sensor JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 30 of 2199

BUSHINGS

REMOVAL

(1) Remove the upper suspension arm from axle.

(2) Position Spacer 8279 over the axle bushing on

a 4x2 vehicle and right side on a 4x4 vehicle.

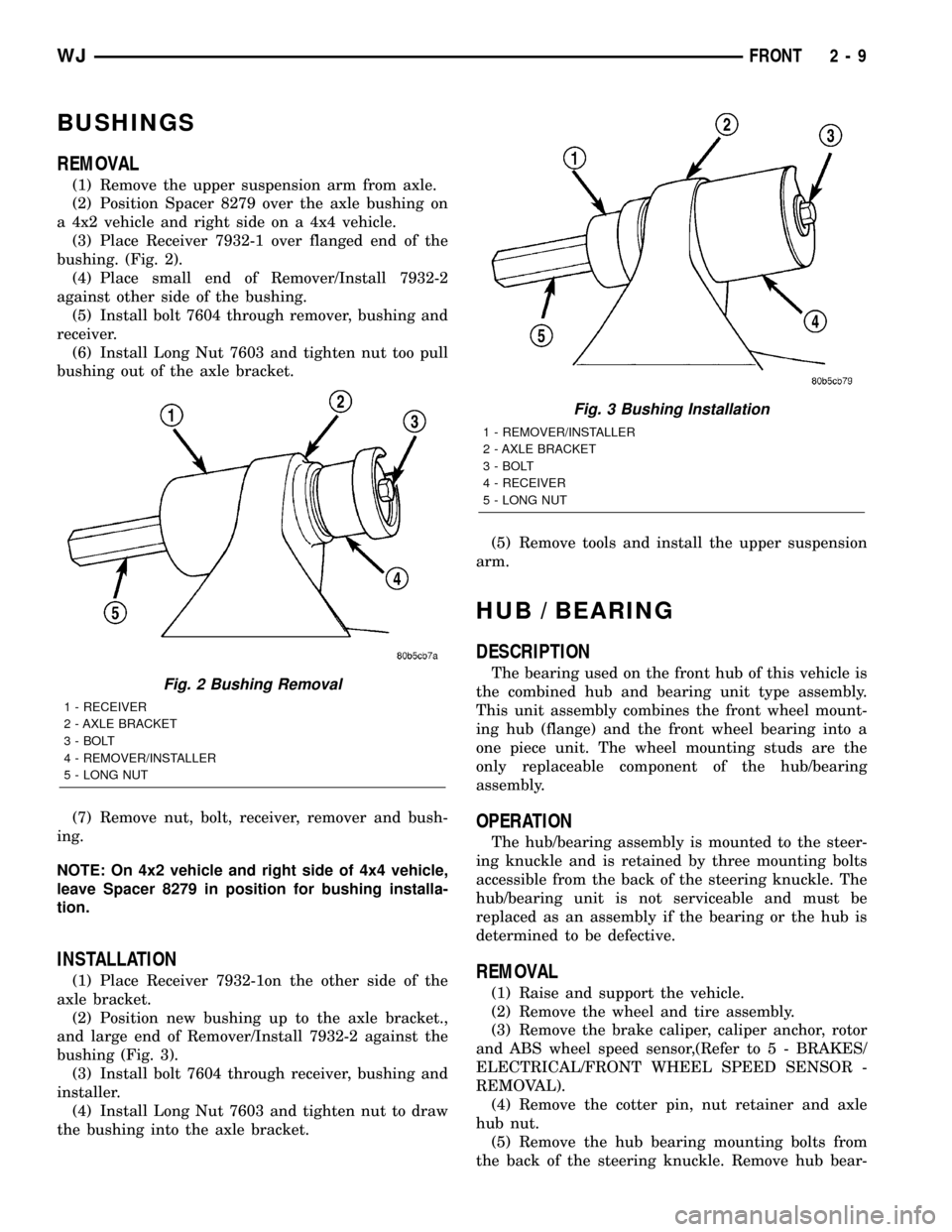

(3) Place Receiver 7932-1 over flanged end of the

bushing. (Fig. 2).

(4) Place small end of Remover/Install 7932-2

against other side of the bushing.

(5) Install bolt 7604 through remover, bushing and

receiver.

(6) Install Long Nut 7603 and tighten nut too pull

bushing out of the axle bracket.

(7) Remove nut, bolt, receiver, remover and bush-

ing.

NOTE: On 4x2 vehicle and right side of 4x4 vehicle,

leave Spacer 8279 in position for bushing installa-

tion.

INSTALLATION

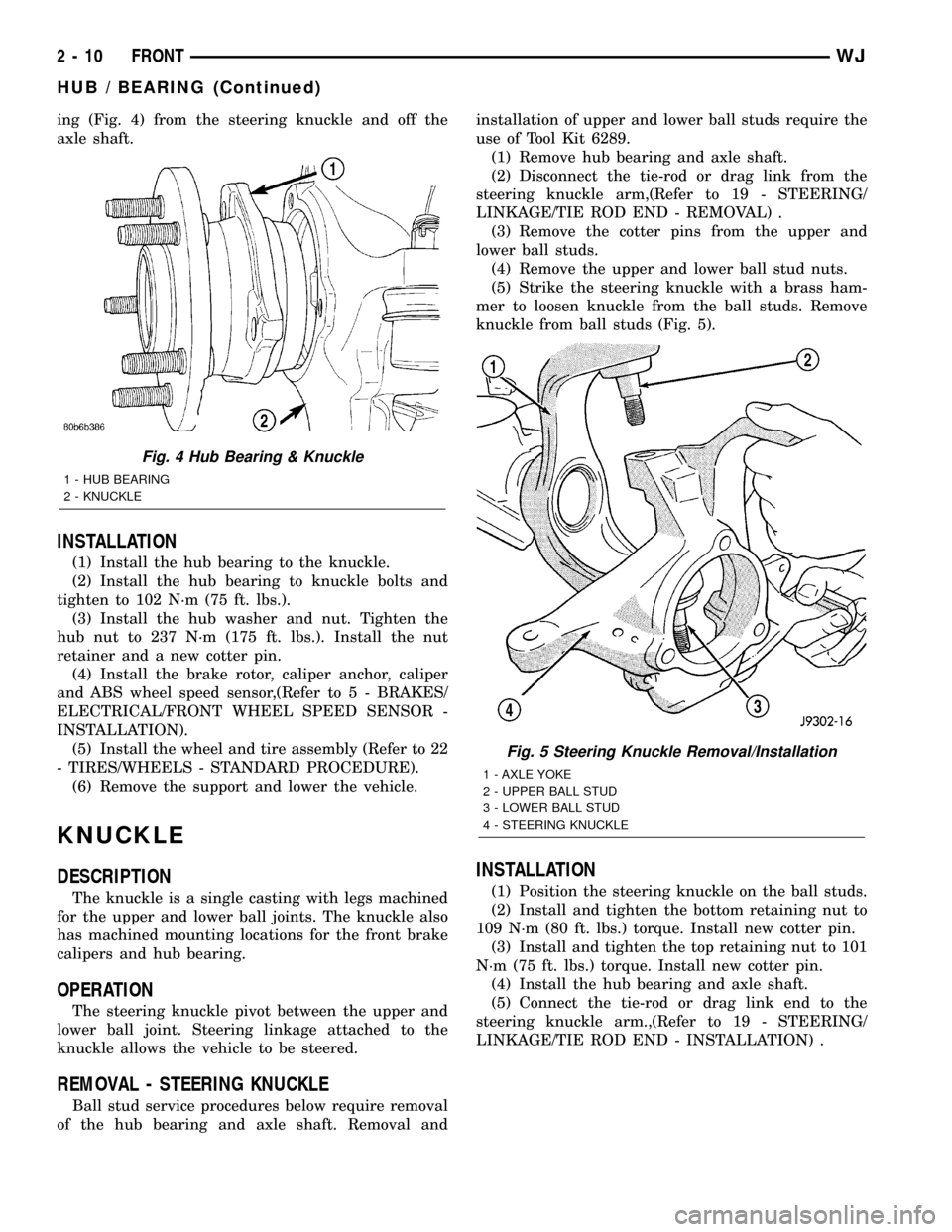

(1) Place Receiver 7932-1on the other side of the

axle bracket.

