Actuator JEEP GRAND CHEROKEE 2003 WJ / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 2126 of 2199

INSTALLATION

INSTALLATION - PANEL OUTLET DOOR

(1) Snap the panel outlet door pivot shaft retainer

on the pivot shaft.

(2) Attach the panel outlet door pivot shaft to the

HVAC case.

(3) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

INSTALLATION - HEAT/DEFROST DOOR

(1) Install the heat/defrost door by snapping the

heat/defrost door pivot shaft into the HVAC case.

(2) Install the heat/defrost door sub-assembly and

tighten the mounting screws to 2.2 N´m (20 in. lbs.).

(3) Attach the metal linkage to the heat/defrost

door lever.

(4) Snap the duct adapter to the bottom of the

heat/defrost door sub-assembly.

(5) Install the 2 floor heat ducts and tighten the

mounting screws to 2.2 N´m (20 in. lbs.)..

(6) Install the evaporator, and styrofoam tray in

the lower case.

(7) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

INSTALLATION - PANEL/DEFROST DOOR

(1) Snap the panel/defrost door pivot shaft retainer

on the pivot shaft.

(2) Attach the panel/defrost door pivot shaft to the

HVAC case.

(3) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

RECIRCULATION DOOR

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Place the HVAC housing right side up on the

work bench.

(3) Unplug the wire/vacuum connector from the

recirculation door actuator.

