Fluid level JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1111 of 2199

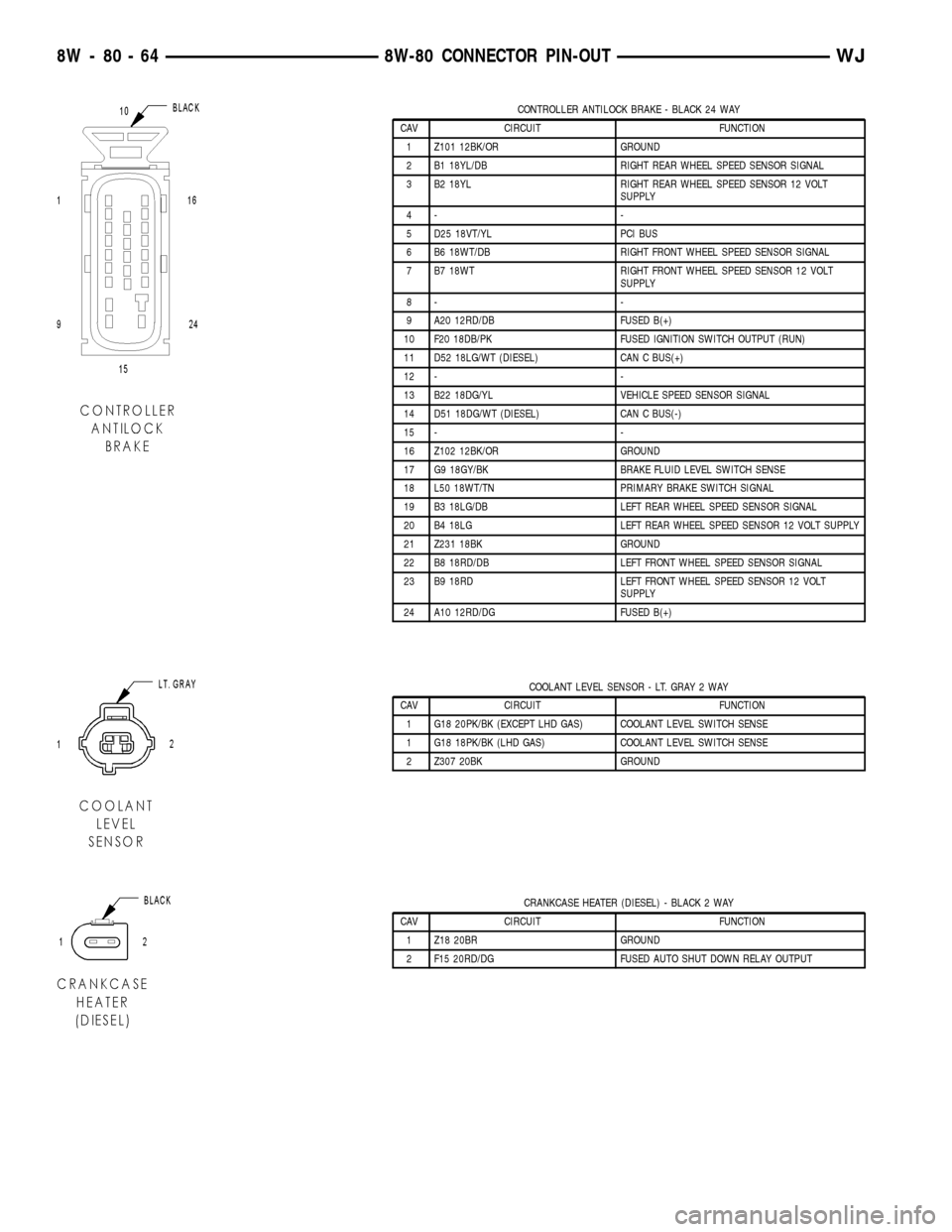

CONTROLLER ANTILOCK BRAKE - BLACK 24 WAY

CAV CIRCUIT FUNCTION

1 Z101 12BK/OR GROUND

2 B1 18YL/DB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

3 B2 18YL RIGHT REAR WHEEL SPEED SENSOR 12 VOLT

SUPPLY

4- -

5 D25 18VT/YL PCI BUS

6 B6 18WT/DB RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

7 B7 18WT RIGHT FRONT WHEEL SPEED SENSOR 12 VOLT

SUPPLY

8- -

9 A20 12RD/DB FUSED B(+)

10 F20 18DB/PK FUSED IGNITION SWITCH OUTPUT (RUN)

11 D52 18LG/WT (DIESEL) CAN C BUS(+)

12 - -

13 B22 18DG/YL VEHICLE SPEED SENSOR SIGNAL

14 D51 18DG/WT (DIESEL) CAN C BUS(-)

15 - -

16 Z102 12BK/OR GROUND

17 G9 18GY/BK BRAKE FLUID LEVEL SWITCH SENSE

18 L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

19 B3 18LG/DB LEFT REAR WHEEL SPEED SENSOR SIGNAL

20 B4 18LG LEFT REAR WHEEL SPEED SENSOR 12 VOLT SUPPLY

21 Z231 18BK GROUND

22 B8 18RD/DB LEFT FRONT WHEEL SPEED SENSOR SIGNAL

23 B9 18RD LEFT FRONT WHEEL SPEED SENSOR 12 VOLT

SUPPLY

24 A10 12RD/DG FUSED B(+)

COOLANT LEVEL SENSOR - LT. GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 G18 20PK/BK (EXCEPT LHD GAS) COOLANT LEVEL SWITCH SENSE

1 G18 18PK/BK (LHD GAS) COOLANT LEVEL SWITCH SENSE

2 Z307 20BK GROUND

CRANKCASE HEATER (DIESEL) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 Z18 20BR GROUND

