Transmission control unit JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 137 of 2199

and therefore creates pressure in the pump. The tun-

ing of the front and rear axle orifices and valves

inside the gerotor pump is unique and each system

includes a torque-limiting pressure relief valve to

protect the clutch pack, which also facilitates vehicle

control under extreme side-to-side traction varia-

tions. The resulting pressure is applied to the clutch

pack and the transfer of torque is completed.

Under conditions in which opposite wheels are on

surfaces with widely different friction characteristics,

Vari-loktdelivers far more torque to the wheel on

the higher traction surface than do conventional

Trac-loktsystems. Because conventional Trac-lokt

differentials are initially pre-loaded to assure torque

transfer, normal driving (where inner and outer

wheel speeds differ during cornering, etc.) produces

torque transfer during even slight side-to-side speed

variations. Since these devices rely on friction from

this preload to transfer torque, normal use tends to

cause wear that reduces the ability of the differential

to transfer torque over time. By design, the Vari-lokt

system is less subject to wear, remaining more con-

sistent over time in its ability to transfer torque. The

coupling assembly is serviced as a unit. From a ser-

vice standpoint the coupling also benefits from using

the same lubricant supply as the ring and pinion

gears.

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears, or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side±gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined

before starting any repair.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

3 - 92 REAR AXLE - 226RBAWJ

REAR AXLE - 226RBA (Continued)

Page 233 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

COOLANT LEVEL

CHANGES IN COOLANT

RESERVE/OVERFLOW

TANK. TEMPERATURE

GAUGE IS IN NORMAL

RANGE1. Level changes are to be expected

as coolant volume fluctuates with

engine temperature. If the level in

the tank was between the FULL and

ADD marks at normal operating

temperature, the level should return

to within that range after operation

at elevated temperatures.1. A normal condition. No repair is necessary.

FAN RUNS ALL THE

TIME1. Fan control sensors inoperative. 1. Check for DTC's. Verify sensor readings.

2. Fan control solenoid stuck9on9. 2. Check fan operation speeds. Refer to fan

speed operation table.

3. Fan control solenoid harness

damaged.3. Check for DTC 1499. Repair as required.

4. Transmission temperature too

high.4. Check for transmission over temp. DTC.

5. Engine coolant temperature too

high.5. (a) Check coolant level. Correct level as

required.

(b) Thermostat stuck. Replace thermostat.

(c) Water pump failed. Replace water pump.

(d) Coolant flow restricted. Clean radiator.

(e) Air flow over radiator obstructed.Remove

obstruction.

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAKS

ULTRAVIOLET LIGHT METHOD

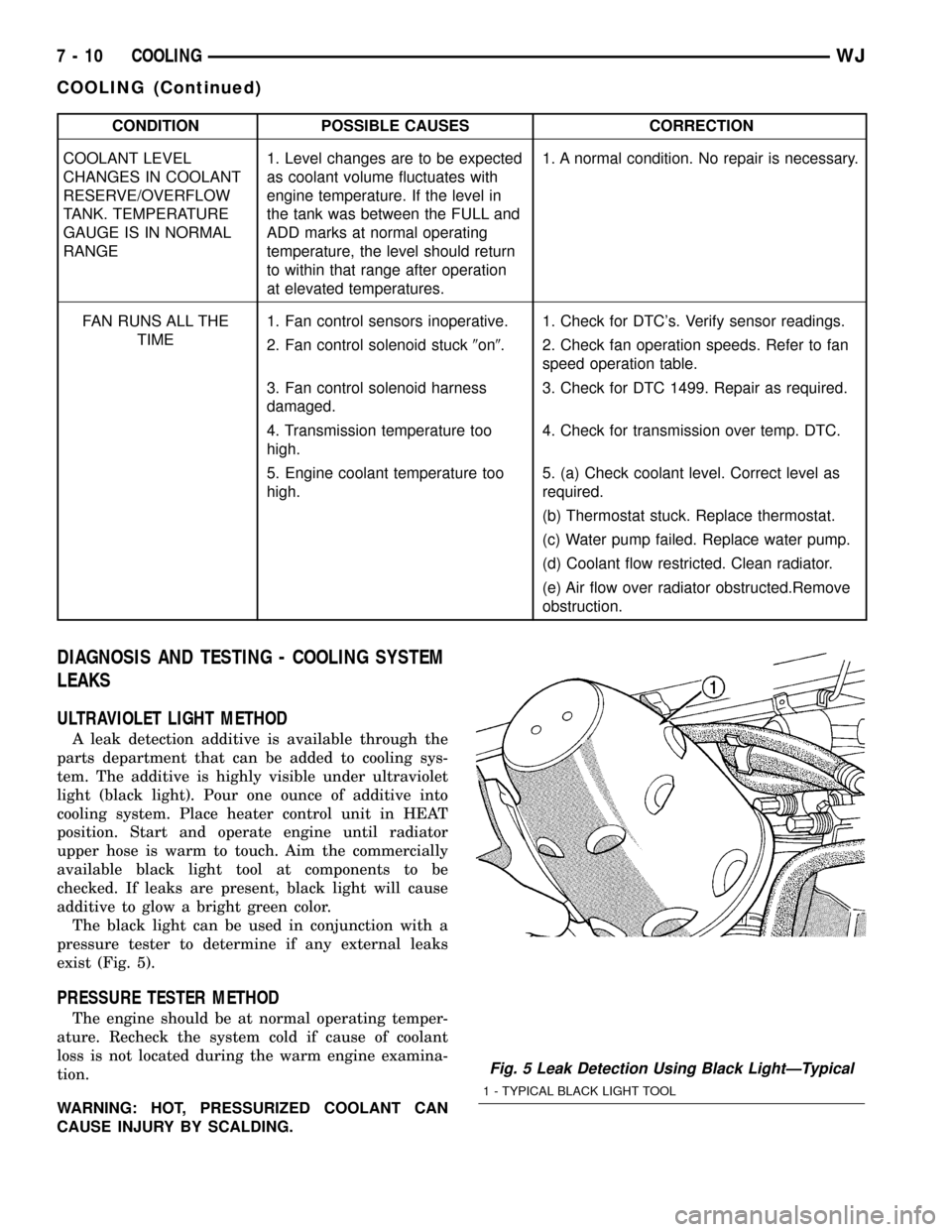

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Fig. 5 Leak Detection Using Black LightÐTypical

1 - TYPICAL BLACK LIGHT TOOL

7 - 10 COOLINGWJ

COOLING (Continued)

Page 264 of 2199

(6) Start the engine and operate at 2400 rpm.

Within ten minutes the air temperature (indicated on

the dial thermometer) should be up to 93É C (200É F).

Fan driveengagementshould have started to occur

at between 91É to 96É C (195É to 205É F). Engage-

ment is distinguishable by a definiteincreasein fan

flow noise (roaring). The timing light also will indi-

cate an increase in the speed of the fan.