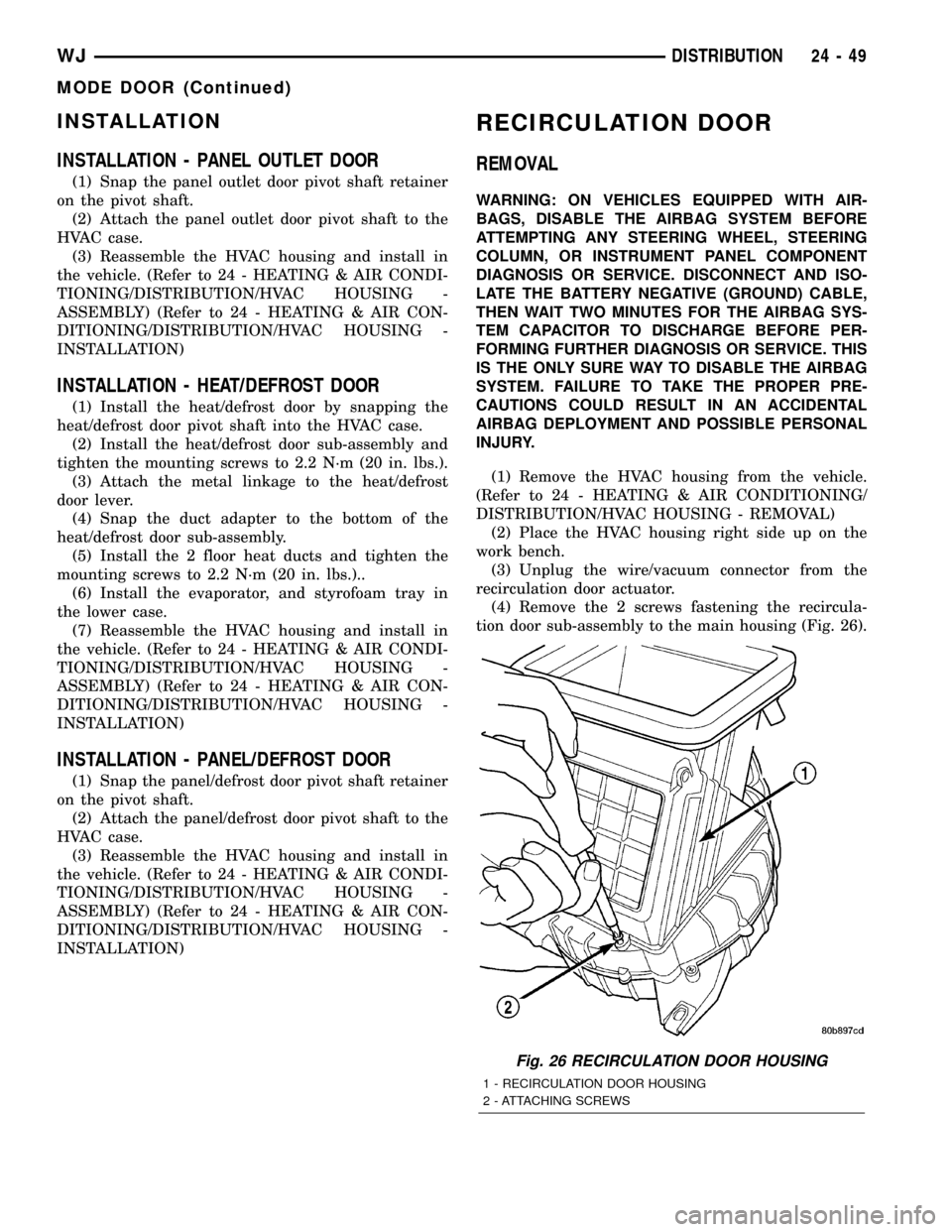

(4) Remove the 2 screws fastening the recircula-

tion door sub-assembly to the main housing (Fig. 26).

Fig. 26 RECIRCULATION DOOR HOUSING

1 - RECIRCULATION DOOR HOUSING

2 - ATTACHING SCREWS

WJDISTRIBUTION 24 - 49

MODE DOOR (Continued)

Page 2127 of 2199

(5) Raise the front of the door sub-assembly while

releasing the 2 tabs holding the rear to the main

housing, and remove the recirculation door housing.

(6) Remove the electric/vacuum actuator from the

recirculation door sub-assembly and set aside.

(7) Pinch the retention tabs holding the recircula-

tion door pivot shaft to the case. The 3 plastic tabs,

located on the inside of the case, are part of the shaft

retainer.

(8) Remove the recirculation door from the recircu-

lation air door housing.

INSTALLATION

(1) Install the recirculation door in the recircula-

tion air door housing by snapping the pivot shaft

retention tabs into the case.

(2) Install the electric/vacuum actuator on the

recirculation door sub-assembly. Check door for bind-

ing after replacement.

(3) Install the recirculation door housing on the

HVAC case and tighten the 2 screws to 2.2 N´m (20

in. lbs.).

(4) Plug in the wire/vacuum connector to the recir-

culation door actuator.

(5) Install the HVAC housing in the vehicle. (Refer

to 24 - HEATING & AIR CONDITIONING/DISTRI-

BUTION/HVAC HOUSING - INSTALLATION)

24 - 50 DISTRIBUTIONWJ

RECIRCULATION DOOR (Continued)

Page 2147 of 2199

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Install the evaporator coil in the bottom half of

the HVAC housing. Be certain that the evaporator

foam insulator wrap is reinstalled.

(2) Reassemble the HVAC housing and install in

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION/HVAC HOUSING -

ASSEMBLY) (Refer to 24 - HEATING & AIR CON-

DITIONING/DISTRIBUTION/HVAC HOUSING -

INSTALLATION)

NOTE: If the evaporator is replaced, add 60 millili-

ters (2 fluid ounces) of refrigerant oil to the refrig-

erant system.

