Actuator JEEP GRAND CHEROKEE 2003 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1183 of 2199

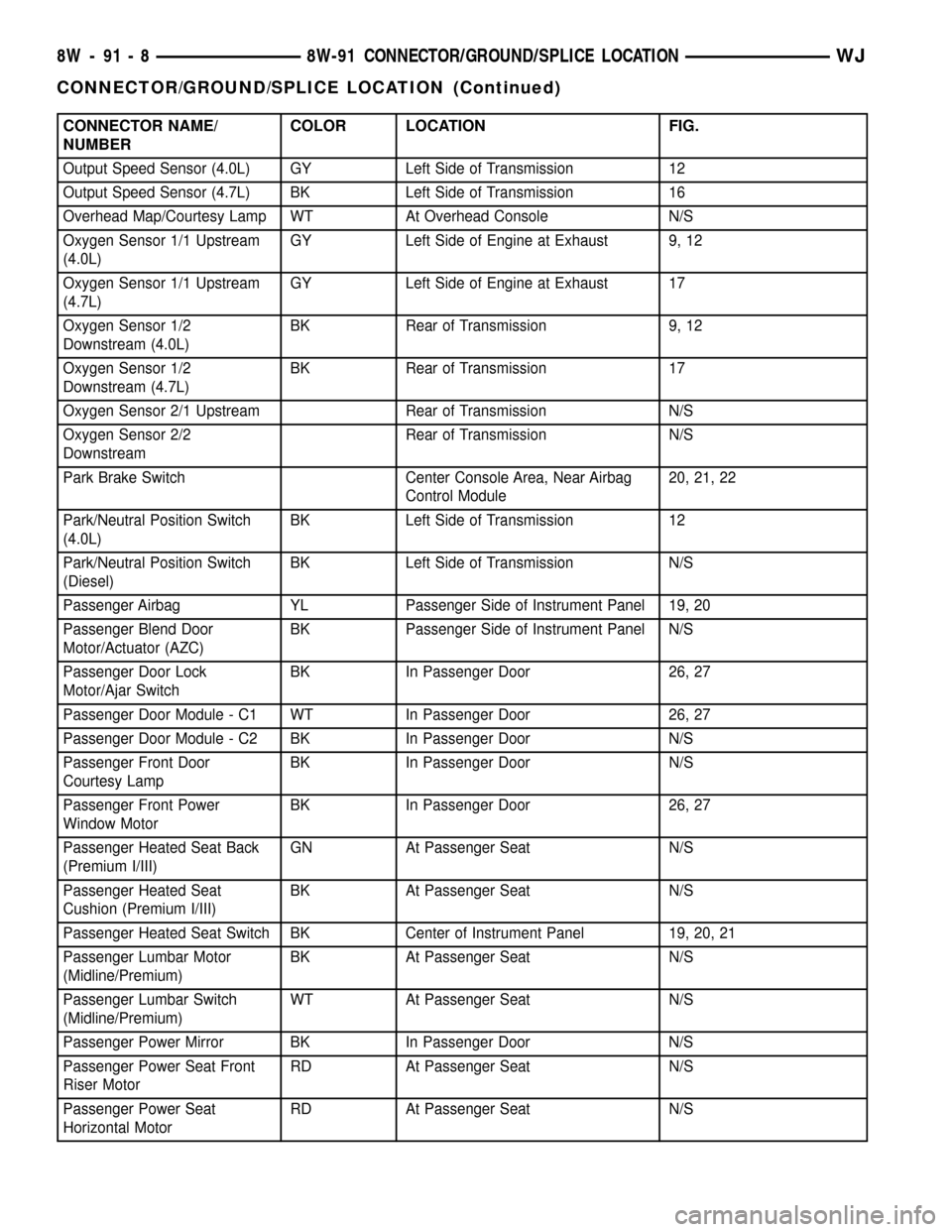

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Output Speed Sensor (4.0L) GY Left Side of Transmission 12