(7) When the air temperature reaches 93É C (200É

F), remove the plastic sheet. Fan drivedisengage-

mentshould have started to occur at between 62É to

85É C (145É to 185É F). A definitedecreaseof fan

flow noise (roaring) should be noticed. If not, replace

the defective viscous fan drive unit.

PWM FAN CONTROL MODULE -

4.0L

DESCRIPTION

The pulse width modulated (PWM) radiator cooling

fan relay is located behind the front bumper fascia

below the right headlamp.

OPERATION

The PWM relay is used to control the speed of the

electric radiator cooling fan. It allows for multiple fan

speeds. This allows for improved fan noise and A/C

performance, better engine cooling, and additional

vehicle power.

PWM relay operation is controlled by the Power-

train Control Module (PCM). To operate the PWM

relay, the PCM looks at inputs from:

²Engine coolant temperature

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

²A/C switch position (A/C request)

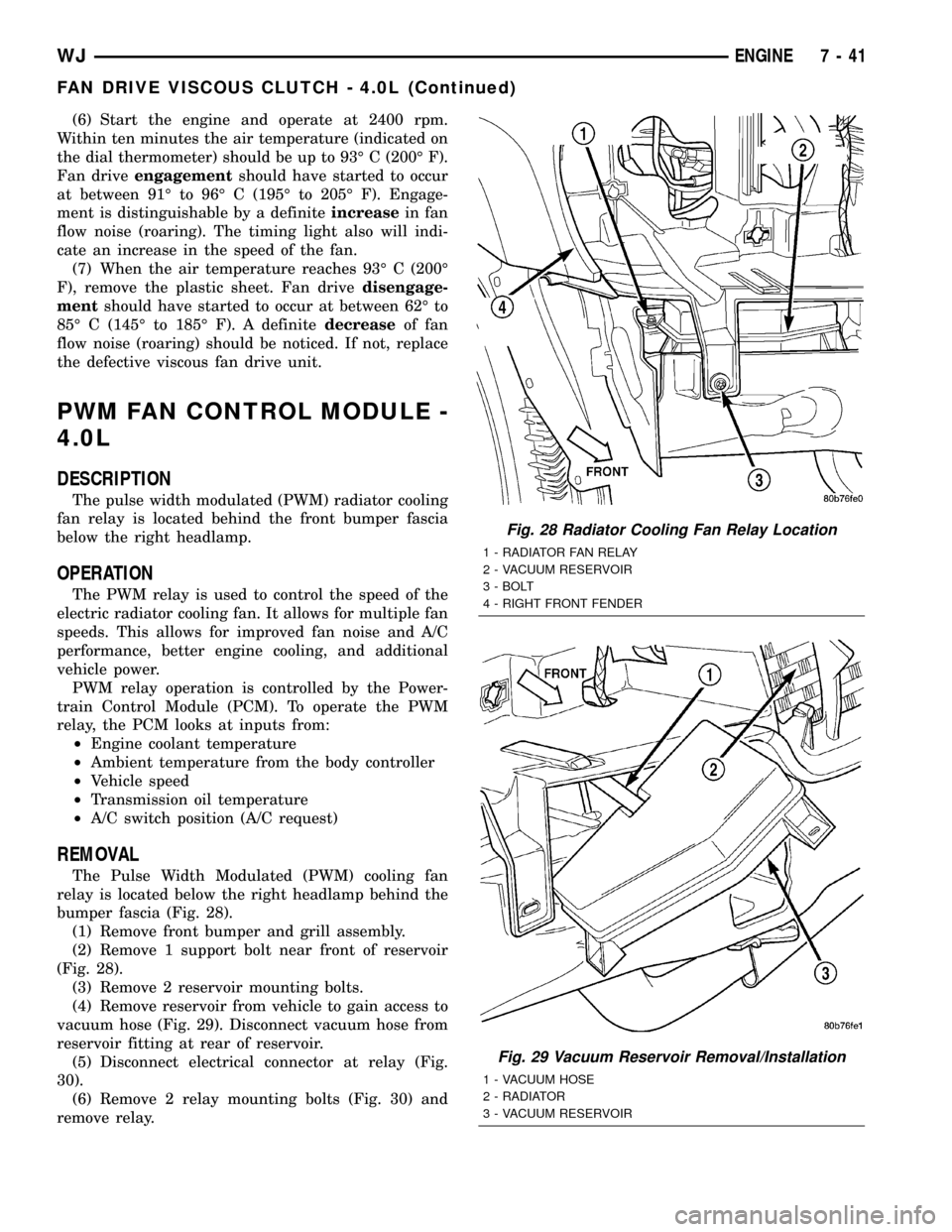

REMOVAL

The Pulse Width Modulated (PWM) cooling fan

relay is located below the right headlamp behind the

bumper fascia (Fig. 28).

(1) Remove front bumper and grill assembly.

(2) Remove 1 support bolt near front of reservoir

(Fig. 28).

(3) Remove 2 reservoir mounting bolts.

(4) Remove reservoir from vehicle to gain access to

vacuum hose (Fig. 29). Disconnect vacuum hose from

reservoir fitting at rear of reservoir.

(5) Disconnect electrical connector at relay (Fig.

30).

(6) Remove 2 relay mounting bolts (Fig. 30) and

remove relay.

Fig. 28 Radiator Cooling Fan Relay Location

1 - RADIATOR FAN RELAY

2 - VACUUM RESERVOIR

3 - BOLT

4 - RIGHT FRONT FENDER

Fig. 29 Vacuum Reservoir Removal/Installation

1 - VACUUM HOSE

2 - RADIATOR

3 - VACUUM RESERVOIR

WJENGINE 7 - 41

FAN DRIVE VISCOUS CLUTCH - 4.0L (Continued)

Page 298 of 2199

REMOVAL - EXHAUST-TO-BODY GROUND

STRAP

(1) Raise and support vehicle.

(2) Remove fasteners from exhaust, crossmember

and transmission/transfer case.

(3) Remove the ground strap.

