Rear hub JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1609 of 2199

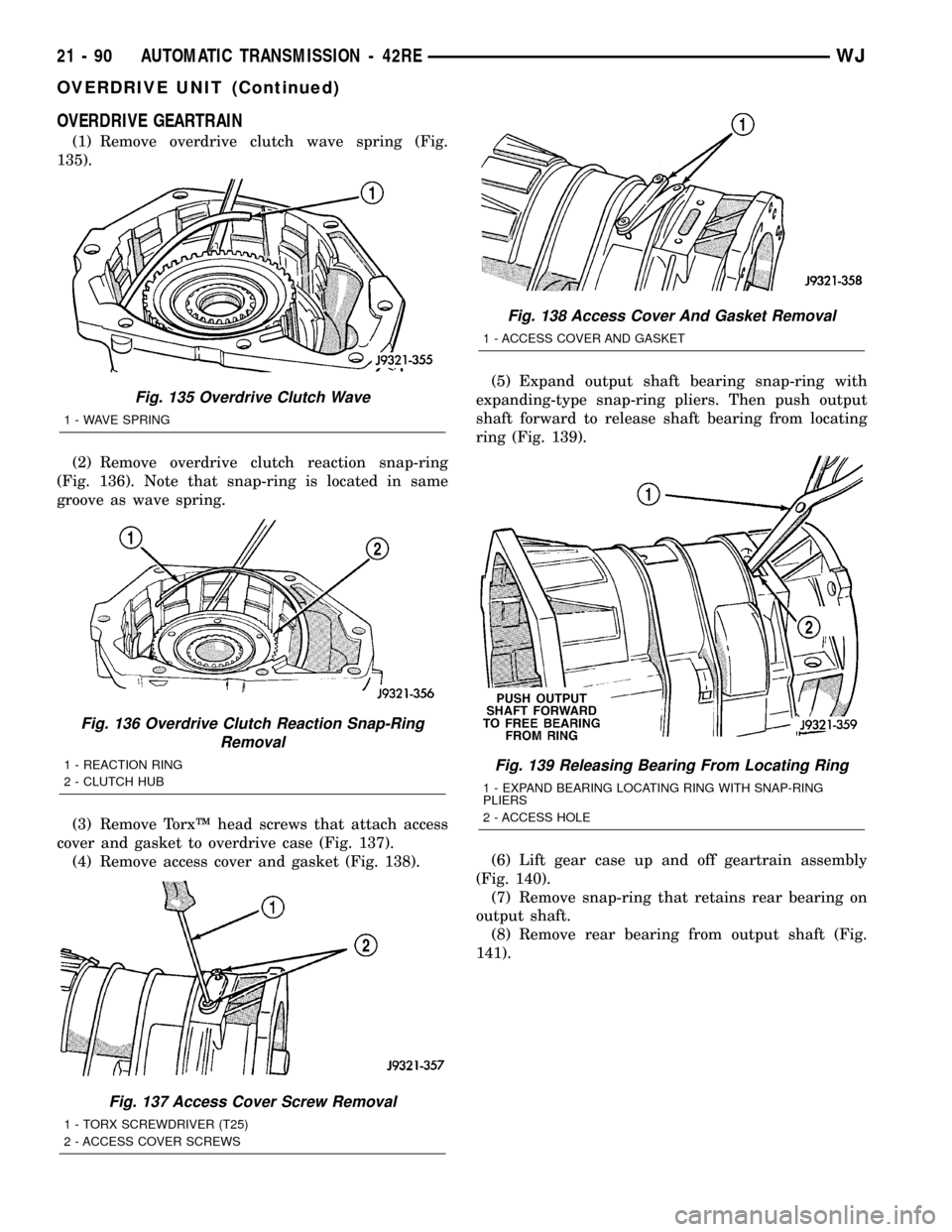

OVERDRIVE GEARTRAIN

(1) Remove overdrive clutch wave spring (Fig.

135).

(2) Remove overdrive clutch reaction snap-ring

(Fig. 136). Note that snap-ring is located in same

groove as wave spring.

(3) Remove TorxŸ head screws that attach access

cover and gasket to overdrive case (Fig. 137).

(4) Remove access cover and gasket (Fig. 138).(5) Expand output shaft bearing snap-ring with

expanding-type snap-ring pliers. Then push output

shaft forward to release shaft bearing from locating

ring (Fig. 139).

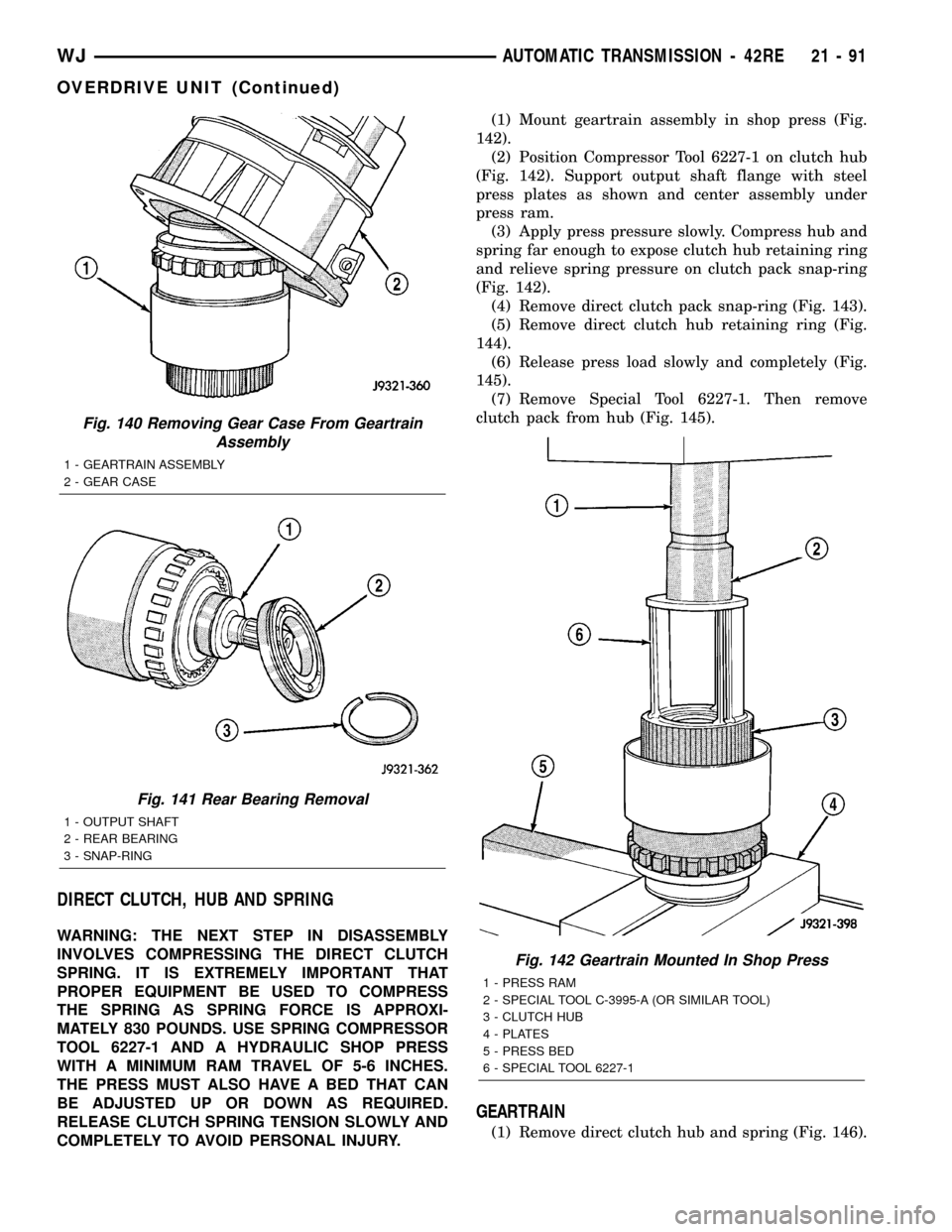

(6) Lift gear case up and off geartrain assembly

(Fig. 140).

