cylinder block drain plug JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 234 of 2199

Carefully remove radiator pressure cap from filler

neck and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck

and examine lower inside sealing seat for nicks,

cracks, paint, dirt and solder residue. Inspect radia-

tor-to- reserve/overflow tank hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of filler neck. If cams are

damaged, seating of pressure cap valve and tester

seal will be affected.

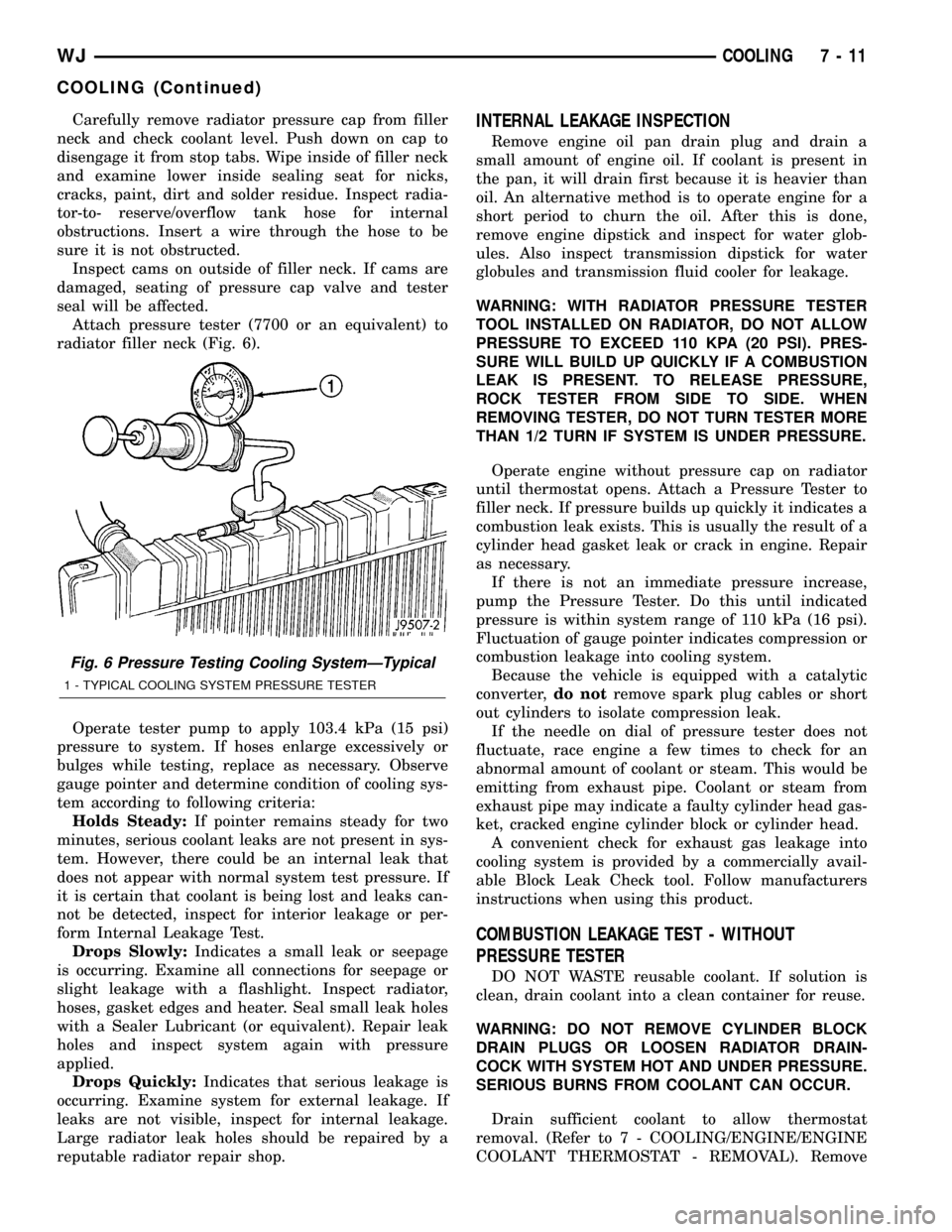

Attach pressure tester (7700 or an equivalent) to

radiator filler neck (Fig. 6).

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-

ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates a

combustion leak exists. This is usually the result of a

cylinder head gasket leak or crack in engine. Repair

as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT - REMOVAL). Remove

Fig. 6 Pressure Testing Cooling SystemÐTypical

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

WJCOOLING 7 - 11

COOLING (Continued)

Page 235 of 2199

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

DIAGNOSIS AND TESTING - COOLING SYSTEM

DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any

removed air.

