Transfer JEEP GRAND CHEROKEE 2002 WJ / 2.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1526 of 2199

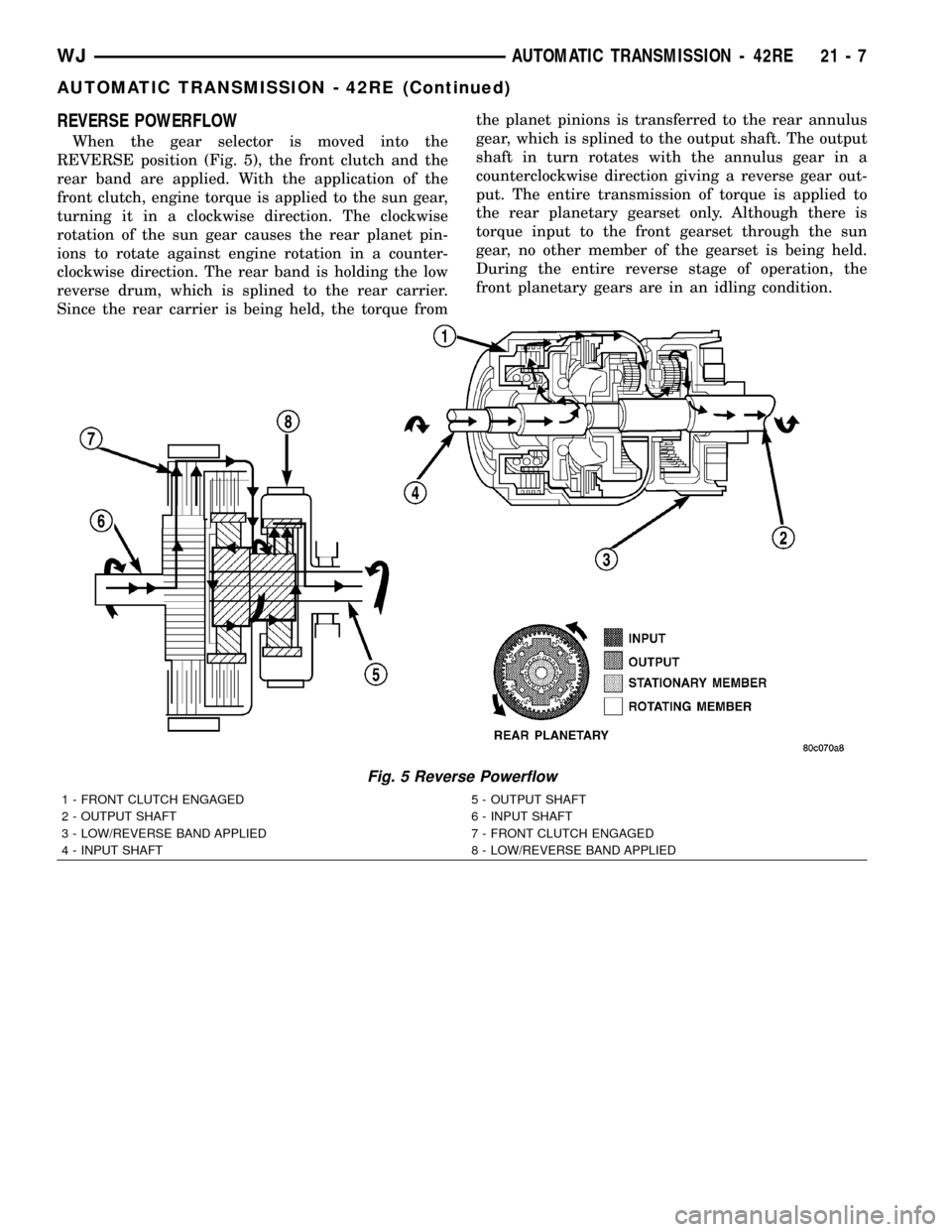

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pin-

ions to rotate against engine rotation in a counter-

clockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.

Since the rear carrier is being held, the torque fromthe planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear out-

put. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

Fig. 5 Reverse Powerflow

1 - FRONT CLUTCH ENGAGED 5 - OUTPUT SHAFT

2 - OUTPUT SHAFT 6 - INPUT SHAFT

3 - LOW/REVERSE BAND APPLIED 7 - FRONT CLUTCH ENGAGED

4 - INPUT SHAFT 8 - LOW/REVERSE BAND APPLIED

WJAUTOMATIC TRANSMISSION - 42RE 21 - 7

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1527 of 2199

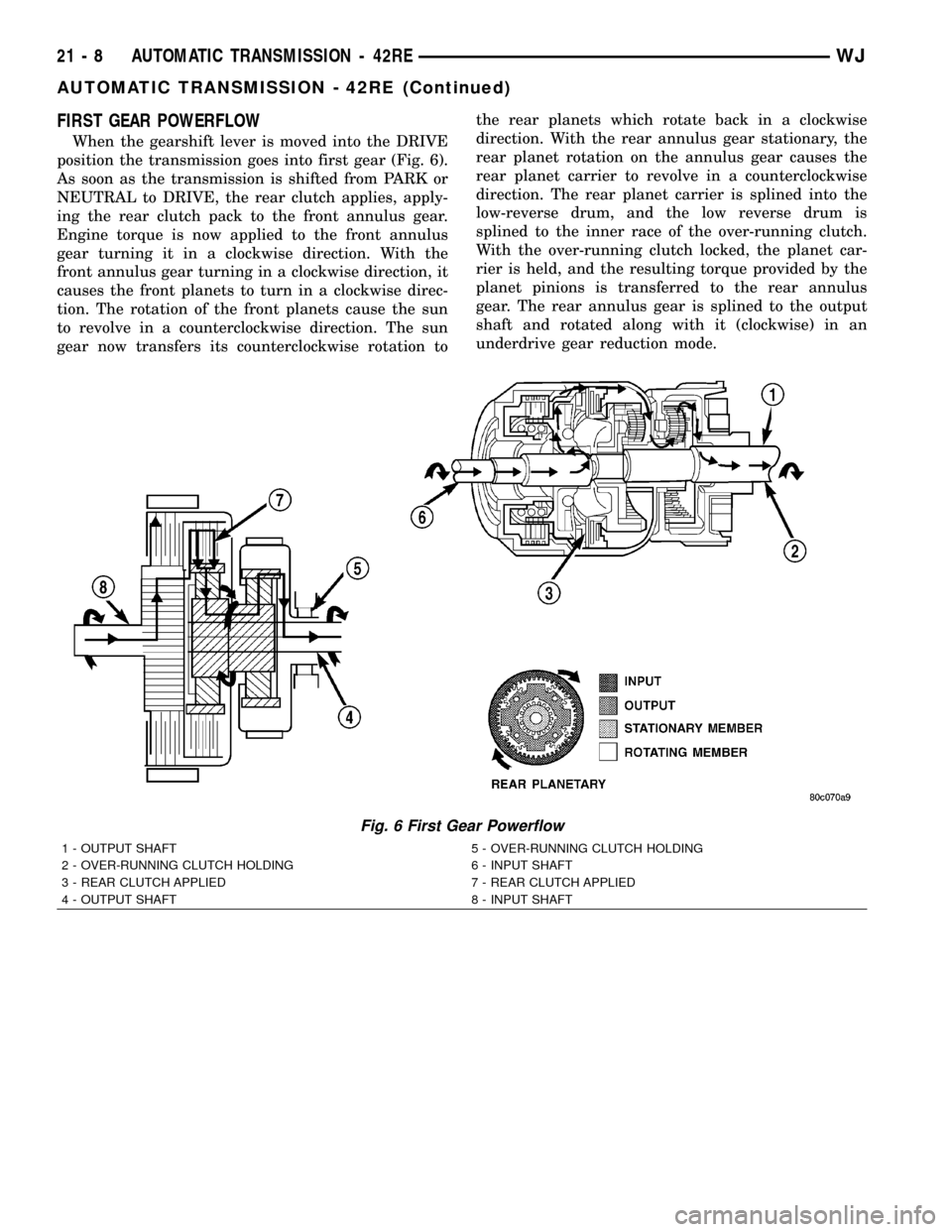

FIRST GEAR POWERFLOW

When the gearshift lever is moved into the DRIVE

position the transmission goes into first gear (Fig. 6).

As soon as the transmission is shifted from PARK or

NEUTRAL to DRIVE, the rear clutch applies, apply-

ing the rear clutch pack to the front annulus gear.

Engine torque is now applied to the front annulus

gear turning it in a clockwise direction. With the

front annulus gear turning in a clockwise direction, it

causes the front planets to turn in a clockwise direc-

tion. The rotation of the front planets cause the sun

to revolve in a counterclockwise direction. The sun

gear now transfers its counterclockwise rotation tothe rear planets which rotate back in a clockwise

direction. With the rear annulus gear stationary, the

rear planet rotation on the annulus gear causes the

rear planet carrier to revolve in a counterclockwise

direction. The rear planet carrier is splined into the

low-reverse drum, and the low reverse drum is

splined to the inner race of the over-running clutch.

With the over-running clutch locked, the planet car-

rier is held, and the resulting torque provided by the

planet pinions is transferred to the rear annulus

gear. The rear annulus gear is splined to the output

shaft and rotated along with it (clockwise) in an

underdrive gear reduction mode.

Fig. 6 First Gear Powerflow

1 - OUTPUT SHAFT 5 - OVER-RUNNING CLUTCH HOLDING

2 - OVER-RUNNING CLUTCH HOLDING 6 - INPUT SHAFT

3 - REAR CLUTCH APPLIED 7 - REAR CLUTCH APPLIED

4 - OUTPUT SHAFT 8 - INPUT SHAFT

21 - 8 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1536 of 2199

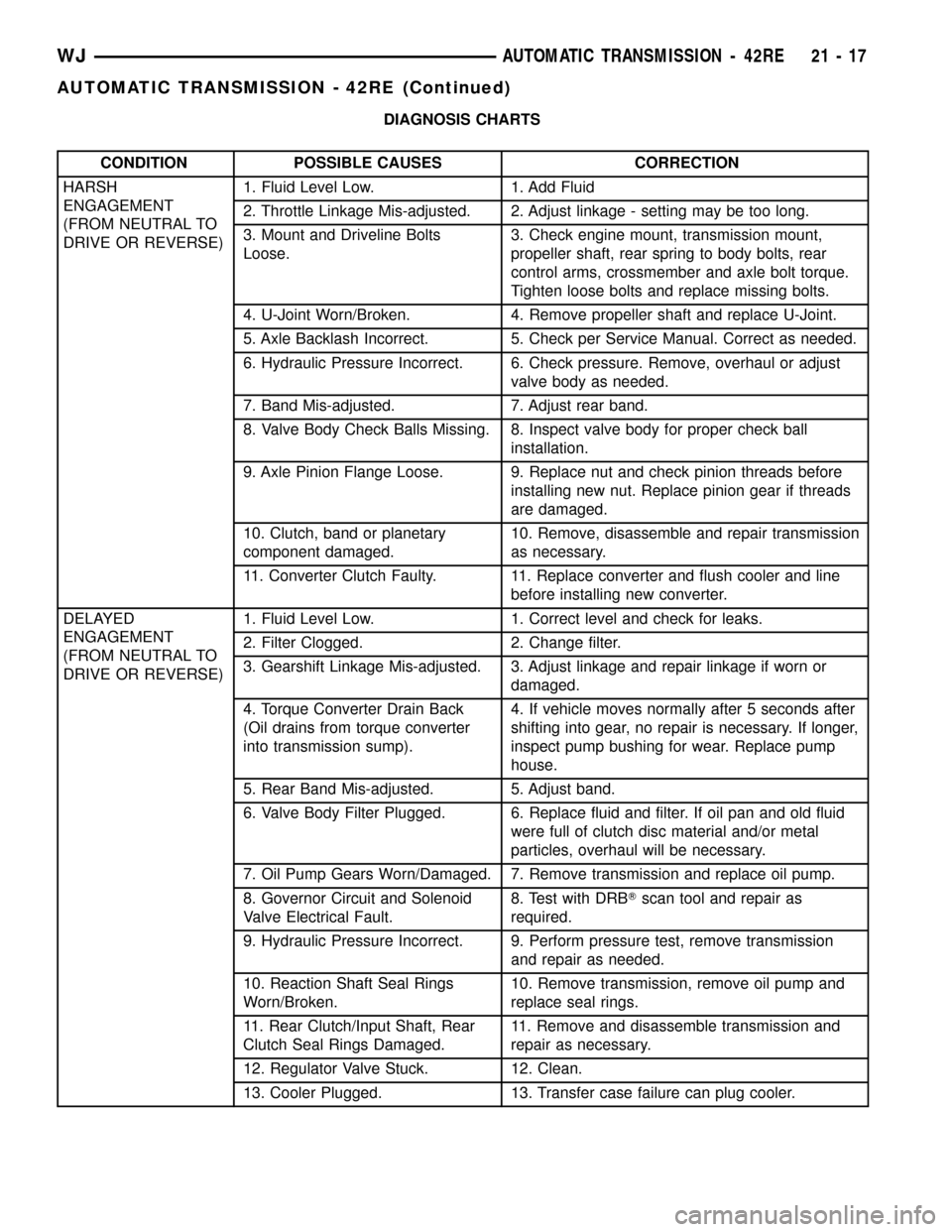

DIAGNOSIS CHARTS

CONDITION POSSIBLE CAUSES CORRECTION

HARSH

ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Add Fluid

2. Throttle Linkage Mis-adjusted. 2. Adjust linkage - setting may be too long.

3. Mount and Driveline Bolts

Loose.3. Check engine mount, transmission mount,

propeller shaft, rear spring to body bolts, rear

control arms, crossmember and axle bolt torque.

Tighten loose bolts and replace missing bolts.

