Round plug JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1924 of 2199

INSTRUMENT PANEL

STUCTURAL DUCT

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO MIN-

UTES FOR THE AIRBAG SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1)Disconnect and isolate the battery negative cable.

(2) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

REMOVAL).

(3) Place the instrument panel on a suitable work

surface. Be certain to take the proper precautions to

protect the instrument panel from any possible cos-

metic damage.

(4)

Remove all of the individual components that

remain secured to the instrument panel structural duct

as described elsewhere in this service information.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Reinstall all of the individual components that

were removed from the instrument panel structural

duct as described elsewhere in this service informa-

tion.

(2) Reinstall the instrument panel into the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

INSTALLATION).

(3) Reconnect the battery negative cable.

INSTRUMENT PANEL TOP

COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

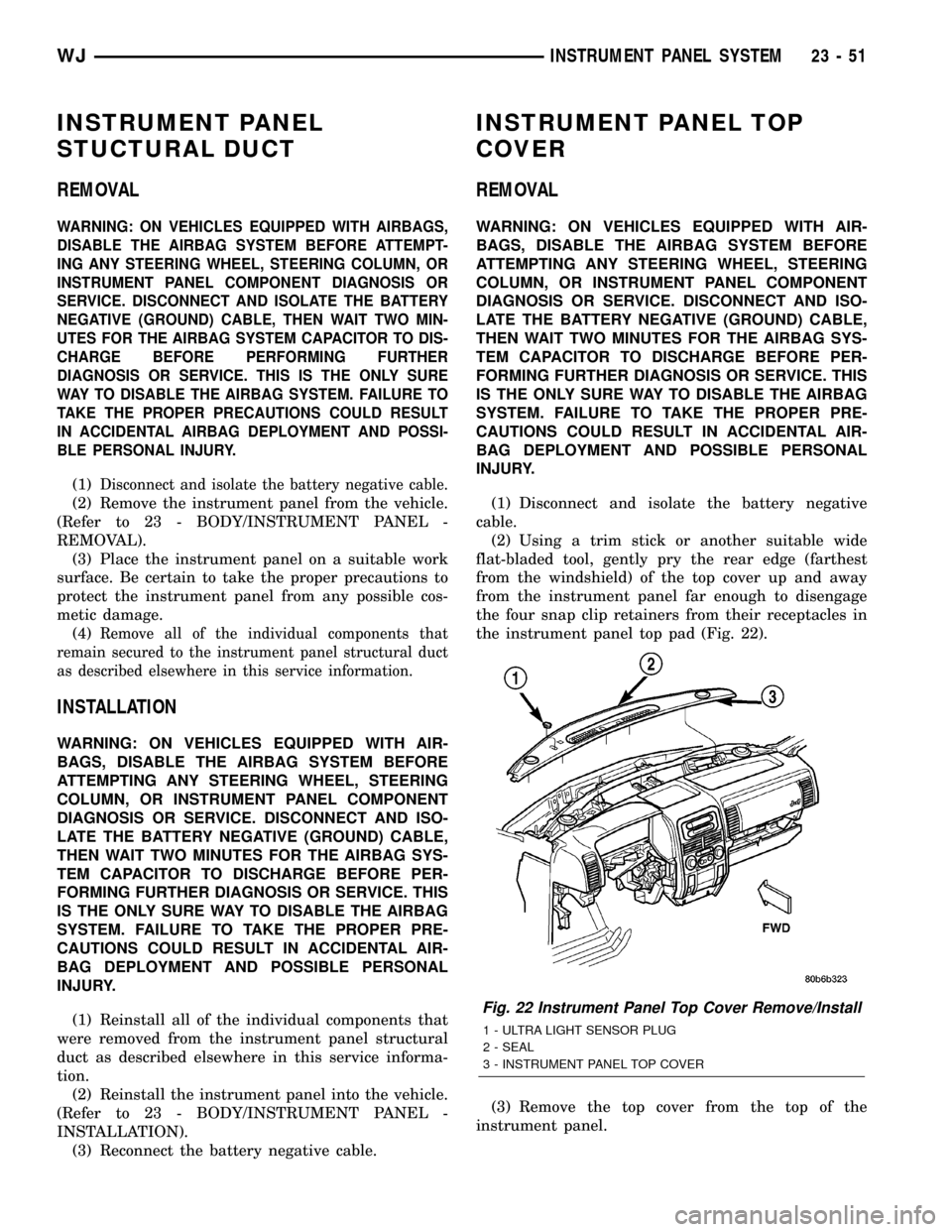

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the rear edge (farthest

from the windshield) of the top cover up and away

from the instrument panel far enough to disengage

the four snap clip retainers from their receptacles in

the instrument panel top pad (Fig. 22).

(3) Remove the top cover from the top of the

instrument panel.

Fig. 22 Instrument Panel Top Cover Remove/Install

1 - ULTRA LIGHT SENSOR PLUG

2 - SEAL

3 - INSTRUMENT PANEL TOP COVER

WJINSTRUMENT PANEL SYSTEM 23 - 51

Page 1925 of 2199

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) If the vehicle is not equipped with the optional

automatic headlamps light sensor/vehicle theft secu-

rity system indicator, be certain that the hole plug is

installed in the clearance hole located to the out-

board side of the driver side defroster outlet in the

instrument panel top cover (Fig. 22).

(2) Before installing the top cover onto the top of

the instrument panel, be certain that the rubber top

cover seal is properly positioned on the forward edge

of the top cover panel.

(3) Position the top cover onto the top of the

instrument panel.

(4) Align the four snap clips on the top cover with

the snap clip receptacles in the instrument panel top

pad.

(5) Press firmly downward on the top cover over

each of the four snap clip locations until each of the

snap clips is fully seated in their receptacles in the

instrument panel top pad.

(6) Reconnect the battery negative cable.

INSTRUMENT PANEL TOP PAD

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the right and left A-pil-

lars. (Refer to 23 - BODY/INTERIOR/A-PILLAR

TRIM - REMOVAL).

(3) Remove the top cover from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - REMOVAL).

(4) Remove the four nuts that secure the instru-

ment panel top pad to the studs on the dash panel

near the windshield fence line (Fig. 23).

(5) Remove the speakers from the instrument

panel top pad. (Refer to 8 - ELECTRICAL/AUDIO/

SPEAKER - REMOVAL - INSTRUMENT PANEL

SPEAKER).

(6) Disengage the retainer that secures each of the

two instrument panel wire harness speaker take outs

to the mounting hole in the instrument panel top

pad. Tuck the loose ends of these speaker take outs

down the defroster ducts to keep them out of the way

during the remainder of this procedure.

(7) If the vehicle is so equipped, remove the two

screws that secure the automatic headlamp light sen-

sor/vehicle theft security system indicator unit to the

instrument panel top pad just outboard of the driver

side defroster outlet. Move the sensor/indicator unit

towards the windshield to keep it out of the way dur-

ing the remainder of this procedure.

(8) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(9) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(10) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(11) Roll the glove box down from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - STANDARD PROCEDURE - GLOVE

BOX ROLL DOWN).