STANDARD PROCEDURE

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 4.7L ENGINE

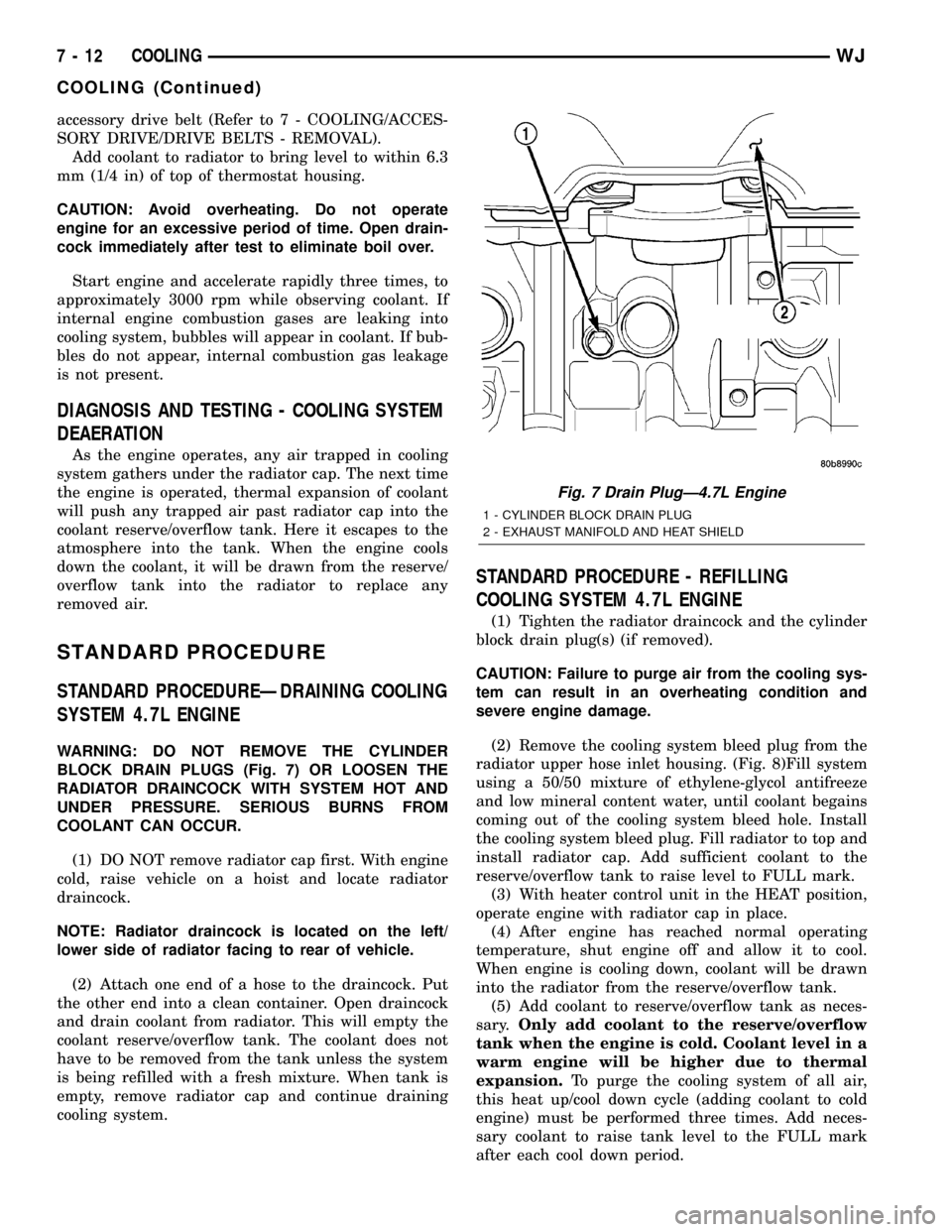

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS (Fig. 7) OR LOOSEN THE

RADIATOR DRAINCOCK WITH SYSTEM HOT AND

UNDER PRESSURE. SERIOUS BURNS FROM

COOLANT CAN OCCUR.

(1) DO NOT remove radiator cap first. With engine

cold, raise vehicle on a hoist and locate radiator

draincock.

NOTE: Radiator draincock is located on the left/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Open draincock

and drain coolant from radiator. This will empty the

coolant reserve/overflow tank. The coolant does not

have to be removed from the tank unless the system

is being refilled with a fresh mixture. When tank is

empty, remove radiator cap and continue draining

cooling system.

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 4.7L ENGINE

(1) Tighten the radiator draincock and the cylinder

block drain plug(s) (if removed).

CAUTION: Failure to purge air from the cooling sys-

tem can result in an overheating condition and

severe engine damage.

(2) Remove the cooling system bleed plug from the

radiator upper hose inlet housing. (Fig. 8)Fill system

using a 50/50 mixture of ethylene-glycol antifreeze

and low mineral content water, until coolant begains

coming out of the cooling system bleed hole. Install

the cooling system bleed plug. Fill radiator to top and

install radiator cap. Add sufficient coolant to the

reserve/overflow tank to raise level to FULL mark.

(3) With heater control unit in the HEAT position,

operate engine with radiator cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

When engine is cooling down, coolant will be drawn

into the radiator from the reserve/overflow tank.

(5) Add coolant to reserve/overflow tank as neces-

sary.Only add coolant to the reserve/overflow

tank when the engine is cold. Coolant level in a

warm engine will be higher due to thermal

expansion.To purge the cooling system of all air,

this heat up/cool down cycle (adding coolant to cold

engine) must be performed three times. Add neces-

sary coolant to raise tank level to the FULL mark

after each cool down period.

Fig. 7 Drain PlugÐ4.7L Engine

1 - CYLINDER BLOCK DRAIN PLUG

2 - EXHAUST MANIFOLD AND HEAT SHIELD

7 - 12 COOLINGWJ

COOLING (Continued)

Page 236 of 2199

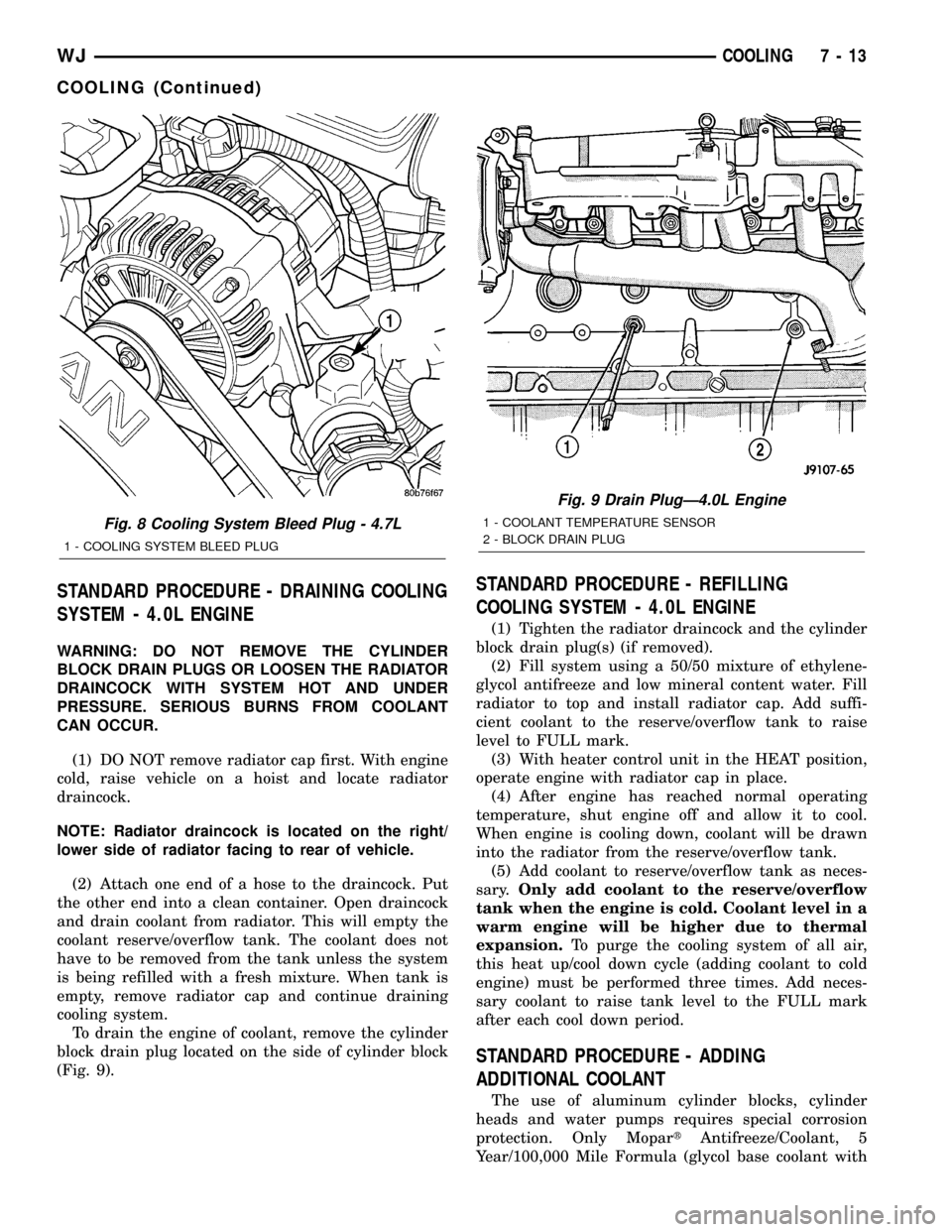

STANDARD PROCEDURE - DRAINING COOLING

SYSTEM - 4.0L ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(1) DO NOT remove radiator cap first. With engine

cold, raise vehicle on a hoist and locate radiator

draincock.