4. U-Joint Worn/Broken. 4. Remove propeller shaft and replace U-Joint.

5. Axle Backlash Incorrect. 5. Check per Service Manual. Correct as needed.

6. Hydraulic Pressure Incorrect. 6. Check pressure. Remove, overhaul or adjust

valve body as needed.

7. Band Mis-adjusted. 7. Adjust rear band.

8. Valve Body Check Balls Missing. 8. Inspect valve body for proper check ball

installation.

9. Axle Pinion Flange Loose. 9. Replace nut and check pinion threads before

installing new nut. Replace pinion gear if threads

are damaged.

10. Clutch, band or planetary

component damaged.10. Remove, disassemble and repair transmission

as necessary.

11. Converter Clutch Faulty. 11. Replace converter and flush cooler and line

before installing new converter.

DELAYED

ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Mis-adjusted. 3. Adjust linkage and repair linkage if worn or

damaged.

4. Torque Converter Drain Back

(Oil drains from torque converter

into transmission sump).4. If vehicle moves normally after 5 seconds after

shifting into gear, no repair is necessary. If longer,

inspect pump bushing for wear. Replace pump

house.

5. Rear Band Mis-adjusted. 5. Adjust band.

6. Valve Body Filter Plugged. 6. Replace fluid and filter. If oil pan and old fluid

were full of clutch disc material and/or metal

particles, overhaul will be necessary.

7. Oil Pump Gears Worn/Damaged. 7. Remove transmission and replace oil pump.

8. Governor Circuit and Solenoid

Valve Electrical Fault.8. Test with DRBTscan tool and repair as

required.

9. Hydraulic Pressure Incorrect. 9. Perform pressure test, remove transmission

and repair as needed.

10. Reaction Shaft Seal Rings

Worn/Broken.10. Remove transmission, remove oil pump and

replace seal rings.

11. Rear Clutch/Input Shaft, Rear

Clutch Seal Rings Damaged.11. Remove and disassemble transmission and

repair as necessary.

12. Regulator Valve Stuck. 12. Clean.

13. Cooler Plugged. 13. Transfer case failure can plug cooler.

WJAUTOMATIC TRANSMISSION - 42RE 21 - 17

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1537 of 2199

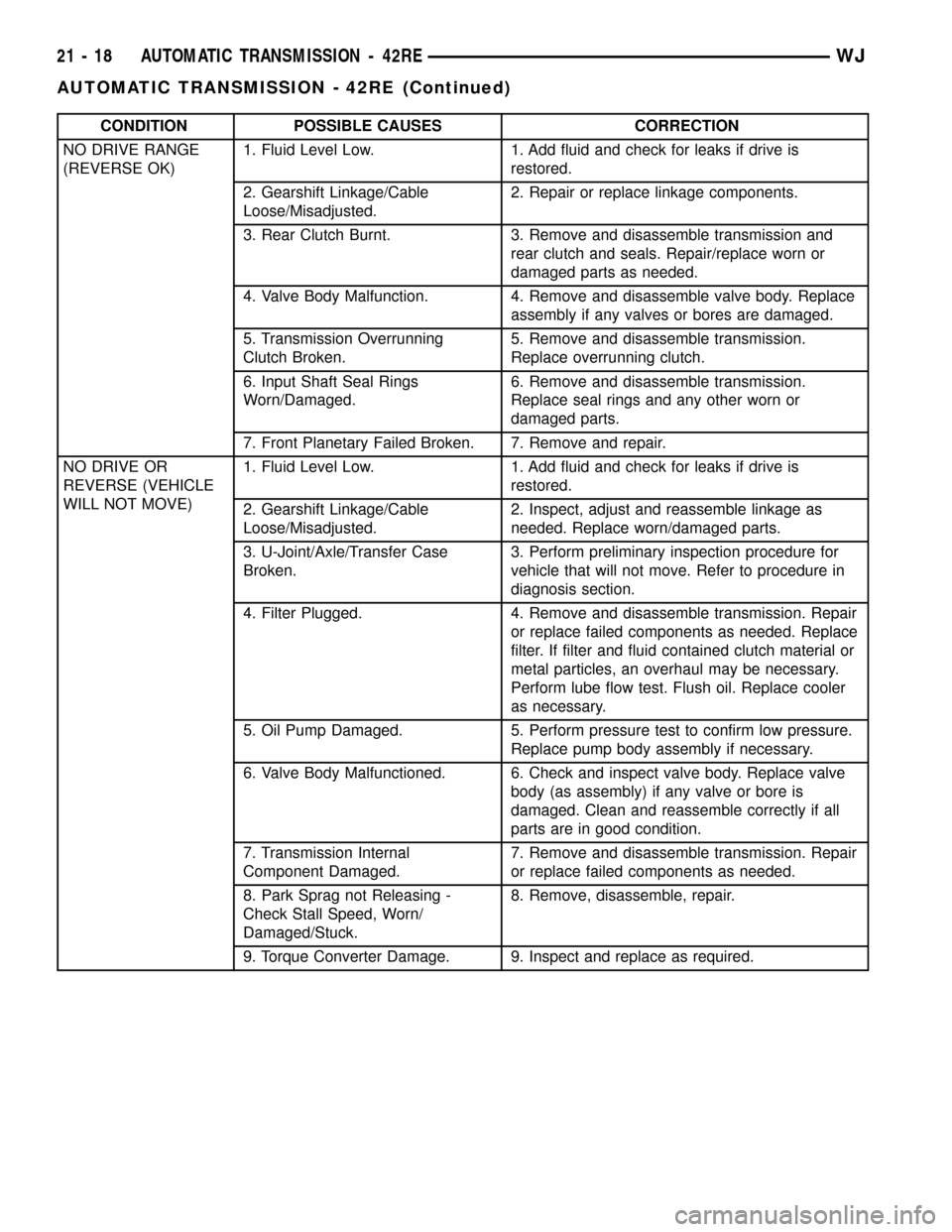

CONDITION POSSIBLE CAUSES CORRECTION

NO DRIVE RANGE

(REVERSE OK)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.2. Repair or replace linkage components.

3. Rear Clutch Burnt. 3. Remove and disassemble transmission and

rear clutch and seals. Repair/replace worn or

damaged parts as needed.

4. Valve Body Malfunction. 4. Remove and disassemble valve body. Replace

assembly if any valves or bores are damaged.

5. Transmission Overrunning

Clutch Broken.5. Remove and disassemble transmission.

Replace overrunning clutch.

6. Input Shaft Seal Rings

Worn/Damaged.6. Remove and disassemble transmission.

Replace seal rings and any other worn or

damaged parts.

7. Front Planetary Failed Broken. 7. Remove and repair.

NO DRIVE OR

REVERSE (VEHICLE

WILL NOT MOVE)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.2. Inspect, adjust and reassemble linkage as

needed. Replace worn/damaged parts.

3. U-Joint/Axle/Transfer Case

Broken.3. Perform preliminary inspection procedure for

vehicle that will not move. Refer to procedure in

diagnosis section.

4. Filter Plugged. 4. Remove and disassemble transmission. Repair

or replace failed components as needed. Replace

filter. If filter and fluid contained clutch material or

metal particles, an overhaul may be necessary.

