Suspension JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 32 of 2199

LOWER BALL JOINT

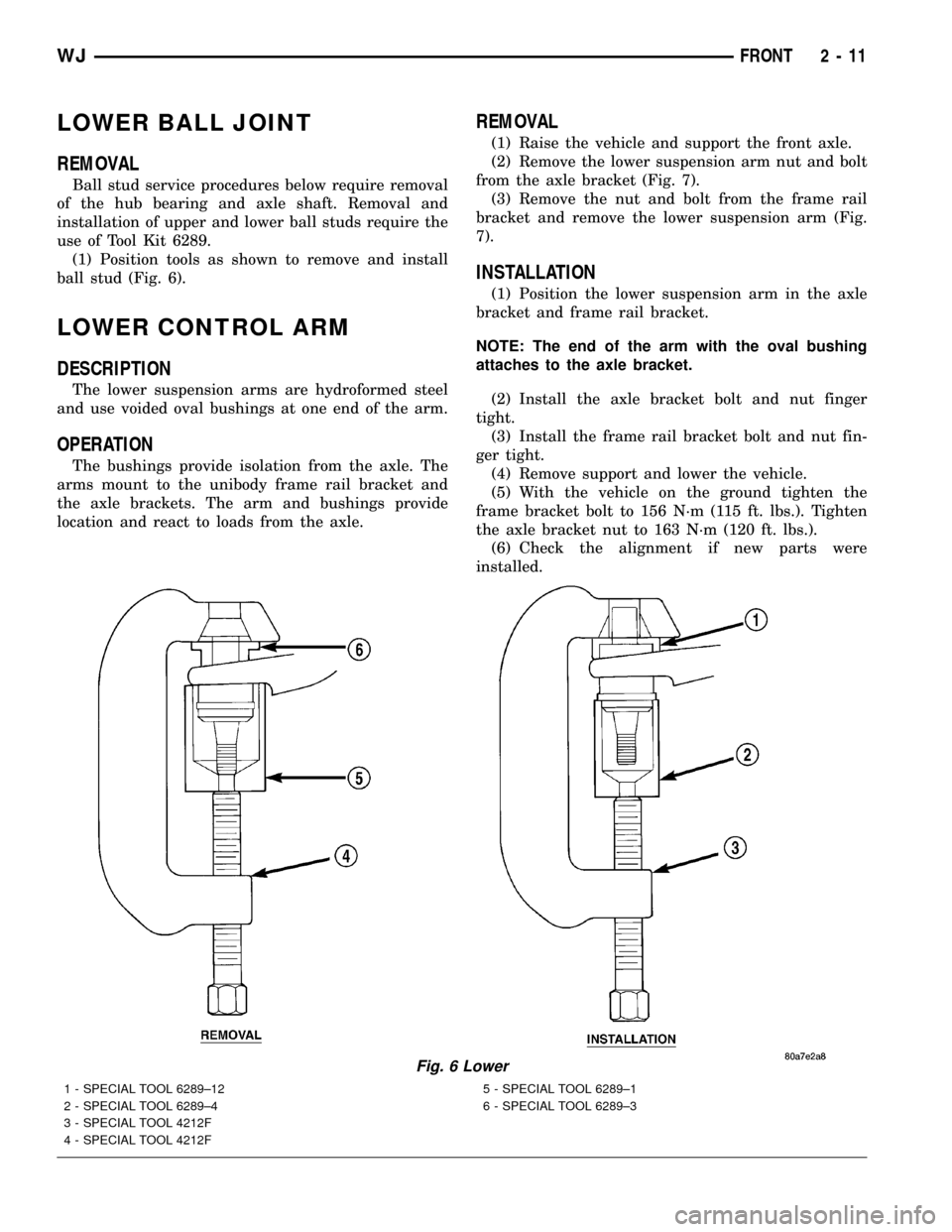

REMOVAL

Ball stud service procedures below require removal

of the hub bearing and axle shaft. Removal and

installation of upper and lower ball studs require the

use of Tool Kit 6289.

(1) Position tools as shown to remove and install

ball stud (Fig. 6).

LOWER CONTROL ARM

DESCRIPTION

The lower suspension arms are hydroformed steel

and use voided oval bushings at one end of the arm.

OPERATION

The bushings provide isolation from the axle. The

arms mount to the unibody frame rail bracket and

the axle brackets. The arm and bushings provide

location and react to loads from the axle.

