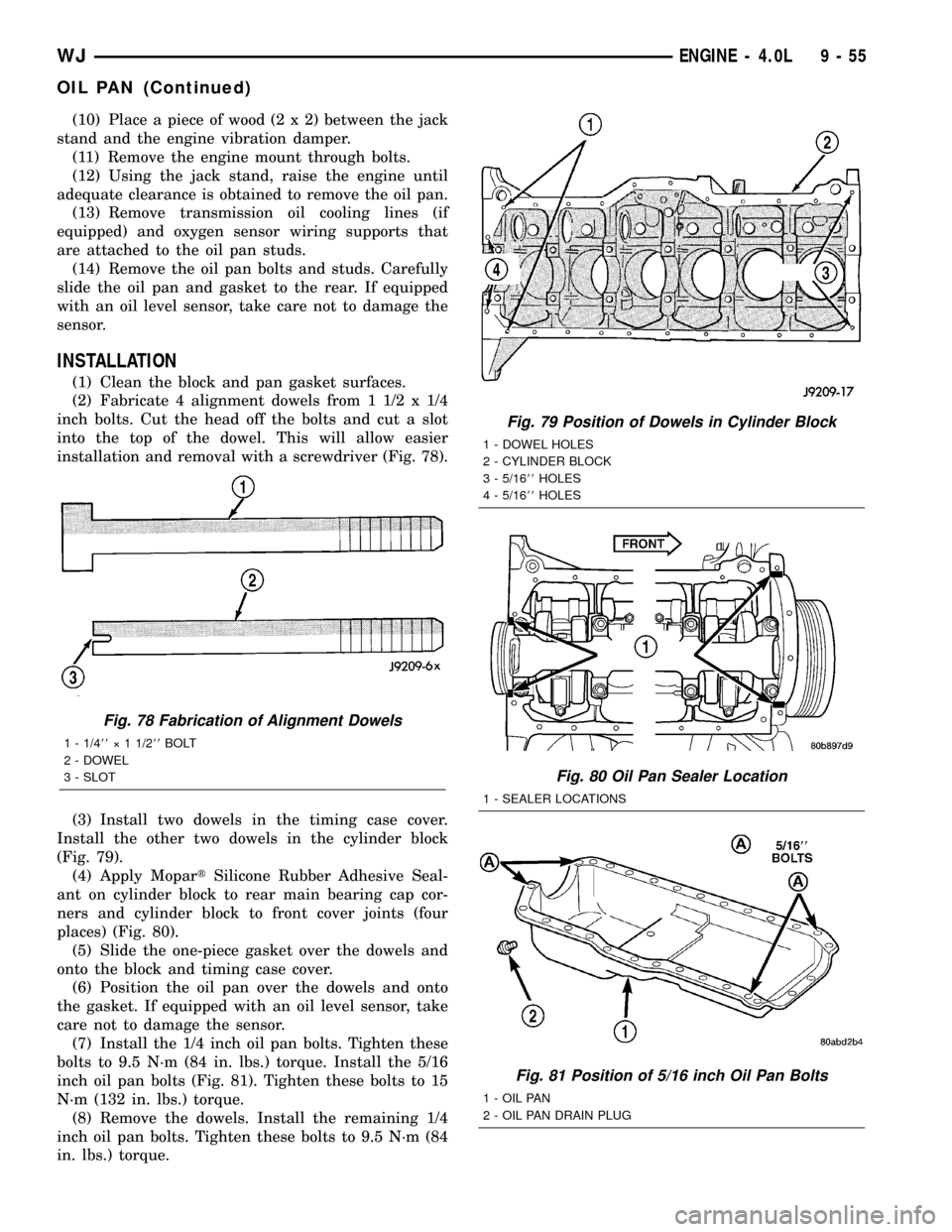

(2) Install cylinder head cover and gasket (Fig. 13).

Tighten the mounting bolts to 10 N´m (85 in. lbs.)

torque.

(3) Connect the CCV hoses.(4) Install control cables and bracket on intake

manifold and tighten bolts to 8.7 N´m (77 in. lbs.)

torque.

(5) Connect control cables to throttle body linkage.

(6) Snap control cables into cylinder head cover

clip.

(7) Connect negative cable to battery.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. All

valves use three bead locks to promote valve rotation

(Fig. 14).

STANDARD PROCEDURE - VALVE SERVICE

VALVE REFACING

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

(1) Use a valve refacing machine to reface the

intake and exhaust valves to the specified angle.

(2) After refacing, a margin of at least 0.787 mm

(0.031 inch) must remain (Fig. 15). If the margin is

less than 0.787 mm (0.031 inch), the valve must be

replaced.

VALVE SEAT REFACING

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

(1) Install a pilot of the correct size in the valve

guide bore. Reface the valve seat to the specified

angle with a good dressing stone. Remove only

enough metal to provide a smooth finish.

(2) Use tapered stones to obtain the specified seat

width when required.