(12) Remove the end cap from the passenger side

lower outboard end of the instrument panel. (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL END CAP - REMOVAL).

(13) Remove the lower right center bezel from the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- REMOVAL).

(14) Remove the glove box lamp and switch from

the instrument panel. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/GLOVE BOX

LAMP/SWITCH - REMOVAL).

23 - 52 INSTRUMENT PANEL SYSTEMWJ

INSTRUMENT PANEL TOP COVER (Continued)

Page 1980 of 2199

INSTALLATION

(1) Position the seal on the door flange.

(2) Firmly press downward to seat seal on the door

flange.

(3)

Install the door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

FDR OUTER BELT

WEATHERSTRIP

REMOVAL

(1) Lower the door glass.

(2) Remove the screw from the inner door panel

attaching the seal to outer door panel (Fig. 4).

(3) Pull the seal rearward to release from the side

view mirror bezel.

(4) Lift seal and separate from door panel.

INSTALLATION

(1) Position seal on the door panel.

(2) Push the seal forward to install under the side

view mirror bezel.

(3) Install the screw from the inner door panel

attaching the seal to outer door panel.

(4) Raise the door glass.

FLIP-UP GLASS

WEATHERSTRIP

REMOVAL

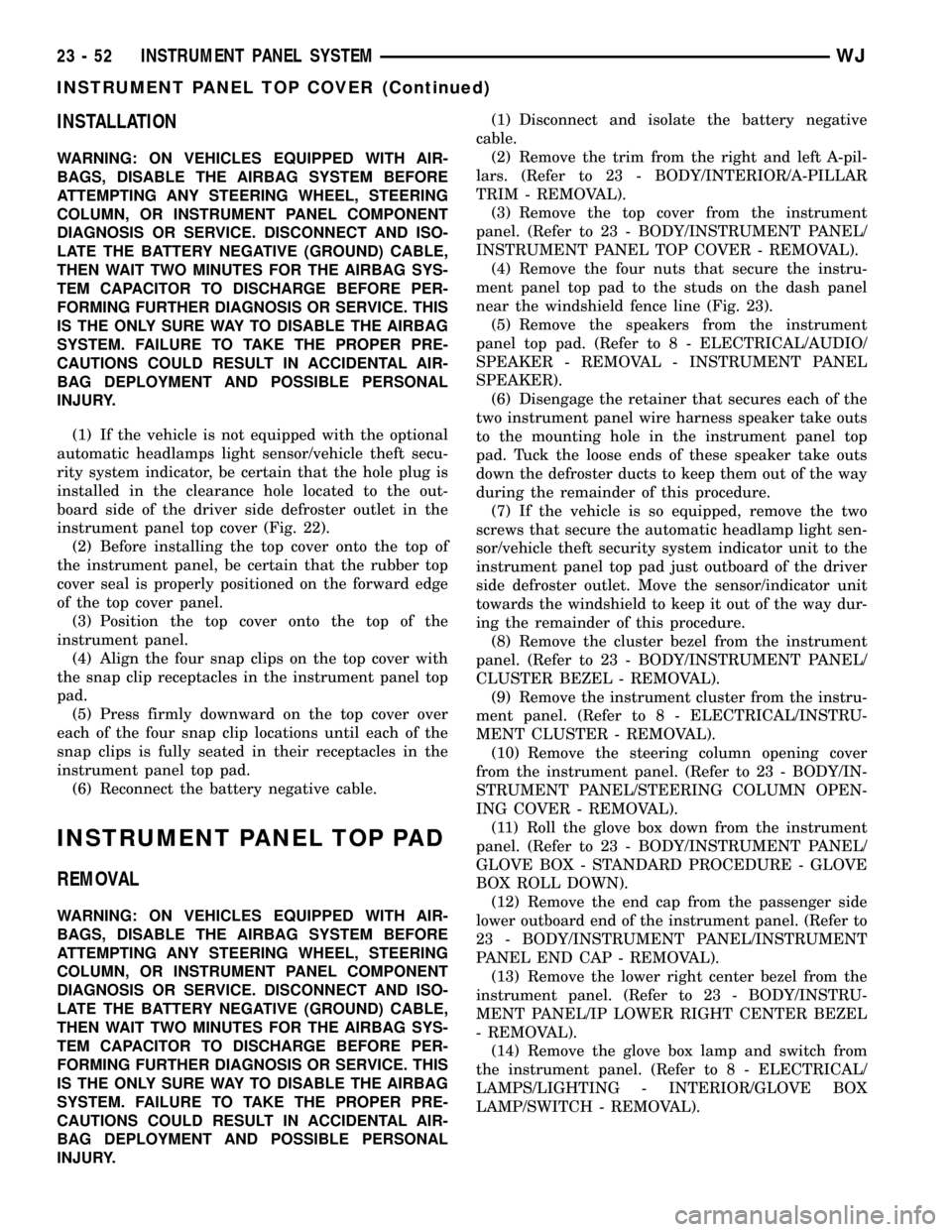

(1) Raise flip up glass.

(2) Carefully pull the seal away from the flange

around the edge of the glass opening (Fig. 5).

(3) Remove it from the vehicle.

INSTALLATION

(1) Thoroughly clean the surface of the flange as

necessary.

(2) Align the weather strip seal with the window

opening corners.

(3) Firmly seat the seal around the entire flange.

But the seal ends together and smooth out any

remaining length.

(4)

Weatherstrip break should be 120mm left of latch

opening. Cut any surplus from non-plug end only.

