Brake light JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1048 of 2199

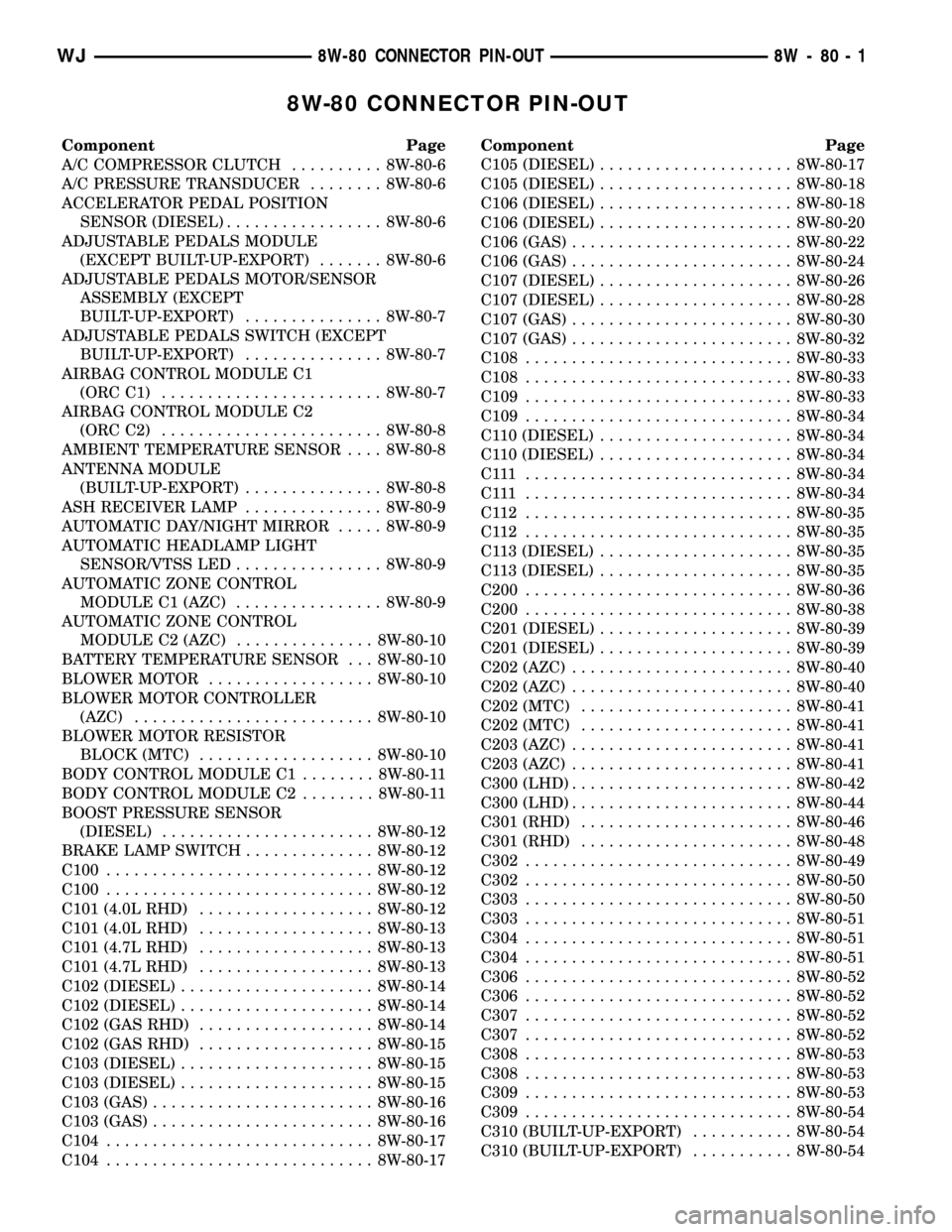

8W-80 CONNECTOR PIN-OUT

Component Page

A/C COMPRESSOR CLUTCH.......... 8W-80-6

A/C PRESSURE TRANSDUCER........ 8W-80-6

ACCELERATOR PEDAL POSITION

SENSOR (DIESEL)................. 8W-80-6

ADJUSTABLE PEDALS MODULE

(EXCEPT BUILT-UP-EXPORT)....... 8W-80-6

ADJUSTABLE PEDALS MOTOR/SENSOR

ASSEMBLY (EXCEPT

BUILT-UP-EXPORT)............... 8W-80-7

ADJUSTABLE PEDALS SWITCH (EXCEPT

BUILT-UP-EXPORT)............... 8W-80-7

AIRBAG CONTROL MODULE C1

(ORC C1)........................ 8W-80-7

AIRBAG CONTROL MODULE C2

(ORC C2)........................ 8W-80-8

AMBIENT TEMPERATURE SENSOR.... 8W-80-8

ANTENNA MODULE

(BUILT-UP-EXPORT)............... 8W-80-8

ASH RECEIVER LAMP............... 8W-80-9

AUTOMATIC DAY/NIGHT MIRROR..... 8W-80-9

AUTOMATIC HEADLAMP LIGHT

SENSOR/VTSS LED................ 8W-80-9

AUTOMATIC ZONE CONTROL

MODULE C1 (AZC)................ 8W-80-9

AUTOMATIC ZONE CONTROL

MODULE C2 (AZC)............... 8W-80-10

BATTERY TEMPERATURE SENSOR . . . 8W-80-10

BLOWER MOTOR.................. 8W-80-10

BLOWER MOTOR CONTROLLER

(AZC).......................... 8W-80-10

BLOWER MOTOR RESISTOR

BLOCK (MTC)................... 8W-80-10

BODY CONTROL MODULE C1........ 8W-80-11

BODY CONTROL MODULE C2........ 8W-80-11

BOOST PRESSURE SENSOR

(DIESEL)....................... 8W-80-12

BRAKE LAMP SWITCH.............. 8W-80-12

C100............................. 8W-80-12

C100............................. 8W-80-12

C101 (4.0L RHD)................... 8W-80-12

C101 (4.0L RHD)................... 8W-80-13

C101 (4.7L RHD)................... 8W-80-13

C101 (4.7L RHD)................... 8W-80-13

C102 (DIESEL)..................... 8W-80-14

C102 (DIESEL)..................... 8W-80-14

C102 (GAS RHD)................... 8W-80-14

C102 (GAS RHD)................... 8W-80-15

C103 (DIESEL)..................... 8W-80-15

C103 (DIESEL)..................... 8W-80-15

C103 (GAS)........................ 8W-80-16

C103 (GAS)........................ 8W-80-16

C104............................. 8W-80-17

C104............................. 8W-80-17Component Page

C105 (DIESEL)..................... 8W-80-17

C105 (DIESEL)..................... 8W-80-18

C106 (DIESEL)..................... 8W-80-18

C106 (DIESEL)..................... 8W-80-20

C106 (GAS)........................ 8W-80-22

C106 (GAS)........................ 8W-80-24

C107 (DIESEL)..................... 8W-80-26

C107 (DIESEL)..................... 8W-80-28

C107 (GAS)........................ 8W-80-30

C107 (GAS)........................ 8W-80-32

C108............................. 8W-80-33

C108............................. 8W-80-33

C109............................. 8W-80-33

C109............................. 8W-80-34

C110 (DIESEL)..................... 8W-80-34

C110 (DIESEL)..................... 8W-80-34

C111 ............................. 8W-80-34

C111 ............................. 8W-80-34

C112 ............................. 8W-80-35

C112 ............................. 8W-80-35

C113 (DIESEL)..................... 8W-80-35

C113 (DIESEL)..................... 8W-80-35

C200............................. 8W-80-36