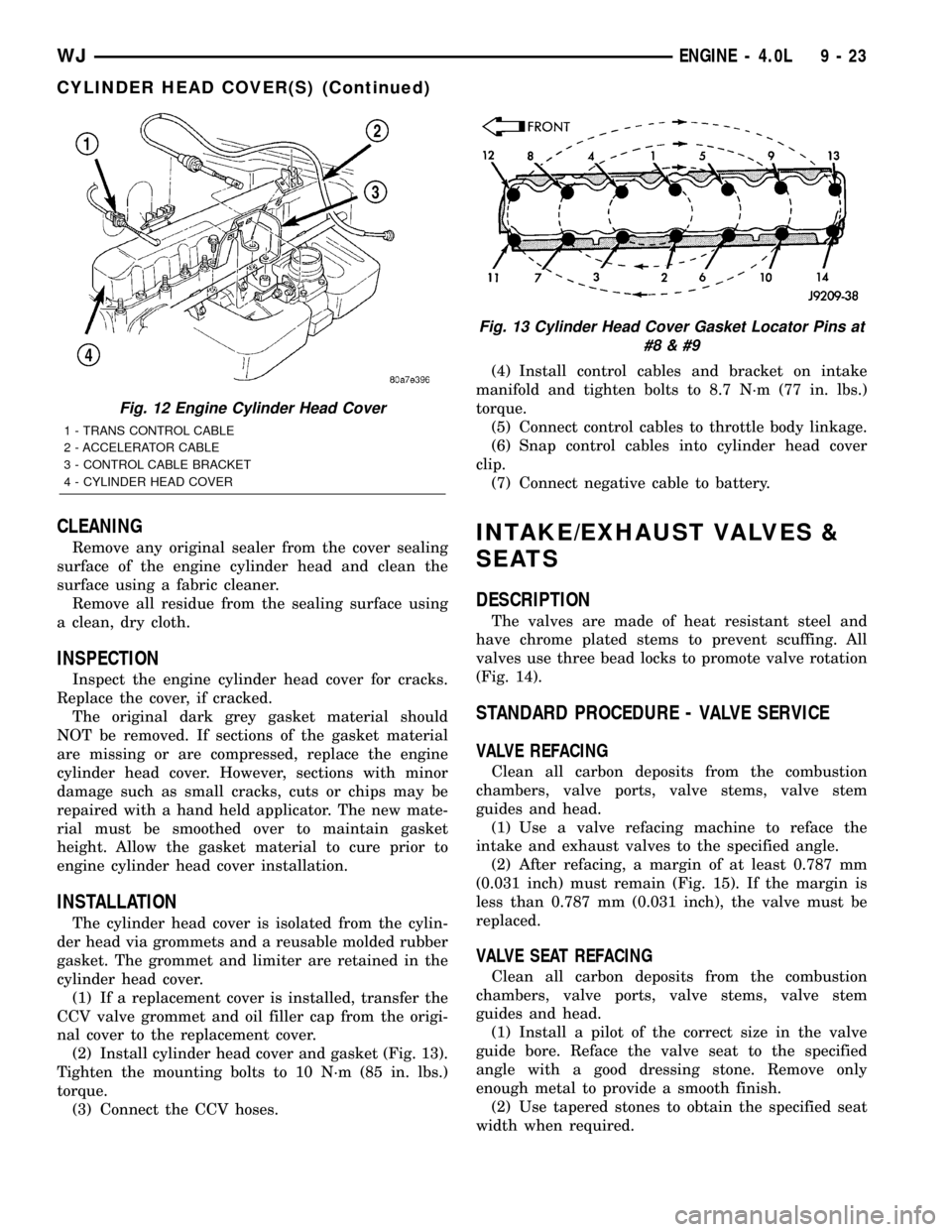

Fig. 12 Engine Cylinder Head Cover

1 - TRANS CONTROL CABLE

2 - ACCELERATOR CABLE

3 - CONTROL CABLE BRACKET

4 - CYLINDER HEAD COVER

Fig. 13 Cylinder Head Cover Gasket Locator Pins at

#8

WJENGINE - 4.0L 9 - 23

CYLINDER HEAD COVER(S) (Continued)

Page 1298 of 2199

(10) Place a piece of wood (2 x 2) between the jack

stand and the engine vibration damper.

(11) Remove the engine mount through bolts.

(12) Using the jack stand, raise the engine until

adequate clearance is obtained to remove the oil pan.

(13) Remove transmission oil cooling lines (if

equipped) and oxygen sensor wiring supports that

are attached to the oil pan studs.

(14) Remove the oil pan bolts and studs. Carefully

slide the oil pan and gasket to the rear. If equipped

with an oil level sensor, take care not to damage the

sensor.

INSTALLATION

(1) Clean the block and pan gasket surfaces.

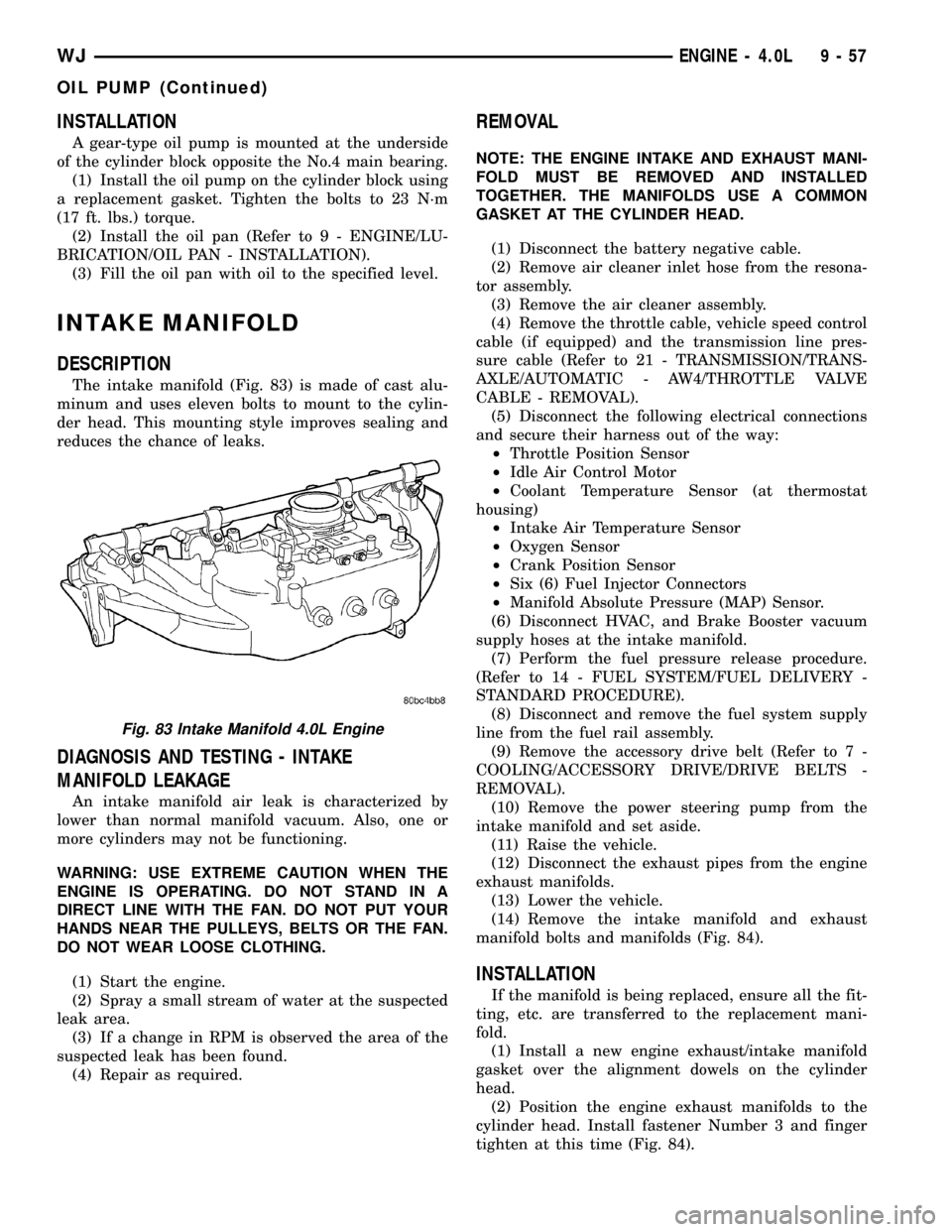

(2) Fabricate 4 alignment dowels from 1 1/2 x 1/4

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier

installation and removal with a screwdriver (Fig. 78).

(3) Install two dowels in the timing case cover.

Install the other two dowels in the cylinder block

(Fig. 79).

(4) Apply MopartSilicone Rubber Adhesive Seal-

ant on cylinder block to rear main bearing cap cor-

ners and cylinder block to front cover joints (four

places) (Fig. 80).

(5) Slide the one-piece gasket over the dowels and

onto the block and timing case cover.

(6) Position the oil pan over the dowels and onto

the gasket. If equipped with an oil level sensor, take

care not to damage the sensor.

(7) Install the 1/4 inch oil pan bolts. Tighten these

bolts to 9.5 N´m (84 in. lbs.) torque. Install the 5/16

inch oil pan bolts (Fig. 81). Tighten these bolts to 15

N´m (132 in. lbs.) torque.

(8) Remove the dowels. Install the remaining 1/4

inch oil pan bolts. Tighten these bolts to 9.5 N´m (84

in. lbs.) torque.

