Electric control JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 510 of 2199

DESCRIPTION - OUTSIDE REAR VIEW MIRROR

An automatic dimming outside rear view mirror is

an available factory-installed option for the driver

side of the vehicle, if the vehicle is also equipped

with the automatic day/night inside rear view mirror.

The automatic dimming outside mirror is completely

controlled by the circuitry of the automatic day/night

inside rear view mirror. The automatic dimming out-

side mirror will automatically change the reflectance

of the driver side outside rear view mirror to protect

the driver from the unwanted headlight glare of

trailing vehicles while driving at night. The auto-

matic dimming outside mirror will only operate when

the ignition switch is in the On position.

The automatic dimming outside mirror sensitivity

cannot be repaired or adjusted. If any component of

this unit is faulty or damaged, the entire automatic

dimming outside mirror unit must be replaced. (Refer

to 8 - ELECTRICAL/POWER MIRRORS/SIDEVIEW

MIRROR - DIAGNOSIS AND TESTING). Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

OPERATION

OPERATION - REAR VIEW MIRROR

The automatic day/night mirror switch allows the

driver a manual control of whether the automatic

dimming feature is operational. This switch is a

momentary rocker-type switch located on the lower

rear-facing surface of the mirror housing. When Auto

is selected, a Light-Emitting Diode (LED) on the mir-

ror housing just to the right of the switch illuminates

to indicate that automatic day/night mirror is turned

on. When Off is selected, the LED is turned off. The

mirror also senses the backup lamp circuit, and will

automatically disable its self-dimming feature when-

ever the transmission gear selector is in the Reverse

position.

A thin layer of electrochromatic material between

two pieces of conductive glass make up the face of

the mirror. Two photocell sensors are used to monitor

light levels and adjust the reflectance of the mirror.

The ambient photocell sensor faces forward, to detect

the outside light levels. The headlamp sensor is

located on the mirror housing just to the left of the

switch and facing rearward, to detect the light level

received at the rear window side of the mirror. When

the difference between the two light levels becomes

too great (the light level received at the rear of themirror is much higher than that at the front of the

mirror), the mirror begins to darken.

On models with an optional driver side automatic

dimming outside mirror, the signal to control the

dimming of that mirror is generated by the auto-

matic day/night inside rear view mirror circuitry.

That signal is then delivered to the driver side out-

side rear view mirror on a hard wired circuit.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the automatic day/night mirror system.

OPERATION - OUTSIDE REAR VIEW MIRROR

The automatic dimming outside mirror is operated

by the same controls and circuitry as the automatic

day/night mirror. When the automatic day/night mir-

ror is turned on or off, the automatic dimming out-

side mirror is likewise turned on or off. Like in the

automatic day/night mirror, a thin layer of electro-

chromatic material between two pieces of conductive

glass make up the face of the automatic dimming

outside mirror. However, the signal to control the

dimming of the outside mirror is generated by the

automatic day/night inside rear view mirror circuitry.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the automatic dimming outside mirror.

DIAGNOSIS AND TESTING - AUTOMATIC DAY /

NIGHT MIRROR

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 3. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(3) Disconnect the overhead wire harness connec-

tor from the automatic day/night mirror connector

receptacle. Check for battery voltage at the fused

ignition switch output (run/start) circuit cavity of the

overhead wire harness connector for the automatic

day/night mirror. If OK, go to Step 4. If not OK,

repair the open fused ignition switch output (run/

start) circuit to the fuse in the junction block as

required.

WJPOWER MIRRORS 8N - 13

AUTOMATIC DAY/NIGHT MIRROR (Continued)

Page 512 of 2199

POWER MIRROR SWITCH

DESCRIPTION

Both the right and left power outside mirrors are

controlled by a single multi-function switch unit

located on the driver side front door trim panel. The

power mirror switch unit includes a three-position

rocker selector switch and four momentary direc-

tional push button switches.

The power mirror switch unit is integral to the

Driver Door Module (DDM). The power mirror switch

cannot be repaired or adjusted and, if faulty or dam-

aged, the entire DDM unit must be replaced. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/DRIVER DOOR MODULE - REMOVAL)

for the DDM service procedures.

OPERATION

The power mirror selector switch is moved right

(right mirror control), left (left mirror control), or

center to turn the power outside mirror system off.

When the selector switch is in the right mirror con-

trol or left mirror control position, one of the four

directional control buttons is depressed to control

movement of the selected mirror up, down, right, or

left. When the selector switch is in the Off position,

depressing any of the directional switches will not

change either mirror position.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the power mirror switches.

SIDEVIEW MIRROR

DESCRIPTION

Mechanically folding, power operated outside rear

view mirrors are standard equipment on this model.

Each power mirror housing contains two electric

motors, two drive mechanisms, an electric heating

grid, the mirror glass case and the mirror glass. One

motor and drive controls mirror up-and-down (verti-

cal) movement, and the other controls right-and-left

(horizontal) movement. If the vehicle is equipped

with the optional memory system, each mirror head

also contains two position potentiometers. One posi-

tion potentiometer monitors the vertical mirror

motor, and the other monitors the horizontal mirror

motor.