(7) Remove snap-ring that retains rear bearing on

output shaft.

(8) Remove rear bearing from output shaft (Fig.

141).

Fig. 135 Overdrive Clutch Wave

1 - WAVE SPRING

Fig. 136 Overdrive Clutch Reaction Snap-Ring

Removal

1 - REACTION RING

2 - CLUTCH HUB

Fig. 137 Access Cover Screw Removal

1 - TORX SCREWDRIVER (T25)

2 - ACCESS COVER SCREWS

Fig. 138 Access Cover And Gasket Removal

1 - ACCESS COVER AND GASKET

Fig. 139 Releasing Bearing From Locating Ring

1 - EXPAND BEARING LOCATING RING WITH SNAP-RING

PLIERS

2 - ACCESS HOLE

21 - 90 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1610 of 2199

DIRECT CLUTCH, HUB AND SPRING

WARNING: THE NEXT STEP IN DISASSEMBLY

INVOLVES COMPRESSING THE DIRECT CLUTCH

SPRING. IT IS EXTREMELY IMPORTANT THAT

PROPER EQUIPMENT BE USED TO COMPRESS

THE SPRING AS SPRING FORCE IS APPROXI-

MATELY 830 POUNDS. USE SPRING COMPRESSOR

TOOL 6227-1 AND A HYDRAULIC SHOP PRESS

WITH A MINIMUM RAM TRAVEL OF 5-6 INCHES.

THE PRESS MUST ALSO HAVE A BED THAT CAN

BE ADJUSTED UP OR DOWN AS REQUIRED.

RELEASE CLUTCH SPRING TENSION SLOWLY AND

COMPLETELY TO AVOID PERSONAL INJURY.(1) Mount geartrain assembly in shop press (Fig.

142).

(2) Position Compressor Tool 6227-1 on clutch hub

(Fig. 142). Support output shaft flange with steel

press plates as shown and center assembly under

press ram.

(3) Apply press pressure slowly. Compress hub and

spring far enough to expose clutch hub retaining ring

and relieve spring pressure on clutch pack snap-ring

(Fig. 142).

(4) Remove direct clutch pack snap-ring (Fig. 143).

(5) Remove direct clutch hub retaining ring (Fig.

144).

(6) Release press load slowly and completely (Fig.

145).

(7) Remove Special Tool 6227-1. Then remove

clutch pack from hub (Fig. 145).

GEARTRAIN

(1) Remove direct clutch hub and spring (Fig. 146).

Fig. 140 Removing Gear Case From Geartrain

Assembly

1 - GEARTRAIN ASSEMBLY

2 - GEAR CASE

Fig. 141 Rear Bearing Removal

1 - OUTPUT SHAFT

2 - REAR BEARING

3 - SNAP-RING

Fig. 142 Geartrain Mounted In Shop Press

1 - PRESS RAM

2 - SPECIAL TOOL C-3995-A (OR SIMILAR TOOL)

3 - CLUTCH HUB

4 - PLATES

5 - PRESS BED

6 - SPECIAL TOOL 6227-1

WJAUTOMATIC TRANSMISSION - 42RE 21 - 91

OVERDRIVE UNIT (Continued)

Page 1612 of 2199

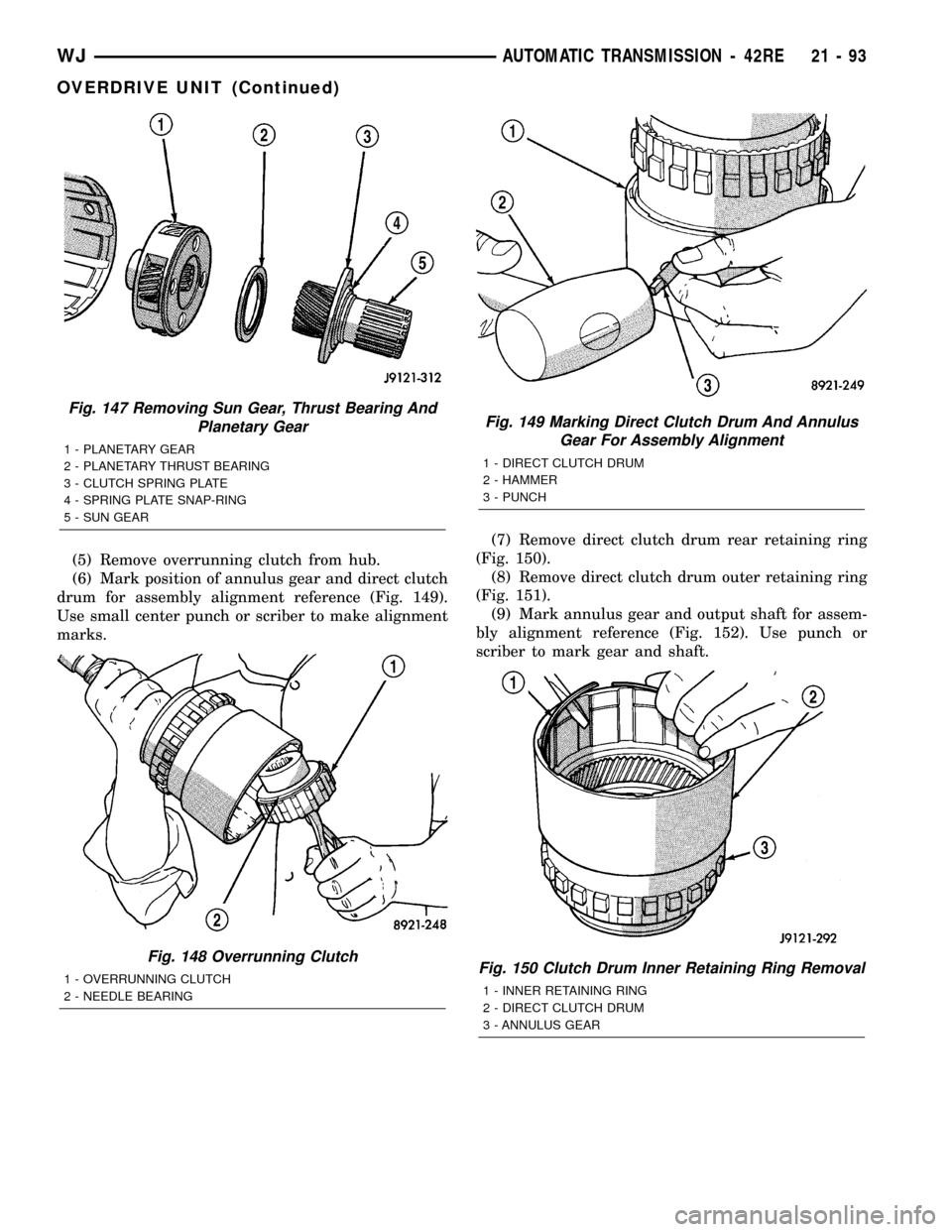

(5) Remove overrunning clutch from hub.