Perform lube flow test. Flush oil. Replace cooler

as necessary.

5. Oil Pump Damaged. 5. Perform pressure test to confirm low pressure.

Replace pump body assembly if necessary.

6. Valve Body Malfunctioned. 6. Check and inspect valve body. Replace valve

body (as assembly) if any valve or bore is

damaged. Clean and reassemble correctly if all

parts are in good condition.

7. Transmission Internal

Component Damaged.7. Remove and disassemble transmission. Repair

or replace failed components as needed.

8. Park Sprag not Releasing -

Check Stall Speed, Worn/

Damaged/Stuck.8. Remove, disassemble, repair.

9. Torque Converter Damage. 9. Inspect and replace as required.

21 - 18 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1546 of 2199

REMOVAL

The overdrive unit can be removed and serviced

separately. It is not necessary to remove the entire

transmission assembly to perform overdrive unit

repairs.

If only the overdrive unit requires service, refer to

Overdrive Removal for proper procedures.

CAUTION: The transmission and torque converter

must be removed as an assembly to avoid compo-

nent damage. The converter driveplate, pump bush-

ing, or oil seal can be damaged if the converter is

left attached to the driveplate during removal. Be

sure to remove the transmission and converter as

an assembly.

(1) Disconnect battery negative cable.

(2) Disconnect and lower or remove necessary

exhaust components.

(3) Disconnect fluid cooler lines at transmission.

(4) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(5) Disconnect and remove crankshaft position sen-

sor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain sensor attaching bolts.

CAUTION: The crankshaft position sensor will be

damaged if the transmission is removed, or

installed, while the sensor is still bolted to the

engine block, or transmission (4.0L only). To avoid

damage, be sure to remove the sensor before

removing the transmission.

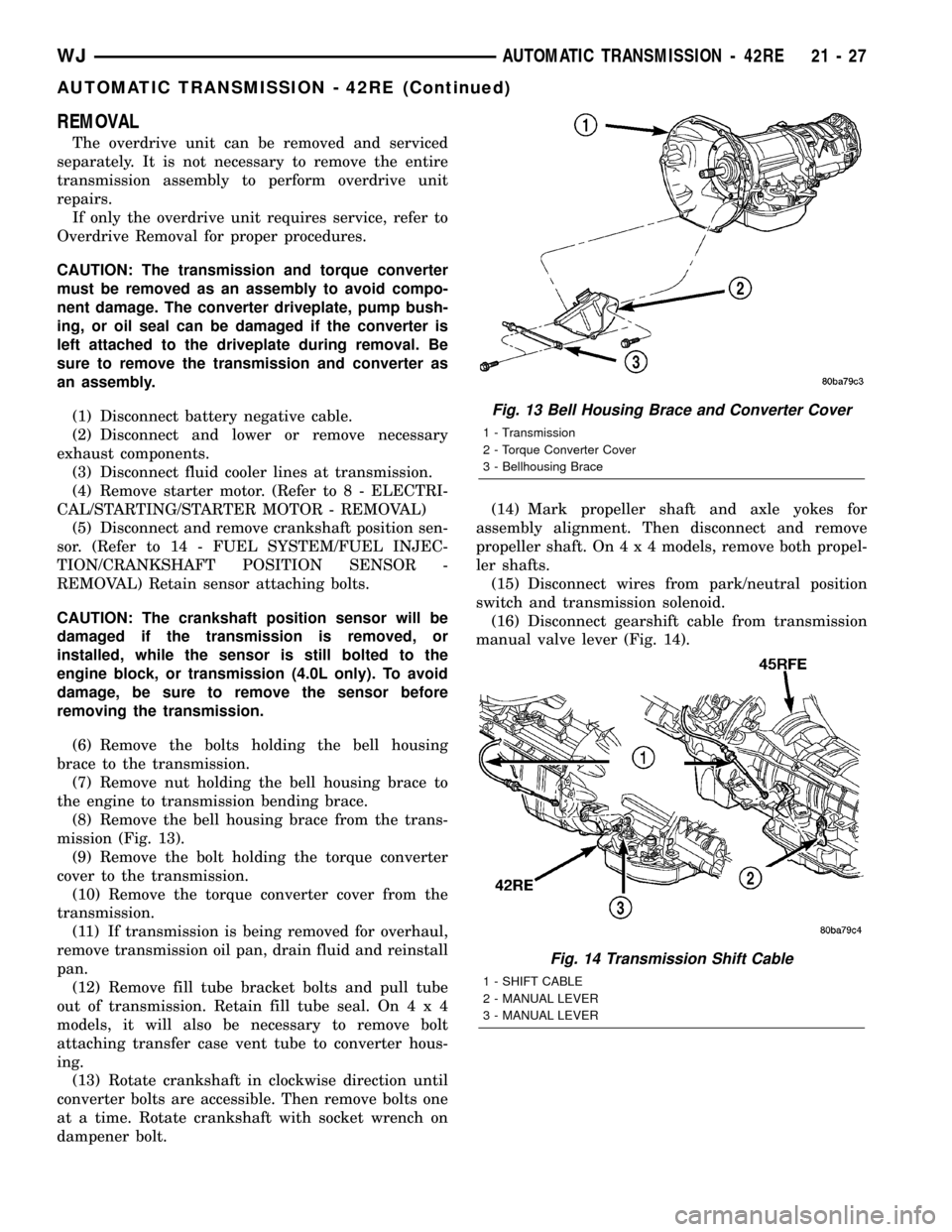

(6) Remove the bolts holding the bell housing

brace to the transmission.

(7) Remove nut holding the bell housing brace to

the engine to transmission bending brace.

(8) Remove the bell housing brace from the trans-

mission (Fig. 13).

(9) Remove the bolt holding the torque converter

cover to the transmission.

(10) Remove the torque converter cover from the

transmission.

(11) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

(12) Remove fill tube bracket bolts and pull tube

out of transmission. Retain fill tube seal. On4x4

models, it will also be necessary to remove bolt

attaching transfer case vent tube to converter hous-

ing.

(13) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.(14) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts.

(15) Disconnect wires from park/neutral position

switch and transmission solenoid.

