manual transmission JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1667 of 2199

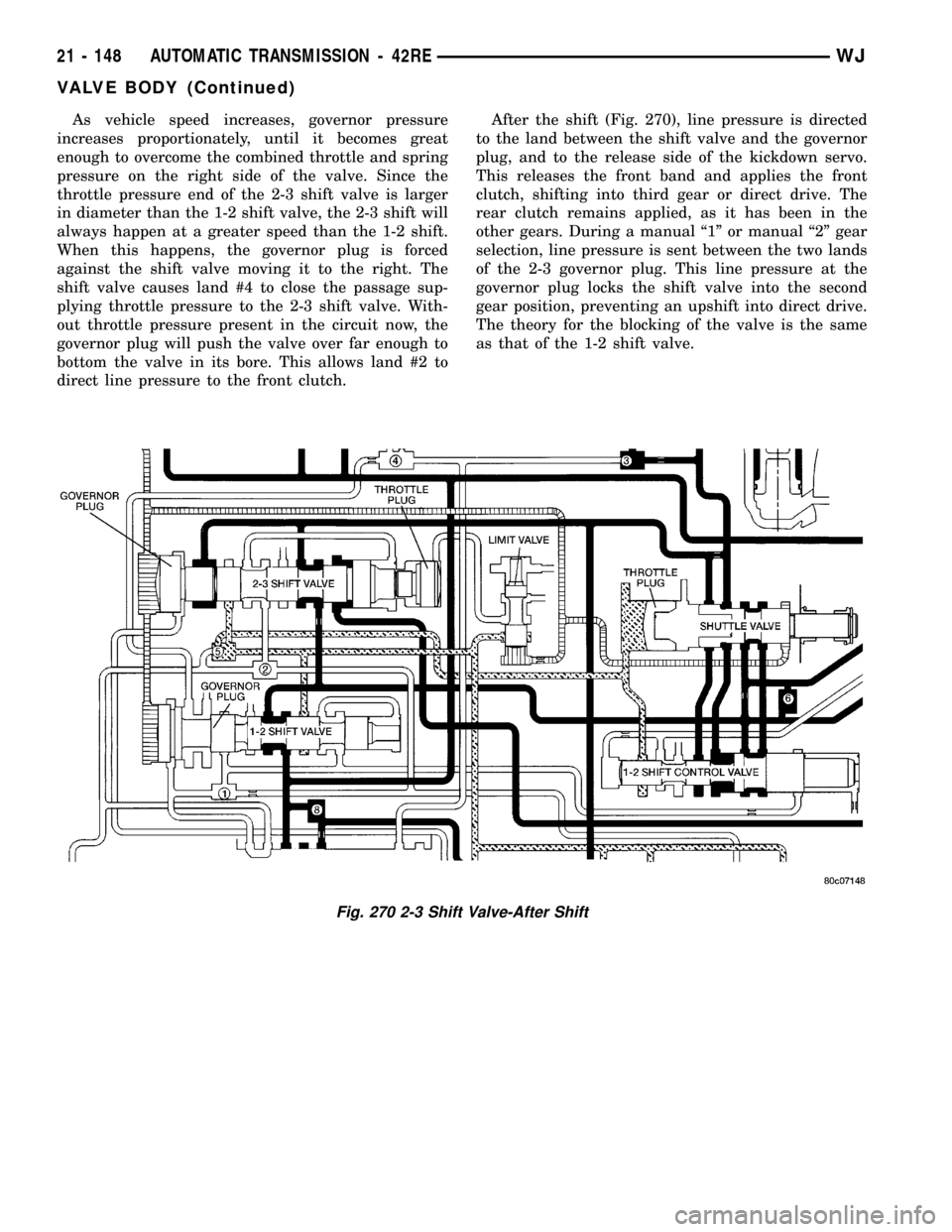

As vehicle speed increases, governor pressure

increases proportionately, until it becomes great

enough to overcome the combined throttle and spring

pressure on the right side of the valve. Since the

throttle pressure end of the 2-3 shift valve is larger

in diameter than the 1-2 shift valve, the 2-3 shift will

always happen at a greater speed than the 1-2 shift.

When this happens, the governor plug is forced

against the shift valve moving it to the right. The

shift valve causes land #4 to close the passage sup-

plying throttle pressure to the 2-3 shift valve. With-

out throttle pressure present in the circuit now, the

governor plug will push the valve over far enough to

bottom the valve in its bore. This allows land #2 to

direct line pressure to the front clutch.After the shift (Fig. 270), line pressure is directed

to the land between the shift valve and the governor

plug, and to the release side of the kickdown servo.

This releases the front band and applies the front

clutch, shifting into third gear or direct drive. The

rear clutch remains applied, as it has been in the

other gears. During a manual ª1º or manual ª2º gear

selection, line pressure is sent between the two lands

of the 2-3 governor plug. This line pressure at the

governor plug locks the shift valve into the second

gear position, preventing an upshift into direct drive.

The theory for the blocking of the valve is the same

as that of the 1-2 shift valve.