(6) Mark position of annulus gear and direct clutch

drum for assembly alignment reference (Fig. 149).

Use small center punch or scriber to make alignment

marks.(7) Remove direct clutch drum rear retaining ring

(Fig. 150).

(8) Remove direct clutch drum outer retaining ring

(Fig. 151).

(9) Mark annulus gear and output shaft for assem-

bly alignment reference (Fig. 152). Use punch or

scriber to mark gear and shaft.

Fig. 147 Removing Sun Gear, Thrust Bearing And

Planetary Gear

1 - PLANETARY GEAR

2 - PLANETARY THRUST BEARING

3 - CLUTCH SPRING PLATE

4 - SPRING PLATE SNAP-RING

5 - SUN GEAR

Fig. 148 Overrunning Clutch

1 - OVERRUNNING CLUTCH

2 - NEEDLE BEARING

Fig. 149 Marking Direct Clutch Drum And Annulus

Gear For Assembly Alignment

1 - DIRECT CLUTCH DRUM

2 - HAMMER

3 - PUNCH

Fig. 150 Clutch Drum Inner Retaining Ring Removal

1 - INNER RETAINING RING

2 - DIRECT CLUTCH DRUM

3 - ANNULUS GEAR

WJAUTOMATIC TRANSMISSION - 42RE 21 - 93

OVERDRIVE UNIT (Continued)

Page 1615 of 2199

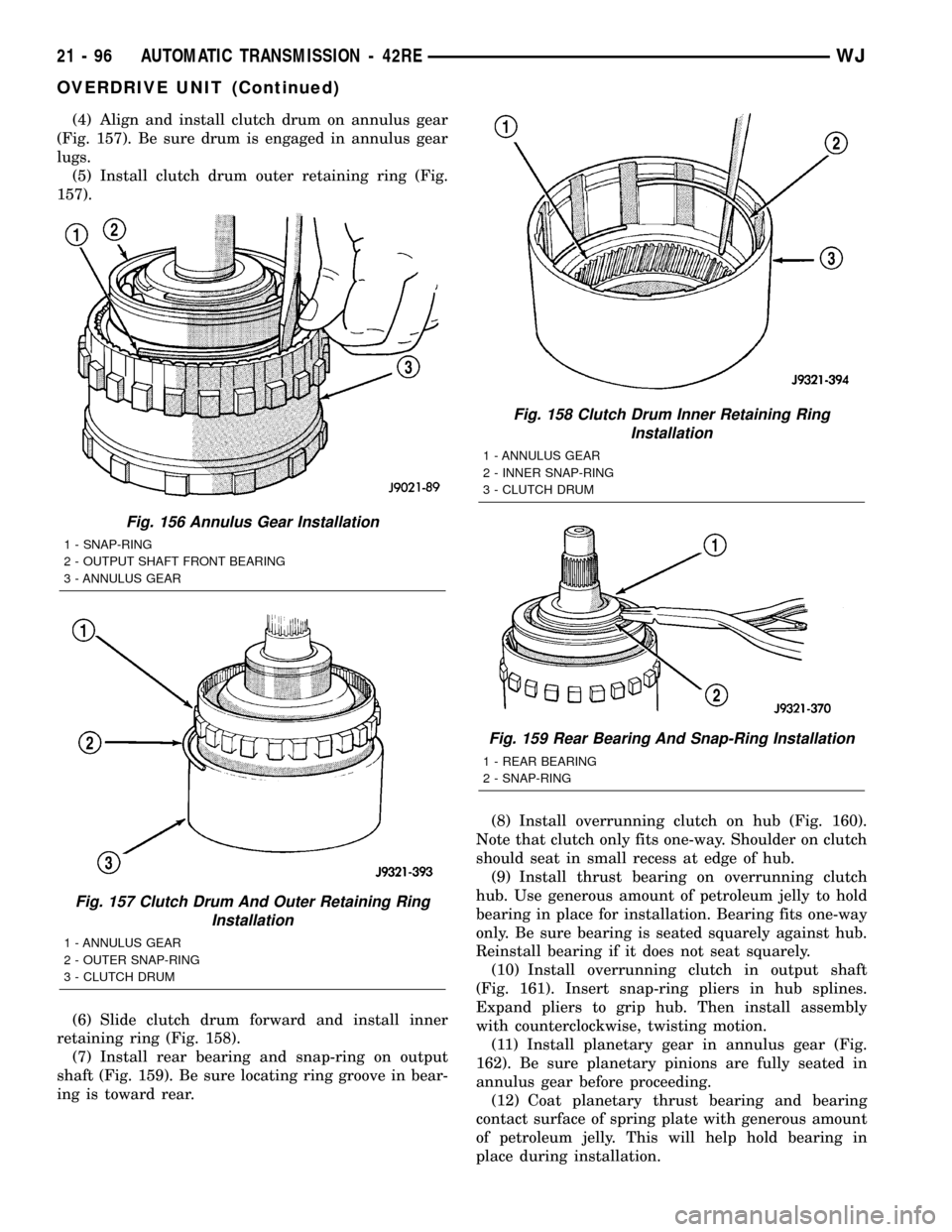

(4) Align and install clutch drum on annulus gear

(Fig. 157). Be sure drum is engaged in annulus gear

lugs.

(5) Install clutch drum outer retaining ring (Fig.

157).

(6) Slide clutch drum forward and install inner

retaining ring (Fig. 158).

(7) Install rear bearing and snap-ring on output

shaft (Fig. 159). Be sure locating ring groove in bear-

ing is toward rear.(8) Install overrunning clutch on hub (Fig. 160).

Note that clutch only fits one-way. Shoulder on clutch

should seat in small recess at edge of hub.

(9) Install thrust bearing on overrunning clutch

hub. Use generous amount of petroleum jelly to hold

bearing in place for installation. Bearing fits one-way

only. Be sure bearing is seated squarely against hub.

Reinstall bearing if it does not seat squarely.

(10) Install overrunning clutch in output shaft

(Fig. 161). Insert snap-ring pliers in hub splines.

Expand pliers to grip hub. Then install assembly

with counterclockwise, twisting motion.

(11) Install planetary gear in annulus gear (Fig.

162). Be sure planetary pinions are fully seated in

annulus gear before proceeding.

(12) Coat planetary thrust bearing and bearing

contact surface of spring plate with generous amount

of petroleum jelly. This will help hold bearing in

place during installation.