C200............................. 8W-80-38

C201 (DIESEL)..................... 8W-80-39

C201 (DIESEL)..................... 8W-80-39

C202 (AZC)........................ 8W-80-40

C202 (AZC)........................ 8W-80-40

C202 (MTC)....................... 8W-80-41

C202 (MTC)....................... 8W-80-41

C203 (AZC)........................ 8W-80-41

C203 (AZC)........................ 8W-80-41

C300 (LHD)........................ 8W-80-42

C300 (LHD)........................ 8W-80-44

C301 (RHD)....................... 8W-80-46

C301 (RHD)....................... 8W-80-48

C302............................. 8W-80-49

C302............................. 8W-80-50

C303............................. 8W-80-50

C303............................. 8W-80-51

C304............................. 8W-80-51

C304............................. 8W-80-51

C306............................. 8W-80-52

C306............................. 8W-80-52

C307............................. 8W-80-52

C307............................. 8W-80-52

C308............................. 8W-80-53

C308............................. 8W-80-53

C309............................. 8W-80-53

C309............................. 8W-80-54

C310 (BUILT-UP-EXPORT)........... 8W-80-54

C310 (BUILT-UP-EXPORT)........... 8W-80-54

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 1

Page 1049 of 2199

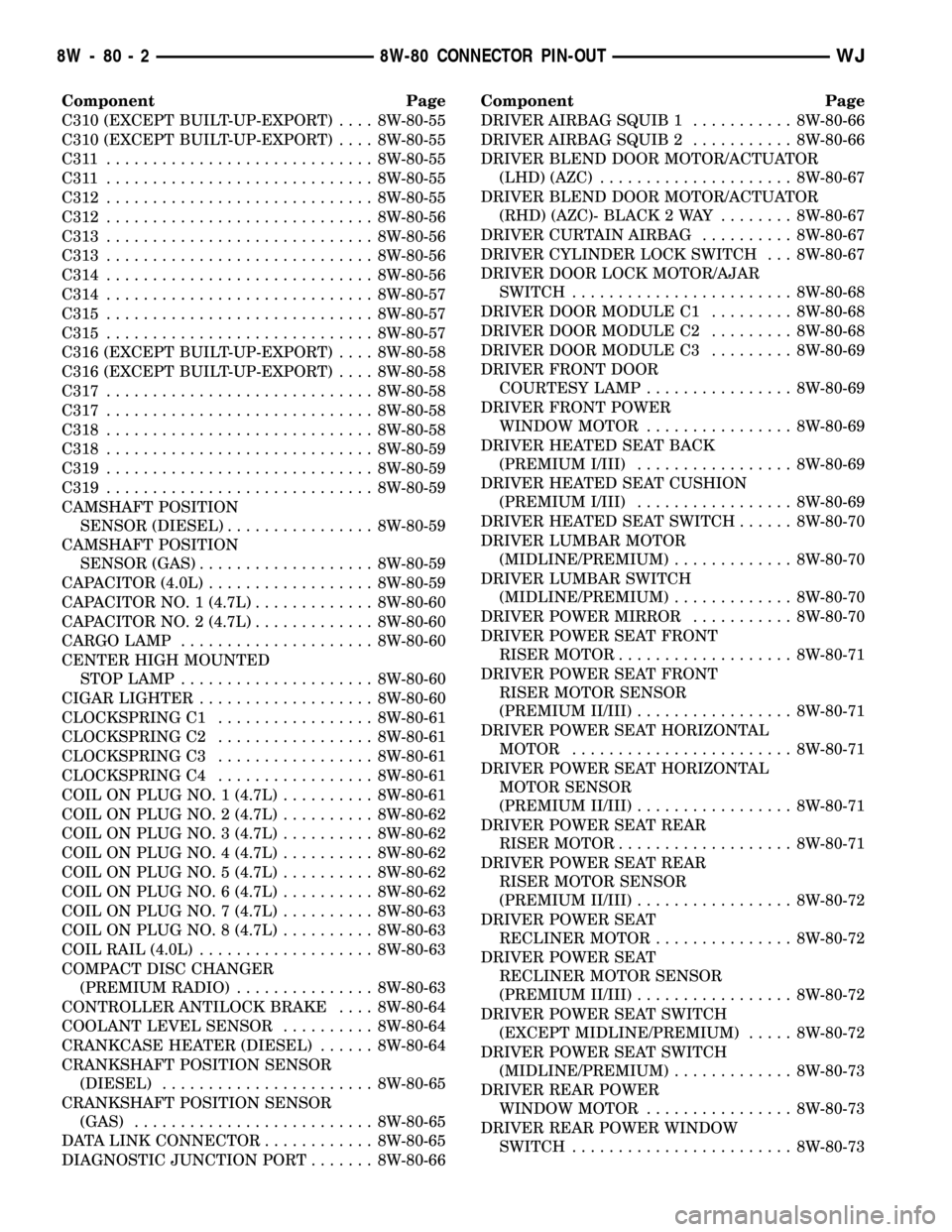

Component Page

C310 (EXCEPT BUILT-UP-EXPORT).... 8W-80-55

C310 (EXCEPT BUILT-UP-EXPORT).... 8W-80-55

C311 ............................. 8W-80-55

C311 ............................. 8W-80-55

C312............................. 8W-80-55

C312............................. 8W-80-56

C313............................. 8W-80-56

C313............................. 8W-80-56

C314............................. 8W-80-56

C314............................. 8W-80-57

C315............................. 8W-80-57

C315............................. 8W-80-57

C316 (EXCEPT BUILT-UP-EXPORT).... 8W-80-58

C316 (EXCEPT BUILT-UP-EXPORT).... 8W-80-58

C317............................. 8W-80-58

C317............................. 8W-80-58

C318............................. 8W-80-58

C318............................. 8W-80-59

C319............................. 8W-80-59

C319............................. 8W-80-59

CAMSHAFT POSITION

SENSOR (DIESEL)................ 8W-80-59

CAMSHAFT POSITION

SENSOR (GAS)................... 8W-80-59

CAPACITOR (4.0L).................. 8W-80-59

CAPACITOR NO. 1 (4.7L)............. 8W-80-60

CAPACITOR NO. 2 (4.7L)............. 8W-80-60

CARGO LAMP..................... 8W-80-60

CENTER HIGH MOUNTED

STOP LAMP..................... 8W-80-60

CIGAR LIGHTER................... 8W-80-60

CLOCKSPRING C1................. 8W-80-61

CLOCKSPRING C2................. 8W-80-61

CLOCKSPRING C3................. 8W-80-61

CLOCKSPRING C4................. 8W-80-61

COIL ON PLUG NO. 1 (4.7L).......... 8W-80-61

COIL ON PLUG NO. 2 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 3 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 4 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 5 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 6 (4.7L).......... 8W-80-62