NOTE: Radiator draincock is located on the right/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Open draincock

and drain coolant from radiator. This will empty the

coolant reserve/overflow tank. The coolant does not

have to be removed from the tank unless the system

is being refilled with a fresh mixture. When tank is

empty, remove radiator cap and continue draining

cooling system.

To drain the engine of coolant, remove the cylinder

block drain plug located on the side of cylinder block

(Fig. 9).

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM - 4.0L ENGINE

(1) Tighten the radiator draincock and the cylinder

block drain plug(s) (if removed).

(2) Fill system using a 50/50 mixture of ethylene-

glycol antifreeze and low mineral content water. Fill

radiator to top and install radiator cap. Add suffi-

cient coolant to the reserve/overflow tank to raise

level to FULL mark.

(3) With heater control unit in the HEAT position,

operate engine with radiator cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

When engine is cooling down, coolant will be drawn

into the radiator from the reserve/overflow tank.

(5) Add coolant to reserve/overflow tank as neces-

sary.Only add coolant to the reserve/overflow

tank when the engine is cold. Coolant level in a

warm engine will be higher due to thermal

expansion.To purge the cooling system of all air,

this heat up/cool down cycle (adding coolant to cold

engine) must be performed three times. Add neces-

sary coolant to raise tank level to the FULL mark

after each cool down period.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

Fig. 8 Cooling System Bleed Plug - 4.7L

1 - COOLING SYSTEM BLEED PLUG

Fig. 9 Drain PlugÐ4.0L Engine

1 - COOLANT TEMPERATURE SENSOR

2 - BLOCK DRAIN PLUG

WJCOOLING 7 - 13

COOLING (Continued)

Page 255 of 2199

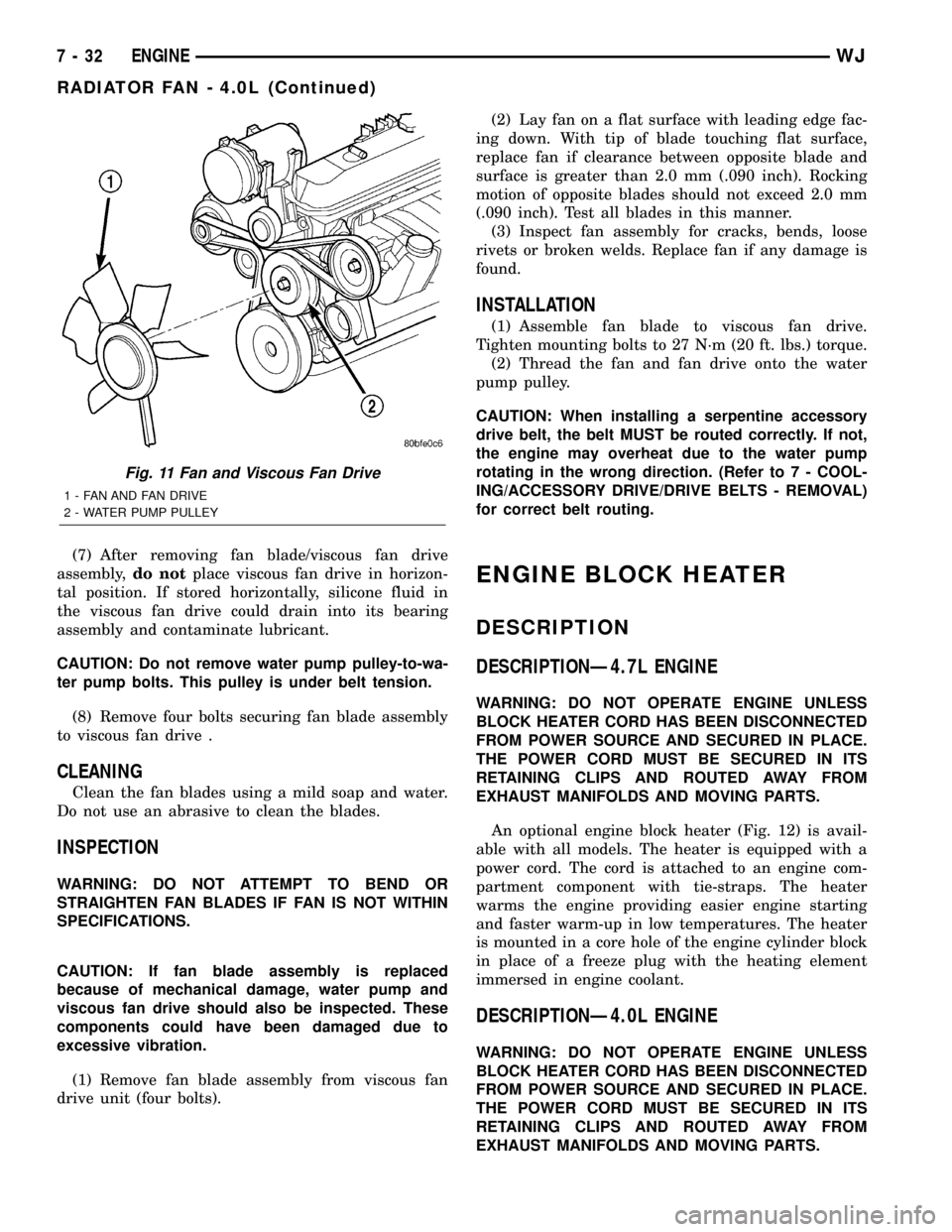

(7) After removing fan blade/viscous fan drive

assembly,do notplace viscous fan drive in horizon-

tal position. If stored horizontally, silicone fluid in

the viscous fan drive could drain into its bearing

assembly and contaminate lubricant.

CAUTION: Do not remove water pump pulley-to-wa-

ter pump bolts. This pulley is under belt tension.

(8) Remove four bolts securing fan blade assembly

to viscous fan drive .

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.

CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

(1) Remove fan blade assembly from viscous fan

drive unit (four bolts).(2) Lay fan on a flat surface with leading edge fac-

ing down. With tip of blade touching flat surface,

replace fan if clearance between opposite blade and

surface is greater than 2.0 mm (.090 inch). Rocking

motion of opposite blades should not exceed 2.0 mm

(.090 inch). Test all blades in this manner.

(3) Inspect fan assembly for cracks, bends, loose

rivets or broken welds. Replace fan if any damage is

found.

INSTALLATION

(1) Assemble fan blade to viscous fan drive.

Tighten mounting bolts to 27 N´m (20 ft. lbs.) torque.

(2) Thread the fan and fan drive onto the water

pump pulley.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction. (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL)

for correct belt routing.

ENGINE BLOCK HEATER

DESCRIPTION

DESCRIPTIONÐ4.7L ENGINE

WARNING: DO NOT OPERATE ENGINE UNLESS

BLOCK HEATER CORD HAS BEEN DISCONNECTED

FROM POWER SOURCE AND SECURED IN PLACE.