Fig. 156 Annulus Gear Installation

1 - SNAP-RING

2 - OUTPUT SHAFT FRONT BEARING

3 - ANNULUS GEAR

Fig. 157 Clutch Drum And Outer Retaining Ring

Installation

1 - ANNULUS GEAR

2 - OUTER SNAP-RING

3 - CLUTCH DRUM

Fig. 158 Clutch Drum Inner Retaining Ring

Installation

1 - ANNULUS GEAR

2 - INNER SNAP-RING

3 - CLUTCH DRUM

Fig. 159 Rear Bearing And Snap-Ring Installation

1 - REAR BEARING

2 - SNAP-RING

21 - 96 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1617 of 2199

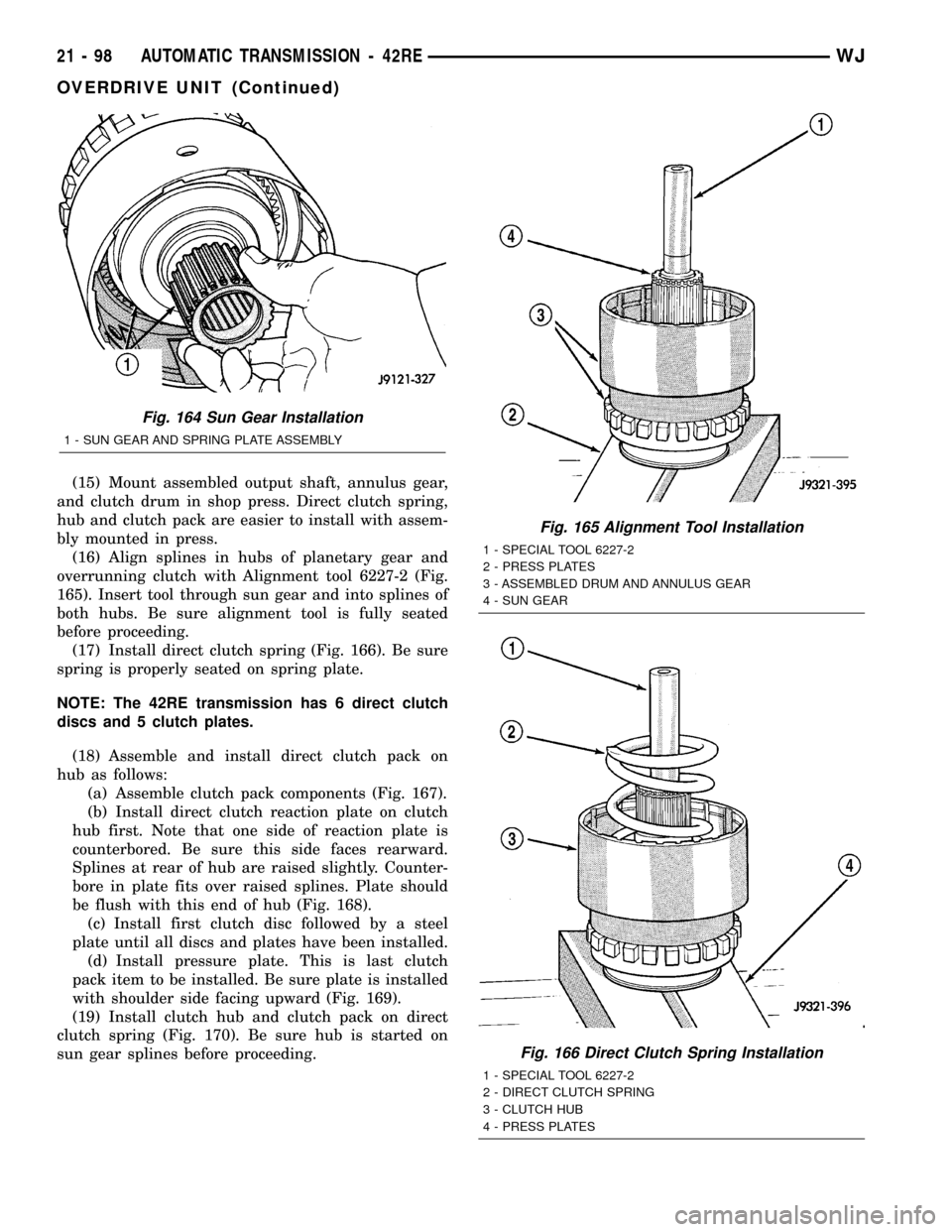

(15) Mount assembled output shaft, annulus gear,

and clutch drum in shop press. Direct clutch spring,

hub and clutch pack are easier to install with assem-

bly mounted in press.

(16) Align splines in hubs of planetary gear and

overrunning clutch with Alignment tool 6227-2 (Fig.

165). Insert tool through sun gear and into splines of

both hubs. Be sure alignment tool is fully seated

before proceeding.

(17) Install direct clutch spring (Fig. 166). Be sure

spring is properly seated on spring plate.

NOTE: The 42RE transmission has 6 direct clutch

discs and 5 clutch plates.

(18) Assemble and install direct clutch pack on

hub as follows:

(a) Assemble clutch pack components (Fig. 167).

(b) Install direct clutch reaction plate on clutch

hub first. Note that one side of reaction plate is

counterbored. Be sure this side faces rearward.

Splines at rear of hub are raised slightly. Counter-

bore in plate fits over raised splines. Plate should

be flush with this end of hub (Fig. 168).

(c) Install first clutch disc followed by a steel

plate until all discs and plates have been installed.

(d) Install pressure plate. This is last clutch

pack item to be installed. Be sure plate is installed

with shoulder side facing upward (Fig. 169).

(19) Install clutch hub and clutch pack on direct

clutch spring (Fig. 170). Be sure hub is started on

sun gear splines before proceeding.