Fig. 78 Fabrication of Alignment Dowels

1 - 1/488ý 1 1/288BOLT

2 - DOWEL

3 - SLOT

Fig. 79 Position of Dowels in Cylinder Block

1 - DOWEL HOLES

2 - CYLINDER BLOCK

3 - 5/1688HOLES

4 - 5/1688HOLES

Fig. 80 Oil Pan Sealer Location

1 - SEALER LOCATIONS

Fig. 81 Position of 5/16 inch Oil Pan Bolts

1 - OIL PAN

2 - OIL PAN DRAIN PLUG

WJENGINE - 4.0L 9 - 55

OIL PAN (Continued)

Page 1300 of 2199

INSTALLATION

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

(1) Install the oil pump on the cylinder block using

a replacement gasket. Tighten the bolts to 23 N´m

(17 ft. lbs.) torque.

(2) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(3) Fill the oil pan with oil to the specified level.

INTAKE MANIFOLD

DESCRIPTION

The intake manifold (Fig. 83) is made of cast alu-

minum and uses eleven bolts to mount to the cylin-

der head. This mounting style improves sealing and

reduces the chance of leaks.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

REMOVAL

NOTE: THE ENGINE INTAKE AND EXHAUST MANI-

FOLD MUST BE REMOVED AND INSTALLED

TOGETHER. THE MANIFOLDS USE A COMMON

GASKET AT THE CYLINDER HEAD.

(1) Disconnect the battery negative cable.

(2) Remove air cleaner inlet hose from the resona-

tor assembly.

(3) Remove the air cleaner assembly.

(4) Remove the throttle cable, vehicle speed control

cable (if equipped) and the transmission line pres-

sure cable (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - AW4/THROTTLE VALVE

CABLE - REMOVAL).

(5) Disconnect the following electrical connections

and secure their harness out of the way:

²Throttle Position Sensor

²Idle Air Control Motor

²Coolant Temperature Sensor (at thermostat

housing)

²Intake Air Temperature Sensor

²Oxygen Sensor

²Crank Position Sensor

²Six (6) Fuel Injector Connectors

²Manifold Absolute Pressure (MAP) Sensor.

(6) Disconnect HVAC, and Brake Booster vacuum

supply hoses at the intake manifold.

(7) Perform the fuel pressure release procedure.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(8) Disconnect and remove the fuel system supply

line from the fuel rail assembly.

(9) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(10) Remove the power steering pump from the

intake manifold and set aside.

(11) Raise the vehicle.

(12) Disconnect the exhaust pipes from the engine

exhaust manifolds.

(13) Lower the vehicle.

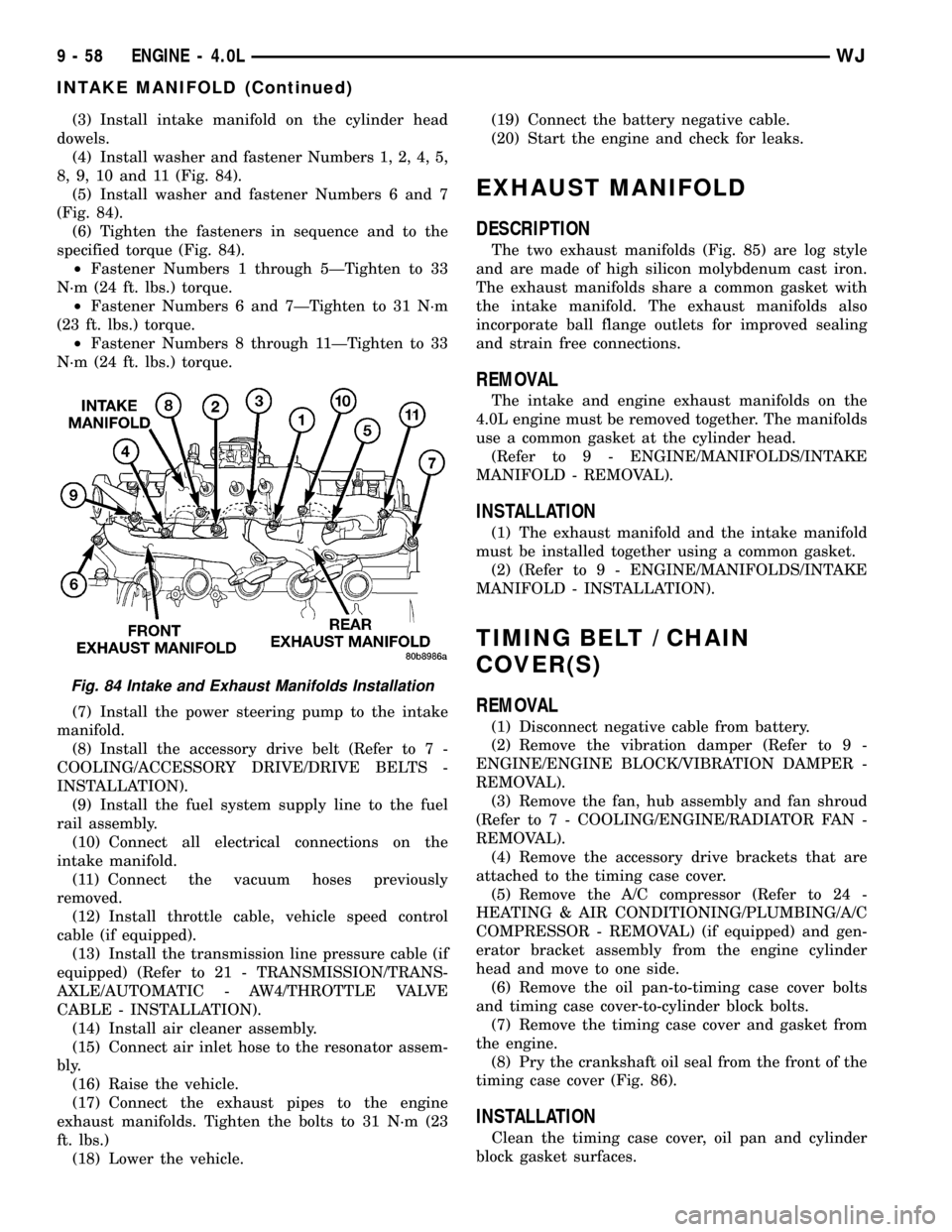

(14) Remove the intake manifold and exhaust

manifold bolts and manifolds (Fig. 84).

INSTALLATION

If the manifold is being replaced, ensure all the fit-

ting, etc. are transferred to the replacement mani-

fold.

(1) Install a new engine exhaust/intake manifold

gasket over the alignment dowels on the cylinder

head.

(2) Position the engine exhaust manifolds to the

cylinder head. Install fastener Number 3 and finger

tighten at this time (Fig. 84).

Fig. 83 Intake Manifold 4.0L Engine

WJENGINE - 4.0L 9 - 57

OIL PUMP (Continued)

Page 1301 of 2199

(3) Install intake manifold on the cylinder head

dowels.

(4) Install washer and fastener Numbers 1, 2, 4, 5,

8, 9, 10 and 11 (Fig. 84).

(5) Install washer and fastener Numbers 6 and 7

(Fig. 84).

(6) Tighten the fasteners in sequence and to the

specified torque (Fig. 84).