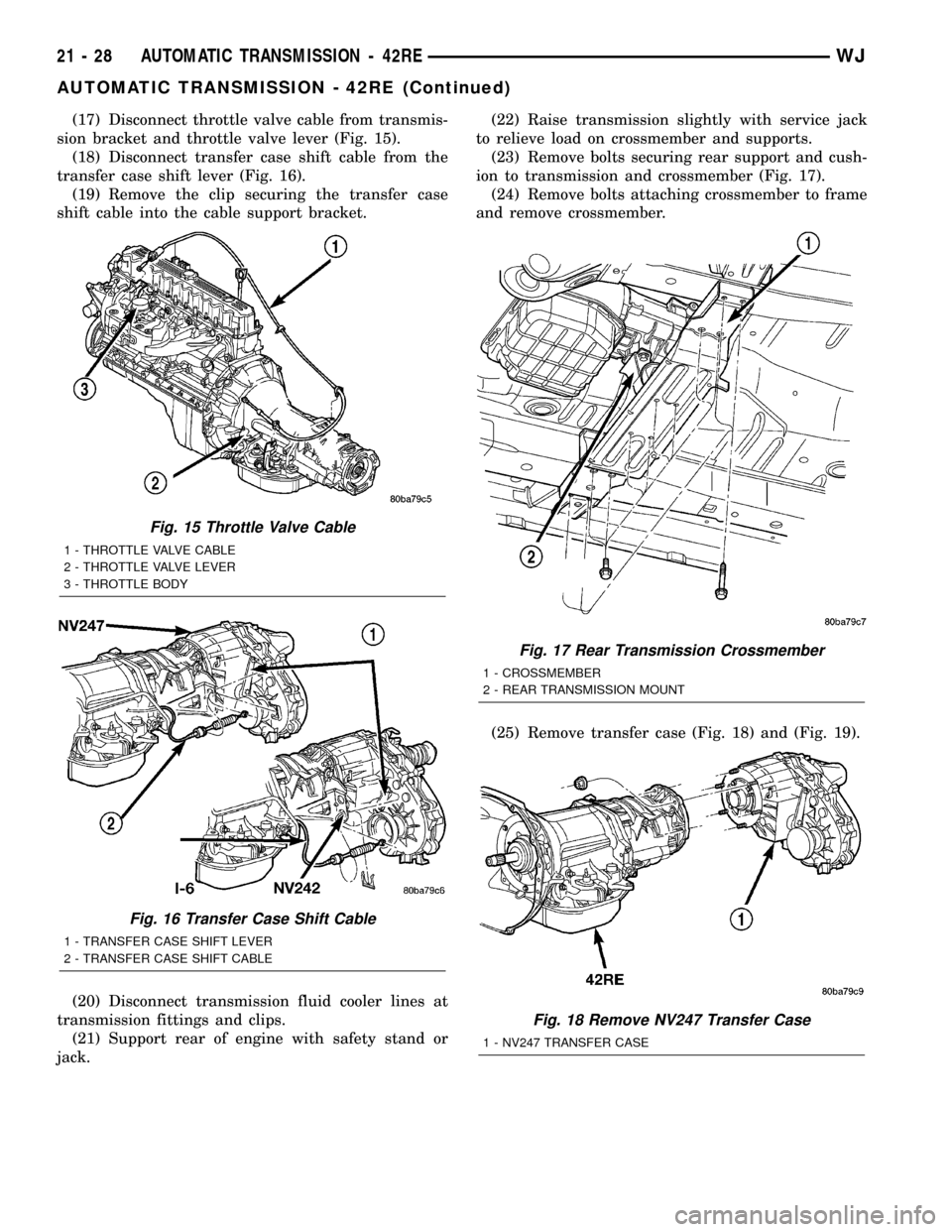

(16) Disconnect gearshift cable from transmission

manual valve lever (Fig. 14).

Fig. 13 Bell Housing Brace and Converter Cover

1 - Transmission

2 - Torque Converter Cover

3 - Bellhousing Brace

Fig. 14 Transmission Shift Cable

1 - SHIFT CABLE

2 - MANUAL LEVER

3 - MANUAL LEVER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 27

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1547 of 2199

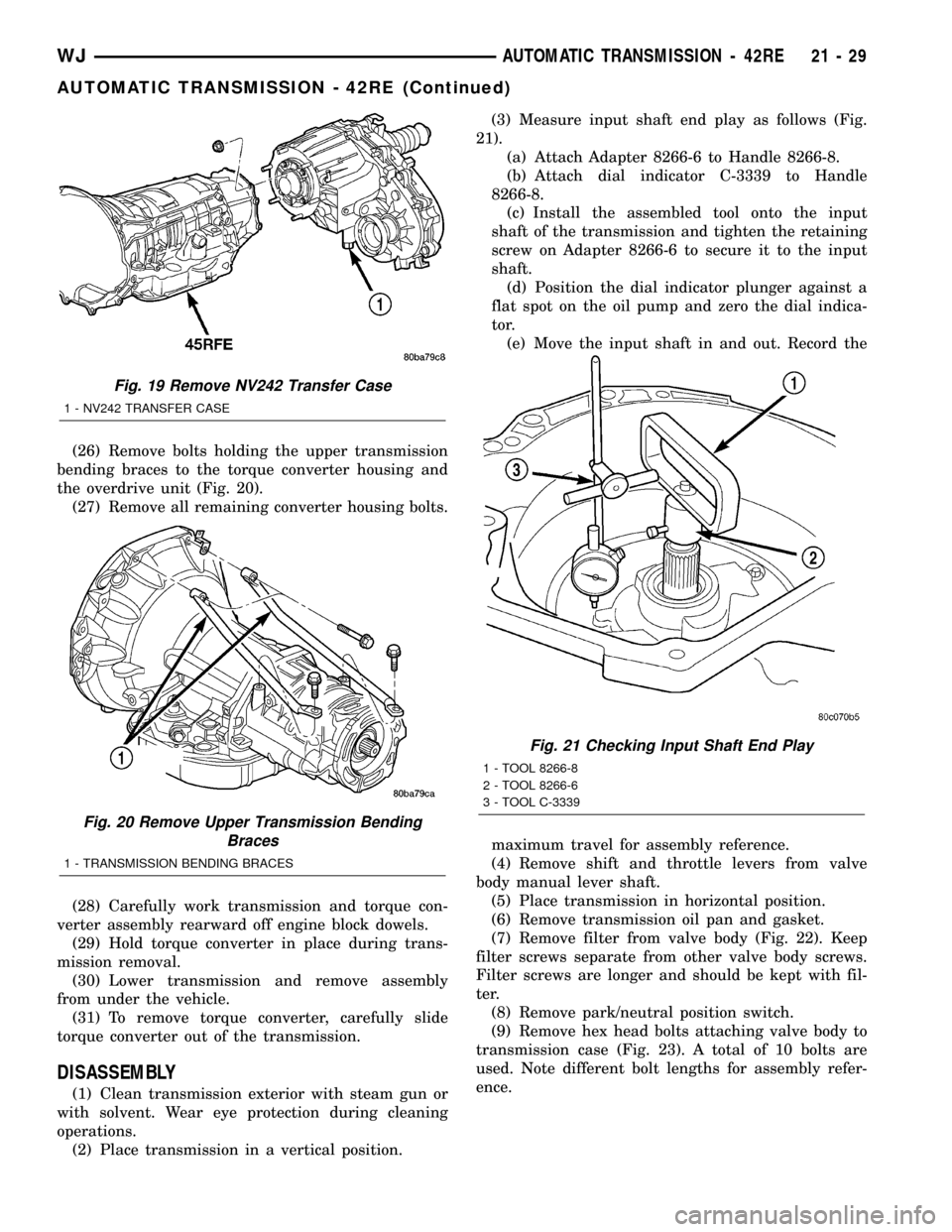

(17) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever (Fig. 15).