(2) Position new bushing up to the axle bracket.,

and large end of Remover/Install 7932-2 against the

bushing (Fig. 3).

(3) Install bolt 7604 through receiver, bushing and

installer.

(4) Install Long Nut 7603 and tighten nut to draw

the bushing into the axle bracket.(5) Remove tools and install the upper suspension

arm.

HUB / BEARING

DESCRIPTION

The bearing used on the front hub of this vehicle is

the combined hub and bearing unit type assembly.

This unit assembly combines the front wheel mount-

ing hub (flange) and the front wheel bearing into a

one piece unit. The wheel mounting studs are the

only replaceable component of the hub/bearing

assembly.

OPERATION

The hub/bearing assembly is mounted to the steer-

ing knuckle and is retained by three mounting bolts

accessible from the back of the steering knuckle. The

hub/bearing unit is not serviceable and must be

replaced as an assembly if the bearing or the hub is

determined to be defective.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake caliper, caliper anchor, rotor

and ABS wheel speed sensor,(Refer to 5 - BRAKES/

ELECTRICAL/FRONT WHEEL SPEED SENSOR -

REMOVAL).

(4) Remove the cotter pin, nut retainer and axle

hub nut.

(5) Remove the hub bearing mounting bolts from

the back of the steering knuckle. Remove hub bear-

Fig. 2 Bushing Removal

1 - RECEIVER

2 - AXLE BRACKET

3 - BOLT

4 - REMOVER/INSTALLER

5 - LONG NUT

Fig. 3 Bushing Installation

1 - REMOVER/INSTALLER

2 - AXLE BRACKET

3 - BOLT

4 - RECEIVER

5 - LONG NUT

WJFRONT 2 - 9

Page 31 of 2199

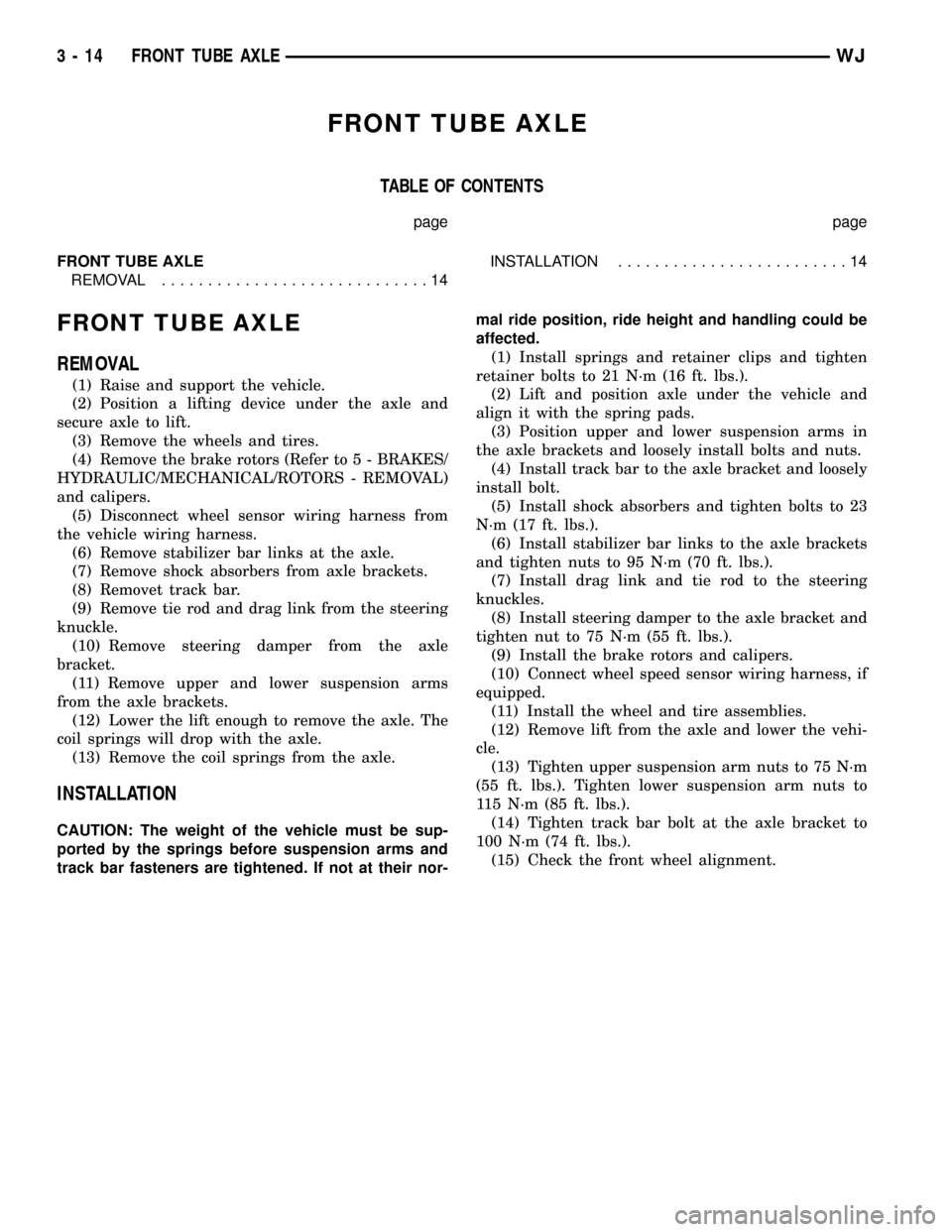

ing (Fig. 4) from the steering knuckle and off the

axle shaft.

INSTALLATION

(1) Install the hub bearing to the knuckle.

(2) Install the hub bearing to knuckle bolts and

tighten to 102 N´m (75 ft. lbs.).

(3) Install the hub washer and nut. Tighten the

hub nut to 237 N´m (175 ft. lbs.). Install the nut

retainer and a new cotter pin.

(4) Install the brake rotor, caliper anchor, caliper

and ABS wheel speed sensor,(Refer to 5 - BRAKES/

ELECTRICAL/FRONT WHEEL SPEED SENSOR -

INSTALLATION).

(5) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS - STANDARD PROCEDURE).

(6) Remove the support and lower the vehicle.

KNUCKLE

DESCRIPTION

The knuckle is a single casting with legs machined

for the upper and lower ball joints. The knuckle also

has machined mounting locations for the front brake

calipers and hub bearing.

OPERATION

The steering knuckle pivot between the upper and

lower ball joint. Steering linkage attached to the

knuckle allows the vehicle to be steered.