INSTALLATION

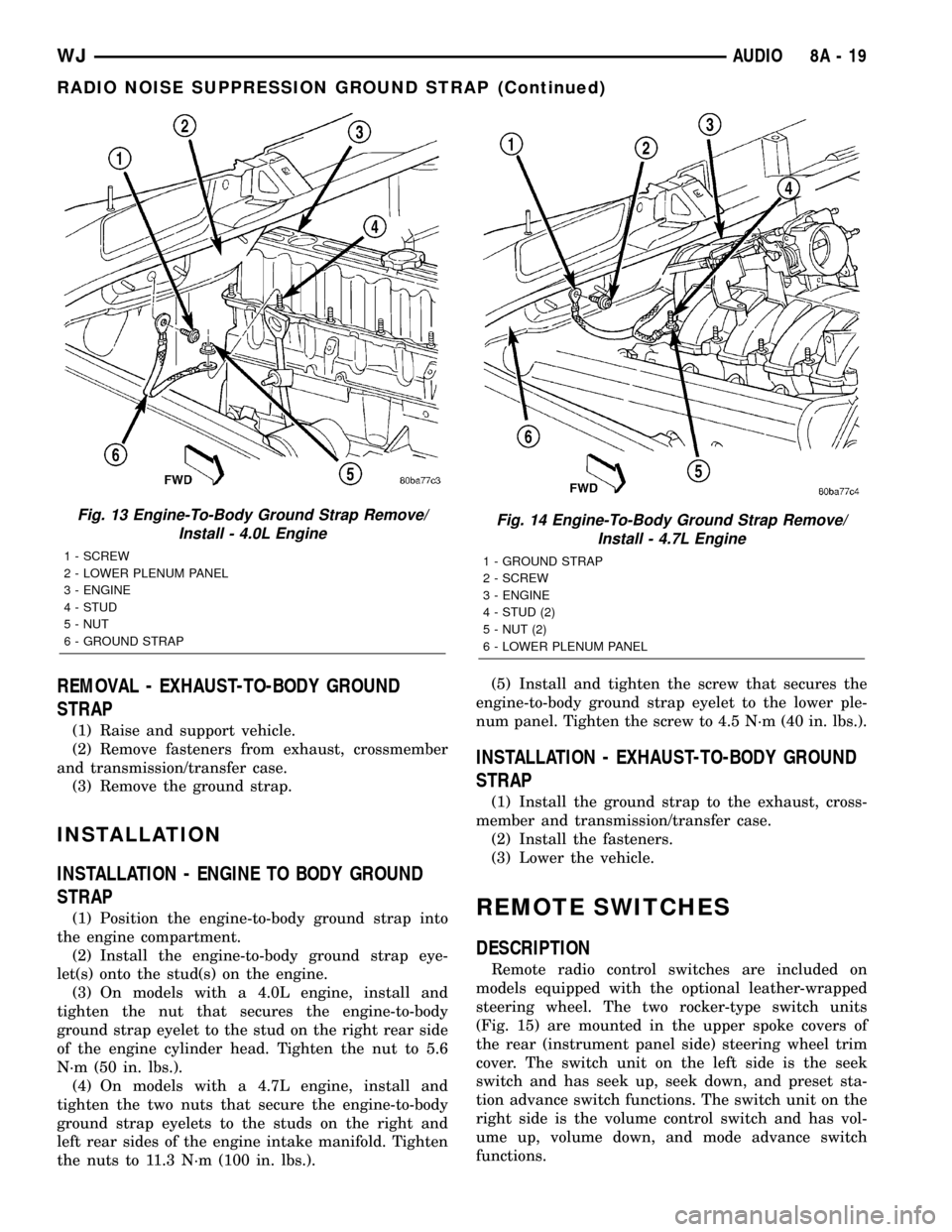

INSTALLATION - ENGINE TO BODY GROUND

STRAP

(1) Position the engine-to-body ground strap into

the engine compartment.

(2) Install the engine-to-body ground strap eye-

let(s) onto the stud(s) on the engine.

(3) On models with a 4.0L engine, install and

tighten the nut that secures the engine-to-body

ground strap eyelet to the stud on the right rear side

of the engine cylinder head. Tighten the nut to 5.6

N´m (50 in. lbs.).

(4) On models with a 4.7L engine, install and

tighten the two nuts that secure the engine-to-body

ground strap eyelets to the studs on the right and

left rear sides of the engine intake manifold. Tighten

the nuts to 11.3 N´m (100 in. lbs.).(5) Install and tighten the screw that secures the

engine-to-body ground strap eyelet to the lower ple-

num panel. Tighten the screw to 4.5 N´m (40 in. lbs.).

INSTALLATION - EXHAUST-TO-BODY GROUND

STRAP

(1) Install the ground strap to the exhaust, cross-

member and transmission/transfer case.

(2) Install the fasteners.

(3) Lower the vehicle.

REMOTE SWITCHES

DESCRIPTION

Remote radio control switches are included on

models equipped with the optional leather-wrapped

steering wheel. The two rocker-type switch units

(Fig. 15) are mounted in the upper spoke covers of

the rear (instrument panel side) steering wheel trim

cover. The switch unit on the left side is the seek

switch and has seek up, seek down, and preset sta-

tion advance switch functions. The switch unit on the

right side is the volume control switch and has vol-

ume up, volume down, and mode advance switch

functions.

Fig. 13 Engine-To-Body Ground Strap Remove/

Install - 4.0L Engine

1 - SCREW

2 - LOWER PLENUM PANEL

3 - ENGINE

4 - STUD

5 - NUT

6 - GROUND STRAP

Fig. 14 Engine-To-Body Ground Strap Remove/

Install - 4.7L Engine

1 - GROUND STRAP

2 - SCREW

3 - ENGINE

4 - STUD (2)

5 - NUT (2)

6 - LOWER PLENUM PANEL

WJAUDIO 8A - 19

RADIO NOISE SUPPRESSION GROUND STRAP (Continued)

Page 315 of 2199

(5) Connect the two instrument panel wire harness

connectors to the BCM.

(6) Reinstall the instrument panel fuse cover to

the bottom of the BCM and JB unit. (Refer to 8 -

ELECTRICAL/POWER DISTRIBUTION/FUSE

COVER - INSTALLATION).

(7) Connect the battery negative cable.

COMMUNICATION

DESCRIPTION

The Programmable Communication Interface (PCI)

data bus system is a single wire multiplex system

used for vehicle communications. Multiplexing is a

system that enables the transmission of several mes-

sages over a single channel or circuit.

Many of the control modules in a vehicle require

information from the same sensing device. Multiplex-

ing reduces wire harness complexity, sensor current

loads and controller hardware because each sensing

device is connected to only one controller, which

reads and distributes the sensor information to the

other controllers over the data bus. Also, because

each controller on the data bus can access the con-

troller sensor inputs to every other controller on the

data bus, more function and feature capabilities are

possible.

A multiplex system allows the information flowing

between controllers to be monitored using a diagnos-

tic scan tool. This system allows a control module to

broadcast message data out onto the bus where all

other control modules can read the messages that are

being sent. When a module reads a message on the

data bus that it requires, it relays that message to

its microprocessor. Each module ignores the mes-

sages on the data bus that it dosen't recognize.

OPERATION

Data exchange between modules is achieved by

serial transmission of encoded data over a single wire

broadcast network. The PCI data bus messages are

carried over the bus in the form of Variable Pulse

Width Modulated (VPWM) signals. The PCI data bus

speed is an average 10.4 Kilo-bits per second (Kbps).