An optional driver side automatic dimming mirror

is able to automatically change its reflectance level.

This mirror is controlled by the circuitry of the auto-

matic day/night inside rear view mirror. A thin layer

of electrochromic material between two pieces of con-

ductive glass make up the face of the mirror. (Refer

to 8 - ELECTRICAL/POWER MIRRORS/AUTO-MATIC DAY / NIGHT MIRROR - DESCRIPTION) for

more information on this feature.

The power mirror unit cannot be repaired. Only

the mirror glass and glass case are serviced sepa-

rately. The replacement mirror glass is supplied with

an instruction sheet that details the recommended

replacement procedure. If any other component of the

power mirror unit is faulty or damaged, the entire

power mirror unit must be replaced.

OPERATION

Each of the two outside power mirrors includes two

reversible electric motors that are secured within the

power mirror housing. Each motor moves the mirror

case and glass through an integral drive unit. When

a power mirror motor is supplied with battery cur-

rent and ground, it moves the mirror case and glass

through its drive unit in one direction. When the bat-

tery current and ground feeds to the motor are

reversed, it moves the mirror case and glass in the

opposite direction.

The power mirrors are equipped with a standard

equipment electric heating grid that is applied to the

back of each outside rear view mirror glass. When an

electrical current is passed through the resistor wire

of the heating grid, it warms the mirror glass. (Refer

to 8 - ELECTRICAL/HEATED MIRRORS -

DESCRIPTION) for more information on the opera-

tion of the heated mirrors and the rear window

defogger system.

If the driver side mirror is equipped with the auto-

matic dimming outside mirror option, two photocell

sensors on the inside rear view mirror are used to

monitor light levels and adjust the reflectance of both

the inside and driver side outside mirrors. This

change in reflectance helps to reduce the glare of

headlamps approaching the vehicle from the rear.

(Refer to 8 - ELECTRICAL/POWER MIRRORS/AU-

TOMATIC DAY / NIGHT MIRROR - OPERATION)

for more information on this feature.

If the vehicle is equipped with the optional mem-

ory system, the Driver Door Module (DDM) and the

Passenger Door Module (PDM) store the mirror posi-

tion information as monitored through the mirror

motor position potentiometers. When the memory

system requests a recall of the stored mirror position,

the DDM and the PDM are able to duplicate the

stored mirror positions by moving the mirror motors

until the potentiometer readings match the stored

values.

WJPOWER MIRRORS 8N - 15

Page 515 of 2199

POWER SEAT SYSTEM

TABLE OF CONTENTS

page page

POWER SEAT SYSTEM

DESCRIPTION

DESCRIPTION........................18

DESCRIPTION - MEMORY SYSTEM.......19

OPERATION

OPERATION - POWER SEAT SYSTEM.....20

OPERATION - MEMORY SYSTEM.........20

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER SEAT

SYSTEM............................20

DIAGNOSIS & TESTING - MEMORY

SYSTEM............................20

DRIVER SEAT SWITCH

DESCRIPTION.........................21

OPERATION...........................21

DIAGNOSIS AND TESTING - DRIVER SEAT

SWITCH............................22

REMOVAL.............................23

INSTALLATION.........................23

LUMBAR CONTROL SWITCH

DESCRIPTION.........................24

OPERATION...........................24

DIAGNOSIS AND TESTING - POWER LUMBAR

SWITCH............................24

REMOVAL.............................24

INSTALLATION.........................25

LUMBAR MOTOR

DESCRIPTION.........................25OPERATION...........................26

DIAGNOSIS AND TESTING - POWER LUMBAR

ADJUSTER..........................26

MEMORY SET SWITCH

DESCRIPTION.........................26

OPERATION...........................26

DIAGNOSIS AND TESTING - MEMORY

SWITCH............................27

REMOVAL.............................27

INSTALLATION.........................27

PASSENGER SEAT SWITCH

DESCRIPTION.........................27

OPERATION...........................28

DIAGNOSIS AND TESTING - PASSENGER

SEAT SWITCH........................28

REMOVAL.............................29

INSTALLATION.........................29

RECLINER MOTOR

DESCRIPTION.........................30

OPERATION...........................30

DIAGNOSIS AND TESTING - RECLINER

MOTOR .............................30

POWER SEAT TRACK

DESCRIPTION.........................31

OPERATION...........................32

DIAGNOSIS AND TESTING - POWER SEAT

TRACK.............................32

POWER SEAT SYSTEM

DESCRIPTION

DESCRIPTION

Driver and passenger power front seats are an

available factory-installed option for this vehicle. The

power seat system option allows the driver and front

seat passenger to electrically adjust their seating

positions for optimum control and comfort using the

power seat switches located on the outboard seat

cushion side shield of each front seat. The power seat

system receives battery current through a fuse in the

Power Distribution Center (PDC) and a circuit

breaker in the junction block so that the power seats

remain operational, regardless of the ignition switch

position.Four power seat options are offered on this vehicle,

depending upon the model. They are as follows:

²Six-way power drivers seat with manual

passenger seat- This power seat package is an

option on Laredo models equipped with cloth-

trimmed seats and includes a six-way adjustable

driver seat track with manual seat back recliners.