FRONT DOOR 2ND

WEATHERSTRIP

REMOVAL

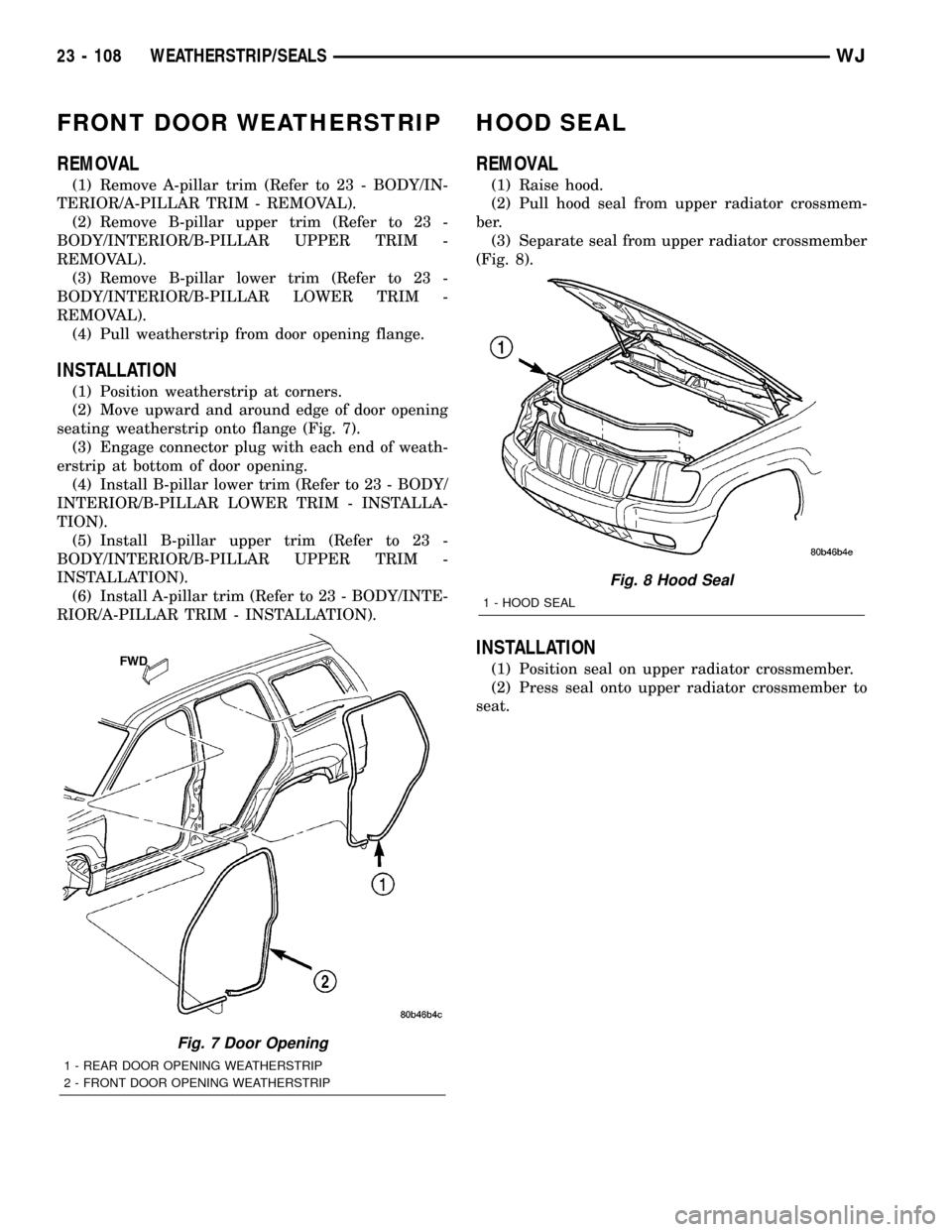

The front door secondary weatherstrip is attached

to the door shutface with push-in fasteners.(1) Open door.

(2) Using a trim panel removal tool, remove

push-in fasteners attaching secondary weatherstrip

to door shutface (Fig. 6).

(3) Separate secondary weatherstrip from door.

INSTALLATION

(1) Clean contact area as necessary.

(2) Position secondary weatherstrip on door shut-

face.

(3) Install push-in fasteners attaching secondary

weatherstrip to door shutface.

Fig. 5 Flip-up Glass Weatherstrip

1 - WEATHERSTRIP

2 - LIFTGATE W/FLIP-UP GLASS

Fig. 6 Front Door Secondary Weatherstrip

1 - SECONDARY WEATHERSTRIP

WJWEATHERSTRIP/SEALS 23 - 107

FRONT DOOR INNER BELT WEATHERSTRIP (Continued)

Page 1981 of 2199

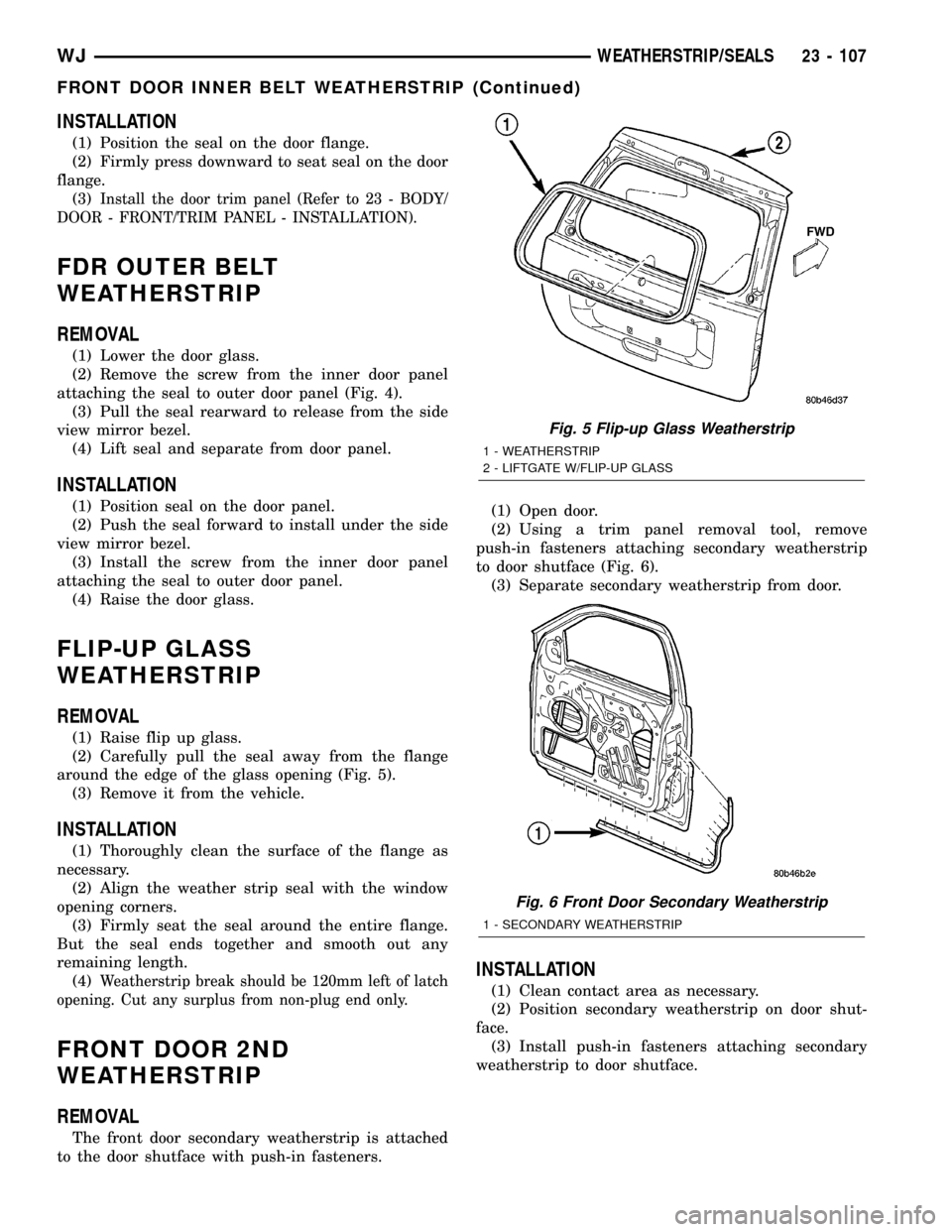

FRONT DOOR WEATHERSTRIP

REMOVAL

(1) Remove A-pillar trim (Refer to 23 - BODY/IN-

TERIOR/A-PILLAR TRIM - REMOVAL).

(2) Remove B-pillar upper trim (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL).