2 F15 20RD/DG FUSED AUTO SHUT DOWN RELAY OUTPUT

8W - 80 - 64 8W-80 CONNECTOR PIN-OUTWJ

Page 1174 of 2199

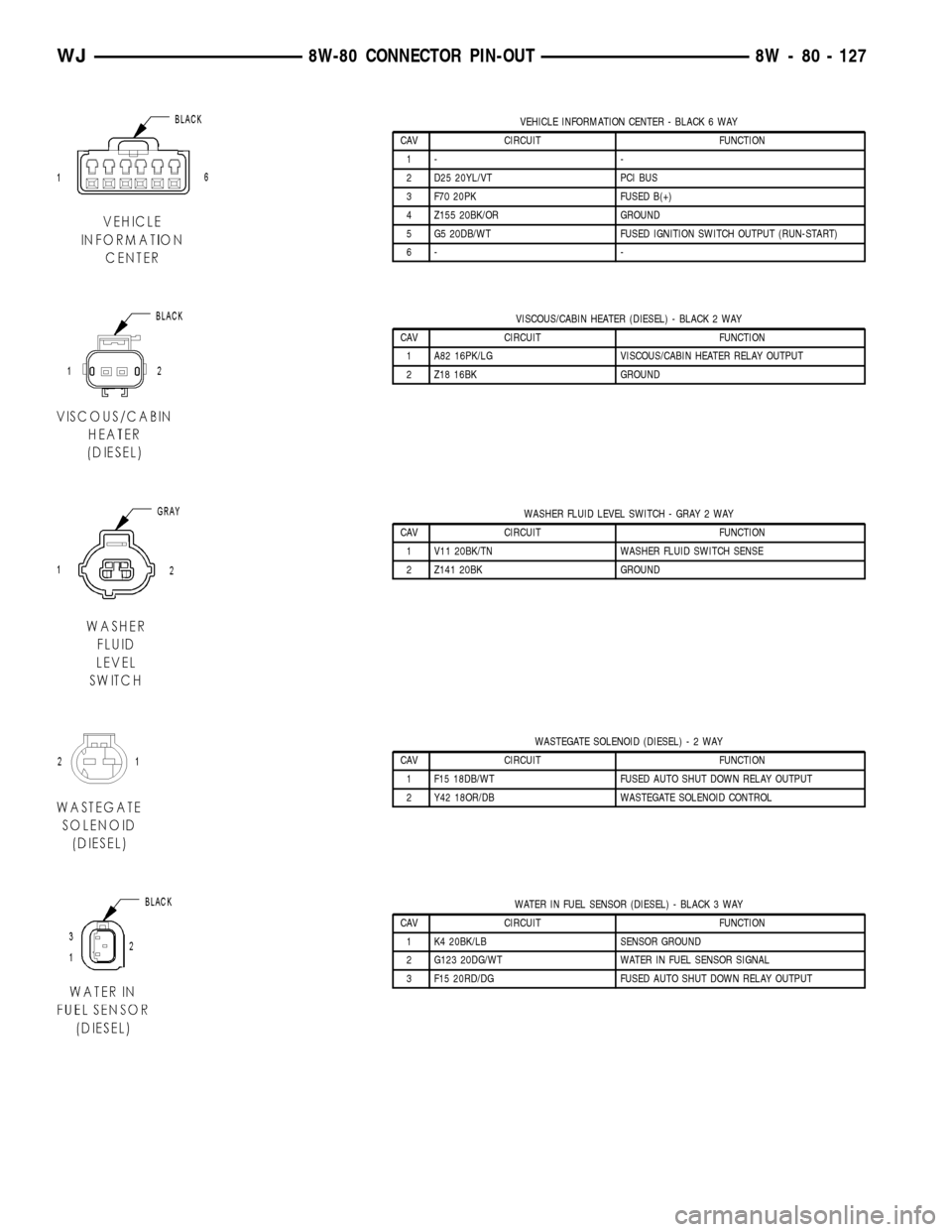

VEHICLE INFORMATION CENTER - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1- -

2 D25 20YL/VT PCI BUS

3 F70 20PK FUSED B(+)

4 Z155 20BK/OR GROUND

5 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

6- -

VISCOUS/CABIN HEATER (DIESEL) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 A82 16PK/LG VISCOUS/CABIN HEATER RELAY OUTPUT

2 Z18 16BK GROUND

WASHER FLUID LEVEL SWITCH - GRAY 2 WAY

CAV CIRCUIT FUNCTION

1 V11 20BK/TN WASHER FLUID SWITCH SENSE

2 Z141 20BK GROUND

WASTEGATE SOLENOID (DIESEL)-2WAY

CAV CIRCUIT FUNCTION

1 F15 18DB/WT FUSED AUTO SHUT DOWN RELAY OUTPUT

2 Y42 18OR/DB WASTEGATE SOLENOID CONTROL

WATER IN FUEL SENSOR (DIESEL) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K4 20BK/LB SENSOR GROUND

2 G123 20DG/WT WATER IN FUEL SENSOR SIGNAL

3 F15 20RD/DG FUSED AUTO SHUT DOWN RELAY OUTPUT

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 127

Page 1186 of 2199

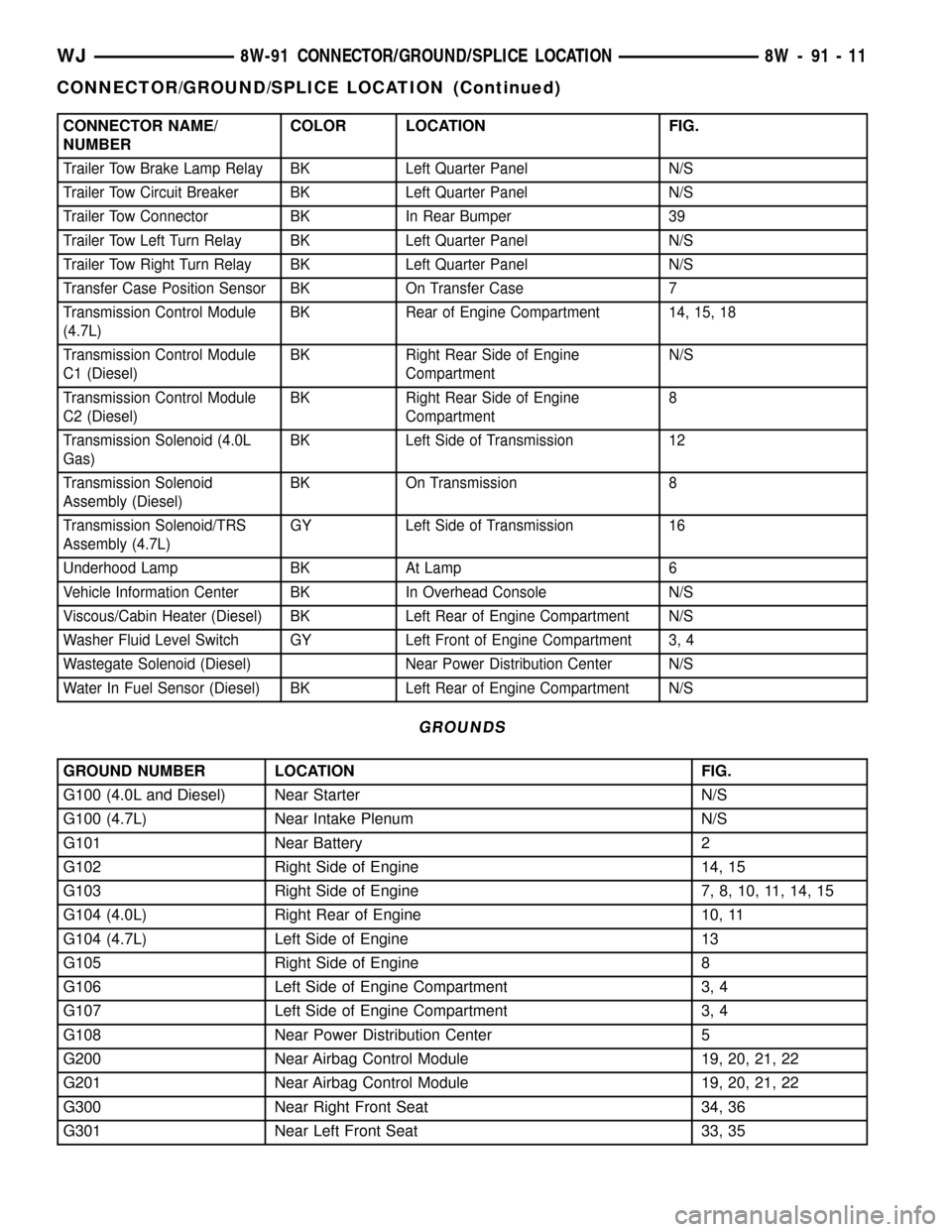

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Trailer Tow Brake Lamp Relay BK Left Quarter Panel N/S