Fig. 270 2-3 Shift Valve-After Shift

21 - 148 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1672 of 2199

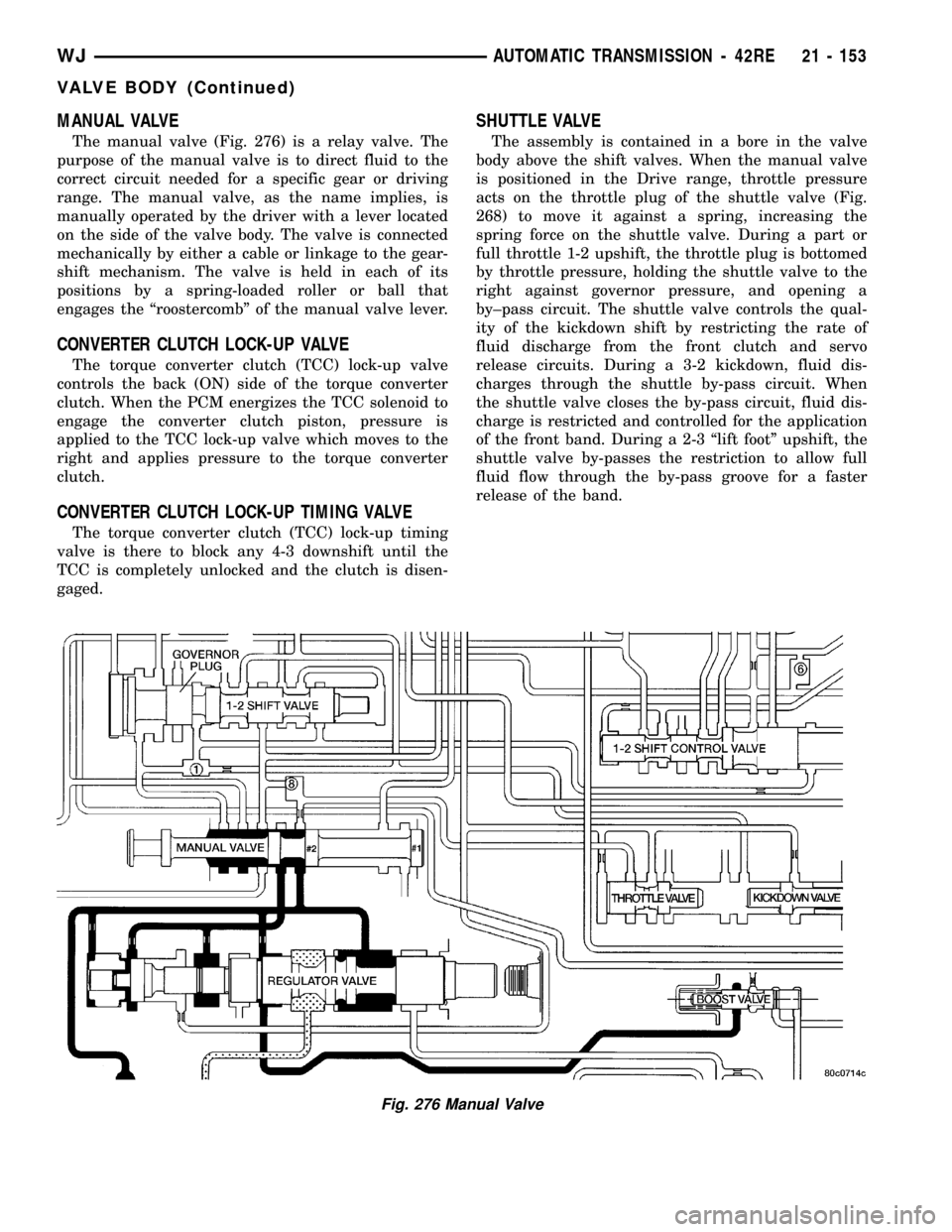

MANUAL VALVE

The manual valve (Fig. 276) is a relay valve. The

purpose of the manual valve is to direct fluid to the

correct circuit needed for a specific gear or driving

range. The manual valve, as the name implies, is

manually operated by the driver with a lever located

on the side of the valve body. The valve is connected

mechanically by either a cable or linkage to the gear-

shift mechanism. The valve is held in each of its

positions by a spring-loaded roller or ball that

engages the ªroostercombº of the manual valve lever.

CONVERTER CLUTCH LOCK-UP VALVE

The torque converter clutch (TCC) lock-up valve

controls the back (ON) side of the torque converter

clutch. When the PCM energizes the TCC solenoid to

engage the converter clutch piston, pressure is

applied to the TCC lock-up valve which moves to the

right and applies pressure to the torque converter

clutch.

CONVERTER CLUTCH LOCK-UP TIMING VALVE

The torque converter clutch (TCC) lock-up timing

valve is there to block any 4-3 downshift until the

TCC is completely unlocked and the clutch is disen-

gaged.

SHUTTLE VALVE

The assembly is contained in a bore in the valve

body above the shift valves. When the manual valve

is positioned in the Drive range, throttle pressure

acts on the throttle plug of the shuttle valve (Fig.

268) to move it against a spring, increasing the

spring force on the shuttle valve. During a part or

full throttle 1-2 upshift, the throttle plug is bottomed

by throttle pressure, holding the shuttle valve to the

right against governor pressure, and opening a

by±pass circuit. The shuttle valve controls the qual-

ity of the kickdown shift by restricting the rate of

fluid discharge from the front clutch and servo

release circuits. During a 3-2 kickdown, fluid dis-

charges through the shuttle by-pass circuit. When

the shuttle valve closes the by-pass circuit, fluid dis-

charge is restricted and controlled for the application

of the front band. During a 2-3 ªlift footº upshift, the

shuttle valve by-passes the restriction to allow full

fluid flow through the by-pass groove for a faster

release of the band.

Fig. 276 Manual Valve

WJAUTOMATIC TRANSMISSION - 42RE 21 - 153

VALVE BODY (Continued)