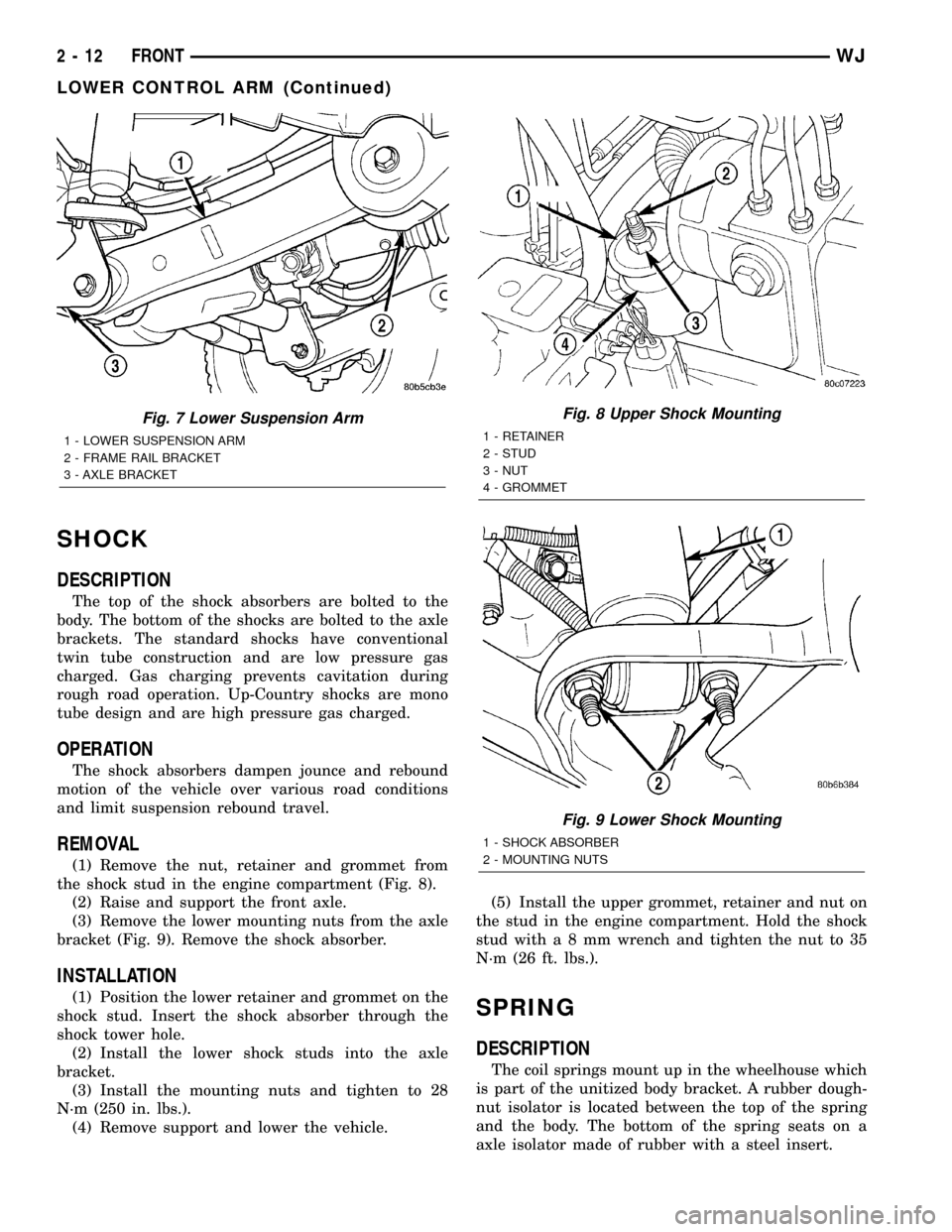

REMOVAL

(1) Raise the vehicle and support the front axle.

(2) Remove the lower suspension arm nut and bolt

from the axle bracket (Fig. 7).

(3) Remove the nut and bolt from the frame rail

bracket and remove the lower suspension arm (Fig.

7).

INSTALLATION

(1) Position the lower suspension arm in the axle

bracket and frame rail bracket.

NOTE: The end of the arm with the oval bushing

attaches to the axle bracket.

(2) Install the axle bracket bolt and nut finger

tight.

(3) Install the frame rail bracket bolt and nut fin-

ger tight.

(4) Remove support and lower the vehicle.

(5) With the vehicle on the ground tighten the

frame bracket bolt to 156 N´m (115 ft. lbs.). Tighten

the axle bracket nut to 163 N´m (120 ft. lbs.).

(6) Check the alignment if new parts were

installed.

Fig. 6 Lower

1 - SPECIAL TOOL 6289±12

2 - SPECIAL TOOL 6289±4

3 - SPECIAL TOOL 4212F

4 - SPECIAL TOOL 4212F5 - SPECIAL TOOL 6289±1

6 - SPECIAL TOOL 6289±3

WJFRONT 2 - 11

Page 33 of 2199

SHOCK

DESCRIPTION

The top of the shock absorbers are bolted to the

body. The bottom of the shocks are bolted to the axle

brackets. The standard shocks have conventional

twin tube construction and are low pressure gas

charged. Gas charging prevents cavitation during

rough road operation. Up-Country shocks are mono

tube design and are high pressure gas charged.

OPERATION

The shock absorbers dampen jounce and rebound

motion of the vehicle over various road conditions

and limit suspension rebound travel.

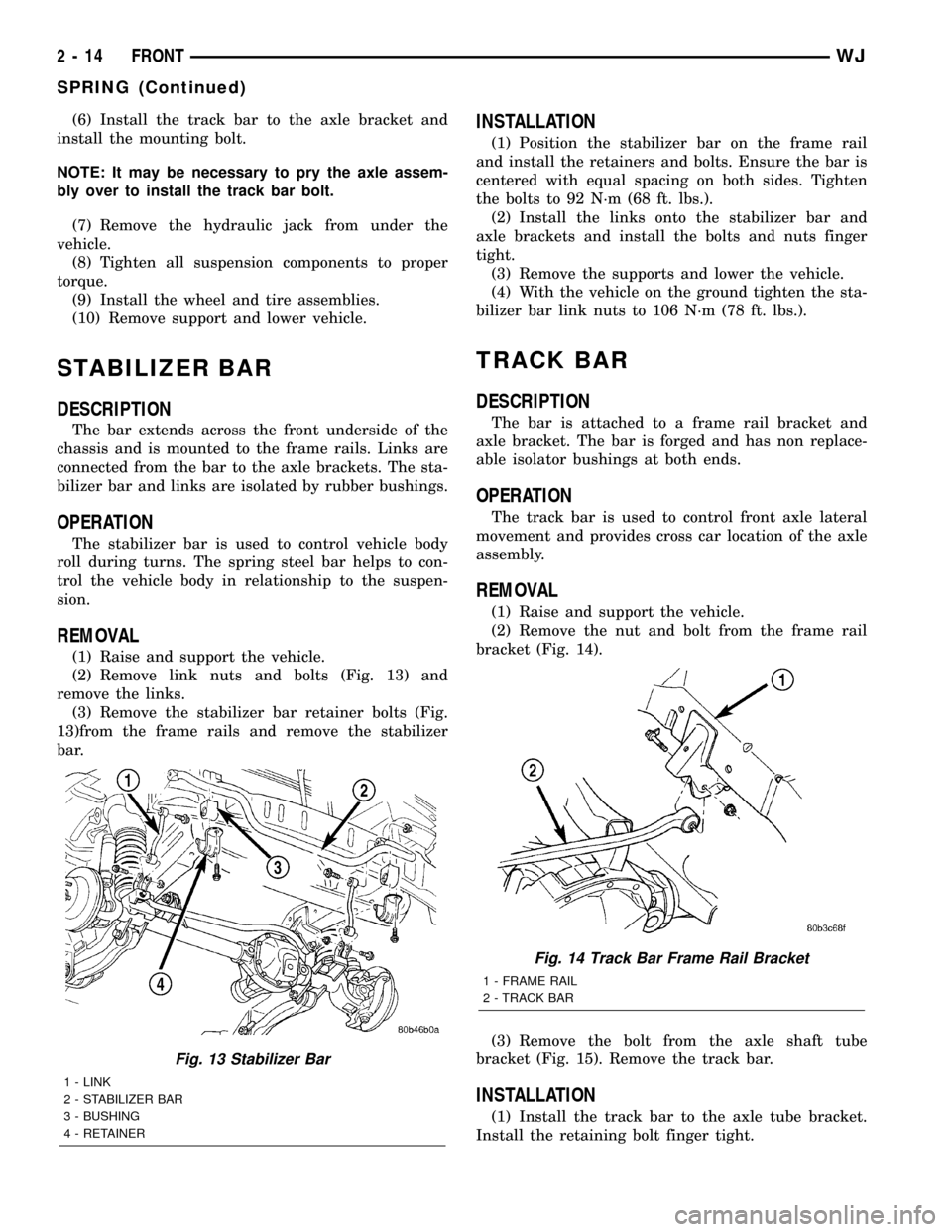

REMOVAL

(1) Remove the nut, retainer and grommet from

the shock stud in the engine compartment (Fig. 8).

(2) Raise and support the front axle.

(3) Remove the lower mounting nuts from the axle

bracket (Fig. 9). Remove the shock absorber.

INSTALLATION

(1) Position the lower retainer and grommet on the

shock stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower shock studs into the axle

bracket.

(3) Install the mounting nuts and tighten to 28

N´m (250 in. lbs.).