REMOVAL - STEERING KNUCKLE

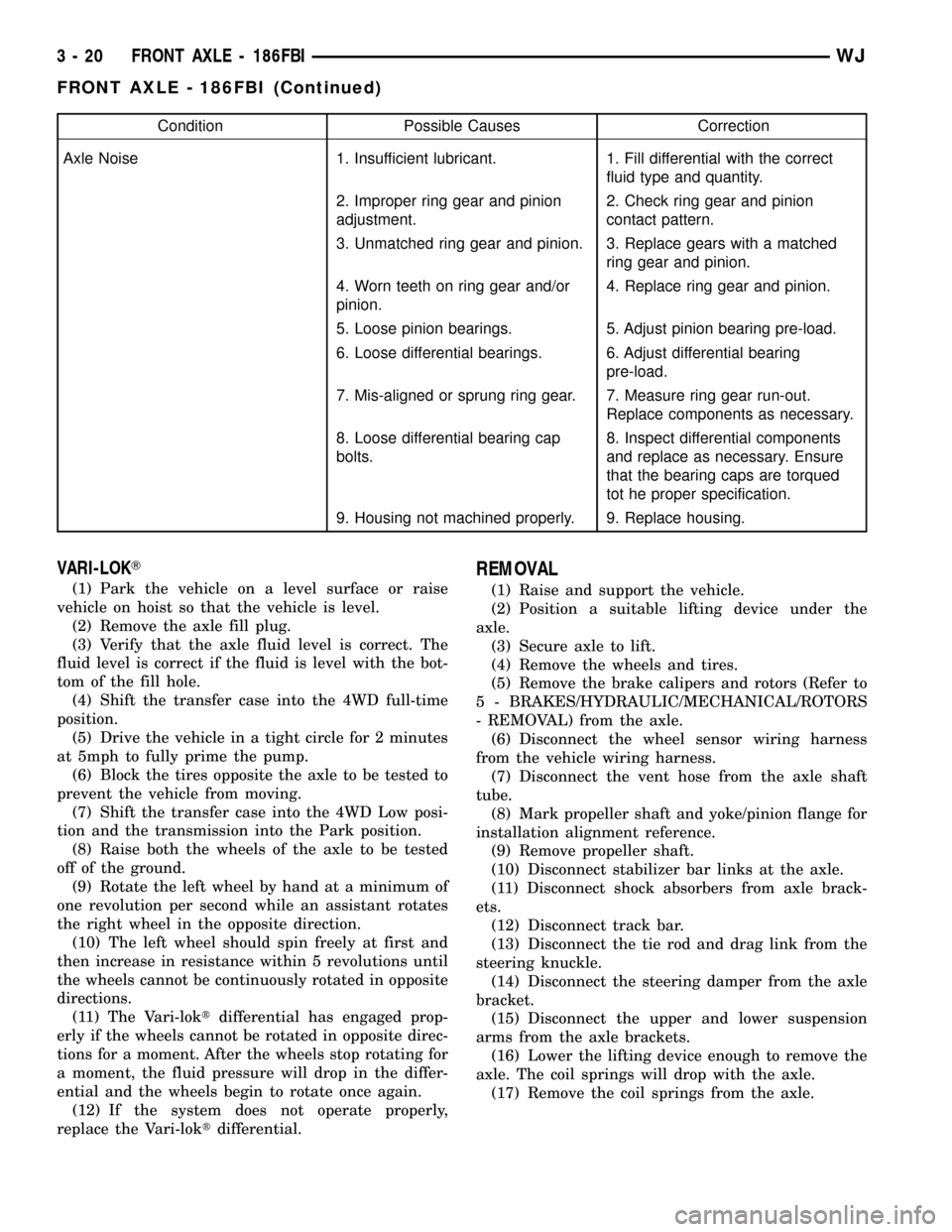

Ball stud service procedures below require removal

of the hub bearing and axle shaft. Removal andinstallation of upper and lower ball studs require the

use of Tool Kit 6289.

(1) Remove hub bearing and axle shaft.

(2) Disconnect the tie-rod or drag link from the

steering knuckle arm,(Refer to 19 - STEERING/

LINKAGE/TIE ROD END - REMOVAL) .

(3) Remove the cotter pins from the upper and

lower ball studs.

(4) Remove the upper and lower ball stud nuts.

(5) Strike the steering knuckle with a brass ham-

mer to loosen knuckle from the ball studs. Remove

knuckle from ball studs (Fig. 5).

INSTALLATION

(1) Position the steering knuckle on the ball studs.

(2) Install and tighten the bottom retaining nut to

109 N´m (80 ft. lbs.) torque. Install new cotter pin.

(3) Install and tighten the top retaining nut to 101

N´m (75 ft. lbs.) torque. Install new cotter pin.

(4) Install the hub bearing and axle shaft.

(5) Connect the tie-rod or drag link end to the

steering knuckle arm.,(Refer to 19 - STEERING/

LINKAGE/TIE ROD END - INSTALLATION) .

Fig. 4 Hub Bearing & Knuckle

1 - HUB BEARING

2 - KNUCKLE

Fig. 5 Steering Knuckle Removal/Installation

1 - AXLE YOKE

2 - UPPER BALL STUD

3 - LOWER BALL STUD

4 - STEERING KNUCKLE

2 - 10 FRONTWJ

HUB / BEARING (Continued)

Page 59 of 2199

FRONT TUBE AXLE

TABLE OF CONTENTS

page page

FRONT TUBE AXLE

REMOVAL.............................14INSTALLATION.........................14

FRONT TUBE AXLE

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle and

secure axle to lift.

(3) Remove the wheels and tires.

(4) Remove the brake rotors (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - REMOVAL)

and calipers.

(5) Disconnect wheel sensor wiring harness from

the vehicle wiring harness.

(6) Remove stabilizer bar links at the axle.

(7) Remove shock absorbers from axle brackets.

(8) Removet track bar.

(9) Remove tie rod and drag link from the steering

knuckle.

(10) Remove steering damper from the axle

bracket.

(11) Remove upper and lower suspension arms

from the axle brackets.

(12) Lower the lift enough to remove the axle. The

coil springs will drop with the axle.

(13) Remove the coil springs from the axle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners are tightened. If not at their nor-mal ride position, ride height and handling could be

affected.

(1) Install springs and retainer clips and tighten

retainer bolts to 21 N´m (16 ft. lbs.).

(2) Lift and position axle under the vehicle and

align it with the spring pads.

(3) Position upper and lower suspension arms in

the axle brackets and loosely install bolts and nuts.

(4) Install track bar to the axle bracket and loosely

install bolt.

(5) Install shock absorbers and tighten bolts to 23

N´m (17 ft. lbs.).

(6) Install stabilizer bar links to the axle brackets

and tighten nuts to 95 N´m (70 ft. lbs.).

(7) Install drag link and tie rod to the steering

knuckles.

(8) Install steering damper to the axle bracket and

tighten nut to 75 N´m (55 ft. lbs.).

(9) Install the brake rotors and calipers.

(10) Connect wheel speed sensor wiring harness, if

equipped.

(11) Install the wheel and tire assemblies.

(12) Remove lift from the axle and lower the vehi-

cle.

(13) Tighten upper suspension arm nuts to 75 N´m

(55 ft. lbs.). Tighten lower suspension arm nuts to

115 N´m (85 ft. lbs.).

(14) Tighten track bar bolt at the axle bracket to

100 N´m (74 ft. lbs.).

(15) Check the front wheel alignment.

3 - 14 FRONT TUBE AXLEWJ

Page 65 of 2199

Condition Possible Causes Correction

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

VARI-LOKT

(1) Park the vehicle on a level surface or raise

vehicle on hoist so that the vehicle is level.

(2) Remove the axle fill plug.

(3) Verify that the axle fluid level is correct. The

fluid level is correct if the fluid is level with the bot-

tom of the fill hole.

(4) Shift the transfer case into the 4WD full-time

position.

(5) Drive the vehicle in a tight circle for 2 minutes

at 5mph to fully prime the pump.