Trailer Tow Circuit Breaker BK Left Quarter Panel N/S

Trailer Tow Connector BK In Rear Bumper 39

Trailer Tow Left Turn Relay BK Left Quarter Panel N/S

Trailer Tow Right Turn Relay BK Left Quarter Panel N/S

Transfer Case Position Sensor BK On Transfer Case 7

Transmission Control Module

(4.7L)BK Rear of Engine Compartment 14, 15, 18

Transmission Control Module

C1 (Diesel)BK Right Rear Side of Engine

CompartmentN/S

Transmission Control Module

C2 (Diesel)BK Right Rear Side of Engine

Compartment8

Transmission Solenoid (4.0L

Gas)BK Left Side of Transmission 12

Transmission Solenoid

Assembly (Diesel)BK On Transmission 8

Transmission Solenoid/TRS

Assembly (4.7L)GY Left Side of Transmission 16

Underhood Lamp BK At Lamp 6

Vehicle Information Center BK In Overhead Console N/S

Viscous/Cabin Heater (Diesel) BK Left Rear of Engine Compartment N/S

Washer Fluid Level Switch GY Left Front of Engine Compartment 3, 4

Wastegate Solenoid (Diesel) Near Power Distribution Center N/S

Water In Fuel Sensor (Diesel) BK Left Rear of Engine Compartment N/S

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 (4.0L and Diesel) Near Starter N/S

G100 (4.7L) Near Intake Plenum N/S

G101 Near Battery 2

G102 Right Side of Engine 14, 15

G103 Right Side of Engine 7, 8, 10, 11, 14, 15

G104 (4.0L) Right Rear of Engine 10, 11

G104 (4.7L) Left Side of Engine 13

G105 Right Side of Engine 8

G106 Left Side of Engine Compartment 3, 4

G107 Left Side of Engine Compartment 3, 4

G108 Near Power Distribution Center 5

G200 Near Airbag Control Module 19, 20, 21, 22

G201 Near Airbag Control Module 19, 20, 21, 22

G300 Near Right Front Seat 34, 36

G301 Near Left Front Seat 33, 35

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1189 of 2199

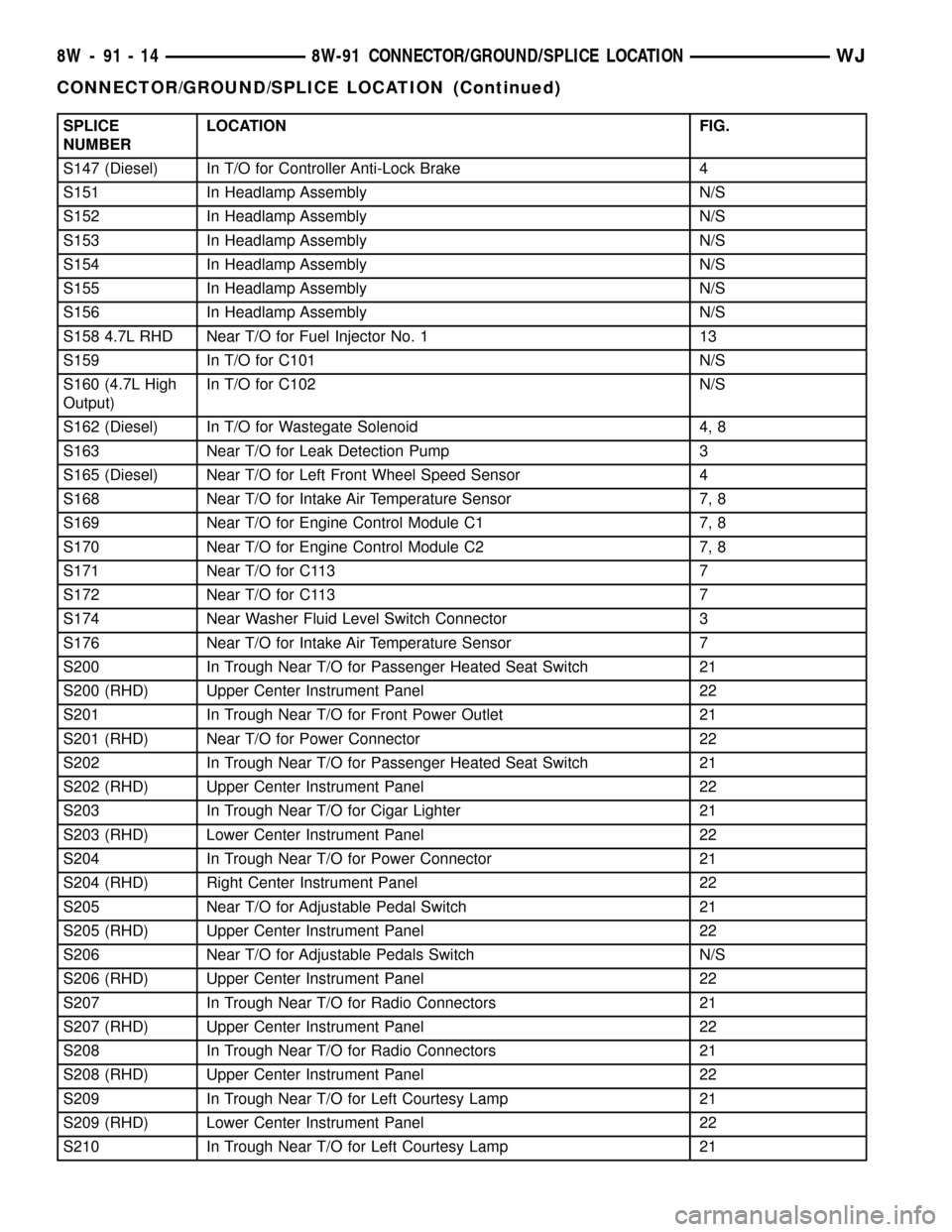

SPLICE

NUMBERLOCATION FIG.