Output Speed Sensor (4.7L) BK Left Side of Transmission 16

Overhead Map/Courtesy Lamp WT At Overhead Console N/S

Oxygen Sensor 1/1 Upstream

(4.0L)GY Left Side of Engine at Exhaust 9, 12

Oxygen Sensor 1/1 Upstream

(4.7L)GY Left Side of Engine at Exhaust 17

Oxygen Sensor 1/2

Downstream (4.0L)BK Rear of Transmission 9, 12

Oxygen Sensor 1/2

Downstream (4.7L)BK Rear of Transmission 17

Oxygen Sensor 2/1 Upstream Rear of Transmission N/S

Oxygen Sensor 2/2

DownstreamRear of Transmission N/S

Park Brake Switch Center Console Area, Near Airbag

Control Module20, 21, 22

Park/Neutral Position Switch

(4.0L)BK Left Side of Transmission 12

Park/Neutral Position Switch

(Diesel)BK Left Side of Transmission N/S

Passenger Airbag YL Passenger Side of Instrument Panel 19, 20

Passenger Blend Door

Motor/Actuator (AZC)BK Passenger Side of Instrument Panel N/S

Passenger Door Lock

Motor/Ajar SwitchBK In Passenger Door 26, 27

Passenger Door Module - C1 WT In Passenger Door 26, 27

Passenger Door Module - C2 BK In Passenger Door N/S

Passenger Front Door

Courtesy LampBK In Passenger Door N/S

Passenger Front Power

Window MotorBK In Passenger Door 26, 27

Passenger Heated Seat Back

(Premium I/III)GN At Passenger Seat N/S

Passenger Heated Seat

Cushion (Premium I/III)BK At Passenger Seat N/S

Passenger Heated Seat Switch BK Center of Instrument Panel 19, 20, 21

Passenger Lumbar Motor

(Midline/Premium)BK At Passenger Seat N/S

Passenger Lumbar Switch

(Midline/Premium)WT At Passenger Seat N/S

Passenger Power Mirror BK In Passenger Door N/S

Passenger Power Seat Front

Riser MotorRD At Passenger Seat N/S

Passenger Power Seat

Horizontal MotorRD At Passenger Seat N/S

8W - 91 - 8 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1184 of 2199

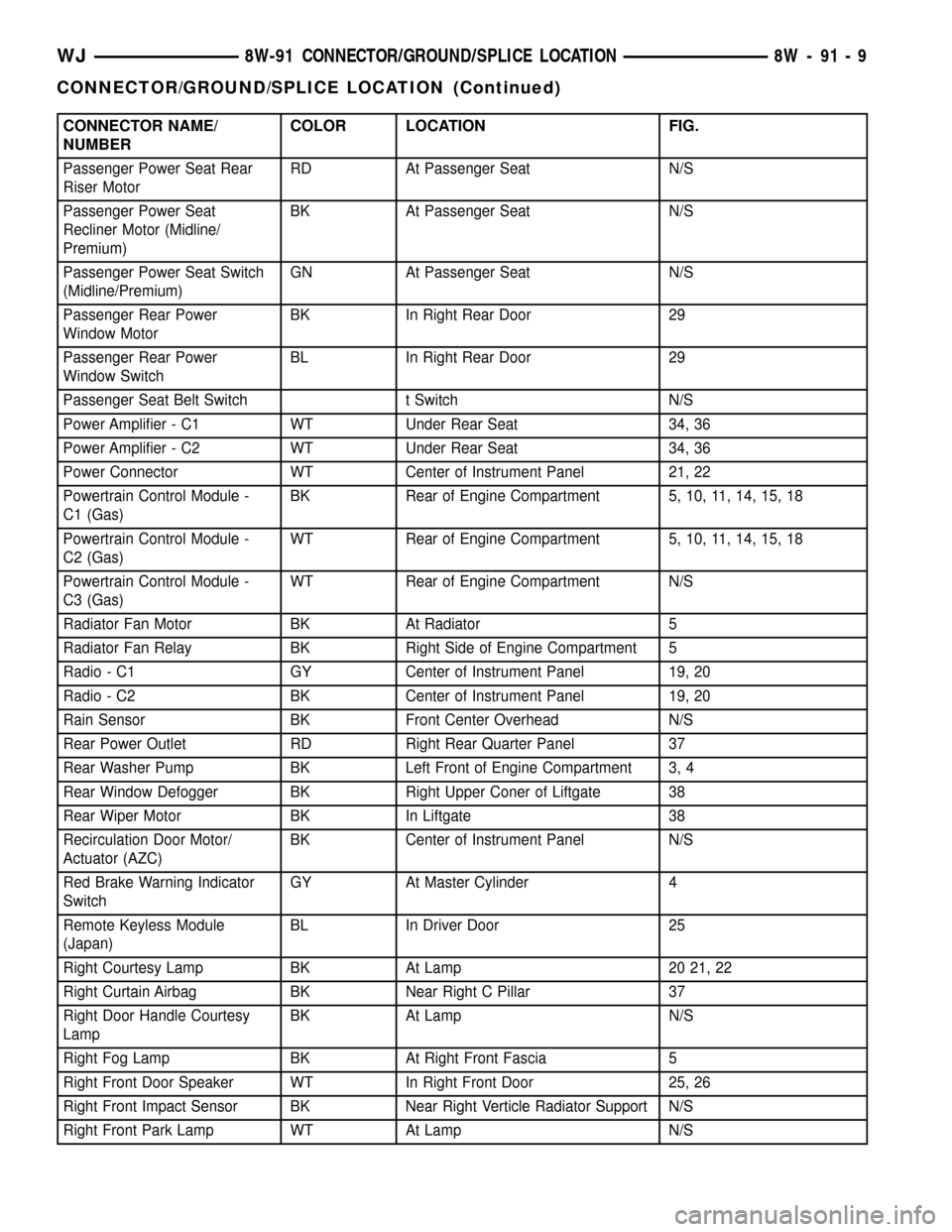

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Passenger Power Seat Rear

Riser MotorRD At Passenger Seat N/S

Passenger Power Seat

Recliner Motor (Midline/

Premium)BK At Passenger Seat N/S

Passenger Power Seat Switch

(Midline/Premium)GN At Passenger Seat N/S

Passenger Rear Power

Window MotorBK In Right Rear Door 29

Passenger Rear Power

Window SwitchBL In Right Rear Door 29

Passenger Seat Belt Switch t Switch N/S

Power Amplifier - C1 WT Under Rear Seat 34, 36

Power Amplifier - C2 WT Under Rear Seat 34, 36

Power Connector WT Center of Instrument Panel 21, 22

Powertrain Control Module -

C1 (Gas)BK Rear of Engine Compartment 5, 10, 11, 14, 15, 18

Powertrain Control Module -

C2 (Gas)WT Rear of Engine Compartment 5, 10, 11, 14, 15, 18

Powertrain Control Module -

C3 (Gas)WT Rear of Engine Compartment N/S

Radiator Fan Motor BK At Radiator 5

Radiator Fan Relay BK Right Side of Engine Compartment 5

Radio - C1 GY Center of Instrument Panel 19, 20

Radio - C2 BK Center of Instrument Panel 19, 20

Rain Sensor BK Front Center Overhead N/S

Rear Power Outlet RD Right Rear Quarter Panel 37

Rear Washer Pump BK Left Front of Engine Compartment 3, 4

Rear Window Defogger BK Right Upper Coner of Liftgate 38

Rear Wiper Motor BK In Liftgate 38

Recirculation Door Motor/

Actuator (AZC)BK Center of Instrument Panel N/S

Red Brake Warning Indicator

SwitchGY At Master Cylinder 4

Remote Keyless Module

(Japan)BL In Driver Door 25

Right Courtesy Lamp BK At Lamp 20 21, 22

Right Curtain Airbag BK Near Right C Pillar 37

Right Door Handle Courtesy

LampBK At Lamp N/S

Right Fog Lamp BK At Right Front Fascia 5

Right Front Door Speaker WT In Right Front Door 25, 26

Right Front Impact Sensor BK Near Right Verticle Radiator Support N/S

Right Front Park Lamp WT At Lamp N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 9