(3) Remove B-pillar lower trim (Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL).

(4) Pull weatherstrip from door opening flange.

INSTALLATION

(1) Position weatherstrip at corners.

(2) Move upward and around edge of door opening

seating weatherstrip onto flange (Fig. 7).

(3) Engage connector plug with each end of weath-

erstrip at bottom of door opening.

(4) Install B-pillar lower trim (Refer to 23 - BODY/

INTERIOR/B-PILLAR LOWER TRIM - INSTALLA-

TION).

(5) Install B-pillar upper trim (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

INSTALLATION).

(6) Install A-pillar trim (Refer to 23 - BODY/INTE-

RIOR/A-PILLAR TRIM - INSTALLATION).

HOOD SEAL

REMOVAL

(1) Raise hood.

(2) Pull hood seal from upper radiator crossmem-

ber.

(3) Separate seal from upper radiator crossmember

(Fig. 8).

INSTALLATION

(1) Position seal on upper radiator crossmember.

(2) Press seal onto upper radiator crossmember to

seat.

Fig. 7 Door Opening

1 - REAR DOOR OPENING WEATHERSTRIP

2 - FRONT DOOR OPENING WEATHERSTRIP

Fig. 8 Hood Seal

1 - HOOD SEAL

23 - 108 WEATHERSTRIP/SEALSWJ

Page 1982 of 2199

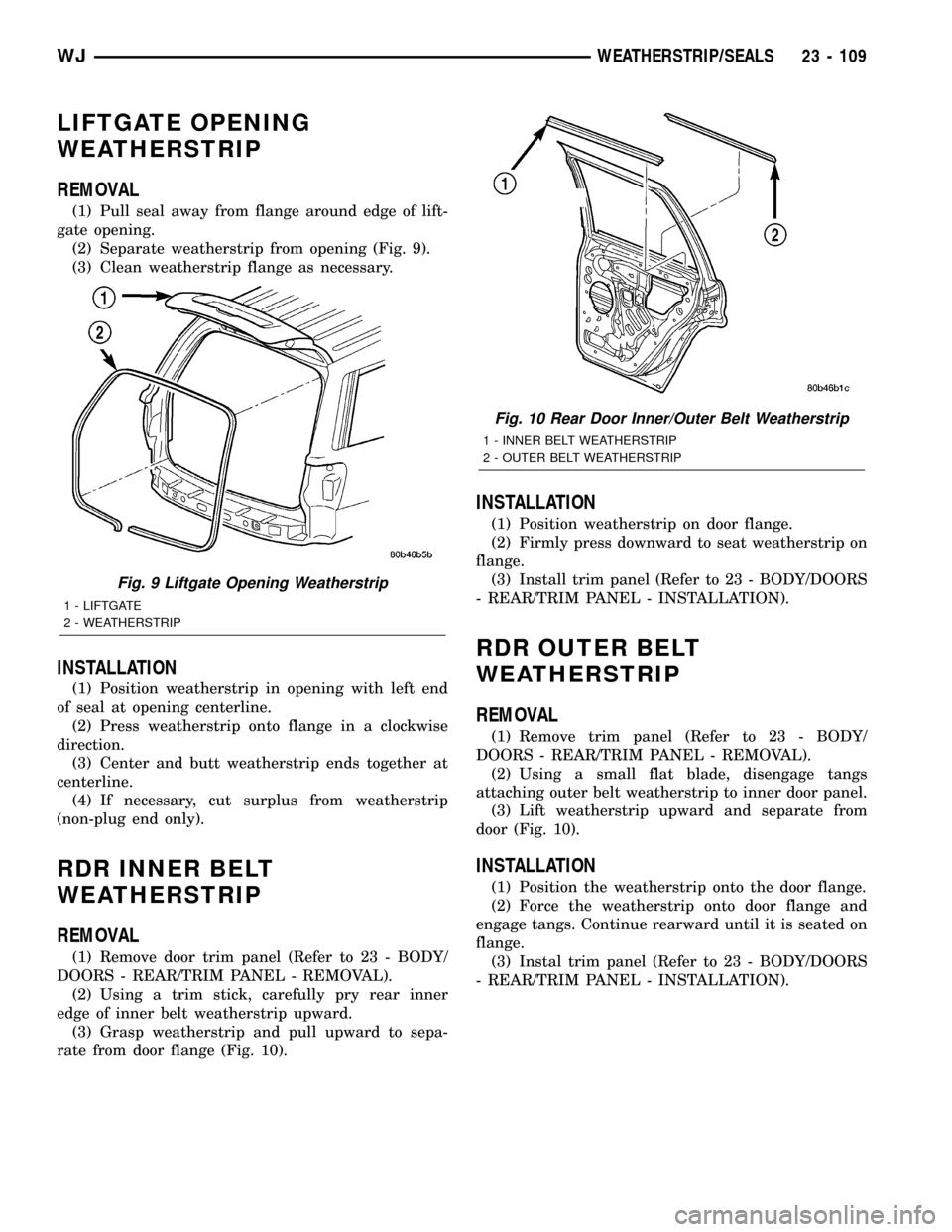

LIFTGATE OPENING

WEATHERSTRIP

REMOVAL

(1) Pull seal away from flange around edge of lift-

gate opening.

(2) Separate weatherstrip from opening (Fig. 9).

(3) Clean weatherstrip flange as necessary.

INSTALLATION

(1) Position weatherstrip in opening with left end

of seal at opening centerline.

(2) Press weatherstrip onto flange in a clockwise

direction.

(3) Center and butt weatherstrip ends together at

centerline.

(4) If necessary, cut surplus from weatherstrip

(non-plug end only).