S147 (Diesel) In T/O for Controller Anti-Lock Brake 4

S151 In Headlamp Assembly N/S

S152 In Headlamp Assembly N/S

S153 In Headlamp Assembly N/S

S154 In Headlamp Assembly N/S

S155 In Headlamp Assembly N/S

S156 In Headlamp Assembly N/S

S158 4.7L RHD Near T/O for Fuel Injector No. 1 13

S159 In T/O for C101 N/S

S160 (4.7L High

Output)In T/O for C102 N/S

S162 (Diesel) In T/O for Wastegate Solenoid 4, 8

S163 Near T/O for Leak Detection Pump 3

S165 (Diesel) Near T/O for Left Front Wheel Speed Sensor 4

S168 Near T/O for Intake Air Temperature Sensor 7, 8

S169 Near T/O for Engine Control Module C1 7, 8

S170 Near T/O for Engine Control Module C2 7, 8

S171 Near T/O for C113 7

S172 Near T/O for C113 7

S174 Near Washer Fluid Level Switch Connector 3

S176 Near T/O for Intake Air Temperature Sensor 7

S200 In Trough Near T/O for Passenger Heated Seat Switch 21

S200 (RHD) Upper Center Instrument Panel 22

S201 In Trough Near T/O for Front Power Outlet 21

S201 (RHD) Near T/O for Power Connector 22

S202 In Trough Near T/O for Passenger Heated Seat Switch 21

S202 (RHD) Upper Center Instrument Panel 22

S203 In Trough Near T/O for Cigar Lighter 21

S203 (RHD) Lower Center Instrument Panel 22

S204 In Trough Near T/O for Power Connector 21

S204 (RHD) Right Center Instrument Panel 22

S205 Near T/O for Adjustable Pedal Switch 21

S205 (RHD) Upper Center Instrument Panel 22

S206 Near T/O for Adjustable Pedals Switch N/S

S206 (RHD) Upper Center Instrument Panel 22

S207 In Trough Near T/O for Radio Connectors 21

S207 (RHD) Upper Center Instrument Panel 22

S208 In Trough Near T/O for Radio Connectors 21

S208 (RHD) Upper Center Instrument Panel 22

S209 In Trough Near T/O for Left Courtesy Lamp 21

S209 (RHD) Lower Center Instrument Panel 22

S210 In Trough Near T/O for Left Courtesy Lamp 21

8W - 91 - 14 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1257 of 2199

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(48) Start the engine, inspect for leaks and correct

the fluid levels, as necessary.

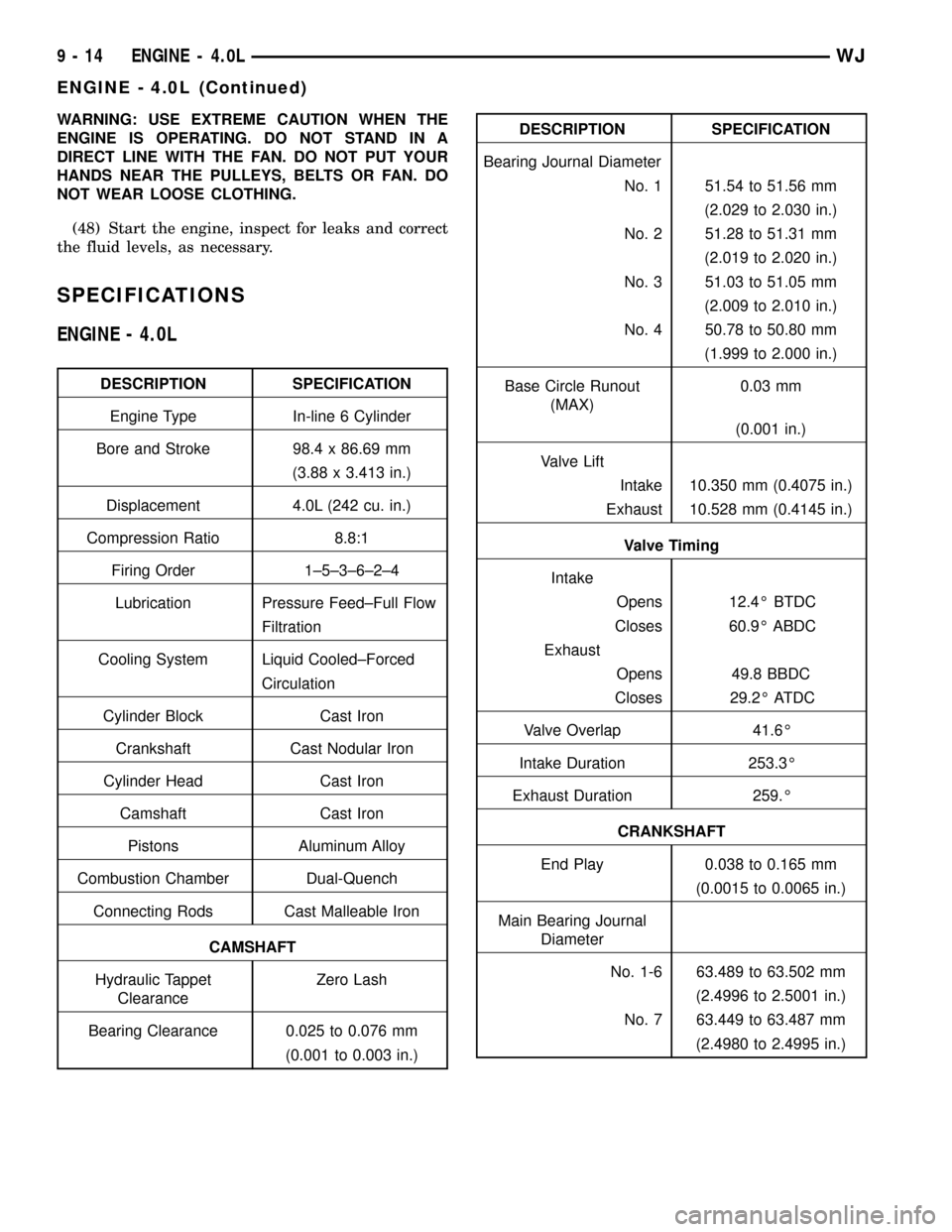

SPECIFICATIONS

ENGINE - 4.0L

DESCRIPTION SPECIFICATION

Engine Type In-line 6 Cylinder

Bore and Stroke 98.4 x 86.69 mm

(3.88 x 3.413 in.)

Displacement 4.0L (242 cu. in.)

Compression Ratio 8.8:1

Firing Order 1±5±3±6±2±4

Lubrication Pressure Feed±Full Flow

Filtration

Cooling System Liquid Cooled±Forced

Circulation

Cylinder Block Cast Iron

Crankshaft Cast Nodular Iron

Cylinder Head Cast Iron

Camshaft Cast Iron

Pistons Aluminum Alloy

Combustion Chamber Dual-Quench

Connecting Rods Cast Malleable Iron

CAMSHAFT

Hydraulic Tappet

ClearanceZero Lash

Bearing Clearance 0.025 to 0.076 mm

(0.001 to 0.003 in.)

DESCRIPTION SPECIFICATION

Bearing Journal Diameter

No. 1 51.54 to 51.56 mm

(2.029 to 2.030 in.)

No. 2 51.28 to 51.31 mm

(2.019 to 2.020 in.)

No. 3 51.03 to 51.05 mm

(2.009 to 2.010 in.)

No. 4 50.78 to 50.80 mm

(1.999 to 2.000 in.)

Base Circle Runout

(MAX)0.03 mm

(0.001 in.)

Valve Lift

Intake 10.350 mm (0.4075 in.)

Exhaust 10.528 mm (0.4145 in.)

Valve Timing

Intake

Opens 12.4É BTDC

Closes 60.9É ABDC

Exhaust

Opens 49.8 BBDC

Closes 29.2É ATDC

Valve Overlap 41.6É

Intake Duration 253.3É

Exhaust Duration 259.É

CRANKSHAFT

End Play 0.038 to 0.165 mm

(0.0015 to 0.0065 in.)