Page 1673 of 2199

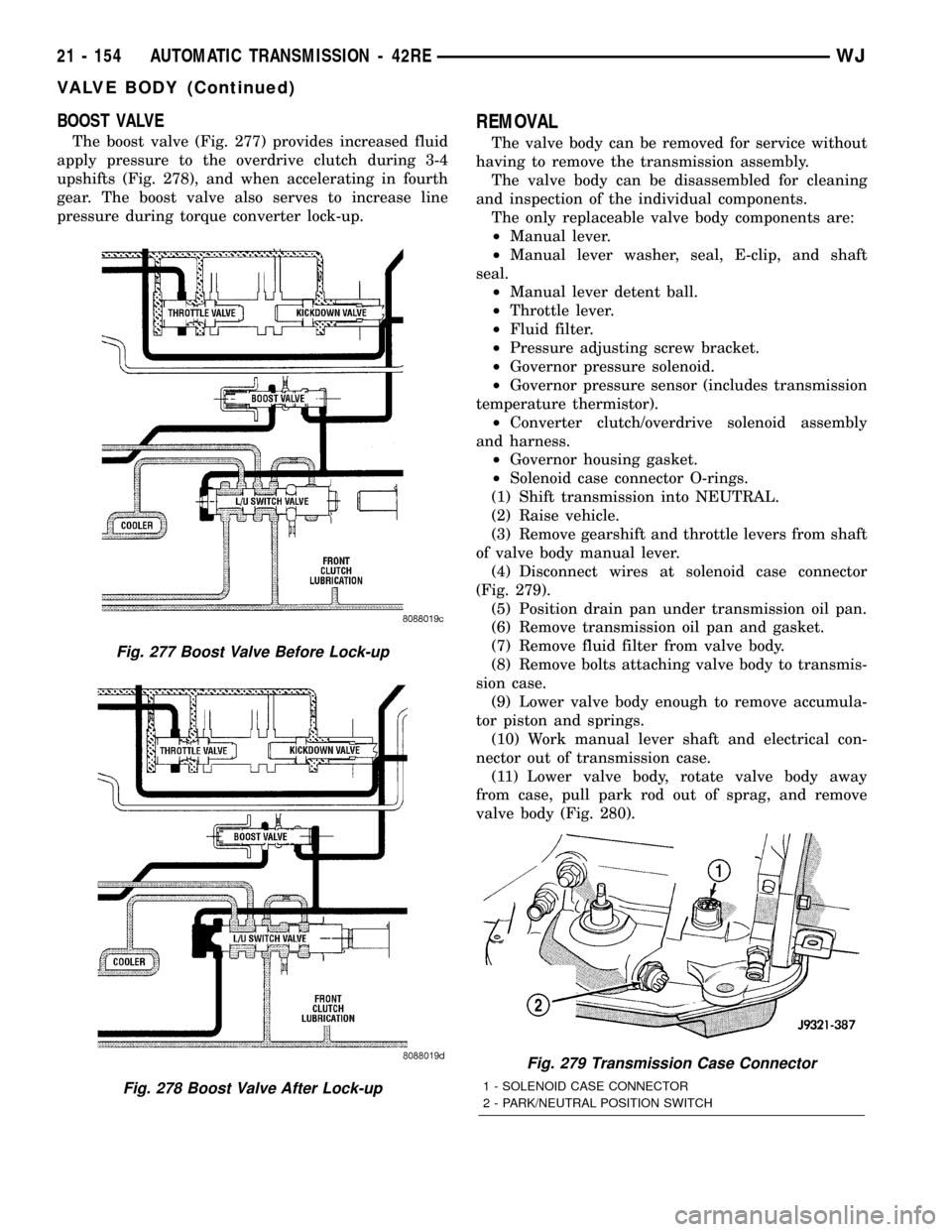

BOOST VALVE

The boost valve (Fig. 277) provides increased fluid

apply pressure to the overdrive clutch during 3-4

upshifts (Fig. 278), and when accelerating in fourth

gear. The boost valve also serves to increase line

pressure during torque converter lock-up.

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components.

The only replaceable valve body components are:

²Manual lever.

²Manual lever washer, seal, E-clip, and shaft

seal.

²Manual lever detent ball.

²Throttle lever.

²Fluid filter.

²Pressure adjusting screw bracket.

²Governor pressure solenoid.

²Governor pressure sensor (includes transmission

temperature thermistor).

²Converter clutch/overdrive solenoid assembly

and harness.

²Governor housing gasket.

²Solenoid case connector O-rings.

(1) Shift transmission into NEUTRAL.

(2) Raise vehicle.

(3) Remove gearshift and throttle levers from shaft

of valve body manual lever.

(4) Disconnect wires at solenoid case connector

(Fig. 279).

(5) Position drain pan under transmission oil pan.

(6) Remove transmission oil pan and gasket.

(7) Remove fluid filter from valve body.

(8) Remove bolts attaching valve body to transmis-

sion case.

(9) Lower valve body enough to remove accumula-

tor piston and springs.

(10) Work manual lever shaft and electrical con-

nector out of transmission case.

(11) Lower valve body, rotate valve body away

from case, pull park rod out of sprag, and remove

valve body (Fig. 280).

Fig. 277 Boost Valve Before Lock-up

Fig. 278 Boost Valve After Lock-up

Fig. 279 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - PARK/NEUTRAL POSITION SWITCH

21 - 154 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1675 of 2199

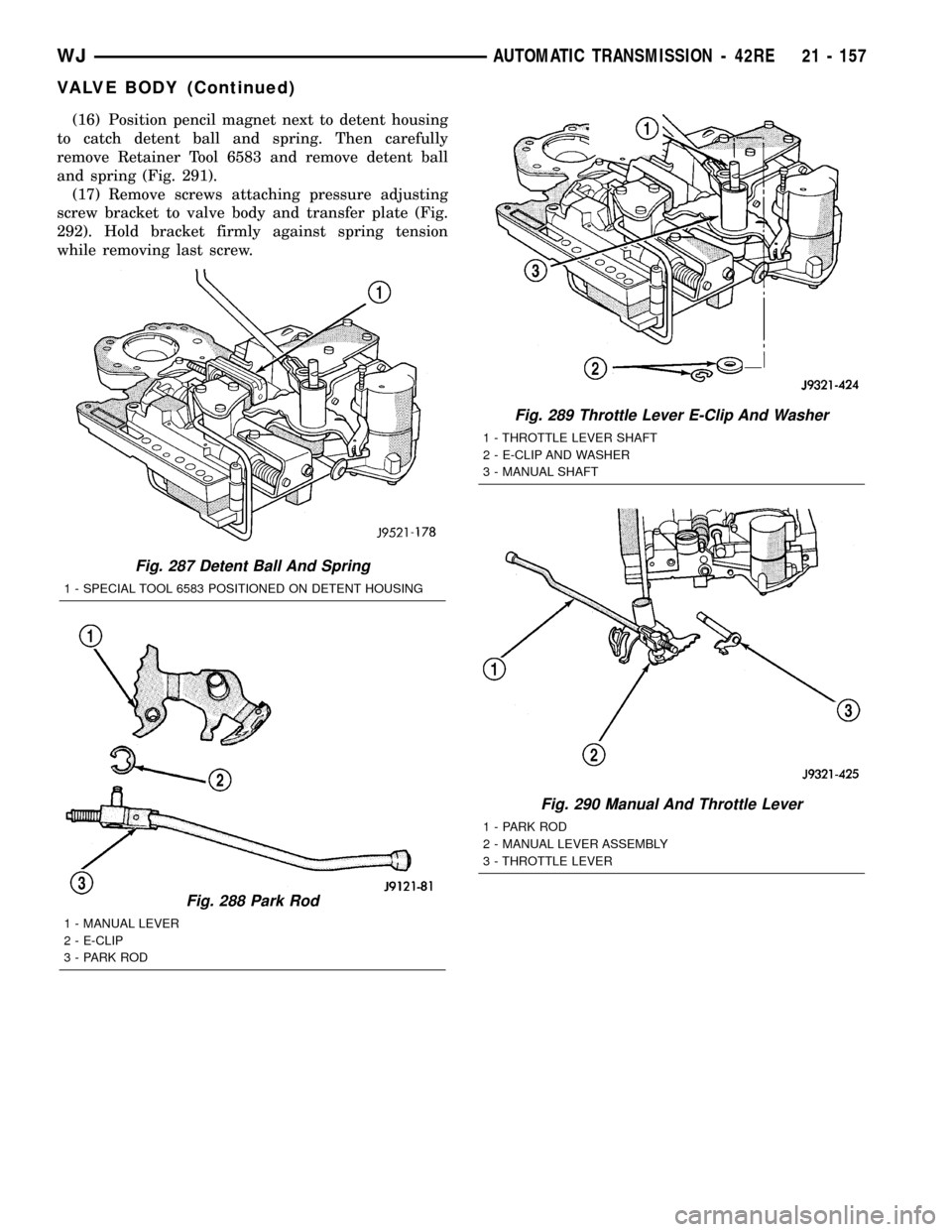

(12) Secure detent ball and spring with Retainer

Tool 6583 (Fig. 287).