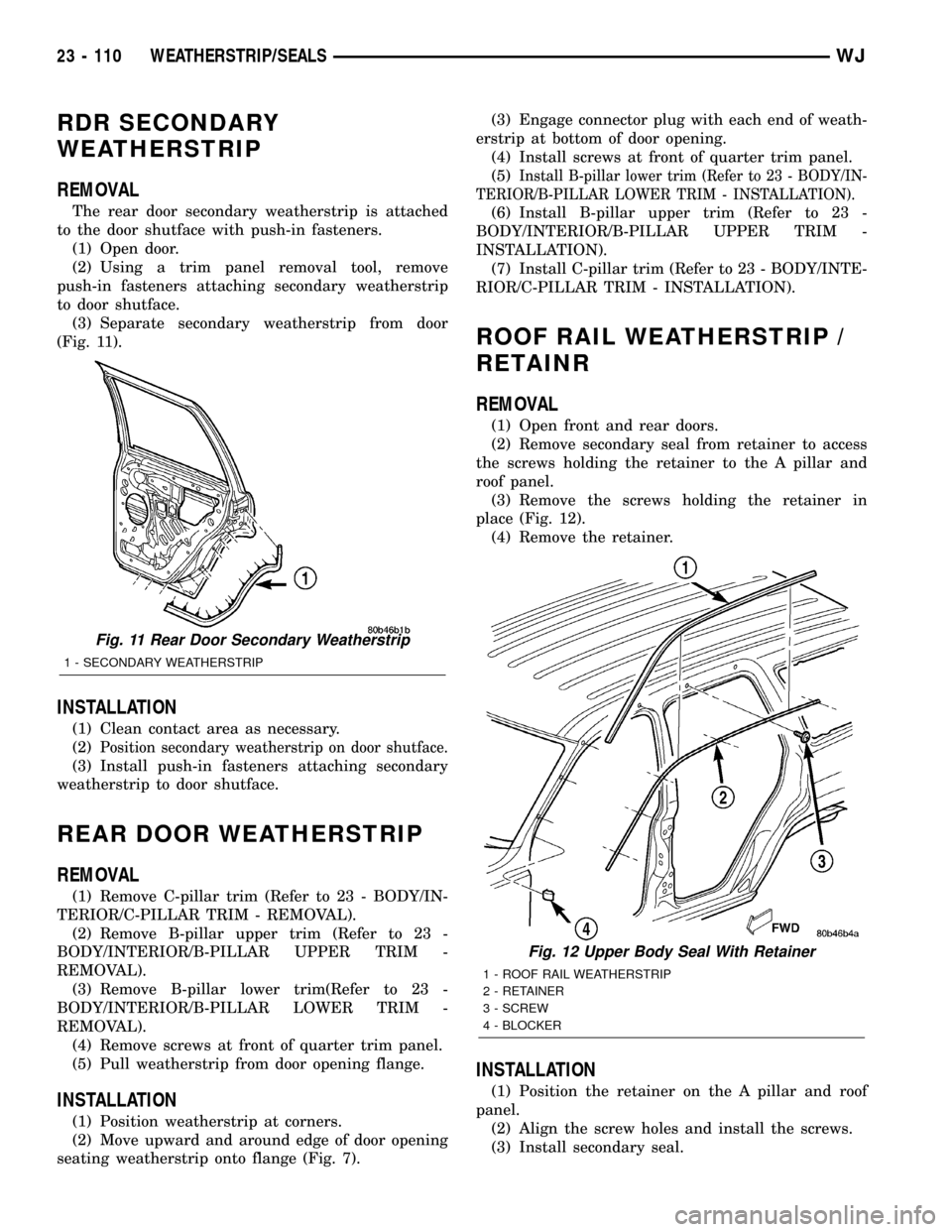

RDR INNER BELT

WEATHERSTRIP

REMOVAL

(1) Remove door trim panel (Refer to 23 - BODY/

DOORS - REAR/TRIM PANEL - REMOVAL).

(2) Using a trim stick, carefully pry rear inner

edge of inner belt weatherstrip upward.

(3) Grasp weatherstrip and pull upward to sepa-

rate from door flange (Fig. 10).

INSTALLATION

(1) Position weatherstrip on door flange.

(2) Firmly press downward to seat weatherstrip on

flange.

(3) Install trim panel (Refer to 23 - BODY/DOORS

- REAR/TRIM PANEL - INSTALLATION).

RDR OUTER BELT

WEATHERSTRIP

REMOVAL

(1) Remove trim panel (Refer to 23 - BODY/

DOORS - REAR/TRIM PANEL - REMOVAL).

(2) Using a small flat blade, disengage tangs

attaching outer belt weatherstrip to inner door panel.

(3) Lift weatherstrip upward and separate from

door (Fig. 10).

INSTALLATION

(1) Position the weatherstrip onto the door flange.

(2) Force the weatherstrip onto door flange and

engage tangs. Continue rearward until it is seated on

flange.

(3) Instal trim panel (Refer to 23 - BODY/DOORS

- REAR/TRIM PANEL - INSTALLATION).

Fig. 9 Liftgate Opening Weatherstrip

1 - LIFTGATE

2 - WEATHERSTRIP

Fig. 10 Rear Door Inner/Outer Belt Weatherstrip

1 - INNER BELT WEATHERSTRIP

2 - OUTER BELT WEATHERSTRIP

WJWEATHERSTRIP/SEALS 23 - 109

Page 1983 of 2199

RDR SECONDARY

WEATHERSTRIP

REMOVAL

The rear door secondary weatherstrip is attached

to the door shutface with push-in fasteners.

(1) Open door.

(2) Using a trim panel removal tool, remove

push-in fasteners attaching secondary weatherstrip

to door shutface.

(3) Separate secondary weatherstrip from door

(Fig. 11).

INSTALLATION

(1) Clean contact area as necessary.

(2)

Position secondary weatherstrip on door shutface.

(3) Install push-in fasteners attaching secondary

weatherstrip to door shutface.

REAR DOOR WEATHERSTRIP

REMOVAL

(1) Remove C-pillar trim (Refer to 23 - BODY/IN-

TERIOR/C-PILLAR TRIM - REMOVAL).

(2) Remove B-pillar upper trim (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL).

(3) Remove B-pillar lower trim(Refer to 23 -

BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL).

(4) Remove screws at front of quarter trim panel.

(5) Pull weatherstrip from door opening flange.

INSTALLATION

(1) Position weatherstrip at corners.

(2) Move upward and around edge of door opening

seating weatherstrip onto flange (Fig. 7).(3) Engage connector plug with each end of weath-

erstrip at bottom of door opening.

(4) Install screws at front of quarter trim panel.

(5)

Install B-pillar lower trim (Refer to 23 - BODY/IN-

TERIOR/B-PILLAR LOWER TRIM - INSTALLATION).

(6) Install B-pillar upper trim (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

INSTALLATION).

(7) Install C-pillar trim (Refer to 23 - BODY/INTE-

RIOR/C-PILLAR TRIM - INSTALLATION).

ROOF RAIL WEATHERSTRIP /

RETAINR

REMOVAL

(1) Open front and rear doors.

(2) Remove secondary seal from retainer to access

the screws holding the retainer to the A pillar and

roof panel.

(3) Remove the screws holding the retainer in

place (Fig. 12).

(4) Remove the retainer.

INSTALLATION

(1) Position the retainer on the A pillar and roof

panel.

(2) Align the screw holes and install the screws.

(3) Install secondary seal.