²Six-way power driver and passenger seat-

This power seat package is an option on Laredo mod-

els equipped with cloth or leather-trimmed seats and

includes six-way adjustable seat tracks with manual

seat back recliners. Heated Seats are available on

leather-trimmed seats.

²Ten-way power drivers seat with Memory

and Six-way power passenger seat- This power

seat package is standard on Limited models. This

option includes a six-way adjustable seat track with

power seat back recliners and power lumbar supports

for the driver and six-way only for the passenger.

8N - 18 POWER SEAT SYSTEMWJ

Page 530 of 2199

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................33

OPERATION...........................34

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................34

POWER WINDOW SWITCH

DESCRIPTION.........................36

OPERATION...........................36

DIAGNOSIS AND TESTING - POWER

WINDOW SWITCH.....................37REMOVAL.............................37

INSTALLATION.........................38

WINDOW MOTOR

DESCRIPTION.........................38

OPERATION...........................38

DIAGNOSIS AND TESTING - WINDOW

MOTOR .............................38

REMOVAL.............................39

INSTALLATION.........................39

POWER WINDOWS

DESCRIPTION

Power operated driver side and passenger side

front and rear door windows are standard factory-in-

stalled equipment on this model. The power window

system allows each of the door windows to be raised

or lowered electrically by operating a switch on the

trim panel for that door. Additionally, the master

switches on the driver side front door trim panel

allow all of the windows to be operated from the

driver seat position. A power window lockout switch

on the driver side front door trim panel will allow the

driver to disable all of the passenger door window

switches.

The power window system functionally operates

when the ignition switch is in the On position. How-

ever, a unique feature of this system will allow the

power windows to be operated for up to forty-five sec-

onds after the ignition switch is turned to the Off

position, or until a front door is opened, whichever

occurs first.

An auto-down feature allows the driver side front

door window to be lowered all the way, even if the

window switch is released. The driver side front door

window switch must be depressed in the down direc-

tion to a second detent to begin an auto-down event.

Depressing the switch again in any direction cancel

the auto-down event and begin movement in the

direction specified.

This group covers the following components of the

power window system:

²Power window switches

²Power window motors.

Certain functions and features of the power win-

dow system rely upon resources shared with other

electronic modules in the vehicle over the Program-mable Communications Interface (PCI) data bus net-

work. The PCI data bus network allows the sharing

of sensor information. This helps to reduce wire har-

ness complexity, internal controller hardware, and

component sensor current loads. At the same time,

this system provides increased reliability, enhanced

diagnostics, and allows the addition of many new fea-

ture capabilities. For diagnosis of these electronic

modules or of the PCI data bus network, the use of a

DRB scan tool and the proper Diagnostic Procedures

manual are recommended.

The other electronic modules that may affect power

window system operation are as follows:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for more information.

²Driver Door Module (DDM)-(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

²Passenger Door Module (PDM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

This group covers diagnosis and service of only the

electrical components in the power window system.

For service of mechanical components, such as the

regulator, lift plate, window tracks, or glass refer to

Body. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds. Follow-

ing are general descriptions of the major components

in the power window system.

WJPOWER WINDOWS 8N - 33

Page 533 of 2199

and no voltage in the neutral position. If OK,(Refer

to 8 - ELECTRICAL/POWER WINDOWS/WINDOW

MOTOR - DIAGNOSIS AND TESTING). If not OK,

replace the faulty door module.

(9) Check the rear door power window switch con-

tinuity. (Refer to 8 - ELECTRICAL/POWER WIN-

DOWS/POWER WINDOW SWITCH - DIAGNOSIS

AND TESTING). If OK, go to Step 10. If not OK,

replace the faulty rear door power window switch.

(10) Disconnect and isolate the battery negative

cable. Reconnect the door wire harness connector to

the rear door power window switch. Disconnect the

door wire harness connector from the inoperative

power window motor wire harness connector. Check

for continuity between the rear window driver up cir-

cuit cavity of the 15-way door wire harness connector

for the door module and a good ground. Repeat the

check for the rear window driver down circuit. In

each case there should be no continuity. If OK, go to

Step 11. If not OK, repair the shorted rear window

driver up or down circuit as required.

(11) Check for continuity between the rear window

driver up circuit cavities of the 15-way door wire har-

ness connector for the door module and the power

window motor wire harness connector. Repeat the

check for the rear window driver down circuit. In

each case there should be continuity. If OK, go to

Step 12. If not OK, repair the open rear window

driver up or down circuit as required.

NOTE: The door module feeds battery current to

both terminals of the rear door power window

motors when the power window lockout switch is in

the Unlock position, until the master window switch

on the driver side front door is actuated. The door

module feeds ground to both terminals of the rear

door power window motor when the power window

lockout switch is in the Lock position, until the

master window switch on the driver side front door

is actuated.