(13) Remove park rod E-clip and separate rod from

manual lever (Fig. 288).

(14) Remove E-clip and washer that retains throt-

tle lever shaft in manual lever (Fig. 289).

(15) Remove manual lever and throttle lever (Fig.

290). Rotate and lift manual lever off valve body and

throttle lever shaft. Then slide throttle lever out of

valve body.

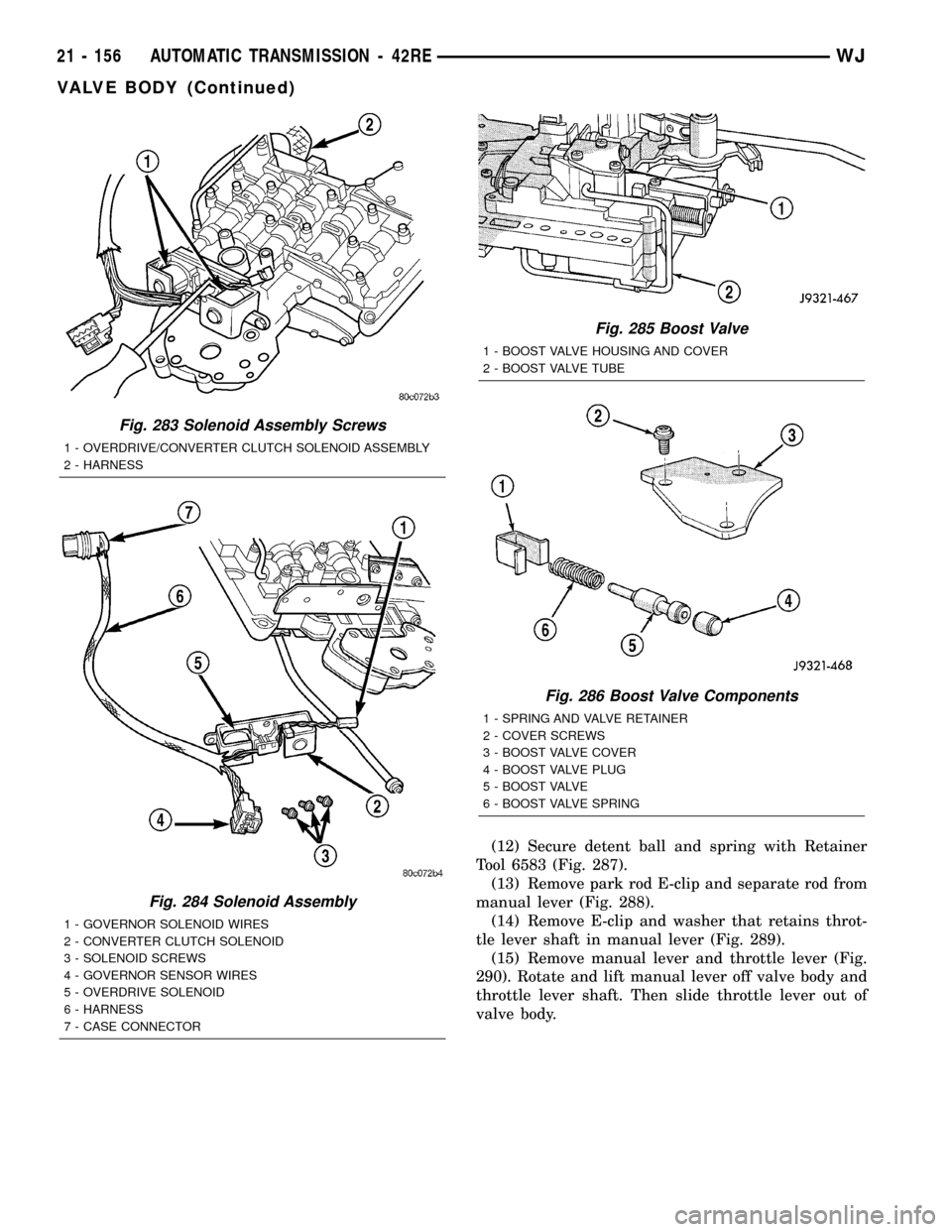

Fig. 283 Solenoid Assembly Screws

1 - OVERDRIVE/CONVERTER CLUTCH SOLENOID ASSEMBLY

2 - HARNESS

Fig. 284 Solenoid Assembly

1 - GOVERNOR SOLENOID WIRES

2 - CONVERTER CLUTCH SOLENOID

3 - SOLENOID SCREWS

4 - GOVERNOR SENSOR WIRES

5 - OVERDRIVE SOLENOID

6 - HARNESS

7 - CASE CONNECTOR

Fig. 285 Boost Valve

1 - BOOST VALVE HOUSING AND COVER

2 - BOOST VALVE TUBE

Fig. 286 Boost Valve Components

1 - SPRING AND VALVE RETAINER

2 - COVER SCREWS

3 - BOOST VALVE COVER

4 - BOOST VALVE PLUG

5 - BOOST VALVE

6 - BOOST VALVE SPRING

21 - 156 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1676 of 2199

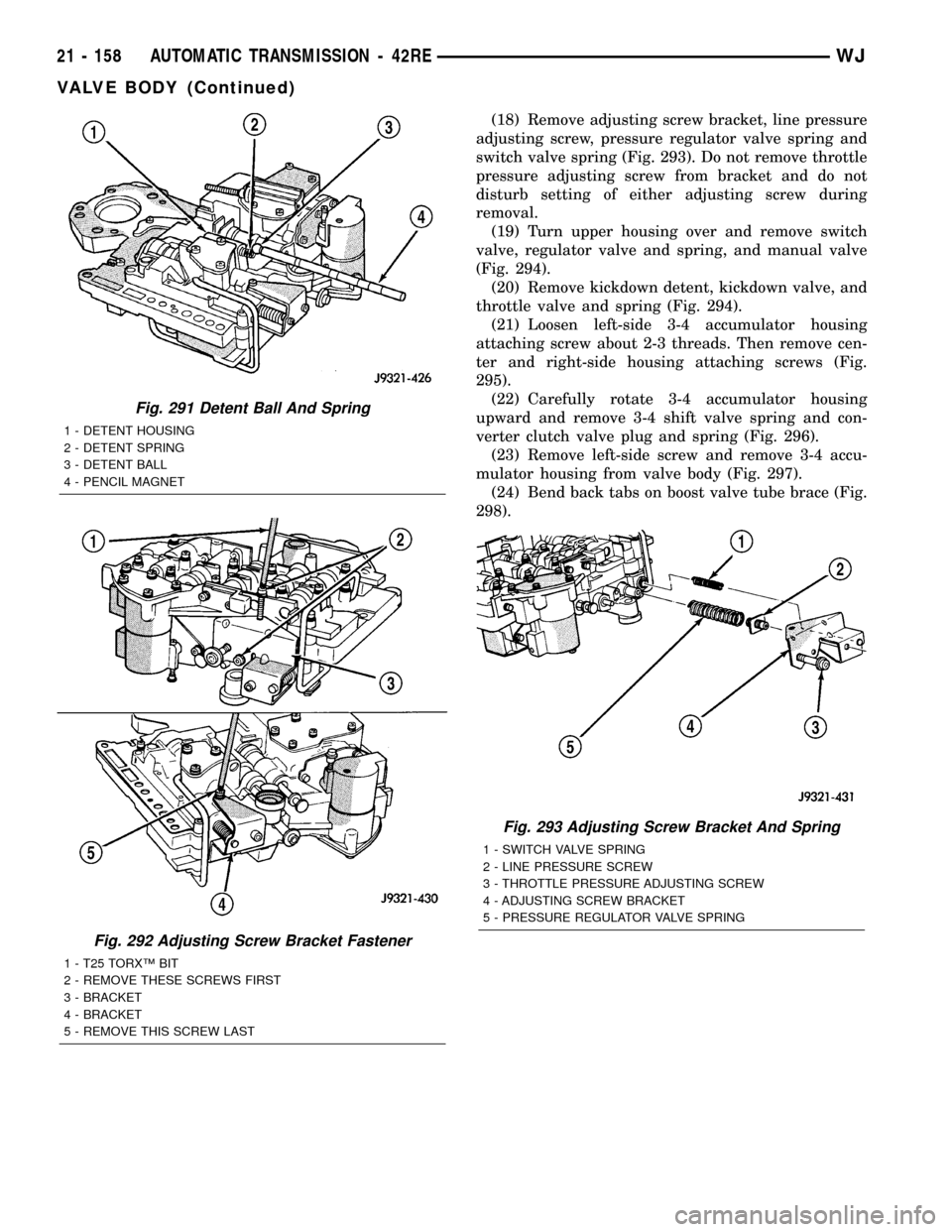

(16) Position pencil magnet next to detent housing

to catch detent ball and spring. Then carefully

remove Retainer Tool 6583 and remove detent ball

and spring (Fig. 291).

(17) Remove screws attaching pressure adjusting

screw bracket to valve body and transfer plate (Fig.

292). Hold bracket firmly against spring tension

while removing last screw.

Fig. 287 Detent Ball And Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 288 Park Rod

1 - MANUAL LEVER

2 - E-CLIP

3 - PARK ROD

Fig. 289 Throttle Lever E-Clip And Washer

1 - THROTTLE LEVER SHAFT

2 - E-CLIP AND WASHER

3 - MANUAL SHAFT

Fig. 290 Manual And Throttle Lever

1 - PARK ROD

2 - MANUAL LEVER ASSEMBLY

3 - THROTTLE LEVER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 157

VALVE BODY (Continued)

Page 1677 of 2199

(18) Remove adjusting screw bracket, line pressure

adjusting screw, pressure regulator valve spring and

switch valve spring (Fig. 293). Do not remove throttle

pressure adjusting screw from bracket and do not

disturb setting of either adjusting screw during

removal.