The voltage network used to transmit messages

requires biasing and termination. Each module on

the PCI data bus system provides its own biasing

and termination. Each module (also referred to as a

node) terminates the bus through a terminating

resistor and a terminating capacitor. The Powertrain

Control Module (PCM) is the only dominant node for

the PCI data bus system.

The PCI bus uses low and high voltage levels to

generate signals. The voltage on the buss varies

between zero and seven and one-half volts. The lowand high voltage levels are generated by means of

variable-pulse width modulation to form signals of

varying length.

When a module is transmitting on the bus, it is

reading the bus at the same time to ensure message

integrity.

Each module is capable of transmitting and receiv-

ing data simultaneously.

The PCI data bus can be monitored using the

DRBIIItscan tool. It is possible for the bus to pass

all DRBIIIttests and still be faulty if the voltage

parameters are all within the specified range and

false messages are being sent.

CONTROLLER ANTILOCK

BRAKE

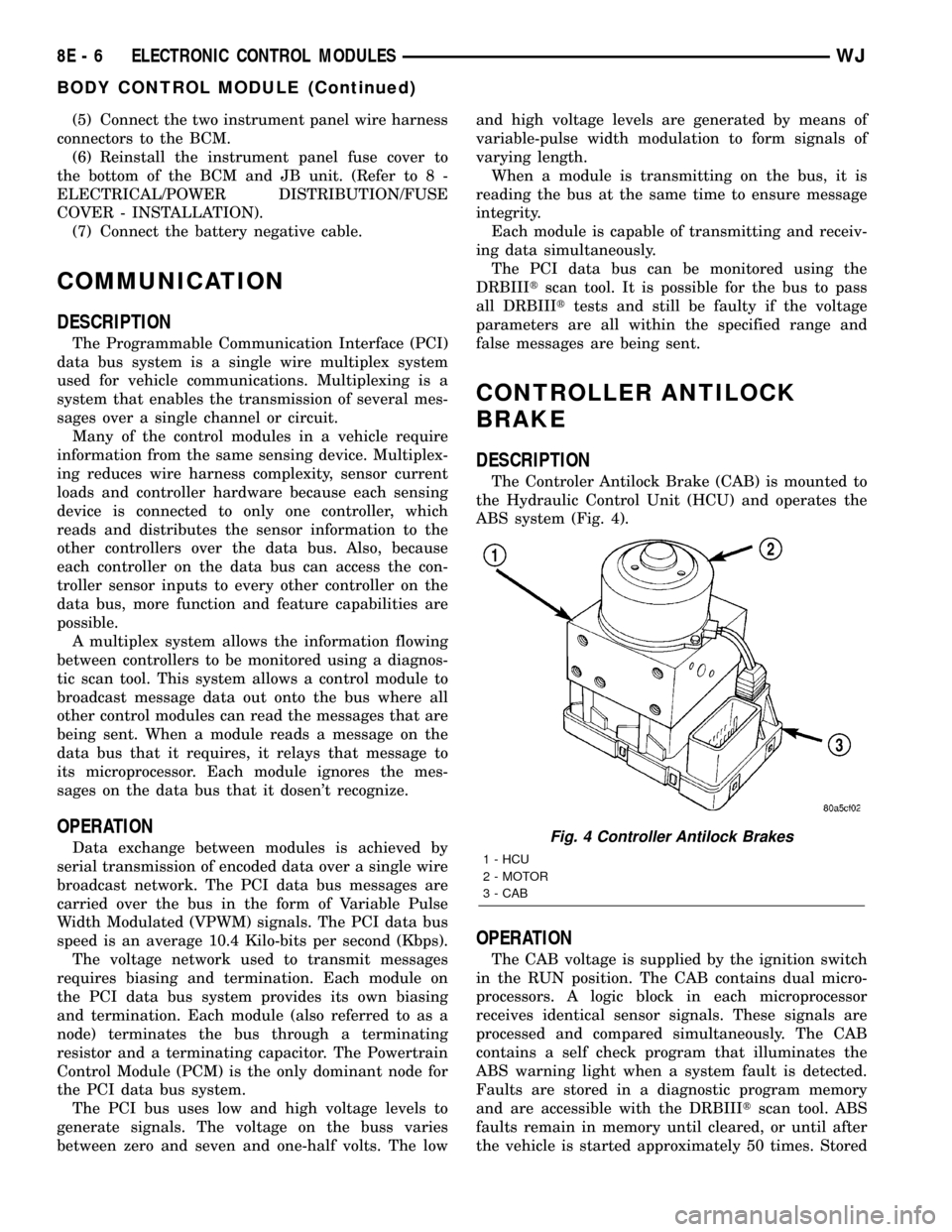

DESCRIPTION

The Controler Antilock Brake (CAB) is mounted to

the Hydraulic Control Unit (HCU) and operates the

ABS system (Fig. 4).

OPERATION

The CAB voltage is supplied by the ignition switch

in the RUN position. The CAB contains dual micro-

processors. A logic block in each microprocessor

receives identical sensor signals. These signals are

processed and compared simultaneously. The CAB

contains a self check program that illuminates the

ABS warning light when a system fault is detected.

Faults are stored in a diagnostic program memory

and are accessible with the DRBIIItscan tool. ABS

faults remain in memory until cleared, or until after

the vehicle is started approximately 50 times. Stored

Fig. 4 Controller Antilock Brakes

1 - HCU

2 - MOTOR

3 - CAB

8E - 6 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)

Page 320 of 2199

Programmable Communications Interface (PCI) data

bus network.

For diagnosis of the HSM, MHSM or the PCI data

bus, a DRBIIItscan tool and the proper Diagnostic

Procedures manual are recommended. The HSM or

MHSM cannot be repaired and, if faulty or damaged,

it must be replaced.

OPERATION

The MSM receives hard wired inputs from the

power seat switch and the potentiometers on each of

the driver side power seat motors. The MSM receives

messages over the PCI data bus from the Driver

Door Module (DDM) (memory switch status), the

Powertrain Control Module (PCM) (vehicle speed sta-

tus), and the Body Control Module (seat belt switch

status).The MSM will prevent the seat memory recall

function from being initiated if the driver side seat

belt is buckled, if the transmission gear selector lever

is not in the Park or Neutral positions, or if the vehi-

cle is moving.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE

Visually inspect the related wiring harness connec-

tors. Look for broken, bent, pushed out, or corroded

terminals. If any of the above conditions are present,

repair as necessary. If not, use a DRBIIItscan tool

and the proper Diagnostic Procedures Manual to test

the HSM or MHSM. For complete circuit diagrams,

refer toPower Seat Premium I/IIIin Wiring Dia-

grams.