(18) Disconnect transfer case shift cable from the

transfer case shift lever (Fig. 16).

(19) Remove the clip securing the transfer case

shift cable into the cable support bracket.

(20) Disconnect transmission fluid cooler lines at

transmission fittings and clips.

(21) Support rear of engine with safety stand or

jack.(22) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

(23) Remove bolts securing rear support and cush-

ion to transmission and crossmember (Fig. 17).

(24) Remove bolts attaching crossmember to frame

and remove crossmember.

(25) Remove transfer case (Fig. 18) and (Fig. 19).

Fig. 15 Throttle Valve Cable

1 - THROTTLE VALVE CABLE

2 - THROTTLE VALVE LEVER

3 - THROTTLE BODY

Fig. 16 Transfer Case Shift Cable

1 - TRANSFER CASE SHIFT LEVER

2 - TRANSFER CASE SHIFT CABLE

Fig. 17 Rear Transmission Crossmember

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

Fig. 18 Remove NV247 Transfer Case

1 - NV247 TRANSFER CASE

21 - 28 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1548 of 2199

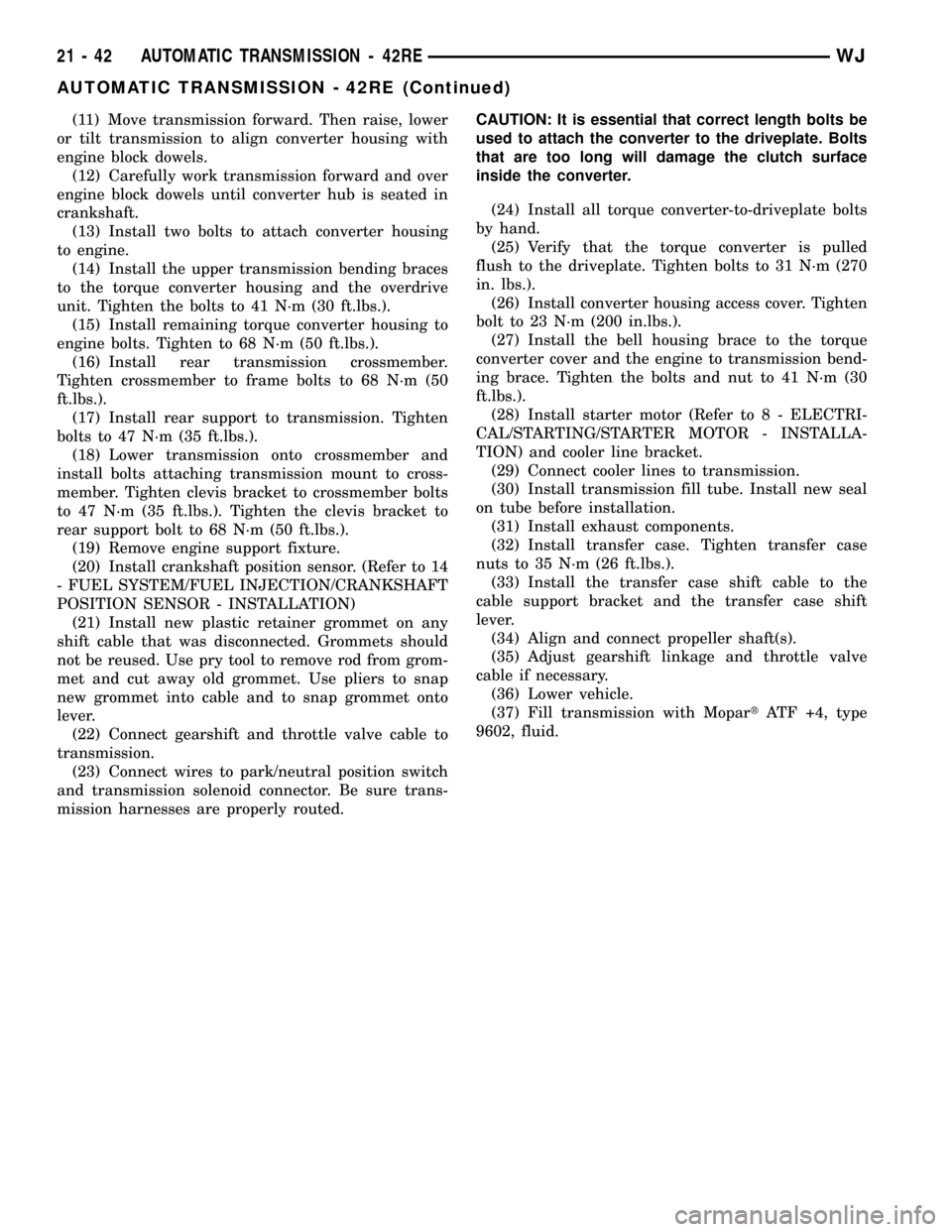

(26) Remove bolts holding the upper transmission

bending braces to the torque converter housing and

the overdrive unit (Fig. 20).

(27) Remove all remaining converter housing bolts.

(28) Carefully work transmission and torque con-

verter assembly rearward off engine block dowels.

(29) Hold torque converter in place during trans-

mission removal.

(30) Lower transmission and remove assembly

from under the vehicle.

(31) To remove torque converter, carefully slide

torque converter out of the transmission.

DISASSEMBLY

(1) Clean transmission exterior with steam gun or

with solvent. Wear eye protection during cleaning

operations.

(2) Place transmission in a vertical position.(3) Measure input shaft end play as follows (Fig.

21).

(a) Attach Adapter 8266-6 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-6 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indica-

tor.

(e) Move the input shaft in and out. Record the

maximum travel for assembly reference.

(4) Remove shift and throttle levers from valve

body manual lever shaft.

(5) Place transmission in horizontal position.

(6) Remove transmission oil pan and gasket.

(7) Remove filter from valve body (Fig. 22). Keep

filter screws separate from other valve body screws.

Filter screws are longer and should be kept with fil-

ter.

(8) Remove park/neutral position switch.

(9) Remove hex head bolts attaching valve body to

transmission case (Fig. 23). A total of 10 bolts are

used. Note different bolt lengths for assembly refer-

ence.

Fig. 19 Remove NV242 Transfer Case

1 - NV242 TRANSFER CASE

Fig. 20 Remove Upper Transmission Bending

Braces

1 - TRANSMISSION BENDING BRACES

Fig. 21 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-6

3 - TOOL C-3339

WJAUTOMATIC TRANSMISSION - 42RE 21 - 29

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1561 of 2199

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(12) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft.

(13) Install two bolts to attach converter housing

to engine.

(14) Install the upper transmission bending braces

to the torque converter housing and the overdrive

unit. Tighten the bolts to 41 N´m (30 ft.lbs.).

(15) Install remaining torque converter housing to

engine bolts. Tighten to 68 N´m (50 ft.lbs.).

(16) Install rear transmission crossmember.

Tighten crossmember to frame bolts to 68 N´m (50

ft.lbs.).

(17) Install rear support to transmission. Tighten

bolts to 47 N´m (35 ft.lbs.).