(12) Reconnect the 15-way door wire harness con-

nector for the door module to the door module con-

nector receptacle. Connect the battery negative cable.

Check for battery voltage at each cavity in the door

wire harness connector for the power window motor.

Each cavity should have battery voltage when the

power window switch is in the neutral position. Each

cavity should also have battery voltage in one other

switch position, either up or down, and zero volts

with the switch in the opposite position. If OK, (Refer

to 8 - ELECTRICAL/POWER WINDOWS/WINDOW

MOTOR - DIAGNOSIS AND TESTING). If not OK,

replace the faulty door module.POWER WINDOW SWITCH

DESCRIPTION

The power window motors are controlled by a two-

way momentary switch mounted on the trim panel of

each passenger door, and four two-way momentary

switches on the driver side front door trim panel. The

driver side front door trim panel also has a two-posi-

tion power window lockout switch. Each power win-

dow switch, except the lockout switch, is illuminated

by a Light-Emitting Diode (LED) that is integral to

the switch paddle.

The front door power window switches and the

power window lockout switch are integral to the

Driver Door Module (DDM) and Passenger Door

Module (PDM). The front door power window

switches and their lamps cannot be adjusted or

repaired and, if faulty or damaged, the entire DDM

or PDM unit must be replaced. The rear door power

window switches and their lamps cannot be adjusted

or repaired but, if faulty or damaged, only the

affected rear door power window switch must be

replaced. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/DRIVER DOOR MODULE -

REMOVAL).

OPERATION

The front door power window switches provide an

up or down (or lock and unlock signal in the case of

the lockout switch) to the door module circuitry. The

Driver Door Module (DDM) circuitry controls the out-

put to the driver side front and rear door power win-

dow motors, and supplies electrical current as

required for the stand-alone operation of the driver

side rear door power window switch. The Passenger

Door Module (PDM) circuitry controls the output to

the passenger side front and rear door power window

motors, and supplies electrical current as required

for the stand-alone operation of the passenger side

rear door power window switch.

When a DDM-integrated master power window

switch for a passenger side window is actuated, or

when the power window lockout switch is actuated to

disable the passenger door power windows, the DDM

circuitry sends a message to the PDM over the Pro-

grammable Communications Interface (PCI) data bus

to control the output to that power window motor(s).

The power window switch for the driver side front

door power window has two detent positions in the

Down direction. The first detent provides normal

power window down operation. If this switch is

depressed to the second detent, the Auto Down cir-

cuitry of the DDM is activated. The Auto-Down cir-

cuitry will automatically move the driver side front

door window to its fully lowered position, even if the

power window switch is released. The Auto-Down

8N - 36 POWER WINDOWSWJ

POWER WINDOWS (Continued)

Page 535 of 2199

INSTALLATION

(1) Position the power window switch to the rear

door trim panel switch receptacle.

(2) Press firmly and evenly on the back of the

power window switch until it snaps into rear door

trim panel switch receptacle.

(3) Install the trim panel onto the rear door. (Refer

to 23 - BODY/DOORS - REAR/TRIM PANEL -

INSTALLATION) for the procedures.

(4) Reconnect the battery negative cable.

WINDOW MOTOR

DESCRIPTION

Power operated front and rear door windows are

standard equipment on this model. Each door has a

permanent magnet reversible electric motor with an

integral right angle gearbox mechanism that oper-

ates the window regulator. In addition, each power

window motor is equipped with an integral self-reset-

ting circuit breaker to protect the motor from over-

loads.

The power window motor gearbox housing is

secured to the window regulator drum housing with

screws. The window regulators used in all four doors

are single vertical post cable-and-drum type. A

molded plastic slider guided by the post is driven by

the regulator cables. The slider raises and lowers the

window glass through a steel lift plate attachment.

Front and rear glass channels within each door guide

and stabilize each end of the glass.

The power window motor and gearbox assembly

cannot be repaired and, if faulty or damaged, the

entire power window motor and gearbox unit must be

replaced. The window regulators are available for

service. (Refer to 23 - BODY/DOOR - FRONT/WIN-

DOW REGULATOR - REMOVAL) or (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

REMOVAL) for the regulator service procedures.

OPERATION

A positive and negative battery connection to the

two motor terminals will cause the power window

motor to rotate in one direction. Reversing the cur-

rent through these same two connections will cause

the motor to rotate in the opposite direction.

When the power window motor operates, it rotates

the regulator cable drum through its gearbox. The

window regulator cable drum is connected through

two cables to the plastic slider on the vertical post.

As the cable drum rotates, it lets cable out on one

side of the drum, and takes cable in on the other side

of the drum. The changes in cable length move the

slider up or down the vertical post, raising or lower-

ing the window glass.If the window regulator or window glass bind,

encounter obstructions, or reach their travel limits it

overloads the power window motor. The overloading

condition causes the power window motor self-reset-

ting circuit breaker to open, which stops the motor

from running.

