Rear hub JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 127 of 2199

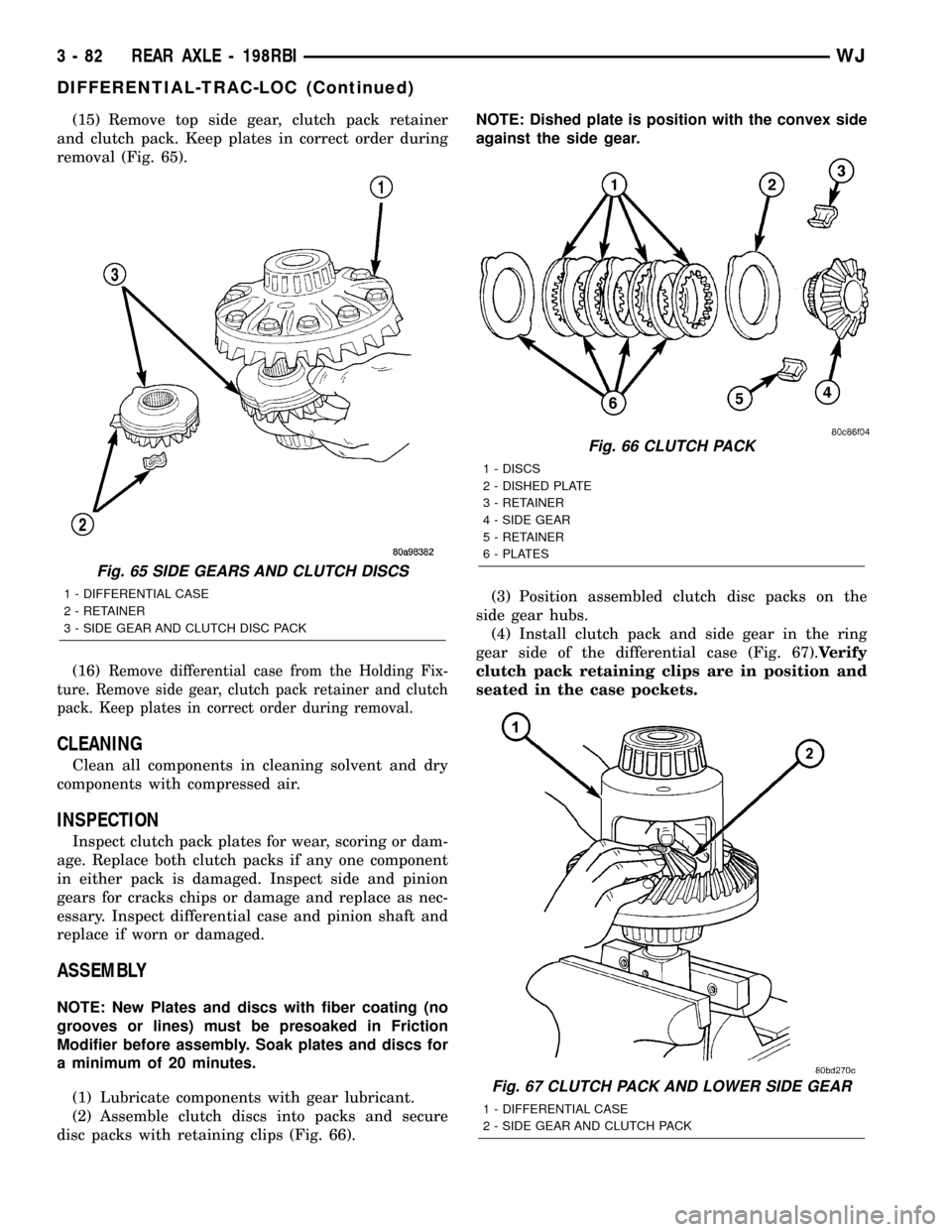

(15) Remove top side gear, clutch pack retainer

and clutch pack. Keep plates in correct order during

removal (Fig. 65).

(16)

Remove differential case from the Holding Fix-

ture. Remove side gear, clutch pack retainer and clutch

pack. Keep plates in correct order during removal.

CLEANING

Clean all components in cleaning solvent and dry

components with compressed air.

INSPECTION

Inspect clutch pack plates for wear, scoring or dam-

age. Replace both clutch packs if any one component

in either pack is damaged. Inspect side and pinion

gears for cracks chips or damage and replace as nec-

essary. Inspect differential case and pinion shaft and

replace if worn or damaged.

ASSEMBLY

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.

(1) Lubricate components with gear lubricant.