THE POWER CORD MUST BE SECURED IN ITS

RETAINING CLIPS AND ROUTED AWAY FROM

EXHAUST MANIFOLDS AND MOVING PARTS.

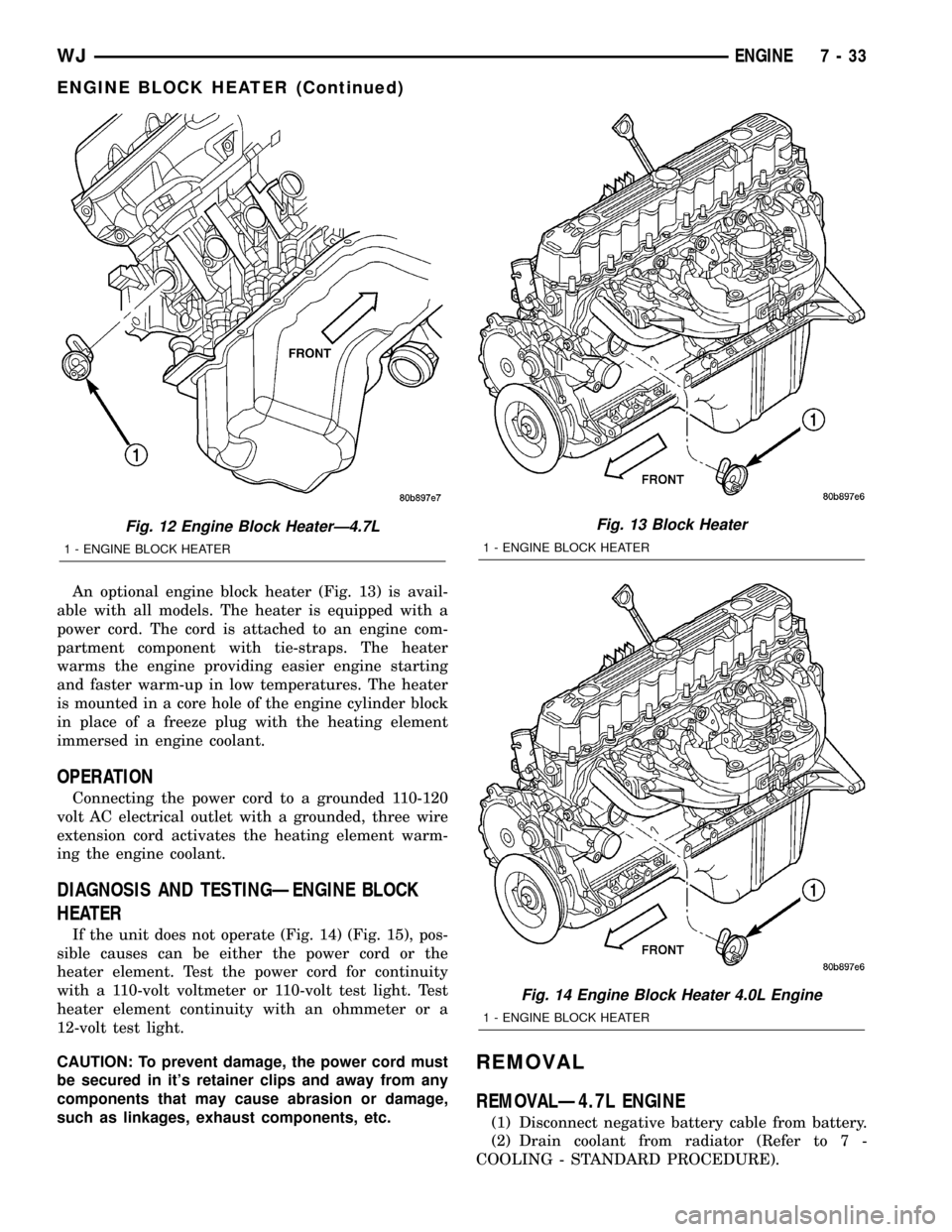

An optional engine block heater (Fig. 12) is avail-

able with all models. The heater is equipped with a

power cord. The cord is attached to an engine com-

partment component with tie-straps. The heater

warms the engine providing easier engine starting

and faster warm-up in low temperatures. The heater

is mounted in a core hole of the engine cylinder block

in place of a freeze plug with the heating element

immersed in engine coolant.

DESCRIPTIONÐ4.0L ENGINE

WARNING: DO NOT OPERATE ENGINE UNLESS

BLOCK HEATER CORD HAS BEEN DISCONNECTED

FROM POWER SOURCE AND SECURED IN PLACE.

THE POWER CORD MUST BE SECURED IN ITS

RETAINING CLIPS AND ROUTED AWAY FROM

EXHAUST MANIFOLDS AND MOVING PARTS.

Fig. 11 Fan and Viscous Fan Drive

1 - FAN AND FAN DRIVE

2 - WATER PUMP PULLEY

7 - 32 ENGINEWJ

RADIATOR FAN - 4.0L (Continued)