DIAGNOSIS AND TESTING - WINDOW MOTOR

Before you proceed with this diagnosis, confirm

proper switch operation. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/DRIVER

DOOR MODULE - OPERATION) or (Refer to 8 -

ELECTRICAL/POWER WINDOWS/POWER WIN-

DOW SWITCH - OPERATION). For complete circuit

diagrams, refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

(1) Remove the trim panel from the door with the

inoperative power window. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL) or

(Refer to 23 - BODY/DOORS - REAR/TRIM PANEL -

REMOVAL) for the procedures.

(2) Disconnect the door wire harness connector

from the power window motor wire harness connec-

tor. Apply battery current to one cavity of the power

window motor wire harness connector, and apply

ground to the other cavity of the connector. The

power window motor should operate in one direction.

Remember, if the window is in the full up or full

down position, the motor will not operate in that

direction by design. If OK, go to Step 3. If not OK,

replace the faulty power window motor.

(3) Reverse the battery and ground connections to

the two cavities of the power window motor wire har-

ness connector. The power window motor should now

operate in the other direction. Remember, if the win-

dow is in the full up or full down position, the motor

will not operate in that direction by design. If OK, go

to Step 4. If not OK, replace the faulty power window

motor.

(4) If the power window motor operates in both

directions, check the operation of the window glass

and regulator mechanism through its complete up

and down travel. There should be no binding or stick-

ing of the window glass or regulator mechanism

through the entire travel range. If not OK, (Refer to

23 - BODY/DOOR - FRONT/WINDOW REGULATOR

- REMOVAL) or (Refer to 23 - BODY/DOORS -

REAR/WINDOW REGULATOR - REMOVAL) to

check for proper installation or damage of the win-

dow glass mounting and operating hardware.

8N - 38 POWER WINDOWSWJ

POWER WINDOW SWITCH (Continued)

Page 541 of 2199

²Passenger Airbag- The passenger airbag is

located on the instrument panel, beneath the instru-

ment panel top pad and above the glove box on the

passenger side of the vehicle.

²Passenger Knee Blocker- The passenger knee

blocker is a structural reinforcement that is integral

to and concealed within the glove box door.

²Side Impact Sensor- Two side impact sensors

are used on vehicles with the optional side curtain

airbags, one left side and one right side. One sensor

is located behind the B-pillar trim near the base of

each B-pillar.

²Side Curtain Airbag- In vehicles equipped

with this option, a side curtain airbag is located on

each inside roof side rail above the headliner, and

extends from the A-pillar to just beyond the C-pillar.

The ACM and the EMIC each contain a central

processing unit and programming that allow them to

communicate with each other using the Programma-

ble Communication Interface (PCI) data bus network.

This method of communication is used by the ACM

for control of the airbag indicator on all models

equipped with dual front airbags. (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

COMMUNICATION - DESCRIPTION).

Hard wired circuitry connects the supplemental

restraint system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system,

and to the supplemental restraint system compo-

nents through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

ACTIVE RESTRAINTS

The primary passenger restraints in this or any

other vehicle are the standard equipment factory-in-

stalled seat belts. Seat belts are referred to as an

active restraint because the vehicle occupants are

required to physically fasten and properly adjust

these restraints in order to benefit from them. See

the owner's manual in the vehicle glove box for more

information on the features, use and operation of all

of the factory-installed active restraints.PASSIVE RESTRAINTS

The passive restraints system is referred to as a

supplemental restraint system because they were

designed and are intended to enhance the protection

for the vehicle occupants of the vehicleonlywhen

used in conjunction with the seat belts. They are

referred to as passive systems because the vehicle

occupants are not required to do anything to make

them operate; however, the vehicle occupants must

be wearing their seat belts in order to obtain the

maximum safety benefit from the factory-installed

supplemental restraint systems.

The supplemental restraint system electrical cir-

cuits are continuously monitored and controlled by a

microprocessor and software contained within the

Airbag Control Module (ACM). An airbag indicator in

the ElectroMechanical Instrument Cluster (EMIC)

illuminates for about seven seconds as a bulb test

each time the ignition switch is turned to the On or

Start positions. Following the bulb test, the airbag

indicator is turned on or off by the ACM to indicate

the status of the supplemental restraint system. If

the airbag indicator comes on at any time other than

during the bulb test, it indicates that there is a prob-

lem in the supplemental restraint system electrical

circuits. Such a problem may cause airbags not to

deploy when required, or to deploy when not

required.

Deployment of the supplemental restraints

depends upon the angle and severity of an impact.

Deployment is not based upon vehicle speed; rather,

deployment is based upon the rate of deceleration as

measured by the forces of gravity (G force) upon the

impact sensors. When an impact is severe enough,

the microprocessor in the ACM signals the inflator

unit of the airbag module to deploy the airbag. Dur-

ing a frontal vehicle impact, the knee blockers work

in concert with properly fastened and adjusted seat

belts to restrain both the driver and the front seat

passenger in the proper position for an airbag deploy-

ment. The knee blockers also absorb and distribute

the crash energy from the driver and the front seat

passenger to the structure of the instrument panel.