Main Bearing Journal

Diameter

No. 1-6 63.489 to 63.502 mm

(2.4996 to 2.5001 in.)

No. 7 63.449 to 63.487 mm

(2.4980 to 2.4995 in.)

9 - 14 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1296 of 2199

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Replace engine oil filter. (Refer to 9 - ENGINE/

LUBRICATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type of engine oil (Refer to LUBRICATION & MAIN-

TENANCE/FLUID TYPES - DESCRIPTION) and

amount of engine oil (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level. Refer to

CRANKCASE OIL LEVEL INSPECTION .

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine.

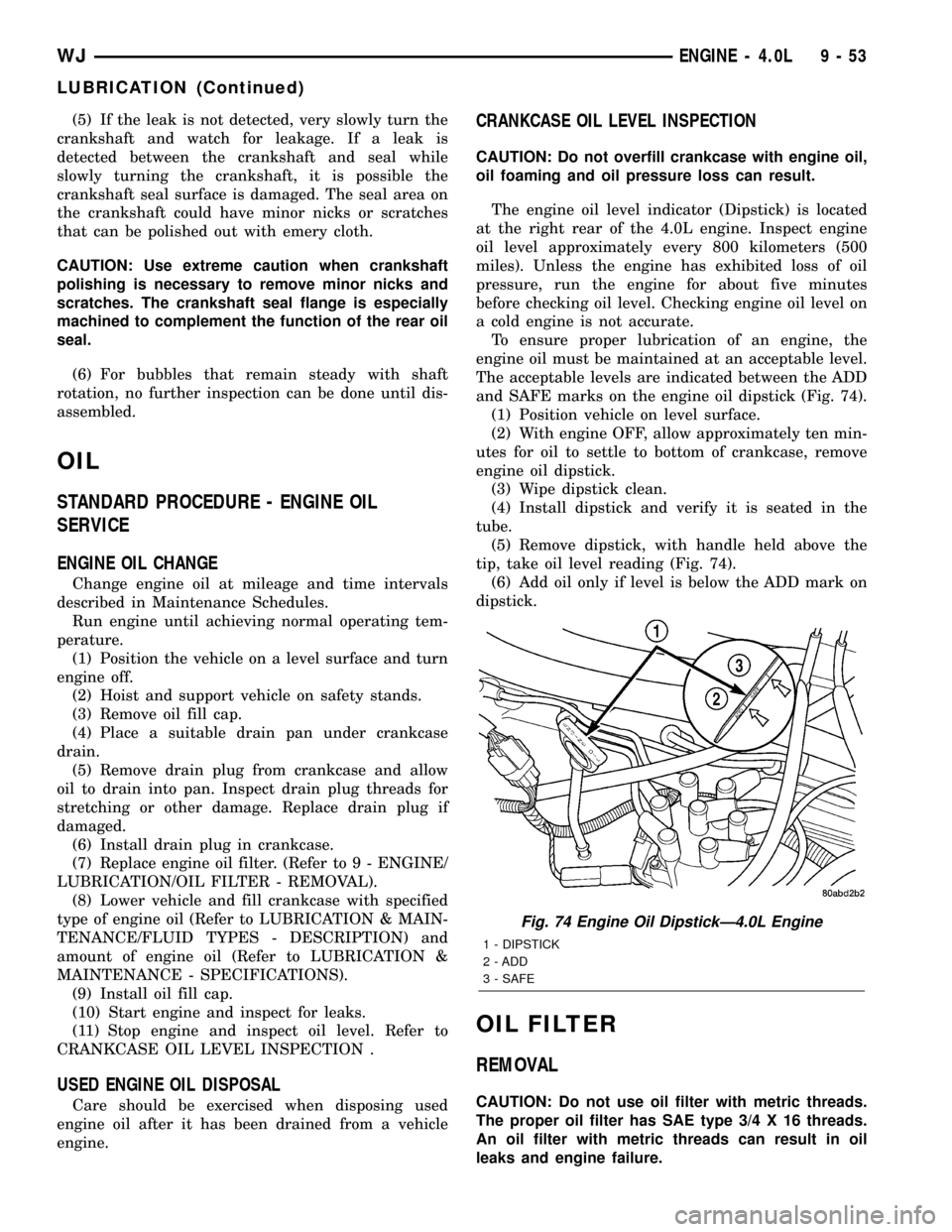

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

The engine oil level indicator (Dipstick) is located

at the right rear of the 4.0L engine. Inspect engine

oil level approximately every 800 kilometers (500

miles). Unless the engine has exhibited loss of oil

pressure, run the engine for about five minutes

before checking oil level. Checking engine oil level on

a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick (Fig. 74).

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading (Fig. 74).

(6) Add oil only if level is below the ADD mark on

dipstick.

OIL FILTER

REMOVAL

CAUTION: Do not use oil filter with metric threads.

The proper oil filter has SAE type 3/4 X 16 threads.

An oil filter with metric threads can result in oil

leaks and engine failure.

Fig. 74 Engine Oil DipstickÐ4.0L Engine

1 - DIPSTICK

2 - ADD

3 - SAFE

WJENGINE - 4.0L 9 - 53

LUBRICATION (Continued)