(6) Block the tires opposite the axle to be tested to

prevent the vehicle from moving.

(7) Shift the transfer case into the 4WD Low posi-

tion and the transmission into the Park position.

(8) Raise both the wheels of the axle to be tested

off of the ground.

(9) Rotate the left wheel by hand at a minimum of

one revolution per second while an assistant rotates

the right wheel in the opposite direction.

(10) The left wheel should spin freely at first and

then increase in resistance within 5 revolutions until

the wheels cannot be continuously rotated in opposite

directions.

(11) The Vari-loktdifferential has engaged prop-

erly if the wheels cannot be rotated in opposite direc-

tions for a moment. After the wheels stop rotating for

a moment, the fluid pressure will drop in the differ-

ential and the wheels begin to rotate once again.

(12) If the system does not operate properly,

replace the Vari-loktdifferential.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a suitable lifting device under the

axle.

(3) Secure axle to lift.

(4) Remove the wheels and tires.

(5) Remove the brake calipers and rotors (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/ROTORS

- REMOVAL) from the axle.

(6) Disconnect the wheel sensor wiring harness

from the vehicle wiring harness.

(7) Disconnect the vent hose from the axle shaft

tube.

(8) Mark propeller shaft and yoke/pinion flange for

installation alignment reference.

(9) Remove propeller shaft.

(10) Disconnect stabilizer bar links at the axle.

(11) Disconnect shock absorbers from axle brack-

ets.

(12) Disconnect track bar.

(13) Disconnect the tie rod and drag link from the

steering knuckle.

(14) Disconnect the steering damper from the axle

bracket.

(15) Disconnect the upper and lower suspension

arms from the axle brackets.

(16) Lower the lifting device enough to remove the

axle. The coil springs will drop with the axle.

(17) Remove the coil springs from the axle.

3 - 20 FRONT AXLE - 186FBIWJ

FRONT AXLE - 186FBI (Continued)

Page 66 of 2199

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners can be tightened. If springs are

not at their normal ride position, ride height and

handling could be affected.

(1) Install the springs and retainer clips. Tighten

the retainer bolts to 21 N´m (16 ft. lbs.).

(2) Support the axle on a lifting device and posi-

tion axle under the vehicle.

(3) Raise the axle and align it with the spring

pads.

(4) Position the upper and lower suspension arms

in the axle brackets. Loosely install bolts and nuts to

hold suspension arms to the axle brackets.

(5) Install vent hose to the axle shaft tube.

(6) Install track bar in the axle bracket and install

the bolt loosely.

(7) Install shock absorbers and tighten the bolts to

23 N´m (17 ft. lbs.).

(8) Install stabilizer bar links to the axle brackets

and tighten the nuts to 95 N´m (70 ft. lbs.).

(9) Install drag link and tie rod to the steering

knuckles.

(10) Install steering damper to the axle bracket

and tighten the nut to 75 N´m (55 ft. lbs.).

(11) Install the brake rotors (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION) and calipers.

(12) Connect the wheel speed sensor wiring har-

ness to the vehicle wiring harness.

(13) Align the previously made marks on the pro-

peller shaft and the yoke/pinion flange.

(14) Install propeller shaft to pinion flange bolts ,

if equipped.

(15) Install propeller shaft to yoke straps and

bolts, if equipped.

(16) Check and fill axle lubricant.

(17) Install the wheel and tire assemblies.

(18) Remove the lifting device from the axle and

lower the vehicle.

(19) Tighten the upper suspension arm nuts to 75

N´m (55 ft. lbs.). Tighten the lower suspension arm

nuts to 115 N´m (85 ft. lbs.).

(20) Tighten the track bar bolt at the axle bracket

to 100 N´m (74 ft. lbs.).

(21) Check the front wheel alignment.

ADJUSTMENTS

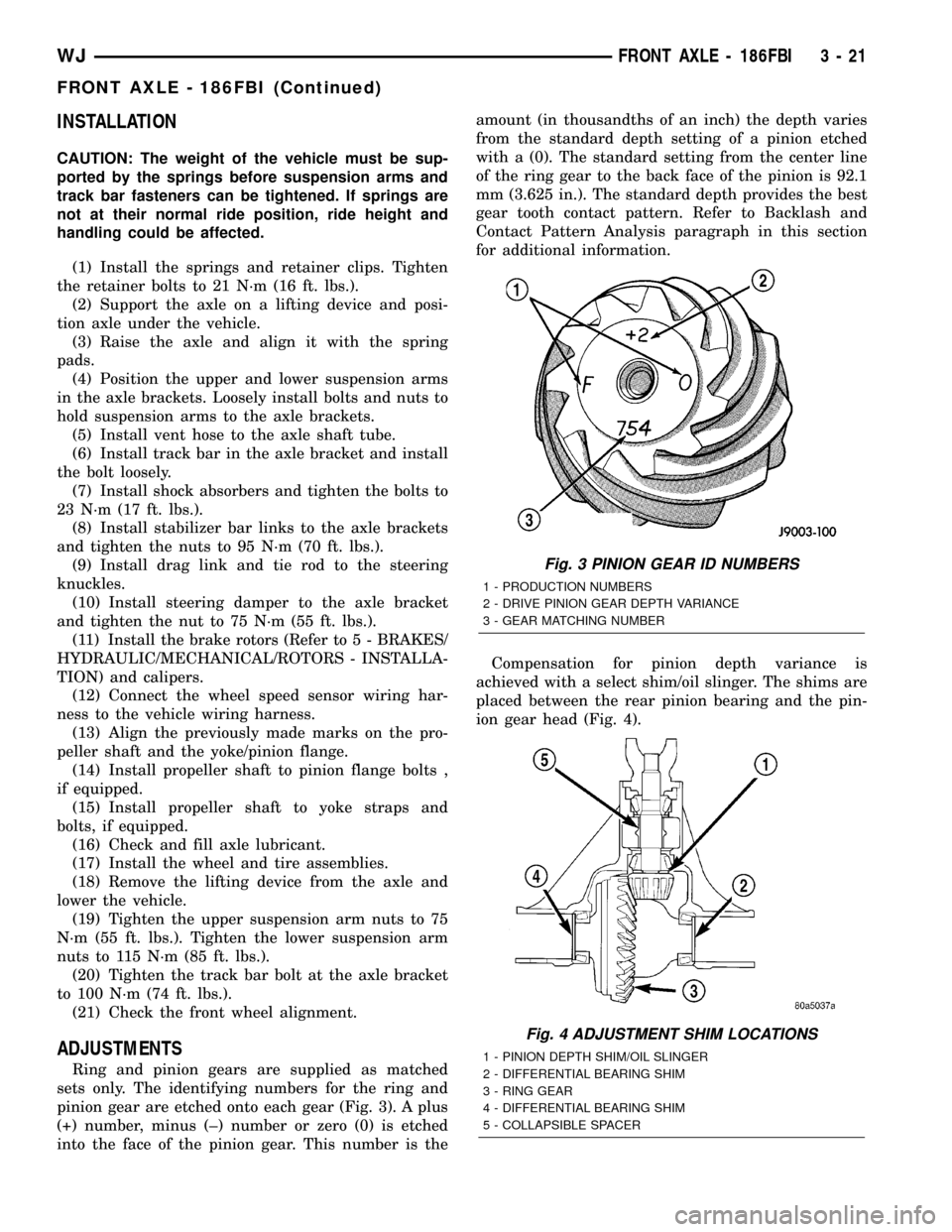

Ring and pinion gears are supplied as matched

sets only. The identifying numbers for the ring and

pinion gear are etched onto each gear (Fig. 3). A plus

(+) number, minus (±) number or zero (0) is etched

into the face of the pinion gear. This number is theamount (in thousandths of an inch) the depth varies

from the standard depth setting of a pinion etched

with a (0). The standard setting from the center line

of the ring gear to the back face of the pinion is 92.1

mm (3.625 in.). The standard depth provides the best

gear tooth contact pattern. Refer to Backlash and

Contact Pattern Analysis paragraph in this section

for additional information.