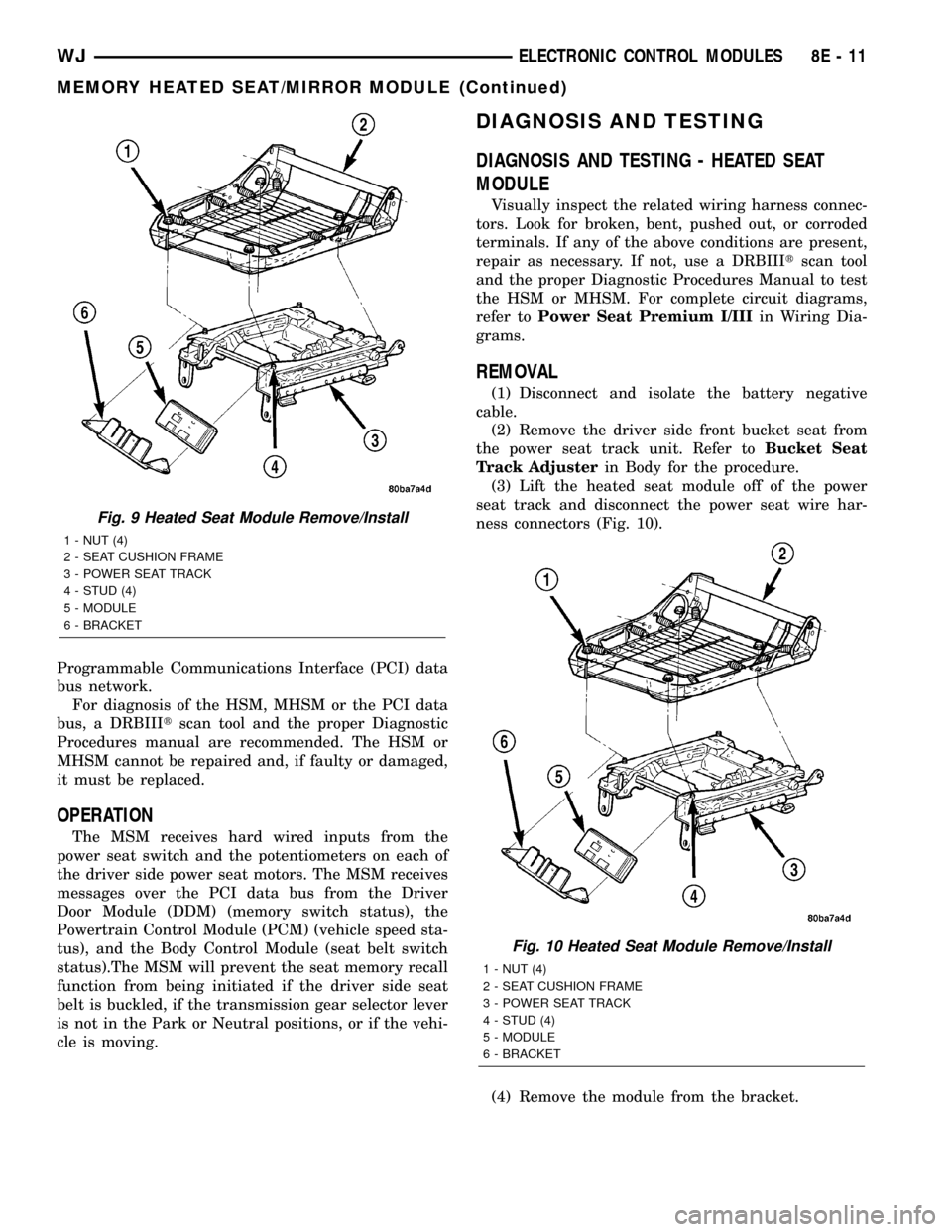

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front bucket seat from

the power seat track unit. Refer toBucket Seat

Track Adjusterin Body for the procedure.

(3) Lift the heated seat module off of the power

seat track and disconnect the power seat wire har-

ness connectors (Fig. 10).

(4) Remove the module from the bracket.

Fig. 9 Heated Seat Module Remove/Install

1 - NUT (4)

2 - SEAT CUSHION FRAME

3 - POWER SEAT TRACK

4 - STUD (4)

5 - MODULE

6 - BRACKET

Fig. 10 Heated Seat Module Remove/Install

1 - NUT (4)

2 - SEAT CUSHION FRAME

3 - POWER SEAT TRACK

4 - STUD (4)

5 - MODULE

6 - BRACKET

WJELECTRONIC CONTROL MODULES 8E - 11

MEMORY HEATED SEAT/MIRROR MODULE (Continued)