Fig. 164 Sun Gear Installation

1 - SUN GEAR AND SPRING PLATE ASSEMBLY

Fig. 165 Alignment Tool Installation

1 - SPECIAL TOOL 6227-2

2 - PRESS PLATES

3 - ASSEMBLED DRUM AND ANNULUS GEAR

4 - SUN GEAR

Fig. 166 Direct Clutch Spring Installation

1 - SPECIAL TOOL 6227-2

2 - DIRECT CLUTCH SPRING

3 - CLUTCH HUB

4 - PRESS PLATES

21 - 98 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1619 of 2199

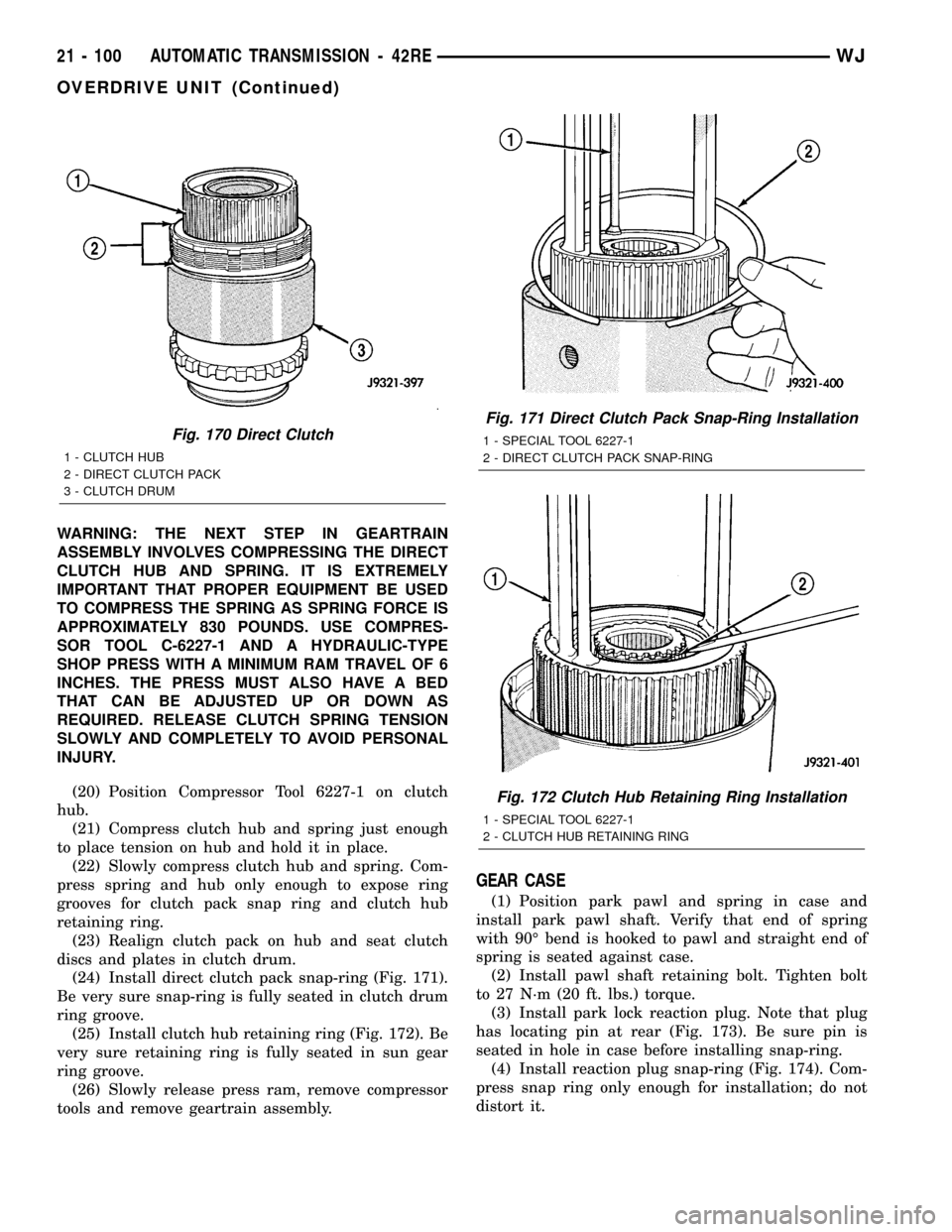

WARNING: THE NEXT STEP IN GEARTRAIN

ASSEMBLY INVOLVES COMPRESSING THE DIRECT

CLUTCH HUB AND SPRING. IT IS EXTREMELY

IMPORTANT THAT PROPER EQUIPMENT BE USED

TO COMPRESS THE SPRING AS SPRING FORCE IS

APPROXIMATELY 830 POUNDS. USE COMPRES-

SOR TOOL C-6227-1 AND A HYDRAULIC-TYPE

SHOP PRESS WITH A MINIMUM RAM TRAVEL OF 6

INCHES. THE PRESS MUST ALSO HAVE A BED

THAT CAN BE ADJUSTED UP OR DOWN AS

REQUIRED. RELEASE CLUTCH SPRING TENSION

SLOWLY AND COMPLETELY TO AVOID PERSONAL

INJURY.

(20) Position Compressor Tool 6227-1 on clutch

hub.

(21) Compress clutch hub and spring just enough

to place tension on hub and hold it in place.

(22) Slowly compress clutch hub and spring. Com-

press spring and hub only enough to expose ring

grooves for clutch pack snap ring and clutch hub

retaining ring.

(23) Realign clutch pack on hub and seat clutch

discs and plates in clutch drum.

(24) Install direct clutch pack snap-ring (Fig. 171).

Be very sure snap-ring is fully seated in clutch drum

ring groove.

(25) Install clutch hub retaining ring (Fig. 172). Be

very sure retaining ring is fully seated in sun gear

ring groove.

(26) Slowly release press ram, remove compressor

tools and remove geartrain assembly.