COIL ON PLUG NO. 7 (4.7L).......... 8W-80-63

COIL ON PLUG NO. 8 (4.7L).......... 8W-80-63

COIL RAIL (4.0L)................... 8W-80-63

COMPACT DISC CHANGER

(PREMIUM RADIO)............... 8W-80-63

CONTROLLER ANTILOCK BRAKE.... 8W-80-64

COOLANT LEVEL SENSOR.......... 8W-80-64

CRANKCASE HEATER (DIESEL)...... 8W-80-64

CRANKSHAFT POSITION SENSOR

(DIESEL)....................... 8W-80-65

CRANKSHAFT POSITION SENSOR

(GAS).......................... 8W-80-65

DATA LINK CONNECTOR............ 8W-80-65

DIAGNOSTIC JUNCTION PORT....... 8W-80-66Component Page

DRIVER AIRBAG SQUIB 1........... 8W-80-66

DRIVER AIRBAG SQUIB 2........... 8W-80-66

DRIVER BLEND DOOR MOTOR/ACTUATOR

(LHD) (AZC)..................... 8W-80-67

DRIVER BLEND DOOR MOTOR/ACTUATOR

(RHD) (AZC)- BLACK 2 WAY........ 8W-80-67

DRIVER CURTAIN AIRBAG.......... 8W-80-67

DRIVER CYLINDER LOCK SWITCH . . . 8W-80-67

DRIVER DOOR LOCK MOTOR/AJAR

SWITCH........................ 8W-80-68

DRIVER DOOR MODULE C1......... 8W-80-68

DRIVER DOOR MODULE C2......... 8W-80-68

DRIVER DOOR MODULE C3......... 8W-80-69

DRIVER FRONT DOOR

COURTESY LAMP................ 8W-80-69

DRIVER FRONT POWER

WINDOW MOTOR................ 8W-80-69

DRIVER HEATED SEAT BACK

(PREMIUM I/III)................. 8W-80-69

DRIVER HEATED SEAT CUSHION

(PREMIUM I/III)................. 8W-80-69

DRIVER HEATED SEAT SWITCH...... 8W-80-70

DRIVER LUMBAR MOTOR

(MIDLINE/PREMIUM)............. 8W-80-70

DRIVER LUMBAR SWITCH

(MIDLINE/PREMIUM)............. 8W-80-70

DRIVER POWER MIRROR........... 8W-80-70

DRIVER POWER SEAT FRONT

RISER MOTOR................... 8W-80-71

DRIVER POWER SEAT FRONT

RISER MOTOR SENSOR

(PREMIUM II/III)................. 8W-80-71

DRIVER POWER SEAT HORIZONTAL

MOTOR........................ 8W-80-71

DRIVER POWER SEAT HORIZONTAL

MOTOR SENSOR

(PREMIUM II/III)................. 8W-80-71

DRIVER POWER SEAT REAR

RISER MOTOR................... 8W-80-71

DRIVER POWER SEAT REAR