Page 326 of 2199

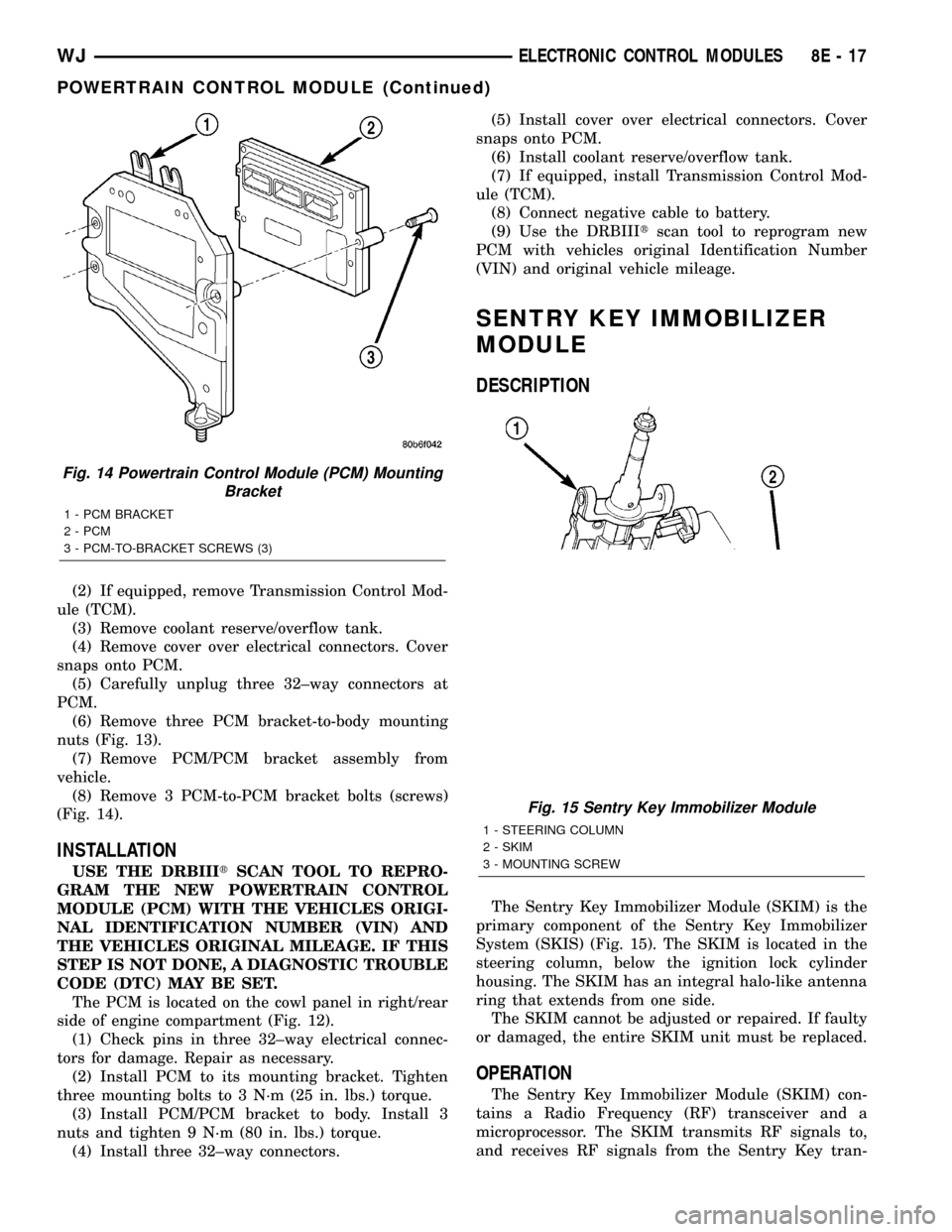

(2) If equipped, remove Transmission Control Mod-

ule (TCM).

(3) Remove coolant reserve/overflow tank.

(4) Remove cover over electrical connectors. Cover

snaps onto PCM.

(5) Carefully unplug three 32±way connectors at

PCM.

(6) Remove three PCM bracket-to-body mounting

nuts (Fig. 13).

(7) Remove PCM/PCM bracket assembly from

vehicle.

(8) Remove 3 PCM-to-PCM bracket bolts (screws)

(Fig. 14).

INSTALLATION

USE THE DRBIIItSCAN TOOL TO REPRO-

GRAM THE NEW POWERTRAIN CONTROL

MODULE (PCM) WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE VEHICLES ORIGINAL MILEAGE. IF THIS

STEP IS NOT DONE, A DIAGNOSTIC TROUBLE

CODE (DTC) MAY BE SET.

The PCM is located on the cowl panel in right/rear

side of engine compartment (Fig. 12).

(1) Check pins in three 32±way electrical connec-

tors for damage. Repair as necessary.

(2) Install PCM to its mounting bracket. Tighten

three mounting bolts to 3 N´m (25 in. lbs.) torque.

(3) Install PCM/PCM bracket to body. Install 3

nuts and tighten 9 N´m (80 in. lbs.) torque.

(4) Install three 32±way connectors.(5) Install cover over electrical connectors. Cover

snaps onto PCM.

(6) Install coolant reserve/overflow tank.

(7) If equipped, install Transmission Control Mod-

ule (TCM).

(8) Connect negative cable to battery.

(9) Use the DRBIIItscan tool to reprogram new

PCM with vehicles original Identification Number

(VIN) and original vehicle mileage.

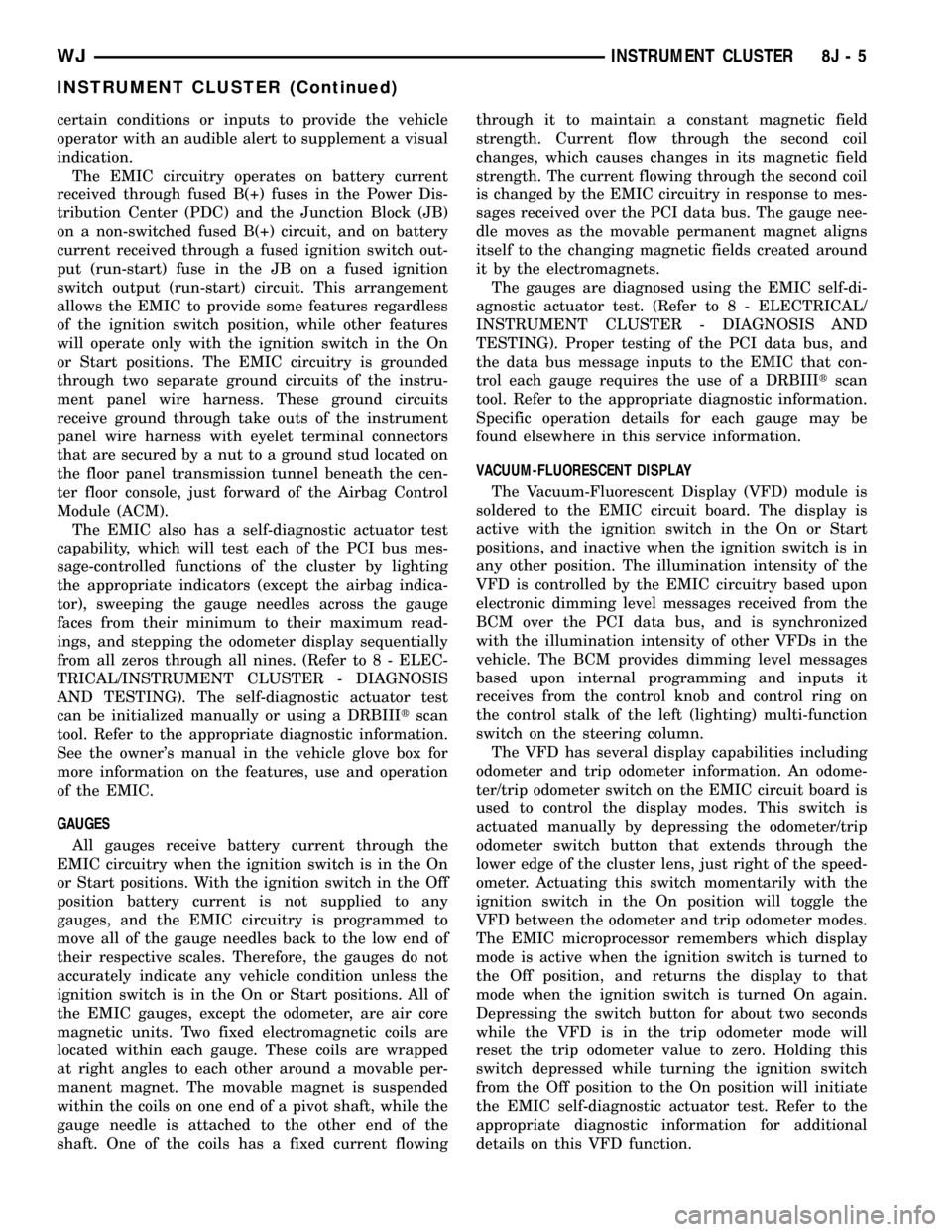

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) is the

primary component of the Sentry Key Immobilizer

System (SKIS) (Fig. 15). The SKIM is located in the

steering column, below the ignition lock cylinder

housing. The SKIM has an integral halo-like antenna

ring that extends from one side.