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1185 of 2199

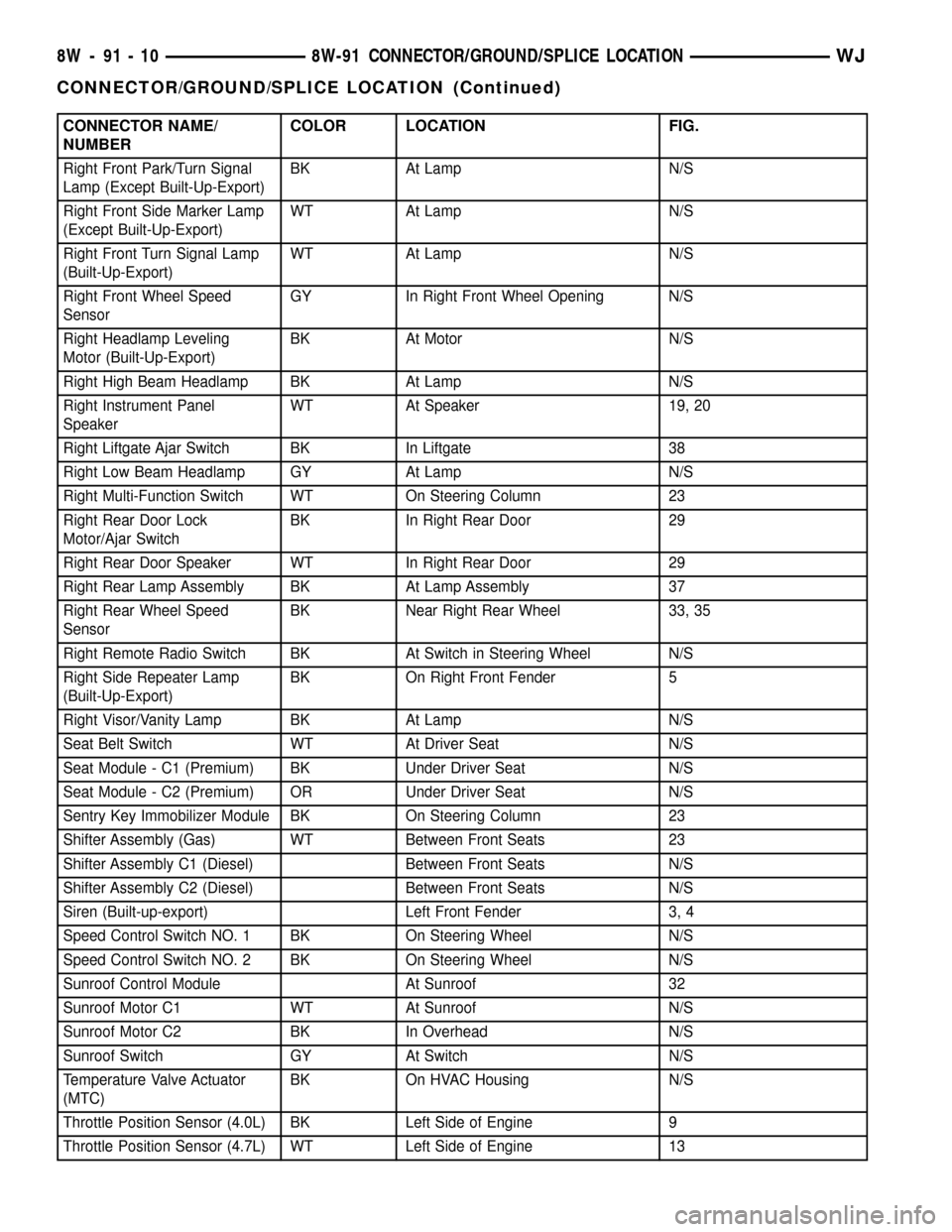

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Right Front Park/Turn Signal