Page 256 of 2199

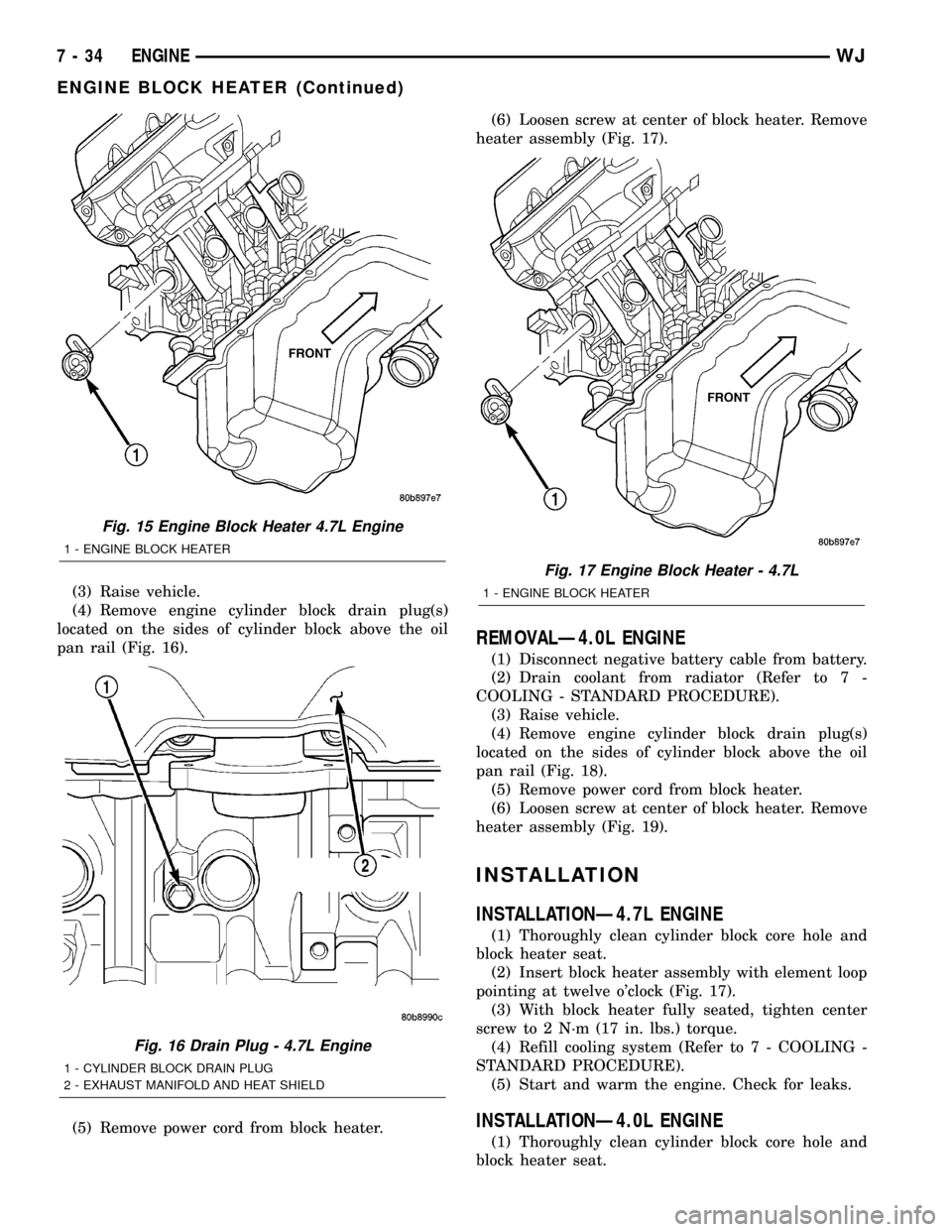

An optional engine block heater (Fig. 13) is avail-

able with all models. The heater is equipped with a

power cord. The cord is attached to an engine com-

partment component with tie-straps. The heater

warms the engine providing easier engine starting

and faster warm-up in low temperatures. The heater

is mounted in a core hole of the engine cylinder block

in place of a freeze plug with the heating element

immersed in engine coolant.

OPERATION

Connecting the power cord to a grounded 110-120

volt AC electrical outlet with a grounded, three wire

extension cord activates the heating element warm-

ing the engine coolant.

DIAGNOSIS AND TESTINGÐENGINE BLOCK

HEATER

If the unit does not operate (Fig. 14) (Fig. 15), pos-

sible causes can be either the power cord or the

heater element. Test the power cord for continuity

with a 110-volt voltmeter or 110-volt test light. Test

heater element continuity with an ohmmeter or a

12-volt test light.

CAUTION: To prevent damage, the power cord must

be secured in it's retainer clips and away from any

components that may cause abrasion or damage,

such as linkages, exhaust components, etc.

REMOVAL

REMOVALÐ4.7L ENGINE

(1) Disconnect negative battery cable from battery.

(2) Drain coolant from radiator (Refer to 7 -

COOLING - STANDARD PROCEDURE).

Fig. 12 Engine Block HeaterÐ4.7L

1 - ENGINE BLOCK HEATER

Fig. 13 Block Heater

1 - ENGINE BLOCK HEATER

Fig. 14 Engine Block Heater 4.0L Engine

1 - ENGINE BLOCK HEATER

WJENGINE 7 - 33

ENGINE BLOCK HEATER (Continued)

Page 257 of 2199

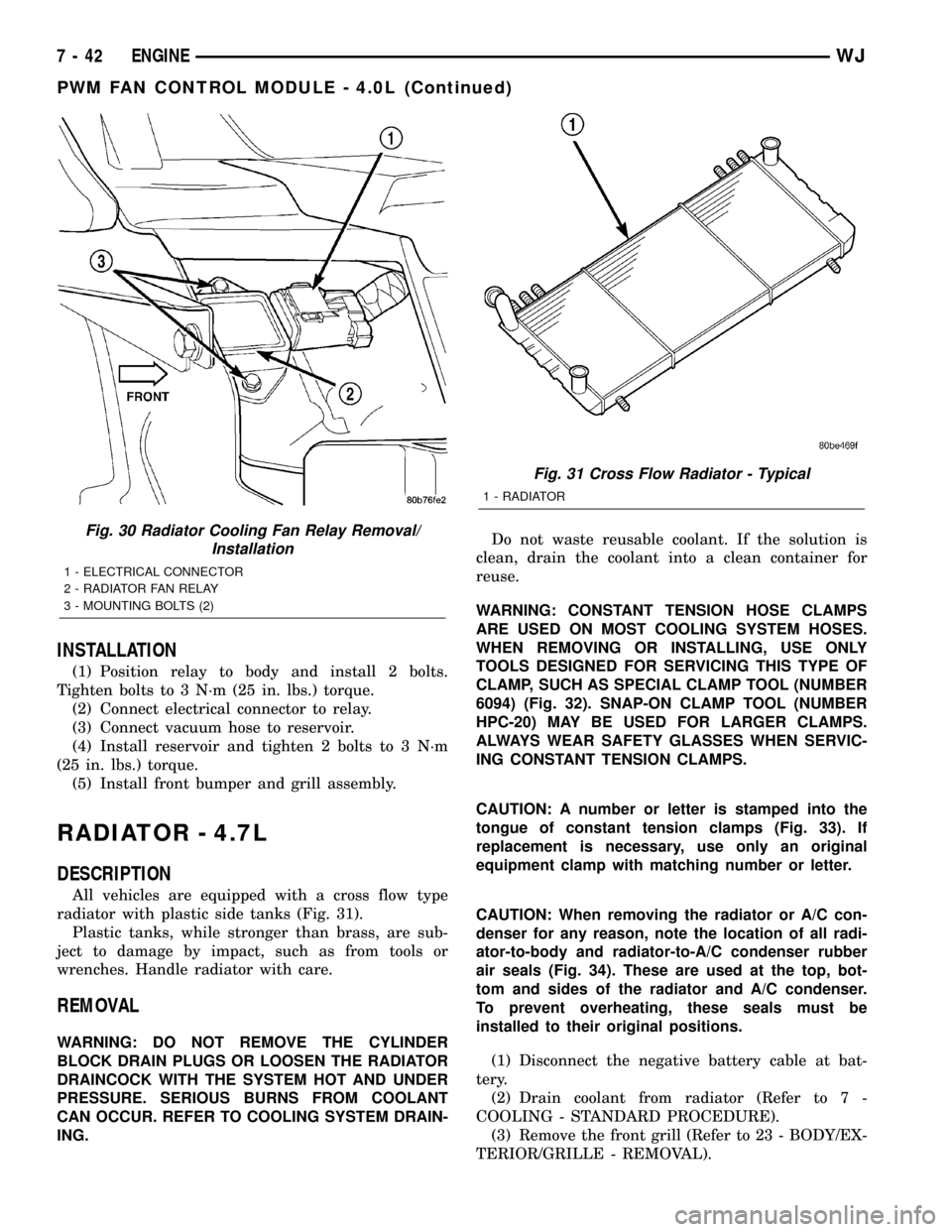

(3) Raise vehicle.