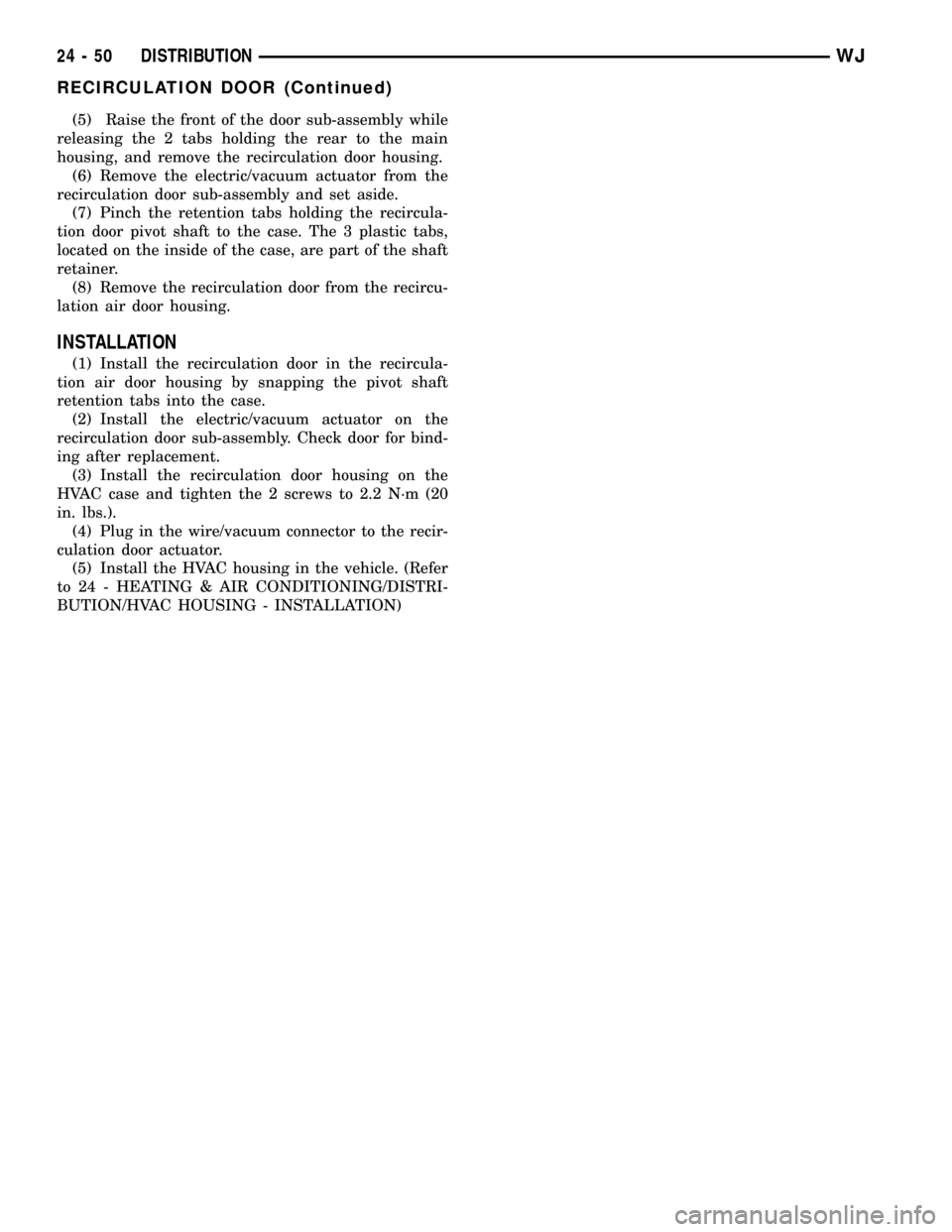

Fig. 11 HVAC HOUSING- CASE SEPARATED

1 - ELECTRICIAL CONNECTORS

2 - VACUUM ACTUATOR

3 - RECIRCULATION DOOR

4 - THERMAL EXPANSION VALVE

5 - BLOWER MOTOR RESISTOR/CONTROLLER

6 - BLOWER WHEEL

7 - EVAPORATOR AND TUBES

8 - FIN SENSOR PROBE9 - BLEND DOOR

10 - PIVOT SHAFT (MOTOR REMOVED)

11 - PANEL/OUTLET DOOR

12 - LOWER HOUSING

13 - VACUUM ACTUATORS

14 - UPPER HOUSING

15 - VACUUM HARNESS

24 - 70 PLUMBINGWJ

A/C EVAPORATOR (Continued)

Page 2148 of 2199

HEATER CORE

DESCRIPTION

The heater core is located in the HVAC housing,

under the instrument panel. It is a heat exchanger

made of rows of tubes and fins.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The temperature

control door allows control of the heater output air

temperature by controlling how much of the air flow-

ing through the HVAC housing is directed through

the heater core. The blower motor speed controls the

volume of air flowing through the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced. Refer to Cooling for

more information on the engine cooling system, the

engine coolant and the heater hoses.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