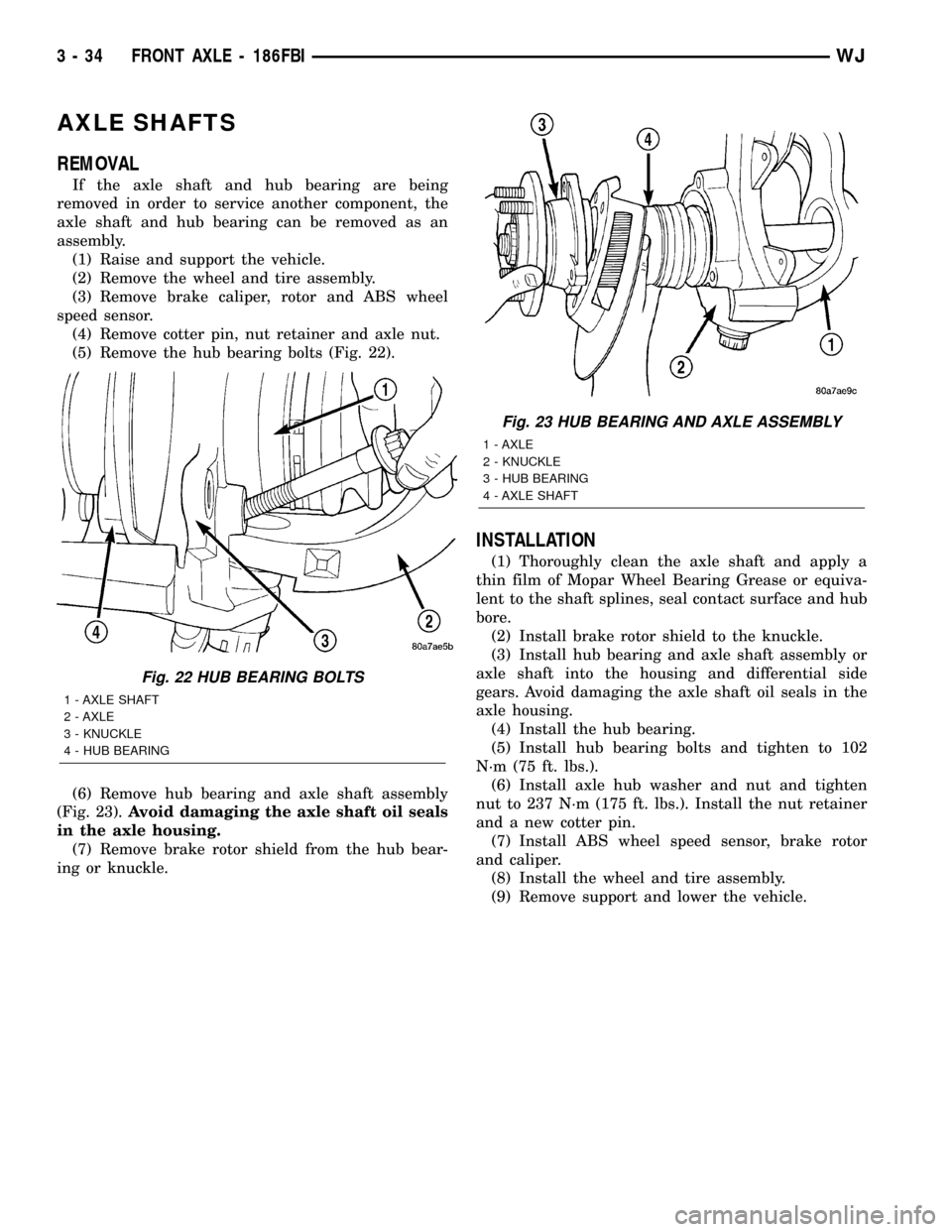

Compensation for pinion depth variance is

achieved with a select shim/oil slinger. The shims are

placed between the rear pinion bearing and the pin-

ion gear head (Fig. 4).

Fig. 3 PINION GEAR ID NUMBERS

1 - PRODUCTION NUMBERS

2 - DRIVE PINION GEAR DEPTH VARIANCE

3 - GEAR MATCHING NUMBER

Fig. 4 ADJUSTMENT SHIM LOCATIONS

1 - PINION DEPTH SHIM/OIL SLINGER

2 - DIFFERENTIAL BEARING SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING SHIM

5 - COLLAPSIBLE SPACER

WJFRONT AXLE - 186FBI 3 - 21

FRONT AXLE - 186FBI (Continued)