Page 1309 of 2199

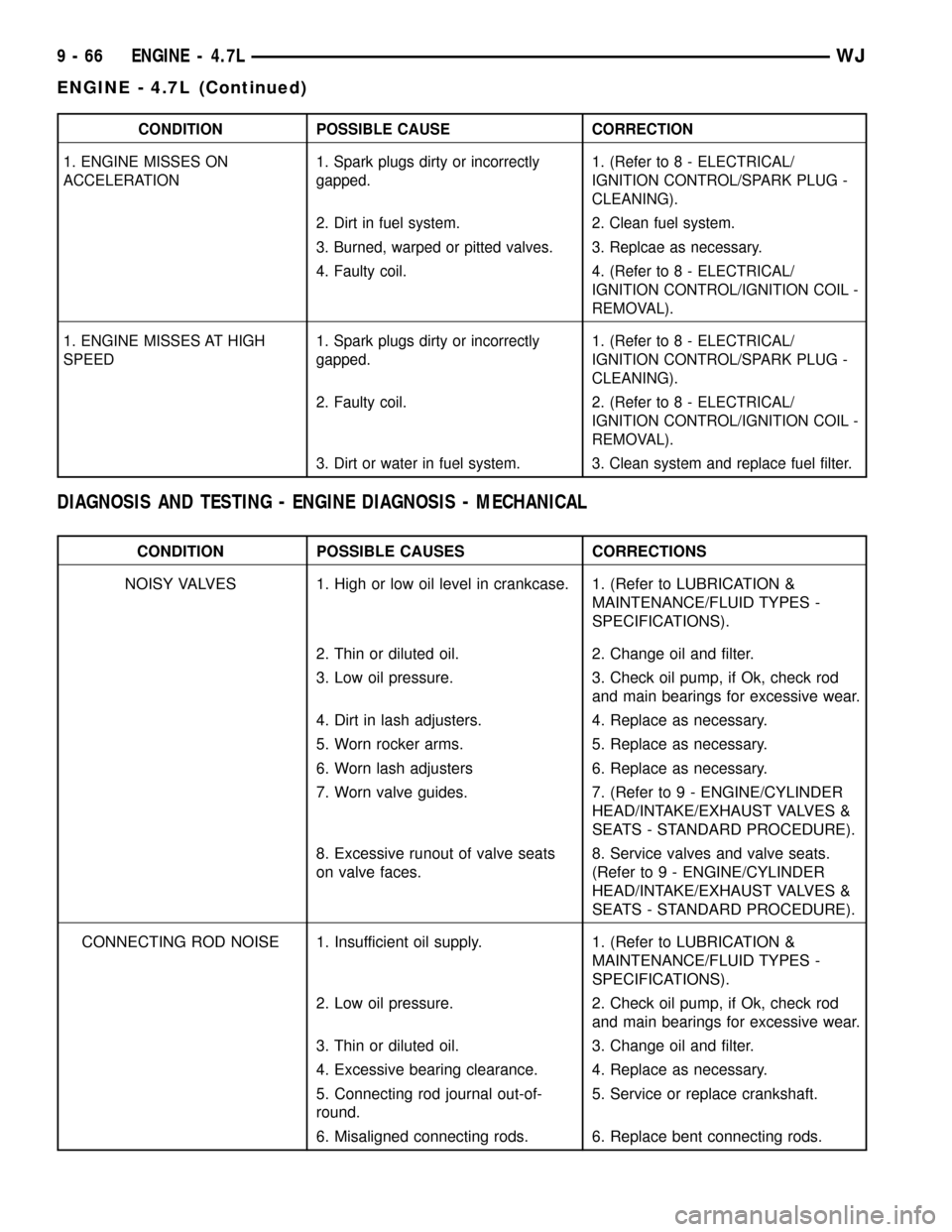

CONDITION POSSIBLE CAUSE CORRECTION

1. ENGINE MISSES ON

ACCELERATION1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

2. Dirt in fuel system. 2. Clean fuel system.

3. Burned, warped or pitted valves. 3. Replcae as necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

1. ENGINE MISSES AT HIGH

SPEED1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

2. Faulty coil. 2. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

3. Dirt or water in fuel system. 3. Clean system and replace fuel filter.

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in crankcase. 1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive wear.

4. Dirt in lash adjusters. 4. Replace as necessary.

5. Worn rocker arms. 5. Replace as necessary.

6. Worn lash adjusters 6. Replace as necessary.

7. Worn valve guides. 7. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE).

8. Excessive runout of valve seats

on valve faces.8. Service valves and valve seats.

(Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE).

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal out-of-

round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

9 - 66 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1421 of 2199

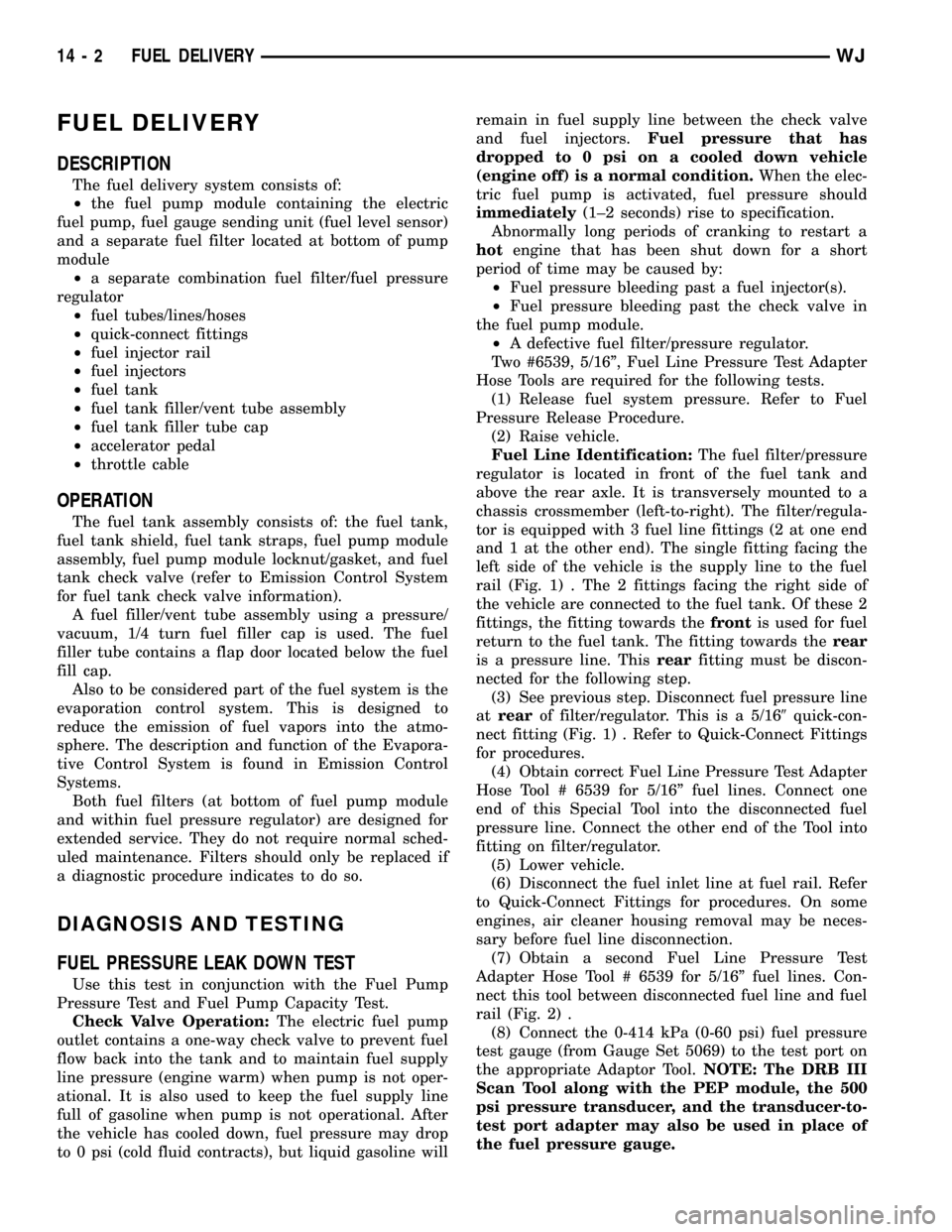

FUEL DELIVERY

DESCRIPTION

The fuel delivery system consists of:

²the fuel pump module containing the electric

fuel pump, fuel gauge sending unit (fuel level sensor)

and a separate fuel filter located at bottom of pump

module

²a separate combination fuel filter/fuel pressure

regulator

²fuel tubes/lines/hoses

²quick-connect fittings

²fuel injector rail

²fuel injectors

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

OPERATION

The fuel tank assembly consists of: the fuel tank,

fuel tank shield, fuel tank straps, fuel pump module

assembly, fuel pump module locknut/gasket, and fuel

tank check valve (refer to Emission Control System

for fuel tank check valve information).

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap.