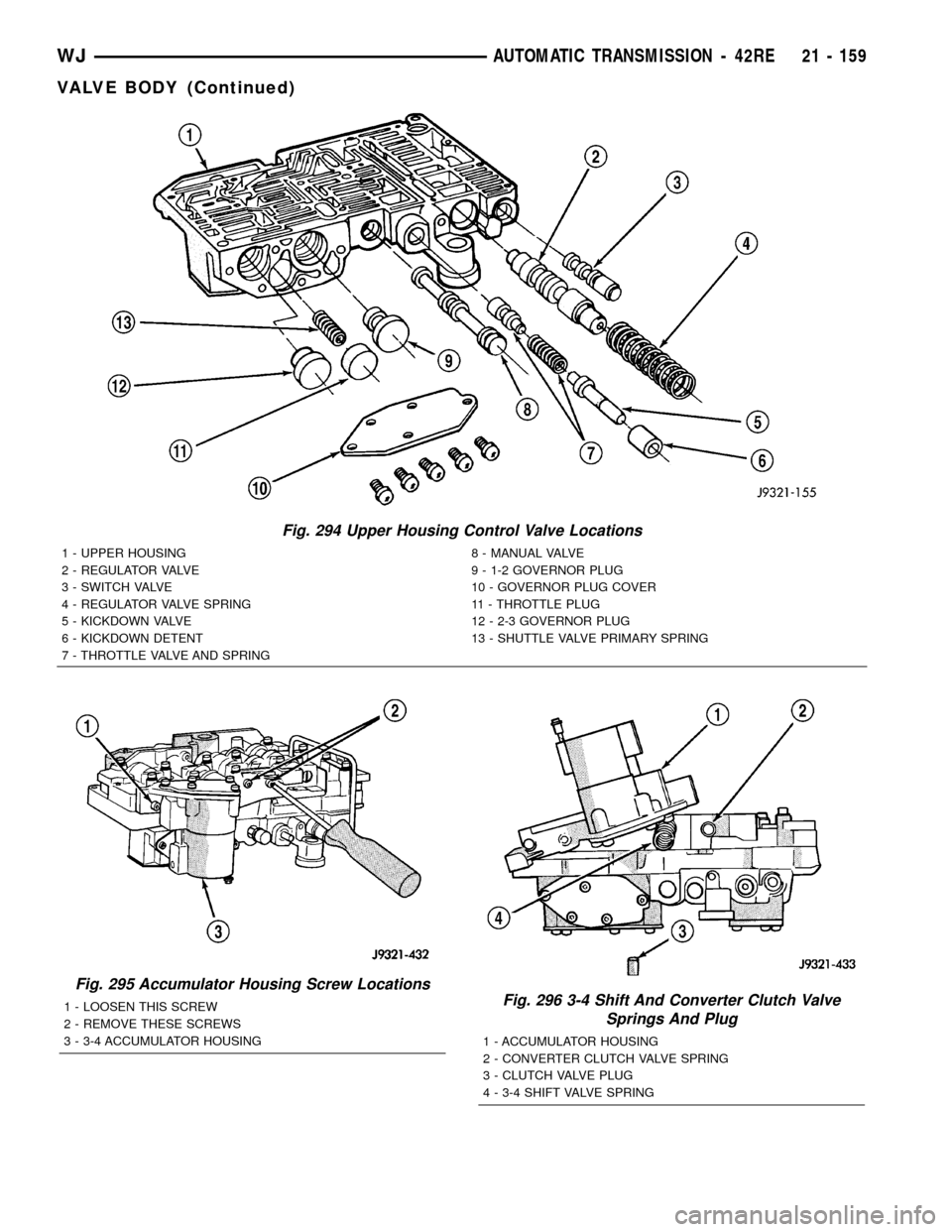

(19) Turn upper housing over and remove switch

valve, regulator valve and spring, and manual valve

(Fig. 294).

(20) Remove kickdown detent, kickdown valve, and

throttle valve and spring (Fig. 294).

(21) Loosen left-side 3-4 accumulator housing

attaching screw about 2-3 threads. Then remove cen-

ter and right-side housing attaching screws (Fig.

295).

(22) Carefully rotate 3-4 accumulator housing

upward and remove 3-4 shift valve spring and con-

verter clutch valve plug and spring (Fig. 296).

(23) Remove left-side screw and remove 3-4 accu-

mulator housing from valve body (Fig. 297).

(24) Bend back tabs on boost valve tube brace (Fig.

298).

Fig. 291 Detent Ball And Spring

1 - DETENT HOUSING

2 - DETENT SPRING

3 - DETENT BALL

4 - PENCIL MAGNET

Fig. 292 Adjusting Screw Bracket Fastener

1 - T25 TORXŸ BIT

2 - REMOVE THESE SCREWS FIRST

3 - BRACKET

4 - BRACKET

5 - REMOVE THIS SCREW LAST

Fig. 293 Adjusting Screw Bracket And Spring

1 - SWITCH VALVE SPRING

2 - LINE PRESSURE SCREW

3 - THROTTLE PRESSURE ADJUSTING SCREW

4 - ADJUSTING SCREW BRACKET

5 - PRESSURE REGULATOR VALVE SPRING

21 - 158 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1678 of 2199

Fig. 294 Upper Housing Control Valve Locations

1 - UPPER HOUSING 8 - MANUAL VALVE

2 - REGULATOR VALVE 9 - 1-2 GOVERNOR PLUG

3 - SWITCH VALVE 10 - GOVERNOR PLUG COVER

4 - REGULATOR VALVE SPRING 11 - THROTTLE PLUG

5 - KICKDOWN VALVE 12 - 2-3 GOVERNOR PLUG

6 - KICKDOWN DETENT 13 - SHUTTLE VALVE PRIMARY SPRING

7 - THROTTLE VALVE AND SPRING

Fig. 295 Accumulator Housing Screw Locations

1 - LOOSEN THIS SCREW

2 - REMOVE THESE SCREWS

3 - 3-4 ACCUMULATOR HOUSINGFig. 296 3-4 Shift And Converter Clutch Valve

Springs And Plug

1 - ACCUMULATOR HOUSING

2 - CONVERTER CLUTCH VALVE SPRING

3 - CLUTCH VALVE PLUG

4 - 3-4 SHIFT VALVE SPRING

WJAUTOMATIC TRANSMISSION - 42RE 21 - 159

VALVE BODY (Continued)

Page 1685 of 2199

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if either

part has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, the

filter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

Valve body bores do not change dimensionally with

use. If the valve body functioned correctly when new,

it will continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

The only serviceable valve body components are

listed below. The remaining valve body components

are serviced only as part of a complete valve body

assembly. Serviceable parts are:

²dual solenoid and harness assembly

²solenoid gasket

²solenoid case connector O-rings and shoulder

bolt

²switch valve and spring

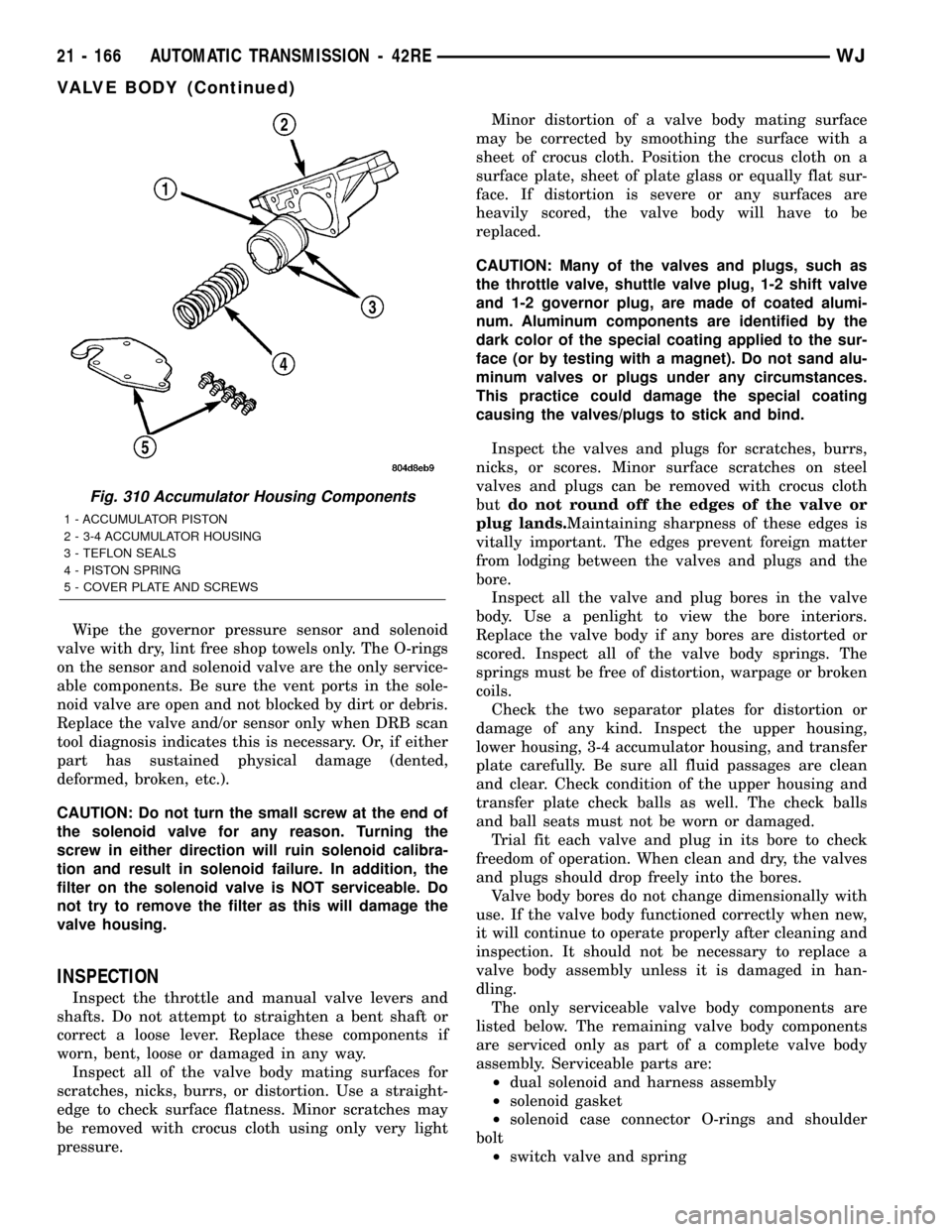

Fig. 310 Accumulator Housing Components

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 166 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1686 of 2199

²pressure adjusting screw and bracket assembly

²throttle lever

²manual lever and shaft seal

²throttle lever shaft seal, washer, and E-clip

²fluid filter and screws

²detent ball and spring

²valve body screws

²governor pressure solenoid

²governor pressure sensor and retaining clip

²park lock rod and E-clip

ASSEMBLY

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the housings resulting in

valve sticking, cross leakage and unsatisfactory

operation. Tighten valve body screws to recom-

mended torque only.

LOWER HOUSING

(1) Lubricate valves, springs, and the housing

valve and plug bores with clean transmission fluid

(Fig. 309).

(2) Install 3-4 timing valve spring and valve in

lower housing.

(3) Install 3-4 quick fill valve in lower housing.

(4) Install 3-4 quick fill valve spring and plug in

housing.

(5) Install timing valve end plate. Tighten end

plate screws to 4 N´m (35 in. lbs.) torque.

3-4 ACCUMULATOR

(1) Lubricate accumulator piston, seals and hous-

ing piston bore with clean transmission fluid (Fig.

310).

(2) Install new seal rings on accumulator piston.

(3) Install piston and spring in housing.

(4) Install end plate on housing.

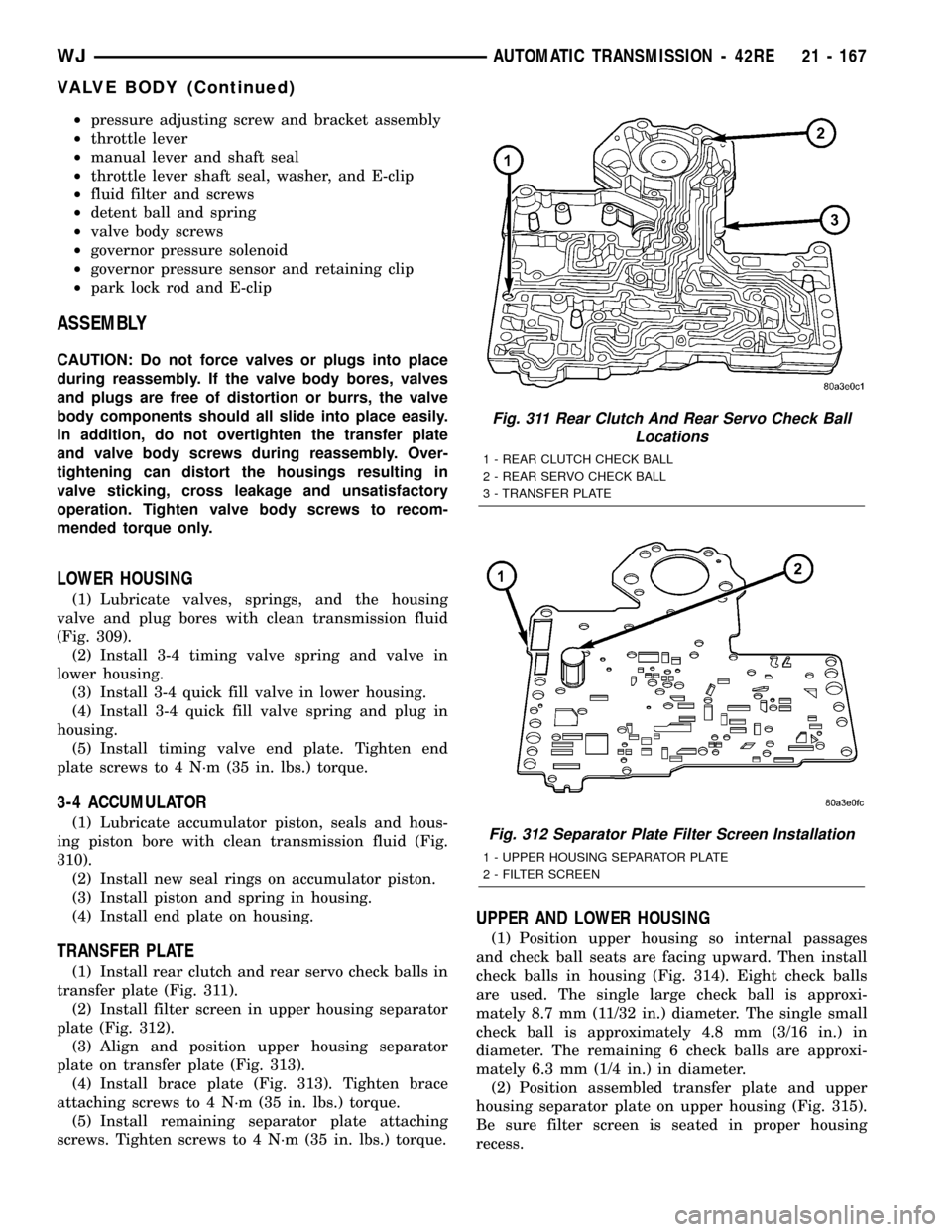

TRANSFER PLATE

(1) Install rear clutch and rear servo check balls in

transfer plate (Fig. 311).

(2) Install filter screen in upper housing separator

plate (Fig. 312).