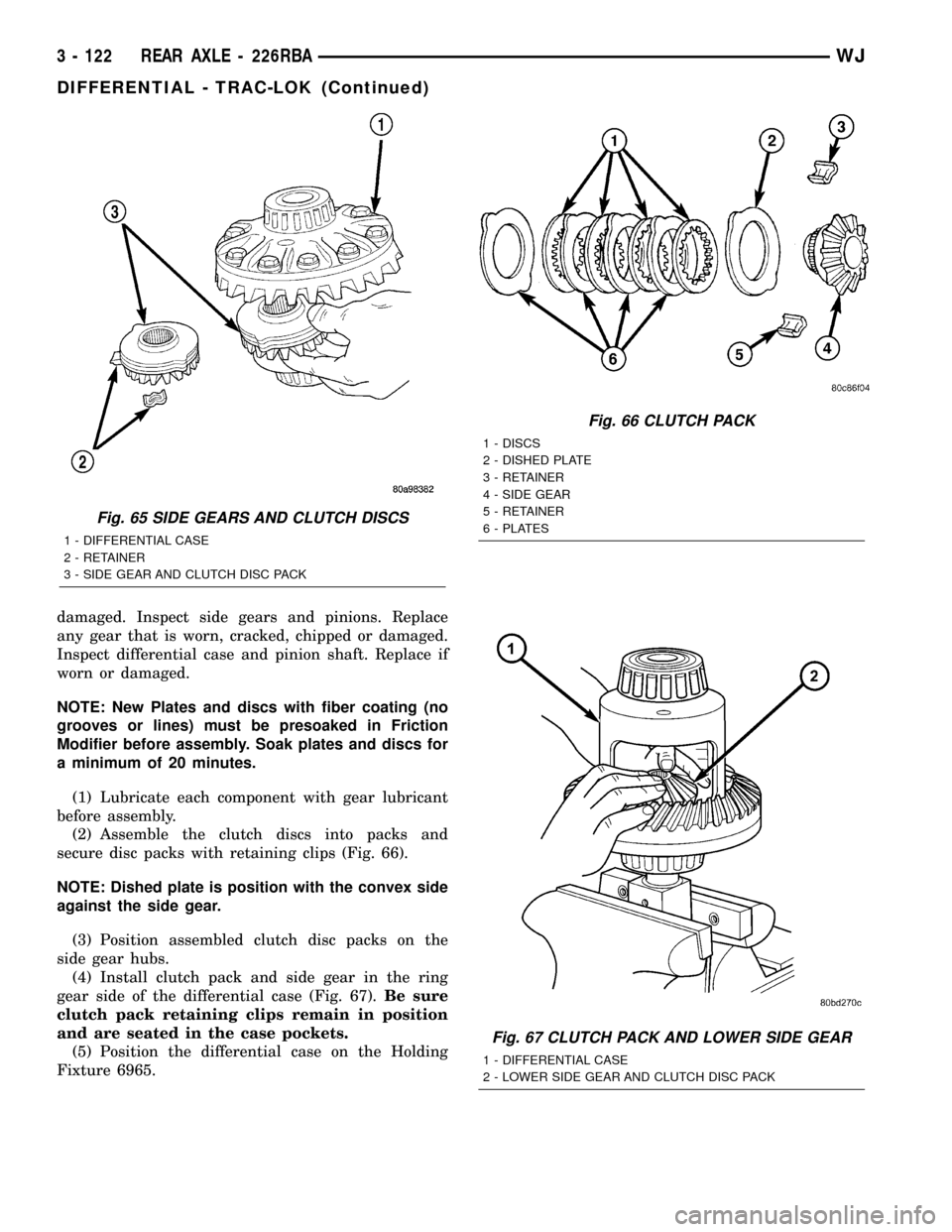

(2) Assemble clutch discs into packs and secure

disc packs with retaining clips (Fig. 66).NOTE: Dished plate is position with the convex side

against the side gear.

(3) Position assembled clutch disc packs on the

side gear hubs.

(4) Install clutch pack and side gear in the ring

gear side of the differential case (Fig. 67).Verify

clutch pack retaining clips are in position and

seated in the case pockets.

Fig. 65 SIDE GEARS AND CLUTCH DISCS

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

Fig. 66 CLUTCH PACK

1 - DISCS

2 - DISHED PLATE

3 - RETAINER

4 - SIDE GEAR

5 - RETAINER

6 - PLATES

Fig. 67 CLUTCH PACK AND LOWER SIDE GEAR

1 - DIFFERENTIAL CASE

2 - SIDE GEAR AND CLUTCH PACK

3 - 82 REAR AXLE - 198RBIWJ

DIFFERENTIAL-TRAC-LOC (Continued)

Page 167 of 2199

damaged. Inspect side gears and pinions. Replace

any gear that is worn, cracked, chipped or damaged.

Inspect differential case and pinion shaft. Replace if

worn or damaged.

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.

(1) Lubricate each component with gear lubricant

before assembly.

(2) Assemble the clutch discs into packs and

secure disc packs with retaining clips (Fig. 66).

NOTE: Dished plate is position with the convex side

against the side gear.

(3) Position assembled clutch disc packs on the

side gear hubs.

(4) Install clutch pack and side gear in the ring

gear side of the differential case (Fig. 67).Be sure

clutch pack retaining clips remain in position

and are seated in the case pockets.

(5) Position the differential case on the Holding

Fixture 6965.

Fig. 65 SIDE GEARS AND CLUTCH DISCS

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

Fig. 66 CLUTCH PACK

1 - DISCS

2 - DISHED PLATE

3 - RETAINER

4 - SIDE GEAR

5 - RETAINER

6 - PLATES

Fig. 67 CLUTCH PACK AND LOWER SIDE GEAR

1 - DIFFERENTIAL CASE

2 - LOWER SIDE GEAR AND CLUTCH DISC PACK

3 - 122 REAR AXLE - 226RBAWJ

DIFFERENTIAL - TRAC-LOK (Continued)

Page 207 of 2199

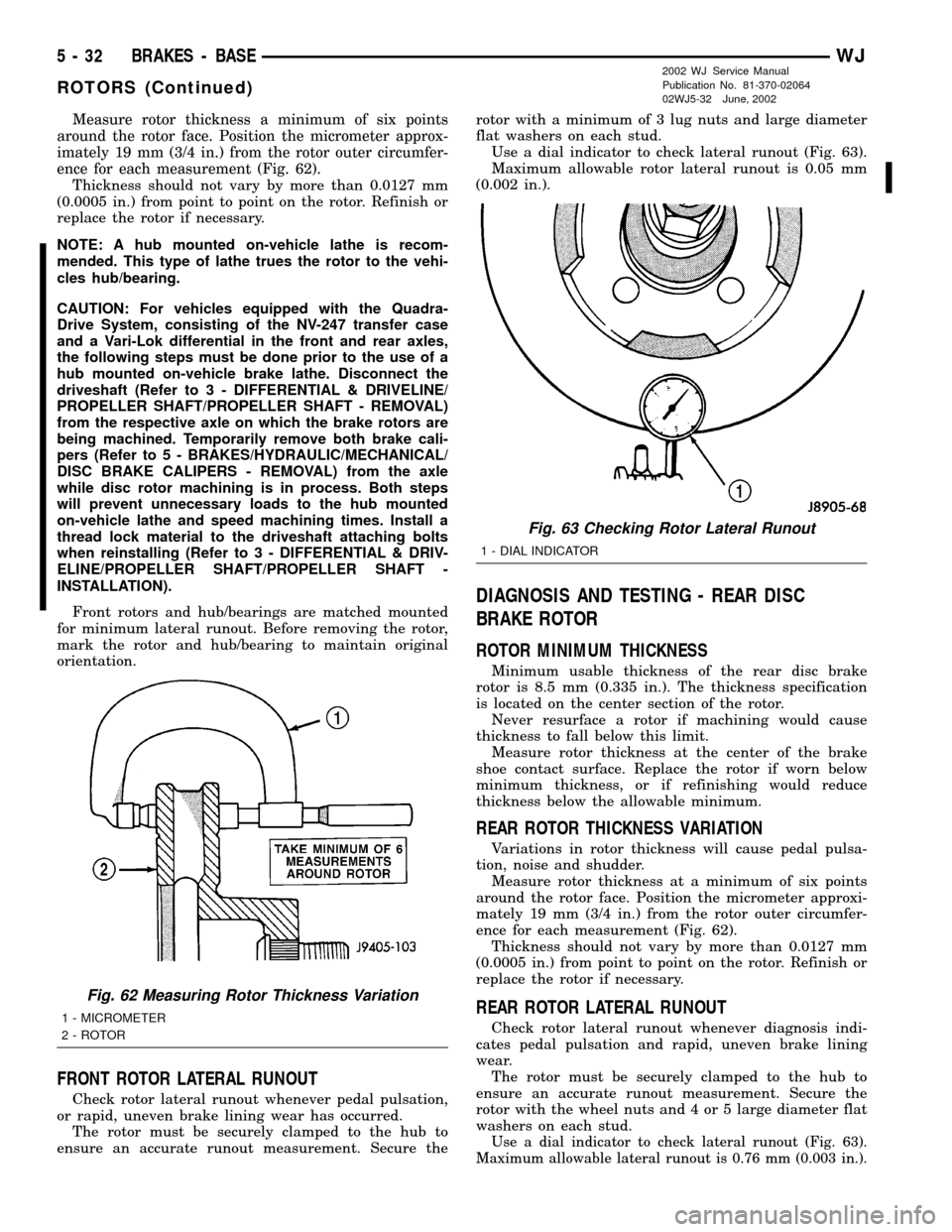

Measure rotor thickness a minimum of six points

around the rotor face. Position the micrometer approx-

imately 19 mm (3/4 in.) from the rotor outer circumfer-

ence for each measurement (Fig. 62).

Thickness should not vary by more than 0.0127 mm

(0.0005 in.) from point to point on the rotor. Refinish or

replace the rotor if necessary.