Lamp (Except Built-Up-Export)BK At Lamp N/S

Right Front Side Marker Lamp

(Except Built-Up-Export)WT At Lamp N/S

Right Front Turn Signal Lamp

(Built-Up-Export)WT At Lamp N/S

Right Front Wheel Speed

SensorGY In Right Front Wheel Opening N/S

Right Headlamp Leveling

Motor (Built-Up-Export)BK At Motor N/S

Right High Beam Headlamp BK At Lamp N/S

Right Instrument Panel

SpeakerWT At Speaker 19, 20

Right Liftgate Ajar Switch BK In Liftgate 38

Right Low Beam Headlamp GY At Lamp N/S

Right Multi-Function Switch WT On Steering Column 23

Right Rear Door Lock

Motor/Ajar SwitchBK In Right Rear Door 29

Right Rear Door Speaker WT In Right Rear Door 29

Right Rear Lamp Assembly BK At Lamp Assembly 37

Right Rear Wheel Speed

SensorBK Near Right Rear Wheel 33, 35

Right Remote Radio Switch BK At Switch in Steering Wheel N/S

Right Side Repeater Lamp

(Built-Up-Export)BK On Right Front Fender 5

Right Visor/Vanity Lamp BK At Lamp N/S

Seat Belt Switch WT At Driver Seat N/S

Seat Module - C1 (Premium) BK Under Driver Seat N/S

Seat Module - C2 (Premium) OR Under Driver Seat N/S

Sentry Key Immobilizer Module BK On Steering Column 23

Shifter Assembly (Gas) WT Between Front Seats 23

Shifter Assembly C1 (Diesel) Between Front Seats N/S

Shifter Assembly C2 (Diesel) Between Front Seats N/S

Siren (Built-up-export) Left Front Fender 3, 4

Speed Control Switch NO. 1 BK On Steering Wheel N/S

Speed Control Switch NO. 2 BK On Steering Wheel N/S

Sunroof Control Module At Sunroof 32

Sunroof Motor C1 WT At Sunroof N/S

Sunroof Motor C2 BK In Overhead N/S

Sunroof Switch GY At Switch N/S

Temperature Valve Actuator

(MTC)BK On HVAC Housing N/S

Throttle Position Sensor (4.0L) BK Left Side of Engine 9

Throttle Position Sensor (4.7L) WT Left Side of Engine 13

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1644 of 2199

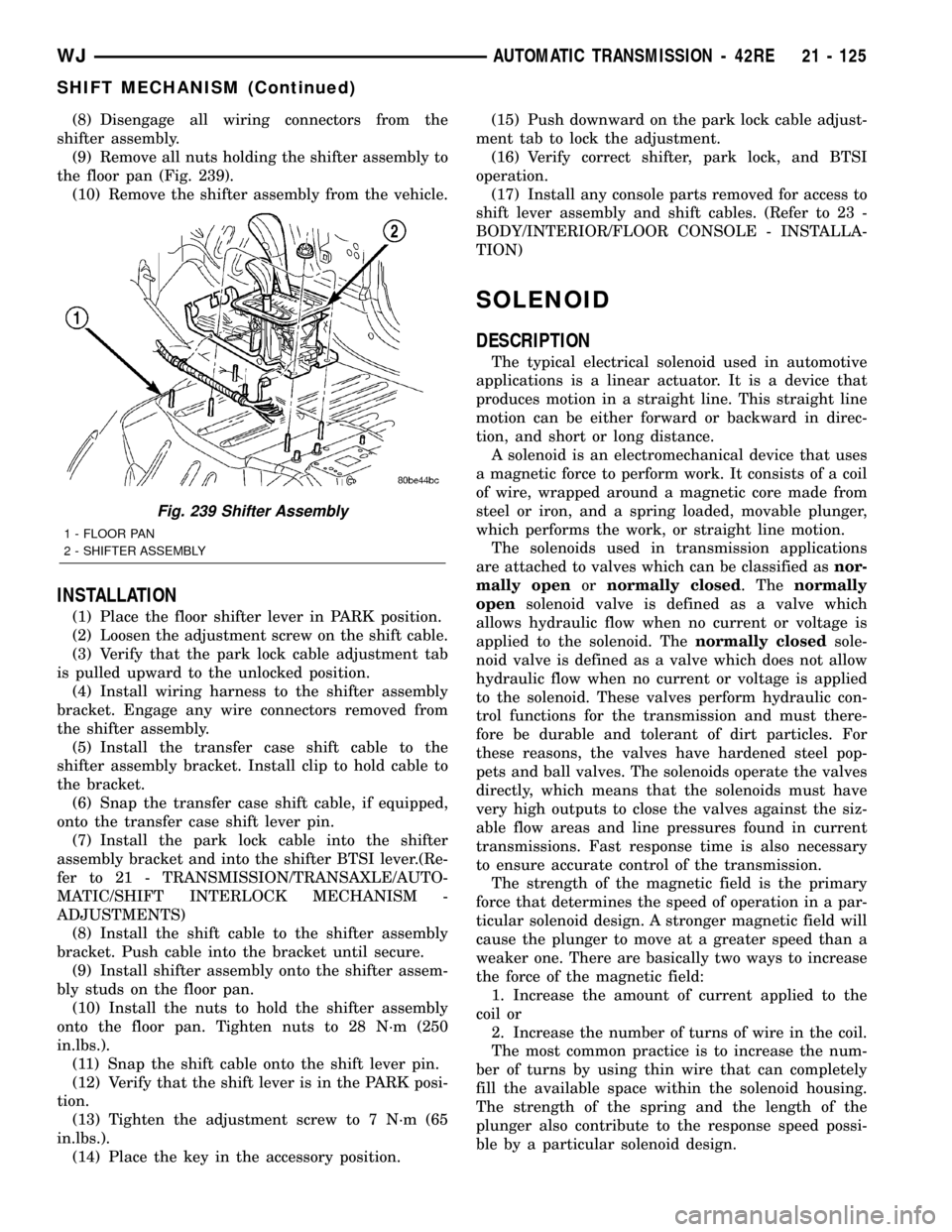

(8) Disengage all wiring connectors from the

shifter assembly.

(9) Remove all nuts holding the shifter assembly to

the floor pan (Fig. 239).

(10) Remove the shifter assembly from the vehicle.

INSTALLATION

(1) Place the floor shifter lever in PARK position.

(2) Loosen the adjustment screw on the shift cable.

(3) Verify that the park lock cable adjustment tab

is pulled upward to the unlocked position.

(4) Install wiring harness to the shifter assembly

bracket. Engage any wire connectors removed from

the shifter assembly.

(5) Install the transfer case shift cable to the

shifter assembly bracket. Install clip to hold cable to

the bracket.

(6) Snap the transfer case shift cable, if equipped,

onto the transfer case shift lever pin.

(7) Install the park lock cable into the shifter

assembly bracket and into the shifter BTSI lever.(Re-

fer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC/SHIFT INTERLOCK MECHANISM -

ADJUSTMENTS)

(8) Install the shift cable to the shifter assembly

bracket. Push cable into the bracket until secure.

(9) Install shifter assembly onto the shifter assem-

bly studs on the floor pan.

(10) Install the nuts to hold the shifter assembly

onto the floor pan. Tighten nuts to 28 N´m (250

in.lbs.).

(11) Snap the shift cable onto the shift lever pin.

(12) Verify that the shift lever is in the PARK posi-

tion.

(13) Tighten the adjustment screw to 7 N´m (65

in.lbs.).

(14) Place the key in the accessory position.(15) Push downward on the park lock cable adjust-

ment tab to lock the adjustment.

(16) Verify correct shifter, park lock, and BTSI

operation.

(17) Install any console parts removed for access to

shift lever assembly and shift cables. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - INSTALLA-

TION)

SOLENOID

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

Fig. 239 Shifter Assembly

1 - FLOOR PAN

2 - SHIFTER ASSEMBLY

WJAUTOMATIC TRANSMISSION - 42RE 21 - 125

SHIFT MECHANISM (Continued)

Page 1782 of 2199

INSTALLATION

(1) Place the floor shifter lever in PARK position.

(2) Loosen the adjustment screw on the shift cable.

(3) Verify that the park lock cable adjustment tab

is pulled upward to the unlocked position.

(4) Install wiring harness to the shifter assembly

bracket. Engage any wire connectors removed from

the shifter assembly.

(5) Install the transfer case shift cable to the

shifter assembly bracket. Install clip to hold cable to

the bracket.

(6) Snap the transfer case shift cable, if equipped,

onto the transfer case shift lever pin.

(7) Install the park lock cable into the shifter

assembly bracket and into the shifter BTSI lever.(Re-

fer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC/SHIFT INTERLOCK MECHANISM -

ADJUSTMENTS)

(8) Install the shift cable to the shifter assembly

bracket. Push cable into the bracket until secure.

(9) Install shifter assembly onto the shifter assem-

bly studs on the floor pan.

(10) Install the nuts to hold the shifter assembly

onto the floor pan. Tighten nuts to 28 N´m (250

in.lbs.).

(11) Snap the shift cable onto the shift lever pin.

(12) Verify that the shift lever is in the PARK posi-

tion.

(13) Tighten the adjustment screw to 7 N´m (65

in.lbs.).

(14) Place the key in the accessory position.

(15) Push downward on the park lock cable adjust-

ment tab to lock the adjustment.

(16) Verify correct shifter, park lock, and BTSI

operation.

(17) Install any console parts removed for access to

shift lever assembly and shift cables. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - INSTALLA-

TION)

SOLENOID SWITCH VALVE

DESCRIPTION

The Solenoid Switch Valve (SSV) is located in the

valve body and controls the direction of the transmis-

sion fluid when the L/R-TCC solenoid is energized.

OPERATION

The Solenoid Switch Valve controls line pressure

from the LR-TCC solenoid. In 1st gear, the SSV will

be in the downshifted position, thus directing fluid to

the L/R clutch circuit. In 2nd, 3rd, 4th,and 5th gears,

the solenoid switch valve will be in the upshifted

position and directs the fluid into the torque con-

verter clutch (TCC) circuit.When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

SOLENOIDS

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-

fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

1. Increase the amount of current applied to the

coil or

2. Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 263

SHIFT MECHANISM (Continued)