Fig. 11 Rear Door Secondary Weatherstrip

1 - SECONDARY WEATHERSTRIP

Fig. 12 Upper Body Seal With Retainer

1 - ROOF RAIL WEATHERSTRIP

2 - RETAINER

3 - SCREW

4 - BLOCKER

23 - 110 WEATHERSTRIP/SEALSWJ

Page 2083 of 2199

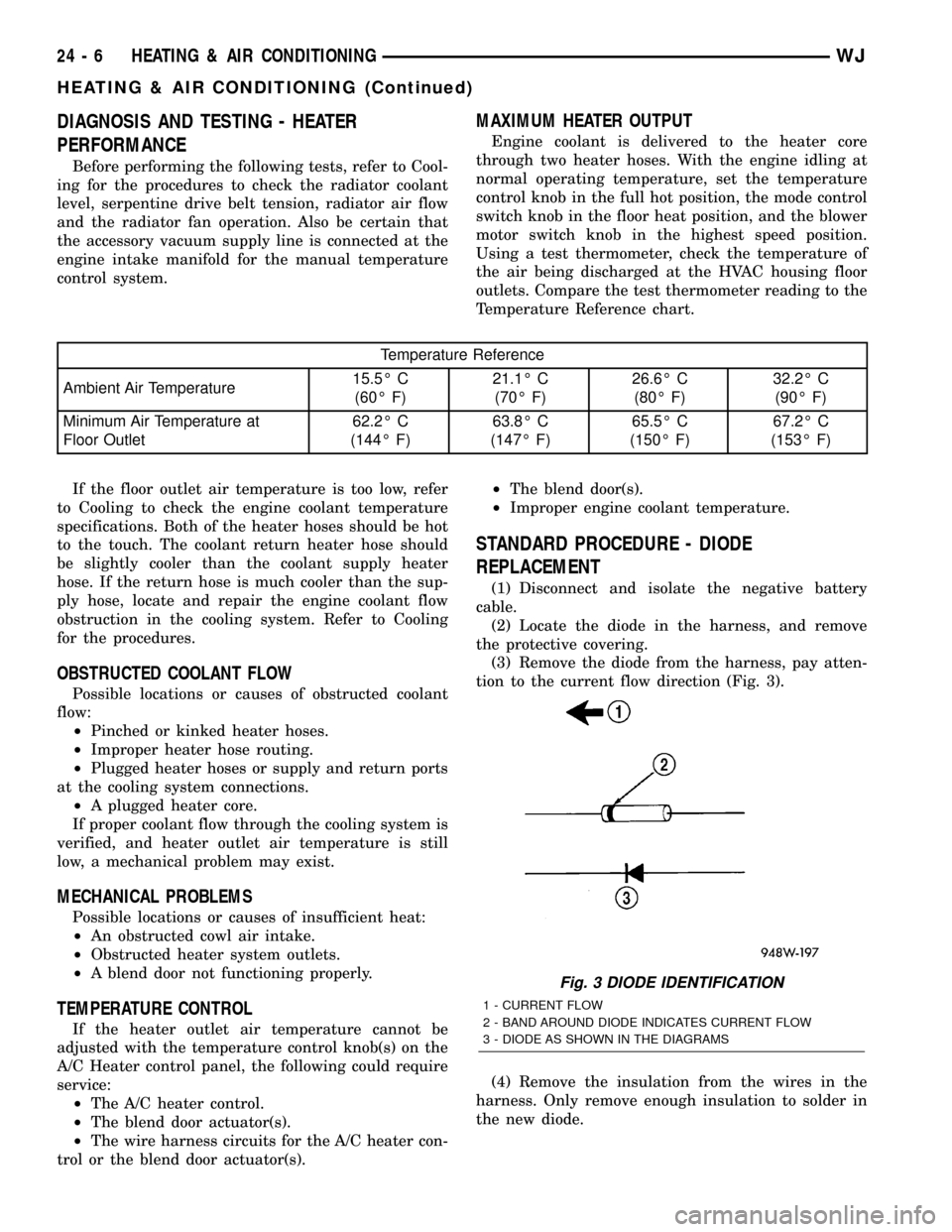

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE

Before performing the following tests, refer to Cool-

ing for the procedures to check the radiator coolant

level, serpentine drive belt tension, radiator air flow

and the radiator fan operation. Also be certain that

the accessory vacuum supply line is connected at the

engine intake manifold for the manual temperature

control system.

MAXIMUM HEATER OUTPUT

Engine coolant is delivered to the heater core

through two heater hoses. With the engine idling at

normal operating temperature, set the temperature

control knob in the full hot position, the mode control

switch knob in the floor heat position, and the blower

motor switch knob in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged at the HVAC housing floor

outlets. Compare the test thermometer reading to the

Temperature Reference chart.

Temperature Reference

Ambient Air Temperature15.5É C

(60É F)21.1É C

(70É F)26.6É C

(80É F)32.2É C

(90É F)

Minimum Air Temperature at

Floor Outlet62.2É C

(144É F)63.8É C

(147É F)65.5É C

(150É F)67.2É C

(153É F)

If the floor outlet air temperature is too low, refer

to Cooling to check the engine coolant temperature

specifications. Both of the heater hoses should be hot

to the touch. The coolant return heater hose should

be slightly cooler than the coolant supply heater

hose. If the return hose is much cooler than the sup-

ply hose, locate and repair the engine coolant flow

obstruction in the cooling system. Refer to Cooling

for the procedures.

OBSTRUCTED COOLANT FLOW

Possible locations or causes of obstructed coolant

flow:

²Pinched or kinked heater hoses.

²Improper heater hose routing.

²Plugged heater hoses or supply and return ports

at the cooling system connections.

²A plugged heater core.

If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is still

low, a mechanical problem may exist.

MECHANICAL PROBLEMS

Possible locations or causes of insufficient heat:

²An obstructed cowl air intake.

²Obstructed heater system outlets.

²A blend door not functioning properly.

TEMPERATURE CONTROL

If the heater outlet air temperature cannot be

adjusted with the temperature control knob(s) on the

A/C Heater control panel, the following could require

service:

²The A/C heater control.

²The blend door actuator(s).

²The wire harness circuits for the A/C heater con-

trol or the blend door actuator(s).²The blend door(s).

²Improper engine coolant temperature.

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect and isolate the negative battery

cable.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 3).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

Fig. 3 DIODE IDENTIFICATION

1 - CURRENT FLOW

2 - BAND AROUND DIODE INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN THE DIAGRAMS