NOTE: A hub mounted on-vehicle lathe is recom-

mended. This type of lathe trues the rotor to the vehi-

cles hub/bearing.

CAUTION: For vehicles equipped with the Quadra-

Drive System, consisting of the NV-247 transfer case

and a Vari-Lok differential in the front and rear axles,

the following steps must be done prior to the use of a

hub mounted on-vehicle brake lathe. Disconnect the

driveshaft (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT - REMOVAL)

from the respective axle on which the brake rotors are

being machined. Temporarily remove both brake cali-

pers (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - REMOVAL) from the axle

while disc rotor machining is in process. Both steps

will prevent unnecessary loads to the hub mounted

on-vehicle lathe and speed machining times. Install a

thread lock material to the driveshaft attaching bolts

when reinstalling (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION).

Front rotors and hub/bearings are matched mounted

for minimum lateral runout. Before removing the rotor,

mark the rotor and hub/bearing to maintain original

orientation.

FRONT ROTOR LATERAL RUNOUT

Check rotor lateral runout whenever pedal pulsation,

or rapid, uneven brake lining wear has occurred.

The rotor must be securely clamped to the hub to

ensure an accurate runout measurement. Secure therotor with a minimum of 3 lug nuts and large diameter

flat washers on each stud.

Use a dial indicator to check lateral runout (Fig. 63).

Maximum allowable rotor lateral runout is 0.05 mm

(0.002 in.).

DIAGNOSIS AND TESTING - REAR DISC

BRAKE ROTOR

ROTOR MINIMUM THICKNESS

Minimum usable thickness of the rear disc brake

rotor is 8.5 mm (0.335 in.). The thickness specification

is located on the center section of the rotor.

Never resurface a rotor if machining would cause

thickness to fall below this limit.

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if worn below

minimum thickness, or if refinishing would reduce

thickness below the allowable minimum.

REAR ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pulsa-

tion, noise and shudder.

Measure rotor thickness at a minimum of six points

around the rotor face. Position the micrometer approxi-

mately 19 mm (3/4 in.) from the rotor outer circumfer-

ence for each measurement (Fig. 62).

Thickness should not vary by more than 0.0127 mm

(0.0005 in.) from point to point on the rotor. Refinish or

replace the rotor if necessary.

REAR ROTOR LATERAL RUNOUT

Check rotor lateral runout whenever diagnosis indi-

cates pedal pulsation and rapid, uneven brake lining

wear.

The rotor must be securely clamped to the hub to

ensure an accurate runout measurement. Secure the

rotor with the wheel nuts and 4 or 5 large diameter flat

washers on each stud.

Use a dial indicator to check lateral runout (Fig. 63).

Maximum allowable lateral runout is 0.76 mm (0.003 in.).

Fig. 62 Measuring Rotor Thickness Variation

1 - MICROMETER

2 - ROTOR

Fig. 63 Checking Rotor Lateral Runout

1 - DIAL INDICATOR

5 - 32 BRAKES - BASEWJ

ROTORS (Continued)

2002 WJ Service Manual

Publication No. 81-370-02064

02WJ5-32 June, 2002

Page 208 of 2199

STANDARD PROCEDURE - DISC ROTOR

MACHINING

CAUTION: For vehicles equipped with the Quadra-

Drive System, consisting of the NV-247 transfer case

and a Vari-Lok differential in the front and rear axles,

the following steps must be done prior to the use of a

hub mounted on-vehicle brake lathe. Disconnect the

driveshaft (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT - REMOVAL)

from the respective axle on which the brake rotors are

being machined. Temporarily remove both brake cali-

pers (Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

DISC BRAKE CALIPERS - REMOVAL) from the axle

while disc rotor machining is in process. Both steps

will prevent unnecessary loads to the hub mounted

on-vehicle lathe and speed machining times. Install a

thread lock material to the driveshaft attaching bolts

when reinstalling (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION).

NOTE: A hub mounted on-vehicle lathe is recom-

mended. This type of lathe trues the rotor to the vehi-

cles hub/bearing.

The disc brake rotor can be machined if scored or

worn. The lathe must machine both sides of the rotor

simultaneously with dual cutter heads. The rotor

mounting surface must be clean before placing on the

lathe. Equipment capable of machining only one side at

a time may produce a tapered rotor.

CAUTION: Brake rotors that do not meet minimum

thickness specifications before or after machining

must be replaced.

REMOVAL

REMOVAL - FRONT DISC BRAKE ROTOR

NOTE: Front rotors and hub/bearings are matched

mounted for minimum lateral runout. Before removing

the rotor, mark the rotor and hub/bearing to maintain

original orientation.