The SKIM cannot be adjusted or repaired. If faulty

or damaged, the entire SKIM unit must be replaced.

OPERATION

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a

microprocessor. The SKIM transmits RF signals to,

and receives RF signals from the Sentry Key tran-

Fig. 14 Powertrain Control Module (PCM) Mounting

Bracket

1 - PCM BRACKET

2 - PCM

3 - PCM-TO-BRACKET SCREWS (3)

Fig. 15 Sentry Key Immobilizer Module

1 - STEERING COLUMN

2 - SKIM

3 - MOUNTING SCREW

WJELECTRONIC CONTROL MODULES 8E - 17

POWERTRAIN CONTROL MODULE (Continued)

Page 420 of 2199

certain conditions or inputs to provide the vehicle

operator with an audible alert to supplement a visual

indication.

The EMIC circuitry operates on battery current

received through fused B(+) fuses in the Power Dis-

tribution Center (PDC) and the Junction Block (JB)

on a non-switched fused B(+) circuit, and on battery

current received through a fused ignition switch out-

put (run-start) fuse in the JB on a fused ignition

switch output (run-start) circuit. This arrangement

allows the EMIC to provide some features regardless

of the ignition switch position, while other features

will operate only with the ignition switch in the On

or Start positions. The EMIC circuitry is grounded

through two separate ground circuits of the instru-

ment panel wire harness. These ground circuits

receive ground through take outs of the instrument

panel wire harness with eyelet terminal connectors

that are secured by a nut to a ground stud located on

the floor panel transmission tunnel beneath the cen-

ter floor console, just forward of the Airbag Control

Module (ACM).

The EMIC also has a self-diagnostic actuator test

capability, which will test each of the PCI bus mes-

sage-controlled functions of the cluster by lighting

the appropriate indicators (except the airbag indica-

tor), sweeping the gauge needles across the gauge

faces from their minimum to their maximum read-

ings, and stepping the odometer display sequentially

from all zeros through all nines. (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). The self-diagnostic actuator test

can be initialized manually or using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EMIC.

GAUGES

All gauges receive battery current through the

EMIC circuitry when the ignition switch is in the On

or Start positions. With the ignition switch in the Off

position battery current is not supplied to any

gauges, and the EMIC circuitry is programmed to

move all of the gauge needles back to the low end of

their respective scales. Therefore, the gauges do not

accurately indicate any vehicle condition unless the

ignition switch is in the On or Start positions. All of

the EMIC gauges, except the odometer, are air core

magnetic units. Two fixed electromagnetic coils are

located within each gauge. These coils are wrapped

at right angles to each other around a movable per-

manent magnet. The movable magnet is suspended

within the coils on one end of a pivot shaft, while the

gauge needle is attached to the other end of the

shaft. One of the coils has a fixed current flowingthrough it to maintain a constant magnetic field

strength. Current flow through the second coil

changes, which causes changes in its magnetic field

strength. The current flowing through the second coil

is changed by the EMIC circuitry in response to mes-

sages received over the PCI data bus. The gauge nee-

dle moves as the movable permanent magnet aligns

itself to the changing magnetic fields created around

it by the electromagnets.

The gauges are diagnosed using the EMIC self-di-

agnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus, and

the data bus message inputs to the EMIC that con-

trol each gauge requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Specific operation details for each gauge may be

found elsewhere in this service information.

VACUUM-FLUORESCENT DISPLAY

The Vacuum-Fluorescent Display (VFD) module is

soldered to the EMIC circuit board. The display is

active with the ignition switch in the On or Start

positions, and inactive when the ignition switch is in

any other position. The illumination intensity of the

VFD is controlled by the EMIC circuitry based upon

electronic dimming level messages received from the

BCM over the PCI data bus, and is synchronized

with the illumination intensity of other VFDs in the

vehicle. The BCM provides dimming level messages

based upon internal programming and inputs it

receives from the control knob and control ring on

the control stalk of the left (lighting) multi-function

switch on the steering column.

The VFD has several display capabilities including

odometer and trip odometer information. An odome-

ter/trip odometer switch on the EMIC circuit board is

used to control the display modes. This switch is

actuated manually by depressing the odometer/trip

odometer switch button that extends through the

lower edge of the cluster lens, just right of the speed-

ometer. Actuating this switch momentarily with the

ignition switch in the On position will toggle the

VFD between the odometer and trip odometer modes.

The EMIC microprocessor remembers which display

mode is active when the ignition switch is turned to

the Off position, and returns the display to that

mode when the ignition switch is turned On again.

Depressing the switch button for about two seconds

while the VFD is in the trip odometer mode will

reset the trip odometer value to zero. Holding this

switch depressed while turning the ignition switch

from the Off position to the On position will initiate

the EMIC self-diagnostic actuator test. Refer to the

appropriate diagnostic information for additional

details on this VFD function.

WJINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 421 of 2199

The VFD is diagnosed using the EMIC self-diag-

nostic actuator test. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the data bus message inputs to the EMIC that con-

trol the VFD functions requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Specific operation details for the odometer

and trip odometer functions of the VFD may be found

elsewhere in this service information.

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC circuit

board. The turn signal indicators are hard wired. The

brake indicator is controlled by PCI data bus mes-

sages from the Controller Antilock Brake (CAB) as

well as by hard wired park brake switch and brake

fluid level switch inputs to the EMIC. The Malfunc-

tion Indicator Lamp (MIL) is normally controlled by

PCI data bus messages from the Powertrain Control

Module (PCM); however, if the EMIC loses PCI data

bus communication, the EMIC circuitry will automat-

ically turn the MIL on until PCI data bus communi-

cation is restored. The EMIC uses PCI data bus

messages from the Airbag Control Module (ACM), the

BCM, the PCM, the CAB, the Sentry Key Immobi-

lizer Module (SKIM), and the Transmission Control

Module (TCM) to control all of the remaining indica-

tors.

The various indicators are controlled by different

strategies; some receive fused ignition switch output

from the EMIC circuitry and have a switched ground,

others are grounded through the EMIC circuitry and

have a switched battery feed, while still others are

completely controlled by the EMIC microprocessor

based upon various hard wired and electronic mes-

sage inputs. Some indicators are illuminated at a

fixed intensity, while the illumination intensity of

others is synchronized with that of the EMIC general

illumination lamps.