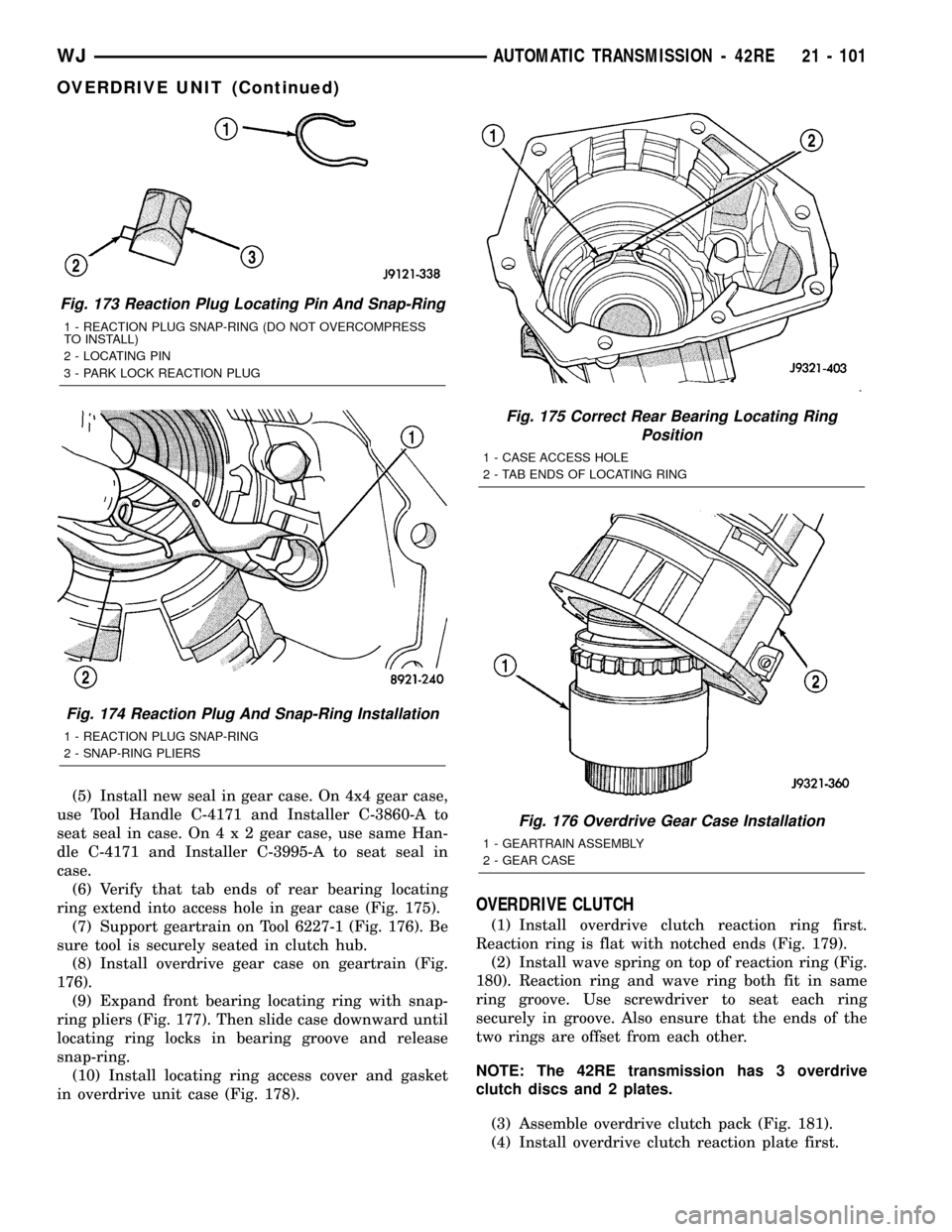

GEAR CASE

(1) Position park pawl and spring in case and

install park pawl shaft. Verify that end of spring

with 90É bend is hooked to pawl and straight end of

spring is seated against case.

(2) Install pawl shaft retaining bolt. Tighten bolt

to 27 N´m (20 ft. lbs.) torque.

(3) Install park lock reaction plug. Note that plug

has locating pin at rear (Fig. 173). Be sure pin is

seated in hole in case before installing snap-ring.

(4) Install reaction plug snap-ring (Fig. 174). Com-

press snap ring only enough for installation; do not

distort it.

Fig. 170 Direct Clutch

1 - CLUTCH HUB

2 - DIRECT CLUTCH PACK

3 - CLUTCH DRUM

Fig. 171 Direct Clutch Pack Snap-Ring Installation

1 - SPECIAL TOOL 6227-1

2 - DIRECT CLUTCH PACK SNAP-RING

Fig. 172 Clutch Hub Retaining Ring Installation

1 - SPECIAL TOOL 6227-1

2 - CLUTCH HUB RETAINING RING

21 - 100 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1620 of 2199

(5) Install new seal in gear case. On 4x4 gear case,

use Tool Handle C-4171 and Installer C-3860-A to

seat seal in case. On4x2gear case, use same Han-

dle C-4171 and Installer C-3995-A to seat seal in

case.

(6) Verify that tab ends of rear bearing locating

ring extend into access hole in gear case (Fig. 175).

(7) Support geartrain on Tool 6227-1 (Fig. 176). Be

sure tool is securely seated in clutch hub.

(8) Install overdrive gear case on geartrain (Fig.

176).

(9) Expand front bearing locating ring with snap-

ring pliers (Fig. 177). Then slide case downward until

locating ring locks in bearing groove and release

snap-ring.

(10) Install locating ring access cover and gasket

in overdrive unit case (Fig. 178).

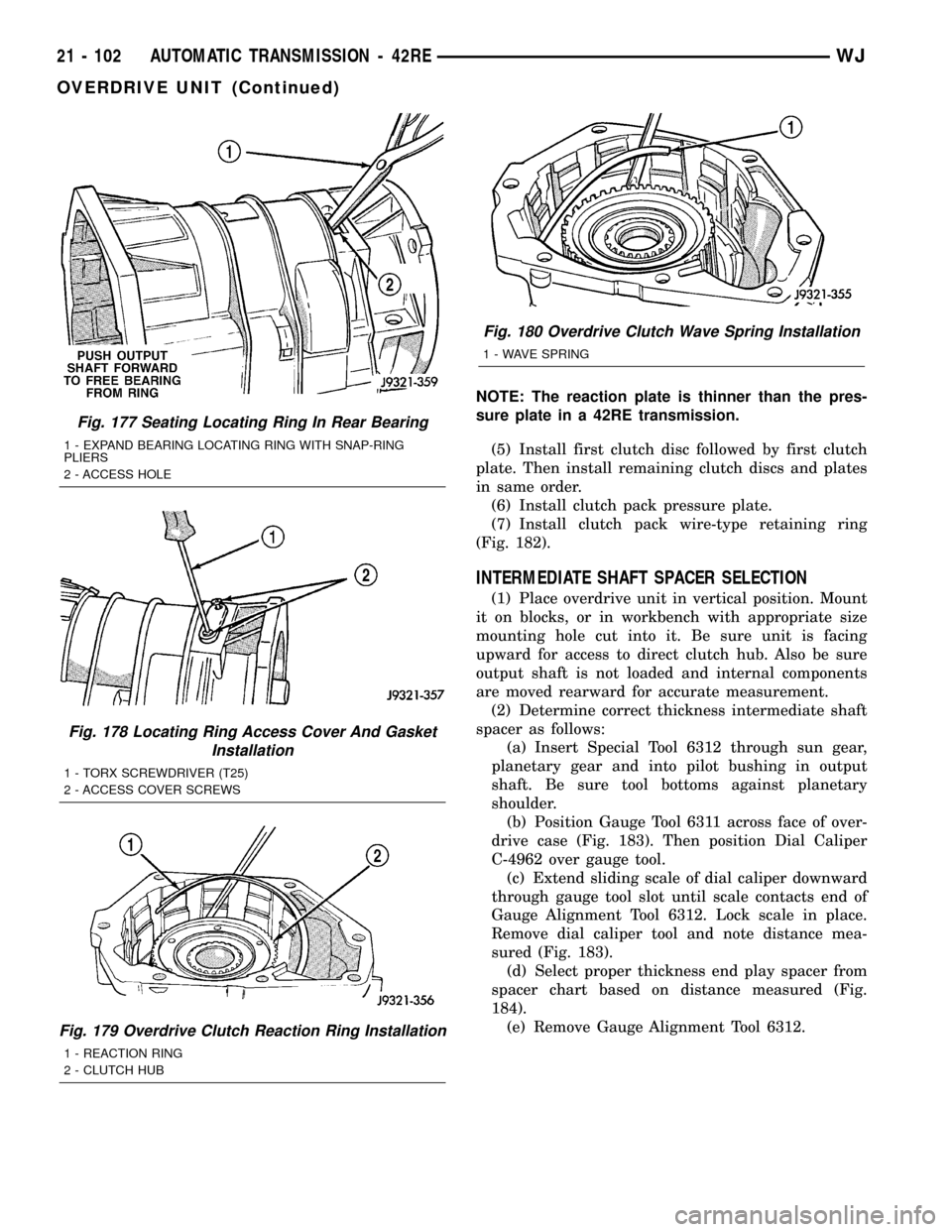

OVERDRIVE CLUTCH

(1) Install overdrive clutch reaction ring first.

Reaction ring is flat with notched ends (Fig. 179).

(2) Install wave spring on top of reaction ring (Fig.

180). Reaction ring and wave ring both fit in same

ring groove. Use screwdriver to seat each ring

securely in groove. Also ensure that the ends of the

two rings are offset from each other.

NOTE: The 42RE transmission has 3 overdrive

clutch discs and 2 plates.