Page 79 of 2199

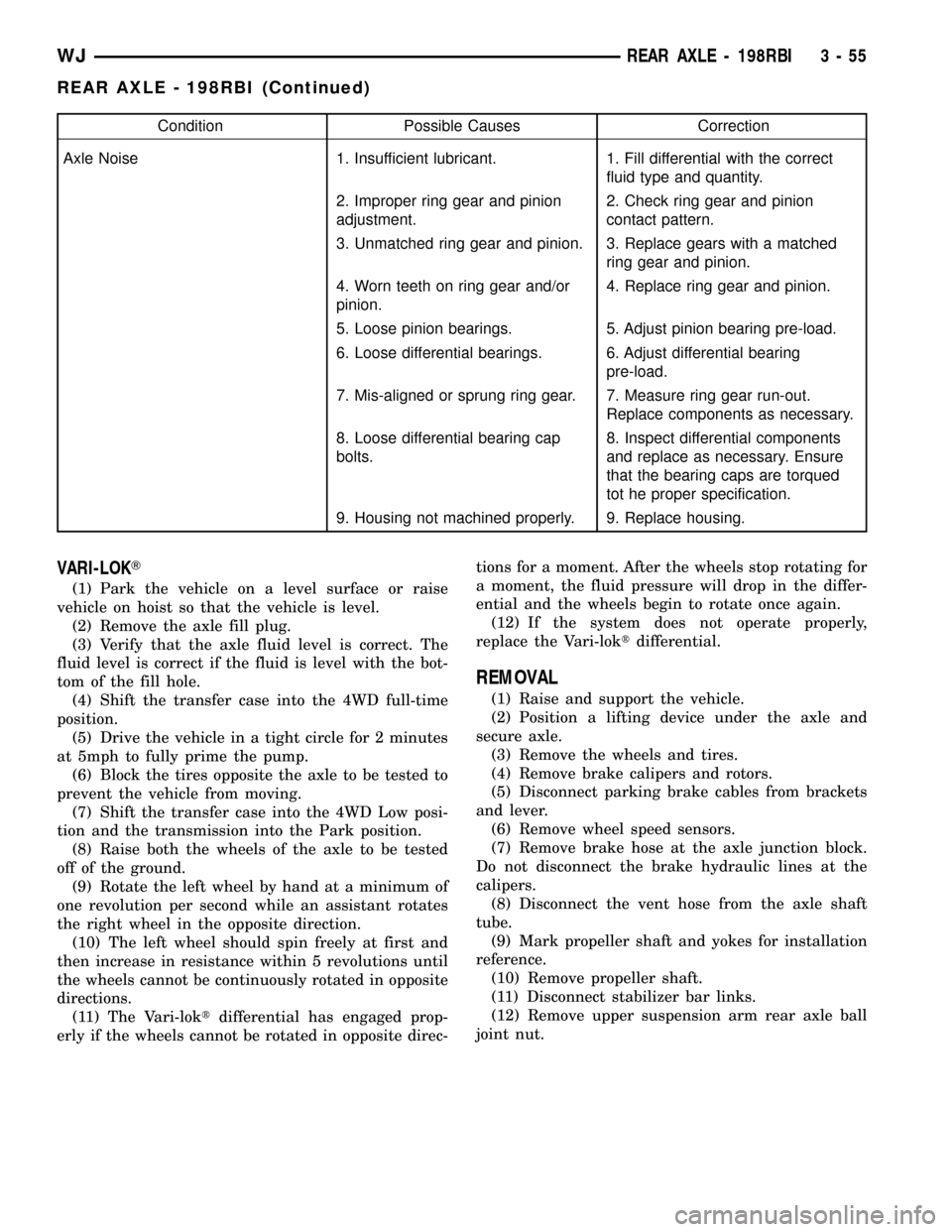

AXLE SHAFTS

REMOVAL

If the axle shaft and hub bearing are being

removed in order to service another component, the

axle shaft and hub bearing can be removed as an

assembly.

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove brake caliper, rotor and ABS wheel

speed sensor.

(4) Remove cotter pin, nut retainer and axle nut.

(5) Remove the hub bearing bolts (Fig. 22).

(6) Remove hub bearing and axle shaft assembly

(Fig. 23).Avoid damaging the axle shaft oil seals

in the axle housing.

(7) Remove brake rotor shield from the hub bear-

ing or knuckle.

INSTALLATION

(1) Thoroughly clean the axle shaft and apply a

thin film of Mopar Wheel Bearing Grease or equiva-

lent to the shaft splines, seal contact surface and hub

bore.

(2) Install brake rotor shield to the knuckle.

(3) Install hub bearing and axle shaft assembly or

axle shaft into the housing and differential side

gears. Avoid damaging the axle shaft oil seals in the

axle housing.

(4) Install the hub bearing.

(5) Install hub bearing bolts and tighten to 102

N´m (75 ft. lbs.).

(6) Install axle hub washer and nut and tighten

nut to 237 N´m (175 ft. lbs.). Install the nut retainer

and a new cotter pin.

(7) Install ABS wheel speed sensor, brake rotor

and caliper.

(8) Install the wheel and tire assembly.

(9) Remove support and lower the vehicle.

Fig. 22 HUB BEARING BOLTS

1 - AXLE SHAFT

2 - AXLE

3 - KNUCKLE

4 - HUB BEARING

Fig. 23 HUB BEARING AND AXLE ASSEMBLY

1 - AXLE

2 - KNUCKLE

3 - HUB BEARING

4 - AXLE SHAFT

3 - 34 FRONT AXLE - 186FBIWJ

Page 100 of 2199

Condition Possible Causes Correction

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

VARI-LOKT

(1) Park the vehicle on a level surface or raise

vehicle on hoist so that the vehicle is level.

(2) Remove the axle fill plug.

(3) Verify that the axle fluid level is correct. The

fluid level is correct if the fluid is level with the bot-

tom of the fill hole.

(4) Shift the transfer case into the 4WD full-time

position.

(5) Drive the vehicle in a tight circle for 2 minutes

at 5mph to fully prime the pump.

(6) Block the tires opposite the axle to be tested to

prevent the vehicle from moving.

(7) Shift the transfer case into the 4WD Low posi-

tion and the transmission into the Park position.

(8) Raise both the wheels of the axle to be tested

off of the ground.

(9) Rotate the left wheel by hand at a minimum of

one revolution per second while an assistant rotates

the right wheel in the opposite direction.

(10) The left wheel should spin freely at first and

then increase in resistance within 5 revolutions until

the wheels cannot be continuously rotated in opposite

directions.

(11) The Vari-loktdifferential has engaged prop-

erly if the wheels cannot be rotated in opposite direc-tions for a moment. After the wheels stop rotating for

a moment, the fluid pressure will drop in the differ-

ential and the wheels begin to rotate once again.

(12) If the system does not operate properly,

replace the Vari-loktdifferential.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle and

secure axle.

(3) Remove the wheels and tires.

(4) Remove brake calipers and rotors.

(5) Disconnect parking brake cables from brackets

and lever.

(6) Remove wheel speed sensors.

(7) Remove brake hose at the axle junction block.

Do not disconnect the brake hydraulic lines at the

calipers.

(8) Disconnect the vent hose from the axle shaft

tube.

(9) Mark propeller shaft and yokes for installation

reference.

(10) Remove propeller shaft.

(11) Disconnect stabilizer bar links.

(12) Remove upper suspension arm rear axle ball

joint nut.

WJREAR AXLE - 198RBI 3 - 55

REAR AXLE - 198RBI (Continued)

Page 101 of 2199

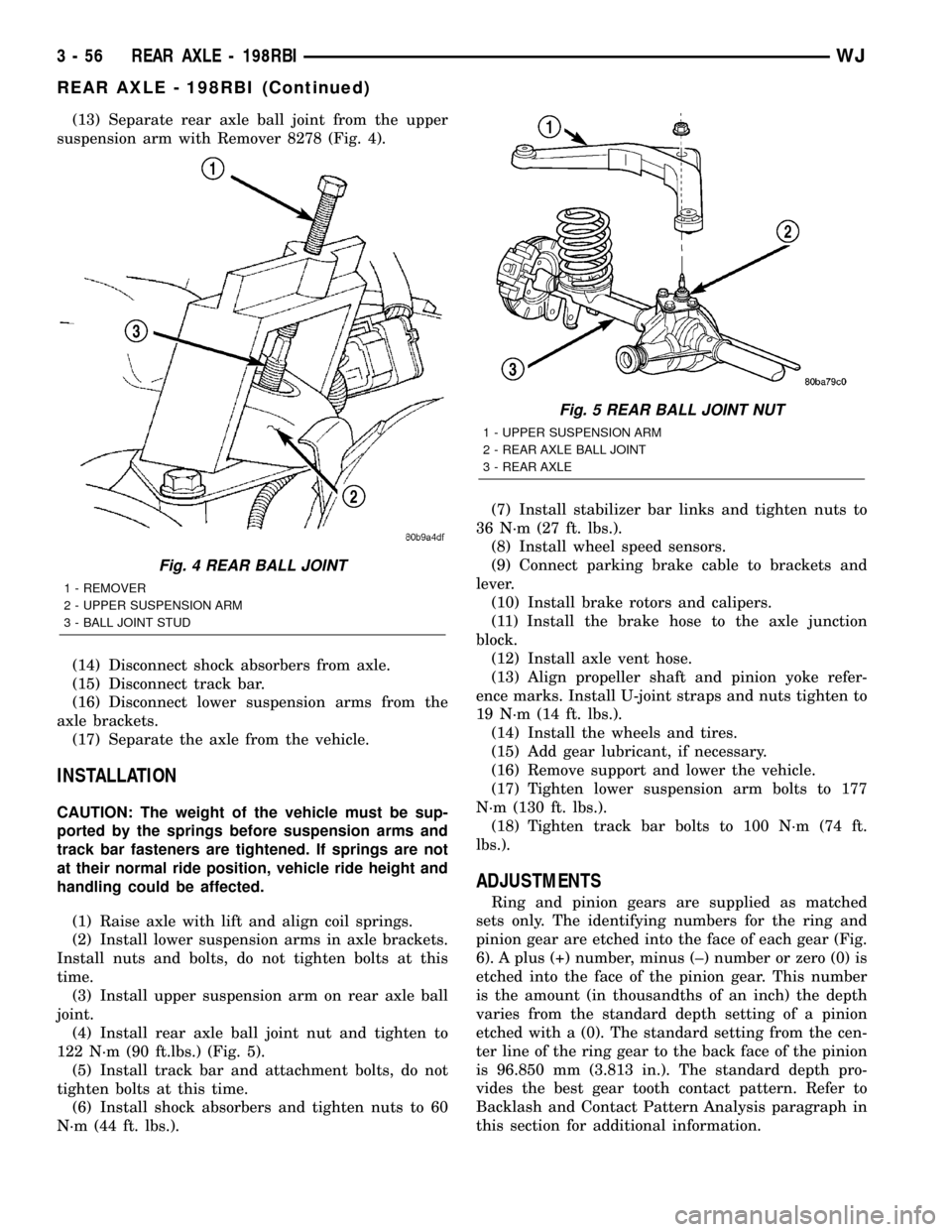

(13) Separate rear axle ball joint from the upper

suspension arm with Remover 8278 (Fig. 4).