Page 1881 of 2199

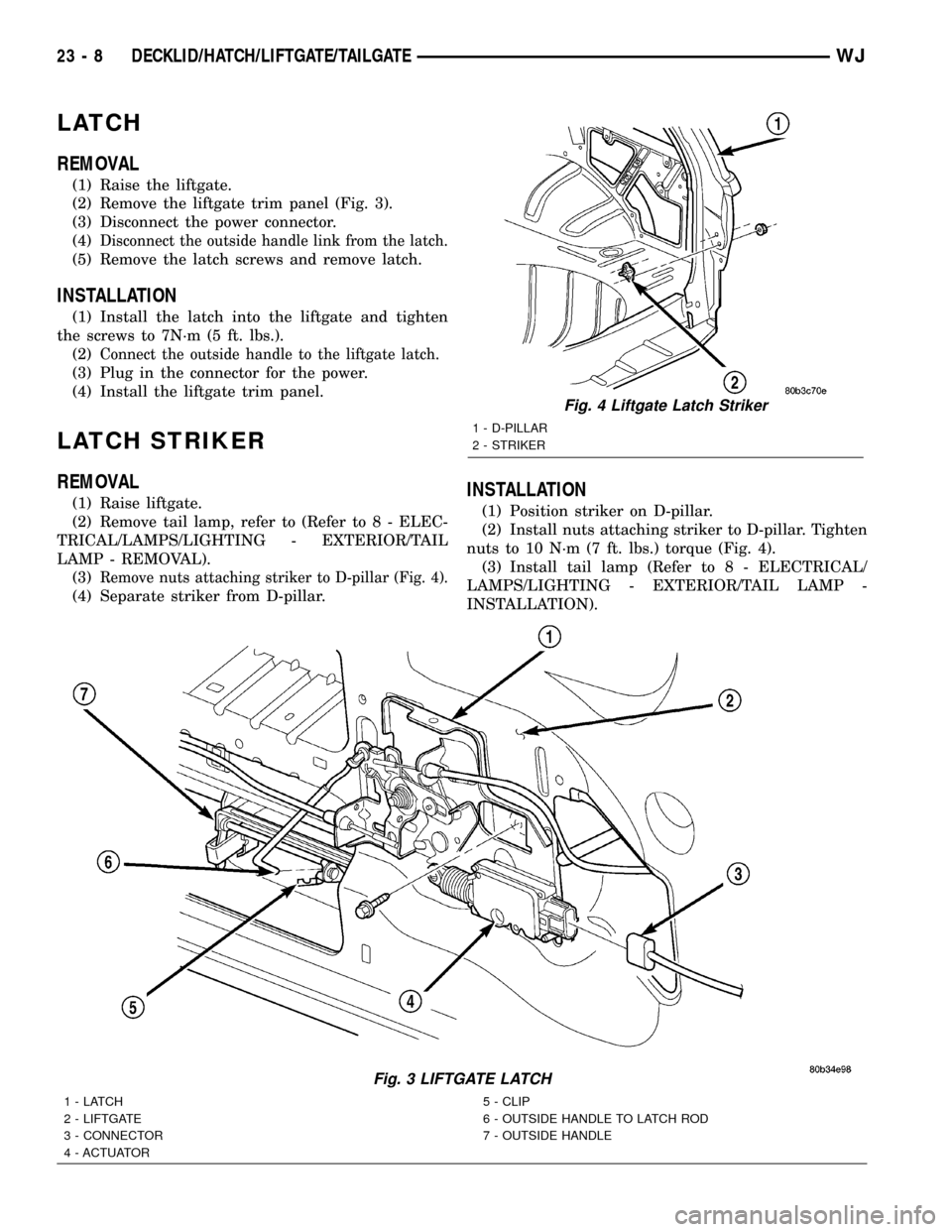

LATCH

REMOVAL

(1) Raise the liftgate.

(2) Remove the liftgate trim panel (Fig. 3).

(3) Disconnect the power connector.

(4)

Disconnect the outside handle link from the latch.

(5) Remove the latch screws and remove latch.

INSTALLATION

(1) Install the latch into the liftgate and tighten

the screws to 7N´m (5 ft. lbs.).

(2)

Connect the outside handle to the liftgate latch.

(3) Plug in the connector for the power.

(4) Install the liftgate trim panel.

LATCH STRIKER

REMOVAL

(1) Raise liftgate.

(2) Remove tail lamp, refer to (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP - REMOVAL).

(3)

Remove nuts attaching striker to D-pillar (Fig. 4).

(4) Separate striker from D-pillar.

INSTALLATION

(1) Position striker on D-pillar.

(2) Install nuts attaching striker to D-pillar. Tighten

nuts to 10 N´m (7 ft. lbs.) torque (Fig. 4).

(3) Install tail lamp (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/TAIL LAMP -

INSTALLATION).