²Fastener Numbers 1 through 5ÐTighten to 33

N´m (24 ft. lbs.) torque.

²Fastener Numbers 6 and 7ÐTighten to 31 N´m

(23 ft. lbs.) torque.

²Fastener Numbers 8 through 11ÐTighten to 33

N´m (24 ft. lbs.) torque.

(7) Install the power steering pump to the intake

manifold.

(8) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(9) Install the fuel system supply line to the fuel

rail assembly.

(10) Connect all electrical connections on the

intake manifold.

(11) Connect the vacuum hoses previously

removed.

(12) Install throttle cable, vehicle speed control

cable (if equipped).

(13) Install the transmission line pressure cable (if

equipped) (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - AW4/THROTTLE VALVE

CABLE - INSTALLATION).

(14) Install air cleaner assembly.

(15) Connect air inlet hose to the resonator assem-

bly.

(16) Raise the vehicle.

(17) Connect the exhaust pipes to the engine

exhaust manifolds. Tighten the bolts to 31 N´m (23

ft. lbs.)

(18) Lower the vehicle.(19) Connect the battery negative cable.

(20) Start the engine and check for leaks.

EXHAUST MANIFOLD

DESCRIPTION

The two exhaust manifolds (Fig. 85) are log style

and are made of high silicon molybdenum cast iron.

The exhaust manifolds share a common gasket with

the intake manifold. The exhaust manifolds also

incorporate ball flange outlets for improved sealing

and strain free connections.

REMOVAL

The intake and engine exhaust manifolds on the

4.0L engine must be removed together. The manifolds

use a common gasket at the cylinder head.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - REMOVAL).

INSTALLATION

(1) The exhaust manifold and the intake manifold

must be installed together using a common gasket.

(2) (Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - INSTALLATION).

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(3) Remove the fan, hub assembly and fan shroud

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(4) Remove the accessory drive brackets that are

attached to the timing case cover.

(5) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL) (if equipped) and gen-

erator bracket assembly from the engine cylinder

head and move to one side.

(6) Remove the oil pan-to-timing case cover bolts

and timing case cover-to-cylinder block bolts.

(7) Remove the timing case cover and gasket from

the engine.

(8) Pry the crankshaft oil seal from the front of the

timing case cover (Fig. 86).

INSTALLATION

Clean the timing case cover, oil pan and cylinder

block gasket surfaces.

Fig. 84 Intake and Exhaust Manifolds Installation

9 - 58 ENGINE - 4.0LWJ

INTAKE MANIFOLD (Continued)

Page 1314 of 2199

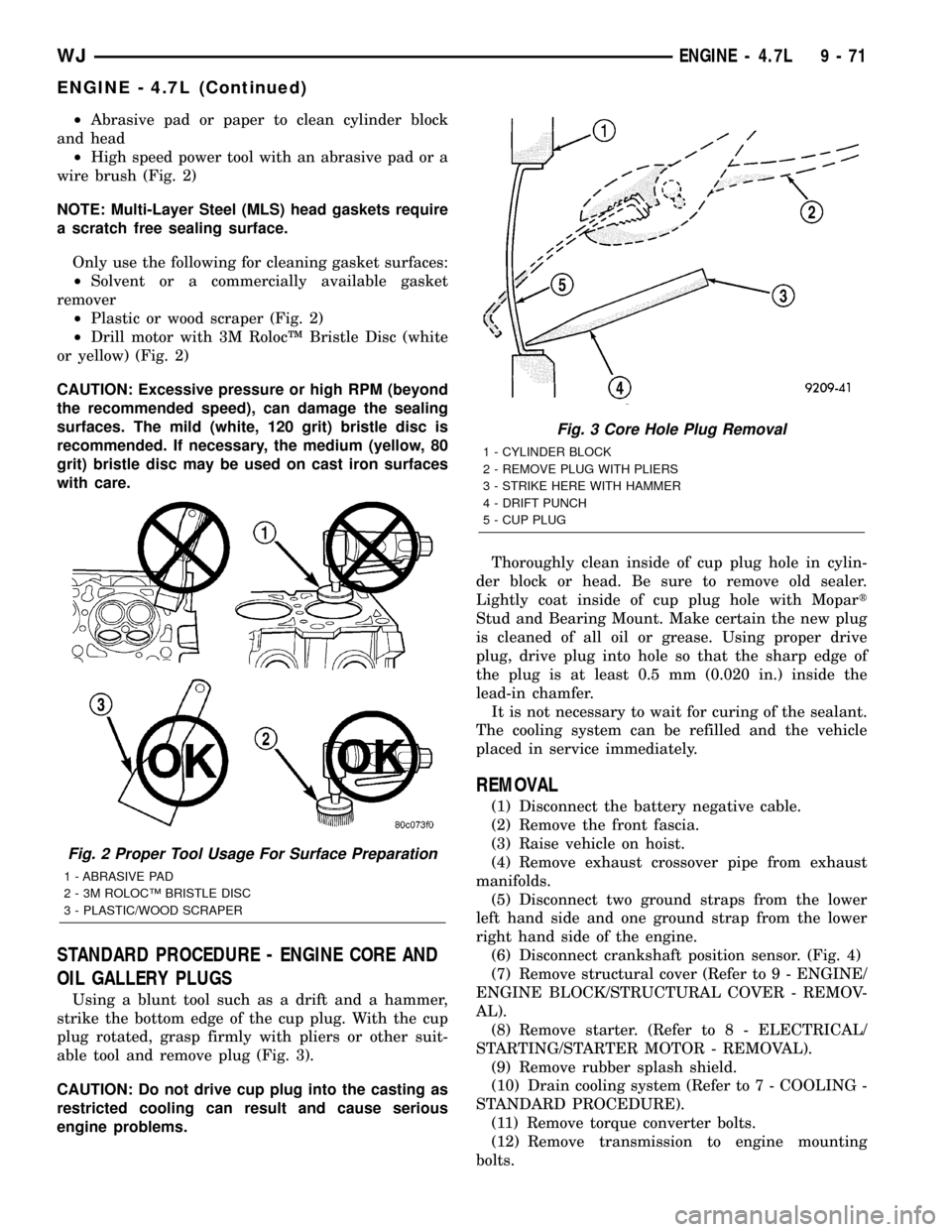

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 2)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 2)

²Drill motor with 3M RolocŸ Bristle Disc (white

or yellow) (Fig. 2)

CAUTION: Excessive pressure or high RPM (beyond

the recommended speed), can damage the sealing

surfaces. The mild (white, 120 grit) bristle disc is

recommended. If necessary, the medium (yellow, 80

grit) bristle disc may be used on cast iron surfaces

with care.