(14) Disconnect shock absorbers from axle.

(15) Disconnect track bar.

(16) Disconnect lower suspension arms from the

axle brackets.

(17) Separate the axle from the vehicle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners are tightened. If springs are not

at their normal ride position, vehicle ride height and

handling could be affected.

(1) Raise axle with lift and align coil springs.

(2) Install lower suspension arms in axle brackets.

Install nuts and bolts, do not tighten bolts at this

time.

(3) Install upper suspension arm on rear axle ball

joint.

(4) Install rear axle ball joint nut and tighten to

122 N´m (90 ft.lbs.) (Fig. 5).

(5) Install track bar and attachment bolts, do not

tighten bolts at this time.

(6) Install shock absorbers and tighten nuts to 60

N´m (44 ft. lbs.).(7) Install stabilizer bar links and tighten nuts to

36 N´m (27 ft. lbs.).

(8) Install wheel speed sensors.

(9) Connect parking brake cable to brackets and

lever.

(10) Install brake rotors and calipers.

(11) Install the brake hose to the axle junction

block.

(12) Install axle vent hose.

(13) Align propeller shaft and pinion yoke refer-

ence marks. Install U-joint straps and nuts tighten to

19 N´m (14 ft. lbs.).

(14) Install the wheels and tires.

(15) Add gear lubricant, if necessary.

(16) Remove support and lower the vehicle.

(17) Tighten lower suspension arm bolts to 177

N´m (130 ft. lbs.).

(18) Tighten track bar bolts to 100 N´m (74 ft.

lbs.).

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets only. The identifying numbers for the ring and

pinion gear are etched into the face of each gear (Fig.

6). A plus (+) number, minus (±) number or zero (0) is

etched into the face of the pinion gear. This number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

etched with a (0). The standard setting from the cen-

ter line of the ring gear to the back face of the pinion

is 96.850 mm (3.813 in.). The standard depth pro-

vides the best gear tooth contact pattern. Refer to

Backlash and Contact Pattern Analysis paragraph in

this section for additional information.

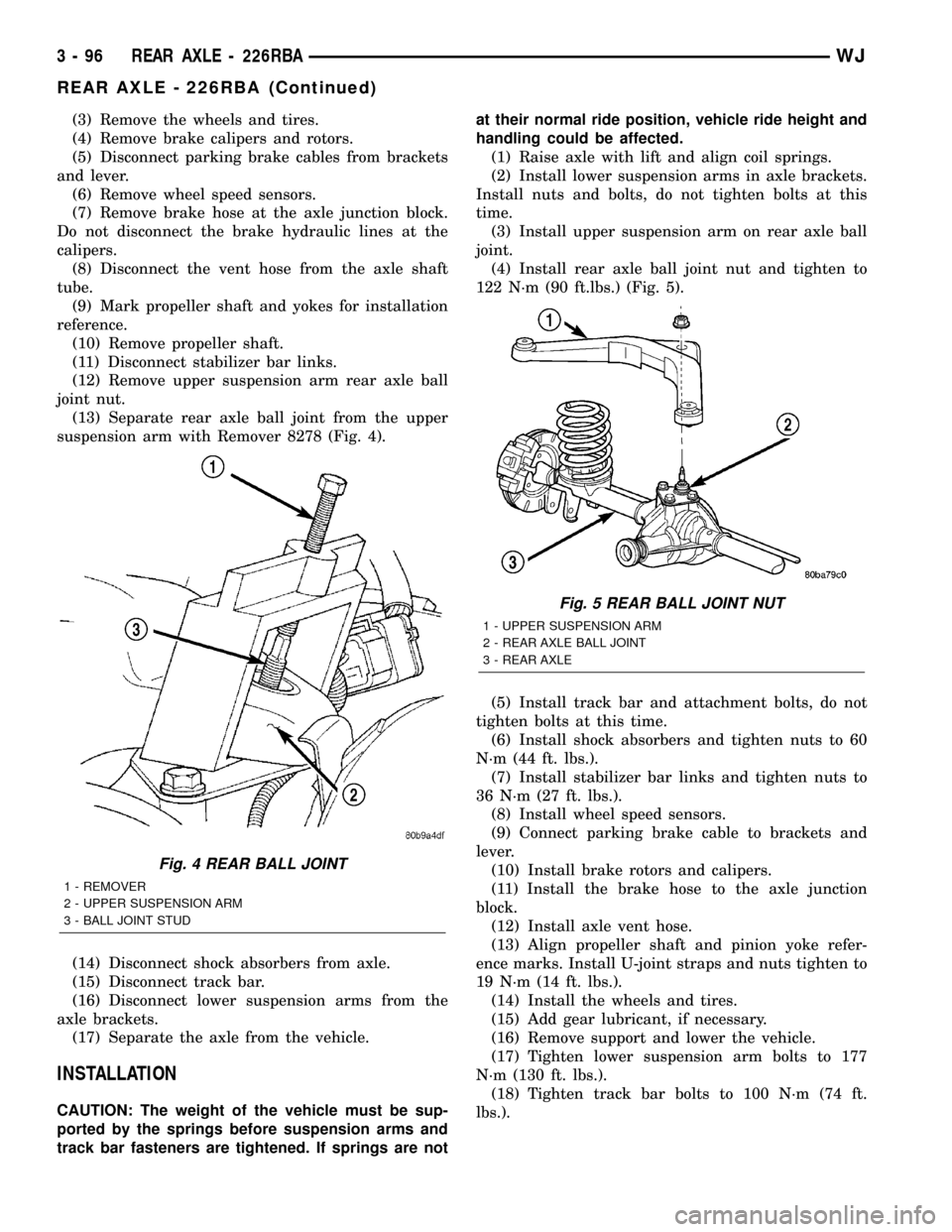

Fig. 4 REAR BALL JOINT

1 - REMOVER

2 - UPPER SUSPENSION ARM

3 - BALL JOINT STUD

Fig. 5 REAR BALL JOINT NUT

1 - UPPER SUSPENSION ARM

2 - REAR AXLE BALL JOINT

3 - REAR AXLE

3 - 56 REAR AXLE - 198RBIWJ

REAR AXLE - 198RBI (Continued)

Page 141 of 2199

(3) Remove the wheels and tires.

(4) Remove brake calipers and rotors.

(5) Disconnect parking brake cables from brackets

and lever.

(6) Remove wheel speed sensors.

(7) Remove brake hose at the axle junction block.

Do not disconnect the brake hydraulic lines at the

calipers.

(8) Disconnect the vent hose from the axle shaft

tube.

(9) Mark propeller shaft and yokes for installation

reference.

(10) Remove propeller shaft.