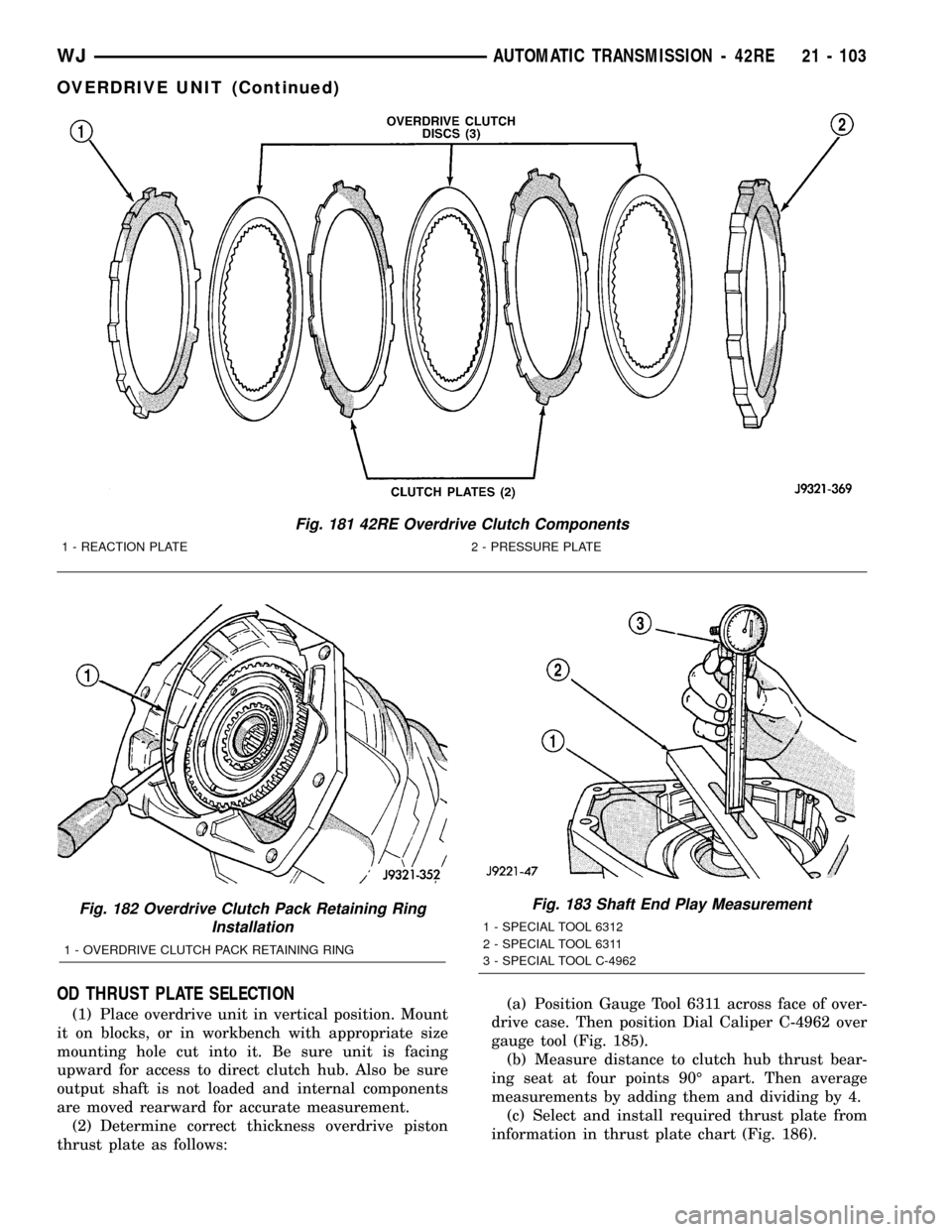

(3) Assemble overdrive clutch pack (Fig. 181).

(4) Install overdrive clutch reaction plate first.

Fig. 173 Reaction Plug Locating Pin And Snap-Ring

1 - REACTION PLUG SNAP-RING (DO NOT OVERCOMPRESS

TO INSTALL)

2 - LOCATING PIN

3 - PARK LOCK REACTION PLUG

Fig. 174 Reaction Plug And Snap-Ring Installation

1 - REACTION PLUG SNAP-RING

2 - SNAP-RING PLIERS

Fig. 175 Correct Rear Bearing Locating Ring

Position

1 - CASE ACCESS HOLE

2 - TAB ENDS OF LOCATING RING

Fig. 176 Overdrive Gear Case Installation

1 - GEARTRAIN ASSEMBLY

2 - GEAR CASE

WJAUTOMATIC TRANSMISSION - 42RE 21 - 101

OVERDRIVE UNIT (Continued)

Page 1621 of 2199

NOTE: The reaction plate is thinner than the pres-

sure plate in a 42RE transmission.

(5) Install first clutch disc followed by first clutch

plate. Then install remaining clutch discs and plates

in same order.

(6) Install clutch pack pressure plate.

(7) Install clutch pack wire-type retaining ring

(Fig. 182).

INTERMEDIATE SHAFT SPACER SELECTION

(1) Place overdrive unit in vertical position. Mount

it on blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be sure

output shaft is not loaded and internal components

are moved rearward for accurate measurement.

(2) Determine correct thickness intermediate shaft

spacer as follows:

(a) Insert Special Tool 6312 through sun gear,

planetary gear and into pilot bushing in output

shaft. Be sure tool bottoms against planetary

shoulder.

(b) Position Gauge Tool 6311 across face of over-

drive case (Fig. 183). Then position Dial Caliper

C-4962 over gauge tool.

(c) Extend sliding scale of dial caliper downward

through gauge tool slot until scale contacts end of

Gauge Alignment Tool 6312. Lock scale in place.

Remove dial caliper tool and note distance mea-

sured (Fig. 183).

(d) Select proper thickness end play spacer from

spacer chart based on distance measured (Fig.

184).

(e) Remove Gauge Alignment Tool 6312.

Fig. 177 Seating Locating Ring In Rear Bearing

1 - EXPAND BEARING LOCATING RING WITH SNAP-RING

PLIERS

2 - ACCESS HOLE

Fig. 178 Locating Ring Access Cover And Gasket

Installation

1 - TORX SCREWDRIVER (T25)