Fig. 3 LIFTGATE LATCH

1-LATCH

2 - LIFTGATE

3 - CONNECTOR

4 - ACTUATOR5 - CLIP

6 - OUTSIDE HANDLE TO LATCH ROD

7 - OUTSIDE HANDLE

Fig. 4 Liftgate Latch Striker

1 - D-PILLAR

2 - STRIKER

23 - 8 DECKLID/HATCH/LIFTGATE/TAILGATEWJ

Page 1884 of 2199

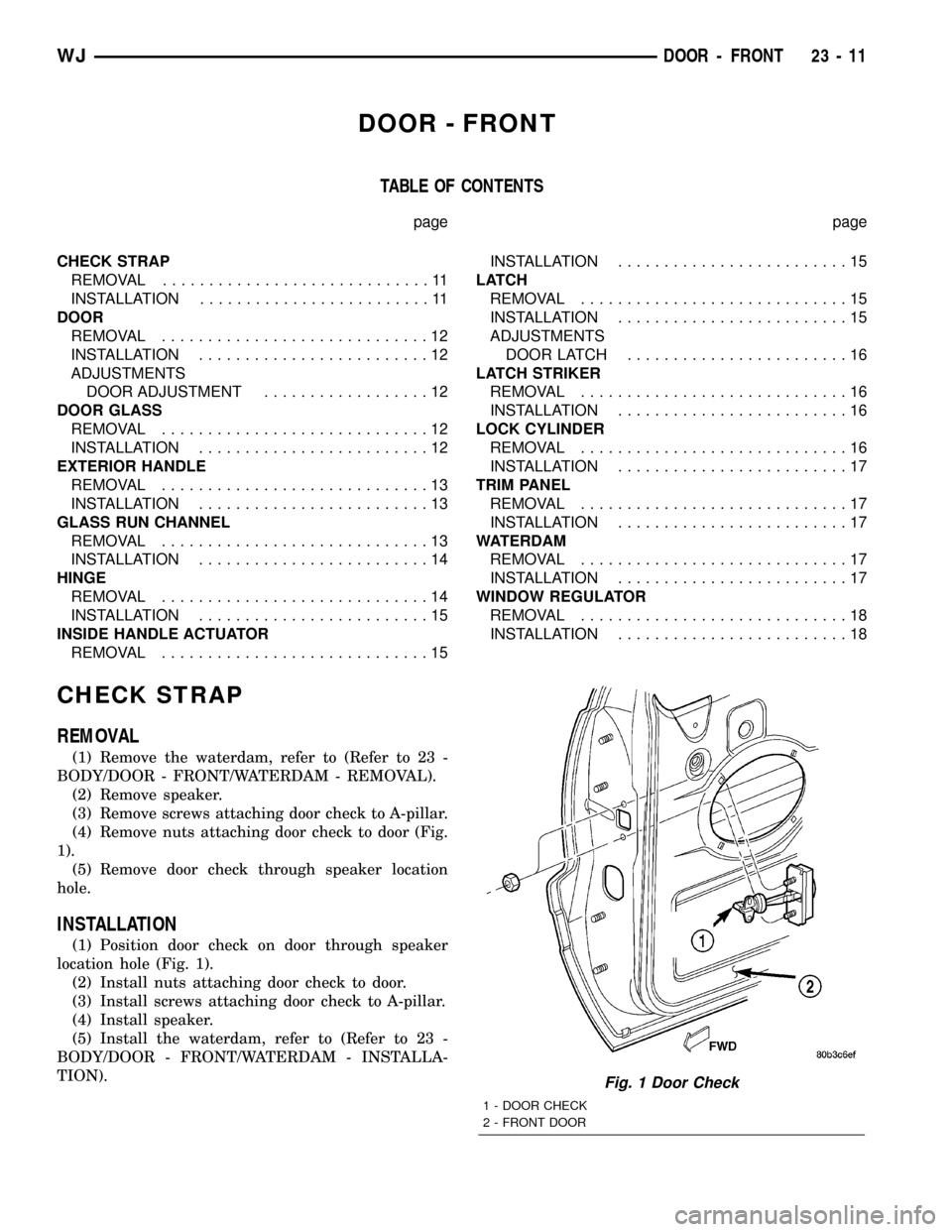

DOOR - FRONT

TABLE OF CONTENTS

page page

CHECK STRAP

REMOVAL.............................11

INSTALLATION.........................11

DOOR

REMOVAL.............................12

INSTALLATION.........................12

ADJUSTMENTS

DOOR ADJUSTMENT..................12

DOOR GLASS

REMOVAL.............................12

INSTALLATION.........................12

EXTERIOR HANDLE

REMOVAL.............................13

INSTALLATION.........................13

GLASS RUN CHANNEL

REMOVAL.............................13

INSTALLATION.........................14

HINGE

REMOVAL.............................14

INSTALLATION.........................15

INSIDE HANDLE ACTUATOR

REMOVAL.............................15INSTALLATION.........................15

LATCH

REMOVAL.............................15

INSTALLATION.........................15

ADJUSTMENTS

DOOR LATCH........................16

LATCH STRIKER

REMOVAL.............................16

INSTALLATION.........................16

LOCK CYLINDER

REMOVAL.............................16

INSTALLATION.........................17

TRIM PANEL

REMOVAL.............................17

INSTALLATION.........................17

WATERDAM

REMOVAL.............................17

INSTALLATION.........................17

WINDOW REGULATOR

REMOVAL.............................18

INSTALLATION.........................18

CHECK STRAP

REMOVAL

(1) Remove the waterdam, refer to (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - REMOVAL).

(2) Remove speaker.

(3) Remove screws attaching door check to A-pillar.

(4) Remove nuts attaching door check to door (Fig.

1).

(5) Remove door check through speaker location

hole.

INSTALLATION

(1) Position door check on door through speaker

location hole (Fig. 1).

(2) Install nuts attaching door check to door.

(3) Install screws attaching door check to A-pillar.

(4) Install speaker.

(5) Install the waterdam, refer to (Refer to 23 -

BODY/DOOR - FRONT/WATERDAM - INSTALLA-

TION).

Fig. 1 Door Check

1 - DOOR CHECK

2 - FRONT DOOR

WJDOOR - FRONT 23 - 11

Page 1888 of 2199

INSTALLATION

(1) Position hinge on ªAº pillar. (Use 3MtFast and

Firm or equivalent on the hinge to body mating sur-

face as a sealant.)

(2) Install hinge to body bolts, but do not tighten.

(3) Align the hinge to the reference marks and

torque the bolts to 35N´m (26 ft. lbs.).

(4) Install the door on the hinge and align with the

reference marks.

(5) Tighten the door to hinge fasteners.

(6) For adjustment see door adjustment procedure.

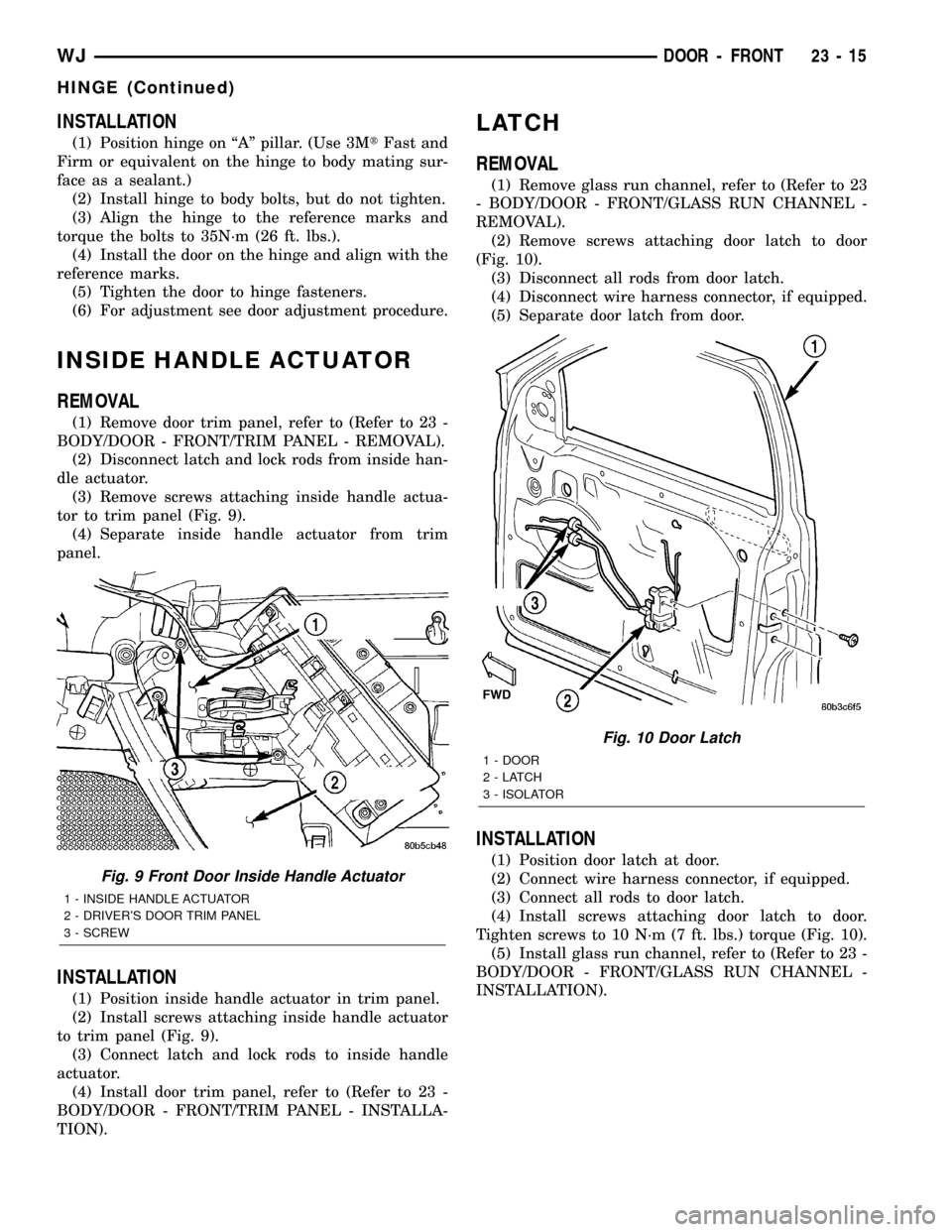

INSIDE HANDLE ACTUATOR

REMOVAL

(1) Remove door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Disconnect latch and lock rods from inside han-

dle actuator.