RISER MOTOR SENSOR

(PREMIUM II/III)................. 8W-80-72

DRIVER POWER SEAT

RECLINER MOTOR............... 8W-80-72

DRIVER POWER SEAT

RECLINER MOTOR SENSOR

(PREMIUM II/III)................. 8W-80-72

DRIVER POWER SEAT SWITCH

(EXCEPT MIDLINE/PREMIUM)..... 8W-80-72

DRIVER POWER SEAT SWITCH

(MIDLINE/PREMIUM)............. 8W-80-73

DRIVER REAR POWER

WINDOW MOTOR................ 8W-80-73

DRIVER REAR POWER WINDOW

SWITCH........................ 8W-80-73

8W - 80 - 2 8W-80 CONNECTOR PIN-OUTWJ

Page 1107 of 2199

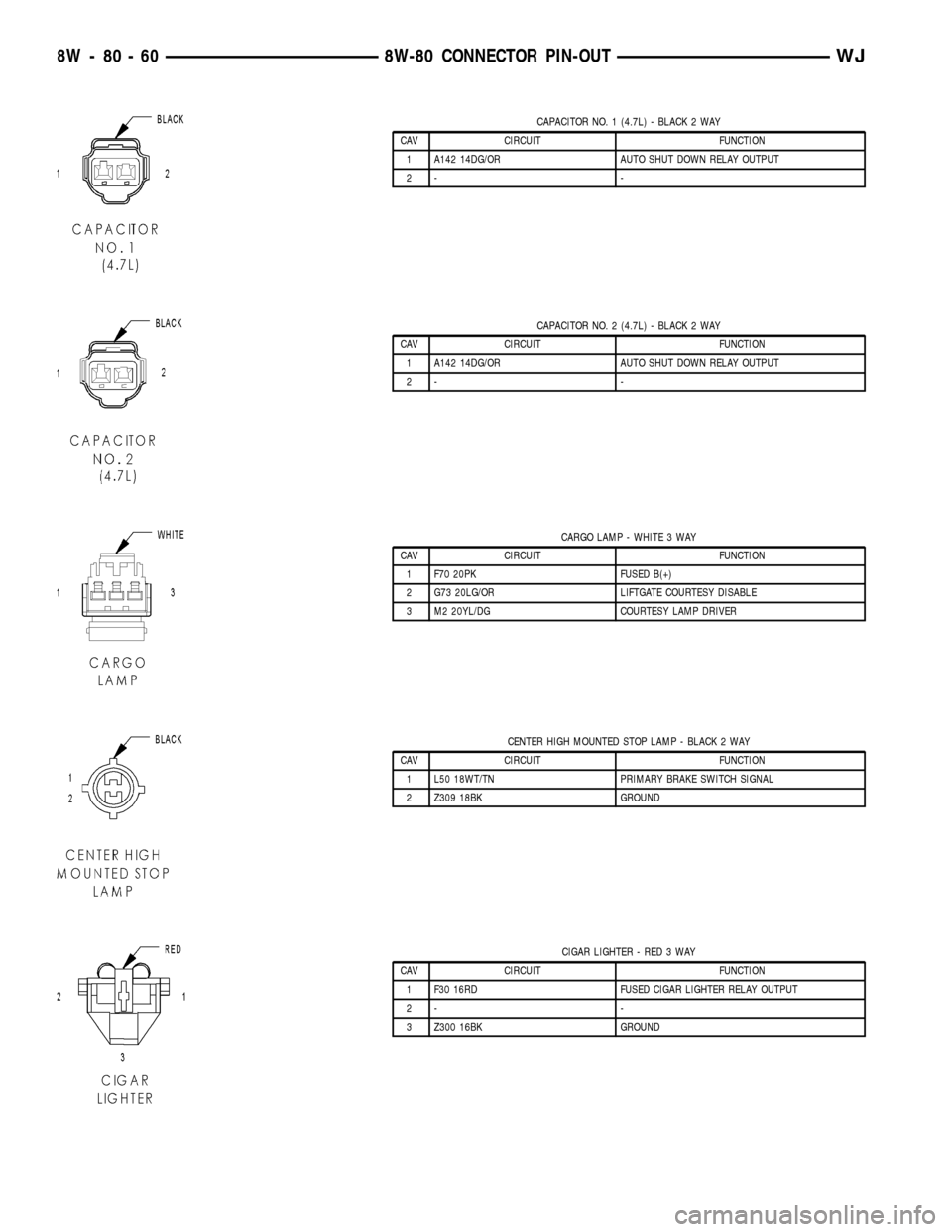

CAPACITOR NO. 1 (4.7L) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 A142 14DG/OR AUTO SHUT DOWN RELAY OUTPUT

2- -

CAPACITOR NO. 2 (4.7L) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 A142 14DG/OR AUTO SHUT DOWN RELAY OUTPUT

2- -

CARGO LAMP - WHITE 3 WAY

CAV CIRCUIT FUNCTION

1 F70 20PK FUSED B(+)

2 G73 20LG/OR LIFTGATE COURTESY DISABLE

3 M2 20YL/DG COURTESY LAMP DRIVER

CENTER HIGH MOUNTED STOP LAMP - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

2 Z309 18BK GROUND

CIGAR LIGHTER - RED 3 WAY

CAV CIRCUIT FUNCTION

1 F30 16RD FUSED CIGAR LIGHTER RELAY OUTPUT

2- -

3 Z300 16BK GROUND

8W - 80 - 60 8W-80 CONNECTOR PIN-OUTWJ

Page 1169 of 2199

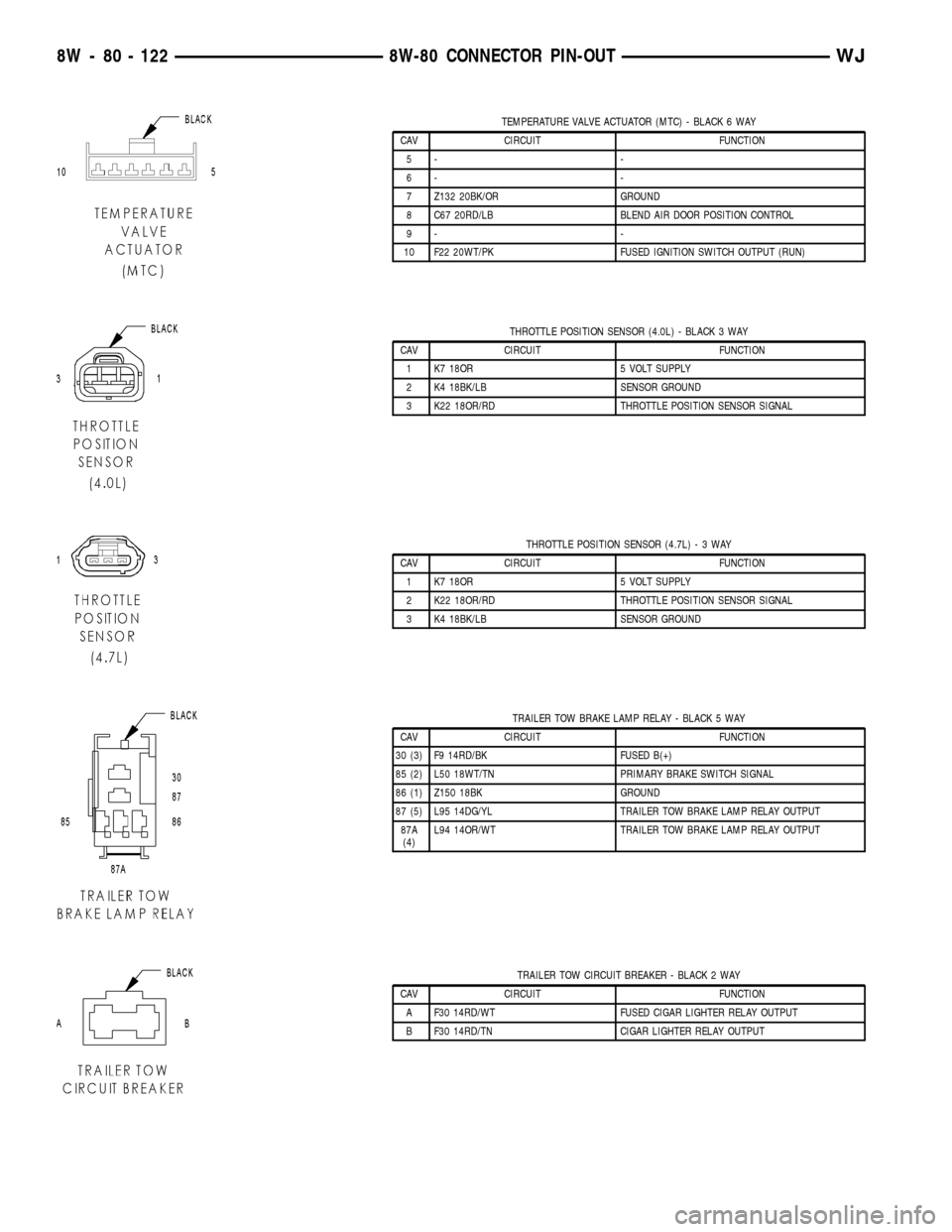

TEMPERATURE VALVE ACTUATOR (MTC) - BLACK 6 WAY

CAV CIRCUIT FUNCTION

5- -

6- -

7 Z132 20BK/OR GROUND

8 C67 20RD/LB BLEND AIR DOOR POSITION CONTROL

9- -

10 F22 20WT/PK FUSED IGNITION SWITCH OUTPUT (RUN)

THROTTLE POSITION SENSOR (4.0L) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K7 18OR 5 VOLT SUPPLY

2 K4 18BK/LB SENSOR GROUND

3 K22 18OR/RD THROTTLE POSITION SENSOR SIGNAL

THROTTLE POSITION SENSOR (4.7L)-3WAY

CAV CIRCUIT FUNCTION

1 K7 18OR 5 VOLT SUPPLY

2 K22 18OR/RD THROTTLE POSITION SENSOR SIGNAL

3 K4 18BK/LB SENSOR GROUND

TRAILER TOW BRAKE LAMP RELAY - BLACK 5 WAY

CAV CIRCUIT FUNCTION

30 (3) F9 14RD/BK FUSED B(+)