24 - 6 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2088 of 2199

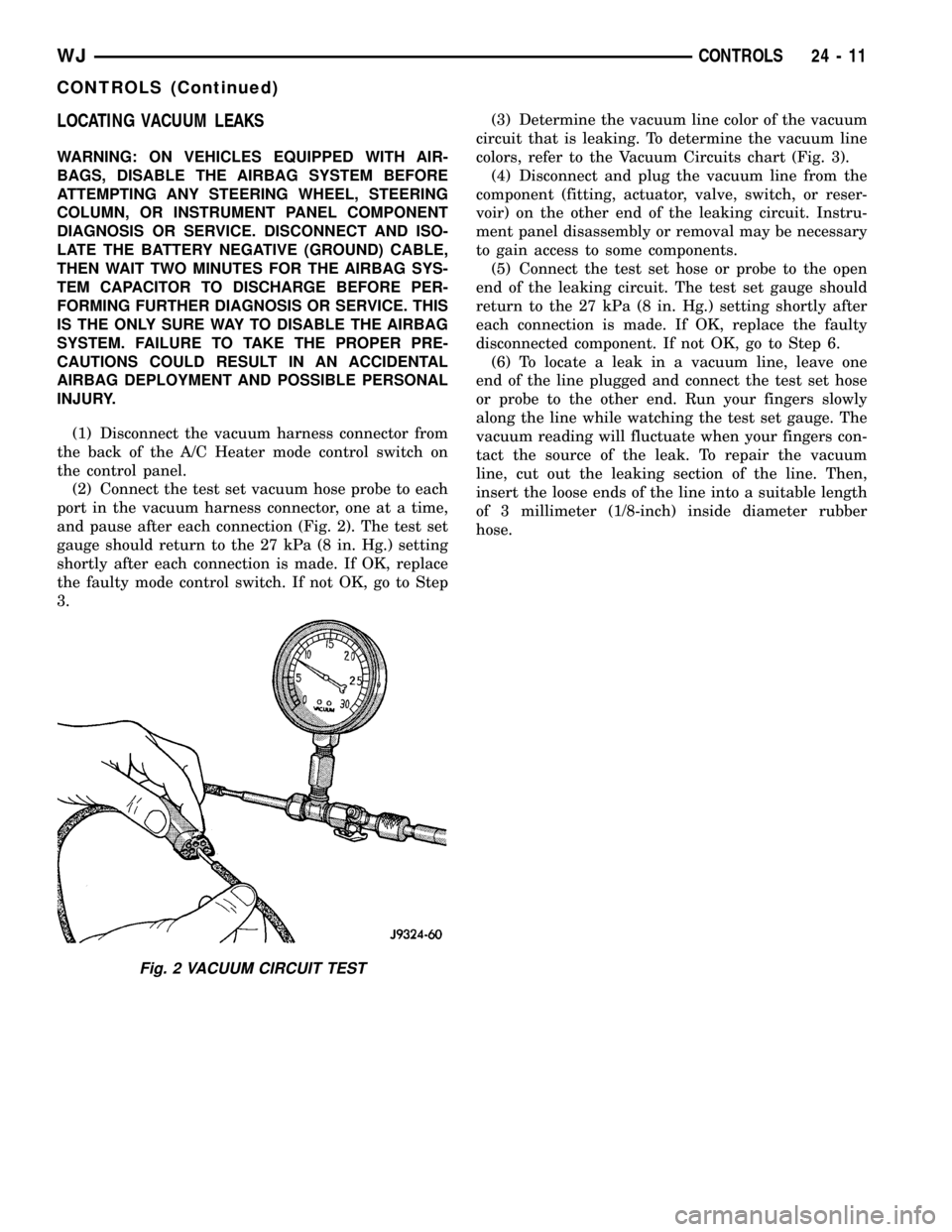

LOCATING VACUUM LEAKS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect the vacuum harness connector from

the back of the A/C Heater mode control switch on

the control panel.

(2) Connect the test set vacuum hose probe to each

port in the vacuum harness connector, one at a time,

and pause after each connection (Fig. 2). The test set

gauge should return to the 27 kPa (8 in. Hg.) setting

shortly after each connection is made. If OK, replace

the faulty mode control switch. If not OK, go to Step

3.(3) Determine the vacuum line color of the vacuum

circuit that is leaking. To determine the vacuum line

colors, refer to the Vacuum Circuits chart (Fig. 3).

(4) Disconnect and plug the vacuum line from the

component (fitting, actuator, valve, switch, or reser-

voir) on the other end of the leaking circuit. Instru-

ment panel disassembly or removal may be necessary

to gain access to some components.

(5) Connect the test set hose or probe to the open

end of the leaking circuit. The test set gauge should

return to the 27 kPa (8 in. Hg.) setting shortly after

each connection is made. If OK, replace the faulty

disconnected component. If not OK, go to Step 6.

(6) To locate a leak in a vacuum line, leave one

end of the line plugged and connect the test set hose

or probe to the other end. Run your fingers slowly

along the line while watching the test set gauge. The

vacuum reading will fluctuate when your fingers con-

tact the source of the leak. To repair the vacuum

line, cut out the leaking section of the line. Then,

insert the loose ends of the line into a suitable length

of 3 millimeter (1/8-inch) inside diameter rubber

hose.

Fig. 2 VACUUM CIRCUIT TEST

WJCONTROLS 24 - 11

CONTROLS (Continued)