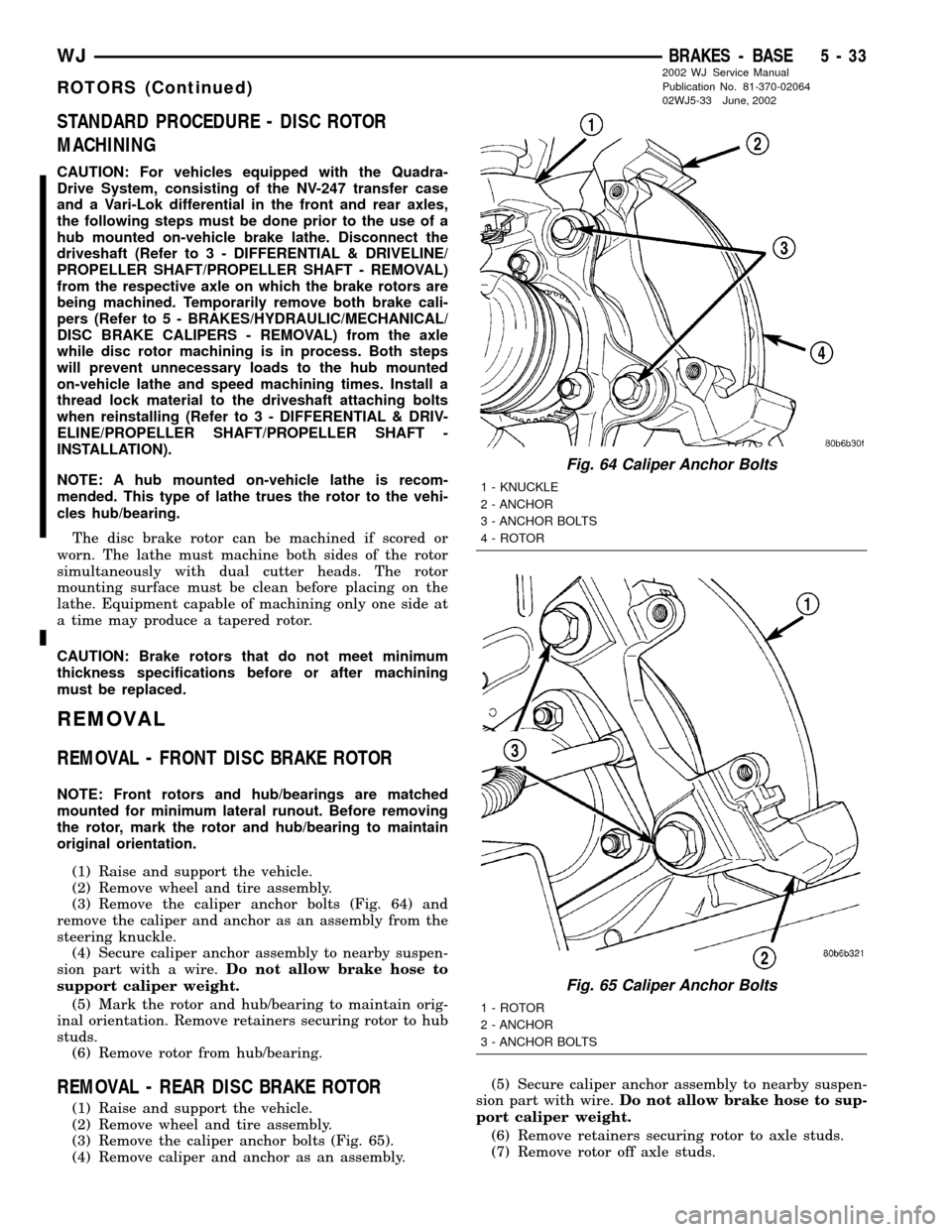

(1) Raise and support the vehicle.

(2) Remove wheel and tire assembly.

(3) Remove the caliper anchor bolts (Fig. 64) and

remove the caliper and anchor as an assembly from the

steering knuckle.

(4) Secure caliper anchor assembly to nearby suspen-

sion part with a wire.Do not allow brake hose to

support caliper weight.

(5) Mark the rotor and hub/bearing to maintain orig-

inal orientation. Remove retainers securing rotor to hub

studs.

(6) Remove rotor from hub/bearing.

REMOVAL - REAR DISC BRAKE ROTOR

(1) Raise and support the vehicle.

(2) Remove wheel and tire assembly.

(3) Remove the caliper anchor bolts (Fig. 65).

(4) Remove caliper and anchor as an assembly.(5) Secure caliper anchor assembly to nearby suspen-

sion part with wire.Do not allow brake hose to sup-

port caliper weight.

(6) Remove retainers securing rotor to axle studs.

(7) Remove rotor off axle studs.

Fig. 64 Caliper Anchor Bolts

1 - KNUCKLE

2 - ANCHOR

3 - ANCHOR BOLTS

4 - ROTOR

Fig. 65 Caliper Anchor Bolts

1 - ROTOR

2 - ANCHOR

3 - ANCHOR BOLTS

WJBRAKES - BASE 5 - 33

ROTORS (Continued)

2002 WJ Service Manual

Publication No. 81-370-02064

02WJ5-33 June, 2002

Page 209 of 2199

INSTALLATION

INSTALLATION - FRONT DISC BRAKE ROTOR

NOTE: If a new rotor is installed it must be match

mounted to the hub/bearing.

(1) Install rotor on hub studs in its original loca-

tion.

(2) Install the caliper anchor assembly on the

knuckle. Install anchor bolts and tighten to 90-115

N´m (66-85 ft. lbs.).

(3) Install wheel and tire assembly.

(4) Remove support and lower the vehicle.

(5) Pump brake pedal to seat caliper pistons and

brake shoes. Do not move vehicle until firm brake

pedal is obtained.

INSTALLATION - REAR DISC BRAKE ROTOR

(1) Install rotor on axle studs.

(2) Install the caliper anchor assembly.

(3) Install anchor bolts and tighten to 90-115 N´m

(66-85 ft. lbs.).

(4) Install wheel and tire assembly.

(5) Remove support and lower the vehicle.

(6) Pump brake pedal until caliper pistons and

brake shoes are seated.

PARKING BRAKE

OPERATION

The parking brakes operated by a automatic ten-

sioner mechanism built into the hand lever and cable

system. The front cable is connected to the hand

lever and the equalizer. The rear cables attached to

the equalizer and the parking brake shoe actuator.

A set of drum type brake shoes are used for park-

ing brakes. The shoes are mounted to the rear disc

brake adaptor. The parking brake drum is integrated

into the rear disc brake rotor.

Parking brake cable adjustment is controlled by an

automatic tensioner mechanism. The only adjust-

ment if necessary is to the park brake shoes if the

linings are worn.

DIAGNOSIS AND TESTING - PARKING BRAKE

NOTE: Parking brake adjustment is controlled by an

automatic cable tensioner and does not require

adjustment. The only adjustment that may be nec-

essary would be to the park brake shoes if they are

worn.

The parking brake switch is in circuit with the red

warning lamp in the dash. The switch will cause the

lamp to illuminate only when the parking brakes are

applied. If the lamp remains on after parking brake

release, the switch or wires are faulty.

If the red lamp comes on a fault has occurred in

the front or rear brake hydraulic system.

If the red warning lamp and yellow warning lamp

come on, the electronic brake distribution may be at

fault.

In most cases, the actual cause of an improperly

functioning parking brake (too loose/too tight/won't

hold), can be traced to a parking brake component.

NOTE: The leading cause of improper parking brake

operation, is excessive clearance between the park-

ing brake shoes and the shoe braking surface.

Excessive clearance is a result of lining and/or

drum wear, drum surface machined oversize.

Excessive parking brake lever travel (sometimes

described as a loose lever or too loose condition), is

the result of worn brake shoes, improper brake shoe

adjustment, or improperly assembled brake parts.

A too loose condition can also be caused by inoper-

ative or improperly assembled parking brake shoe

parts.

A condition where the parking brakes do not hold,

will most probably be due to a wheel brake compo-

nent.

Items to look for when diagnosing a parking brake

problem, are:

²Brake shoe wear

²Drum surface (in rear rotor) machined oversize

²Front cable not secured to lever

²Rear cable not attached to actuator

²Rear cable seized

²Parking brake lever not seated

²Parking brake lever bind

5 - 34 BRAKES - BASEWJ

ROTORS (Continued)