(4) Remove engine cylinder block drain plug(s)

located on the sides of cylinder block above the oil

pan rail (Fig. 16).

(5) Remove power cord from block heater.(6) Loosen screw at center of block heater. Remove

heater assembly (Fig. 17).

REMOVALÐ4.0L ENGINE

(1) Disconnect negative battery cable from battery.

(2) Drain coolant from radiator (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(3) Raise vehicle.

(4) Remove engine cylinder block drain plug(s)

located on the sides of cylinder block above the oil

pan rail (Fig. 18).

(5) Remove power cord from block heater.

(6) Loosen screw at center of block heater. Remove

heater assembly (Fig. 19).

INSTALLATION

INSTALLATIONÐ4.7L ENGINE

(1) Thoroughly clean cylinder block core hole and

block heater seat.

(2) Insert block heater assembly with element loop

pointing at twelve o'clock (Fig. 17).

(3) With block heater fully seated, tighten center

screw to 2 N´m (17 in. lbs.) torque.

(4) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Start and warm the engine. Check for leaks.

INSTALLATIONÐ4.0L ENGINE

(1) Thoroughly clean cylinder block core hole and

block heater seat.

Fig. 15 Engine Block Heater 4.7L Engine

1 - ENGINE BLOCK HEATER

Fig. 16 Drain Plug - 4.7L Engine

1 - CYLINDER BLOCK DRAIN PLUG

2 - EXHAUST MANIFOLD AND HEAT SHIELD

Fig. 17 Engine Block Heater - 4.7L

1 - ENGINE BLOCK HEATER

7 - 34 ENGINEWJ

ENGINE BLOCK HEATER (Continued)

Page 265 of 2199

INSTALLATION

(1) Position relay to body and install 2 bolts.

Tighten bolts to 3 N´m (25 in. lbs.) torque.

(2) Connect electrical connector to relay.

(3) Connect vacuum hose to reservoir.

(4) Install reservoir and tighten 2 bolts to 3 N´m

(25 in. lbs.) torque.

(5) Install front bumper and grill assembly.

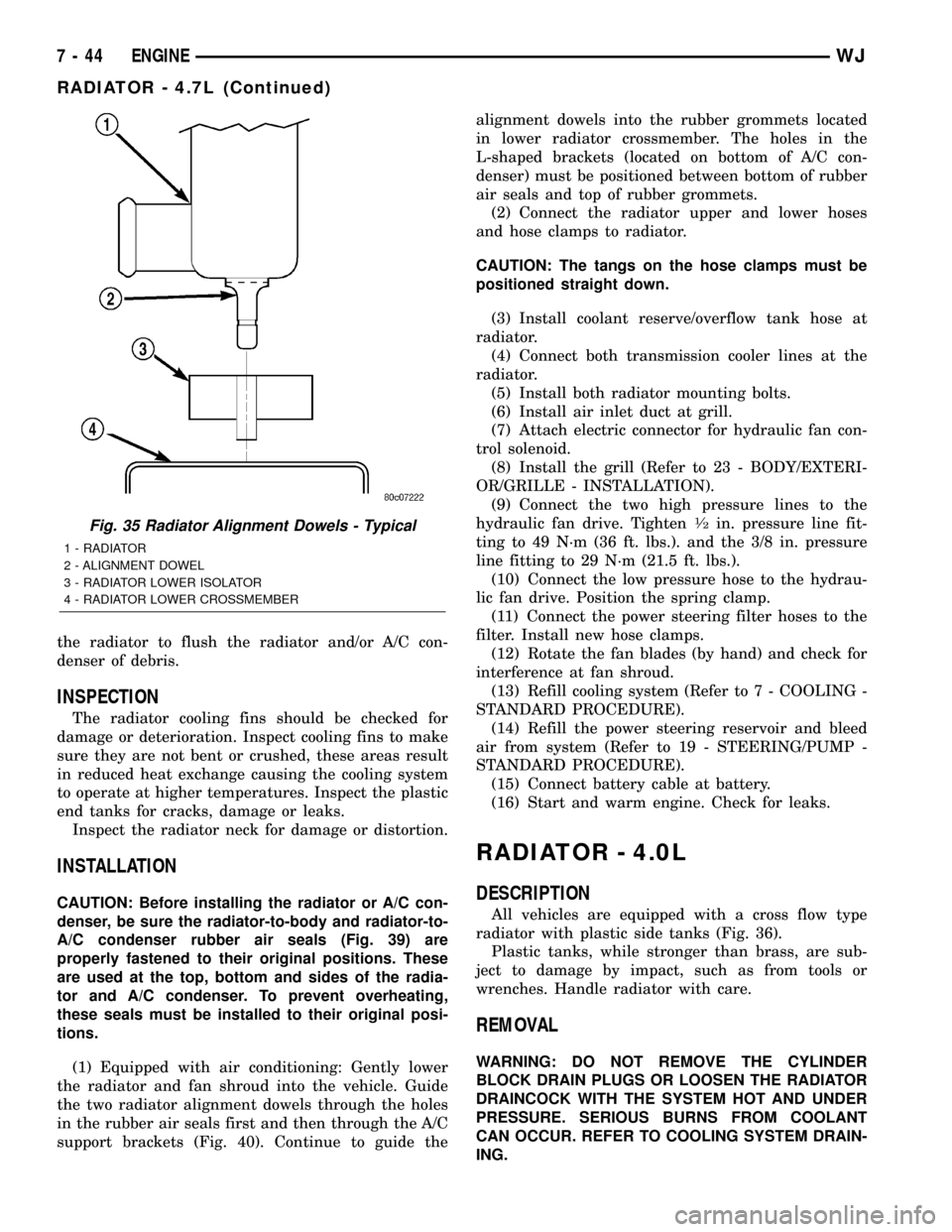

RADIATOR - 4.7L

DESCRIPTION

All vehicles are equipped with a cross flow type

radiator with plastic side tanks (Fig. 31).

Plastic tanks, while stronger than brass, are sub-

ject to damage by impact, such as from tools or

wrenches. Handle radiator with care.

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR. REFER TO COOLING SYSTEM DRAIN-

ING.Do not waste reusable coolant. If the solution is

clean, drain the coolant into a clean container for

reuse.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (Fig. 32). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS.

ALWAYS WEAR SAFETY GLASSES WHEN SERVIC-

ING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 33). If

replacement is necessary, use only an original

equipment clamp with matching number or letter.

CAUTION: When removing the radiator or A/C con-

denser for any reason, note the location of all radi-

ator-to-body and radiator-to-A/C condenser rubber

air seals (Fig. 34). These are used at the top, bot-

tom and sides of the radiator and A/C condenser.

To prevent overheating, these seals must be

installed to their original positions.

(1) Disconnect the negative battery cable at bat-

tery.

(2) Drain coolant from radiator (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(3) Remove the front grill (Refer to 23 - BODY/EX-

TERIOR/GRILLE - REMOVAL).