Also to be considered part of the fuel system is the

evaporation control system. This is designed to

reduce the emission of fuel vapors into the atmo-

sphere. The description and function of the Evapora-

tive Control System is found in Emission Control

Systems.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

DIAGNOSIS AND TESTING

FUEL PRESSURE LEAK DOWN TEST

Use this test in conjunction with the Fuel Pump

Pressure Test and Fuel Pump Capacity Test.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply line

full of gasoline when pump is not operational. After

the vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline willremain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

Abnormally long periods of cranking to restart a

hotengine that has been shut down for a short

period of time may be caused by:

²Fuel pressure bleeding past a fuel injector(s).

²Fuel pressure bleeding past the check valve in

the fuel pump module.

²A defective fuel filter/pressure regulator.

Two #6539, 5/16º, Fuel Line Pressure Test Adapter

Hose Tools are required for the following tests.

(1) Release fuel system pressure. Refer to Fuel

Pressure Release Procedure.

(2) Raise vehicle.

Fuel Line Identification:The fuel filter/pressure

regulator is located in front of the fuel tank and

above the rear axle. It is transversely mounted to a

chassis crossmember (left-to-right). The filter/regula-

tor is equipped with 3 fuel line fittings (2 at one end

and 1 at the other end). The single fitting facing the

left side of the vehicle is the supply line to the fuel

rail (Fig. 1) . The 2 fittings facing the right side of

the vehicle are connected to the fuel tank. Of these 2

fittings, the fitting towards thefrontis used for fuel

return to the fuel tank. The fitting towards therear

is a pressure line. Thisrearfitting must be discon-

nected for the following step.

(3) See previous step. Disconnect fuel pressure line

atrearof filter/regulator. This is a 5/169quick-con-

nect fitting (Fig. 1) . Refer to Quick-Connect Fittings

for procedures.

(4) Obtain correct Fuel Line Pressure Test Adapter

Hose Tool # 6539 for 5/16º fuel lines. Connect one

end of this Special Tool into the disconnected fuel

pressure line. Connect the other end of the Tool into

fitting on filter/regulator.

(5) Lower vehicle.

(6) Disconnect the fuel inlet line at fuel rail. Refer

to Quick-Connect Fittings for procedures. On some

engines, air cleaner housing removal may be neces-

sary before fuel line disconnection.

(7) Obtain a second Fuel Line Pressure Test

Adapter Hose Tool # 6539 for 5/16º fuel lines. Con-

nect this tool between disconnected fuel line and fuel

rail (Fig. 2) .

(8) Connect the 0-414 kPa (0-60 psi) fuel pressure

test gauge (from Gauge Set 5069) to the test port on

the appropriate Adaptor Tool.NOTE: The DRB III

Scan Tool along with the PEP module, the 500

psi pressure transducer, and the transducer-to-

test port adapter may also be used in place of

the fuel pressure gauge.

14 - 2 FUEL DELIVERYWJ

Page 1479 of 2199

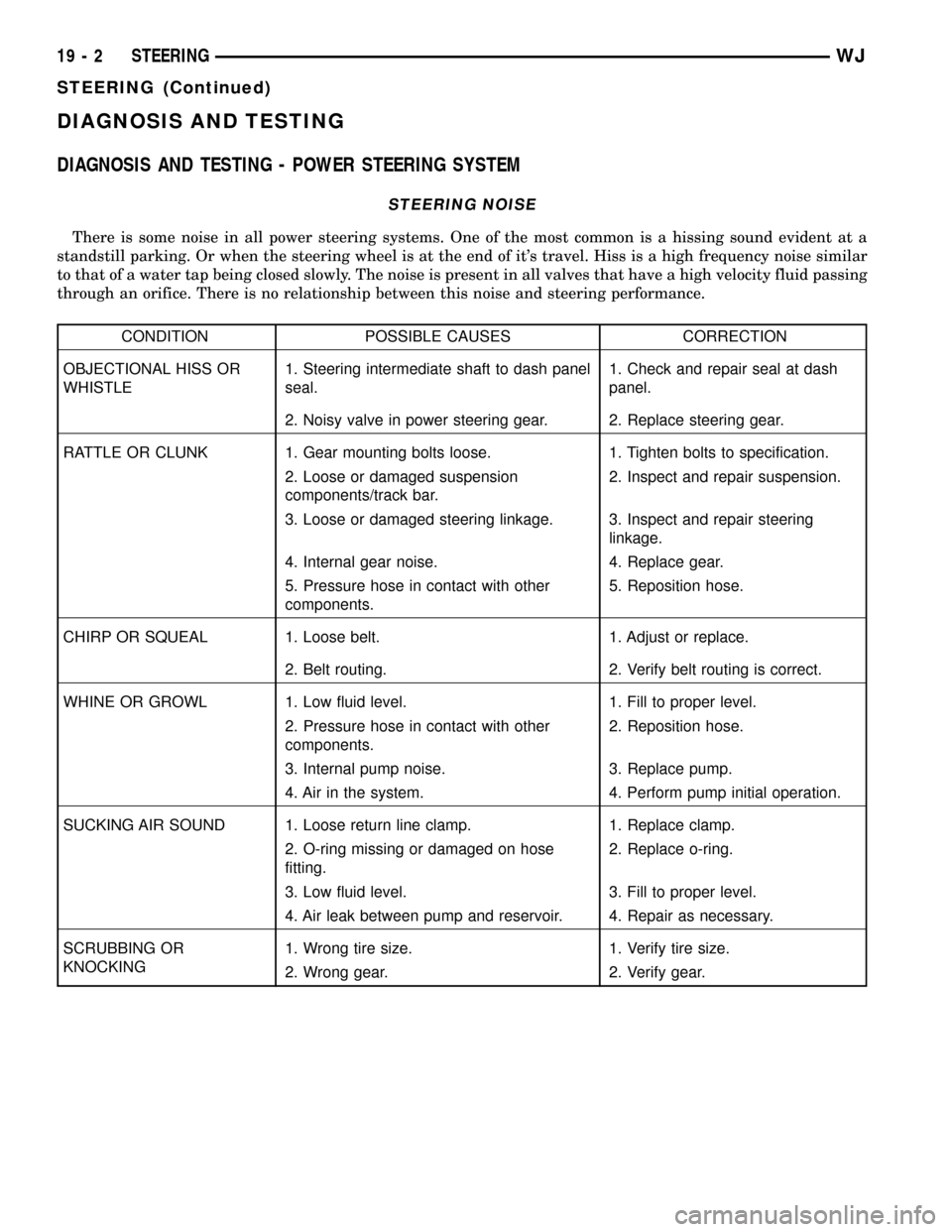

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER STEERING SYSTEM

STEERING NOISE

There is some noise in all power steering systems. One of the most common is a hissing sound evident at a

standstill parking. Or when the steering wheel is at the end of it's travel. Hiss is a high frequency noise similar

to that of a water tap being closed slowly. The noise is present in all valves that have a high velocity fluid passing

through an orifice. There is no relationship between this noise and steering performance.

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONAL HISS OR

WHISTLE1. Steering intermediate shaft to dash panel

seal.1. Check and repair seal at dash

panel.