(3) Remove screws attaching inside handle actua-

tor to trim panel (Fig. 9).

(4) Separate inside handle actuator from trim

panel.

INSTALLATION

(1) Position inside handle actuator in trim panel.

(2) Install screws attaching inside handle actuator

to trim panel (Fig. 9).

(3) Connect latch and lock rods to inside handle

actuator.

(4) Install door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION).

LATCH

REMOVAL

(1) Remove glass run channel, refer to (Refer to 23

- BODY/DOOR - FRONT/GLASS RUN CHANNEL -

REMOVAL).

(2) Remove screws attaching door latch to door

(Fig. 10).

(3) Disconnect all rods from door latch.

(4) Disconnect wire harness connector, if equipped.

(5) Separate door latch from door.

INSTALLATION

(1) Position door latch at door.

(2) Connect wire harness connector, if equipped.

(3) Connect all rods to door latch.

(4) Install screws attaching door latch to door.

Tighten screws to 10 N´m (7 ft. lbs.) torque (Fig. 10).

(5) Install glass run channel, refer to (Refer to 23 -

BODY/DOOR - FRONT/GLASS RUN CHANNEL -

INSTALLATION).

Fig. 9 Front Door Inside Handle Actuator

1 - INSIDE HANDLE ACTUATOR

2 - DRIVER'S DOOR TRIM PANEL

3 - SCREW

Fig. 10 Door Latch

1 - DOOR

2-LATCH

3 - ISOLATOR

WJDOOR - FRONT 23 - 15

HINGE (Continued)

Page 1890 of 2199

INSTALLATION

(1) Connect lock cylinder switch, if equipped.

(2) Position lock cylinder in door handle.

(3) Position lock cylinder retainer and install

screw (Fig. 13).

(4) Install outside door handle, refer to (Refer to

23 - BODY/DOOR - FRONT/EXTERIOR HANDLE -

INSTALLATION).

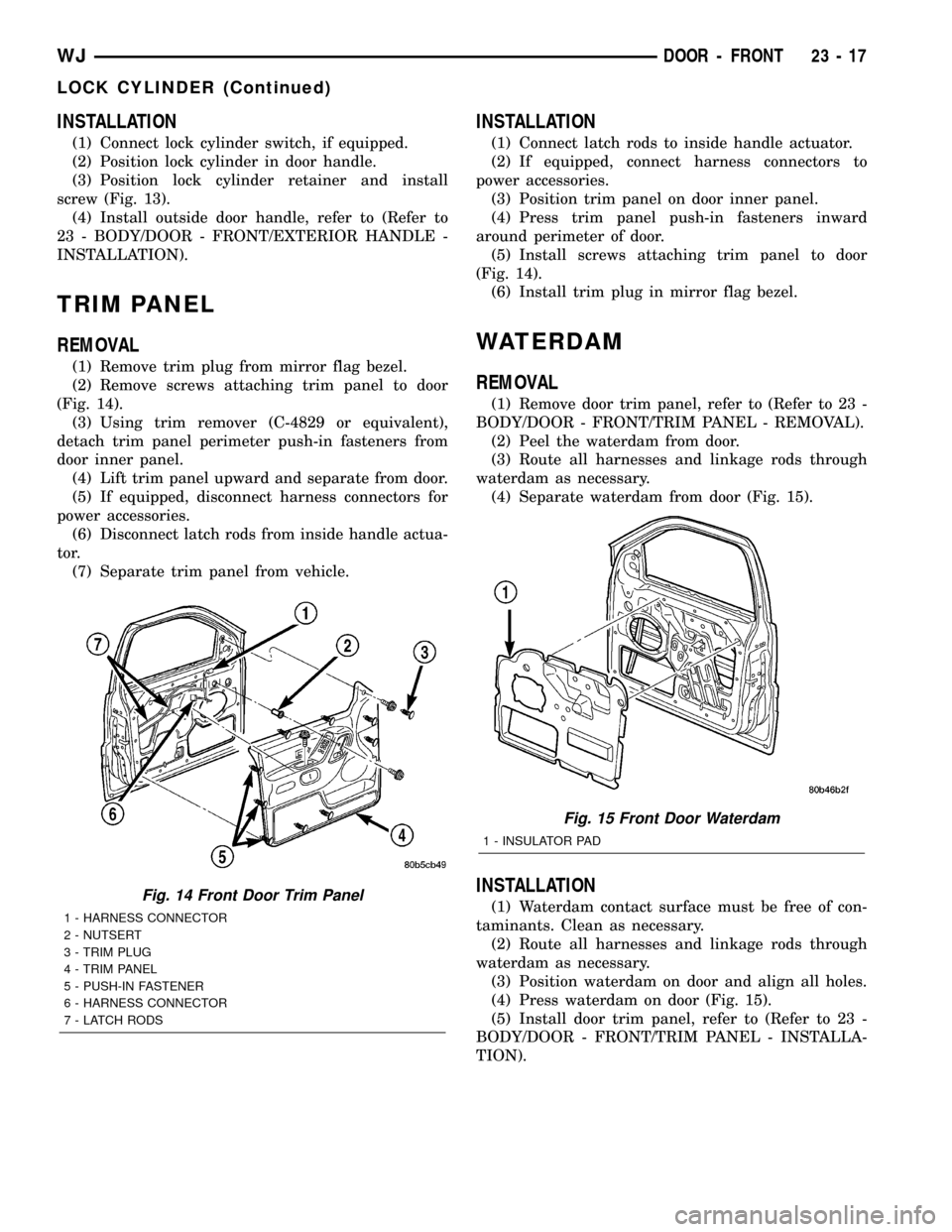

TRIM PANEL

REMOVAL

(1) Remove trim plug from mirror flag bezel.

(2) Remove screws attaching trim panel to door

(Fig. 14).

(3) Using trim remover (C-4829 or equivalent),

detach trim panel perimeter push-in fasteners from

door inner panel.

(4) Lift trim panel upward and separate from door.

(5) If equipped, disconnect harness connectors for

power accessories.

(6) Disconnect latch rods from inside handle actua-

tor.