(4) Remove support and lower the vehicle.(5) Install the upper grommet, retainer and nut on

the stud in the engine compartment. Hold the shock

stud witha8mmwrench and tighten the nut to 35

N´m (26 ft. lbs.).SPRING

DESCRIPTION

The coil springs mount up in the wheelhouse which

is part of the unitized body bracket. A rubber dough-

nut isolator is located between the top of the spring

and the body. The bottom of the spring seats on a

axle isolator made of rubber with a steel insert.

Fig. 7 Lower Suspension Arm

1 - LOWER SUSPENSION ARM

2 - FRAME RAIL BRACKET

3 - AXLE BRACKET

Fig. 8 Upper Shock Mounting

1 - RETAINER

2 - STUD

3 - NUT

4 - GROMMET

Fig. 9 Lower Shock Mounting

1 - SHOCK ABSORBER

2 - MOUNTING NUTS

2 - 12 FRONTWJ

LOWER CONTROL ARM (Continued)

Page 35 of 2199

(6) Install the track bar to the axle bracket and

install the mounting bolt.

NOTE: It may be necessary to pry the axle assem-

bly over to install the track bar bolt.

(7) Remove the hydraulic jack from under the

vehicle.

(8) Tighten all suspension components to proper

torque.

(9) Install the wheel and tire assemblies.

(10) Remove support and lower vehicle.

STABILIZER BAR

DESCRIPTION

The bar extends across the front underside of the

chassis and is mounted to the frame rails. Links are

connected from the bar to the axle brackets. The sta-

bilizer bar and links are isolated by rubber bushings.

OPERATION

The stabilizer bar is used to control vehicle body

roll during turns. The spring steel bar helps to con-

trol the vehicle body in relationship to the suspen-

sion.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove link nuts and bolts (Fig. 13) and

remove the links.

(3) Remove the stabilizer bar retainer bolts (Fig.

13)from the frame rails and remove the stabilizer

bar.

INSTALLATION

(1) Position the stabilizer bar on the frame rail

and install the retainers and bolts. Ensure the bar is

centered with equal spacing on both sides. Tighten

the bolts to 92 N´m (68 ft. lbs.).

(2) Install the links onto the stabilizer bar and

axle brackets and install the bolts and nuts finger

tight.

(3) Remove the supports and lower the vehicle.

(4) With the vehicle on the ground tighten the sta-

bilizer bar link nuts to 106 N´m (78 ft. lbs.).

TRACK BAR

DESCRIPTION

The bar is attached to a frame rail bracket and

axle bracket. The bar is forged and has non replace-

able isolator bushings at both ends.

OPERATION

The track bar is used to control front axle lateral

movement and provides cross car location of the axle

assembly.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the nut and bolt from the frame rail

bracket (Fig. 14).

(3) Remove the bolt from the axle shaft tube

bracket (Fig. 15). Remove the track bar.

INSTALLATION

(1) Install the track bar to the axle tube bracket.

Install the retaining bolt finger tight.

Fig. 13 Stabilizer Bar

1 - LINK

2 - STABILIZER BAR

3 - BUSHING

4 - RETAINER

Fig. 14 Track Bar Frame Rail Bracket

1 - FRAME RAIL

2 - TRACK BAR

2 - 14 FRONTWJ

SPRING (Continued)

Page 37 of 2199

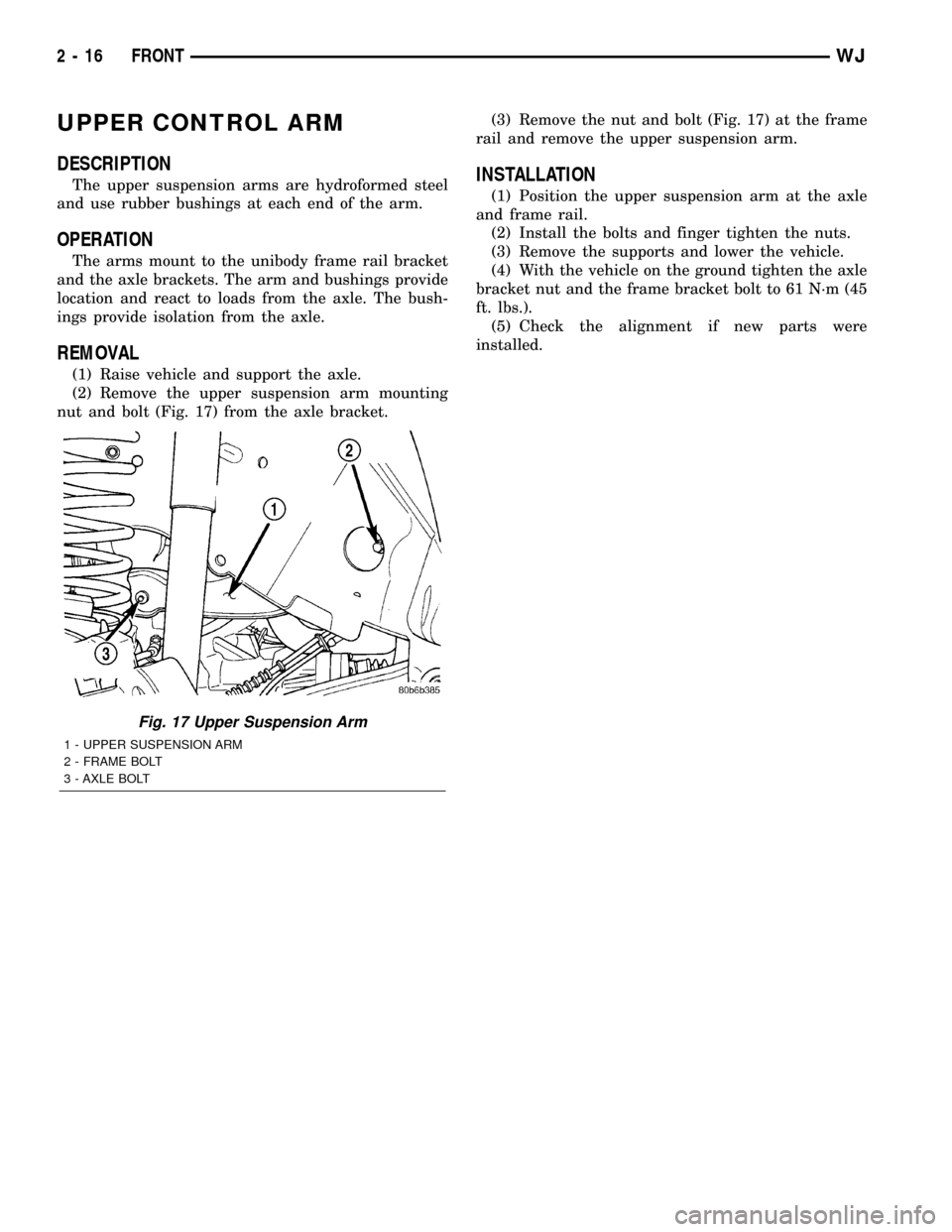

UPPER CONTROL ARM

DESCRIPTION

The upper suspension arms are hydroformed steel

and use rubber bushings at each end of the arm.