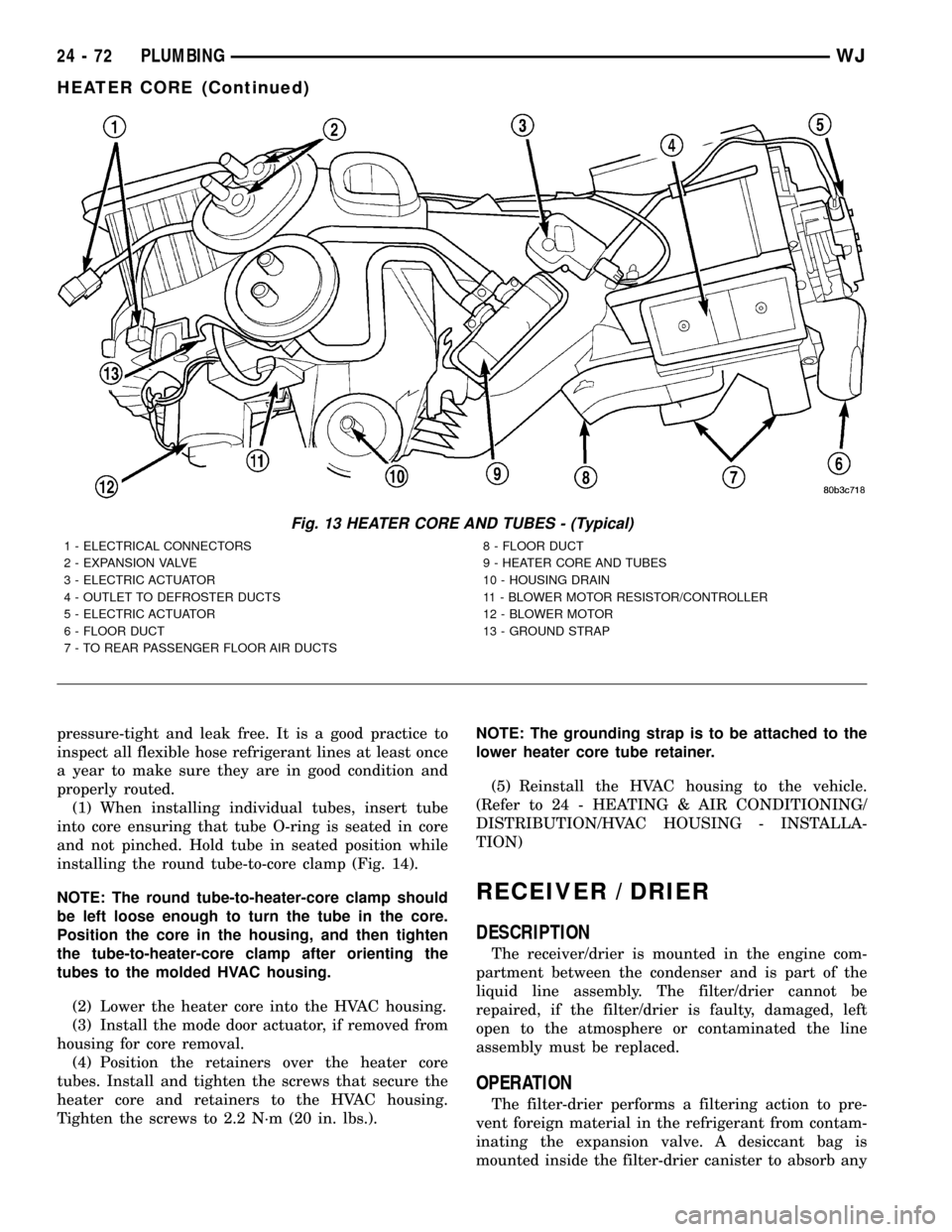

(1) Remove the HVAC housing from the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL)

(2) Remove the foam gasket surrounding the core

tubes.