2 - ACCESS COVER SCREWS

Fig. 179 Overdrive Clutch Reaction Ring Installation

1 - REACTION RING

2 - CLUTCH HUB

Fig. 180 Overdrive Clutch Wave Spring Installation

1 - WAVE SPRING

21 - 102 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1622 of 2199

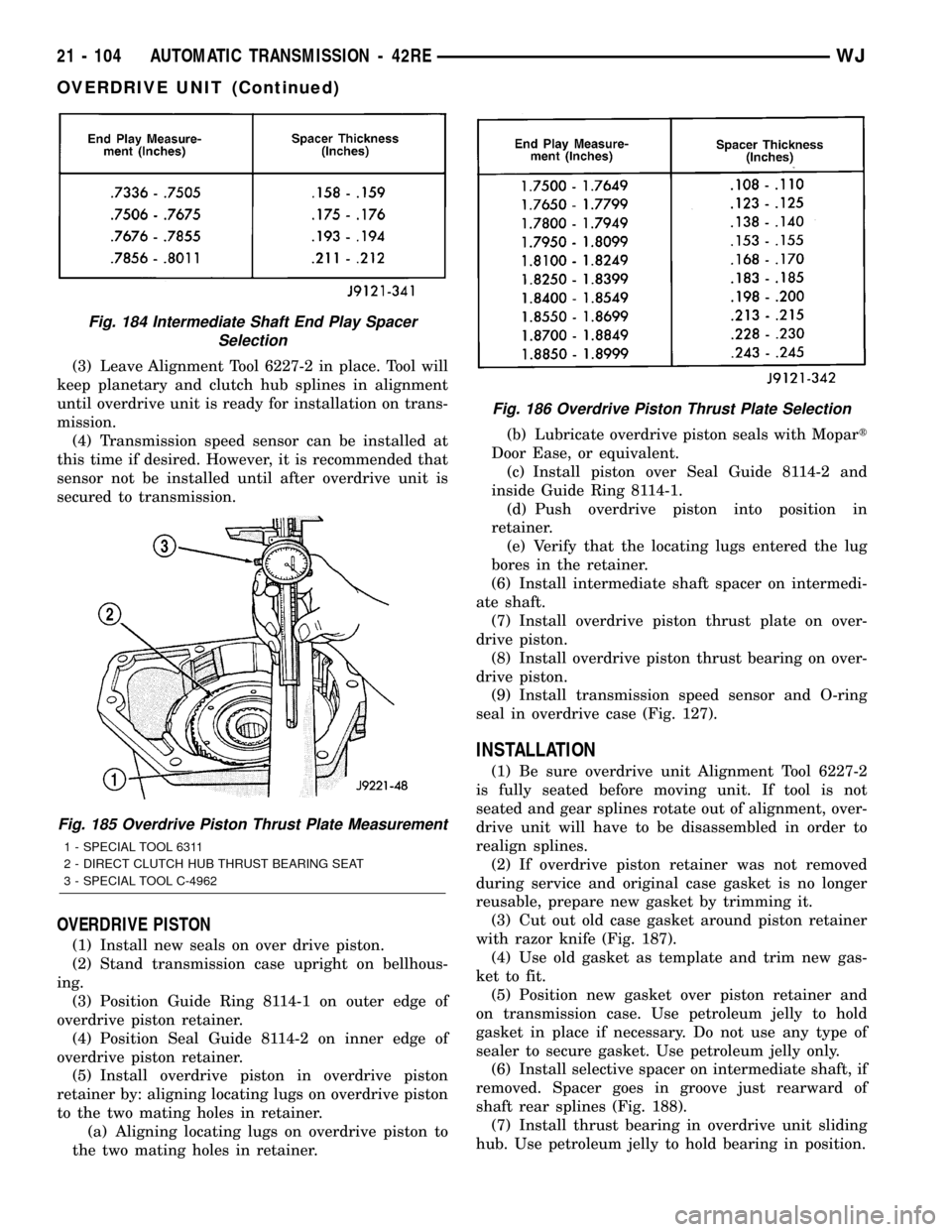

OD THRUST PLATE SELECTION

(1) Place overdrive unit in vertical position. Mount

it on blocks, or in workbench with appropriate size

mounting hole cut into it. Be sure unit is facing

upward for access to direct clutch hub. Also be sure

output shaft is not loaded and internal components

are moved rearward for accurate measurement.

(2) Determine correct thickness overdrive piston

thrust plate as follows:(a) Position Gauge Tool 6311 across face of over-

drive case. Then position Dial Caliper C-4962 over

gauge tool (Fig. 185).

(b) Measure distance to clutch hub thrust bear-

ing seat at four points 90É apart. Then average

measurements by adding them and dividing by 4.

(c) Select and install required thrust plate from

information in thrust plate chart (Fig. 186).

Fig. 181 42RE Overdrive Clutch Components

1 - REACTION PLATE 2 - PRESSURE PLATE

Fig. 182 Overdrive Clutch Pack Retaining Ring

Installation

1 - OVERDRIVE CLUTCH PACK RETAINING RING

Fig. 183 Shaft End Play Measurement

1 - SPECIAL TOOL 6312

2 - SPECIAL TOOL 6311

3 - SPECIAL TOOL C-4962

WJAUTOMATIC TRANSMISSION - 42RE 21 - 103

OVERDRIVE UNIT (Continued)

Page 1623 of 2199

(3) Leave Alignment Tool 6227-2 in place. Tool will

keep planetary and clutch hub splines in alignment

until overdrive unit is ready for installation on trans-

mission.

(4) Transmission speed sensor can be installed at

this time if desired. However, it is recommended that

sensor not be installed until after overdrive unit is

secured to transmission.

OVERDRIVE PISTON

(1) Install new seals on over drive piston.

(2) Stand transmission case upright on bellhous-

ing.

(3) Position Guide Ring 8114-1 on outer edge of

overdrive piston retainer.

(4) Position Seal Guide 8114-2 on inner edge of

overdrive piston retainer.

(5) Install overdrive piston in overdrive piston

retainer by: aligning locating lugs on overdrive piston

to the two mating holes in retainer.

(a) Aligning locating lugs on overdrive piston to

the two mating holes in retainer.(b) Lubricate overdrive piston seals with Mopart

Door Ease, or equivalent.

(c) Install piston over Seal Guide 8114-2 and

inside Guide Ring 8114-1.

(d) Push overdrive piston into position in

retainer.

(e) Verify that the locating lugs entered the lug

bores in the retainer.

(6) Install intermediate shaft spacer on intermedi-

ate shaft.

(7) Install overdrive piston thrust plate on over-

drive piston.

(8) Install overdrive piston thrust bearing on over-

drive piston.

(9) Install transmission speed sensor and O-ring

seal in overdrive case (Fig. 127).

INSTALLATION

(1) Be sure overdrive unit Alignment Tool 6227-2

is fully seated before moving unit. If tool is not

seated and gear splines rotate out of alignment, over-

drive unit will have to be disassembled in order to

realign splines.

(2) If overdrive piston retainer was not removed

during service and original case gasket is no longer

reusable, prepare new gasket by trimming it.

(3) Cut out old case gasket around piston retainer

with razor knife (Fig. 187).

(4) Use old gasket as template and trim new gas-

ket to fit.

(5) Position new gasket over piston retainer and

on transmission case. Use petroleum jelly to hold

gasket in place if necessary. Do not use any type of

sealer to secure gasket. Use petroleum jelly only.

(6) Install selective spacer on intermediate shaft, if

removed. Spacer goes in groove just rearward of

shaft rear splines (Fig. 188).

(7) Install thrust bearing in overdrive unit sliding

hub. Use petroleum jelly to hold bearing in position.

Fig. 184 Intermediate Shaft End Play Spacer

Selection

Fig. 185 Overdrive Piston Thrust Plate Measurement

1 - SPECIAL TOOL 6311

2 - DIRECT CLUTCH HUB THRUST BEARING SEAT

3 - SPECIAL TOOL C-4962

Fig. 186 Overdrive Piston Thrust Plate Selection

21 - 104 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)