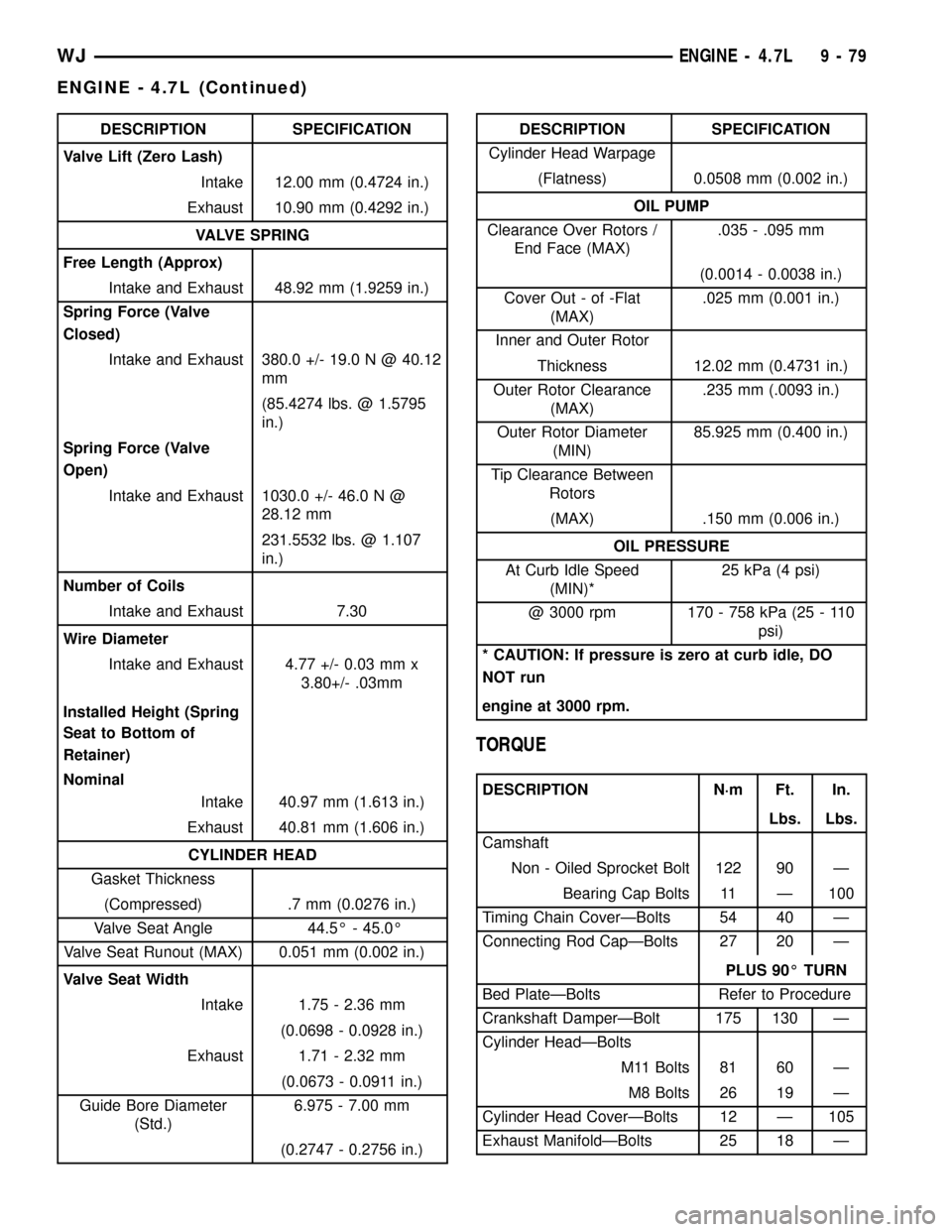

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 3).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the front fascia.

(3) Raise vehicle on hoist.

(4) Remove exhaust crossover pipe from exhaust

manifolds.

(5) Disconnect two ground straps from the lower

left hand side and one ground strap from the lower

right hand side of the engine.

(6) Disconnect crankshaft position sensor. (Fig. 4)

(7) Remove structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - REMOV-

AL).

(8) Remove starter. (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

(9) Remove rubber splash shield.

(10) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(11) Remove torque converter bolts.

(12) Remove transmission to engine mounting

bolts.

Fig. 2 Proper Tool Usage For Surface Preparation

1 - ABRASIVE PAD

2 - 3M ROLOCŸ BRISTLE DISC

3 - PLASTIC/WOOD SCRAPER

Fig. 3 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.7L 9 - 71

ENGINE - 4.7L (Continued)

Page 1322 of 2199

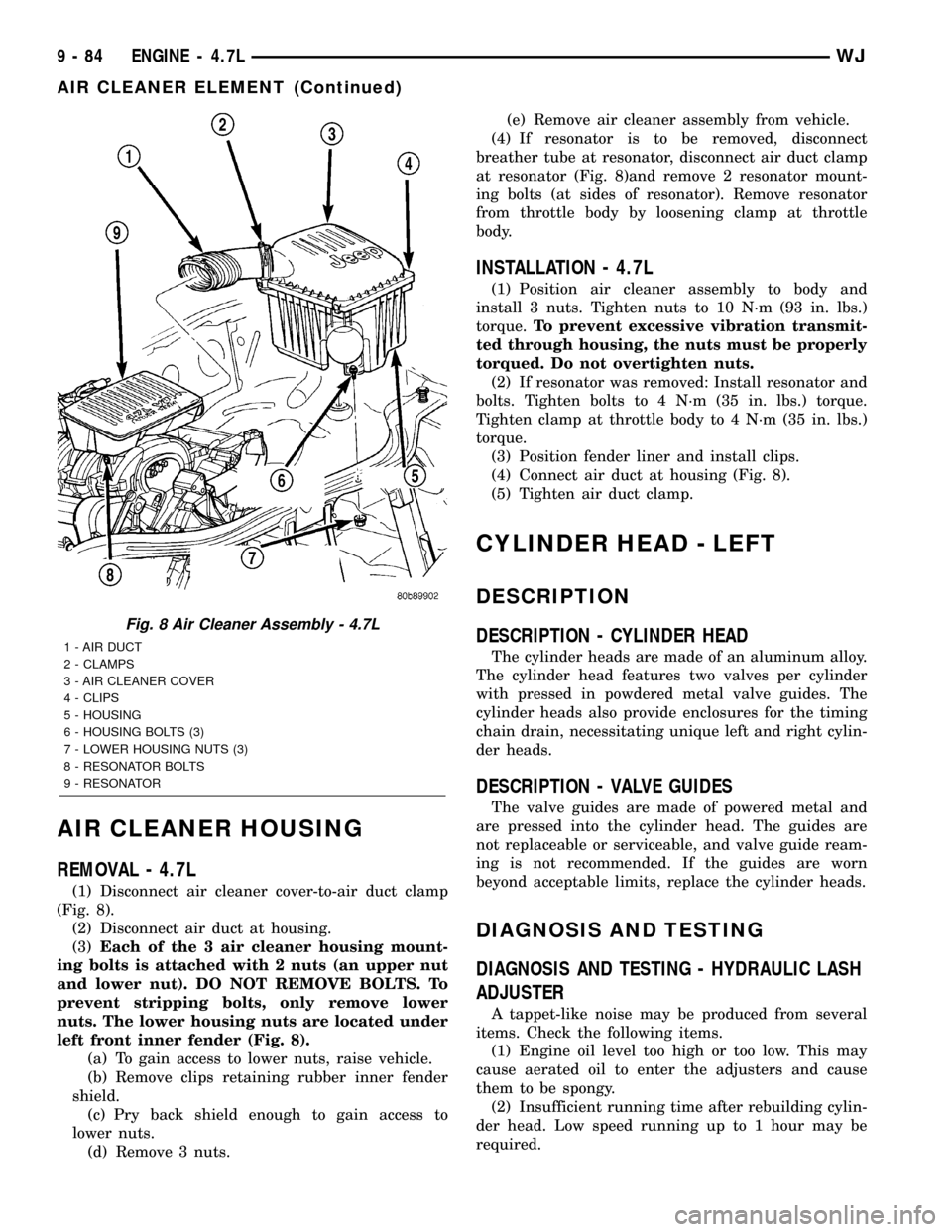

DESCRIPTION SPECIFICATION

Valve Lift (Zero Lash)

Intake 12.00 mm (0.4724 in.)