OPERATION

The arms mount to the unibody frame rail bracket

and the axle brackets. The arm and bushings provide

location and react to loads from the axle. The bush-

ings provide isolation from the axle.

REMOVAL

(1) Raise vehicle and support the axle.

(2) Remove the upper suspension arm mounting

nut and bolt (Fig. 17) from the axle bracket.(3) Remove the nut and bolt (Fig. 17) at the frame

rail and remove the upper suspension arm.

INSTALLATION

(1) Position the upper suspension arm at the axle

and frame rail.

(2) Install the bolts and finger tighten the nuts.

(3) Remove the supports and lower the vehicle.

(4) With the vehicle on the ground tighten the axle

bracket nut and the frame bracket bolt to 61 N´m (45

ft. lbs.).

(5) Check the alignment if new parts were

installed.

Fig. 17 Upper Suspension Arm

1 - UPPER SUSPENSION ARM

2 - FRAME BOLT

3 - AXLE BOLT

2 - 16 FRONTWJ

Page 38 of 2199

REAR

TABLE OF CONTENTS

page page

REAR

DESCRIPTION.........................17

WARNING.............................17

DIAGNOSIS AND TESTING - REAR

SUSPENSION........................18

SPECIFICATIONS

TORQUE CHART......................18

SPECIAL TOOLS

REAR SUSPENSION...................19

LOWER CONTROL ARM

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................19

INSTALLATION.........................19

SHOCK

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................19

INSTALLATION.........................19

SPRING

DESCRIPTION.........................20OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

STABILIZER BAR

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................21

UPPER BALL JOINT

DESCRIPTION - UPPER SUSPENSION ARM,

BUSHINGS, AND BALL JOINT............21

OPERATION - UPPER SUSPENSION ARM,

BUSHINGS, AND BALL JOINT............21

REMOVAL.............................21

INSTALLATION.........................22

UPPER CONTROL ARM

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................23

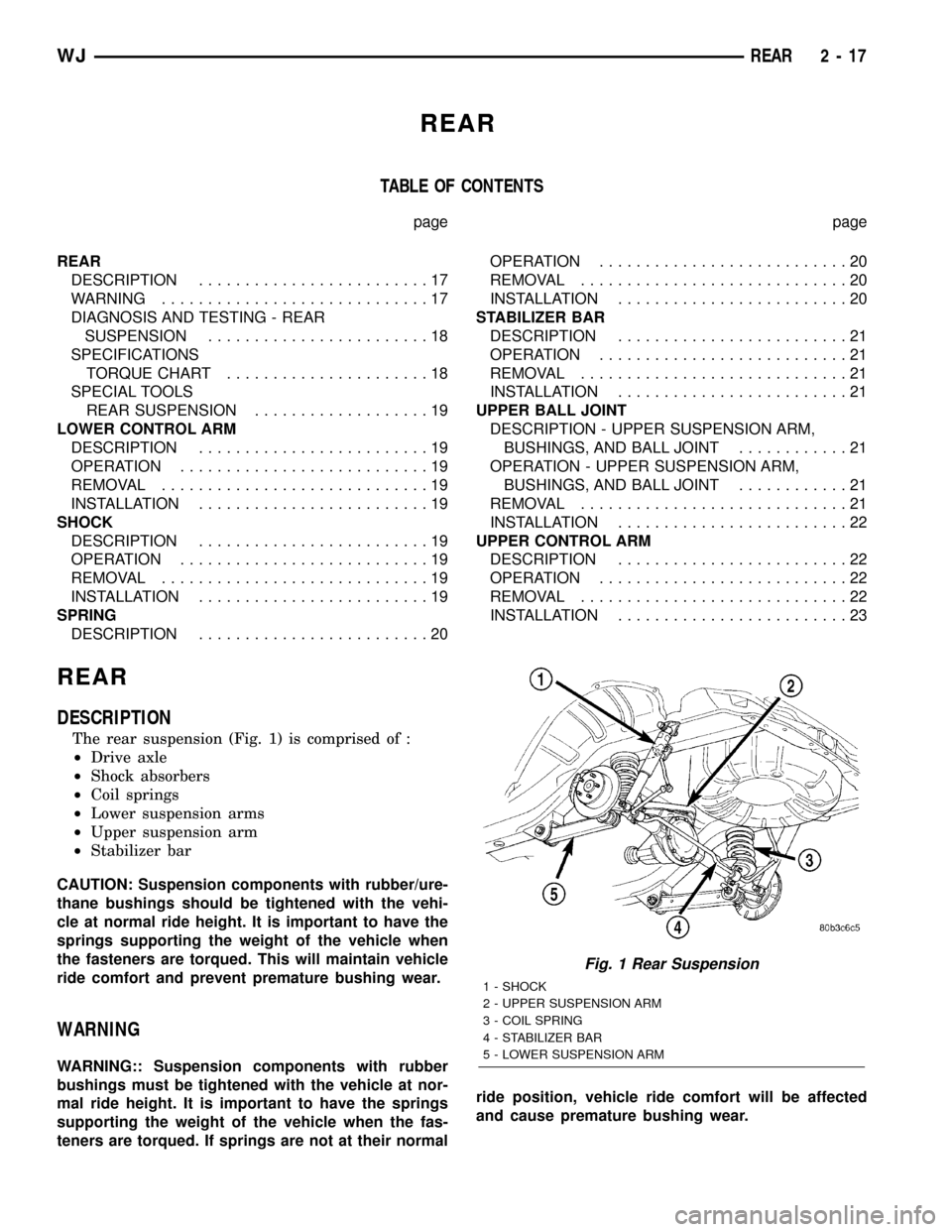

REAR

DESCRIPTION

The rear suspension (Fig. 1) is comprised of :

²Drive axle

²Shock absorbers

²Coil springs

²Lower suspension arms

²Upper suspension arm

²Stabilizer bar

CAUTION: Suspension components with rubber/ure-

thane bushings should be tightened with the vehi-

cle at normal ride height. It is important to have the

springs supporting the weight of the vehicle when

the fasteners are torqued. This will maintain vehicle

ride comfort and prevent premature bushing wear.

WARNING

WARNING:: Suspension components with rubber

bushings must be tightened with the vehicle at nor-

mal ride height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normalride position, vehicle ride comfort will be affected

and cause premature bushing wear.

Fig. 1 Rear Suspension

1 - SHOCK

2 - UPPER SUSPENSION ARM

3 - COIL SPRING

4 - STABILIZER BAR

5 - LOWER SUSPENSION ARM

WJREAR 2 - 17

Page 39 of 2199

DIAGNOSIS AND TESTING - REAR

SUSPENSION

CONDITION POSSIBLE CAUSES CORRECTION

VEHICLE INSTABILITY 1. Loose or worn wheel bearings. 1. Replace wheel bearings.

2. Loose, worn or bent suspension

components.2. Inspect, tighten or replace components

as necessary.

3. Tire pressure. 3. Adjust tire pressure.

VEHICLE PULLS TO ONE

SIDE1. Weak or broken spring. 1. Replace spring.