(3) Align and position upper housing separator

plate on transfer plate (Fig. 313).

(4) Install brace plate (Fig. 313). Tighten brace

attaching screws to 4 N´m (35 in. lbs.) torque.

(5) Install remaining separator plate attaching

screws. Tighten screws to 4 N´m (35 in. lbs.) torque.

UPPER AND LOWER HOUSING

(1) Position upper housing so internal passages

and check ball seats are facing upward. Then install

check balls in housing (Fig. 314). Eight check balls

are used. The single large check ball is approxi-

mately 8.7 mm (11/32 in.) diameter. The single small

check ball is approximately 4.8 mm (3/16 in.) in

diameter. The remaining 6 check balls are approxi-

mately 6.3 mm (1/4 in.) in diameter.

(2) Position assembled transfer plate and upper

housing separator plate on upper housing (Fig. 315).

Be sure filter screen is seated in proper housing

recess.

Fig. 311 Rear Clutch And Rear Servo Check Ball

Locations

1 - REAR CLUTCH CHECK BALL

2 - REAR SERVO CHECK BALL

3 - TRANSFER PLATE

Fig. 312 Separator Plate Filter Screen Installation

1 - UPPER HOUSING SEPARATOR PLATE

2 - FILTER SCREEN

WJAUTOMATIC TRANSMISSION - 42RE 21 - 167

VALVE BODY (Continued)

Page 1689 of 2199

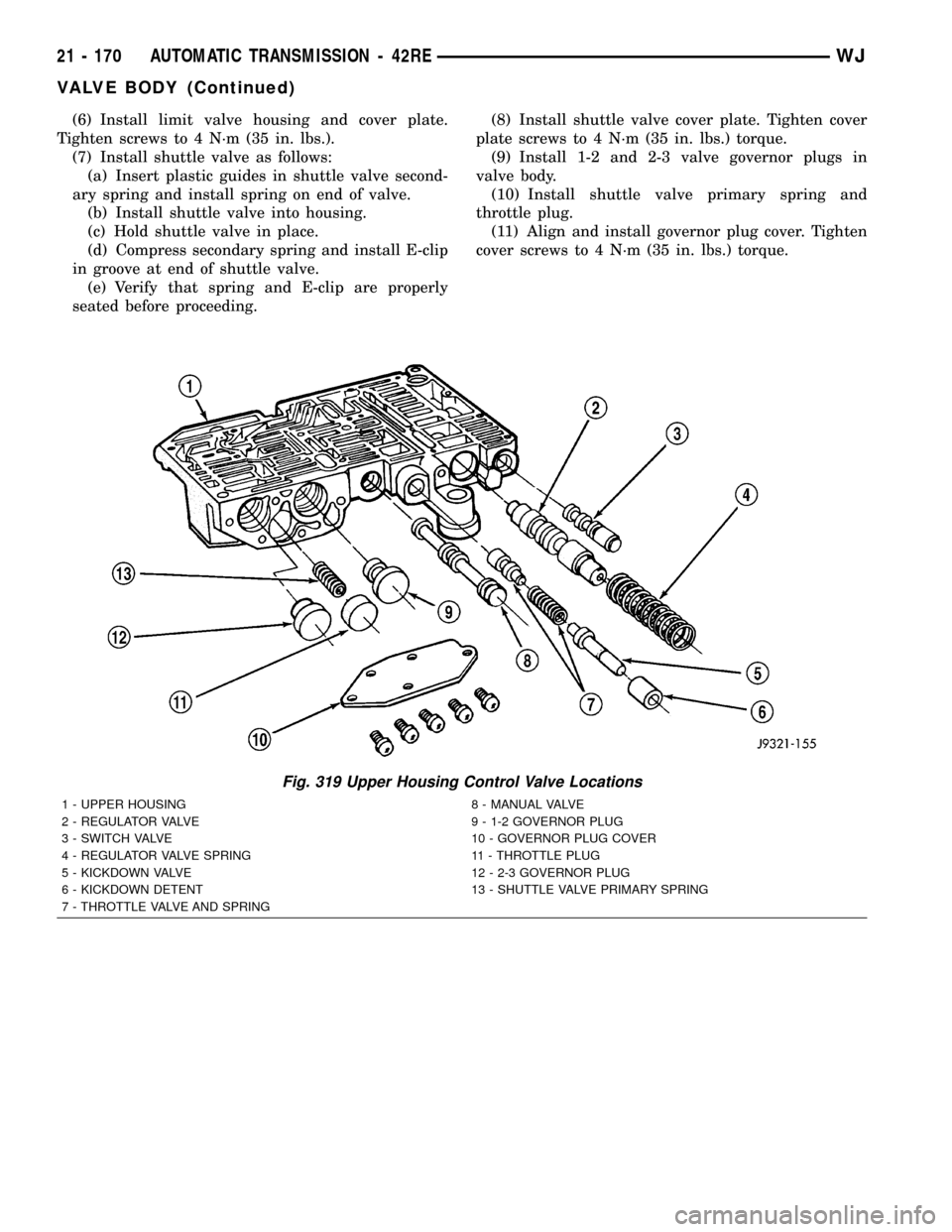

(6) Install limit valve housing and cover plate.

Tighten screws to 4 N´m (35 in. lbs.).

(7) Install shuttle valve as follows:

(a) Insert plastic guides in shuttle valve second-

ary spring and install spring on end of valve.

(b) Install shuttle valve into housing.

(c) Hold shuttle valve in place.

(d) Compress secondary spring and install E-clip

in groove at end of shuttle valve.

(e) Verify that spring and E-clip are properly

seated before proceeding.(8) Install shuttle valve cover plate. Tighten cover

plate screws to 4 N´m (35 in. lbs.) torque.

(9) Install 1-2 and 2-3 valve governor plugs in

valve body.

(10) Install shuttle valve primary spring and

throttle plug.

(11) Align and install governor plug cover. Tighten

cover screws to 4 N´m (35 in. lbs.) torque.

Fig. 319 Upper Housing Control Valve Locations

1 - UPPER HOUSING 8 - MANUAL VALVE

2 - REGULATOR VALVE 9 - 1-2 GOVERNOR PLUG

3 - SWITCH VALVE 10 - GOVERNOR PLUG COVER

4 - REGULATOR VALVE SPRING 11 - THROTTLE PLUG

5 - KICKDOWN VALVE 12 - 2-3 GOVERNOR PLUG

6 - KICKDOWN DETENT 13 - SHUTTLE VALVE PRIMARY SPRING

7 - THROTTLE VALVE AND SPRING

21 - 170 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)