Exhaust 10.90 mm (0.4292 in.)

VALVE SPRING

Free Length (Approx)

Intake and Exhaust 48.92 mm (1.9259 in.)

Spring Force (Valve

Closed)

Intake and Exhaust 380.0 +/- 19.0 N @ 40.12

mm

(85.4274 lbs. @ 1.5795

in.)

Spring Force (Valve

Open)

Intake and Exhaust 1030.0 +/- 46.0 N @

28.12 mm

231.5532 lbs. @ 1.107

in.)

Number of Coils

Intake and Exhaust 7.30

Wire Diameter

Intake and Exhaust 4.77 +/- 0.03 mm x

3.80+/- .03mm

Installed Height (Spring

Seat to Bottom of

Retainer)

Nominal

Intake 40.97 mm (1.613 in.)

Exhaust 40.81 mm (1.606 in.)

CYLINDER HEAD

Gasket Thickness

(Compressed) .7 mm (0.0276 in.)

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.051 mm (0.002 in.)

Valve Seat Width

Intake 1.75 - 2.36 mm

(0.0698 - 0.0928 in.)

Exhaust 1.71 - 2.32 mm

(0.0673 - 0.0911 in.)

Guide Bore Diameter

(Std.)6.975 - 7.00 mm

(0.2747 - 0.2756 in.)DESCRIPTION SPECIFICATION

Cylinder Head Warpage

(Flatness) 0.0508 mm (0.002 in.)

OIL PUMP

Clearance Over Rotors /

End Face (MAX).035 - .095 mm

(0.0014 - 0.0038 in.)

Cover Out - of -Flat

(MAX).025 mm (0.001 in.)

Inner and Outer Rotor

Thickness 12.02 mm (0.4731 in.)

Outer Rotor Clearance

(MAX).235 mm (.0093 in.)

Outer Rotor Diameter

(MIN)85.925 mm (0.400 in.)

Tip Clearance Between

Rotors

(MAX) .150 mm (0.006 in.)

OIL PRESSURE

At Curb Idle Speed

(MIN)*25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run

engine at 3000 rpm.

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Camshaft

Non - Oiled Sprocket Bolt 122 90 Ð

Bearing Cap Bolts 11 Ð 100

Timing Chain CoverÐBolts 54 40 Ð

Connecting Rod CapÐBolts 27 20 Ð

PLUS 90É TURN

Bed PlateÐBolts Refer to Procedure

Crankshaft DamperÐBolt 175 130 Ð

Cylinder HeadÐBolts

M11 Bolts 81 60 Ð

M8 Bolts 26 19 Ð

Cylinder Head CoverÐBolts 12 Ð 105

Exhaust ManifoldÐBolts 25 18 Ð

WJENGINE - 4.7L 9 - 79

ENGINE - 4.7L (Continued)

Page 1327 of 2199

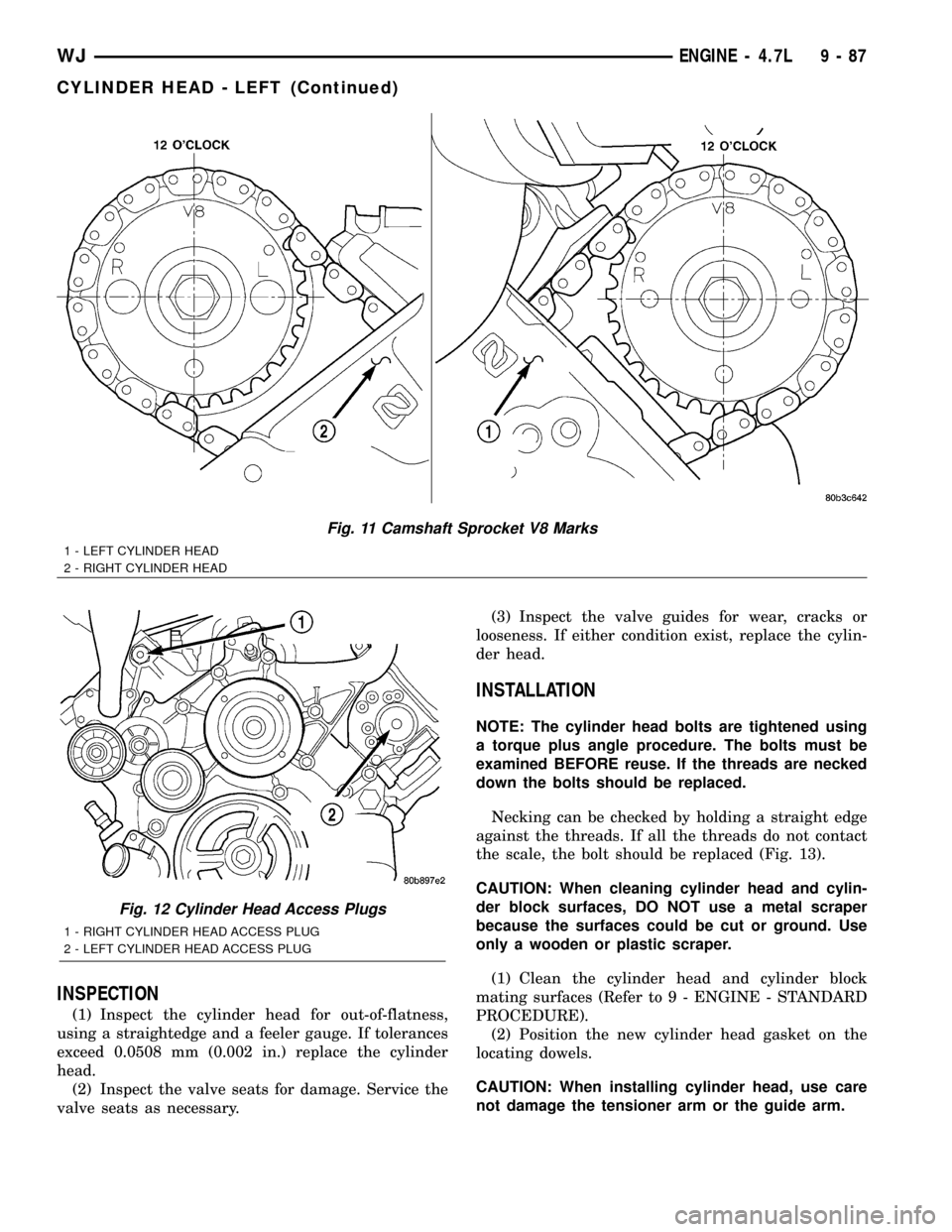

AIR CLEANER HOUSING

REMOVAL - 4.7L

(1) Disconnect air cleaner cover-to-air duct clamp

(Fig. 8).