NOTE: Notice the orientation of the irregularly

shaped gasket on the tubes. The gasket must be

placed correctly to ensure proper sealing against

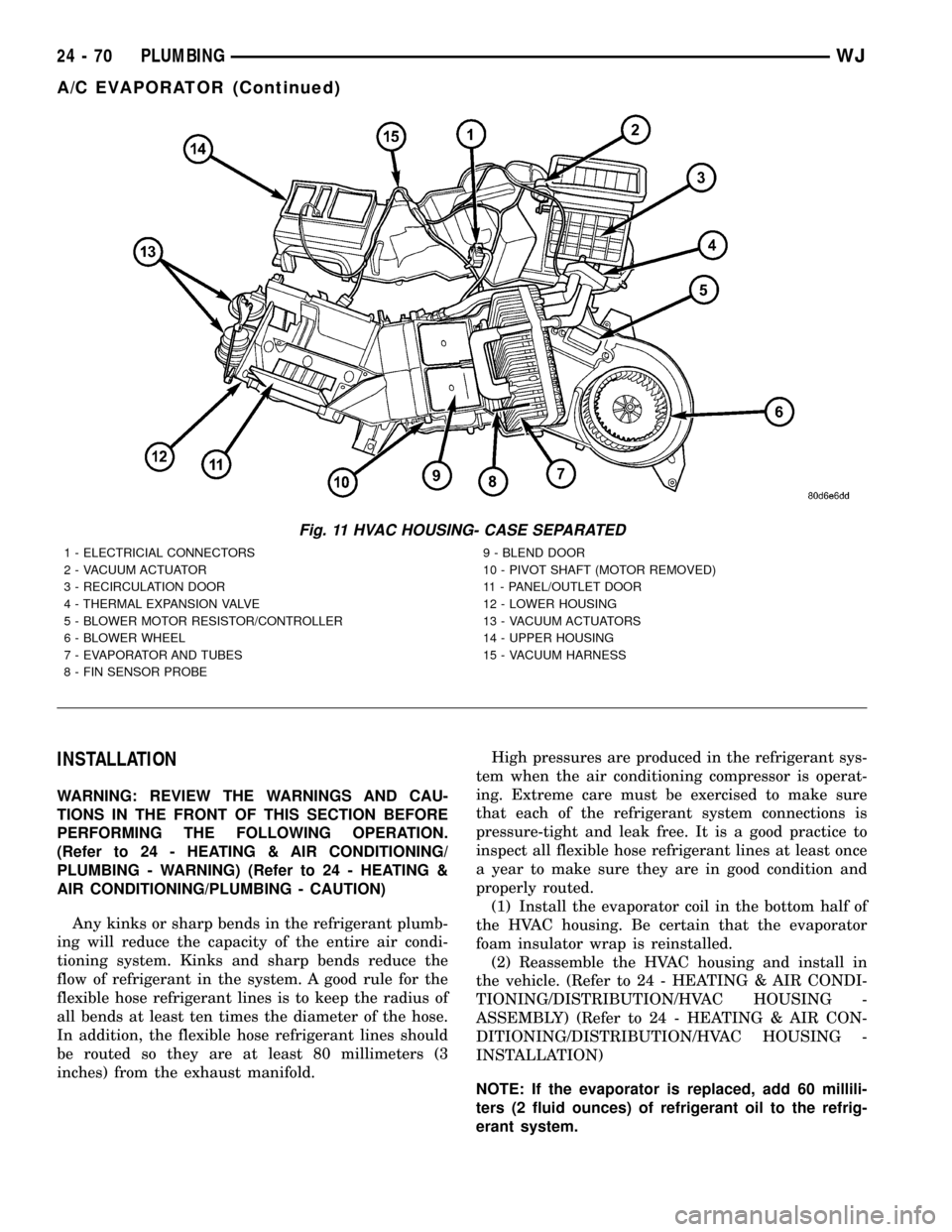

the body during reinstallation.(3)

Remove the screws and retainers that secure the

heater core and tubes to the HVAC housing (Fig. 12).

(4) Remove the mode door actuator if necessary,

for clearance to remove the core.