(18) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member. Tighten clevis bracket to crossmember bolts

to 47 N´m (35 ft.lbs.). Tighten the clevis bracket to

rear support bolt to 68 N´m (50 ft.lbs.).

(19) Remove engine support fixture.

(20) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

(21) Install new plastic retainer grommet on any

shift cable that was disconnected. Grommets should

not be reused. Use pry tool to remove rod from grom-

met and cut away old grommet. Use pliers to snap

new grommet into cable and to snap grommet onto

lever.

(22) Connect gearshift and throttle valve cable to

transmission.

(23) Connect wires to park/neutral position switch

and transmission solenoid connector. Be sure trans-

mission harnesses are properly routed.CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

(24) Install all torque converter-to-driveplate bolts

by hand.

(25) Verify that the torque converter is pulled

flush to the driveplate. Tighten bolts to 31 N´m (270

in. lbs.).

(26) Install converter housing access cover. Tighten

bolt to 23 N´m (200 in.lbs.).

(27) Install the bell housing brace to the torque

converter cover and the engine to transmission bend-

ing brace. Tighten the bolts and nut to 41 N´m (30

ft.lbs.).

(28) Install starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - INSTALLA-

TION) and cooler line bracket.

(29) Connect cooler lines to transmission.

(30) Install transmission fill tube. Install new seal

on tube before installation.

(31) Install exhaust components.

(32) Install transfer case. Tighten transfer case

nuts to 35 N´m (26 ft.lbs.).

(33) Install the transfer case shift cable to the

cable support bracket and the transfer case shift

lever.

(34) Align and connect propeller shaft(s).

(35) Adjust gearshift linkage and throttle valve

cable if necessary.

(36) Lower vehicle.

(37) Fill transmission with MopartATF +4, type

9602, fluid.

21 - 42 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1575 of 2199

PRESSURE TEST

Overdrive clutch Fourth gear only Pressure should be 469-496 kPa (68-72 psi) with

closed throttle and increase to 620-896 kPa (90-130

psi) at 1/2 to 3/4 throttle.

Line pressure (at

accumulator)Closed throttle 372-414 kPa (54-60 psi).

Front servo Third or Fourth gear only No more than 21 kPa (3 psi) lower than line pressure.

Rear servo 1 range No more than 21 kPa (3 psi) lower than line pressure.

R range 1103 kPa (160 psi) at idle, builds to 1862 kPa (270 psi)

at 1600 rpm.

Governor D range closed throttle Pressure should respond smoothly to changes in mph

and return to 0-7 kPa (0-1.5 psi) when stopped with

transmission in D, 1, 2. Pressure above 7 kPa (1.5 psi)

at stand still will prevent transmission from

downshifting.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fitting, cooler line at trans 18 13 -

Bolt, torque convertor 31 - 270

Bolt, clevis bracket to crossmember 47 35 -

Bolt, clevis bracket to rear support 68 50 -

Bolt, driveplate to crankshaft 75 55 -

Plug, front band reaction 17 13 -

Locknut, front band adj. 34 25 -

Switch, park/neutral 34 25 -

Bolt, fluid pan 17 13 -

Screws, fluid filter 4 - 35

Bolt, oil pump 20 15 -

Bolt, overrunning clutch cam 17 13 -

Bolt, O/D to trans. 34 25 -

Bolt, O/D piston retainer 17 13 -

Plug, pressure test port 14 10 -

Bolt, reaction shaft support 20 15 -

Locknut, rear band 41 30 -

Bolt, speedometer adapter 11 - 100

Screw, vehicle speed sensor 2.5 - 21

Bolt, valve body to case 12 - 100

Sensor, trans speed 27 20 -

Screw, solenoid wiring connector 4 - 35

Screw, solenoid to transfer plate 4 - 35

21 - 56 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1584 of 2199

(8) Engine starts must be possible with shifter

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gate

positions other than PARK or NEUTRAL.

(9) With shifter lever handle push-button not

depressed and lever detent in:

²PARK position- apply forward force on center of

handle and remove pressure. Engine start must be

possible.

²PARK position- apply rearward force on center

of handle and remove pressure. Engine start must be

possible.

²NEUTRAL position- engine start must be possi-

ble.

²NEUTRAL position, engine running and brakes

applied- Apply forward force on center of shift han-

dle. Transmission should not be able to shift into

REVERSE detent.

ELECTRONIC GOVERNOR

DESCRIPTION

Governor pressure is controlled electronically. Com-

ponents used for governor pressure control include:

²Governor body

²Valve body transfer plate

²Governor pressure solenoid valve

²Governor pressure sensor

²Fluid temperature thermistor

²Throttle position sensor (TPS)

²Transmission speed sensor

²Powertrain control module (PCM)