Fig. 30 Radiator Cooling Fan Relay Removal/

Installation

1 - ELECTRICAL CONNECTOR

2 - RADIATOR FAN RELAY

3 - MOUNTING BOLTS (2)

Fig. 31 Cross Flow Radiator - Typical

1 - RADIATOR

7 - 42 ENGINEWJ

PWM FAN CONTROL MODULE - 4.0L (Continued)

Page 267 of 2199

the radiator to flush the radiator and/or A/C con-

denser of debris.

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals (Fig. 39) are

properly fastened to their original positions. These

are used at the top, bottom and sides of the radia-

tor and A/C condenser. To prevent overheating,

these seals must be installed to their original posi-

tions.

(1) Equipped with air conditioning: Gently lower

the radiator and fan shroud into the vehicle. Guide

the two radiator alignment dowels through the holes

in the rubber air seals first and then through the A/C

support brackets (Fig. 40). Continue to guide thealignment dowels into the rubber grommets located

in lower radiator crossmember. The holes in the

L-shaped brackets (located on bottom of A/C con-

denser) must be positioned between bottom of rubber

air seals and top of rubber grommets.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator.

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator.

(4) Connect both transmission cooler lines at the

radiator.

(5) Install both radiator mounting bolts.

(6) Install air inlet duct at grill.

(7) Attach electric connector for hydraulic fan con-

trol solenoid.

(8) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(9) Connect the two high pressure lines to the

hydraulic fan drive. Tighten

1¤2in. pressure line fit-

ting to 49 N´m (36 ft. lbs.). and the 3/8 in. pressure

line fitting to 29 N´m (21.5 ft. lbs.).

(10) Connect the low pressure hose to the hydrau-

lic fan drive. Position the spring clamp.

(11) Connect the power steering filter hoses to the

filter. Install new hose clamps.

(12) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(13) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Refill the power steering reservoir and bleed

air from system (Refer to 19 - STEERING/PUMP -

STANDARD PROCEDURE).

(15) Connect battery cable at battery.

(16) Start and warm engine. Check for leaks.

RADIATOR - 4.0L

DESCRIPTION

All vehicles are equipped with a cross flow type

radiator with plastic side tanks (Fig. 36).

Plastic tanks, while stronger than brass, are sub-

ject to damage by impact, such as from tools or

wrenches. Handle radiator with care.

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR. REFER TO COOLING SYSTEM DRAIN-

ING.

Fig. 35 Radiator Alignment Dowels - Typical

1 - RADIATOR

2 - ALIGNMENT DOWEL

3 - RADIATOR LOWER ISOLATOR

4 - RADIATOR LOWER CROSSMEMBER

7 - 44 ENGINEWJ

RADIATOR - 4.7L (Continued)

Page 1254 of 2199

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

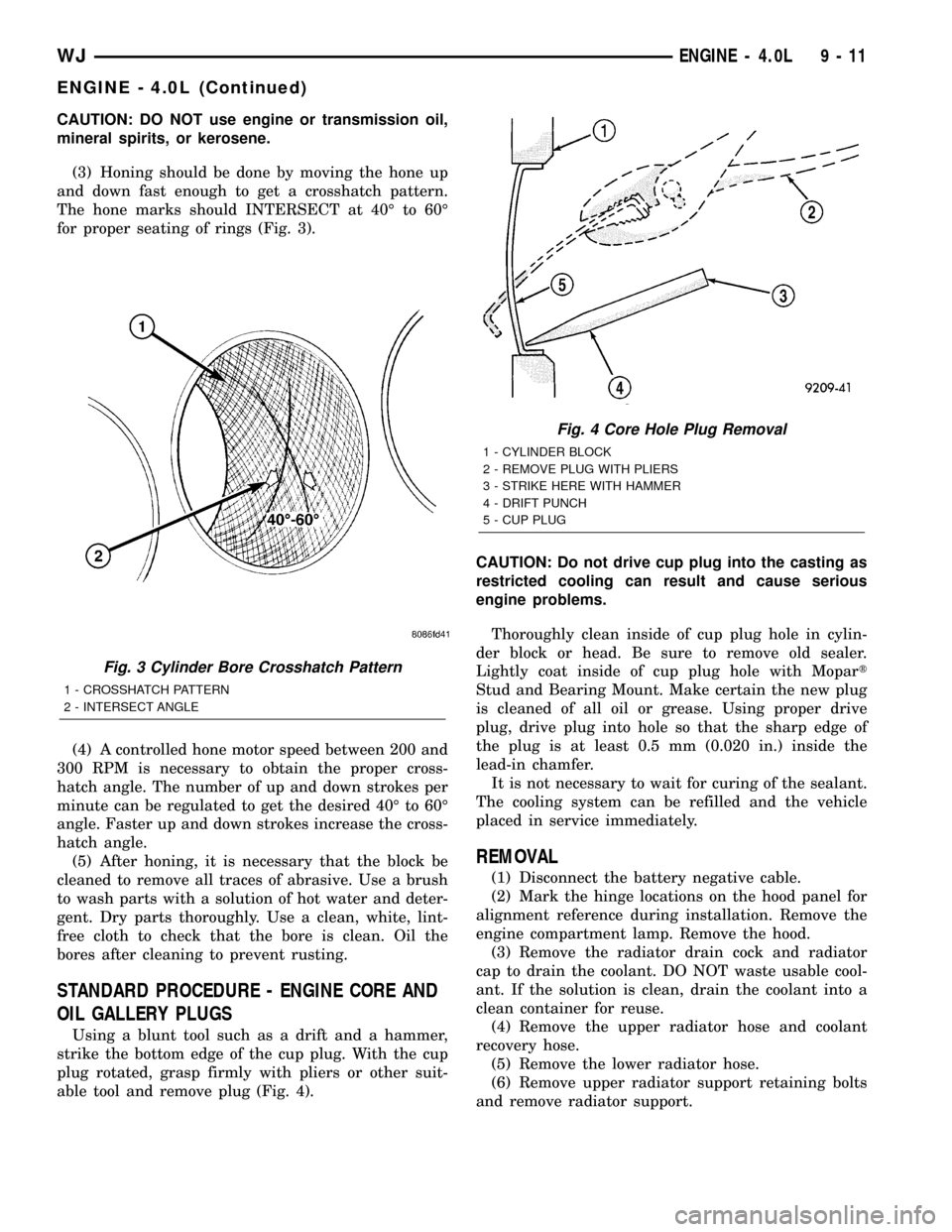

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 4).CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Mark the hinge locations on the hood panel for

alignment reference during installation. Remove the

engine compartment lamp. Remove the hood.

(3) Remove the radiator drain cock and radiator

cap to drain the coolant. DO NOT waste usable cool-

ant. If the solution is clean, drain the coolant into a

clean container for reuse.

(4) Remove the upper radiator hose and coolant

recovery hose.

(5) Remove the lower radiator hose.

(6) Remove upper radiator support retaining bolts

and remove radiator support.