2. Noisy valve in power steering gear. 2. Replace steering gear.

RATTLE OR CLUNK 1. Gear mounting bolts loose. 1. Tighten bolts to specification.

2. Loose or damaged suspension

components/track bar.2. Inspect and repair suspension.

3. Loose or damaged steering linkage. 3. Inspect and repair steering

linkage.

4. Internal gear noise. 4. Replace gear.

5. Pressure hose in contact with other

components.5. Reposition hose.

CHIRP OR SQUEAL 1. Loose belt. 1. Adjust or replace.

2. Belt routing. 2. Verify belt routing is correct.

WHINE OR GROWL 1. Low fluid level. 1. Fill to proper level.

2. Pressure hose in contact with other

components.2. Reposition hose.

3. Internal pump noise. 3. Replace pump.

4. Air in the system. 4. Perform pump initial operation.

SUCKING AIR SOUND 1. Loose return line clamp. 1. Replace clamp.

2. O-ring missing or damaged on hose

fitting.2. Replace o-ring.

3. Low fluid level. 3. Fill to proper level.

4. Air leak between pump and reservoir. 4. Repair as necessary.

SCRUBBING OR

KNOCKING1. Wrong tire size. 1. Verify tire size.

2. Wrong gear. 2. Verify gear.

19 - 2 STEERINGWJ

STEERING (Continued)

Page 1480 of 2199

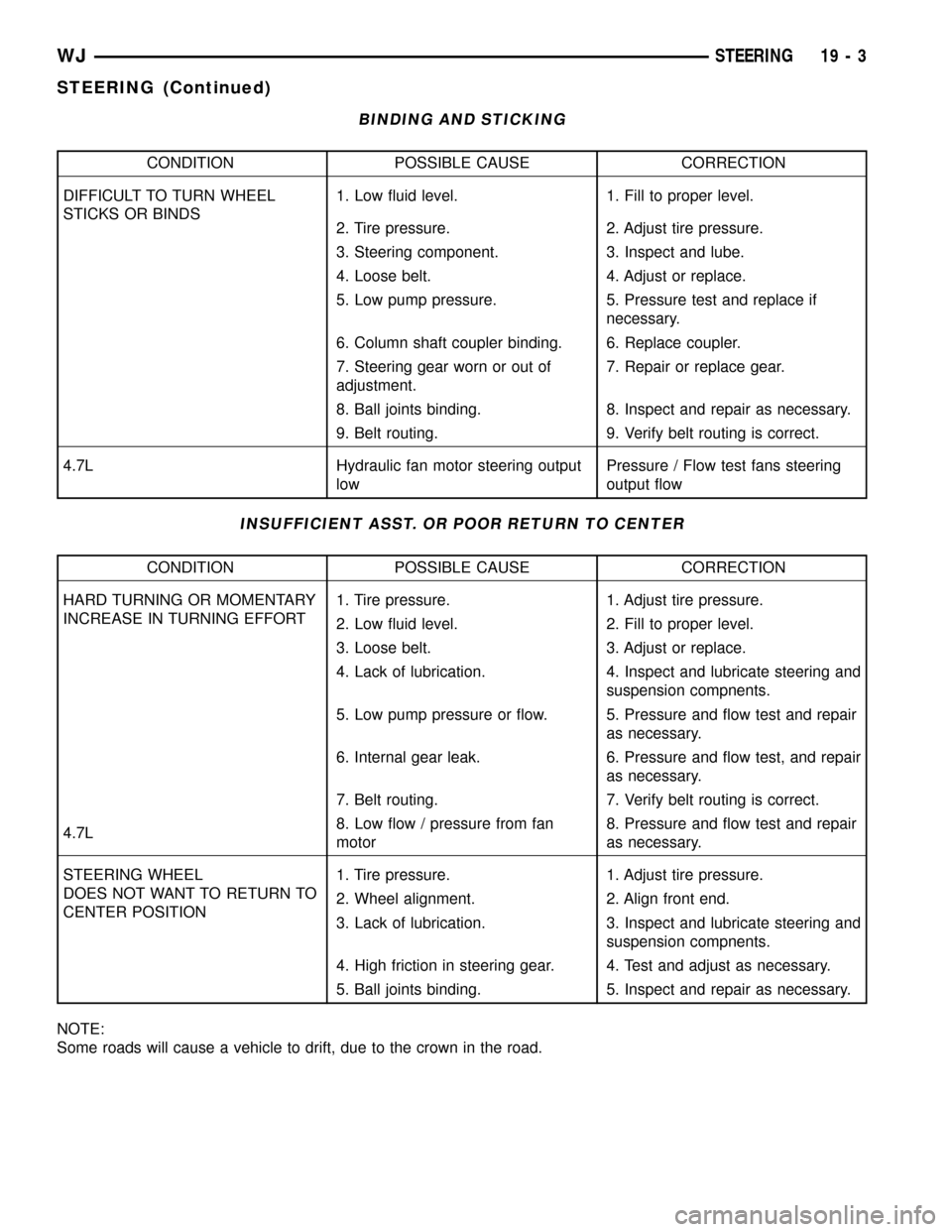

BINDING AND STICKING

CONDITION POSSIBLE CAUSE CORRECTION

DIFFICULT TO TURN WHEEL

STICKS OR BINDS1. Low fluid level. 1. Fill to proper level.

2. Tire pressure. 2. Adjust tire pressure.

3. Steering component. 3. Inspect and lube.

4. Loose belt. 4. Adjust or replace.

5. Low pump pressure. 5. Pressure test and replace if

necessary.

6. Column shaft coupler binding. 6. Replace coupler.

7. Steering gear worn or out of

adjustment.7. Repair or replace gear.

8. Ball joints binding. 8. Inspect and repair as necessary.

9. Belt routing. 9. Verify belt routing is correct.

4.7L Hydraulic fan motor steering output

lowPressure / Flow test fans steering

output flow

INSUFFICIENT ASST. OR POOR RETURN TO CENTER

CONDITION POSSIBLE CAUSE CORRECTION

HARD TURNING OR MOMENTARY

INCREASE IN TURNING EFFORT1. Tire pressure. 1. Adjust tire pressure.

2. Low fluid level. 2. Fill to proper level.

3. Loose belt. 3. Adjust or replace.

4. Lack of lubrication. 4. Inspect and lubricate steering and

suspension compnents.

5. Low pump pressure or flow. 5. Pressure and flow test and repair

as necessary.

6. Internal gear leak. 6. Pressure and flow test, and repair

as necessary.

7. Belt routing. 7. Verify belt routing is correct.

4.7L8. Low flow / pressure from fan

motor8. Pressure and flow test and repair

as necessary.

STEERING WHEEL

DOES NOT WANT TO RETURN TO

CENTER POSITION1. Tire pressure. 1. Adjust tire pressure.

2. Wheel alignment. 2. Align front end.

3. Lack of lubrication. 3. Inspect and lubricate steering and

suspension compnents.

4. High friction in steering gear. 4. Test and adjust as necessary.

5. Ball joints binding. 5. Inspect and repair as necessary.

NOTE:

Some roads will cause a vehicle to drift, due to the crown in the road.

WJSTEERING 19 - 3

STEERING (Continued)