Page 214 of 2199

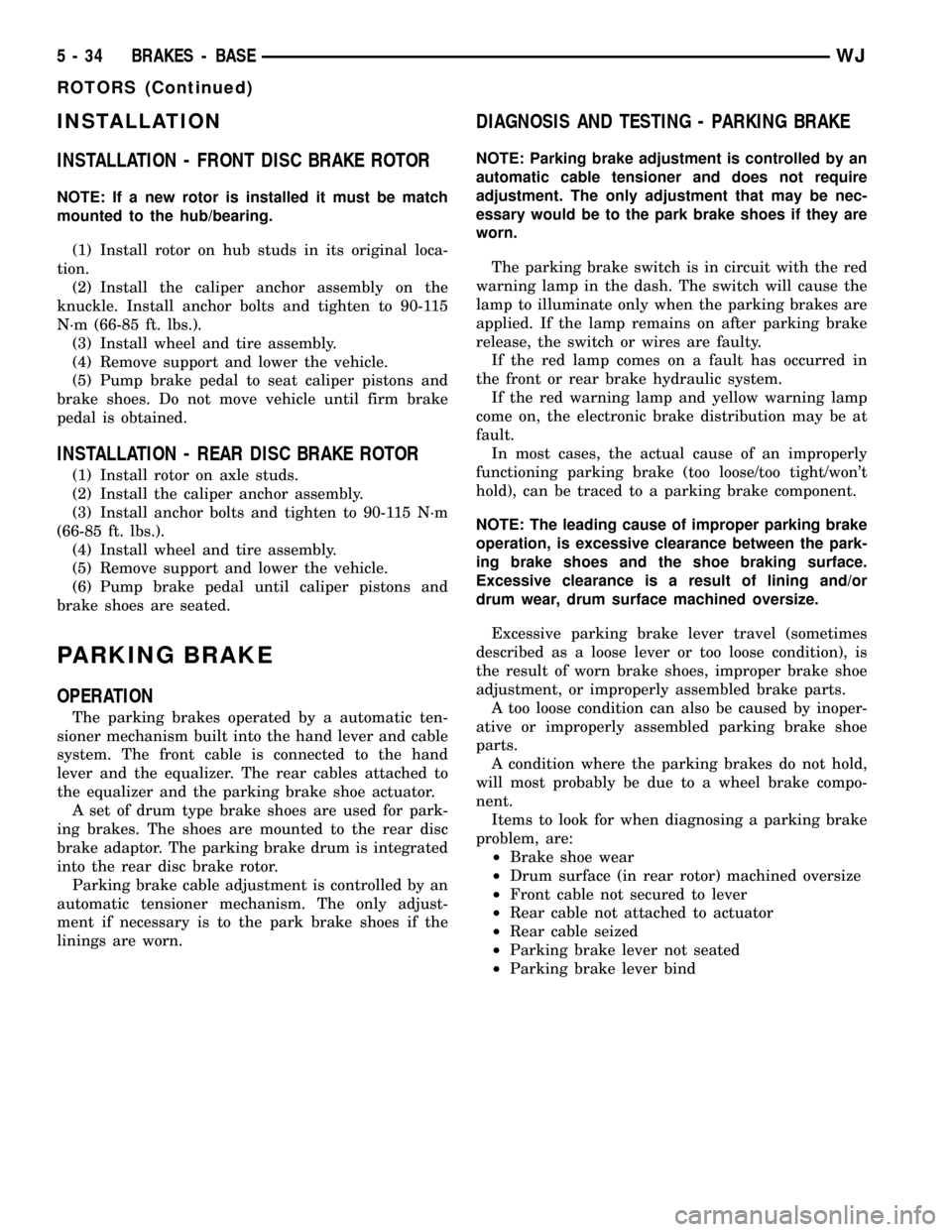

(8) Remove the park brake lever mounting nuts

and console bracket (Fig. 80).

(9) Lift the lever assembly off the mounting studs

and pull the front cable out of the lever bracket.

INSTALLATION

(1) Install the lever assembly on the mounting

studs while feeding the front cable into the lever

bracket.

(2) Install the console bracket (Fig. 80) and mount-

ing nuts.

(3) Engage the front cable end to the lever.

(4) Connect parking brake switch wire connector.

(5) Pull on the lever to release the lock out spring.

(6) Install center console,(Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - INSTALLATION).

(7) Fold down the rear carpet cover and rear seat.

SHOES

REMOVAL

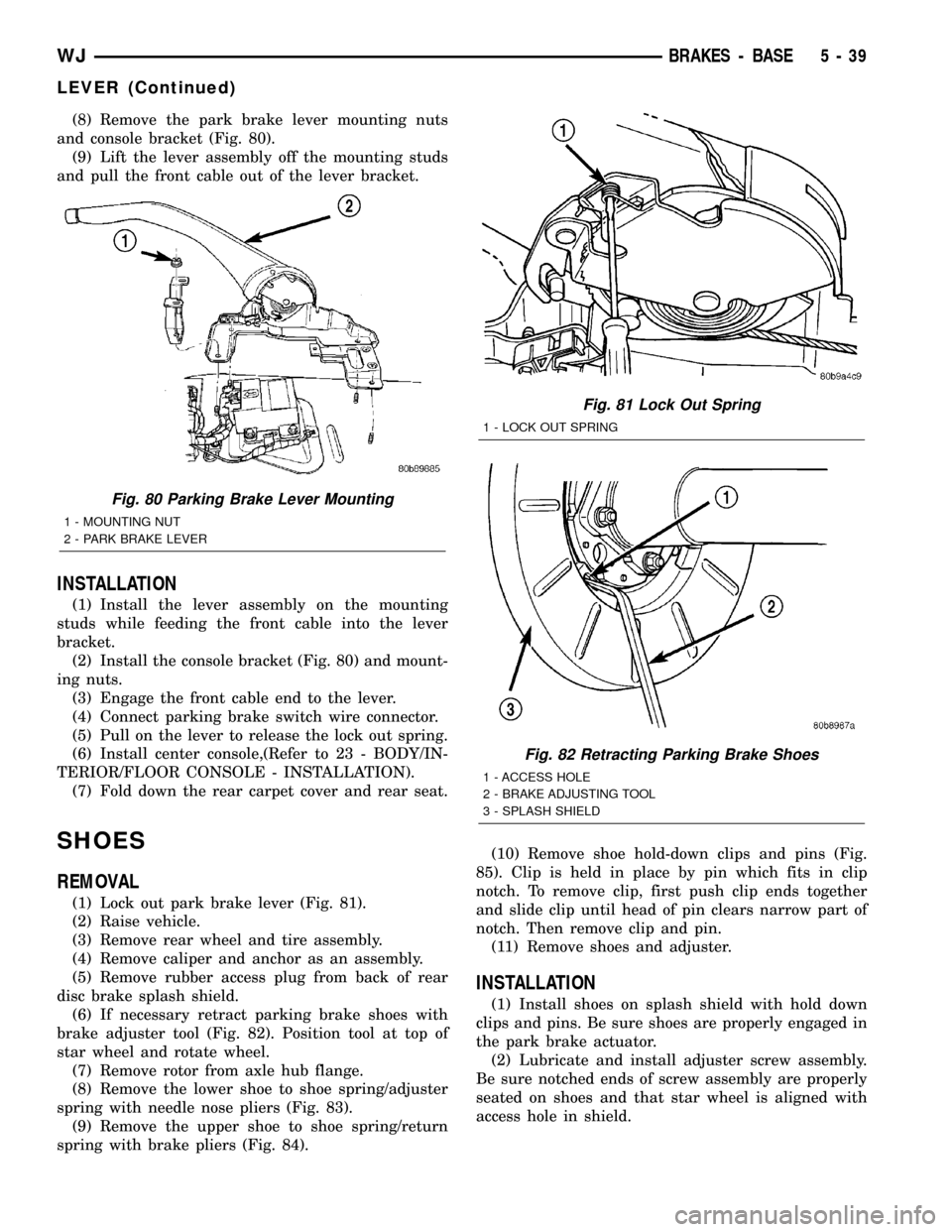

(1) Lock out park brake lever (Fig. 81).

(2) Raise vehicle.

(3) Remove rear wheel and tire assembly.

(4) Remove caliper and anchor as an assembly.

(5) Remove rubber access plug from back of rear

disc brake splash shield.