2. Alignment. 2. Align vehicle to specifications.

3.Tires. 3. Replace tires.

4. Brakes. 4. Repair as necassary.

KNOCKING, RATTLING

OR SQUEAKING1. Worn shock bushings. 1. Replace shock.

2. Loose shock mounting. 2. Tighten to specifications.

3. Shock valve. 3. Replace shock.

4. Loose upper ball joint. 4. Replace ball joint.

5. Loose, worn or bent suspension

components.5. Inspect, tighten or replace components

as necessary.

IMPROPER TRACKING 1. Loose, worn or bent suspension

components.1. Inspect, tighten or replace components

as necessary.

2. Bent axle. 2.Replace axle.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber Upper Nut 108 80 Ð

Shock Absorber Lower Nut 115 85 Ð

Suspension Arm Upper Ball Joint Nut 142 105 Ð

Suspension Arm Upper Frame Bolts 100 74 Ð

Ball Joint Plate Bolts 136 100 Ð

Suspension Arms Lower Axle Bracket Nut 163 120 Ð

Suspension Arms Lower Frame Bracket Nut 156 115 Ð

Stabilizer Bar Retainer Bolts 54 40 Ð

Stabilizer Bar Bar Link Nut 54 40 Ð

Stabilizer Bar Bracket Link Nut 92 68 Ð

2 - 18 REARWJ

REAR (Continued)

Page 40 of 2199

SPECIAL TOOLS

REAR SUSPENSION

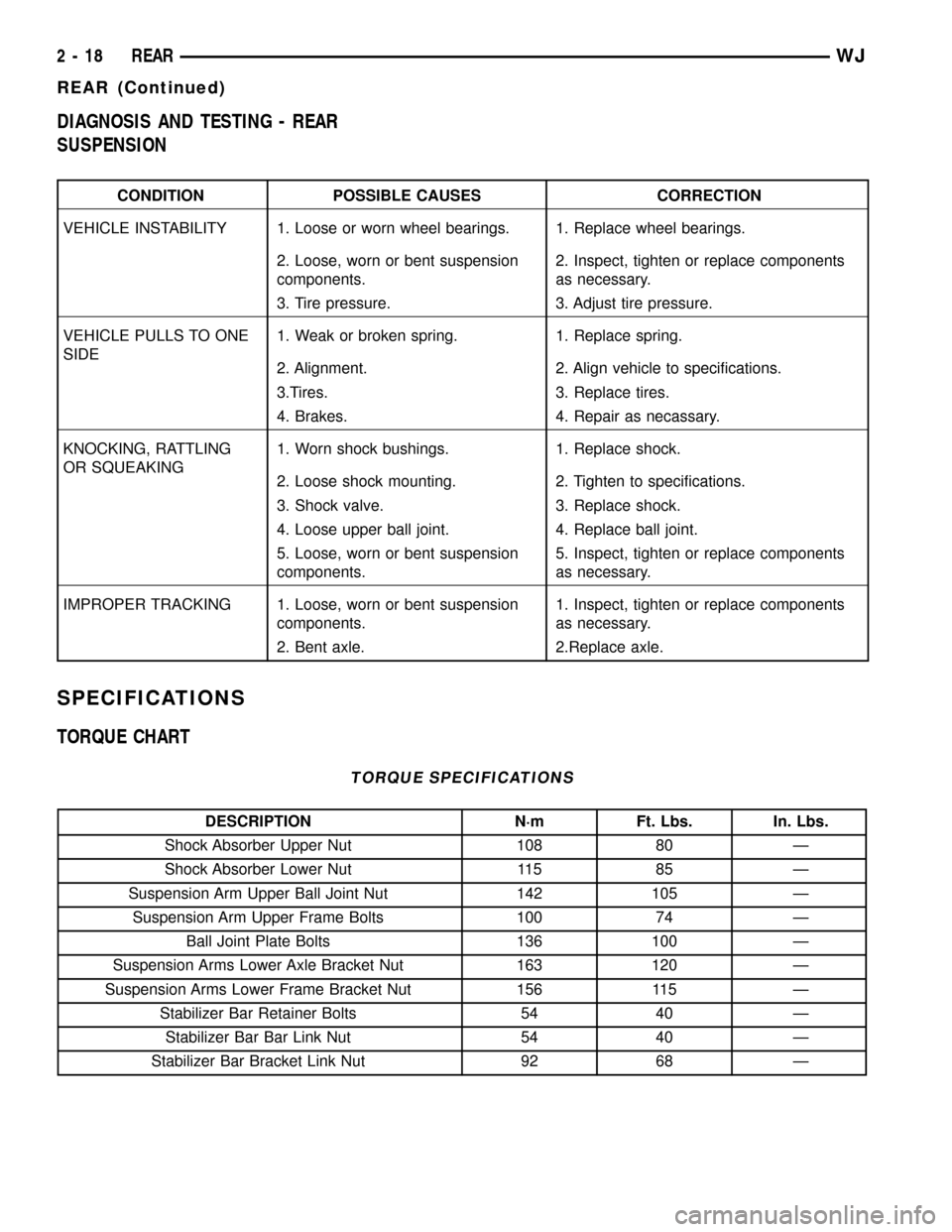

LOWER CONTROL ARM

DESCRIPTION

The lower suspension arms are hydroformed steel

and use voided oval bushings at each end of the arm.

OPERATION

The bushings provide isolation from the axle. The

arms mount to the unibody frame rail bracket and

the axle brackets. The arm and bushings provide

location and react to loads.

REMOVAL

(1) Raise the vehicle and support the rear axle.

(2) Remove the lower suspension arm nut and bolt

from the axle bracket (Fig. 2).

(3) Remove the nut and bolt (Fig. 2) from the

frame rail and remove the lower suspension arm.

INSTALLATION

(1) Position the lower suspension arm in the axle

bracket and frame rail bracket.

NOTE: The end of the arm with the oval bushing

attaches to the axle bracket.

(2) Install the axle bracket bolt and nut finger

tight.

(3) Install the frame rail bracket bolt and nut fin-

ger tight.

(4) Remove the supports and lower the vehicle.

(5) With the vehicle on the ground tighten the nut

at the frame to 156 N´m (115 ft. lbs.). Tighten the

nut at the axle bracket to 163 N´m (120 ft. lbs.).

SHOCK

DESCRIPTION

The top of the shock absorbers are bolted to the

body. The bottom of the shocks are bolted to the axle

brackets. The standard shocks have conventional

twin tube construction and are low pressure gas

charged. Gas charging prevents cavitation during

rough road operation. Up-Country shocks are mono

tube design and are high pressure gas charged.

OPERATION

The shock absorbers dampen jounce and rebound

motion of the vehicle over various road conditions

and limit suspension rebound travel.

REMOVAL

(1) Raise and support the vehicle. Position a

hydraulic jack under the axle to support the axle.

CAUTION: Do not allow the axle to hang from the

upper suspension arm ball joint.

(2) Remove the upper nut and bolt from the frame

bracket (Fig. 3).