Typically, the vehicle occupants recall more about

the events preceding and following a collision than

they have of an airbag deployment itself. This is

because the airbag deployment and deflation occur so

rapidly. In a typical 48 kilometer-per-hour (30 mile-

per-hour) barrier impact, from the moment of impact

until the airbags are fully inflated takes about 40

milliseconds. Within one to two seconds from the

moment of impact, the airbags are almost entirely

deflated. The times cited for these events are approx-

imations, which apply only to a barrier impact at the

given speed. Actual times will vary somewhat,

8O - 4 RESTRAINTSWJ

RESTRAINTS (Continued)

Page 542 of 2199

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

airbag system circuits or components, it stores a

fault code or Diagnostic Trouble Code (DTC) in its

memory circuit and sends an electronic message to

the EMIC to turn on the airbag indicator. Proper

testing of the airbag system components, the Pro-

grammable Communication Interface (PCI) data bus,

the data bus message inputs to and outputs from the

EMIC or the ACM, as well as the retrieval or erasure

of a DTC from the ACM or EMIC requires the use of

a DRBIIItscan tool. Refer to the appropriate diag-

nostic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passive restraints.

WARNING - RESTRAINT SYSTEM

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE DAIMLERCHRYSLER MOPAR PARTS

CATALOG.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.WARNING: AN AIRBAG INFLATOR UNIT MAY CON-

TAIN SODIUM AZIDE AND POTASSIUM NITRATE.

THESE MATERIALS ARE POISONOUS AND

EXTREMELY FLAMMABLE. CONTACT WITH ACID,

WATER, OR HEAVY METALS MAY PRODUCE HARM-

FUL AND IRRITATING GASES (SODIUM HYDROXIDE

IS FORMED IN THE PRESENCE OF MOISTURE) OR

COMBUSTIBLE COMPOUNDS. AN AIRBAG INFLA-

TOR UNIT MAY ALSO CONTAIN A GAS CANISTER

PRESSURIZED TO OVER 2500 PSI. DO NOT

ATTEMPT TO DISMANTLE AN AIRBAG UNIT OR

TAMPER WITH ITS INFLATOR. DO NOT PUNCTURE,

INCINERATE, OR BRING INTO CONTACT WITH

ELECTRICITY. DO NOT STORE AT TEMPERATURES

EXCEEDING 93É C (200É F).

WARNING: REPLACE ALL RESTRAINT SYSTEM

COMPONENTS ONLY WITH PARTS SPECIFIED IN

THE DAIMLERCHRYSLER MOPAR PARTS CATA-

LOG. SUBSTITUTE PARTS MAY APPEAR INTER-

CHANGEABLE, BUT INTERNAL DIFFERENCES MAY

RESULT IN INFERIOR OCCUPANT PROTECTION.

WARNING: THE FASTENERS, SCREWS, AND

BOLTS ORIGINALLY USED FOR THE RESTRAINT

SYSTEM COMPONENTS HAVE SPECIAL COATINGS

AND ARE SPECIFICALLY DESIGNED FOR THE

RESTRAINT SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANY TIME A

NEW FASTENER IS NEEDED, REPLACE IT WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

DAIMLERCHRYSLER MOPAR PARTS CATALOG.

WARNING: WHEN A STEERING COLUMN HAS AN

AIRBAG UNIT ATTACHED, NEVER PLACE THE COL-

UMN ON THE FLOOR OR ANY OTHER SURFACE

WITH THE STEERING WHEEL OR AIRBAG UNIT

FACE DOWN.

DIAGNOSIS AND TESTING - SUPPLEMENTAL

RESTRAINT SYSTEM

Proper diagnosis and testing of the supplemental

restraint system components, the PCI data bus, the

data bus message inputs to and outputs from the

ElectroMechanical Instrument Cluster (EMIC) or the

Airbag Control Module (ACM), as well as the

retrieval or erasure of a Diagnostic Trouble Code

(DTC) from the ACM requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

WJRESTRAINTS 8O - 5

RESTRAINTS (Continued)

Page 543 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL RESTRAINTS

At no time should any source of electricity be per-

mitted near the inflator on the back of a non-de-

ployed airbag. When carrying a non-deployed airbag,

the trim cover or airbag cushion side of the unit

should be pointed away from the body to minimize

injury in the event of an accidental deployment. If

the airbag unit is placed on a bench or any other sur-

face, the trim cover or airbag cushion side of the unit

should be face up to minimize movement in the event

of an accidental deployment. In addition, the supple-

mental restraint system should be disarmed when-

ever any steering wheel, steering column, driver

airbag, passenger airbag, front impact sensor, side

impact sensor, side curtain airbag, or instrument

panel components require diagnosis or service. Fail-

ure to observe this warning could result in accidental

airbag deployment and possible personal injury.

All damaged, faulty or non-deployed airbags which

are replaced on vehicles are to be handled and dis-

posed of properly. If an airbag unit is faulty or dam-

aged and non-deployed, refer to the Hazardous

Substance Control System for proper disposal. Dis-

pose of all non-deployed and deployed airbags in a

manner consistent with state, provincial, local and

federal regulations.