(2) Disconnect air duct at housing.

(3)Each of the 3 air cleaner housing mount-

ing bolts is attached with 2 nuts (an upper nut

and lower nut). DO NOT REMOVE BOLTS. To

prevent stripping bolts, only remove lower

nuts. The lower housing nuts are located under

left front inner fender (Fig. 8).

(a) To gain access to lower nuts, raise vehicle.

(b) Remove clips retaining rubber inner fender

shield.

(c) Pry back shield enough to gain access to

lower nuts.

(d) Remove 3 nuts.(e) Remove air cleaner assembly from vehicle.

(4) If resonator is to be removed, disconnect

breather tube at resonator, disconnect air duct clamp

at resonator (Fig. 8)and remove 2 resonator mount-

ing bolts (at sides of resonator). Remove resonator

from throttle body by loosening clamp at throttle

body.

INSTALLATION - 4.7L

(1) Position air cleaner assembly to body and

install 3 nuts. Tighten nuts to 10 N´m (93 in. lbs.)

torque.To prevent excessive vibration transmit-

ted through housing, the nuts must be properly

torqued. Do not overtighten nuts.

(2) If resonator was removed: Install resonator and

bolts. Tighten bolts to 4 N´m (35 in. lbs.) torque.

Tighten clamp at throttle body to 4 N´m (35 in. lbs.)

torque.

(3) Position fender liner and install clips.

(4) Connect air duct at housing (Fig. 8).

(5) Tighten air duct clamp.

CYLINDER HEAD - LEFT

DESCRIPTION

DESCRIPTION - CYLINDER HEAD

The cylinder heads are made of an aluminum alloy.

The cylinder head features two valves per cylinder

with pressed in powdered metal valve guides. The

cylinder heads also provide enclosures for the timing

chain drain, necessitating unique left and right cylin-

der heads.

DESCRIPTION - VALVE GUIDES

The valve guides are made of powered metal and

are pressed into the cylinder head. The guides are

not replaceable or serviceable, and valve guide ream-

ing is not recommended. If the guides are worn

beyond acceptable limits, replace the cylinder heads.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

Fig. 8 Air Cleaner Assembly - 4.7L

1 - AIR DUCT

2 - CLAMPS

3 - AIR CLEANER COVER

4 - CLIPS

5 - HOUSING

6 - HOUSING BOLTS (3)

7 - LOWER HOUSING NUTS (3)

8 - RESONATOR BOLTS

9 - RESONATOR

9 - 84 ENGINE - 4.7LWJ

AIR CLEANER ELEMENT (Continued)

Page 1330 of 2199

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

INSTALLATION

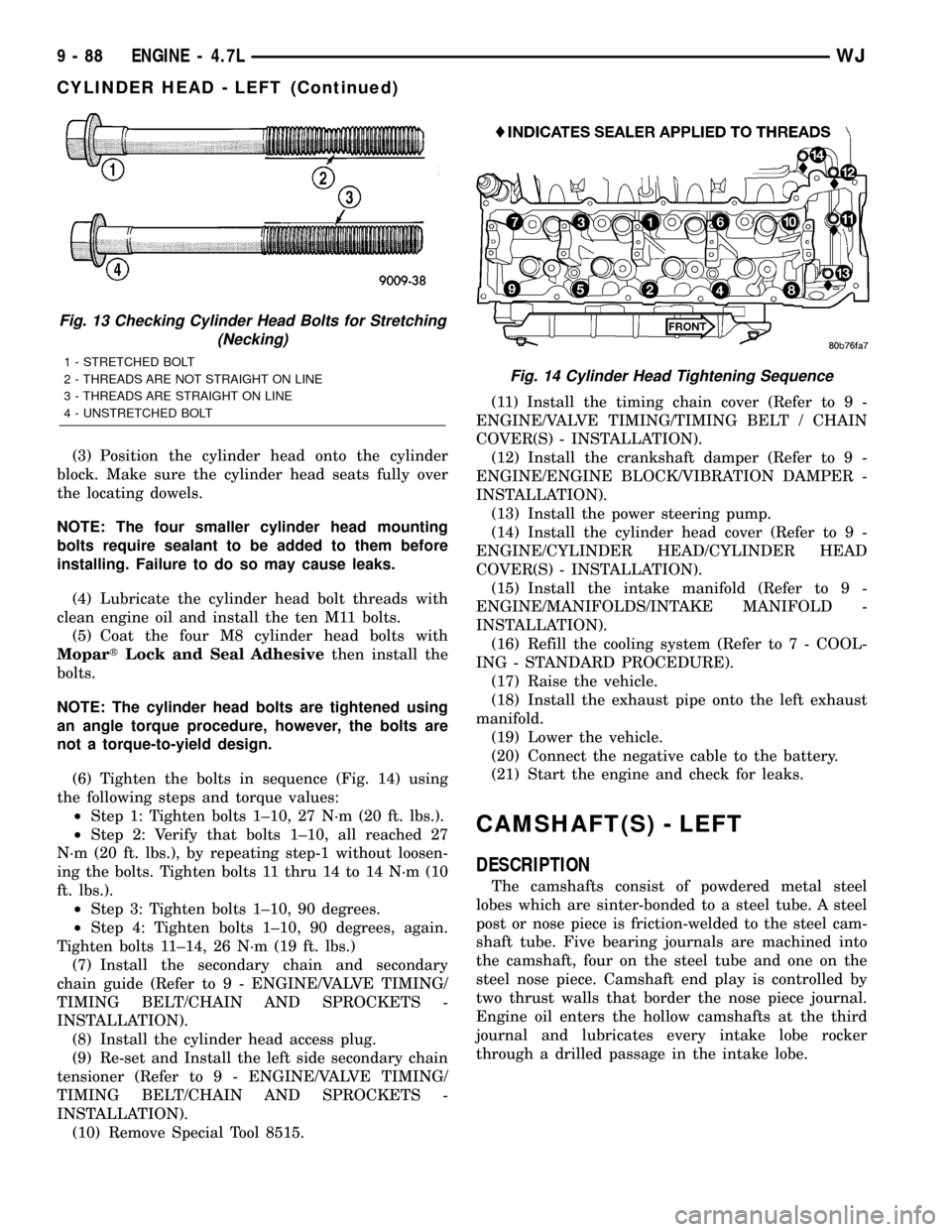

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads. If all the threads do not contact

the scale, the bolt should be replaced (Fig. 13).

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces (Refer to 9 - ENGINE - STANDARD

PROCEDURE).

(2) Position the new cylinder head gasket on the

locating dowels.

CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

Fig. 11 Camshaft Sprocket V8 Marks

1 - LEFT CYLINDER HEAD

2 - RIGHT CYLINDER HEAD

Fig. 12 Cylinder Head Access Plugs

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

WJENGINE - 4.7L 9 - 87

CYLINDER HEAD - LEFT (Continued)

Page 1331 of 2199

(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four smaller cylinder head mounting

bolts require sealant to be added to them before

installing. Failure to do so may cause leaks.

(4) Lubricate the cylinder head bolt threads with

clean engine oil and install the ten M11 bolts.

(5) Coat the four M8 cylinder head bolts with

MopartLock and Seal Adhesivethen install the

bolts.