85 (2) L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

86 (1) Z150 18BK GROUND

87 (5) L95 14DG/YL TRAILER TOW BRAKE LAMP RELAY OUTPUT

87A

(4)L94 14OR/WT TRAILER TOW BRAKE LAMP RELAY OUTPUT

TRAILER TOW CIRCUIT BREAKER - BLACK 2 WAY

CAV CIRCUIT FUNCTION

A F30 14RD/WT FUSED CIGAR LIGHTER RELAY OUTPUT

B F30 14RD/TN CIGAR LIGHTER RELAY OUTPUT

8W - 80 - 122 8W-80 CONNECTOR PIN-OUTWJ

Page 1170 of 2199

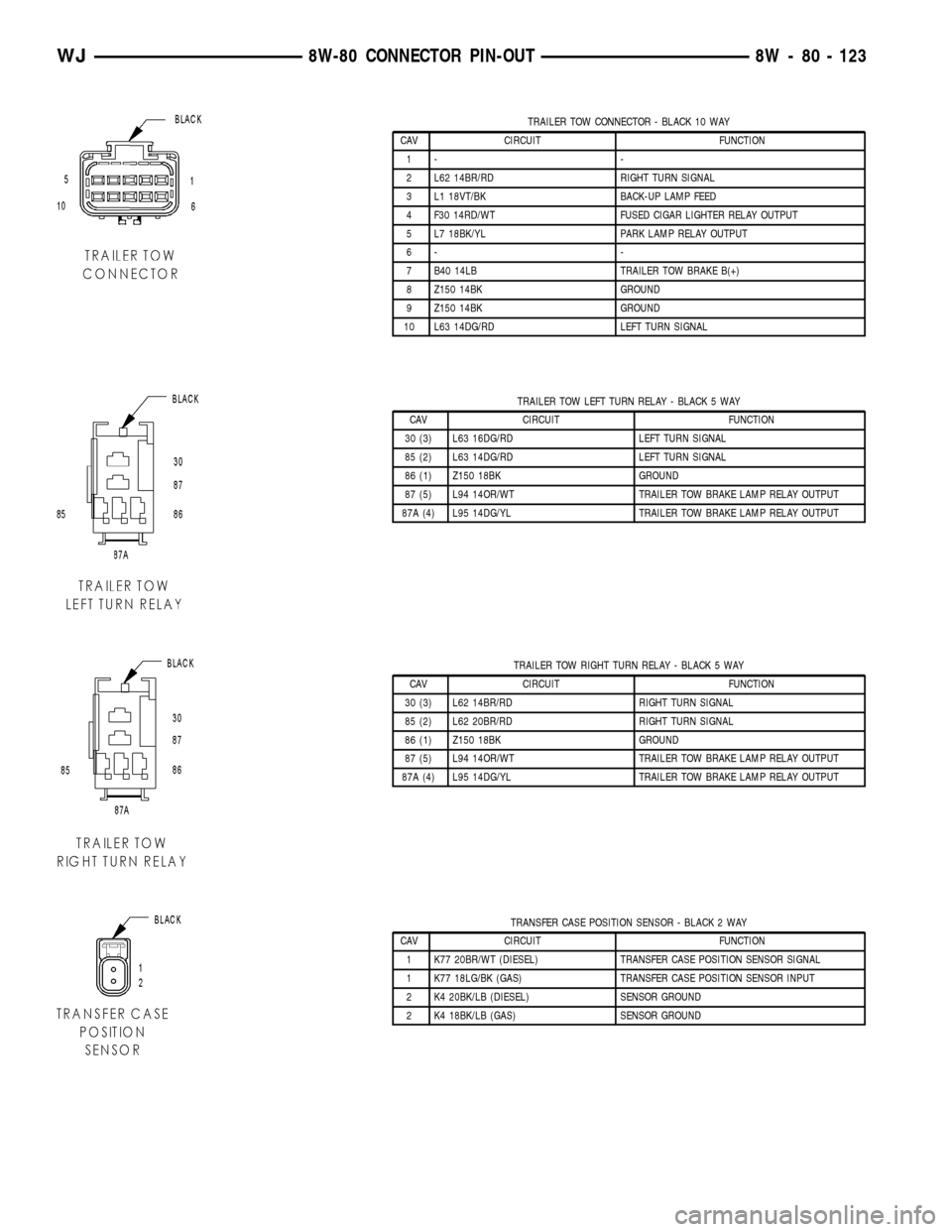

TRAILER TOW CONNECTOR - BLACK 10 WAY

CAV CIRCUIT FUNCTION

1- -

2 L62 14BR/RD RIGHT TURN SIGNAL

3 L1 18VT/BK BACK-UP LAMP FEED

4 F30 14RD/WT FUSED CIGAR LIGHTER RELAY OUTPUT

5 L7 18BK/YL PARK LAMP RELAY OUTPUT

6- -

7 B40 14LB TRAILER TOW BRAKE B(+)

8 Z150 14BK GROUND

9 Z150 14BK GROUND

10 L63 14DG/RD LEFT TURN SIGNAL

TRAILER TOW LEFT TURN RELAY - BLACK 5 WAY

CAV CIRCUIT FUNCTION

30 (3) L63 16DG/RD LEFT TURN SIGNAL

85 (2) L63 14DG/RD LEFT TURN SIGNAL

86 (1) Z150 18BK GROUND

87 (5) L94 14OR/WT TRAILER TOW BRAKE LAMP RELAY OUTPUT

87A (4) L95 14DG/YL TRAILER TOW BRAKE LAMP RELAY OUTPUT

TRAILER TOW RIGHT TURN RELAY - BLACK 5 WAY

CAV CIRCUIT FUNCTION

30 (3) L62 14BR/RD RIGHT TURN SIGNAL

85 (2) L62 20BR/RD RIGHT TURN SIGNAL

86 (1) Z150 18BK GROUND

87 (5) L94 14OR/WT TRAILER TOW BRAKE LAMP RELAY OUTPUT

87A (4) L95 14DG/YL TRAILER TOW BRAKE LAMP RELAY OUTPUT

TRANSFER CASE POSITION SENSOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K77 20BR/WT (DIESEL) TRANSFER CASE POSITION SENSOR SIGNAL