SUPPLEMENTAL RESTRAINT STORAGE

Airbags must be stored in their original, special

container until they are used for service. Also, they

must be stored in a clean, dry environment; away

from sources of extreme heat, sparks, and high elec-

trical energy. Always place or store any airbag on a

surface with its trim cover or airbag cushion side fac-ing up, to minimize movement in case of an acciden-

tal deployment.

STANDARD PROCEDURE - SERVICE AFTER A

SUPPLEMENTAL RESTRAINT DEPLOYMENT

Any vehicle which is to be returned to use follow-

ing a supplemental restraint deployment, must have

the deployed restraints replaced. In addition, if the

driver airbag has been deployed, the clockspring

must be replaced. If the passenger airbag is

deployed, the instrument panel top pad must be

replaced. If a side curtain airbag has been deployed,

the complete airbag unit, the headliner, as well as

the upper A, B, C and D-pillar trim must be replaced.

These components are not intended for reuse and

will be damaged or weakened as a result of a supple-

mental restraint deployment, which may or may not

be obvious during a visual inspection.

The passenger airbag mounting points on the

instrument panel structural duct must be closely

inspected for damage, and the instrument panel

assembly replaced if structural duct damage is evi-

dent. On vehicles with an optional sunroof, the sun-

roof drain tubes and hoses must be closely inspected

following a side curtain airbag deployment. It is also

critical that the mounting surfaces and/or mounting

brackets for the front and side impact sensors be

closely inspected and restored to their original condi-

tions following any vehicle impact damage. Because

the ACM and each impact sensor are used by the

supplemental restraint system to monitor or confirm

the direction and severity of a vehicle impact,

improper orientation or insecure fastening of these

components may cause airbags not to deploy when

required, or to deploy when not required.

All other vehicle components should be closely

inspected following any supplemental restraint

deployment, but are to be replaced only as required

by the extent of the visible damage incurred.

AIRBAG SQUIB STATUS

Multistage airbags with multiple initiators (squibs)

must be checked to determine that all squibs were

used during the deployment event. The driver and

passenger airbags in this model are deployed by elec-

trical signals generated by the Airbag Control Mod-

ule (ACM) through the driver or passenger squib 1

and squib 2 circuits to the two initiators in the air-

bag inflators. Typically, both initiators are used and

all potentially hazardous chemicals are burned dur-

ing an airbag deployment event. However, it is possi-

ble for only one initiator to be used due to an airbag

system fault; therefore, it is always necessary to con-

firm that both initiators have been used in order to

avoid the improper handling or disposal of poten-

tially live pyrotechnic or hazardous materials. The

8O - 6 RESTRAINTSWJ

RESTRAINTS (Continued)

Page 546 of 2199

(4) Check to be certain that nobody is in the vehi-

cle, then reconnect the battery negative cable.

(5) Using the DRBIIIt, read and record the active

(current) Diagnostic Trouble Code (DTC) data.

(6) Next, use the DRBIIItto read and record any

stored (historical) DTC data.

(7) If any DTC is found in Step 5 or Step 6, refer

to the appropriate diagnostic information.

(8) Use the DRBIIItto erase the stored DTC data.

If any problems remain, the stored DTC data will not

erase. Refer to the appropriate diagnostic informa-

tion to diagnose any stored DTC that will not erase.

If the stored DTC information is successfully erased,

go to Step 9.

(9) Turn the ignition switch to the Off position for

about fifteen seconds, and then back to the On posi-

tion. Observe the airbag indicator in the instrument

cluster. It should light for six to eight seconds, and

then go out. This indicates that the supplemental

restraint system is functioning normally and that the

repairs are complete. If the airbag indicator fails to

light, or lights and stays on, there is still an active

supplemental restraint system fault or malfunction.

Refer to the appropriate diagnostic information to

diagnose the problem.