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

Fig. 4 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.0L 9 - 11

ENGINE - 4.0L (Continued)

Page 1260 of 2199

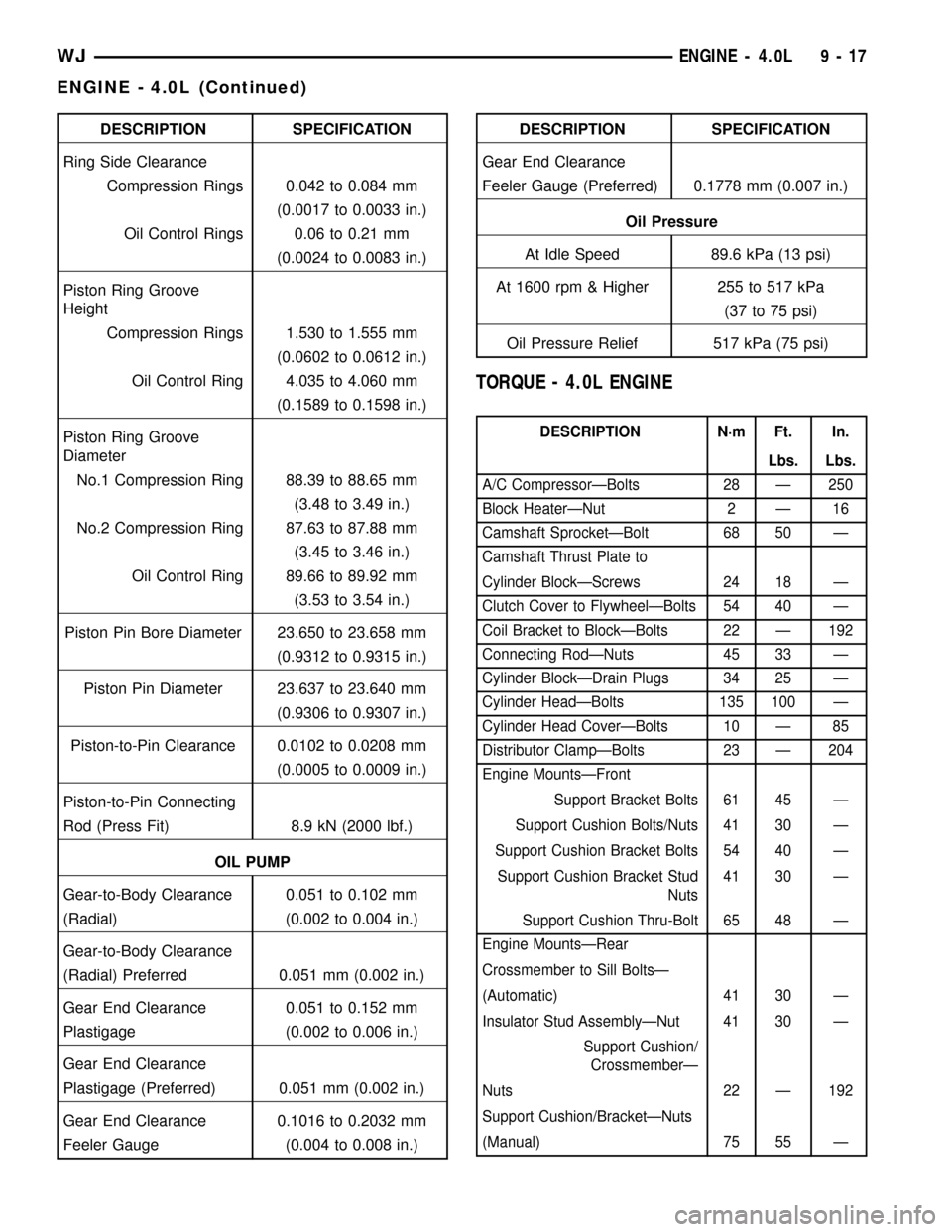

DESCRIPTION SPECIFICATION

Ring Side Clearance

Compression Rings 0.042 to 0.084 mm

(0.0017 to 0.0033 in.)

Oil Control Rings 0.06 to 0.21 mm

(0.0024 to 0.0083 in.)

Piston Ring Groove

Height

Compression Rings 1.530 to 1.555 mm

(0.0602 to 0.0612 in.)

Oil Control Ring 4.035 to 4.060 mm

(0.1589 to 0.1598 in.)

Piston Ring Groove

Diameter

No.1 Compression Ring 88.39 to 88.65 mm

(3.48 to 3.49 in.)

No.2 Compression Ring 87.63 to 87.88 mm

(3.45 to 3.46 in.)

Oil Control Ring 89.66 to 89.92 mm

(3.53 to 3.54 in.)

Piston Pin Bore Diameter 23.650 to 23.658 mm

(0.9312 to 0.9315 in.)

Piston Pin Diameter 23.637 to 23.640 mm

(0.9306 to 0.9307 in.)

Piston-to-Pin Clearance 0.0102 to 0.0208 mm

(0.0005 to 0.0009 in.)

Piston-to-Pin Connecting

Rod (Press Fit) 8.9 kN (2000 lbf.)

OIL PUMP

Gear-to-Body Clearance 0.051 to 0.102 mm

(Radial) (0.002 to 0.004 in.)

Gear-to-Body Clearance

(Radial) Preferred 0.051 mm (0.002 in.)

Gear End Clearance 0.051 to 0.152 mm

Plastigage (0.002 to 0.006 in.)

Gear End Clearance

Plastigage (Preferred) 0.051 mm (0.002 in.)

Gear End Clearance 0.1016 to 0.2032 mm

Feeler Gauge (0.004 to 0.008 in.)DESCRIPTION SPECIFICATION

Gear End Clearance

Feeler Gauge (Preferred) 0.1778 mm (0.007 in.)

Oil Pressure

At Idle Speed 89.6 kPa (13 psi)

At 1600 rpm & Higher 255 to 517 kPa

(37 to 75 psi)

Oil Pressure Relief 517 kPa (75 psi)

TORQUE - 4.0L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

A/C CompressorÐBolts 28 Ð 250

Block HeaterÐNut 2 Ð 16

Camshaft SprocketÐBolt 68 50 Ð

Camshaft Thrust Plate to

Cylinder BlockÐScrews 24 18 Ð

Clutch Cover to FlywheelÐBolts 54 40 Ð

Coil Bracket to BlockÐBolts 22 Ð 192

Connecting RodÐNuts 45 33 Ð

Cylinder BlockÐDrain Plugs 34 25 Ð

Cylinder HeadÐBolts 135 100 Ð

Cylinder Head CoverÐBolts 10 Ð 85

Distributor ClampÐBolts 23 Ð 204

Engine MountsÐFront

Support Bracket Bolts 61 45 Ð

Support Cushion Bolts/Nuts 41 30 Ð

Support Cushion Bracket Bolts 54 40 Ð

Support Cushion Bracket Stud

Nuts41 30 Ð

Support Cushion Thru-Bolt 65 48 Ð

Engine MountsÐRear

Crossmember to Sill BoltsÐ

(Automatic) 41 30 Ð

Insulator Stud AssemblyÐNut 41 30 Ð

Support Cushion/

CrossmemberÐ

Nuts 22 Ð 192

Support Cushion/BracketÐNuts

(Manual) 75 55 Ð

WJENGINE - 4.0L 9 - 17

ENGINE - 4.0L (Continued)