1 K77 18LG/BK (GAS) TRANSFER CASE POSITION SENSOR INPUT

2 K4 20BK/LB (DIESEL) SENSOR GROUND

2 K4 18BK/LB (GAS) SENSOR GROUND

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 123

Page 1176 of 2199

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

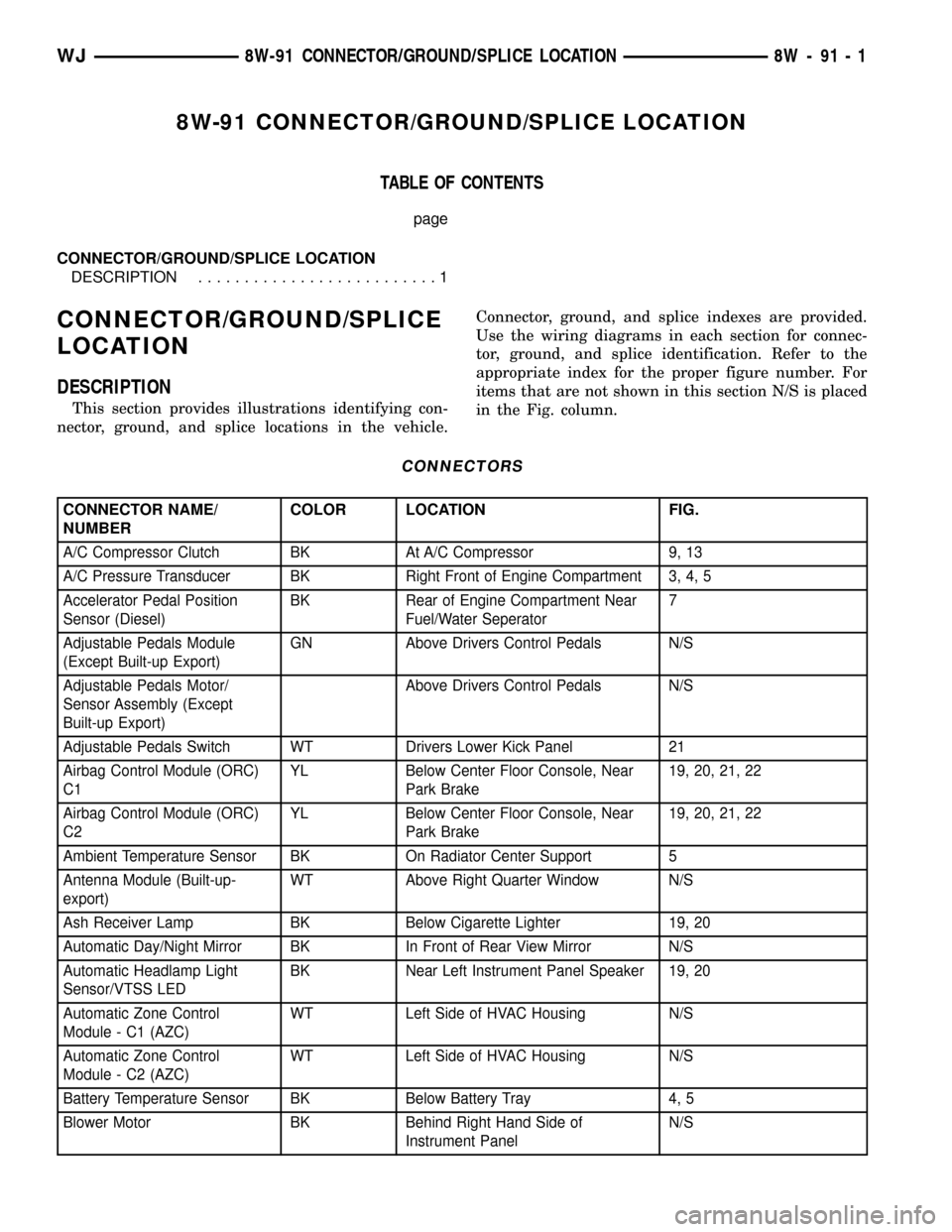

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.Connector, ground, and splice indexes are provided.

Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

appropriate index for the proper figure number. For

items that are not shown in this section N/S is placed

in the Fig. column.

CONNECTORS

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

A/C Compressor Clutch BK At A/C Compressor 9, 13

A/C Pressure Transducer BK Right Front of Engine Compartment 3, 4, 5

Accelerator Pedal Position

Sensor (Diesel)BK Rear of Engine Compartment Near

Fuel/Water Seperator7

Adjustable Pedals Module

(Except Built-up Export)GN Above Drivers Control Pedals N/S

Adjustable Pedals Motor/

Sensor Assembly (Except

Built-up Export)Above Drivers Control Pedals N/S

Adjustable Pedals Switch WT Drivers Lower Kick Panel 21

Airbag Control Module (ORC)

C1YL Below Center Floor Console, Near

Park Brake19, 20, 21, 22

Airbag Control Module (ORC)