Page 2094 of 2199

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

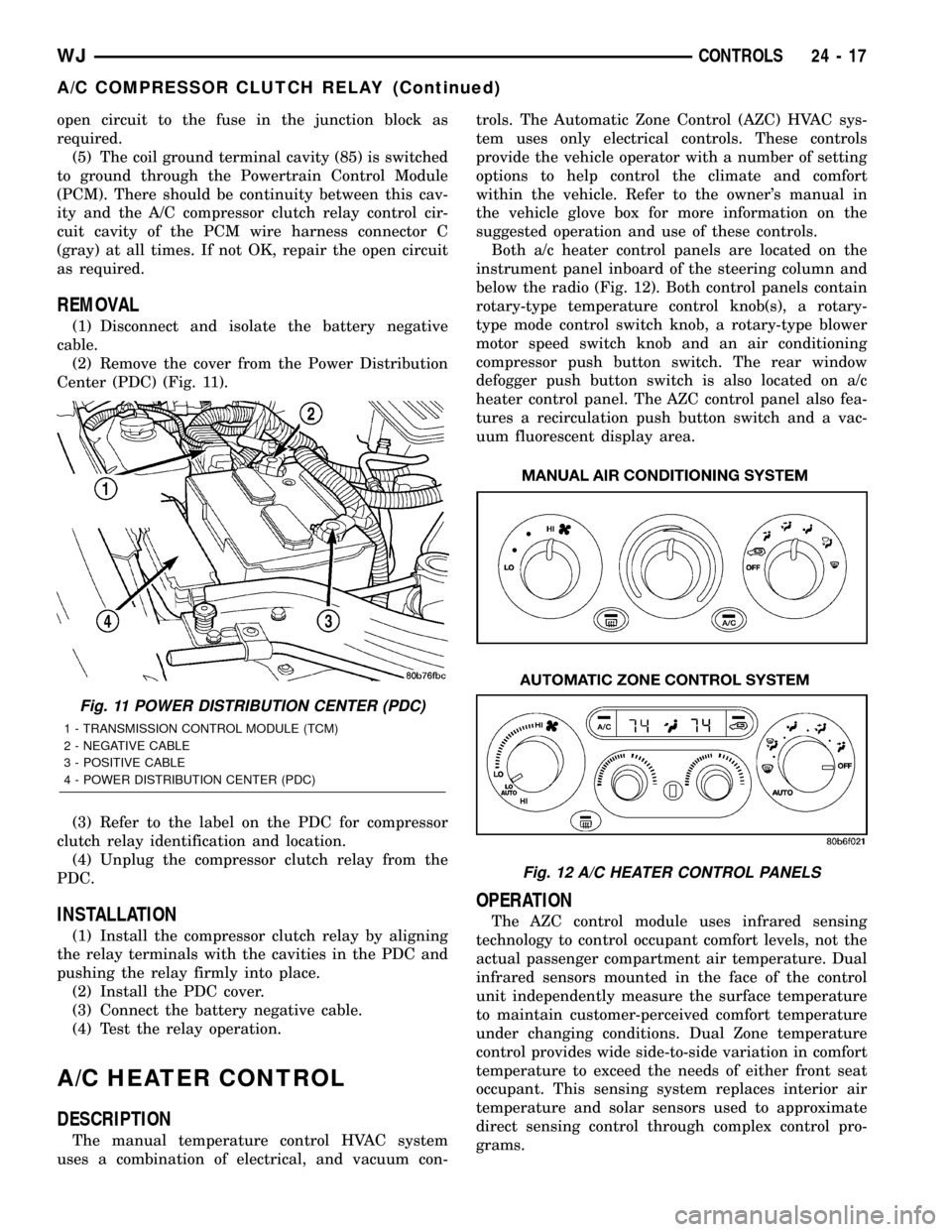

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

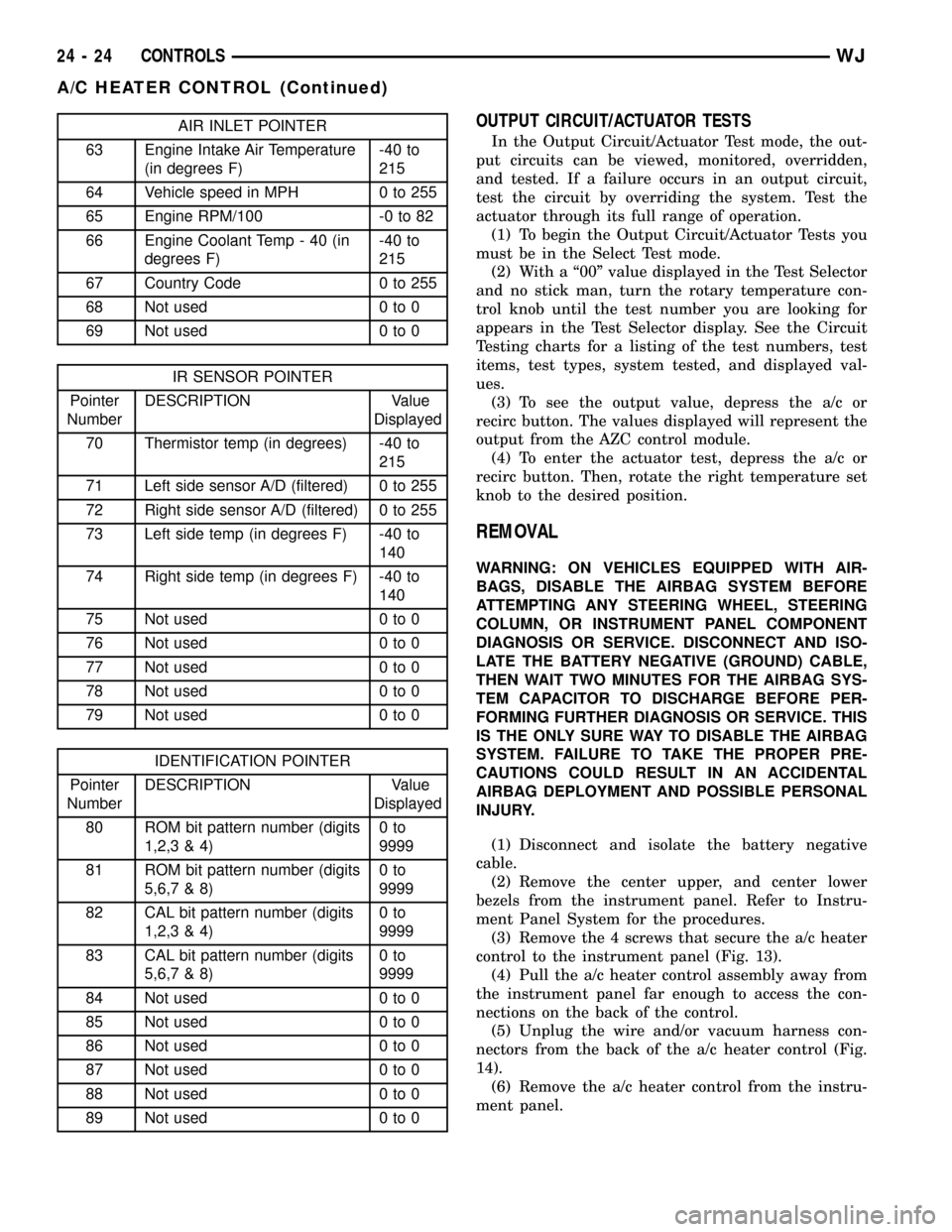

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2101 of 2199

AIR INLET POINTER

63 Engine Intake Air Temperature

(in degrees F)-40 to

215

64 Vehicle speed in MPH 0 to 255

65 Engine RPM/100 -0 to 82

66 Engine Coolant Temp - 40 (in

degrees F)-40 to

215

67 Country Code 0 to 255

68 Not used 0 to 0

69 Not used 0 to 0

IR SENSOR POINTER

Pointer

NumberDESCRIPTION Value

Displayed

70 Thermistor temp (in degrees) -40 to

215

71 Left side sensor A/D (filtered) 0 to 255

72 Right side sensor A/D (filtered) 0 to 255

73 Left side temp (in degrees F) -40 to

140

74 Right side temp (in degrees F) -40 to

140

75 Not used 0 to 0

76 Not used 0 to 0

77 Not used 0 to 0

78 Not used 0 to 0

79 Not used 0 to 0

IDENTIFICATION POINTER

Pointer

NumberDESCRIPTION Value

Displayed

80 ROM bit pattern number (digits

1,2,3 & 4)0to

9999

81 ROM bit pattern number (digits

5,6,7 & 8)0to

9999

82 CAL bit pattern number (digits

1,2,3 & 4)0to

9999

83 CAL bit pattern number (digits

5,6,7 & 8)0to

9999

84 Not used 0 to 0

85 Not used 0 to 0

86 Not used 0 to 0

87 Not used 0 to 0

88 Not used 0 to 0

89 Not used 0 to 0

OUTPUT CIRCUIT/ACTUATOR TESTS

In the Output Circuit/Actuator Test mode, the out-

put circuits can be viewed, monitored, overridden,

and tested. If a failure occurs in an output circuit,

test the circuit by overriding the system. Test the

actuator through its full range of operation.

(1) To begin the Output Circuit/Actuator Tests you

must be in the Select Test mode.

(2) With a ª00º value displayed in the Test Selector

and no stick man, turn the rotary temperature con-

trol knob until the test number you are looking for

appears in the Test Selector display. See the Circuit

Testing charts for a listing of the test numbers, test

items, test types, system tested, and displayed val-

ues.

(3) To see the output value, depress the a/c or

recirc button. The values displayed will represent the

output from the AZC control module.

(4) To enter the actuator test, depress the a/c or

recirc button. Then, rotate the right temperature set

knob to the desired position.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center upper, and center lower

bezels from the instrument panel. Refer to Instru-

ment Panel System for the procedures.

(3) Remove the 4 screws that secure the a/c heater

control to the instrument panel (Fig. 13).

(4) Pull the a/c heater control assembly away from

the instrument panel far enough to access the con-

nections on the back of the control.

(5) Unplug the wire and/or vacuum harness con-

nectors from the back of the a/c heater control (Fig.

14).

(6) Remove the a/c heater control from the instru-

ment panel.

24 - 24 CONTROLSWJ

A/C HEATER CONTROL (Continued)