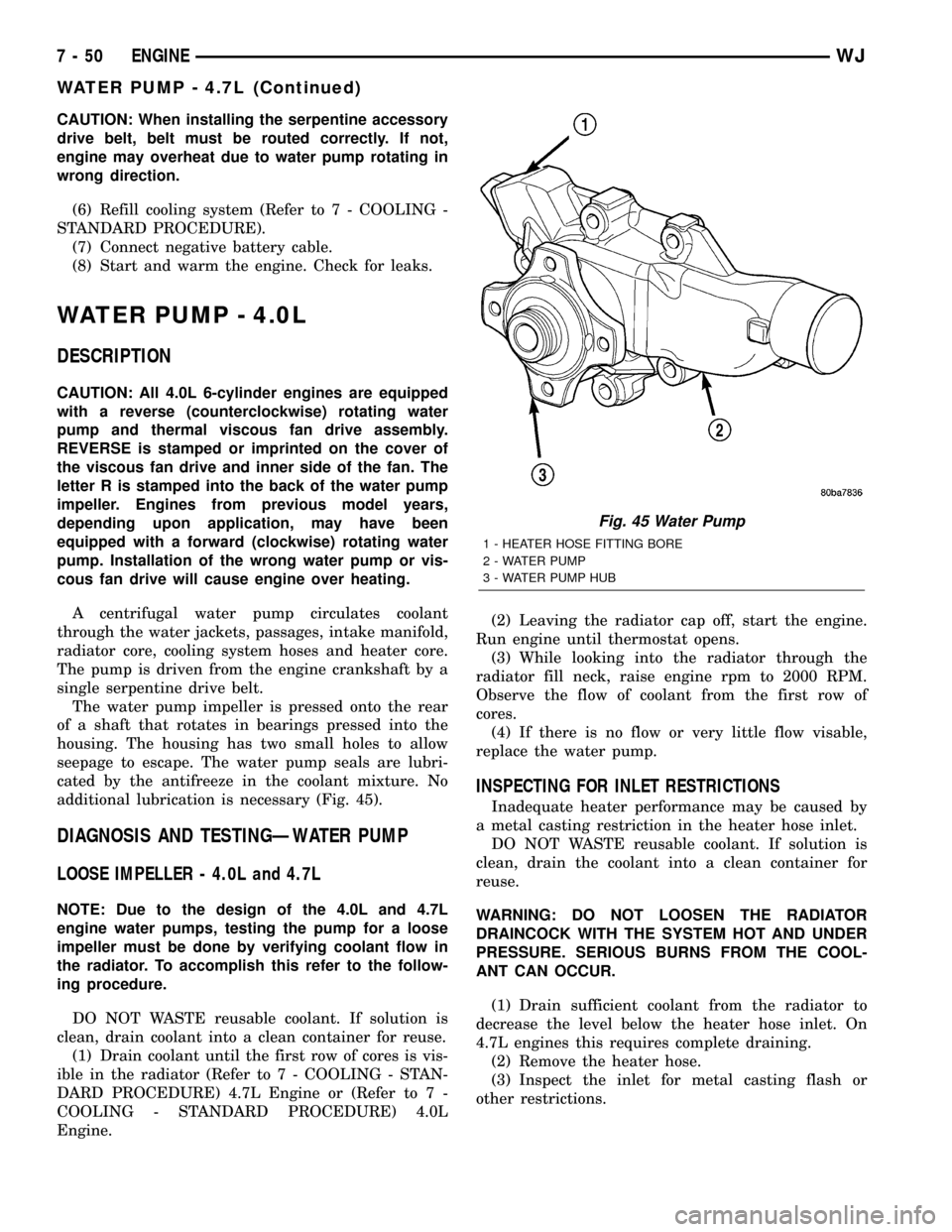

(6) If necessary retract parking brake shoes with

brake adjuster tool (Fig. 82). Position tool at top of

star wheel and rotate wheel.

(7) Remove rotor from axle hub flange.

(8) Remove the lower shoe to shoe spring/adjuster

spring with needle nose pliers (Fig. 83).

(9) Remove the upper shoe to shoe spring/return

spring with brake pliers (Fig. 84).(10) Remove shoe hold-down clips and pins (Fig.

85). Clip is held in place by pin which fits in clip

notch. To remove clip, first push clip ends together

and slide clip until head of pin clears narrow part of

notch. Then remove clip and pin.

(11) Remove shoes and adjuster.

INSTALLATION

(1) Install shoes on splash shield with hold down

clips and pins. Be sure shoes are properly engaged in

the park brake actuator.

(2) Lubricate and install adjuster screw assembly.

Be sure notched ends of screw assembly are properly

seated on shoes and that star wheel is aligned with

access hole in shield.

Fig. 80 Parking Brake Lever Mounting

1 - MOUNTING NUT

2 - PARK BRAKE LEVER

Fig. 81 Lock Out Spring

1 - LOCK OUT SPRING

Fig. 82 Retracting Parking Brake Shoes

1 - ACCESS HOLE

2 - BRAKE ADJUSTING TOOL

3 - SPLASH SHIELD

WJBRAKES - BASE 5 - 39

LEVER (Continued)

Page 273 of 2199

CAUTION: When installing the serpentine accessory

drive belt, belt must be routed correctly. If not,

engine may overheat due to water pump rotating in

wrong direction.

(6) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Connect negative battery cable.

(8) Start and warm the engine. Check for leaks.

WATER PUMP - 4.0L

DESCRIPTION

CAUTION: All 4.0L 6-cylinder engines are equipped

with a reverse (counterclockwise) rotating water

pump and thermal viscous fan drive assembly.

REVERSE is stamped or imprinted on the cover of

the viscous fan drive and inner side of the fan. The

letter R is stamped into the back of the water pump

impeller. Engines from previous model years,

depending upon application, may have been

equipped with a forward (clockwise) rotating water

pump. Installation of the wrong water pump or vis-

cous fan drive will cause engine over heating.