(3) Remove the lower nut and bolt from the axle

bracket. Remove the shock absorber.

INSTALLATION

(1) Install the shock absorber in the frame bracket

and install the bolt and nut.

(2) Install the shock absorber in the axle bracket

and install the bolt and nut.

(3) Tighten the upper mounting nuts to 108 N´m

(80 ft. lbs.). Tighten the lower mounting nuts to 115

N´m (85 ft. lbs.).

(4) Remove the supports and lower the vehicle.

Remover 8278

Fig. 2 Lower Suspension Arm

1 - LOWER SUSPENSION ARM

2 - AXLE BRACKET

3 - FRAME BRACKET

WJREAR 2 - 19

REAR (Continued)

Page 42 of 2199

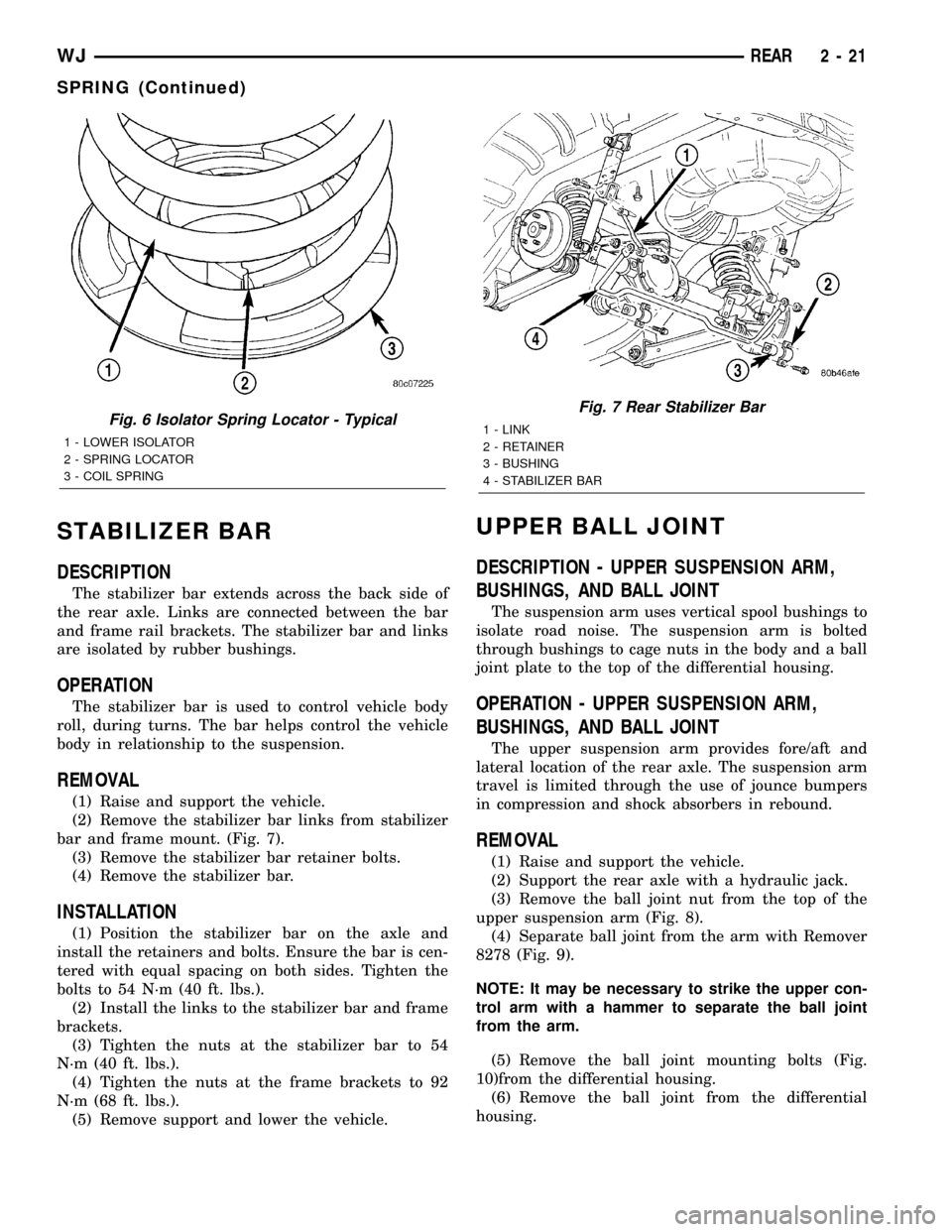

STABILIZER BAR

DESCRIPTION

The stabilizer bar extends across the back side of

the rear axle. Links are connected between the bar

and frame rail brackets. The stabilizer bar and links

are isolated by rubber bushings.

OPERATION

The stabilizer bar is used to control vehicle body

roll, during turns. The bar helps control the vehicle

body in relationship to the suspension.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the stabilizer bar links from stabilizer

bar and frame mount. (Fig. 7).

(3) Remove the stabilizer bar retainer bolts.

(4) Remove the stabilizer bar.

INSTALLATION

(1) Position the stabilizer bar on the axle and

install the retainers and bolts. Ensure the bar is cen-

tered with equal spacing on both sides. Tighten the

bolts to 54 N´m (40 ft. lbs.).

(2) Install the links to the stabilizer bar and frame

brackets.

(3) Tighten the nuts at the stabilizer bar to 54

N´m (40 ft. lbs.).

(4) Tighten the nuts at the frame brackets to 92

N´m (68 ft. lbs.).

(5) Remove support and lower the vehicle.

UPPER BALL JOINT

DESCRIPTION - UPPER SUSPENSION ARM,

BUSHINGS, AND BALL JOINT

The suspension arm uses vertical spool bushings to

isolate road noise. The suspension arm is bolted

through bushings to cage nuts in the body and a ball

joint plate to the top of the differential housing.

OPERATION - UPPER SUSPENSION ARM,

BUSHINGS, AND BALL JOINT

The upper suspension arm provides fore/aft and

lateral location of the rear axle. The suspension arm

travel is limited through the use of jounce bumpers

in compression and shock absorbers in rebound.