(11) Disconnect stabilizer bar links.

(12) Remove upper suspension arm rear axle ball

joint nut.

(13) Separate rear axle ball joint from the upper

suspension arm with Remover 8278 (Fig. 4).

(14) Disconnect shock absorbers from axle.

(15) Disconnect track bar.

(16) Disconnect lower suspension arms from the

axle brackets.

(17) Separate the axle from the vehicle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before suspension arms and

track bar fasteners are tightened. If springs are notat their normal ride position, vehicle ride height and

handling could be affected.

(1) Raise axle with lift and align coil springs.

(2) Install lower suspension arms in axle brackets.

Install nuts and bolts, do not tighten bolts at this

time.

(3) Install upper suspension arm on rear axle ball

joint.

(4) Install rear axle ball joint nut and tighten to

122 N´m (90 ft.lbs.) (Fig. 5).

(5) Install track bar and attachment bolts, do not

tighten bolts at this time.

(6) Install shock absorbers and tighten nuts to 60

N´m (44 ft. lbs.).

(7) Install stabilizer bar links and tighten nuts to

36 N´m (27 ft. lbs.).

(8) Install wheel speed sensors.

(9) Connect parking brake cable to brackets and

lever.

(10) Install brake rotors and calipers.

(11) Install the brake hose to the axle junction

block.

(12) Install axle vent hose.

(13) Align propeller shaft and pinion yoke refer-

ence marks. Install U-joint straps and nuts tighten to

19 N´m (14 ft. lbs.).

(14) Install the wheels and tires.

(15) Add gear lubricant, if necessary.

(16) Remove support and lower the vehicle.

(17) Tighten lower suspension arm bolts to 177

N´m (130 ft. lbs.).

(18) Tighten track bar bolts to 100 N´m (74 ft.

lbs.).

Fig. 4 REAR BALL JOINT

1 - REMOVER

2 - UPPER SUSPENSION ARM

3 - BALL JOINT STUD

Fig. 5 REAR BALL JOINT NUT

1 - UPPER SUSPENSION ARM

2 - REAR AXLE BALL JOINT

3 - REAR AXLE

3 - 96 REAR AXLE - 226RBAWJ

REAR AXLE - 226RBA (Continued)

Page 182 of 2199

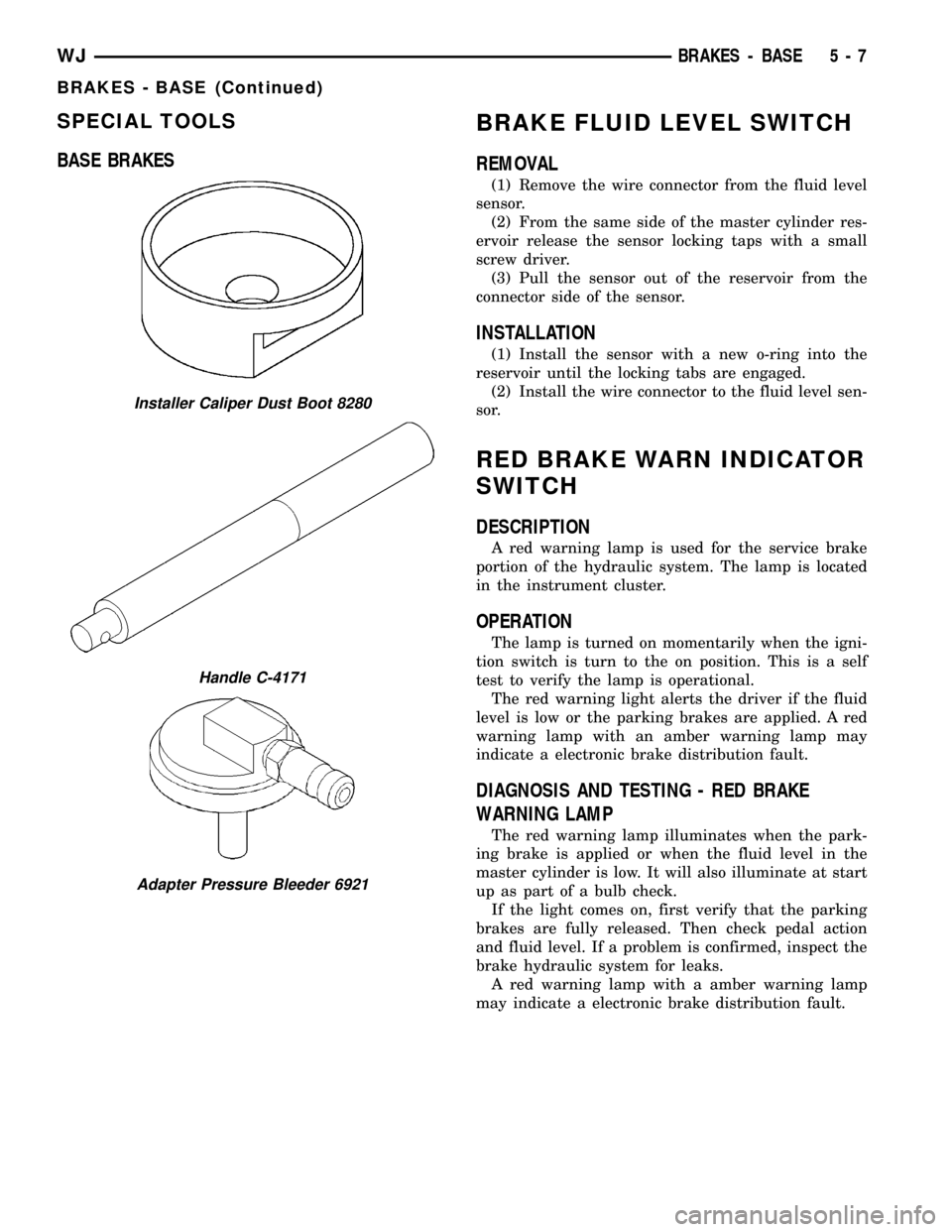

SPECIAL TOOLS

BASE BRAKESBRAKE FLUID LEVEL SWITCH

REMOVAL

(1) Remove the wire connector from the fluid level

sensor.

(2) From the same side of the master cylinder res-

ervoir release the sensor locking taps with a small

screw driver.

(3) Pull the sensor out of the reservoir from the

connector side of the sensor.

INSTALLATION

(1) Install the sensor with a new o-ring into the

reservoir until the locking tabs are engaged.

(2) Install the wire connector to the fluid level sen-

sor.

RED BRAKE WARN INDICATOR

SWITCH

DESCRIPTION

A red warning lamp is used for the service brake

portion of the hydraulic system. The lamp is located

in the instrument cluster.

OPERATION

The lamp is turned on momentarily when the igni-

tion switch is turn to the on position. This is a self

test to verify the lamp is operational.

The red warning light alerts the driver if the fluid

level is low or the parking brakes are applied. A red

warning lamp with an amber warning lamp may

indicate a electronic brake distribution fault.

DIAGNOSIS AND TESTING - RED BRAKE

WARNING LAMP

The red warning lamp illuminates when the park-

ing brake is applied or when the fluid level in the

master cylinder is low. It will also illuminate at start

up as part of a bulb check.

If the light comes on, first verify that the parking

brakes are fully released. Then check pedal action

and fluid level. If a problem is confirmed, inspect the

brake hydraulic system for leaks.

A red warning lamp with a amber warning lamp

may indicate a electronic brake distribution fault.

Installer Caliper Dust Boot 8280

Handle C-4171

Adapter Pressure Bleeder 6921

WJBRAKES - BASE 5 - 7

BRAKES - BASE (Continued)