C2YL Below Center Floor Console, Near

Park Brake19, 20, 21, 22

Ambient Temperature Sensor BK On Radiator Center Support 5

Antenna Module (Built-up-

export)WT Above Right Quarter Window N/S

Ash Receiver Lamp BK Below Cigarette Lighter 19, 20

Automatic Day/Night Mirror BK In Front of Rear View Mirror N/S

Automatic Headlamp Light

Sensor/VTSS LEDBK Near Left Instrument Panel Speaker 19, 20

Automatic Zone Control

Module - C1 (AZC)WT Left Side of HVAC Housing N/S

Automatic Zone Control

Module - C2 (AZC)WT Left Side of HVAC Housing N/S

Battery Temperature Sensor BK Below Battery Tray 4, 5

Blower Motor BK Behind Right Hand Side of

Instrument PanelN/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 1

Page 1189 of 2199

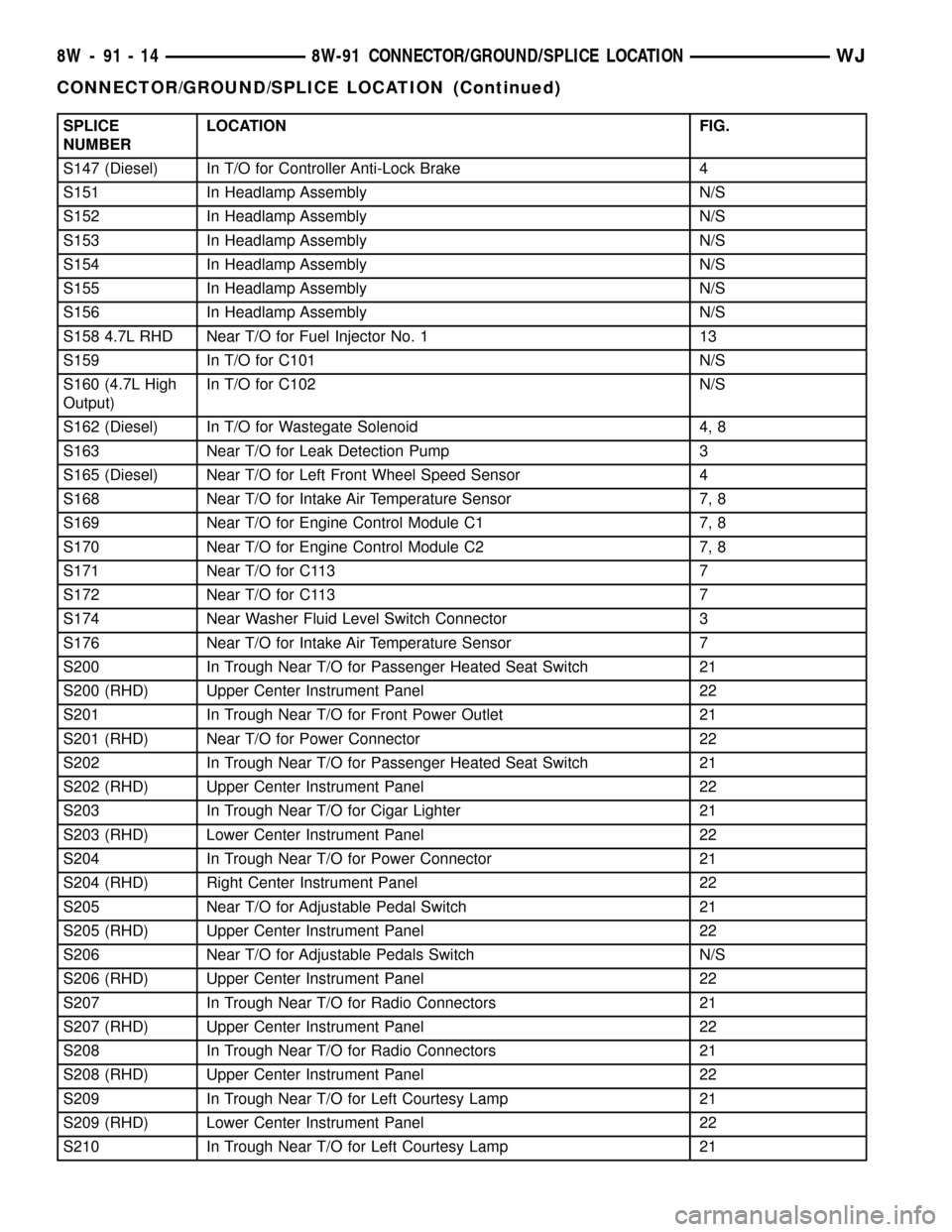

SPLICE

NUMBERLOCATION FIG.

S147 (Diesel) In T/O for Controller Anti-Lock Brake 4

S151 In Headlamp Assembly N/S

S152 In Headlamp Assembly N/S

S153 In Headlamp Assembly N/S

S154 In Headlamp Assembly N/S

S155 In Headlamp Assembly N/S

S156 In Headlamp Assembly N/S

S158 4.7L RHD Near T/O for Fuel Injector No. 1 13

S159 In T/O for C101 N/S

S160 (4.7L High

Output)In T/O for C102 N/S

S162 (Diesel) In T/O for Wastegate Solenoid 4, 8

S163 Near T/O for Leak Detection Pump 3

S165 (Diesel) Near T/O for Left Front Wheel Speed Sensor 4

S168 Near T/O for Intake Air Temperature Sensor 7, 8

S169 Near T/O for Engine Control Module C1 7, 8

S170 Near T/O for Engine Control Module C2 7, 8

S171 Near T/O for C113 7

S172 Near T/O for C113 7

S174 Near Washer Fluid Level Switch Connector 3

S176 Near T/O for Intake Air Temperature Sensor 7

S200 In Trough Near T/O for Passenger Heated Seat Switch 21

S200 (RHD) Upper Center Instrument Panel 22

S201 In Trough Near T/O for Front Power Outlet 21

S201 (RHD) Near T/O for Power Connector 22

S202 In Trough Near T/O for Passenger Heated Seat Switch 21

S202 (RHD) Upper Center Instrument Panel 22

S203 In Trough Near T/O for Cigar Lighter 21

S203 (RHD) Lower Center Instrument Panel 22

S204 In Trough Near T/O for Power Connector 21

S204 (RHD) Right Center Instrument Panel 22

S205 Near T/O for Adjustable Pedal Switch 21

S205 (RHD) Upper Center Instrument Panel 22

S206 Near T/O for Adjustable Pedals Switch N/S

S206 (RHD) Upper Center Instrument Panel 22

S207 In Trough Near T/O for Radio Connectors 21

S207 (RHD) Upper Center Instrument Panel 22

S208 In Trough Near T/O for Radio Connectors 21

S208 (RHD) Upper Center Instrument Panel 22

S209 In Trough Near T/O for Left Courtesy Lamp 21

S209 (RHD) Lower Center Instrument Panel 22

S210 In Trough Near T/O for Left Courtesy Lamp 21

8W - 91 - 14 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1381 of 2199

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install ignition coil towers (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

(10) Install coolant temperature sensor (Refer to 7

- COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - INSTALLATION).

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Install right side engine lifting stud.

(14) Install generator including electrical connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - INSTALLATION).

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Install air conditioning compressor including

electrical connections.

(17) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(19) Install cowl to hood seal (Refer to 23 - BODY/

WEATHERSTRIP/SEALS/COWL WEATHERSTRIP -

INSTALLATION).

(20) Install air cleaner housing and throttle body

resonator. Tighten resonator bolts 4.5 N´m (40 in.

lbs.).

(21) Connect negative cable to battery.

EXHAUST MANIFOLD - LEFT

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nutthat is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

(1) Disconnect negative cable for battery.

(2) Hoist vehicle.

(3) Disconnect exhaust pipe at manifold.

(4) Lower vehicle.

(5) Remove air cleaner housing and tube.

(6) Remove the front two exhaust heat shield

retaining fasteners. Raise vehicle and remove the

fasteners at rear of heat shield.

(7) Remove heat shield (Fig. 107).

(8) Lower vehicle and remove the upper exhaust

manifold retaining bolts (Fig. 107).

(9) Raise vehicle and remove the lower exhaust

manifold retaining bolts (Fig. 107).

(10) Remove exhaust manifold and gasket (Fig.

107). Manifold is removed from below the engine

compartment.

CLEANING

(1) Clean the exhaust manifold using a suitable

cleaning solvent, then allow to air dry.

(2) Clean all gasket residue from the manifold

mating surface.

INSPECTION

(1) Inspect the exhaust manifold for cracks in the

mating surface and at every mounting bolt hole.

(2) Using a straight edge and a feeler gauge, check

the mating surface for warp and twist.