NOTE: The cylinder head bolts are tightened using

an angle torque procedure, however, the bolts are

not a torque-to-yield design.

(6) Tighten the bolts in sequence (Fig. 14) using

the following steps and torque values:

²Step 1: Tighten bolts 1±10, 27 N´m (20 ft. lbs.).

²Step 2: Verify that bolts 1±10, all reached 27

N´m (20 ft. lbs.), by repeating step-1 without loosen-

ing the bolts. Tighten bolts 11 thru 14 to 14 N´m (10

ft. lbs.).

²Step 3: Tighten bolts 1±10, 90 degrees.

²Step 4: Tighten bolts 1±10, 90 degrees, again.

Tighten bolts 11±14, 26 N´m (19 ft. lbs.)

(7) Install the secondary chain and secondary

chain guide (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(8) Install the cylinder head access plug.

(9) Re-set and Install the left side secondary chain

tensioner (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(10) Remove Special Tool 8515.(11) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(12) Install the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(13) Install the power steering pump.

(14) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(15) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(16) Refill the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(17) Raise the vehicle.

(18) Install the exhaust pipe onto the left exhaust

manifold.

(19) Lower the vehicle.

(20) Connect the negative cable to the battery.

(21) Start the engine and check for leaks.

CAMSHAFT(S) - LEFT

DESCRIPTION

The camshafts consist of powdered metal steel

lobes which are sinter-bonded to a steel tube. A steel

post or nose piece is friction-welded to the steel cam-

shaft tube. Five bearing journals are machined into

the camshaft, four on the steel tube and one on the

steel nose piece. Camshaft end play is controlled by

two thrust walls that border the nose piece journal.

Engine oil enters the hollow camshafts at the third

journal and lubricates every intake lobe rocker

through a drilled passage in the intake lobe.

Fig. 13 Checking Cylinder Head Bolts for Stretching

(Necking)

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLTFig. 14 Cylinder Head Tightening Sequence

9 - 88 ENGINE - 4.7LWJ

CYLINDER HEAD - LEFT (Continued)

Page 1333 of 2199

(7) Using the pliers, gently allow the camshaft to

rotate 15É clockwise until the camshaft is in the neu-

tral position (no valve load).

(8) Starting at the outside working inward, loosen

the camshaft bearing cap retaining bolts 1/2 turn at

a time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

(9) Remove the camshaft bearing caps and the

camshaft.

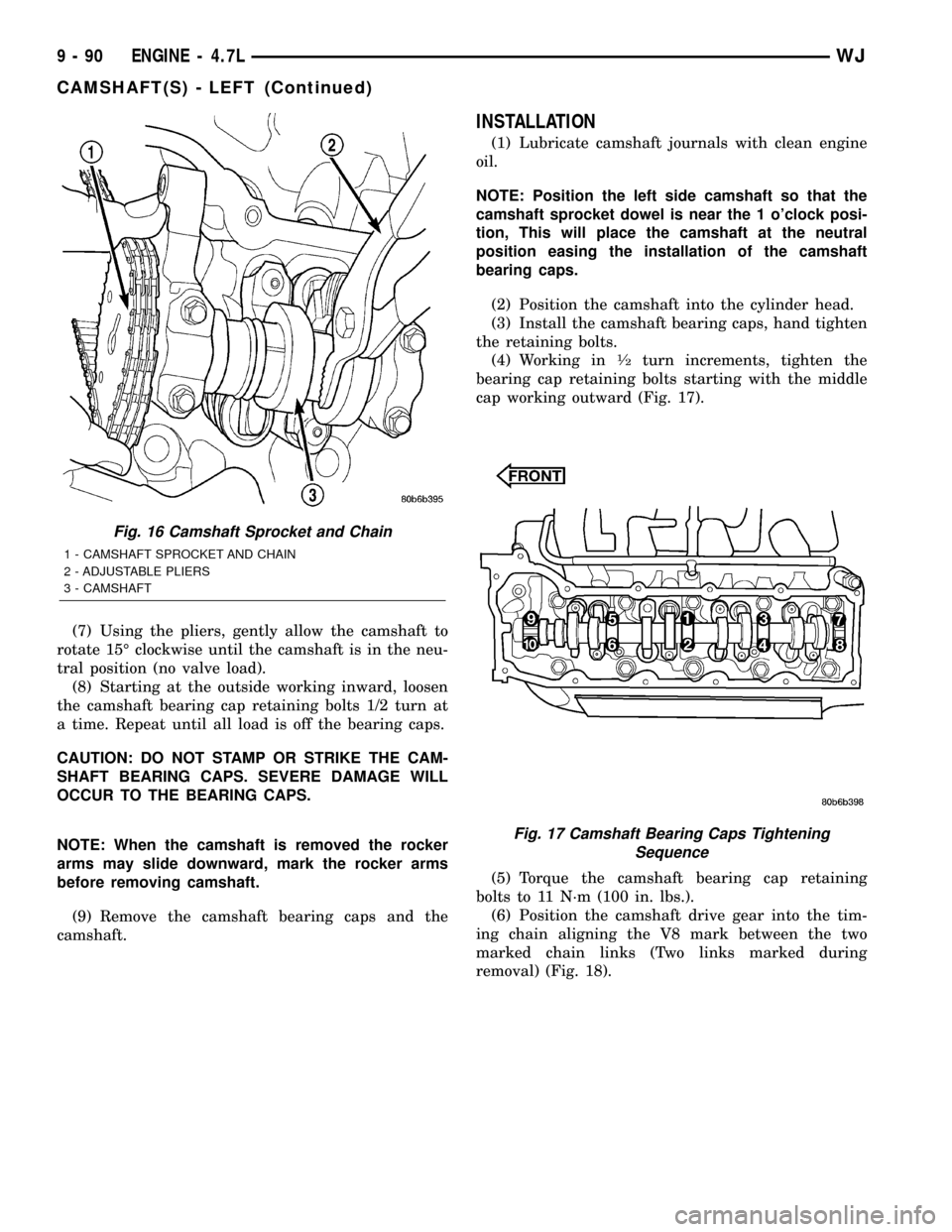

INSTALLATION

(1) Lubricate camshaft journals with clean engine

oil.

NOTE: Position the left side camshaft so that the

camshaft sprocket dowel is near the 1 o'clock posi-

tion, This will place the camshaft at the neutral

position easing the installation of the camshaft

bearing caps.

(2) Position the camshaft into the cylinder head.

(3) Install the camshaft bearing caps, hand tighten

the retaining bolts.

(4) Working in

1¤2turn increments, tighten the

bearing cap retaining bolts starting with the middle

cap working outward (Fig. 17).

(5) Torque the camshaft bearing cap retaining

bolts to 11 N´m (100 in. lbs.).

(6) Position the camshaft drive gear into the tim-

ing chain aligning the V8 mark between the two

marked chain links (Two links marked during

removal) (Fig. 18).

Fig. 16 Camshaft Sprocket and Chain

1 - CAMSHAFT SPROCKET AND CHAIN

2 - ADJUSTABLE PLIERS

3 - CAMSHAFT

Fig. 17 Camshaft Bearing Caps Tightening

Sequence

9 - 90 ENGINE - 4.7LWJ

CAMSHAFT(S) - LEFT (Continued)