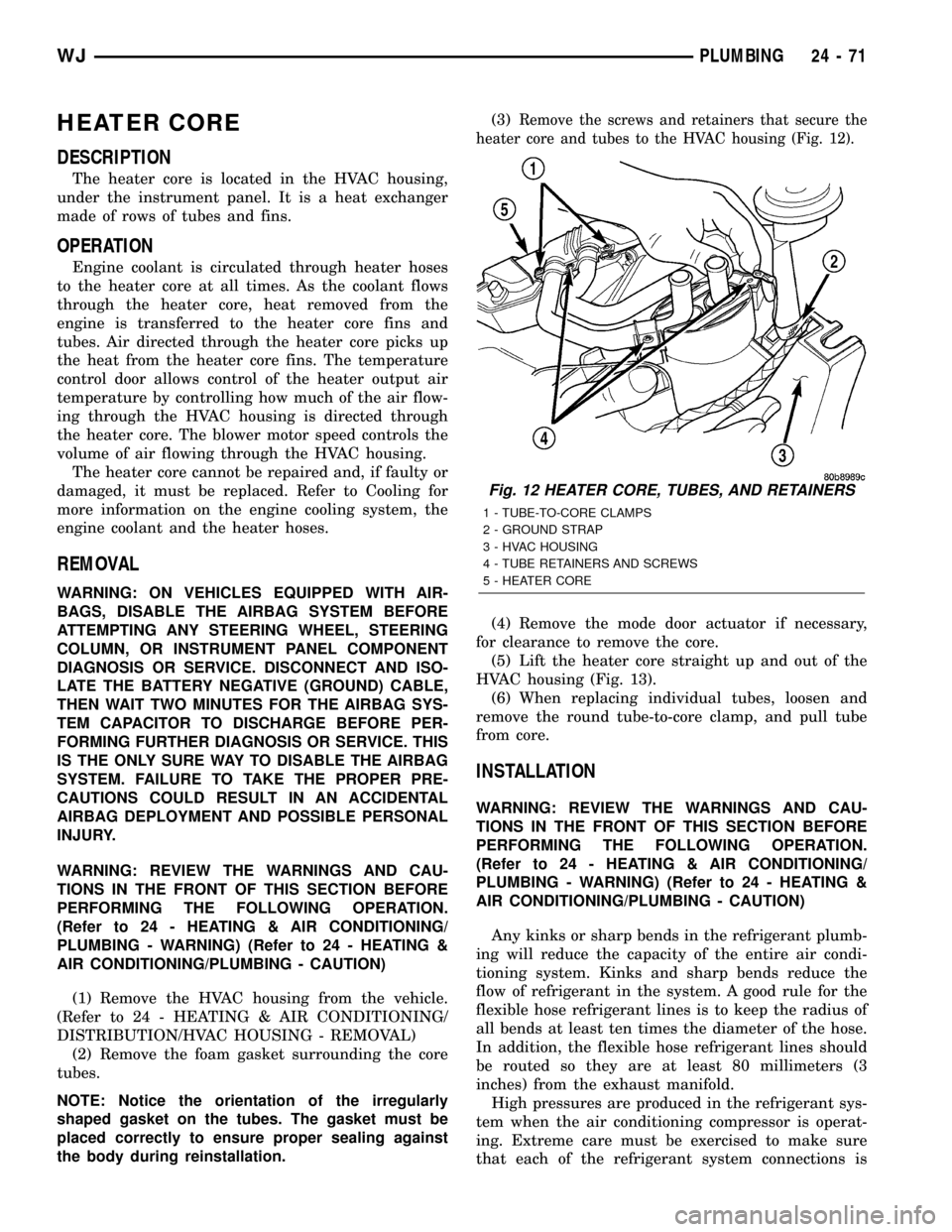

(5) Lift the heater core straight up and out of the

HVAC housing (Fig. 13).

(6) When replacing individual tubes, loosen and

remove the round tube-to-core clamp, and pull tube

from core.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

Fig. 12 HEATER CORE, TUBES, AND RETAINERS

1 - TUBE-TO-CORE CLAMPS

2 - GROUND STRAP

3 - HVAC HOUSING

4 - TUBE RETAINERS AND SCREWS

5 - HEATER CORE

WJPLUMBING 24 - 71

Page 2149 of 2199

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) When installing individual tubes, insert tube

into core ensuring that tube O-ring is seated in core

and not pinched. Hold tube in seated position while

installing the round tube-to-core clamp (Fig. 14).

NOTE: The round tube-to-heater-core clamp should

be left loose enough to turn the tube in the core.

Position the core in the housing, and then tighten

the tube-to-heater-core clamp after orienting the

tubes to the molded HVAC housing.

(2) Lower the heater core into the HVAC housing.

(3) Install the mode door actuator, if removed from

housing for core removal.

(4) Position the retainers over the heater core

tubes. Install and tighten the screws that secure the

heater core and retainers to the HVAC housing.

Tighten the screws to 2.2 N´m (20 in. lbs.).NOTE: The grounding strap is to be attached to the

lower heater core tube retainer.

(5) Reinstall the HVAC housing to the vehicle.

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - INSTALLA-

TION)

RECEIVER / DRIER

DESCRIPTION

The receiver/drier is mounted in the engine com-

partment between the condenser and is part of the

liquid line assembly. The filter/drier cannot be

repaired, if the filter/drier is faulty, damaged, left

open to the atmosphere or contaminated the line

assembly must be replaced.