(3) Inspect the manifold to exhaust pipe mating

surface for cracks, gouges, or other damage that

would prevent sealing.

INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners (Fig.

107). DO NOT tighten until all fasteners are in

place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners (Fig. 107). Tighten all manifold bolts

starting at center and working outward to 25 N´m

(18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield (Fig. 107).

Tighten fasteners to 8 N´m (72 in. lbs.), then loosen

45 degrees.

(5) Install air cleaner housing and tube.

(6) Connect exhaust pipe to manifold.

(7) Connect negative cable to battery.

9 - 138 ENGINE - 4.7LWJ

INTAKE MANIFOLD (Continued)

Page 2184 of 2199

INSTALLATION - FIXED ORIFICE FITTING

When installing fixed orifice fitting, be sure loca-

tions of fixed orifice fitting and air inlet fitting (Fig.

9) have not been inadvertently exchanged. The fixed

orifice fitting is light grey in color and is located at

rearof valve cover. The air inlet fitting is black in

color and is located atfrontof valve cover.

(1) Connect fitting to CCV breather tube.

(2) Return fixed orifice fitting to valve cover grom-

met.

EVAP/PURGE SOLENOID

DESCRIPTION

The duty cycle EVAP canister purge solenoid (DCP)

regulates the rate of vapor flow from the EVAP can-

ister to the intake manifold. The Powertrain Control

Module (PCM) operates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM cycles

(energizes and de-energizes) the solenoid 5 or 10

times per second, depending upon operating condi-

tions. The PCM varies the vapor flow rate by chang-

ing solenoid pulse width. Pulse width is the amount

of time that the solenoid is energized. The PCM

adjusts solenoid pulse width based on engine operat-

ing condition.

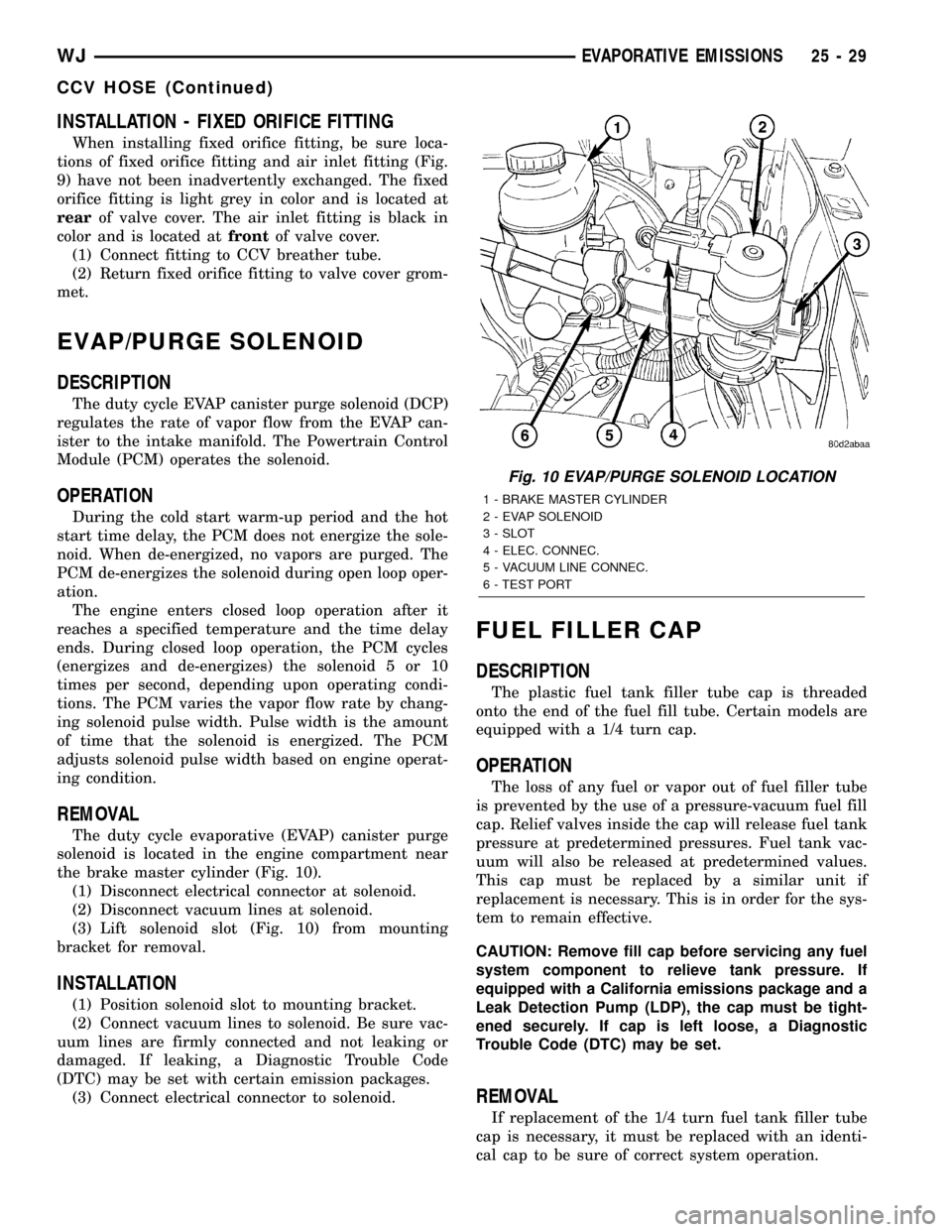

REMOVAL

The duty cycle evaporative (EVAP) canister purge

solenoid is located in the engine compartment near

the brake master cylinder (Fig. 10).

(1) Disconnect electrical connector at solenoid.

(2) Disconnect vacuum lines at solenoid.

(3) Lift solenoid slot (Fig. 10) from mounting

bracket for removal.

INSTALLATION

(1) Position solenoid slot to mounting bracket.

(2) Connect vacuum lines to solenoid. Be sure vac-

uum lines are firmly connected and not leaking or

damaged. If leaking, a Diagnostic Trouble Code

(DTC) may be set with certain emission packages.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. Certain models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with a California emissions package and a

Leak Detection Pump (LDP), the cap must be tight-

ened securely. If cap is left loose, a Diagnostic

Trouble Code (DTC) may be set.

REMOVAL

If replacement of the 1/4 turn fuel tank filler tube

cap is necessary, it must be replaced with an identi-

cal cap to be sure of correct system operation.

Fig. 10 EVAP/PURGE SOLENOID LOCATION

1 - BRAKE MASTER CYLINDER

2 - EVAP SOLENOID

3 - SLOT

4 - ELEC. CONNEC.

5 - VACUUM LINE CONNEC.

6 - TEST PORT

WJEVAPORATIVE EMISSIONS 25 - 29

CCV HOSE (Continued)