(7) Separate trim panel from vehicle.

INSTALLATION

(1) Connect latch rods to inside handle actuator.

(2) If equipped, connect harness connectors to

power accessories.

(3) Position trim panel on door inner panel.

(4) Press trim panel push-in fasteners inward

around perimeter of door.

(5) Install screws attaching trim panel to door

(Fig. 14).

(6) Install trim plug in mirror flag bezel.

WATERDAM

REMOVAL

(1) Remove door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(2) Peel the waterdam from door.

(3) Route all harnesses and linkage rods through

waterdam as necessary.

(4) Separate waterdam from door (Fig. 15).

INSTALLATION

(1) Waterdam contact surface must be free of con-

taminants. Clean as necessary.

(2) Route all harnesses and linkage rods through

waterdam as necessary.

(3) Position waterdam on door and align all holes.

(4) Press waterdam on door (Fig. 15).

(5) Install door trim panel, refer to (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - INSTALLA-

TION).Fig. 14 Front Door Trim Panel

1 - HARNESS CONNECTOR

2 - NUTSERT

3 - TRIM PLUG

4 - TRIM PANEL

5 - PUSH-IN FASTENER

6 - HARNESS CONNECTOR

7 - LATCH RODS

Fig. 15 Front Door Waterdam

1 - INSULATOR PAD

WJDOOR - FRONT 23 - 17

LOCK CYLINDER (Continued)

Page 1892 of 2199

DOORS - REAR

TABLE OF CONTENTS

page page

CHECK STRAP

REMOVAL.............................19

INSTALLATION.........................19

DOOR

REMOVAL.............................20

INSTALLATION.........................20

DOOR GLASS

REMOVAL.............................20

INSTALLATION.........................20

EXTERIOR HANDLE

REMOVAL.............................20

INSTALLATION.........................21

HINGE

REMOVAL.............................21

INSTALLATION.........................21

INSIDE HANDLE ACTUATOR

REMOVAL.............................22INSTALLATION.........................22

LATCH

REMOVAL.............................22

INSTALLATION.........................22

LATCH STRIKER

REMOVAL.............................23

INSTALLATION.........................23

TRIM PANEL

REMOVAL.............................23

INSTALLATION.........................23

WATERDAM

REMOVAL.............................23

INSTALLATION.........................24

WINDOW REGULATOR

REMOVAL.............................24

INSTALLATION.........................24

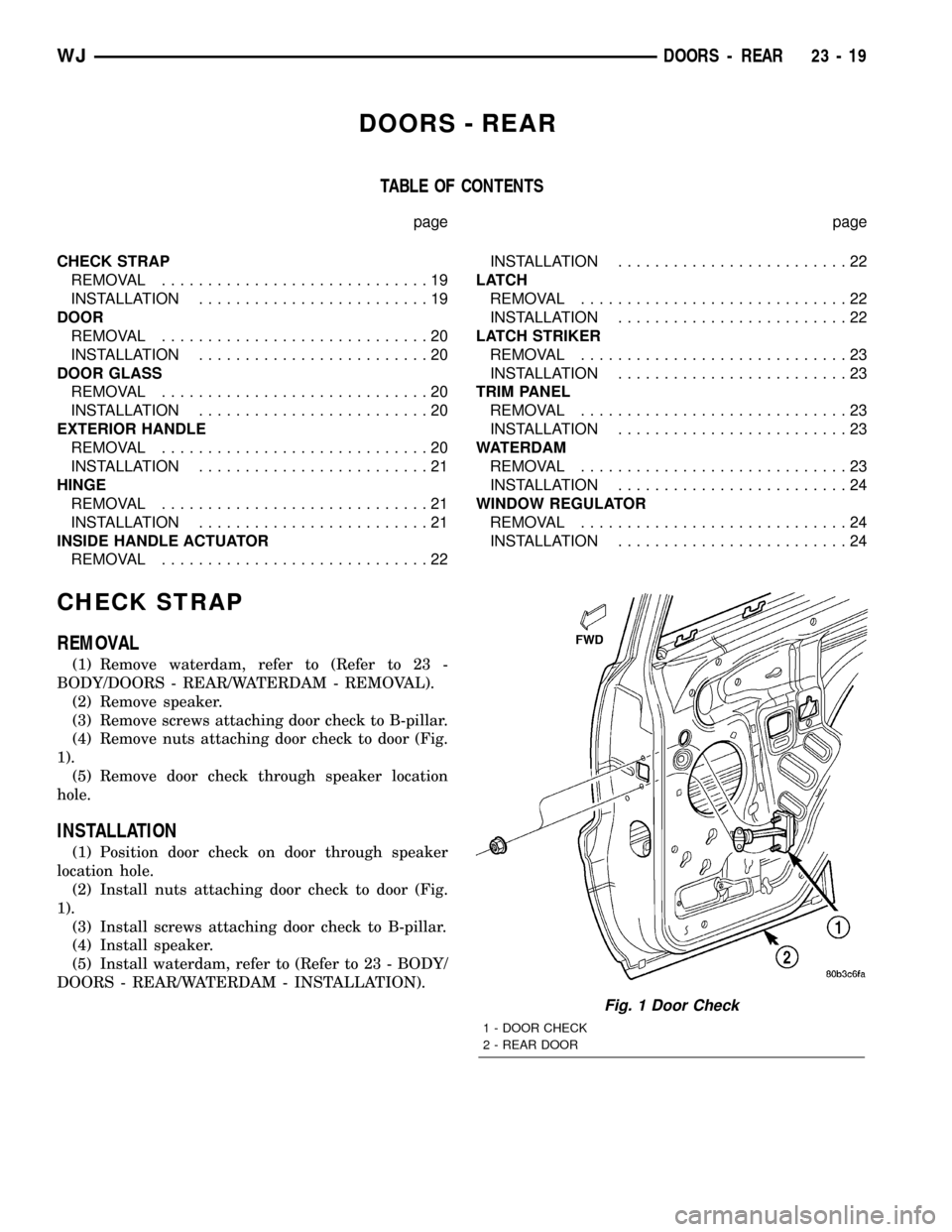

CHECK STRAP

REMOVAL

(1) Remove waterdam, refer to (Refer to 23 -

BODY/DOORS - REAR/WATERDAM - REMOVAL).

(2) Remove speaker.

(3) Remove screws attaching door check to B-pillar.

(4) Remove nuts attaching door check to door (Fig.

1).

(5) Remove door check through speaker location

hole.

INSTALLATION

(1) Position door check on door through speaker

location hole.

(2) Install nuts attaching door check to door (Fig.

1).

(3) Install screws attaching door check to B-pillar.

(4) Install speaker.

(5) Install waterdam, refer to (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - INSTALLATION).

Fig. 1 Door Check

1 - DOOR CHECK

2 - REAR DOOR

WJDOORS - REAR 23 - 19