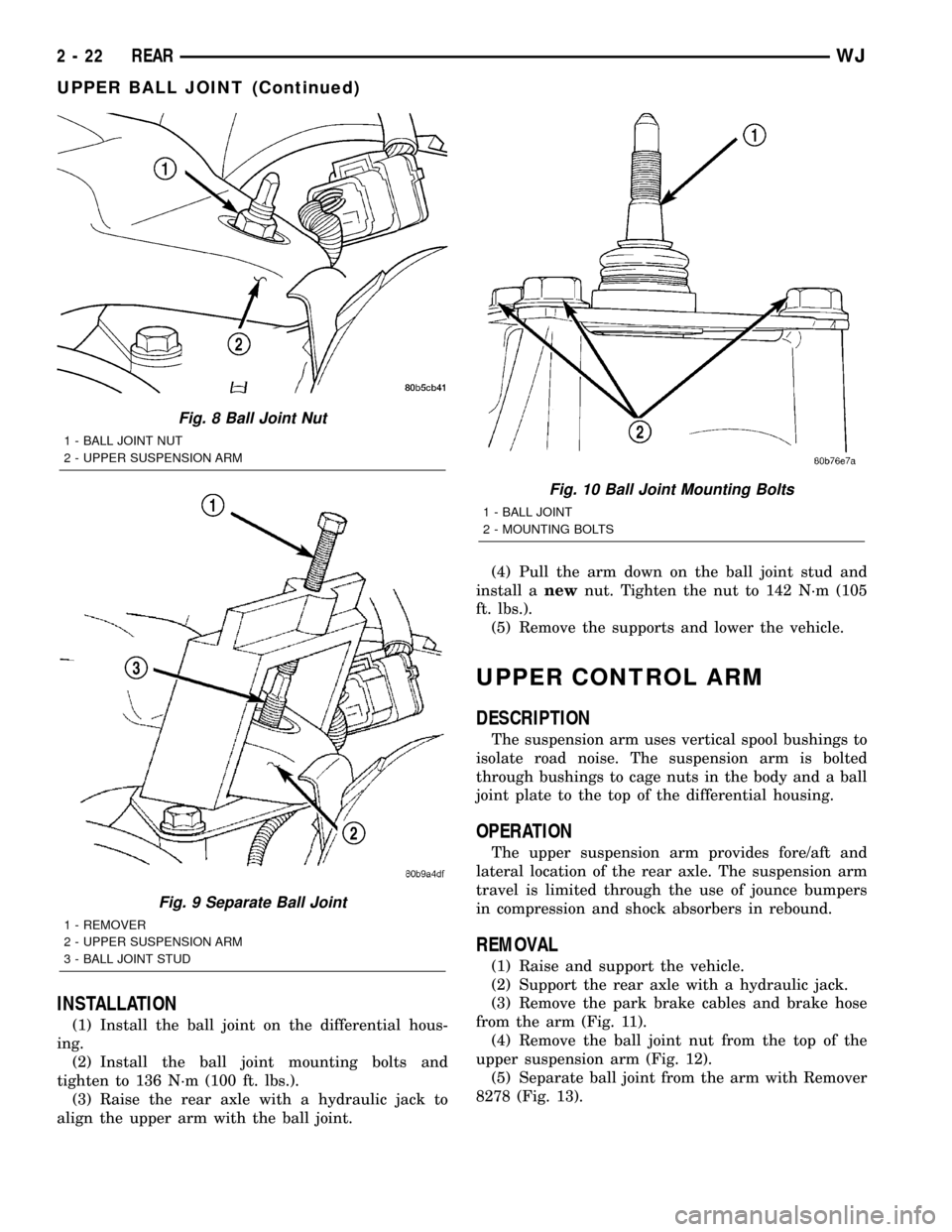

REMOVAL

(1) Raise and support the vehicle.

(2) Support the rear axle with a hydraulic jack.

(3) Remove the ball joint nut from the top of the

upper suspension arm (Fig. 8).

(4) Separate ball joint from the arm with Remover

8278 (Fig. 9).

NOTE: It may be necessary to strike the upper con-

trol arm with a hammer to separate the ball joint

from the arm.

(5) Remove the ball joint mounting bolts (Fig.

10)from the differential housing.

(6) Remove the ball joint from the differential

housing.

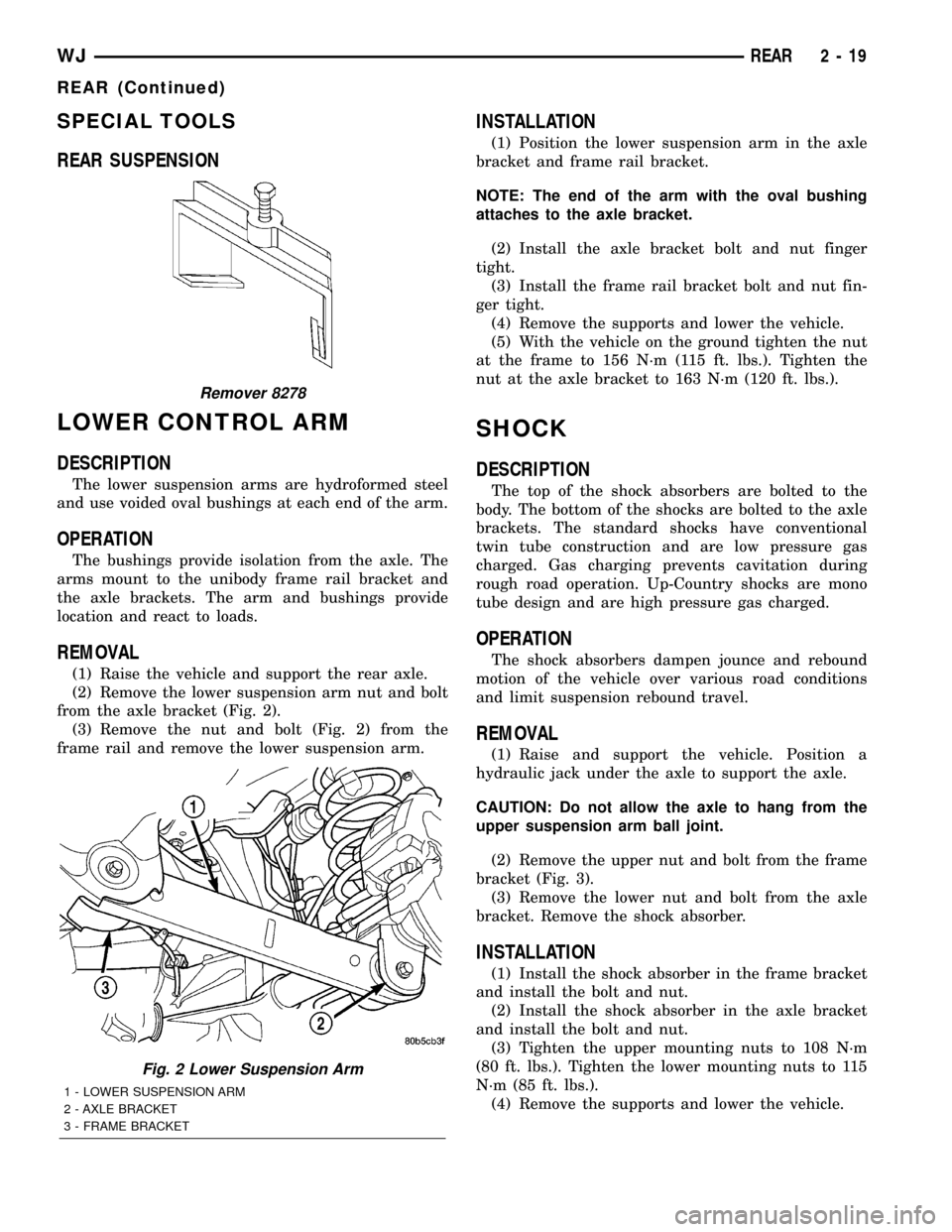

Fig. 6 Isolator Spring Locator - Typical

1 - LOWER ISOLATOR

2 - SPRING LOCATOR

3 - COIL SPRING

Fig. 7 Rear Stabilizer Bar

1 - LINK

2 - RETAINER

3 - BUSHING

4 - STABILIZER BAR

WJREAR 2 - 21

SPRING (Continued)

Page 43 of 2199

INSTALLATION

(1) Install the ball joint on the differential hous-

ing.