AIRBAG CONTROL MODULE

DESCRIPTION

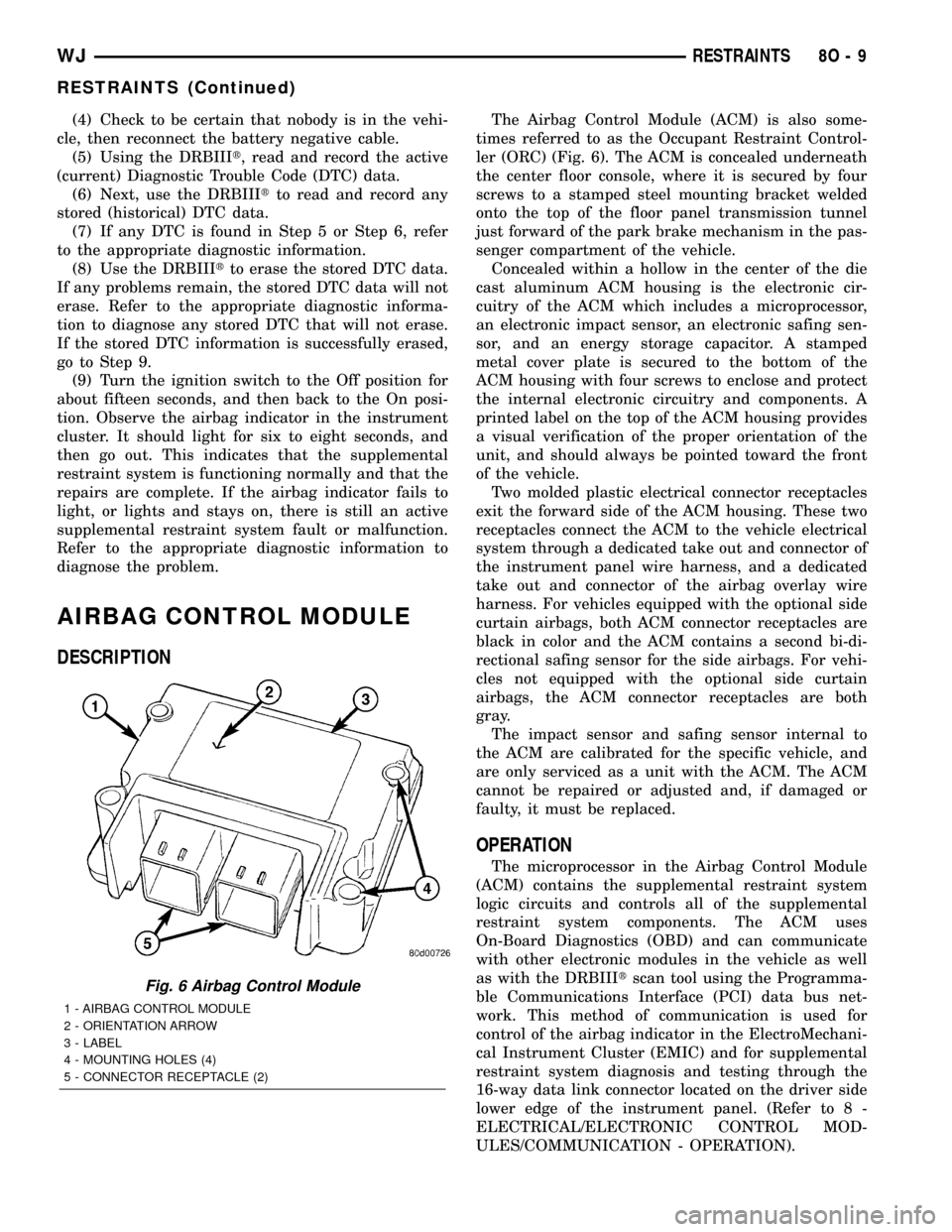

The Airbag Control Module (ACM) is also some-

times referred to as the Occupant Restraint Control-

ler (ORC) (Fig. 6). The ACM is concealed underneath

the center floor console, where it is secured by four

screws to a stamped steel mounting bracket welded

onto the top of the floor panel transmission tunnel

just forward of the park brake mechanism in the pas-

senger compartment of the vehicle.

Concealed within a hollow in the center of the die

cast aluminum ACM housing is the electronic cir-

cuitry of the ACM which includes a microprocessor,

an electronic impact sensor, an electronic safing sen-

sor, and an energy storage capacitor. A stamped

metal cover plate is secured to the bottom of the

ACM housing with four screws to enclose and protect

the internal electronic circuitry and components. A

printed label on the top of the ACM housing provides

a visual verification of the proper orientation of the

unit, and should always be pointed toward the front

of the vehicle.

Two molded plastic electrical connector receptacles

exit the forward side of the ACM housing. These two

receptacles connect the ACM to the vehicle electrical

system through a dedicated take out and connector of

the instrument panel wire harness, and a dedicated

take out and connector of the airbag overlay wire

harness. For vehicles equipped with the optional side

curtain airbags, both ACM connector receptacles are

black in color and the ACM contains a second bi-di-

rectional safing sensor for the side airbags. For vehi-

cles not equipped with the optional side curtain

airbags, the ACM connector receptacles are both

gray.

The impact sensor and safing sensor internal to

the ACM are calibrated for the specific vehicle, and

are only serviced as a unit with the ACM. The ACM

cannot be repaired or adjusted and, if damaged or

faulty, it must be replaced.

OPERATION

The microprocessor in the Airbag Control Module

(ACM) contains the supplemental restraint system

logic circuits and controls all of the supplemental

restraint system components. The ACM uses

On-Board Diagnostics (OBD) and can communicate

with other electronic modules in the vehicle as well

as with the DRBIIItscan tool using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used for

control of the airbag indicator in the ElectroMechani-

cal Instrument Cluster (EMIC) and for supplemental

restraint system diagnosis and testing through the

16-way data link connector located on the driver side

lower edge of the instrument panel. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

Fig. 6 Airbag Control Module

1 - AIRBAG CONTROL MODULE

2 - ORIENTATION ARROW

3 - LABEL

4 - MOUNTING HOLES (4)

5 - CONNECTOR RECEPTACLE (2)

WJRESTRAINTS 8O - 9

RESTRAINTS (Continued)