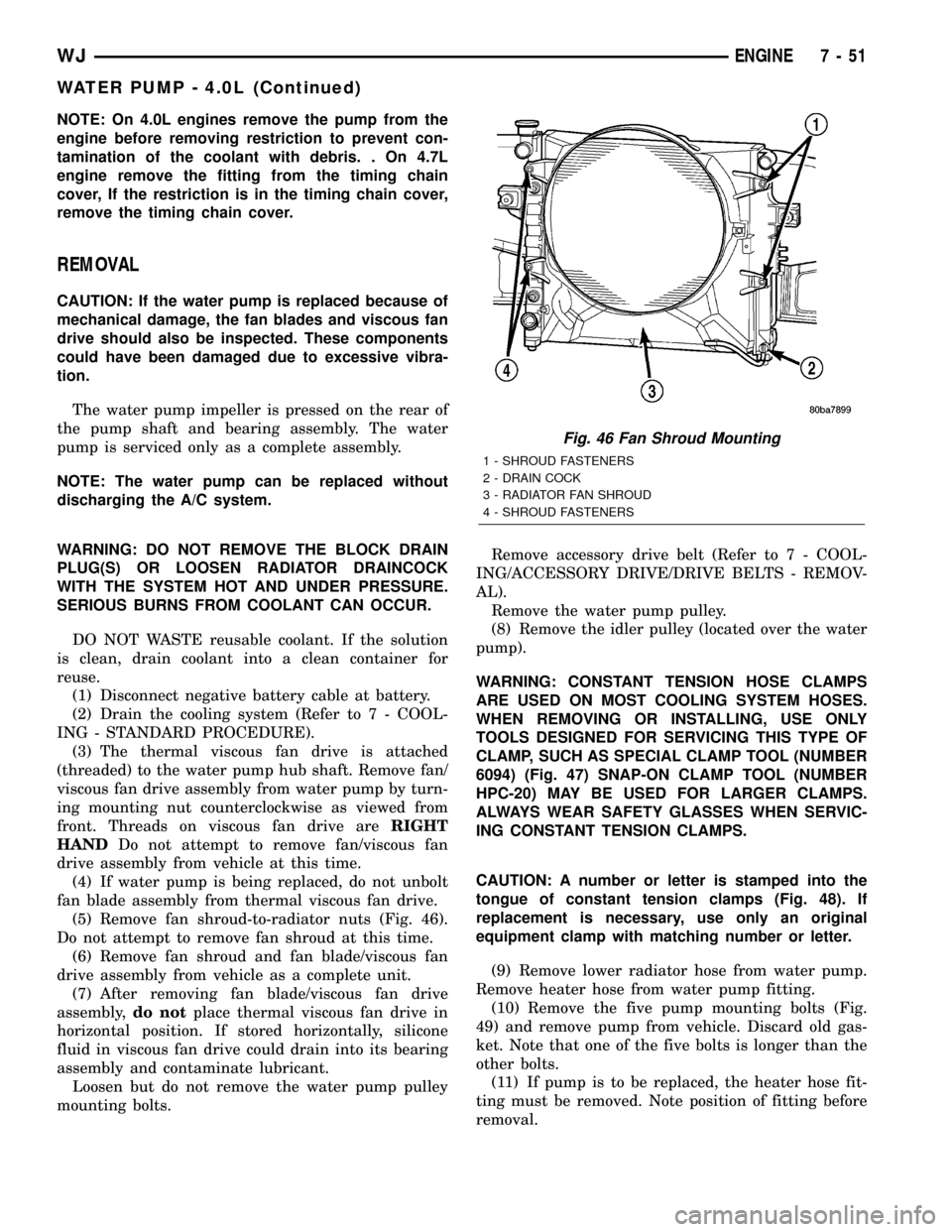

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

single serpentine drive belt.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has two small holes to allow

seepage to escape. The water pump seals are lubri-

cated by the antifreeze in the coolant mixture. No

additional lubrication is necessary (Fig. 45).

DIAGNOSIS AND TESTINGÐWATER PUMP

LOOSE IMPELLER - 4.0L and 4.7L

NOTE: Due to the design of the 4.0L and 4.7L

engine water pumps, testing the pump for a loose

impeller must be done by verifying coolant flow in

the radiator. To accomplish this refer to the follow-

ing procedure.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

(1) Drain coolant until the first row of cores is vis-

ible in the radiator (Refer to 7 - COOLING - STAN-

DARD PROCEDURE) 4.7L Engine or (Refer to 7 -

COOLING - STANDARD PROCEDURE) 4.0L

Engine.(2) Leaving the radiator cap off, start the engine.

Run engine until thermostat opens.

(3) While looking into the radiator through the

radiator fill neck, raise engine rpm to 2000 RPM.

Observe the flow of coolant from the first row of

cores.

(4) If there is no flow or very little flow visable,

replace the water pump.

INSPECTING FOR INLET RESTRICTIONS

Inadequate heater performance may be caused by

a metal casting restriction in the heater hose inlet.

DO NOT WASTE reusable coolant. If solution is

clean, drain the coolant into a clean container for

reuse.

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.

(1) Drain sufficient coolant from the radiator to

decrease the level below the heater hose inlet. On

4.7L engines this requires complete draining.

(2) Remove the heater hose.

(3) Inspect the inlet for metal casting flash or

other restrictions.

Fig. 45 Water Pump

1 - HEATER HOSE FITTING BORE

2 - WATER PUMP

3 - WATER PUMP HUB

7 - 50 ENGINEWJ

WATER PUMP - 4.7L (Continued)

Page 274 of 2199

NOTE: On 4.0L engines remove the pump from the

engine before removing restriction to prevent con-

tamination of the coolant with debris. . On 4.7L

engine remove the fitting from the timing chain

cover, If the restriction is in the timing chain cover,

remove the timing chain cover.

REMOVAL

CAUTION: If the water pump is replaced because of

mechanical damage, the fan blades and viscous fan

drive should also be inspected. These components

could have been damaged due to excessive vibra-

tion.

The water pump impeller is pressed on the rear of

the pump shaft and bearing assembly. The water

pump is serviced only as a complete assembly.

NOTE: The water pump can be replaced without

discharging the A/C system.

WARNING: DO NOT REMOVE THE BLOCK DRAIN

PLUG(S) OR LOOSEN RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain coolant into a clean container for

reuse.

(1) Disconnect negative battery cable at battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) The thermal viscous fan drive is attached

(threaded) to the water pump hub shaft. Remove fan/

viscous fan drive assembly from water pump by turn-

ing mounting nut counterclockwise as viewed from

front. Threads on viscous fan drive areRIGHT

HANDDo not attempt to remove fan/viscous fan

drive assembly from vehicle at this time.

(4) If water pump is being replaced, do not unbolt

fan blade assembly from thermal viscous fan drive.

(5) Remove fan shroud-to-radiator nuts (Fig. 46).

Do not attempt to remove fan shroud at this time.

(6) Remove fan shroud and fan blade/viscous fan

drive assembly from vehicle as a complete unit.

(7) After removing fan blade/viscous fan drive

assembly,do notplace thermal viscous fan drive in

horizontal position. If stored horizontally, silicone

fluid in viscous fan drive could drain into its bearing

assembly and contaminate lubricant.

Loosen but do not remove the water pump pulley

mounting bolts.Remove accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

Remove the water pump pulley.

(8) Remove the idler pulley (located over the water

pump).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (Fig. 47) SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS.

ALWAYS WEAR SAFETY GLASSES WHEN SERVIC-

ING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 48). If

replacement is necessary, use only an original

equipment clamp with matching number or letter.

(9) Remove lower radiator hose from water pump.

Remove heater hose from water pump fitting.

(10) Remove the five pump mounting bolts (Fig.

49) and remove pump from vehicle. Discard old gas-

ket. Note that one of the five bolts is longer than the

other bolts.

(11) If pump is to be replaced, the heater hose fit-

ting must be removed. Note position of fitting before

removal.

Fig. 46 Fan Shroud Mounting

1 - SHROUD FASTENERS

2 - DRAIN COCK

3 - RADIATOR FAN SHROUD

4 - SHROUD FASTENERS

WJENGINE 7 - 51

WATER PUMP - 4.0L (Continued)

Page 551 of 2199

INSTALLATION

The following service procedure applies to vehicles

manufactured for sale in North America, which have

removable child seat tether anchor brackets that are

located on the inner liftgate opening header. Vehicles

manufactured for sale in Rest-Of-World (ROW) mar-

kets have child tether anchors that are integral to,

and are only serviced with the rear seat back panels.

(1) Position the child tether anchor bracket onto

the inner liftgate opening header (Fig. 12).

(2) Install and tighten the screw that secures the

child tether anchor bracket to the inner liftgate open-

ing header. Tighten the screw to 11.8 N´m (105 in.

lbs.).