(2) Install the ball joint mounting bolts and

tighten to 136 N´m (100 ft. lbs.).

(3) Raise the rear axle with a hydraulic jack to

align the upper arm with the ball joint.(4) Pull the arm down on the ball joint stud and

install anewnut. Tighten the nut to 142 N´m (105

ft. lbs.).

(5) Remove the supports and lower the vehicle.

UPPER CONTROL ARM

DESCRIPTION

The suspension arm uses vertical spool bushings to

isolate road noise. The suspension arm is bolted

through bushings to cage nuts in the body and a ball

joint plate to the top of the differential housing.

OPERATION

The upper suspension arm provides fore/aft and

lateral location of the rear axle. The suspension arm

travel is limited through the use of jounce bumpers

in compression and shock absorbers in rebound.

REMOVAL

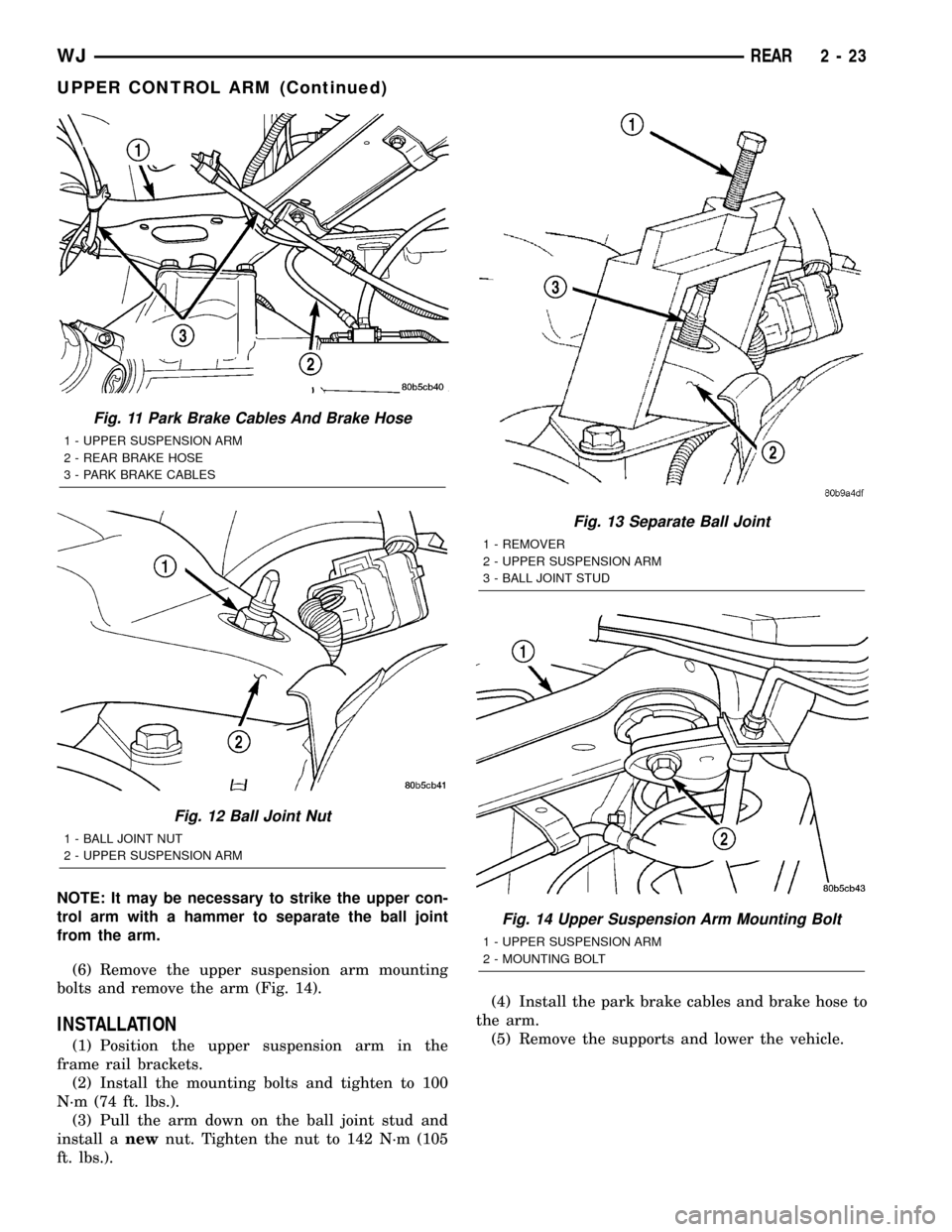

(1) Raise and support the vehicle.

(2) Support the rear axle with a hydraulic jack.

(3) Remove the park brake cables and brake hose

from the arm (Fig. 11).

(4) Remove the ball joint nut from the top of the

upper suspension arm (Fig. 12).

(5) Separate ball joint from the arm with Remover

8278 (Fig. 13).

Fig. 8 Ball Joint Nut

1 - BALL JOINT NUT

2 - UPPER SUSPENSION ARM

Fig. 9 Separate Ball Joint

1 - REMOVER

2 - UPPER SUSPENSION ARM

3 - BALL JOINT STUD

Fig. 10 Ball Joint Mounting Bolts

1 - BALL JOINT

2 - MOUNTING BOLTS

2 - 22 REARWJ

UPPER BALL JOINT (Continued)

Page 44 of 2199

NOTE: It may be necessary to strike the upper con-

trol arm with a hammer to separate the ball joint

from the arm.

(6) Remove the upper suspension arm mounting

bolts and remove the arm (Fig. 14).

INSTALLATION

(1) Position the upper suspension arm in the

frame rail brackets.

(2) Install the mounting bolts and tighten to 100

N´m (74 ft. lbs.).

(3) Pull the arm down on the ball joint stud and

install anewnut. Tighten the nut to 142 N´m (105

ft. lbs.).(4) Install the park brake cables and brake hose to

the arm.

(5) Remove the supports and lower the vehicle.

Fig. 11 Park Brake Cables And Brake Hose

1 - UPPER SUSPENSION ARM

2 - REAR BRAKE HOSE

3 - PARK BRAKE CABLES

Fig. 12 Ball Joint Nut

1 - BALL JOINT NUT

2 - UPPER SUSPENSION ARM

Fig. 13 Separate Ball Joint

1 - REMOVER

2 - UPPER SUSPENSION ARM

3 - BALL JOINT STUD

Fig. 14 Upper Suspension Arm Mounting Bolt

1 - UPPER SUSPENSION ARM

2 - MOUNTING BOLT

WJREAR 2 - 23

UPPER CONTROL ARM (Continued)