The hard wired indicators are diagnosed using con-

ventional diagnostic methods. The EMIC and PCI

bus message controlled indicators are diagnosed

using the EMIC self-diagnostic actuator test. (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER -

DIAGNOSIS AND TESTING). Proper testing of the

PCI data bus and the electronic data bus message

inputs to the EMIC that control each indicator

require the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information. Specific details of

the operation for each indicator may be found else-

where in this service information.CLUSTER ILLUMINATION

Two types of general cluster illumination are avail-

able in this model. Base versions of the EMIC have

several incandescent illumination lamps, while pre-

mium versions of the EMIC have a single electro-lu-

minescent lamp. Both types of lamps provide cluster

back lighting whenever the exterior lighting is

turned On with the control knob on the left (lighting)

multi-function switch control stalk. The illumination

intensity of these lamps is adjusted by the EMIC

microprocessor based upon electronic dimming level

messages received from the Body Control Module

(BCM) over the PCI data bus. The BCM provides

electronic dimming level messages to the EMIC

based upon internal programming and inputs it

receives when the control ring on the left (lighting)

multi-function switch control stalk is rotated (down

to dim, up to brighten) to one of six available minor

detent positions.

The incandescent illumination lamps receive bat-

tery current at all times, while the ground for these

lamps is controlled by a 12-volt Pulse Width Modu-

lated (PWM) output of the EMIC electronic circuitry.

The illumination intensity of these bulbs and of the

vacuum-fluorescent electronic display are controlled

by the instrument cluster microprocessor based upon

dimming level messages received from the Body Con-

trol Module (BCM) over the PCI data bus. The BCM

uses inputs from the headlamp and panel dimmer

switches within the left (lighting) multi-function

switch control stalk and internal programming to

decide what dimming level message is required. The

BCM then sends the proper dimming level messages

to the EMIC over the PCI data bus.

The electro-luminescent lamp unit consists of lay-

ers of phosphor, carbon, idium tin oxide, and dielec-

tric applied by a silk-screen process between two

polyester membranes and includes a short pigtail

wire and connector. The lamp pigtail wire is con-

nected to a small connector receptacle on the EMIC

circuit board through a small clearance hole in the

cluster housing rear cover. The EMIC electronic cir-

cuitry also uses a PWM strategy to control the illu-

mination intensity of this lamp; however, the EMIC

powers this lamp with an Alternating Current (AC)

rated at 80 volts rms (root mean squared) and 415

Hertz, which excites the phosphor particles causing

them to luminesce.

The BCM also has several hard wired panel lamp

driver outputs and sends the proper panel lamps

dimming level messages over the PCI data bus to

coordinate the illumination intensity of all of the

instrument panel lighting and the VFDs of other

electronic modules on the PCI data bus. Vehicles

equipped with the Auto Headlamps option have an

automatic parade mode. In this mode, the BCM uses

8J - 6 INSTRUMENT CLUSTERWJ

INSTRUMENT CLUSTER (Continued)

Page 441 of 2199

Base cluster gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. Premium cluster gauge illumination is pro-

vided by an integral electro-luminescent lamp that is

serviced as a unit with the instrument cluster. The

oil pressure gauge is serviced as a unit with the

instrument cluster.

OPERATION

The oil pressure gauge gives an indication to the

vehicle operator of the engine oil pressure. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

oil pressure gauge is an air core magnetic unit that

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (run-start) circuit whenever the igni-

tion switch is in the On or Start positions. The clus-

ter is programmed to move the gauge needle back to

the low end of the scale after the ignition switch is

turned to the Off position. The instrument cluster

circuitry controls the gauge needle position and pro-

vides the following features:

²Engine Oil Pressure Normal Message- Each

time the cluster receives a message from the PCM

indicating the engine oil pressure is within the nor-

mal operating range [above 0.28 kg/cm (above 4

psi), the gauge needle is moved to the relative pres-

sure position of the gauge scale.

²Engine Oil Pressure Low Message- Each

time the cluster receives a message from the PCM

indicating the engine oil pressure is about 0.28

kg/cm or lower (about 4 psi or lower), the gauge

needle is moved to the far left (low) end of the gauge

scale. The gauge needle remains at the low end of

the scale until the cluster receives a message from

the PCM indicating that the engine oil pressure is

about 0.56 kg/cm or higher (about 8 psi or higher).

²Communication Error- If the cluster fails to

receive an engine oil pressure message, it will hold

the gauge needle at the last indication for about

twelve seconds or until a new engine oil pressure

message is received, whichever occurs first. After

twelve seconds, the cluster will return the gauge nee-

dle to the low end of the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back in order

to confirm the functionality of the gauge and the

cluster control circuitry.

The PCM continually monitors the engine oil pres-

sure sensor to determine the engine oil pressure. ThePCM then sends the proper engine oil pressure mes-

sages to the instrument cluster. For further diagnosis

of the oil pressure gauge or the instrument cluster

circuitry that controls the gauge, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). If the instrument cluster turns on

the check gauges indicator due to a low oil pressure

gauge reading, it may indicate that the engine or the

engine oiling system requires service. For proper

diagnosis of the engine oil pressure sensor, the PCM,

the PCI data bus, or the electronic message inputs to

the instrument cluster that control the oil pressure

gauge, a DRBIIItscan tool is required. Refer to the

appropriate diagnostic information.

OVERDRIVE OFF INDICATOR

DESCRIPTION

An overdrive off indicator is standard equipment

on all gasoline engine instrument clusters. The over-

drive off indicator is located in the lower edge of the

tachometer gauge dial face in the instrument cluster.

The overdrive off indicator consists of the words ªO/D

OFFº imprinted on an amber lens. The lens is

located behind a cutout in the opaque layer of the

tachometer gauge dial face overlay. The dark outer

layer of the gauge dial face overlay prevents the indi-

cator from being clearly visible when it is not illumi-

nated. The words ªO/D OFFº appear silhouetted

against an amber field through the translucent outer

layer of the gauge dial face overlay when the indica-

tor is illuminated from behind by a replaceable

incandescent bulb and bulb holder unit located on

the instrument cluster electronic circuit board. When

the exterior lighting is turned On, the illumination

intensity of the overdrive off indicator is dimmable,

which is adjusted using the panel lamps dimmer con-

trol ring on the control stalk of the left multi-func-

tion switch. The overdrive off indicator lens is

serviced as a unit with the instrument cluster.

OPERATION

The overdrive off indicator gives an indication to

the vehicle operator when the Off position of the

overdrive off switch has been selected, disabling the

electronically controlled overdrive feature of the auto-

matic transmission. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster over the Programmable

Communications Interface (PCI) data bus. These

messages are sent by the Powertrain Control Module

(PCM) or by the Transmission Control Module

(TCM), depending on the model of the automatic

transmission. The overdrive off indicator bulb is com-

8J - 26 INSTRUMENT CLUSTERWJ

OIL PRESSURE GAUGE (Continued)