OPERATION

The filter-drier performs a filtering action to pre-

vent foreign material in the refrigerant from contam-

inating the expansion valve. A desiccant bag is

mounted inside the filter-drier canister to absorb any

Fig. 13 HEATER CORE AND TUBES - (Typical)

1 - ELECTRICAL CONNECTORS

2 - EXPANSION VALVE

3 - ELECTRIC ACTUATOR

4 - OUTLET TO DEFROSTER DUCTS

5 - ELECTRIC ACTUATOR

6 - FLOOR DUCT

7 - TO REAR PASSENGER FLOOR AIR DUCTS8 - FLOOR DUCT

9 - HEATER CORE AND TUBES

10 - HOUSING DRAIN

11 - BLOWER MOTOR RESISTOR/CONTROLLER

12 - BLOWER MOTOR

13 - GROUND STRAP

24 - 72 PLUMBINGWJ

HEATER CORE (Continued)

Page 2157 of 2199

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connect

the DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

DESCRIPTION - DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

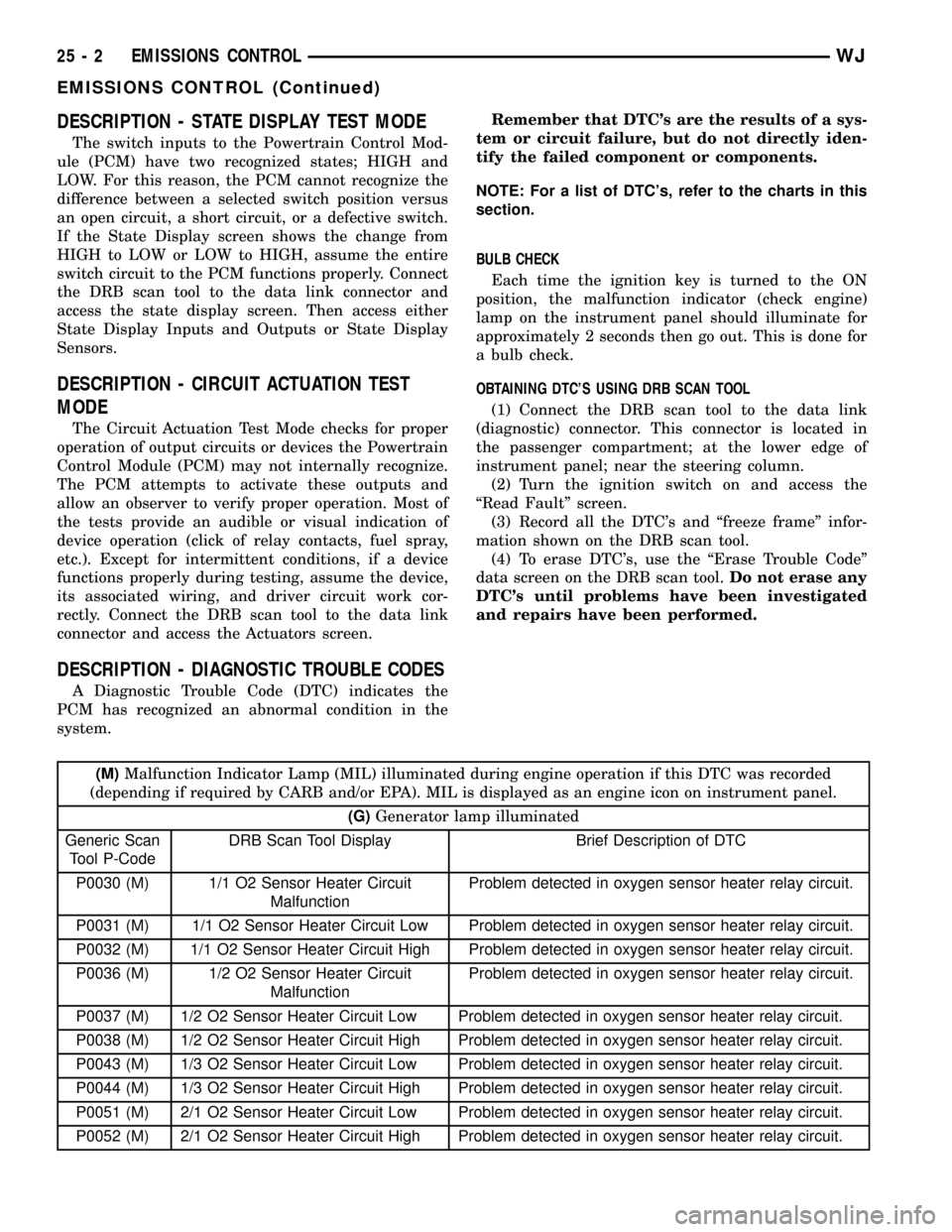

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0030 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0031 (M) 1/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0032 (M) 1/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0036 (M) 1/2 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0037 (M) 1/2 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0038 (M) 1/2 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0043 (M) 1/3 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0044 (M) 1/3 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0051 (M) 2/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0052 (M) 2/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

25 - 2 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)