(3) Reinstall the cover into the child tether anchor

bezel in the headliner near the liftgate opening

header.

CLOCKSPRING

DESCRIPTION

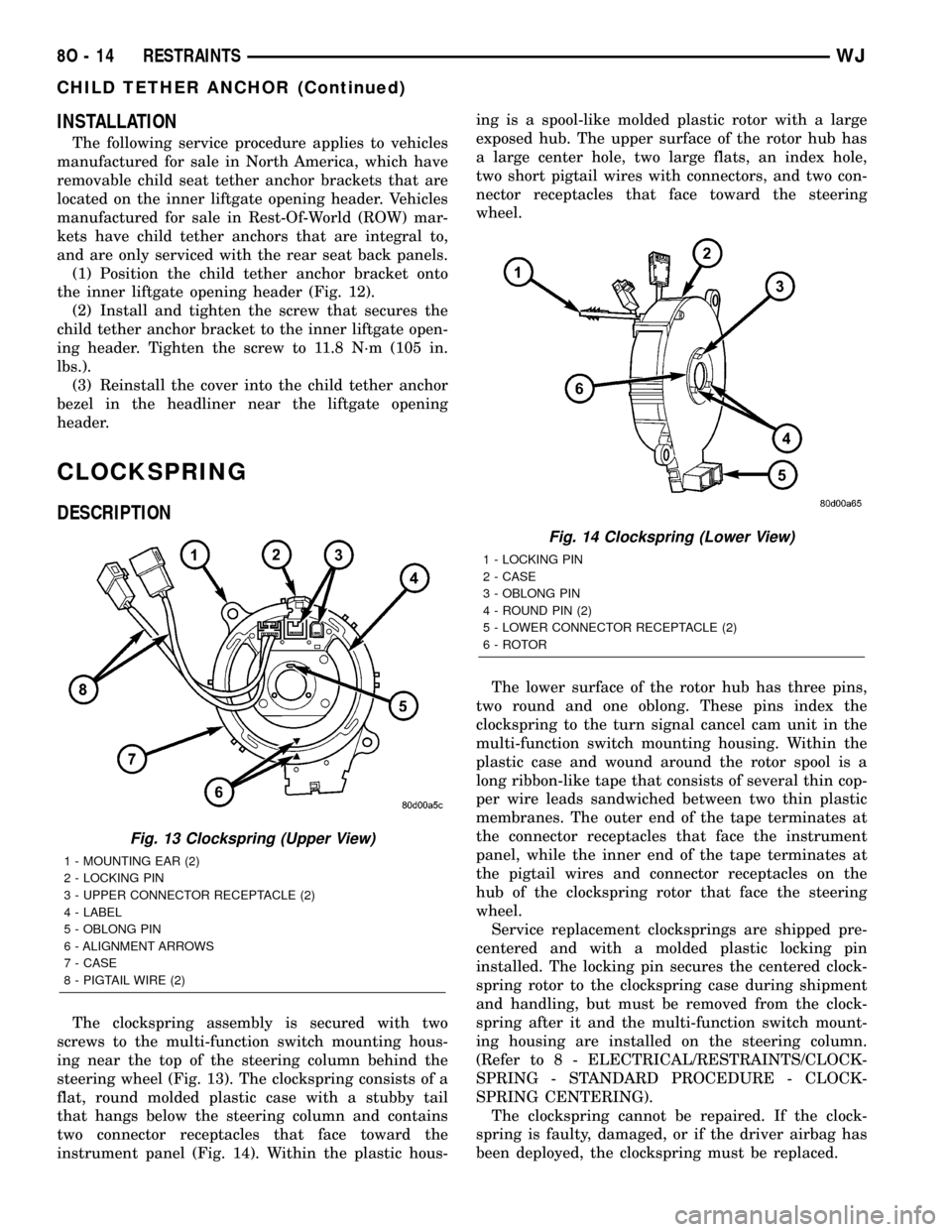

The clockspring assembly is secured with two

screws to the multi-function switch mounting hous-

ing near the top of the steering column behind the

steering wheel (Fig. 13). The clockspring consists of a

flat, round molded plastic case with a stubby tail

that hangs below the steering column and contains

two connector receptacles that face toward the

instrument panel (Fig. 14). Within the plastic hous-ing is a spool-like molded plastic rotor with a large

exposed hub. The upper surface of the rotor hub has

a large center hole, two large flats, an index hole,

two short pigtail wires with connectors, and two con-

nector receptacles that face toward the steering

wheel.

The lower surface of the rotor hub has three pins,

two round and one oblong. These pins index the

clockspring to the turn signal cancel cam unit in the

multi-function switch mounting housing. Within the

plastic case and wound around the rotor spool is a

long ribbon-like tape that consists of several thin cop-

per wire leads sandwiched between two thin plastic

membranes. The outer end of the tape terminates at

the connector receptacles that face the instrument

panel, while the inner end of the tape terminates at

the pigtail wires and connector receptacles on the

hub of the clockspring rotor that face the steering

wheel.

Service replacement clocksprings are shipped pre-

centered and with a molded plastic locking pin

installed. The locking pin secures the centered clock-

spring rotor to the clockspring case during shipment

and handling, but must be removed from the clock-

spring after it and the multi-function switch mount-

ing housing are installed on the steering column.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - STANDARD PROCEDURE - CLOCK-

SPRING CENTERING).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

Fig. 13 Clockspring (Upper View)

1 - MOUNTING EAR (2)

2 - LOCKING PIN

3 - UPPER CONNECTOR RECEPTACLE (2)

4 - LABEL

5 - OBLONG PIN

6 - ALIGNMENT ARROWS

7 - CASE

8 - PIGTAIL WIRE (2)

Fig. 14 Clockspring (Lower View)

1 - LOCKING PIN

2 - CASE

3 - OBLONG PIN

4 - ROUND PIN (2)

5 - LOWER CONNECTOR RECEPTACLE (2)

6 - ROTOR

8O - 14 RESTRAINTSWJ

CHILD TETHER ANCHOR (Continued)

Page 1310 of 2199

CONDITION POSSIBLE CAUSES CORRECTIONS

MAIN BEARING NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check thrust washers for wear.

6. Crankshaft journal out-of round. 6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.7. Tighten to correct torque

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - LUBRICATION

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Gaskets and O-Rings. 1.

(a) Misaligned or damaged. (a) Replace as necessary.

(b) Loose fasteners, broken or

porous metal parts.(b) Tighten fasteners, Repair or

replace metal parts.

2. Crankshaft rear seal 2. Replace as necessary (Refer to 9 -

ENGINE/ENGINE BLOCK/

CRANKSHAFT OIL SEAL - REAR -

REMOVAL).

3. Crankshaft seal flange.

Scratched, nicked or grooved.3. Polish or replace crankshaft.

4. Oil pan flange cracked. 4. Replace oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

5. Timing chain cover seal, damaged

or misaligned.5. Replace seal (Refer to 9 -

ENGINE/ENGINE BLOCK/

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL).

6. Scratched or damaged vibration

damper hub.6. Polish or replace damper.

WJENGINE - 4.7L 9 - 67

ENGINE - 4.7L (Continued)