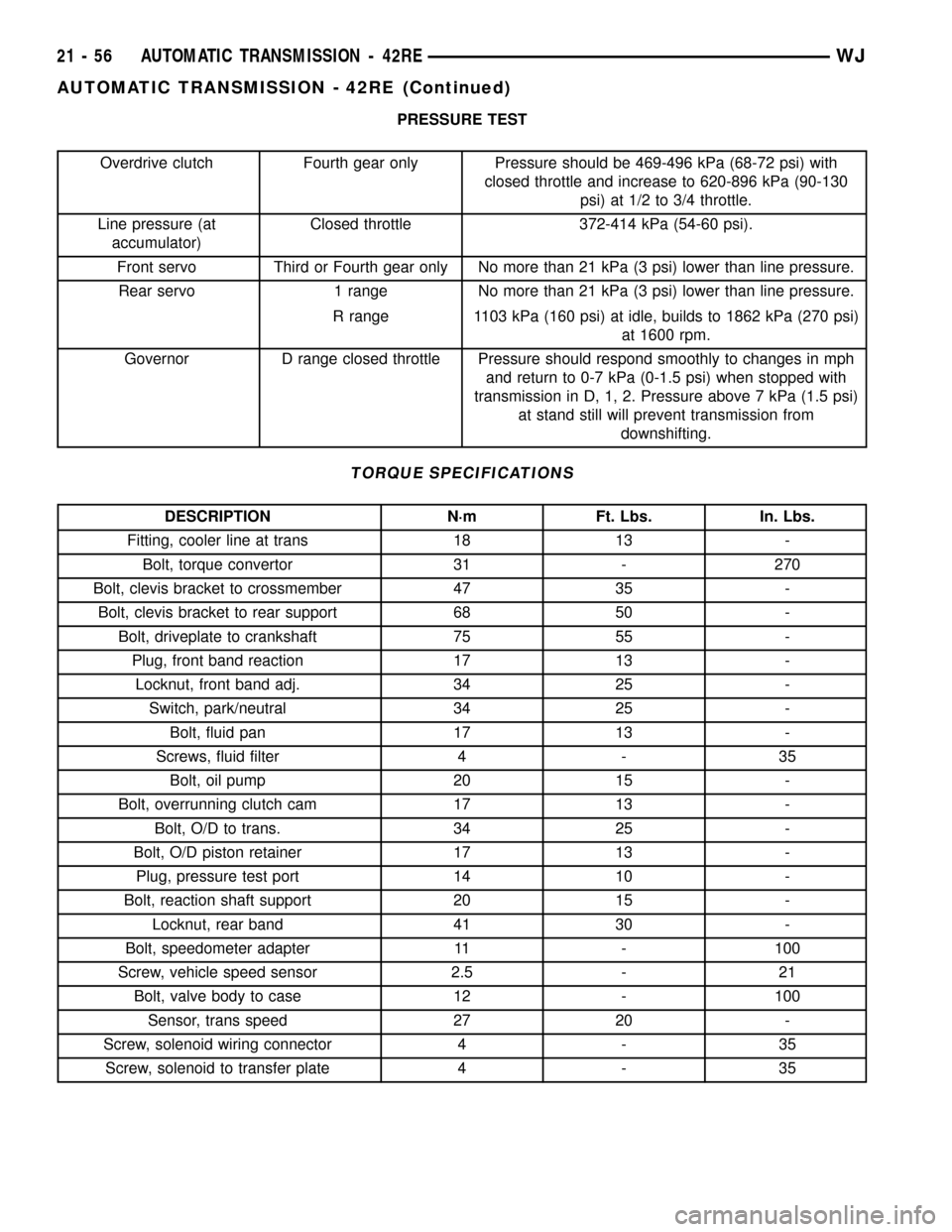

GOVERNOR PRESSURE SOLENOID VALVE

The solenoid valve is a duty-cycle solenoid which

regulates the governor pressure needed for upshifts

and downshifts. It is an electro-hydraulic device

located in the governor body on the valve body trans-

fer plate (Fig. 73).

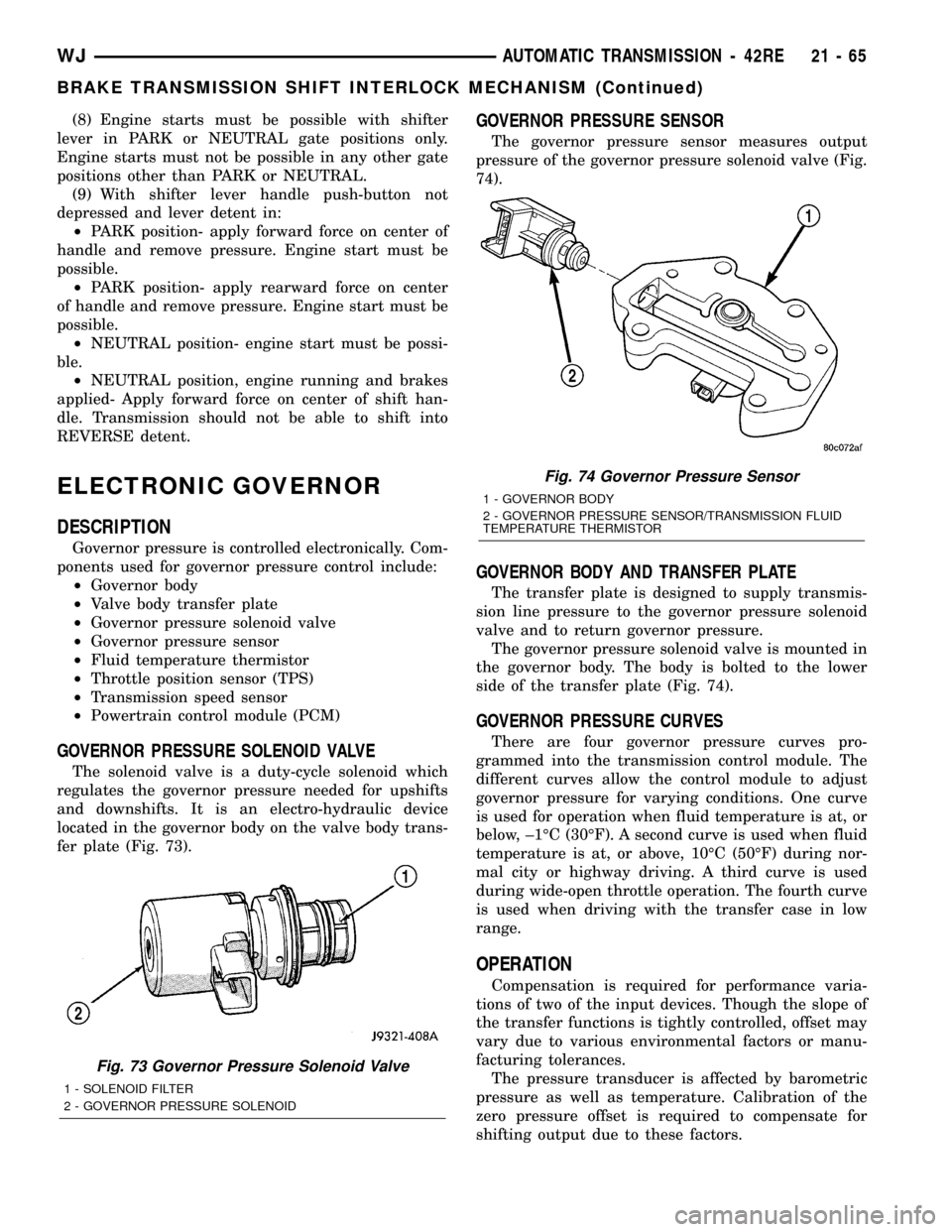

GOVERNOR PRESSURE SENSOR

The governor pressure sensor measures output

pressure of the governor pressure solenoid valve (Fig.

74).

GOVERNOR BODY AND TRANSFER PLATE

The transfer plate is designed to supply transmis-

sion line pressure to the governor pressure solenoid

valve and to return governor pressure.

The governor pressure solenoid valve is mounted in

the governor body. The body is bolted to the lower

side of the transfer plate (Fig. 74).

GOVERNOR PRESSURE CURVES

There are four governor pressure curves pro-

grammed into the transmission control module. The

different curves allow the control module to adjust

governor pressure for varying conditions. One curve

is used for operation when fluid temperature is at, or

below, ±1ÉC (30ÉF). A second curve is used when fluid

temperature is at, or above, 10ÉC (50ÉF) during nor-

mal city or highway driving. A third curve is used

during wide-open throttle operation. The fourth curve

is used when driving with the transfer case in low

range.

OPERATION

Compensation is required for performance varia-

tions of two of the input devices. Though the slope of

the transfer functions is tightly controlled, offset may

vary due to various environmental factors or manu-

facturing tolerances.

The pressure transducer is affected by barometric

pressure as well as temperature. Calibration of the

zero pressure offset is required to compensate for

shifting output due to these factors.

Fig. 73 Governor Pressure Solenoid Valve

1 - SOLENOID FILTER

2 - GOVERNOR PRESSURE SOLENOID

Fig. 74 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

WJAUTOMATIC TRANSMISSION - 42RE 21 - 65

BRAKE TRANSMISSION SHIFT INTERLOCK MECHANISM (Continued)